charging DATSUN PICK-UP 1977 Service Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 146 of 537

The

non

California

type

operates

as

follows

secondary

air

is

sucked

through

the

air

pump

air

cleaner

into

the

air

pump

driven

by

the

crank

pulley

It

is

then

discharged

through

the

check

valve

to

the

air

gallety

where

it

is

distributed

to

each

exhaust

porL

The

secondary

air

is

then

injected

from

the

injection

nozzle

into

the

exhaust

port

near

the

exhaust

valve

The

air

relief

valve

opens

only

when

the

discharge

pressure

of

the

air

pump

surpasses

the

spring

force

of

the

air

relief

valve

during

high

speed

opera

tion

When

the

air

relief

valve

opens

the

secondary

air

is

discharged

in

to

the

carburetor

air

c1eaner

The

anti

backfire

valve

opens

when

the

intake

manifold

vacuum

reaches

a

predetermined

value

during

decelera

tion

and

permits

fresh

air

to

now

into

the

intake

manifold

from

the

air

cleaner

f

I

Jl

rn

l

I

Air

pump

2

Air

pump

air

cleaner

3

Emergency

air

relief

valve

4

Air

relief

valve

riu

Qj

j

I

@

Emission

Control

System

To

intake

manifold

The

California

type

includes

in

addition

to

the

components

of

the

non

California

type

an

air

control

valve

and

an

emergency

air

relief

valve

The

air

control

valve

opens

when

the

sum

of

the

air

pump

discharge

pressure

and

the

intake

manifold

vacu

um

applied

to

the

diaphmgm

reaches

a

predetermined

level

and

discharges

the

secondary

air

into

the

air

cleaner

When

the

pressure

becomes

low

the

valve

doses

with

the

spring

force

of

3

5

Air

cleaner

6

Check

valve

7

Air

gallery

pipe

8

Carburetor

EC

13

To

intake

manifold

Air

diSlcharge

to

intake

manifold

Secondary

air

EC297

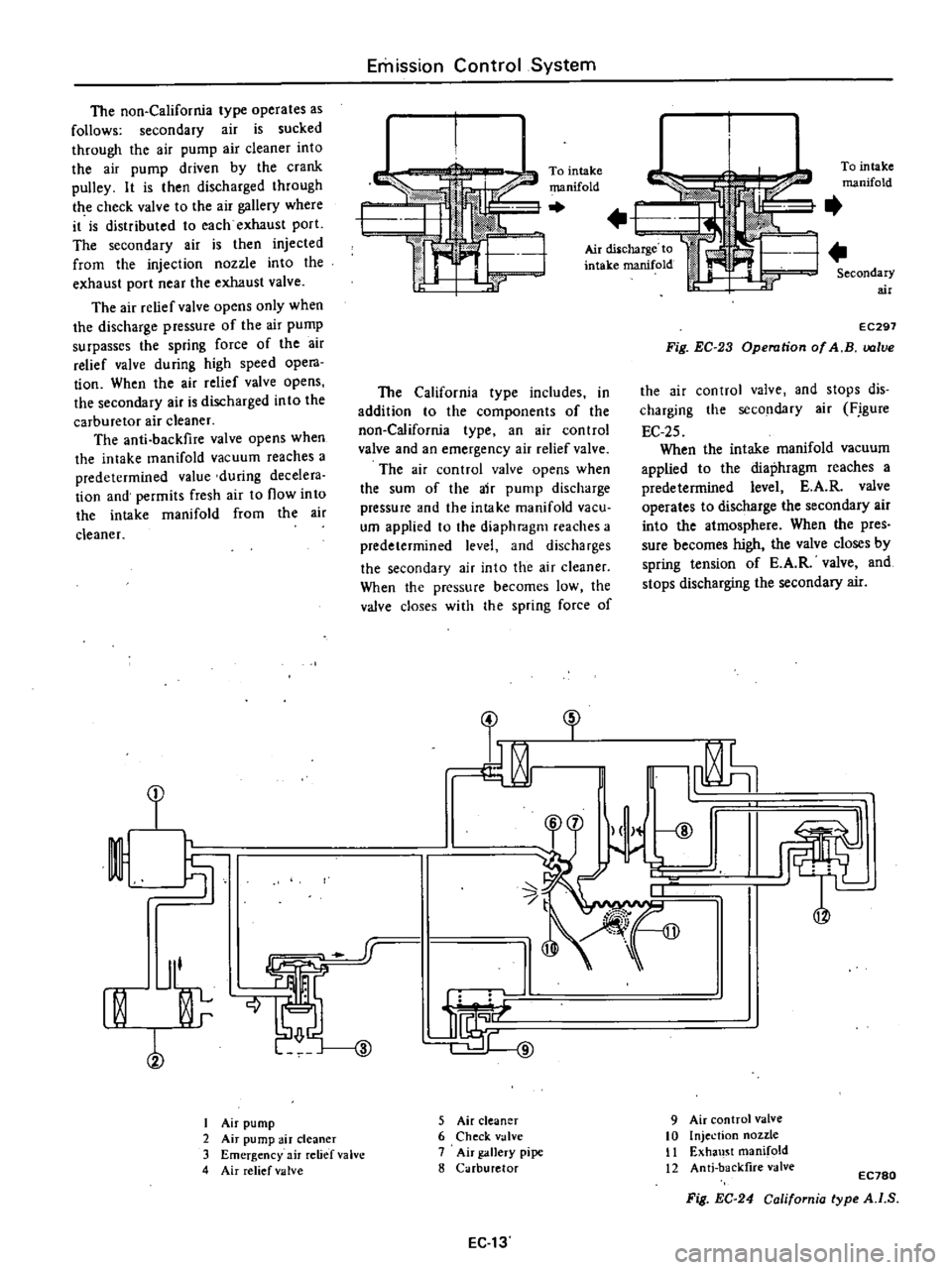

Fig

EC

23

Operation

of

A

B

lve

the

air

control

valve

and

stops

dis

charging

the

secondary

air

F

igure

EC

25

When

the

intake

manifold

vacuum

applied

to

the

diaphragm

reaches

a

predetermined

level

E

A

R

valve

operates

to

discharge

the

