ECU DATSUN B110 1973 Service Manual PDF

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 445 of 513

ENGINE

ElECTRICAL

SYSTEM

Ambient

temperature

Rated

regulating

voltage

roC

OF

V

10

14

14

6

to

15

6

0

32

14

45

to

15

45

10

50

14

3

to

15

3

20

68

14

15

to

15

15

30

86

14

0

to

15

0

40

104

13

85

to

14

85

Note

8

Do

not

measure

voltage

immediately

after

driv

ing

Do

this

while

regulator

is

cold

b

To

measure

voltage

raise

engine

speed

gradual

ly

from

idling

to

rated

speed

c

Voltage

may

be

approximately

O

3V

higher

than

the

rated

for

two

to

three

minutes

after

engine

is

started

or

more

specifically

when

regulator

becomes

self

heated

Measurements

should

then

be

made

within

one

minute

after

starting

engine

or

when

regulator

is

cold

d

The

regulator

is

of

a

temperature

compensating

type

Before

measuring

voltage

be

sure

to

meas

ure

surrounding

temperature

and

correct

measure

ments

according

to

the

table

in

the

left

hand

side

ADJUSTMENT

Voltage

regulator

As

the

result

of

above

measurement

when

the

regu

lating

voltage

is

deviated

from

the

rated

value

adjust

the

regulator

in

accordance

with

the

following

instructions

I

Inspect

contact

surface

and

if

rough

lightly

polish

the

surface

with

fine

emery

paper

500

or

600

2

Measure

each

gap

and

adjust

if

necessary

Adjust

the

core

gap

and

point

gap

in

that

order

No

adjustment

is

required

for

the

yoke

gap

J

Adjusting

core

gap

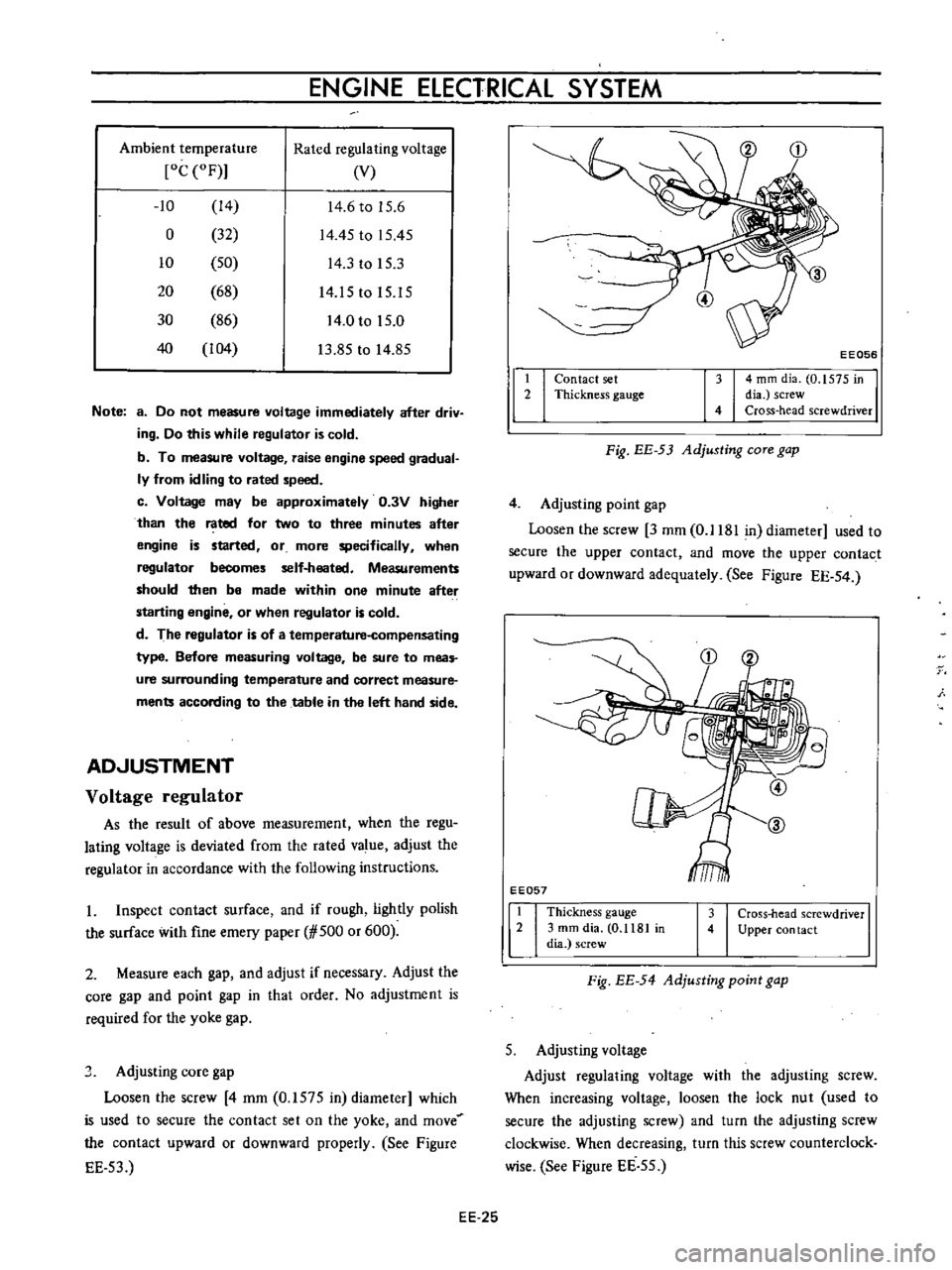

Loosen

the

screw

4

mm

0

1575

in

diameter

which

is

used

to

secure

the

contact

set

on

the

yoke

and

move

the

contact

upward

or

downward

properly

See

Figure

EE

53

t

2

I

I

EE056

4

mm

dia

0

1575

in

dia

screw

Cross

head

screwdriver

Contact

set

Thickness

gauge

Fig

EE

53

Adjusting

COTe

gap

4

Adjusting

point

gap

Loosen

the

screw

3

mm

0

1181

in

diameter

used

to

secure

the

upper

contact

and

move

the

upper

contact

upward

or

downward

adequately

See

Figure

EE

54

EE057

1

Thickness

gauge

2

3

mm

dia

0

1181

in

dia

screw

3

