check oil DATSUN PICK-UP 1977 Service Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 336 of 537

PROPElli

ER

SHAfT

DIFFERENTIAL

G

ARRIERf

Notes

a

PUller

should

be

handled

with

care

in

catchins

the

edge

of

bearing

inner

race

b

Be

careful

not

to

confuse

left

and

right

hand

parts

2

Remove

ring

gear

by

spreading

out

lock

strap

and

loosening

ring

gear

bolts

in

diagonally

3

Punch

off

pinion

mate

shaft

lock

pin

from

ring

gear

side

using

Solid

Punch

ICV31100300

KV31100300

PD022

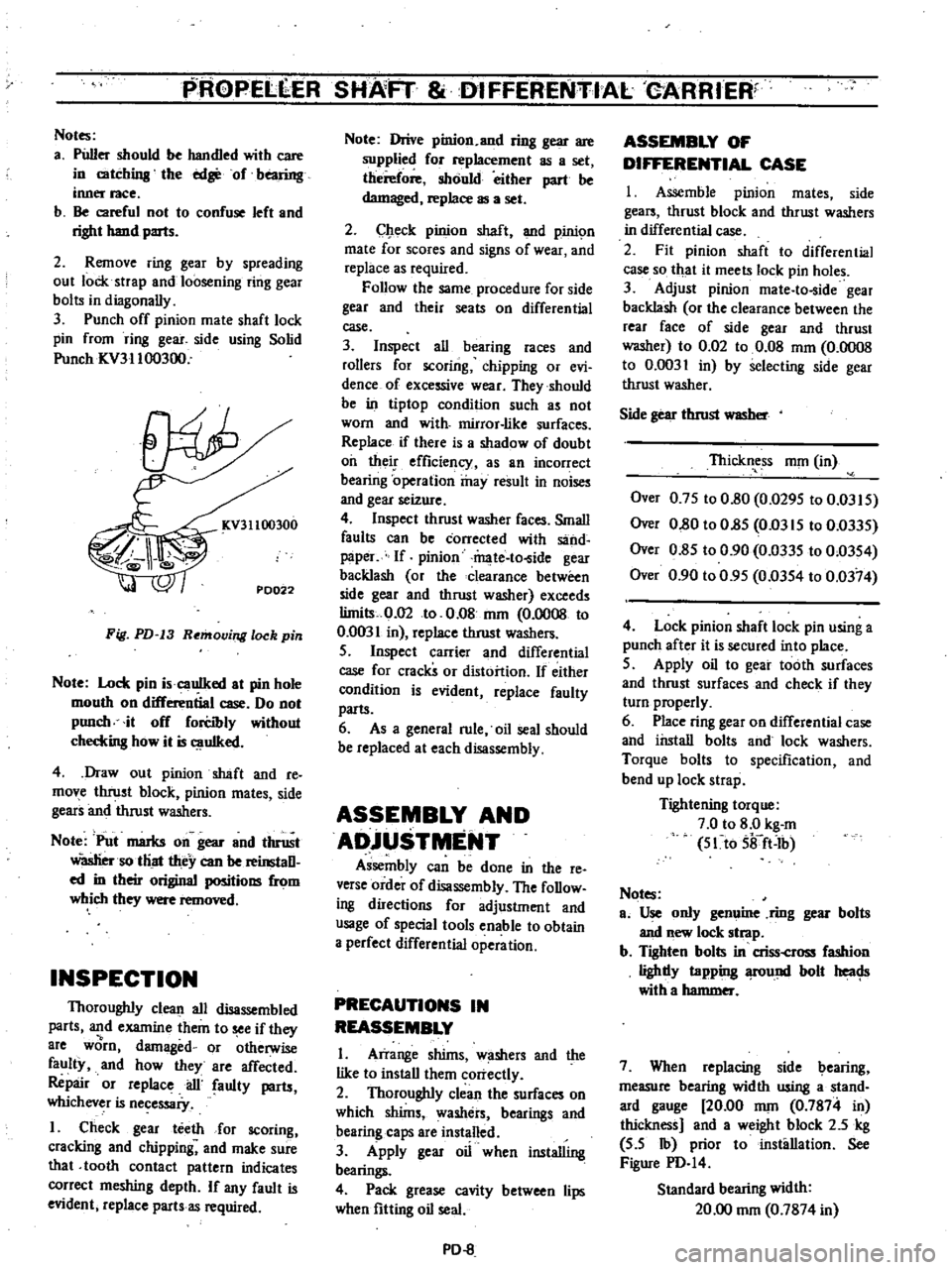

Fig

PD

13

Removing

lock

pin

Note

Lock

pin

i

cauIked

at

pin

hole

mouth

on

differential

case

Do

not

punch

it

off

forCibly

without

checkins

how

it

is

uIked

4

Draw

out

pinion

shaft

and

re

move

thrust

block

pinion

mates

side

gears

and

thrust

washers

Note

Put

marks

on

gear

and

thrust

Wasliersotliat

they

can

be

reinstaD

ed

in

their

original

positions

from

which

they

were

removed

INSPECTION

Thoroughly

clean

all

disassembled

parts

and

examine

them

to

see

if

they

8re

worn

damaged

or

otherwise

faulty

and

how

they

are

affected

Repair

or

replace

ail

faulty

parts

whichever

is

necessaiy

I

Check

gear

teeth

for

scoring

cracking

and

chipping

and

make

sure

that

tooth

contact

pattern

indicates

correct

meshing

depth

If

any

fault

is

evident

replace

parts

as

required

Note

Drive

pinion

and

ring

gear

are

supplied

for

replacement

as

a

set

therefore

should

either

part

be

damaged

replace

as

a

set

2

Check

pinion

shaft

and

pinic

m

mate

for

scores

and

signs

of

wear

and

replace

as

required

Follow

the

same

procedure

for

side

gear

and