secondary

air

into

the

atmosphere

When

the

pres

sure

becomes

high

the

valve

closes

by

spring

tension

of

E

A

R

valve

and

stops

discharging

the

secondary

air

fl

t

9

Air

control

valve

10

Injection

nozzle

II

Exha

l

t

manifold

12

Anti

backfire

valve

EC780

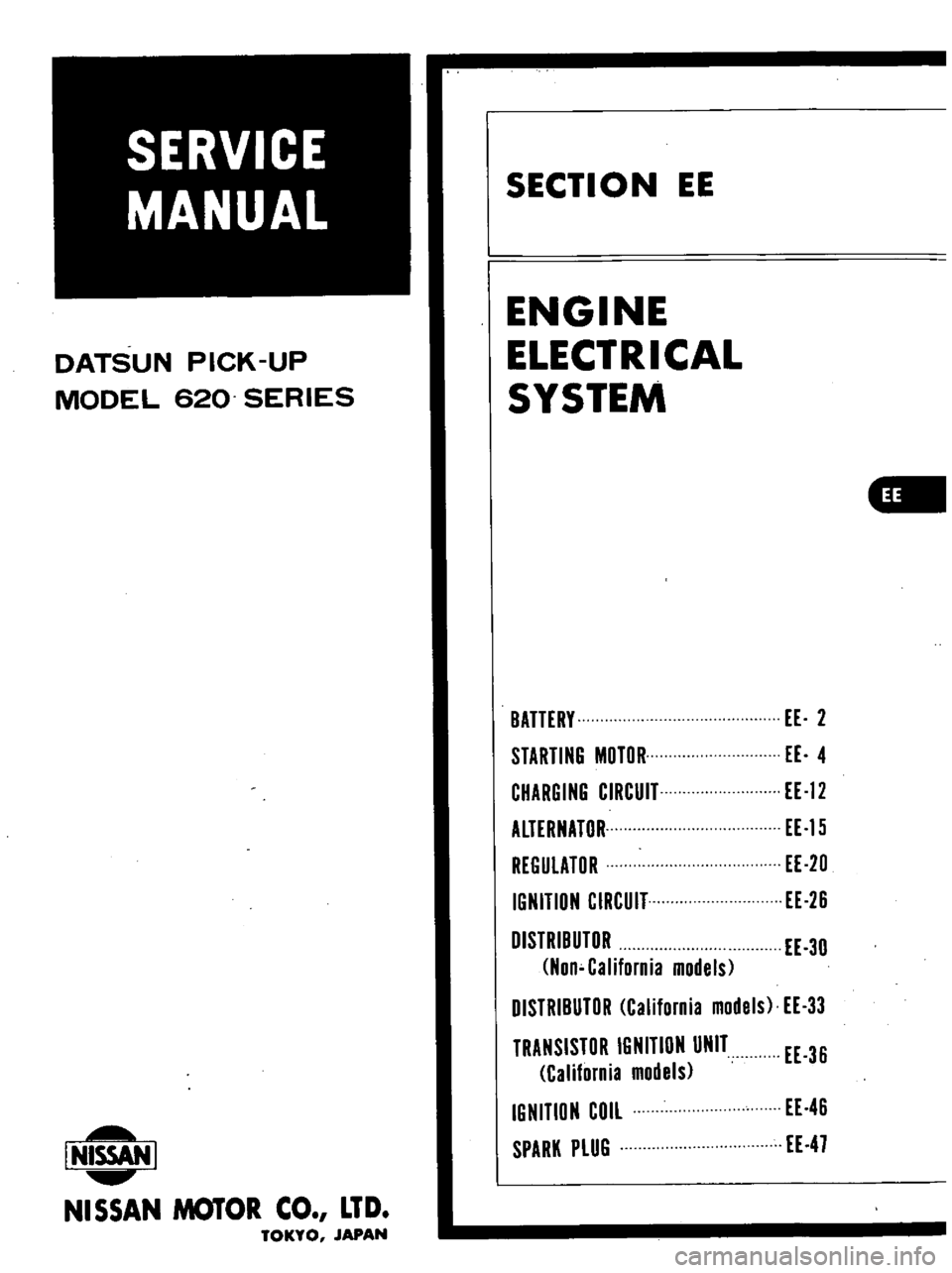

Fig

EC

24

California

type

A

I

S

Page 168 of 537

DATSUN

PICK

UP

MODEL

620

SERIES

I

NISSAN

I

NISSAN

MOTOR

CO

LTD

TOKYO

JAPAN

SECTION

EE

ENGINE

ELECTRICAL

SYSTEM

BATTERY

EE

2

STARTING

MOTOR

EE

4

CHARGING

CIRCUIT

EE

12

ALTERNATOR

EE

15

REGULATOR

EE

20

IGNITION

CIRCUIT

EE

26

DISTRIBUTOR

EE

30

Non

California

models

DISTRIBUTOR

California

models

EE

33

TRANSISTOR

IGNITION

UNIT

California

models

IGNITION

COIL

SPARK

PLUG

EE

36

EE

46

EE

47

Page 169 of 537

REMOVAL

CHECKING

ELECTROLYTE

LEVEL

CHECKING

SPECIFIC

GRAVITY

REMOVAL

I

Disconnect

negative

and

positive

cables

2

Remove

nuts

from

battery

clamps

take

off

clamps

3

Remove

battery

CHECKING

ELECTROLYTE

LEVEL

Remove

six

vent

plugs

and

check

for

electrolyte

level

in

each

cell

If

nccessaJ

pour

distilled

water

CHECKING

SPECIFIC

GRAVITY

Specific

gravity

of

battery

electro

lyte

is

tested

by

a

hydrometer

If

the

srate

of

charge

of

battery

is

60

or

specific

gravity

reading

is

below

1

20

as

corrected

at

200e

680F

bat

tery

must

be

recharged

or

battery

electrolyte

concentration

adjusted

Add

or

subtract

gravity

points

according

to

whether

the

electrolyte

temperature

is

above

or

below

200e

680F

standard

The

gravity

of

electrolyte

chlll

ges

0

0007

for

every

Ioe

1

80F

tem

petature

A

correction

can

then

be

made

by

using

the

following

formula

Engine

Electrical

System

BATTERY

CONTENTS

EE

2

EE

2

EE

2

BATTERY

FREEZING

CHARGING

INST

ALLA

TION

S

20

St

0

0007

t

20

Where

St

Specific

gravity

of

electrolyte

at

tOe

520

Specific

gravity

of

electrolyte

corrected

at

200e

680F

t

Electrolyte

temperature

For

example

A

hydrometer

reading

of

1

260

at

300e

860F

would

be

1

267