Cross

head

screwdriver

4

Upper

con

tact

Fig

EE

54

Adjusting

point

gap

5

Adjusting

voltage

Adjust

regulating

voltage

with

the

adjusting

screw

When

increasing

voltage

loosen

the

lock

nut

used

to

secure

the

adjusting

screw

and

turn

the

adjusting

screw

clockwise

When

decreasing

turn

this

screw

counterclock

wise

See

Figure

EE

55

EE

25

Page 453 of 513

ENGINE

ElECTRICAL

SYSTEM

2

Leakage

due

to

defective

diaphragm

3

Stationary

side

and

moving

side

of

the

breaker

plate

are

sticked

Solution

for

1

is

to

make

complete

fastening

and

2

is

to

replace

it

with

a

new

one

Solution

for

3

is

as

follows

I

The

moving

side

of

the

breaker

plate

is

supported

by

three

steel

balls

at

upper

and

lower

sides

Make

sure

that

these

balls

work

smoothly

2

The

moving

side

of

the

breaker

plate

is

rotated

with

the

stationary

side

pivot

receiver

Make

sure

that

this

pivot

receiver

operates

correctly

When

assembling

be

sure

to

apply

three

steel

balls

to

the

upper

and

lower

sides

and

to

grease

them

DISASSEMBLY

AND

REASSEMBLY

Disassembly

When

the

distributor

is

disconnected

from

engine

position

of

distributor

and

rotor

head

for

housing

must

be

weB

remembered

or

marked

If

distributor

is

installed

incorrectly

it

does

not

operate

correctly

Disassembly

is

to

be

carried

out

in

the

following

sequence

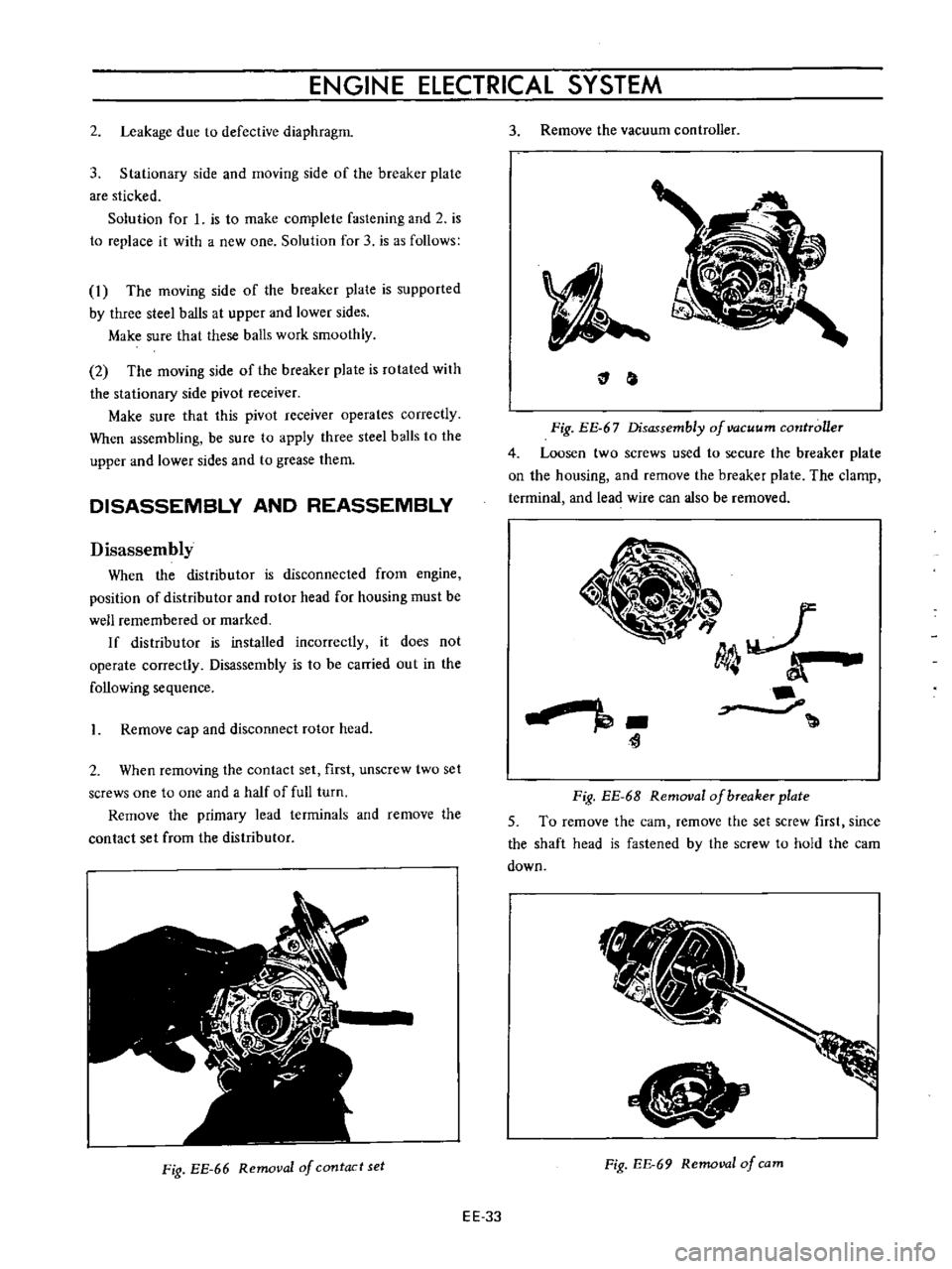

I

Remove

cap

and

disconnect

rotor

head

2

When

removing

the

contact

set

first

unscrew

two

set

screws

one

to

one

and

a

half

of

full

turn

Remove

the

primary

lead

terminals

and

remove

the

contact

set

from

the

distributor

Fig

EE

66

Removal

of

contact

set

EE

33

3

Remove

the

vacuum

controller

Fig

EE

67

Disassembly

of

vacuum

controller

4

Loosen

two

screws

used

to

secure

the

breaker

plate

on

the

housing

and

remove

the

breaker

plate

The

clamp

terminal

and

lead

wire

can

also

be

removed

r

Fig

EE

6B

Removal

ofbTeaker

plate

5

To

remove

the

earn

remove

the

set

screw

first

since

the

shaft

head

is

fastened

by

the

screw

to

hold

the

cam