their

seats

on

differential

case

3

Inspect

all

bearing

races

and

rollers

for

scoring

chipping

or

evi

dence

of

excessive

wear

They

should

be

in

tiptop

condition

such

as

not

worn

and

with

mirror

like

surfaces

Replace

if

there

is

a

shadow

of

doubt

oil

their

efficiency

as

an

incorrect

bearing

operation

may

result

in

noises

and

gear

seizure

4

Inspect

thrust

washer

faces

Small

faults

can

be

corrected

with

sand

paper

If

pinion

mate

to

ide

gear

backlash

or

the

clearance

between

side

gear

and

thrust

washer

exceeds

limits

0

02

to

0

08

nun

0

0008

to

0

0031

in

replace

thrust

washers

S

Inspect

carrier

and

differential

case

for

cracks

or

distortion

If

either

condition

is

evident

replace

faulty

parts

6

As

a

general

rule

oil

seal

should

be

replaced

at

each

disassembly

ASSEMBLY

AND

ADjUSTMENT

Assembly

can

be

done

in

the

reo

verse

order

of

disassembly

The

foDow

ing

directions

for

adjustment

and

usage

of

special

tools

enable

to

obtain

a

perfect

differential

operation

PRECAUTIONS

IN

REASSEMBLY

I

Arrange

shims

w

shers

and

the

like

to

install

them

correctly

2

Thoroughly

clean

the

surfaces

on

which

shims

washers

bearings

and

bearing

caps

are

installed

3

Apply

gear

oil

when

installing

bearings

4

Pack

grease

cavity

between

lips

when

fitting

oil

seal

PD

8

ASSEMBLY

OF

DIFFERENTIAL

CASE

I

Assemble

pinion

mates

side

gears

thrust

block

and

thrust

washers

in

differential

case

2

Fit

pinion

shaft

to

differential

case

so

that

it

meets

lock

pin

holes

3

Adjust

pinion

mate

to

ide

gear

backlash

or

the

clearance

between

the

rear

face

of