corrected

to

200e

6goF

indicating

fully

charged

battery

On

the

other

hand

a

hydro

meter

reading

of

1

220

at

lOoe

140

F

would

be

1

199

corrected

to

200e

680F

indicating

a

partially

charged

battery

The

state

of

charge

of

battery

can

be

determined

by

the

following

table

if

the

specific

gravity

of

electrolyte

is

known

BefOIe

checking

be

sure

that

cells

are

filled

to

correct

level

G

U

o

N

b

t

E

u

ol

1

lilt

I

i

I

m

J

I

I

I

I

J

1

I

J

Sf

to

7

1

II

It

100

0wJIztI

COJJditioD

EE002

Fig

EE

2

ChaJ

ffing

condition

EE

2

1

28

@

126

S

Sow

E

l

l

u

o

o

l

e

u

0

U21

1

101

EE

3

EE

3

EE

3

Read

top

level

with

scale

1

Thermal

gauge

2

Hydrometer

feOOl

Fig

EE

l

Checking

pccme

gravity

Converted

specific

gavity

20

1

Je

I

dOldlOiJ

OSQ

Electrolyte

temperature

oC

EEOO3

Fig

EE

3

Specific

lNWity

at

eiectroly

te

temperature

Page 170 of 537

BATTERY

FREEZING

Battery

electrolyte

freezing

point

varies

with

acid

concentration

or

its

specific

gravity

A

battery

with

an

insufficient

charge

will

freeze

at

lower

temperatures

If

specific

gravity

of

a

battery

falls

below

1

1

this

is

an

0

10

20

30

g

40

I

u

il

SO

I

0

e

60

0

E

70

Engine

Electrical

System

indication

that

battery

is

completely

discharged

and

will

freeze

readily

when

temperatures

fall

below

freezing

Note

Use

extreme

caution

to

avoid

freezing

battery

since

freezing

will

generally

ruin

the

battery

1

80

1

00

1

04

1

08

t

l2

1

16

t

20

1

24

1

28

Specific

gravity

of

electrolyte

CHARGING

I

f

electrolyte

level

is

satisfactory

battery

must

be

charged

when

electro

lyte

gravity

reading

falls

below

1

20

If

battery

on

car

is

quick

charged

to

1

32

EEOQ4

Fig

EE

4

Froezing

point

of

electrolyte

bring

it

up

to

full

charge

the

opera

tion

should

be

carried

out

with

nega

tive

cable

removed

Prior

to

charging

corroded

termi

EE

3

nals

should

be

cleaned

with

a

brush

and

common

baking

soda

solution

In

addition

the

following

items