down

Fig

EE

69

Removal

of

cam

Page 465 of 513

CHASSIS

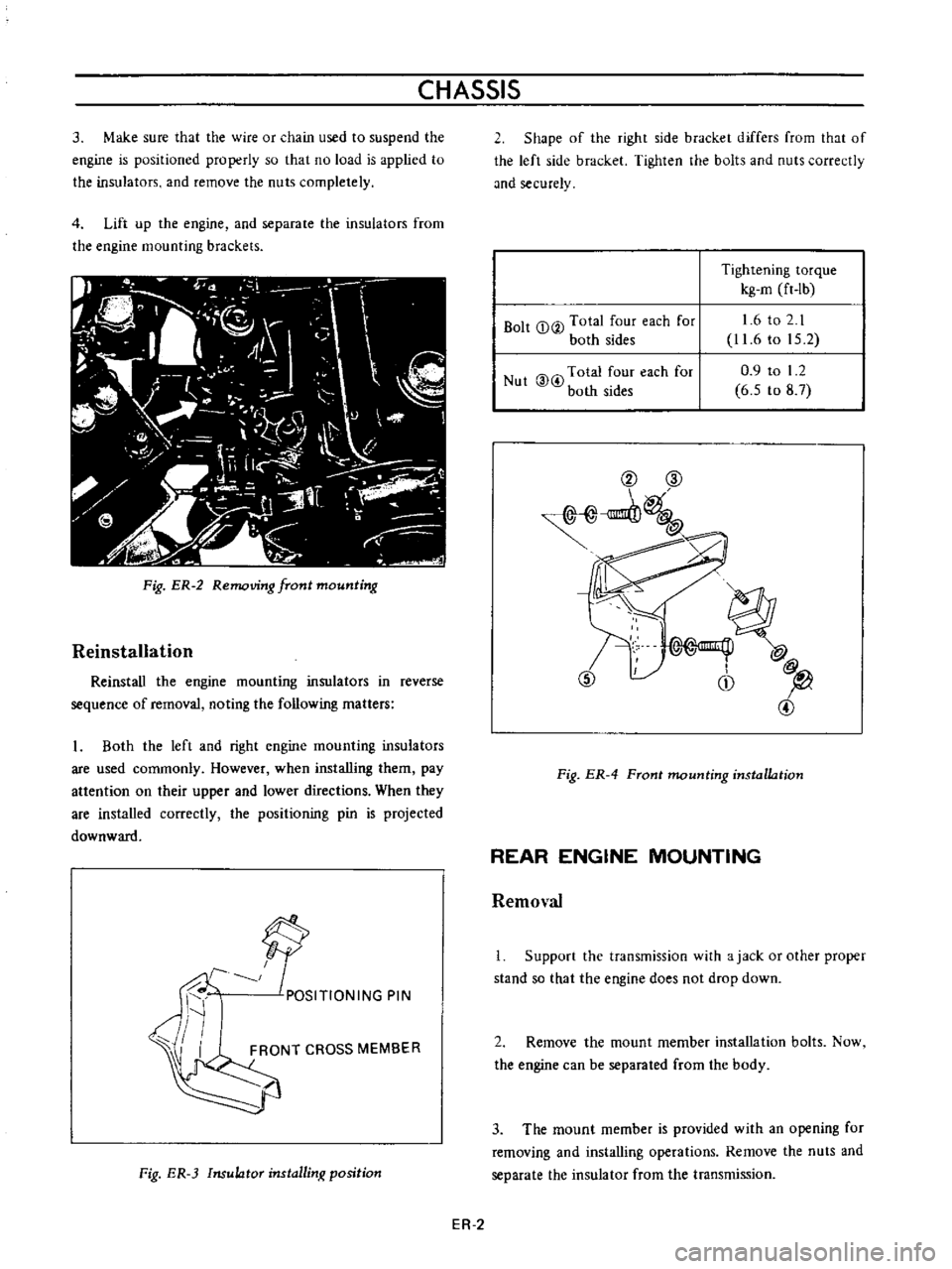

3

Make

sure

that

the

wire

or

chain

used

to

suspend

the

engine

is

positioned

properly

so

that

no

load

is

applied

to

the

insulators

and

remove

the

nuts

completely

4

Lift

up

the

engine

and

separate

the

insulators

from

the

engine

mounting

brackets

l

J

o

II

f

T

io

I

t

i

1

A

t

t

I

21

u

I

1

Qj

1

It

I

j

fi

I

I

lt

y

Ii

Fig

ER

2

Removing

front

mounting

Reinstallation

Reinstall

the

engine

mounting

insulators

in

reverse

sequence

of

removal

noting

the

following

matters

Both

the

left

and

right

engine

mounting

insulators

are

used

commonly

However

when

installing

them

pay

attention

on

their

upper

and

lower

directions

When

they

are

installed

correctly

the

positioning

pin

is

projected

downward

f

9

POSITIONING

PIN

I

FRONT

CROSS

MEMBER

Fig

ER

3

Insulator

installinx

position

2

Shape

of

the

right

side

bracket

differs

from

that

of

the

left

side

bracket

Tighten

the

bolts

and

nuts

correctly

md

securely

Bolt

CD

V

Total

four

each

for

both

sides

Tightening

torque

kg

m

ft

Ib

1

6

to

2

1

11

6

to

15

2

0

9

to

I

2

6

5

to

8

7

Nut

@

i

Total

four

each

for

both

sides

@

CID

1

@

CD

l

Fig

ER

4

Front

mounting

installation

REAR

ENGINE

MOUNTING

Removal

Support

the

transmission

with

ajack

or

other

proper

stand

so

that

the

engine

does

not

drop

down

2

Remove

the

mount

member

installation

bolts

Now

the

engine

can

be

separated

from

the

body

3

The

mount

member

is

provided

with

an

opening

for

removing

and

installing

operations

Remove

the

nuts

and

separate

the

insulator

from

the

transmission

ER

2

Page 466 of 513

ENGINE

REMOVAL

INSTAllATION

Fig

ER

5

Rear

mounting

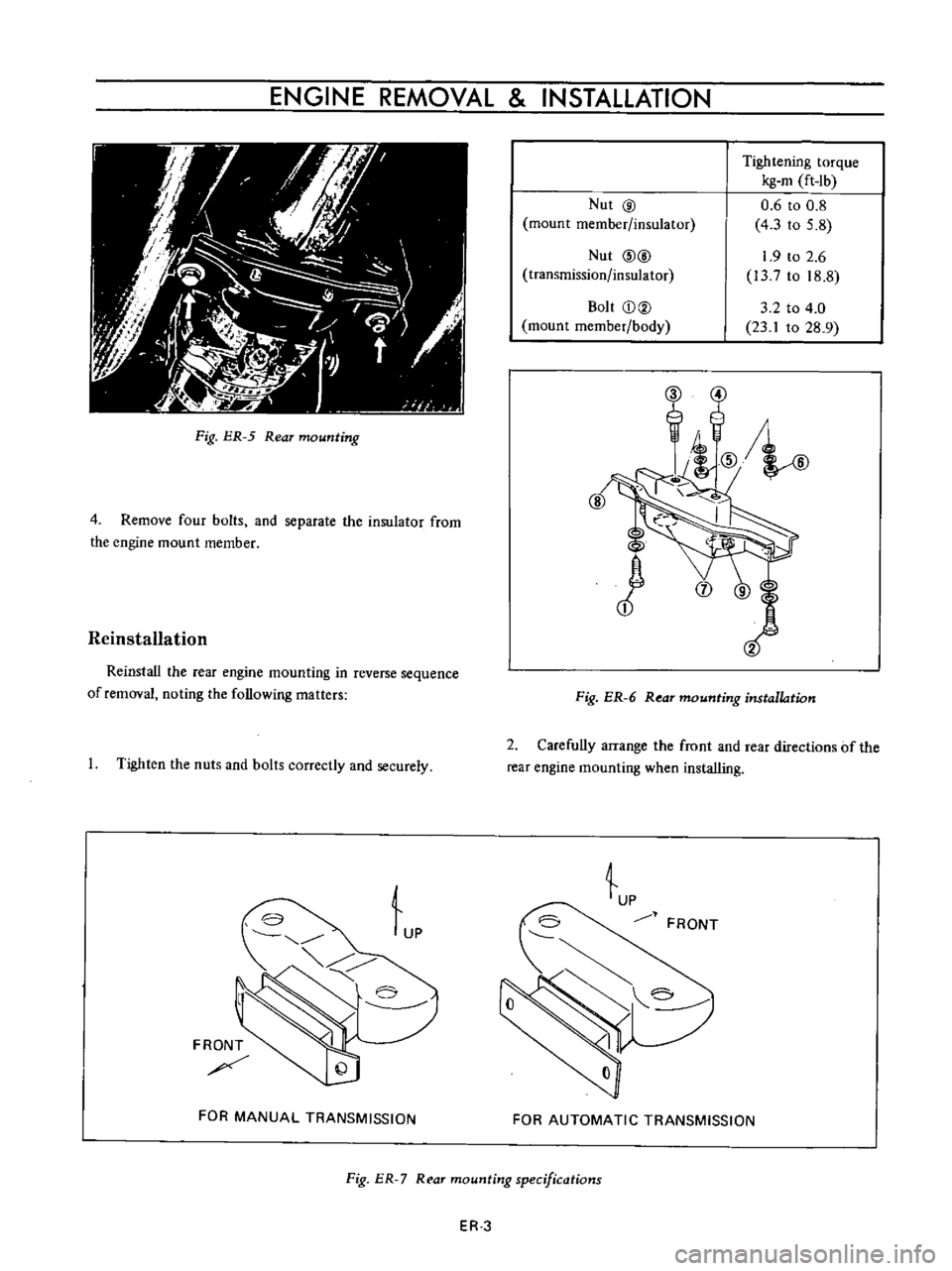

4

Remove

four

bolts

and

separate

the

insulator

from

the

engine

mount

member

Reinstallation

Reinstall

the

rear

engine

mounting

in

reverse

sequence

of

removal

noting

the

following

matters

I

Tighten

the

nuts

and

bolts

correctly

and

securely

Lp

FRONT

FOR