side

gear

and

thrust

washer

to

0

02

to

0

08

mOl

0

0008

to

0

0031

in

by

selecting

side

gear

thrust

washer

Side

gear

thrust

WlISber

Thickness

nun

in

Over

0

7S

to

0

80

0

029S

to

0

03IS

Over

0

80

to

O

8S

Om

IS

to

0

033S

Over

0

8S

to

0

90

0

033S

to

0

03S4

Over

0

90

to

0

9S

0

03S4

to

0

0374

4

Lock

pinion

shaft

lock

pin

using

a

punch

after

it

is

secured

into

place

S

Apply

oil

to

gear

tooth

surfaces

and

thrust

surfaces

and

check

if

they

turn

properly

6

Place

ring

gear

on

differential

case

and

install

bolts

and

lock

washers

Torque

bolts

to

specification

and

bend

up

lock

strap

Tightening

torque

7

0

to

8

0

kg

m

S1to

Sifft

Ib

Notes

ao

Use

only

genuine

ring

gear

bolts

and

new

lock

strap

b

Tighten

bolts

in

criss

cross

fashion

lighdy

tapping

fOund

bolt

heac

Js

with

a

hammer

7

When

replacing

side

bearing

measure

bearing

width

using

a

stand

ard

gauge

20

00

nun

0

7874

in

thickness

and

a

weight

block

2

5

kg

S

S

Ib

prior

to

installation

See

Figure

PD

I4

Standard

bearing

width

20

00

nun

0

7874

in

Page 338 of 537

PROPELLER

SHAFT

DIFFERENTIAL

CARRIER

Ex

2

N

O

68mm

H

3

D

I

S

2

T

N

H

0

S

x

0

01

2

18

0

68

3

1

2

x

Om

2

18

0

68

3

1

2

x

0

01

2

18

0

68

2

x

0

01

2

18

0

68

0

02

N8

0

68

0

02

2

18

i

88

mm

The

correct

washer

is

2

88

mm

thick

Ex

3

N

0

70mm

H

O

0

0

S

O

T

N

H

0

S

x

0

01

2

18

0

70

0

0

0

x

0

01

2

18

0

70

0

x

0

01

2

18

0

70

0

2

18

0

70

2

18

2

88

mm

The

correct

washer

is

2

88

mm

thick

Note

If

lues

signifying

H

D

and

S

are

not

given