should

be

observed

while

battery

is

being

charged

I

Be

sure

that

electrolyte

level

is

above

top

of

each

plate

2

Keep

removed

plugs

in

a

safe

place

3

Do

not

allow

electrolyte

tempera

ture

to

go

over

450C

I130F

4

After

charging

check

to

be

cer

tain

that

specific

gravity

does

not

exceed

1

260

at

200C

680P

Cor

rection

can

be

made

by

adding

dis

tilled

water

into

cells

as

necessary

5

Keep

battery

away

from

open

flame

while

it

is

being

charged

6

After

all

vent

plugs

have

been

tightened

clean

all

sprayed

electrolyte

off

upper

face

of

battery

INSTALLATION

1

Install

and

tighten

clamps

secure

Iy

2

After

clamps

have

been

tightened

clean

battery

cable

terminals

and

apply

grease

to

retard

formation

of

corrosion

Page 179 of 537

Condition

Engine

Electrical

System

Probable

cause

Starting

motor

cranks

slowly

Dirty

or

worn

commutator

Armature

rubs

field

coil

Damaged

solenoid

switch

Starting

motor

operates

but

does

not

crank

engine

Worn

pinion

Locked

pinion

guide

Worn

ring

gear

Starting

motor

will

not

disengage

even

if

ignition

switch

is

turned

off

Damaged

solenoid

switch

Damaged

gear

teeth

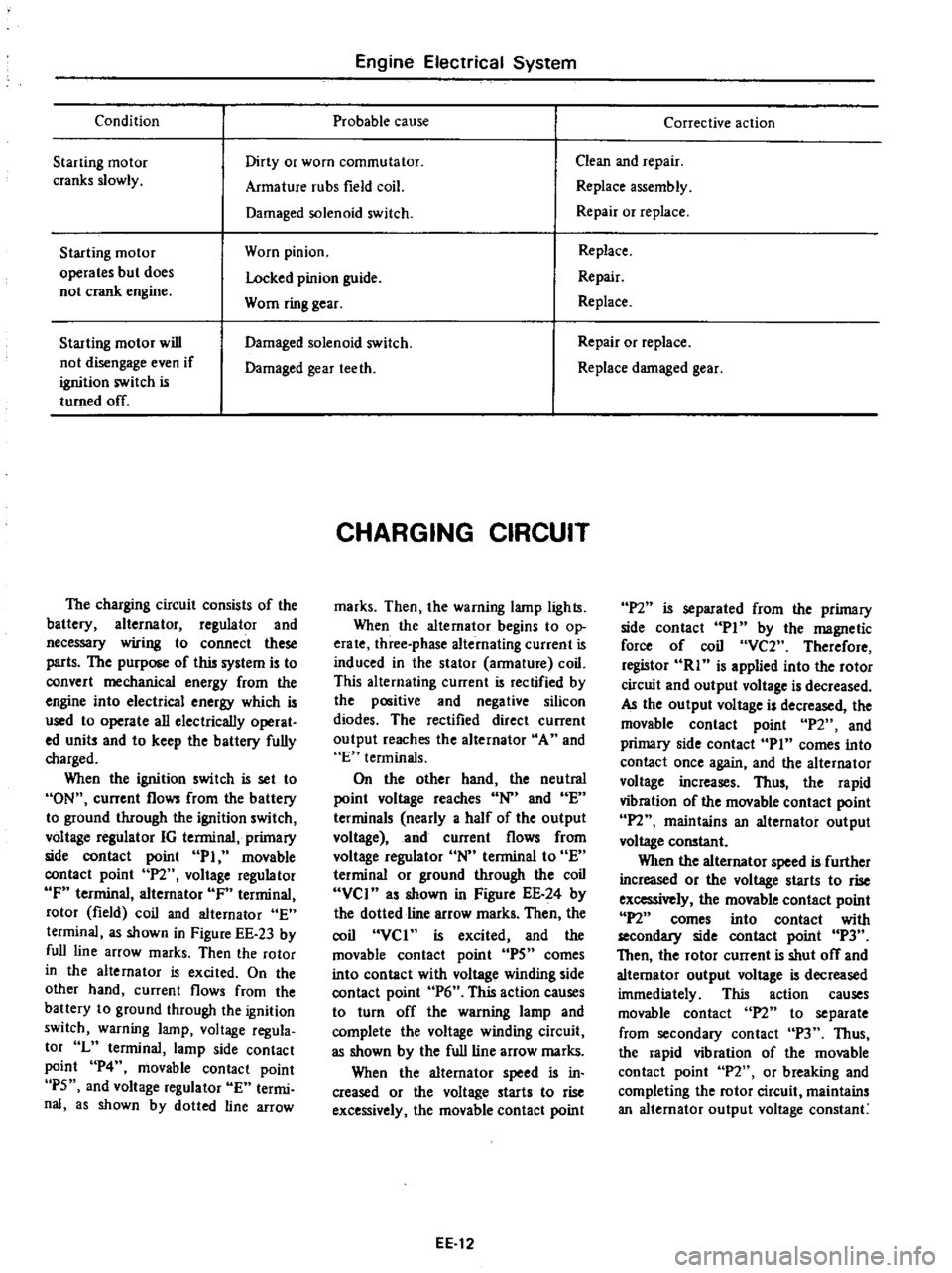

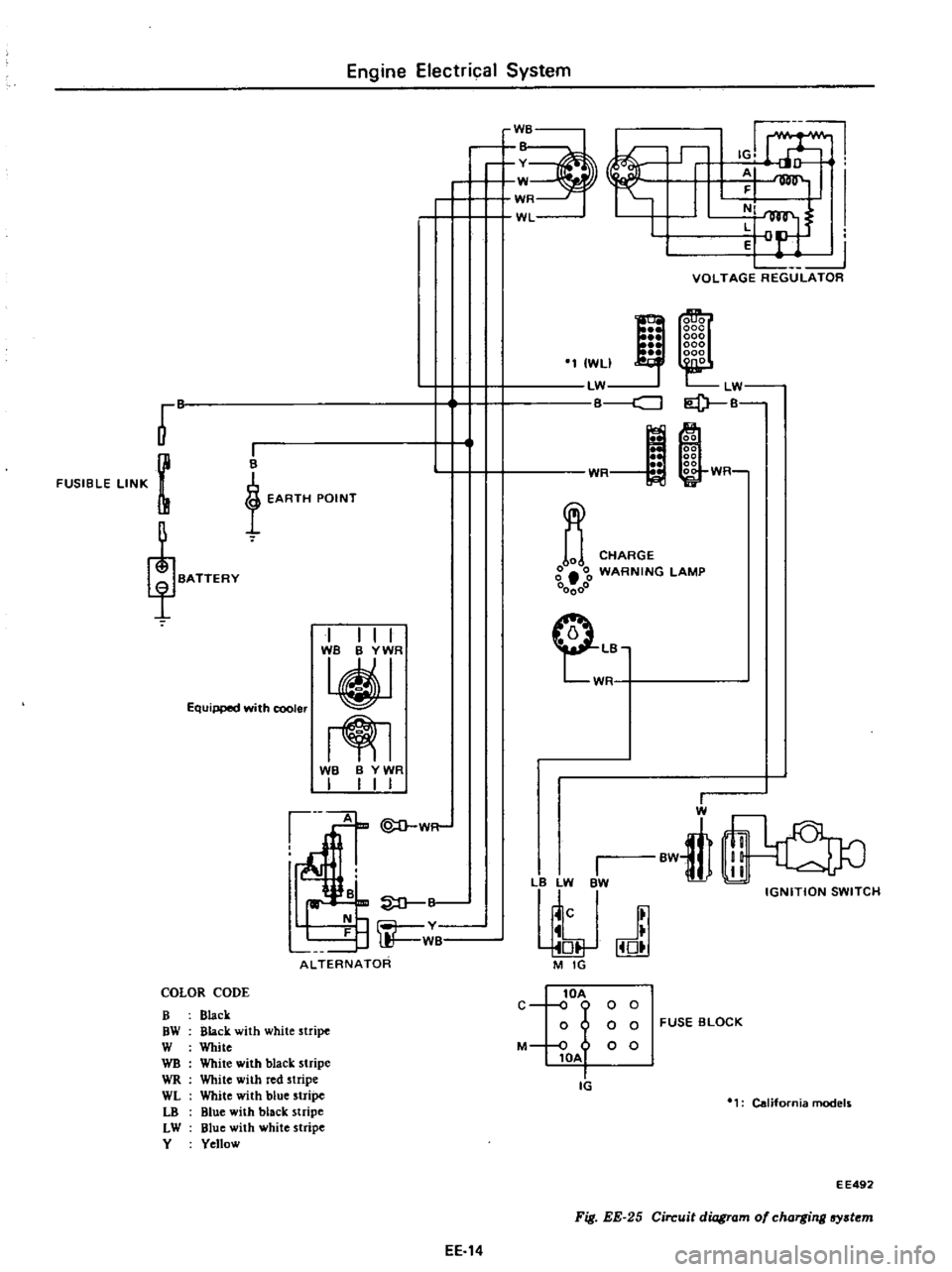

The

charging

circuit

consists

of

the

battery

alternator

regulator

and

necessary

wiring

to

connect

these

parts

The

purpose

of

this

system

is

to

convert

mechanical

energy

from

the

engine

into

electrical

energy

which

is

used

to

operate

all

electrically

operat

ed

units

and

to

keep

the

battery

fully

charged

When

the

ignition

switch

is

set

to

ON

current

flows

from

the

battery

to

ground

through

the

ignition

switch

voltage

regulator

IG

terminal

primary

side

contact

point

PI

movable

contact

point

P2

voltage

regulator

IF

terminal

alternator

IF

terminal

rotor

field

coil

and

alternator

E

terminal

as

shown

in

Figure

EE

23

by

full

line

arrow

marks

Then

the

rotor

in

the

alternator

is

excited

On

the

other

hand

current

flows

from

the

battery

to