MANUAL

TRANSMISSION

Nut

@

mount

member

insulator

Nut

@@

transmission

insulator

Bolt

CD@

mount

member

body

Tightening

torque

kg

m

ft

Ib

0

6

to

0

8

4

3

to

5

8

1

9

to

2

6

l3

to

18

8

3

2

to

4

0

23

1

to

28

9

Fig

ER

6

Rear

mounting

installation

2

Carefully

arrange

the

front

and

rear

directions

of

the

rear

engine

mounting

when

installing

tp

FRONT

FOR

AUTOMATIC

TRANSMISSION

Fig

ER

7

R

ar

mounting

specifications

ER

3

Page 471 of 513

CLUTCH

CLUTCH

CONTENTS

DESCRIPTION

REMOVAL

DISASSEMBL

Y

INSPECTION

AND

ADJUSTMENT

Clutch

assembly

Cll

CL

2

CL

2

CL

2

CL

2

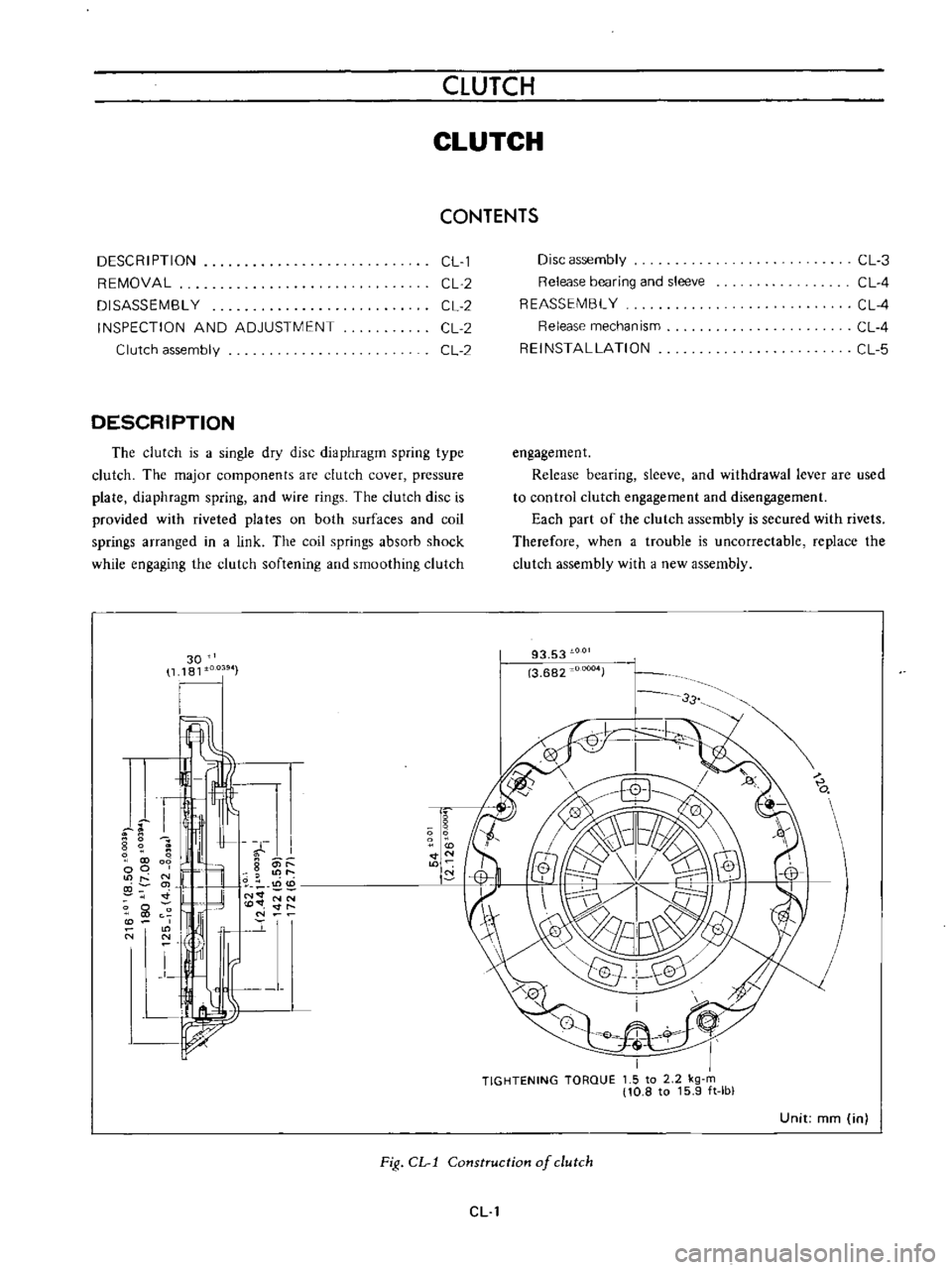

DESCRIPTION

The

clutch

is

a

single

dty

disc

diaphragm

spring

type

clutch

The

major

components

are

clutch

cover

pressure

plate

diaphragm

spring

and

wire

rings

The

clutch

disc

is

provided

with

riveted

pia

tes

on

both

surfaces

and

coil

springs

arranged

in

a

link

The

coil

springs

absorb

shock

while

engaging

the

clutch

softening

and

smoothing

clutch

30

1181

I

4J

I

m

I

I

5

O

N

l

l

9

p

1L

oz

l

t

O

Ii

N

lt

o

O

Vf

I

1

I

t

I

0

tN

00

f

M

g

1

co

0

00

U

N

N

y

Disc

assembly

Release

bearing

and

sleeve

REASSEMBL

Y

CL

3

CL

4

CL

4

CL

4

CL

5

Release

mechanism

REINSTALLATION

engagement

Release

bearing

sleeve

and

withdrawal

lever

are

used

to

control

clutch

engagement

and

disengagement

Each

part

of

the

clutch

assembly

is

secured

with

rivets

Therefore

when

a

trouble

is

uncorrectable

replace

the

clutch

assembly

wHh

J

new

assembly

93

53

3

682

JOOD4

33

Unit

mm

in

Fig

CL

l

Construction

of

clutch

ell

Page 476 of 513

CHASSIS

fulcrum

type

The

mechanical

type

clutch

control

system

consists

of

pendent

clutch

pedal

clutch

control

cable

and

with

drawallever

The

withdrawal

lever

is

of

an

outer

fulcrum

type

which

provides

a

great

lever

ratio

and

thus

force

required

in

depressing

clutch

pedal

is

reduced

CLUTCH

PEDAL

Hydraulic

clutch

Removal

Remove

the

return

spring

2

Loosen

the

lock

nut

of

the

master

cylinder

push

rod

and

disconnect

the