regard

them

as

zero

and

n

C

r

e

After

assembly

check

to

see

that

tooth

contact

is

correct

If

not

readjust

For

the

tooth

contact

pattern

see

page

PJ

12

for

Contact

Pattern

Drive

pinion

adjusting

washer

Thickness

mm

in

2

58

0

1016

2

61

0

1028

2

64

0

1039

2

67

0

1051

2

70

0

1063

2

73

0

107S

2

76

0

1087

2

79

0

1098

2

82

0

1110

2

85

OJ

122

2

88

OJ

134

2

91

0

1146

2

94

0

1IS8

2

97

0

1169

3

00

0

1181

3

03

0

1

193

3

06

0

1205

3

09

0

1217

3

12

0

1228

3

IS

0

1240

3

18

0

I2S2

S

Fit

determined

drive

pinion

ad

justing

washer

in

drive

pinion

and

preSs

fit

rear

bearing

inner

race

in

it

using

Base

ST30901000

ADJUSTMENT

OF

DRIVE

PINIONPI

IELOAD

AdjUst

the

preload

of

drive

pinion

with

spacer

and

washer

between

front

and

rear

bearing

inner

races

This

procedure

has

nothing

to

do

with

thickness

of

drive

pinion

adjust

ing

washer

This

adjustment

must

be

carried

out

without

oil

seal

inserted

I

Lubricate

pinion

front

and

rear

bearings

Install

drive

pinion

in

gear

carrier

Be

sure

that

spacer

t

washer

front

bearing

inner

race

Companion

flange

and

flat

washer

are

fitted

on

pinion

Tighten

nut

to

specified

torque

and

confum

preload

Tightening

torque

14

0

to

17

0

kg

m

101

to

123

ft

lb

PD

l0

Note

Replace

bearing

washer

and

spacer

with

thicker

ones

if

pinion

cannot

be

turned

by

hand

while

it

is

heing

tightened

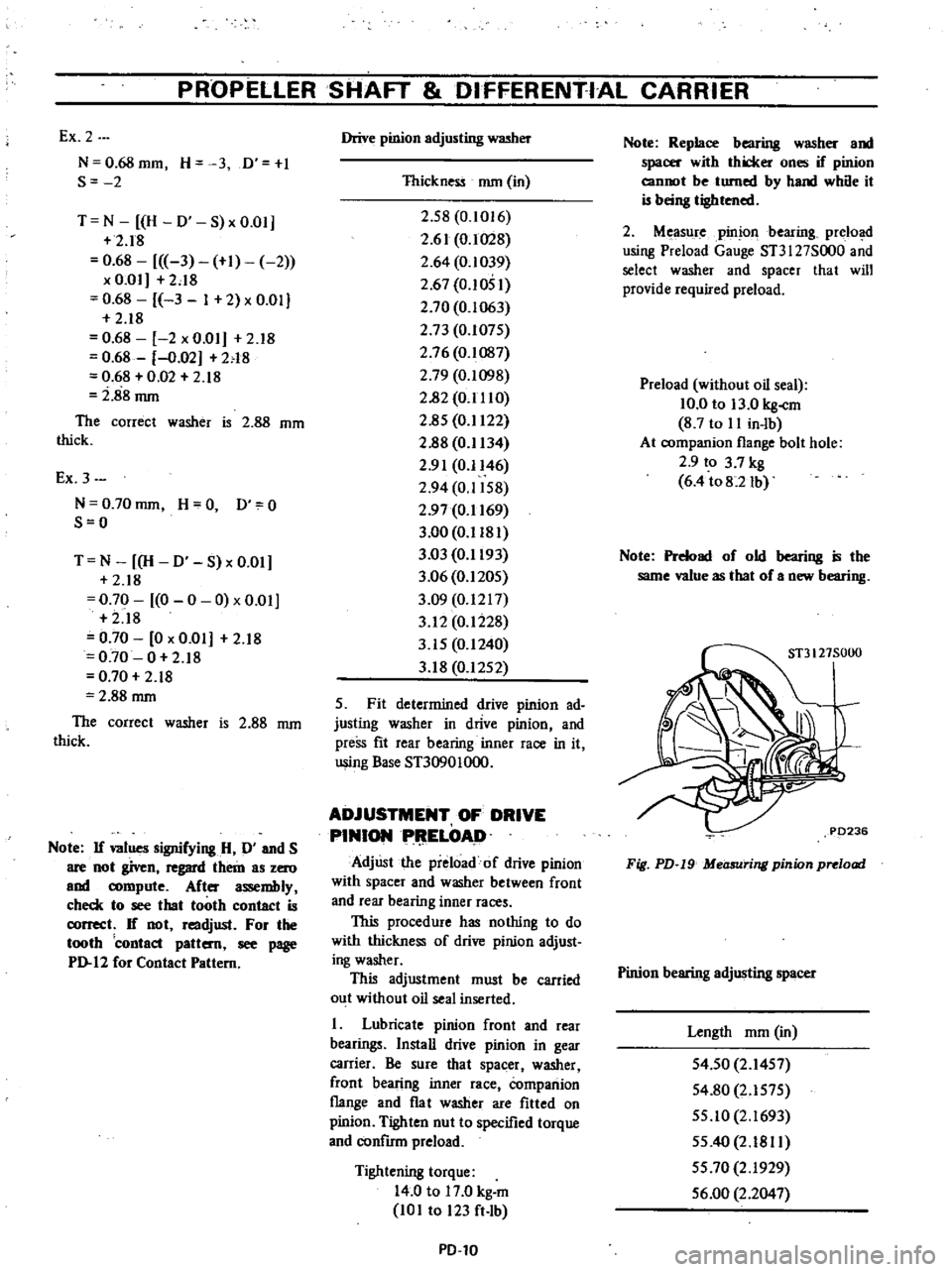

2

Measure

pinion

bearing

prelo

d

using

Preload

Gauge

ST3I

27S000

and

select

washer

and

spacer

that

will

provide

required

preload

Preload

without

oil