ground

through

the

ignition

switch

warning

lamp

voltage

regula

tor

L

terminal

lamp

side

contact

point

P4

movable

contact

point

P5

and

voltage

regulator

E

termi

nal

as

shown

by

dotted

line

arrow

CHARGING

CIRCUIT

marks

Then

the

warning

lamp

lights

When

the

alternator

begins

to

op

erate

three

phase

alternating

current

is

induced

in

the

stator

armature

coil

This

alternating

current

is

rectified

by

the

positive

and

negative

silicon

diodes

The

rectified

direct

current

output

reaches

the

alternator

A

and

E

terminals

On

the

other

hand

the

neutral

point

voltage

reaches

N

and

E

terminals

nearly

a

half

of

the

output

voltage

and

current

flows

from

voltage

regulator

N

terminal

to

E

terminal

or

ground

through

the

coil

VCI

as

shown

in

Figure

EE

24

by

the

dotted

line

arrow

marks

Then

the

coil

VCI

is

excited

and

the

movable

contact

point

IPS

comes

into

contact

with

voltage

winding

side

contact

point

P6

This

action

causes

to

turn

off

the

warning

lamp

and

complete

the

voltage

winding

circuit

as

shown

by

the

full

line

arrow

marks

When

the

alternator

speed

is

in

creased

or

the

voltage

starts

to

rise

excessively

the

movable

contact

point

EE

12

Corrective

action

Clean

and

repair

Replace

assembly

Repair

or

replace

Replace

Repair

Replace

Repair

or

replace

Replace

damaged

gear

P2

is

separated

from

the

primary

side

contact

PI

by

the

magnetic

force

of

coil

VC2

Therefore

registor

RI

is

applied

into

the

rotor

circuit

and

output

voltage

is

decreased

AJ

the

output

voltage

is

decreased

the

movable

contact

point

P2

and

primary

side

contact

Pin

comes

into

contact

once

again

and

the

alternator

voltage

increases

Thus

the

rapid

vibration

of

the

movable

contact

point

IPl

maintains

an

alternator

output

voltage

constant

When

the

alternator

speed

is

further

increased

or

the

voltage

starts

to

rise

excessively

the

movable

contact

point

P2

comes

into

contact

with

secondllJ

side

contact

point

P3

Then

the

rotor