push

rod

end

3

Remove

the

lock

nut

and

washer

of

the

pedal

shaft

and

remove

the

pedal

lever

Inspection

Thoroughly

clean

all

disassembled

parts

indicated

below

and

carefully

check

them

for

wear

damage

and

other

abnormal

conditions

Repair

or

replace

them

with

new

ones

if

required

f

fS

C5

J

dJ

YII

10

1

@

c

i

@

j

1

4

K

Clutch

pedal

free

trrlel

30

mm

1

181

nl

00

@

P

IO

Pedal

head

rubber

2

Return

spring

3

Pedal

lever

bush

4

Fulcrum

pedal

pin

etc

Reinstallation

Reinstall

the

clutch

pedal

in

reverse

sequence

of

removal

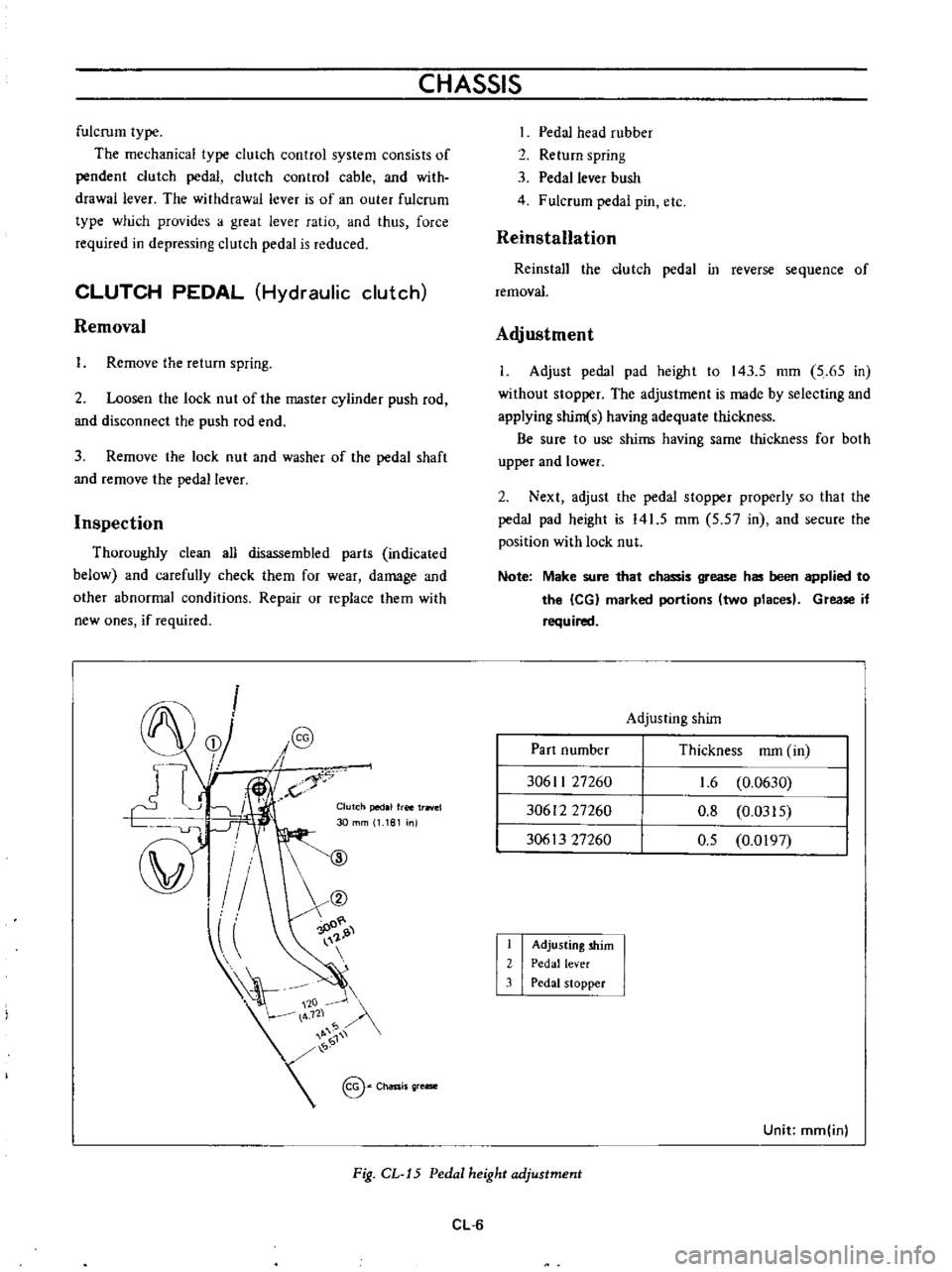

Adjustment

I

Adjust

pedal

pad

height

to

143

5

mm

5

65

in

without

stopper

The

adjustment

is

made

by

selecting

and

applying

shim

s

having

adequate

thickness

Be

sure

to

use

shims

having

same

thickness

for

both

upper

and

lower

2

Next

adjust

the

pedal

stopper

properly

so

that

the

pedal

pad

height

is

141

5

mm

5

57

in

and

secure

the

position

with

lock

nut

Note

Make

sure

that

chassis

grease

has

been

applied

to

the

leG

marked

portions

two

places

Grease

if

required

Adjusting

shim

Part

number

Thickness

mm

in

30611

27260

30612

27260

30613

27260

1

6

0

0630

0

8

0

0315

0

5

0

0197

I

2

3

Adjusting

shim

Pedal

lever

Pedal

stopper

Unit

mm

inl

Fig

CL

J5

Pedal

height

adjustment

CL

6

Page 477 of 513

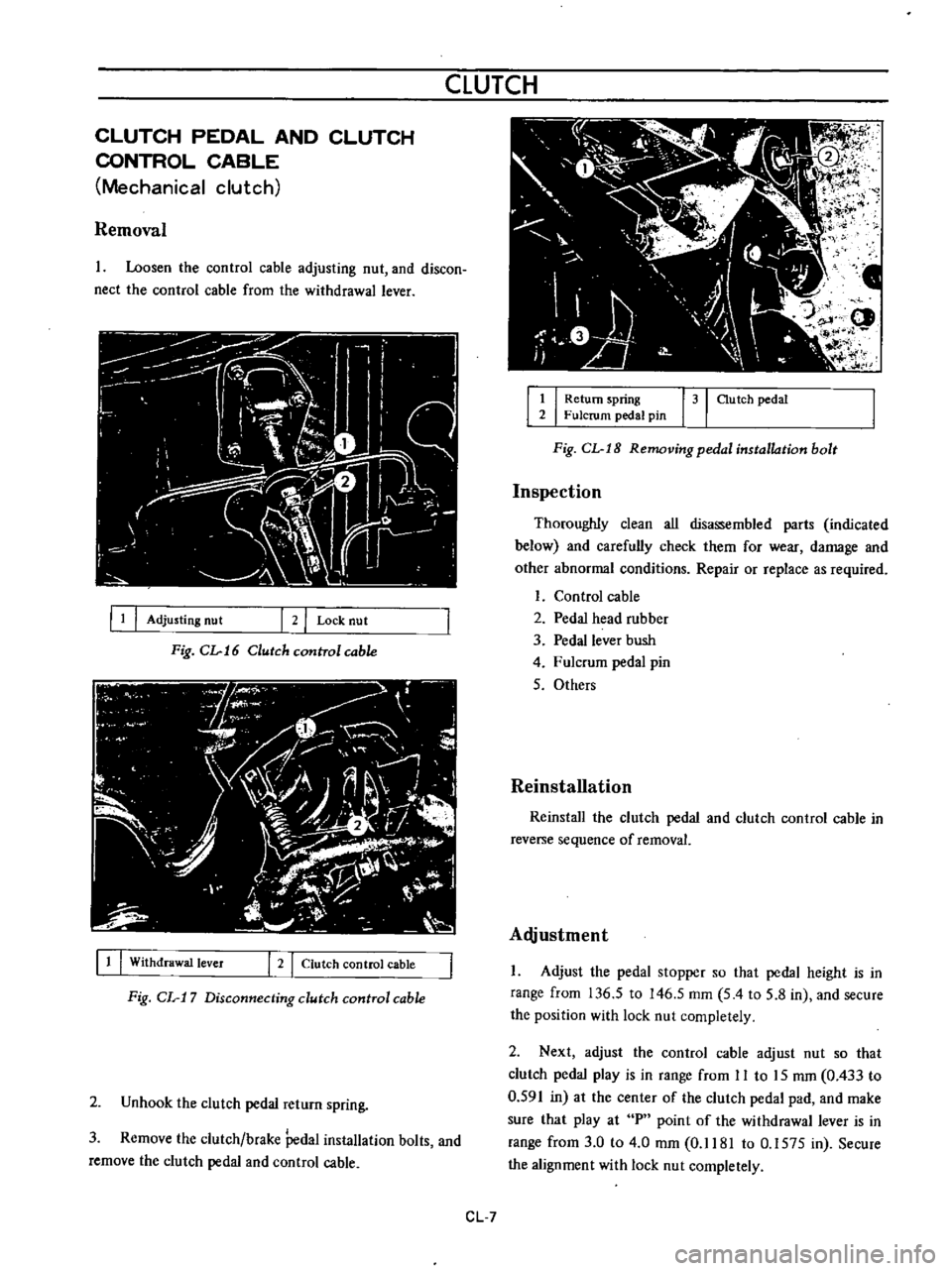

CLUTCH

CLUTCH

PEDAL

AND

CLUTCH

CONTROL

CABLE

Mechanical

clutch

Removal

Loosen

the

control

cable

adjusting

nut

and

discon

nect

the

control

cable

from

the

withdrawal

lever

III

Adjusting

nut

2

I

Lock

nut

Fig

CL

16

Clutch

cunITol

cable

11

I

Withdrawal

lever

I

2

I

Clutch

control

cable

Fig

CL

17

Disconnecting

clutch

control

cable

2

Unhook

the

clutch

pedal

return

spring

3

Remove

the

clutch

brake

Pedal

installation

bolts

and

remove

the

clutch

pedal

and

control

cable

1

I

Return

spring

31

au

tch

pedal

2

Fulcrum

pedal

pin

Fig

CL

I8

Removing

pedal

installation

bolt

Inspection

Thoroughly

clean

all

disassembled

parts

indicated

below

and

carefully