seal

10

0

to

13

0

kg

cm

8

7

to

II

in

lb

At

companion

flange

bolt

hole

2

9

to

3

7

kg

6

4

to8

2Ib

Note

Preload

of

old

bearing

is

the

same

value

as

that

of

a

new

bearing

Fig

PD

19

Measuring

pinion

preload

Pinion

bearing

adjusting

spacer

Length

mOl

in

S4

50

2

14S7

S4

80

2

IS7S

SS

IO

2

1693

5S

40

2

1811

SS

70

2

1929

S6

00

2

2047

Page 339 of 537

PROPELLER

SHAFT

DIFFERENTIAL

CARRIER

Drive

pinion

bearing

adjusting

washer

Thickness

mm

in

over

3

80

to

3

82

0

1496

to

O

lS04

over

3

82

to

3

84

O

lS04

to

0

ISI2

over

3

84

to

3

86

O

lSI2

to

0

IS20

over

3

86

to

3

88

O

lS20

to

O

IS28

over

3

88

to

3

90

O

lS28

to

0

IS3S

over

3

90

to

3

92

0

IS3S

to

O

IS43

over

3

92

to

3

94

0

IS43

to

O

lSS

I

over

3

94

to

3

96

O

lSSI

to

O

lS59

over

3

96

to

3

98

O

lSS9

to

0

IS67

over

3

98

to

4

00

O

lS67

to

O

lS7S

over

4

00

to

4

02

0

S7S

to

O

lS83

over

4

02

to

4

04

O

lS83

to

0

IS91

over

4

04

to

4

06

O

lS9I

to

0

IS98

over

4

06

to

4

08

O

lS98

to

0

1606

over

4

08

to

4

10

0

1606

to

0

1614

3

Check

and

adjust

tooth

contact

pattern

when

former

adjustment

of

bearing

preload

is

completed

Unless

anything

wrong

is

found

remove

drive

pinion

nut

and

companion

flange

and

press

n

oil

seal

into

gear

carrier

using

Oil

Seal

Fitting

Tool

KV38I02SS0

Apply

grease

cavity

be

tween

seal

lips

4

Again

install

companion

flange

and

washer

and

tighteh

nut

to

speci

fied

torque

14

0

to

17

0

kg

m

IO

to

123

ft

lb

S

Measure

preload

again

Preload

with

oil

seal

I

1

0

to

14

0

kg

cm

9

S

to