current

is

shut

off

and

alternator

output

voltage

is

decreased

immediately

This

action

causes

movable

contact

n

to

separate

from

secondary

contact

P3

Thus

the

rapid

vibration

of

the

movable

contact

point

P2

or

breaking

and

completing

the

rotor

circuit

maintains

an

alternator

output

voltage

constant

Page 180 of 537

Engine

Electrical

System

r

l

I

I

I

i

r

Ye

Ff

p

Stator

ma

ture

coiJ

FF

vw

I

I

RI

L

Rot

r

field

C

oil

e

R

I

I

I

I

I

J

1

J

Alternator

Voltage

regulator

11

t

c

I

Fusible

link

t

8

c

J

5

9

i

c

c

0

Battery

t

u

J

EE029

Fig

EE

23

Charging

circuit

II

p

ns

1

Slator

ar

ature

coil

teJ

U

2iI

I

r

R

l

I

I

A3

R2

0

Fusible

link

Roto

field

coil

e

I

I

t

I

I

PS

M

g

j

t

i

H

U

Battery

Lh

A

l

a

o

J

L

V

It

g

t

f

EE030

Fig

EE

24

Charging

circuit

II

EE

13

Page 181 of 537

Engine

Electrical

System

B

v

W

WR

WL

L2

VOLTAGE

REGULATOR

co

LW

I

P

B

r

FUSIBLE

LINK

m

I

WLI

LW

cJ

I

B

t

EARTH

POINT

m

WR

WR

CHARGE

g

00

WARNING

lAMP

00000

Equipped

with

cooler

I

I

I

I

TjT

m

CLB

W

WB

B

YWR

I

I

I

I

1

W

B

rn

ALTERNATOR

I

l

LW

BW

j

J

M

IG

I

W

BwtIl

IGNITION

SWITCH

COLOR

CODE

B

Black

OW

Black

with

white

stripe

W

White

WB

White

with

black

stripe

WR

White

with

red

stripe

WL

White

with

blue

stripe

LO

Blue

with

black

stripe

LW

Blue

with

white

stripe

Y

Yellow

lOA

C

o

0

0

0

o

0

0

FUSE

BLOCK

M

0

0

0

lOA

Ii

California

models

E

E492

Fig

EE

25

Circuit

diagram

of

charging

lfY

t

m

EE

14

Page 182 of 537

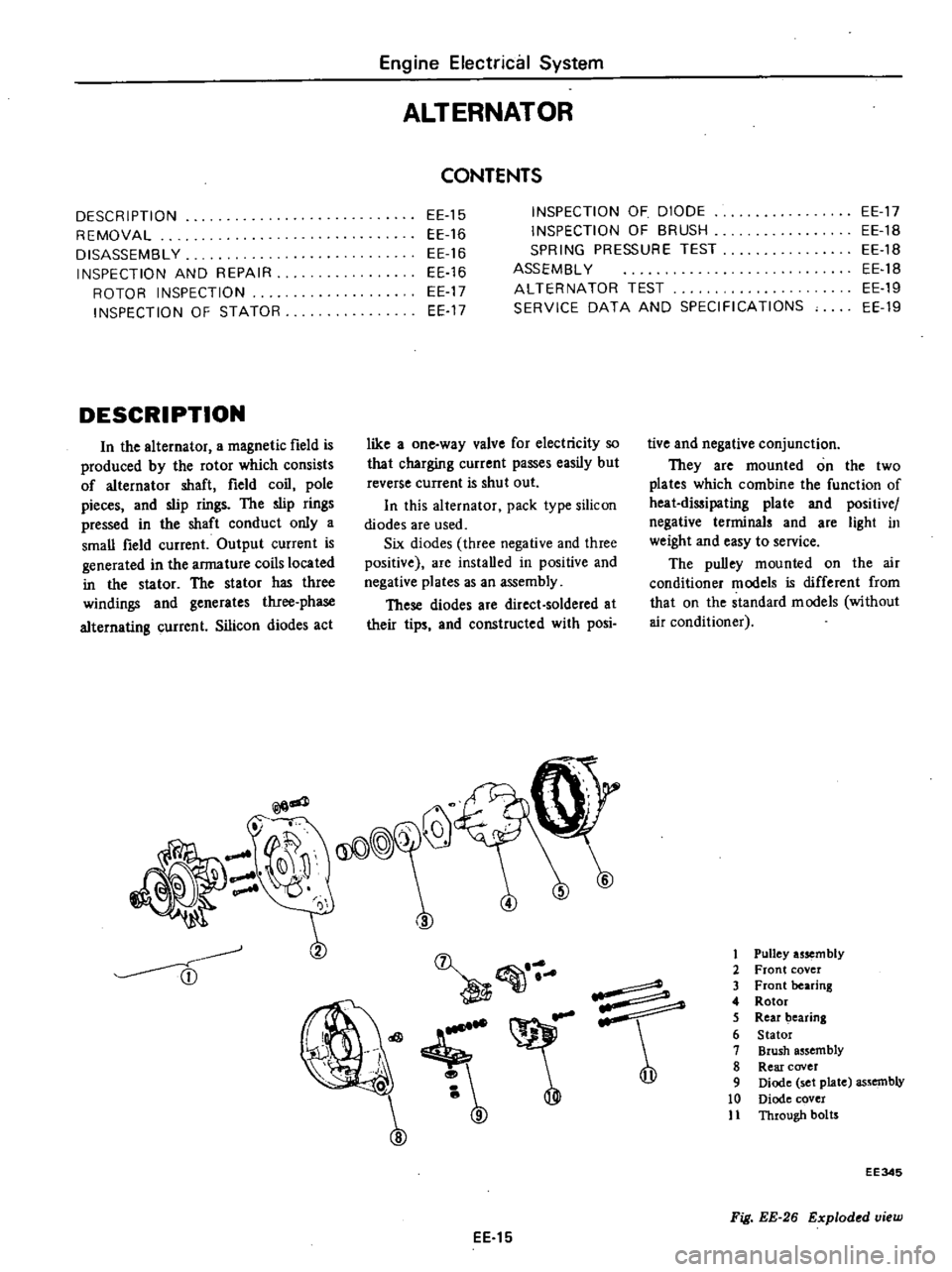

DESCRIPTION

REMOVAL

DISASSEMBLY

INSPECTION

AND

REPAIR

ROTOR

INSPECTION

INSPECTION

OF

STATOR

DESCRIPTION

In

the

alternator

a

magnetic

field

is

produced

by

the

rotor

which

consists

of

alternator

shaft

field

coil

pole

pieces

and

slip

rings

The

slip

rings

pressed

in

the

shaft

conduct

only

a

small

field

current

Output

current

is

generated

in

the

armature

coils

located

in

the

stator

The

stator

has

three

windings