check

them

for

wear

damage

and

other

abnormal

conditions

Repair

or

replace

as

required

Control

cable

2

Pedal

head

rubber

3

Pedal

lever

bush

4

Fulcrum

pedal

pin

5

Others

Reinstallation

Reinstall

the

clutch

pedal

and

clutch

control

cable

in

reverse

sequence

of

removal

Alljustment

Adjust

the

pedal

stopper

so

that

pedal

height

is

in

range

from

136

5

to

146

5

mm

5

4

to

5

8

in

and

secure

the

position

with

lock

nut

completely

2

Next

adjust

the

control

cable

adjust

nut

so

that

clutch

pedal

play

is

in

range

from

II

to

15

mm

0

433

to

0

591

in

at

the

center

of

the

clutch

pedal

pad

and

make

sure

that

play

at

P

point

of

the

withdrawal

lever

is

in

range

from

3

0

to

4

0

mm

0

1181

to

0

1575

in

Secure

the

alignment

with

lock

nut

completely

CL

7

Page 479 of 513

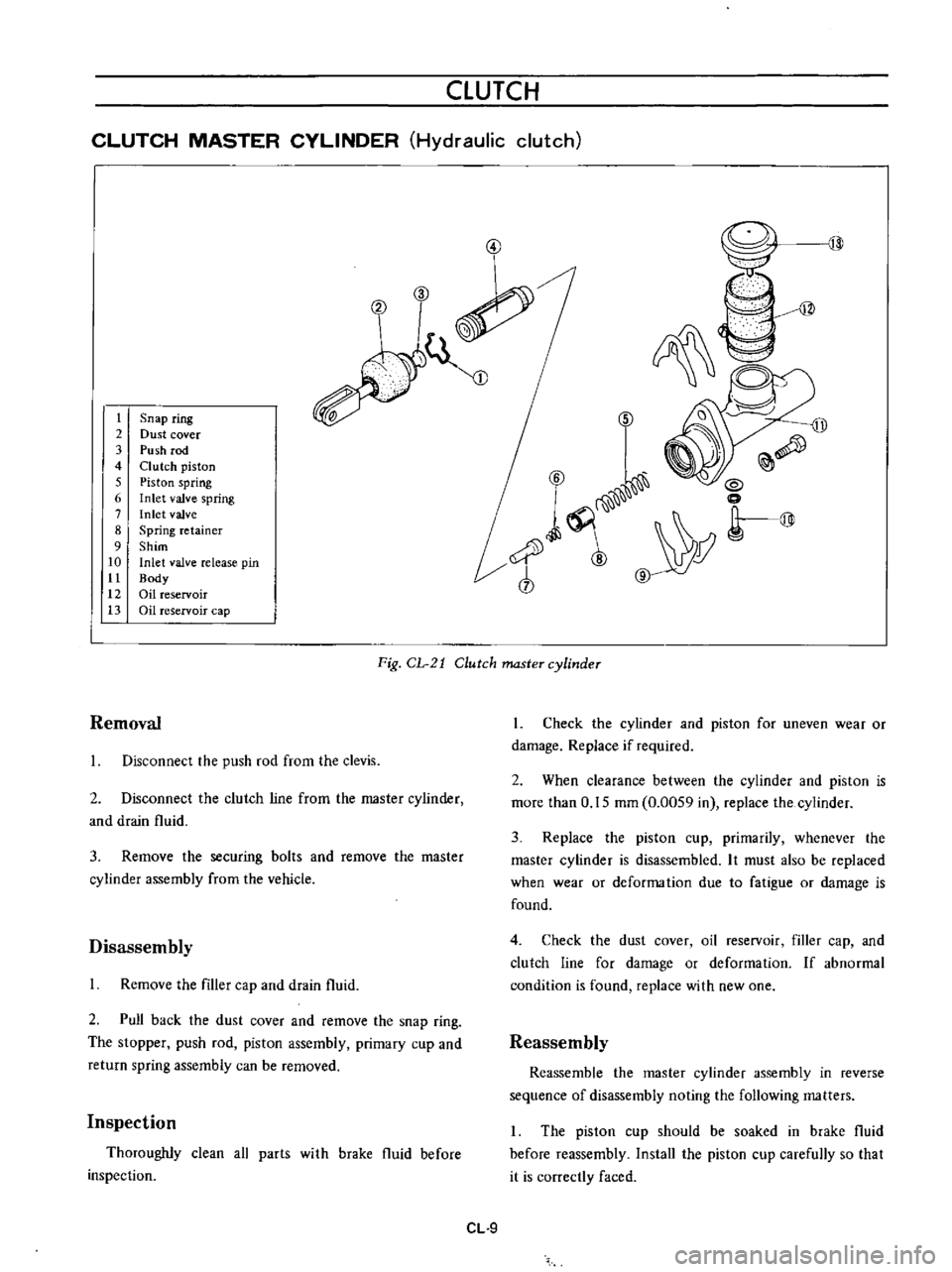

CLUTCH

CLUTCH

MASTER

CYLINDER

Hydraulic

clutch

3

V

t

2

3

4

5

6

7

8

9

10

tt

12

13

Snap

ring

Dust

cover

Push

rod

Clutch

piston

Piston

spring

Inlet

valve

spring

Inlet

valve

Spring

retainer

Shim

Inlet

valve

release

pin

Body

Oil

reservoir

Oil

reservoir

cap

6

D

ll

Q

6

i

0

l

Y

r@

cb

Fig

CL

21

Clutch

master

cylinder

Removal

Disconnect

the

push

rod

from

the

clevis

2

Disconnect

the

clutch

line

from

the

master

cylinder

and

drain

fluid

3

Remove

the

securing

bolts

and

remove

the

master

cylinder

assembly

from

the

vehicle

Disassembly

Remove

the

filler

cap

and

drain

fluid

2

Pull

back

the

dust

cover

and

remove

the

snap

ring

The

stopper

push

rod

piston

assembly

primary

cup

and

return

spring

assembly

can

be

removed

Inspection

Thoroughly

clean

all

parts

with

brake

fluid

before

inspection

CL

9

1

Check

the

cylinder

and

piston

for

uneven

wear

or

damage

Replace

if

required

2

When

clearance

between

the

cylinder

and

piston

is

more

than

0

15

mm

0

0059

in

replace

the

cylinder

3

Replace

the

piston

cup

primarily

whenever

the

master

cylinder

is

disassembled

It

must

also

be

replaced

when

wear

or

deforma

tion

due

to

fatigue

or

damage