12

in

lb

At

companion

flange

bolt

hole

3

1

to

4

0

kg

6

8

to

8

81b

ADJUSTMENT

OF

SIDE

BEARING

SHIMS

I

If

hypoid

gear

set

carrier

dif

ferential

case

or

side

bearing

has

been

replaced

with

new

one

adjust

the

side

bearing

preload

with

adjusting

shim

The

required

thickness

of

adjusting

shim

can

be

calculated

by

the

follow

ing

formulas

T

A

C

D

H

xO

OI

O

l7S

E

T2

B

D

H

xO

OI

O

ISO

F

Where

T

1

Required

thickness

of

left

side

bearing

adjusting

shim

mm

T

2

Required

thickness

of

right

side

bearing

adjusting

shim

mm

A

Figure

marked

on

the

left

side

bearing

housing

of

gear

carrier

B

Figure

marked

on

the

right

side

bearing

of

gear

carrier

C

0

Figure

marked

on

the

differ

entia

case

E

F

These

are

differences

in

width

of

left

or

right

side

bearing

against

the

standard

width

20

00

mOl

mOl

If

bearing

width

is

19

89

the

differ

ence

will

be

as

follows

20

00

19

89

0

11

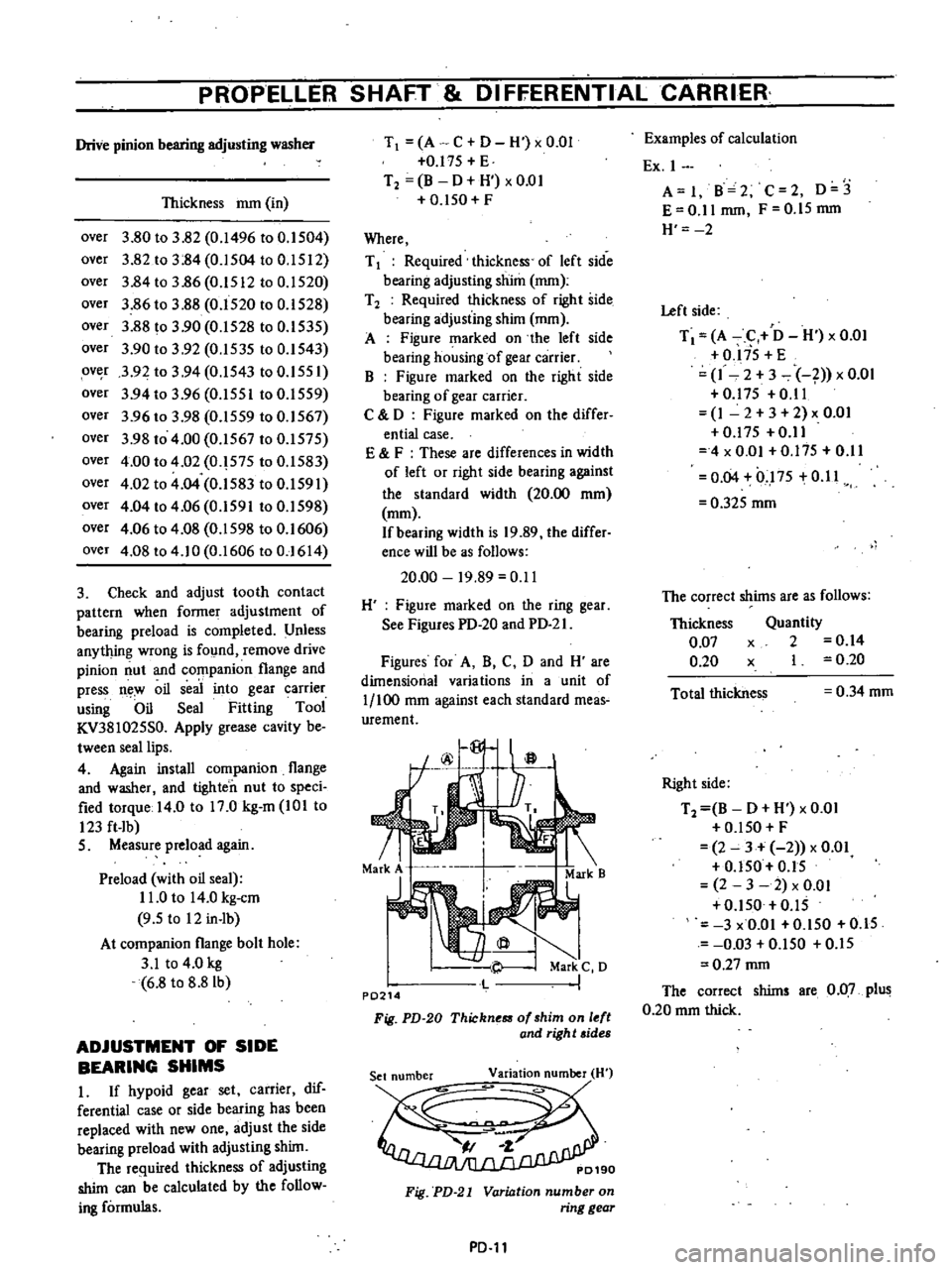

H

Figure

marked

on

the

ring

gear

See

Figures

PD

20

and

PD

2

I

Figures

for

A

B

C

0

and

H

are

dimensional

varia

tions

in

a

unit

of

1

100

mm

against

each

standard

meas

urement

f

@

a

rj

71

Markj

Mark

B

Mark

C

0

P0214

Fig

PD

20

Thickn

of

shim

on

l

ft

and

righ

t

sides

Fig

PD

21

Variation

number

on

ring

gear

PD

ll

Examples

of

calculation

Ex

I

A

I

B

2

C

2

0

3

E

0

11

mm

F

O

IS

mm

H

2

Left

side

T

A

C

0

H

x

0

01

O

liS

E

1

2

3

1

x

0

01

0

17S

0

11

1

2

3

2

x

O

O

O

l7S

0

11

4

x

0

01

0

175

0

11

0

04

0

1

7S

0

11

0

32S

mOl

The

correct

shims

are

as

follows

Thickness