and

generates

three

phase

alternating

current

Silicon

diodes

act

@God

A

tfff

Engine

Electrical

System

ALTERNATOR

CONTENTS

EE

15

EE

16

EE

16

EE

16

EE

17

EE

17

INSPECTION

OF

DIODE

INSPECTION

OF

BRUSH

SPRING

PRESSURE

TEST

ASSEMBL

Y

ALTERNATOR

TEST

SERVICE

DATA

AND

SPECIFICATIONS

EE

17

EE

1B

EE1B

EE

1B

EE19

EE

19

like

a

one

way

valve

for

electricity

so

that

charging

current

passes

easily

but

reverse

current

is

shut

out

In

this

alternator

pack

type

silicon

di

odes

are

used

Six

diodes

three

negative

and

three

positive

are

installed

in

positive

and

negative

plates

as

an

assembly

These

diodes

are

direct

soldered

at

their

tips

and

constructed

with

posi

3

2

I

4

e

o

e

9

tive

and

negative

conjunction

They

are

mounted

on

the

two

plates

which

combine

the

function

of

heat

dissipating

plate

and

positive

negative

terminals

and

are

light

in

weight

and

easy

to

service

The

pulley

mounted

on

the

air

conditioner

models

is

different

from

that

on

the

standard

models

without

air

conditioner

1

Pulley

usem

bly

2

Front

cover

3

Front

bearing

4

Rotor

5

Rear

bearing

6

Stator

7

Brush

assembly

8

Rear

cover

9

Diode

set

plate

assembly

10

Diode

cover

11

Through

botrs

EE

15

EE345

Fig

EE

26

Exploded

view

Page 187 of 537

DESCRIPTION

MEASUREMENT

OF

REGULATOR

VOLTAGE

ADJUSTMENT

VOLTAGE

REGULATOR

DESCRIPTION

The

regulator

consists

basically

of

a

voltage

regulator

and

a

charge

relay

The

voltage

regulator

has

two

sets

of

contact

points

a

lower

set

and

an

upper

set

to

control

alternator

volt

age

An

armature

plate

placed

between

the

two

sets

of

contacts

moves

upward

or

downward

or

vibrates

The

lower

contacts

when

closed

complete

the

jCV

ID@

@

GJ

I

@

@

@

Engine

Electrical

System

REGULATOR

CONTENTS

EE

20

CHARGING

RELAY

SERVICE

DATA

AND

SPECIFICATIONS

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Including

alternatorl

EE

25

EE

23

EE

24

EE

20

EE

23

EE

23

field

circuit

direct

to

ground

and

the

upper