is

found

4

Check

the

dust

cover

oil

reservoir

filler

cap

and

clutch

line

for

damage

or

deformation

If

abnormal

condition

is

found

replace

with

new

one

Reassembly

Reassemble

the

master

cylinder

assembly

in

reverse

sequence

of

disassembly

noting

the

following

matters

The

piston

cup

should

be

soaked

in

brake

fluid

before

reassembly

Install

the

piston

cup

carefully

so

that

it

is

correctly

faced

Page 481 of 513

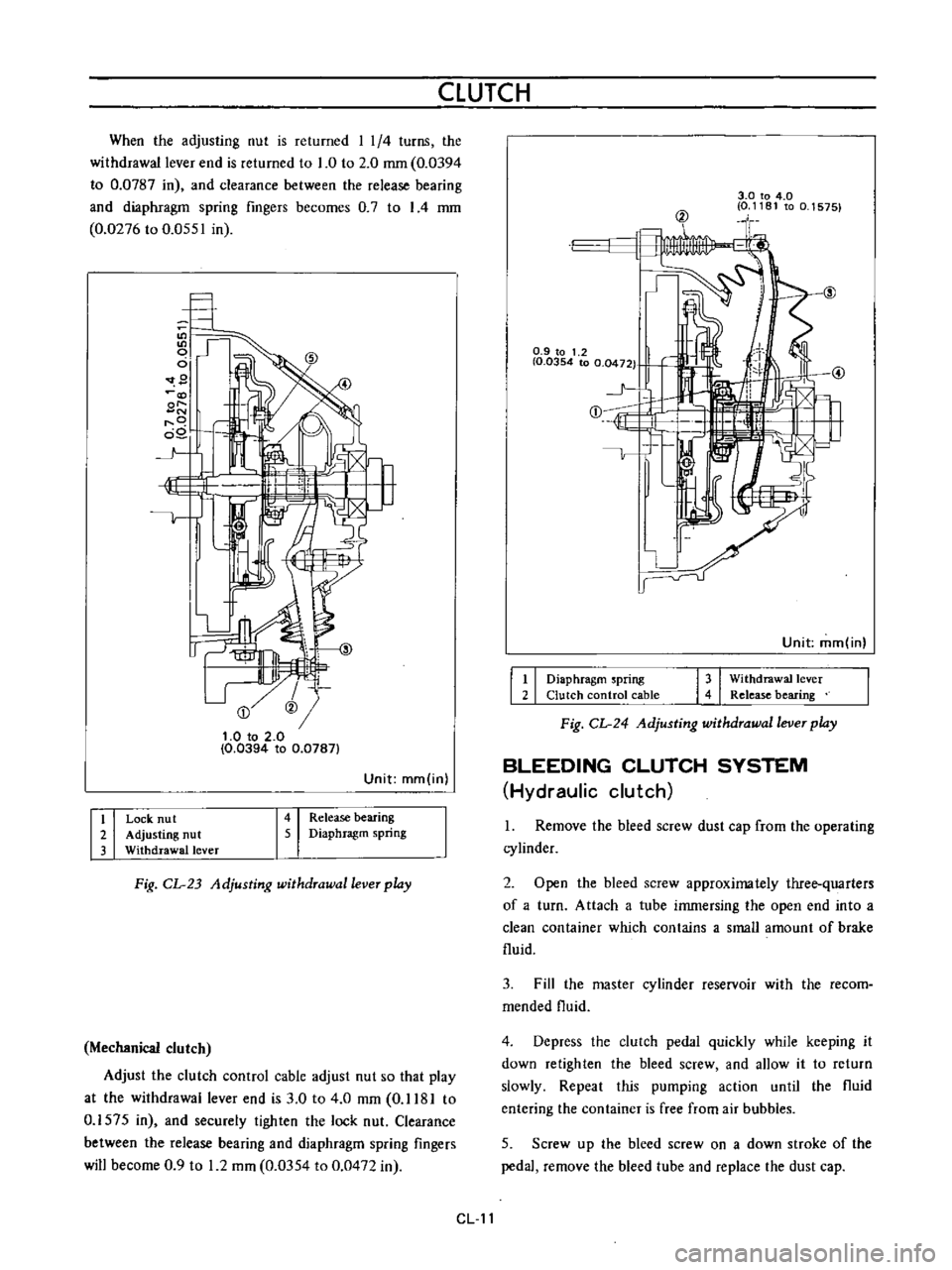

CLUTCH

When

the

adjusting

nut

is

returned

I

1

4

turns

the

withdrawal

lever

end

is

returned

to

1

0

to

2

0

mm

0

0394

to

0

0787

in

and

clearance

between

the

release

bearing

and

diaphragm

spring

fingers

becomes

0

7

to

I

4

mm

0

0276

to

0

0551

in

9

@

t

O

to

2

0

0

0394

to

0

0787

Unit

mm

in

I

i

I

I

I

Release

bearing

Diaphragm

spring

Lock

nu

t

Adjusting

nut

Withdrawal

lever

Fig

CL

23

Adjusting

withdrawal

lever

play

Mechanical

clutch

Adjust

the

clutch

control

cable

adjust

nut

so

that

play

at

the

withdrawal

lever

end

is

3

0

to

4

0

mm

0

1181

to

0

1575

in

and

securely

tighten

the

lock

nut

Clearance

between

the

release

bearing

and

diaphragm

spring

fingers

will

become

0

9

to

1

2

mm

0

0354

to

0

0472

in

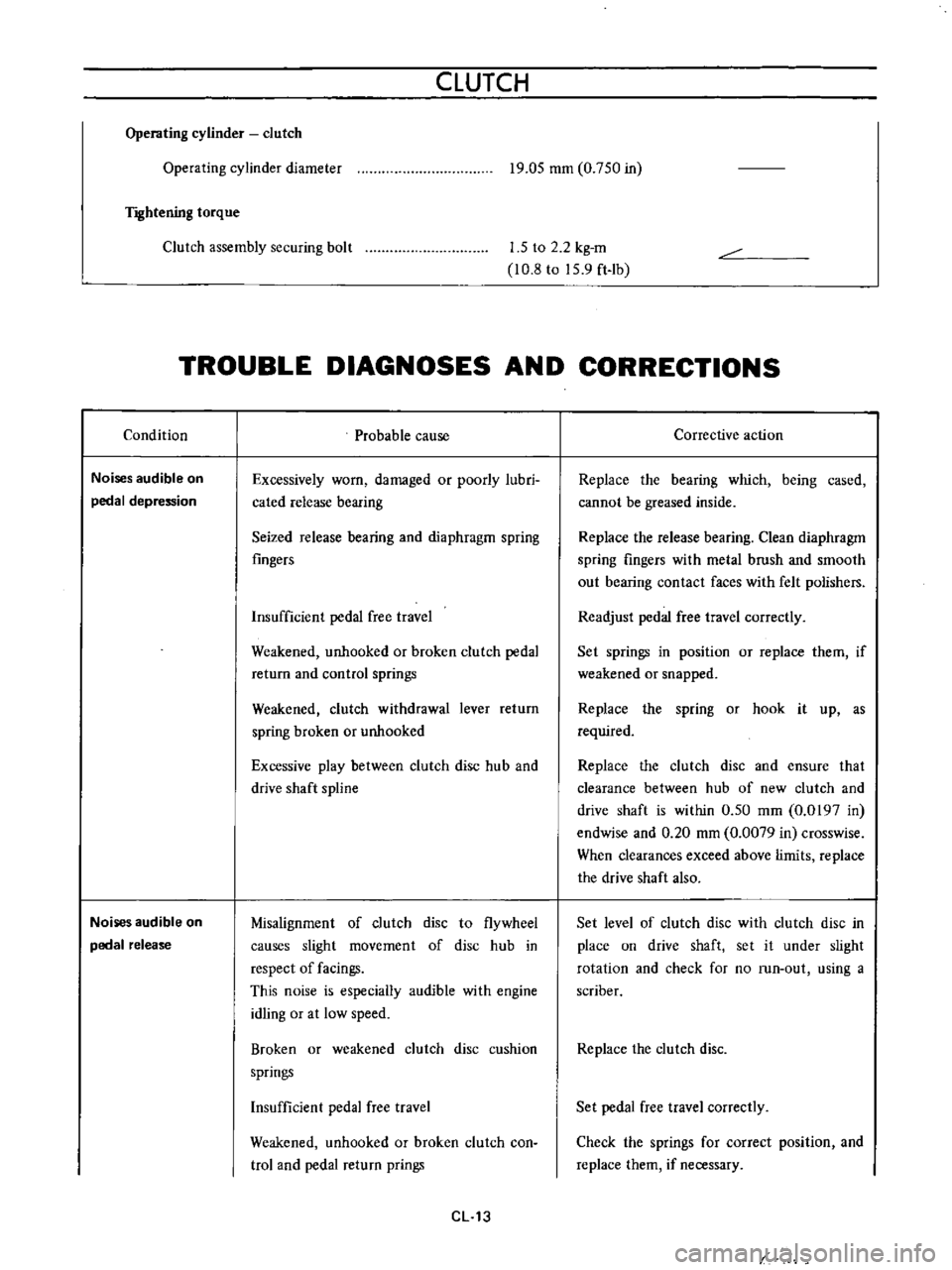

3

0

to

4

0

0

1181

to

0

1575

@

0

9

to

1

2

I

0

0354

to

0

0472

1

j

E

1

Unit

mm

in

I

I

I

I

Diaphragm

spring

Clutch

control

cable

Withdrawal

lever

Release

bearing

Fig

CL

24

Adjusting

withdrawal

lever

play

BLEEDING

CLUTCH

SYSTEM

Hydraulic

clutch

1

Remove

the

bleed

screw

dust

cap

from

the

operating

cylinder

2

Open

the

bleed

screw

approximately

three

quarters

of

a

turn

Attach

a

tube

immersing

the

open

end

into

a

clean

container

which

contains

a

small

amount

of

brake

fluid

3

Fill

the

master

cylinder

reservoir

with

the

recom

mended

fluid

4

Depress

the

clutch

pedal

quickly

while

keeping

it

down

retighten

the

bleed

screw

and

allow

it

to

return

slowly

Repeat

this

pumping

action

until

the

fluid

entering

the

container

is

free

from