contacts

when

closed

complete

the

field

circuit

to

ground

through

a

resistance

field

coil

and

produce

alternator

output

The

charge

relay

i

similar

in

construction

to

the

voltage

regulator

When

the

upper

contacts

are

closed

charge

warning

lamp

goes

on

v

1

Charge

relay

2

Voltage

regulator

EE285

Fig

EE

46

View

of

removing

cover

As

regards

the

construction

the

voltage

regulator

is

very

similar

to

the

charge

relay

as

shown

in

Figure

EE47

@

r

J

CD

@

@

@

Q

@

ID@

ID@

J

t

L

T

@

r

b

r

CD

L

@

j

1

g

f

@

@

EEJ97

J

I1Jlccting

spring

2

Y

kt

g

p

3

Armaturc

4

Core

go

5

Low

Sllccd

lnlacl

h

Point

ap

7

High

speed

conlat

t

8

Contact

c

9

3111111

0

118

ill

di

10

41l1I11W

157in

c1ia

few

II

Cuil

12

lock

nut

J3

Adjllslin

screw

14

Adjll

sting

sprin

15

Yoke

9

Adjusting

screw

10

Lock

nut

11

Coil

12

4mm

0

157

in

dia

screw

13

3mm

0

118

in

dla

crew

14

Contact

iet

15

Voltage

cgulatm

contact

a

Cnl1

Tlll

tion

f

lltagl

l

j

llIOltllT

I

Point

gilp

2

Charge

relay

contllct

3

Core

gap

4

ArlllatlJre

5

Connecting

sprin

6

Yoke

gap

7

Yoh

B

Adjusting

pring

b

Construction

of

charge

relay

Fig

EE

47

Structural

vi

w

EE

20

Page 191 of 537

Engine

Electrical

System

RegulatoI

r

Yellow

terminal

A

W

L

WR

IG

WL

N

Y

E

B

F

WB

Voltmeter

Fig

EE

52

Tuting

charging

re

Qy

EE348

SERVICE

DATA

AND

SPECIFICATIONS

Voltage

legulator

Type

Regulating

voltage

with

fully

charged

battery

Voltage

coil

resistance

RotOI

coil

inserting

resistance

Voltage

coil

series

resistance

Smoothing

resistance

COle

gap

Point

gap

Ch

uge

lay

Release

voltage

Voltage

coil

resistance

Core

gap

Point

gap

v

fl

nun

in

nun

in

V

fl

nun

in

mID

in

TLl

Z

S5C

14

3

to

15

3

at

200C

680F

10

5

at

200C

680F

10

31

40

0

6

to

1

0

0

024

to

0

039

0

35

to

0

45

0

014

to

O

OIS

4

2

to

5

2

at

N

terminal

37

S

at

200C

680F

0

8

to

1

0

0

031

to

0

039

0

4

to

0

6

0

016

to

0

024

Standard

tempelatUIe

gIlIdient

O

OISV

oC

EE

24