air

bubbles

5

Screw

up

the

bleed

screw

on

a

down

stroke

of

the

pedal

remove

the

bleed

tube

and

replace

the

dust

cap

CL

11

Page 483 of 513

CLUTCH

Operating

cylinder

clutch

Operating

cylinder

diameter

T

Ilhtening

torque

19

05

mm

0

750

in

Clutch

assembly

securing

bolt

1

5

to

2

2

kg

m

10

8

to

15

9

ft

Ib

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Condition

Noises

audible

on

pedal

depression

Noises

audible

on

pedal

release

Probable

cause

Excessively

worn

damaged

or

poorly

lubri

cated

release

bearing

Seized

release

bearing

and

diaphragm

spring

fingers

Insufficient

pedal

free

travel

Weakened

unhooked

or

broken

clutch

pedal

return

and

control

springs

Weakened

clutch

withdrawal

lever

return

spring

broken

or

unhooked

Excessive

play

between

clutch

disc

hub

and

drive

shaft

spline

Misalignment

of

clutch

disc

to

flywheel

causes

slight

movement

of

disc

hub

in

respect

of

facings

This

noise

is

especially

audible

with

engine

idling

or

at

low

speed

Broken

or

weakened

clutch

disc

cushion

springs

Insufficient

pedal

free

travel

Weakened

unhooked

or

broken

clutch

con

trol

and

pedal

return

prings

CL

13

Corrective

action

Replace

the

bearing

which

being

cased

cannot

be

greased

inside

Replace

the

release

bearing

Clean

diaphragm

spring

fingers

with

metal

brush

and

smooth

out

bearing

contact

faces

with

felt

polishers

Readjust

pedal

free

travel

correctly

Set

springs

in

position

or

replace

them

if

weakened

or

snapped

Replace

the

spring

or

hook

it

up

as

required

Replace

the

clutch

disc

and

ensure

that

clearance

between

hub

of

new

clutch

and

drive

shaft

is

within

0

50

mm

0

0197

in

endwise

and

0

20

mm

0

0079

in

crosswise

When

clearances

exceed

above

limits

replace

the

drive

shaft

also

Set

level

of

clutch

disc

with

clutch

disc

in

place

on

drive

shaft

set

it

under

slight

rotation

and

check

for

no

run

out

using

a

scriber

Replace

the

clutch

disc

Set

pedal

free

travel

correctly

Check

the

springs

for

correct

position

and

replace

them

if

necessary