0

07

0

20

Quantity

x

2

0

14

x

I

0

20

Total

thickness

0

34

mOl

Right

side

T2

B

0

H

x

0

01

O

lSO

F

2

3

2

x

0

01

O

ISO

0

15

2

3

2

x

0

01

O

ISO

0

15

3

x

O

OI

O

ISO

O

IS

0

03

O

lSO

O

lS

0

27

mm

The

correct

shims

are

0

07

plus

0

20

mm

thick

Page 340 of 537

PROPELLER

SHAFf

DIFFERENTIAL

CARR

IER

Ex

2

A

0

B

3

C

I

0

0

E

0

20

mOl

F

0

17

mOl

H

2

Left

side

T

I

A

C

D

H

x

om

0

17S

E

0

I

0

2

x

0

01

0

I7S

0

20

0

I

0

2

x

0

01

0

17S

0

20

3

Om

0

17S

0

20

0

03

0

17S

0

20

O

34S

mrn

The

correct

shinjs

are

O

OS

plus

0

10

plus

0

20

mrn

thick

Right

side

T2

B

D

H

xO

0l

O

ISO

F

3

0

2

x

om

O

ISO

0

17

3

0

2

x

om

0

150

0

17

S

x

0

01

0

ISO

0

I7

O

OS

0

1S0

0

17

0

37

mrn

The

correct

shims

are

0

07

plus

0

1

0

plus

0

20

mm

thick

Note

If

w1ues

signifying

A

B

C

0

and

H

are

not

given

regard

them

as

zero

and

compute

Aft

assembly

check

to

see

that

preload

and

backlash

are

correct

If

not

readjust

Side

bearing

adjusting

shim

Thickness

mm

in

O

OS

0

0020

0

07

0

0028

0

1

0

0

0039

0

20

0

0079

0

50

0

0197

2

Fit

determined

side

bearing

adjusting

shim

on

differential

case

and

press

fit

left

and

right

side

bearing

inner

races

on

it

using

Side

Bearing

Drift

ST33230000

and

Adapter

ST33061000

3

Install

differential

case

assembly

into

gear

carrie

tapping

with

a

rubber

mallet

4

Align

mark

on

bearing

cap

with

that

on

gear

carrier

and

install

bearing

cap

on

carrier

And

tight

n

bolts

to

specified

torque

Tightening

torque

4

0

to

S

O

kg

m

29

to

36

fHb

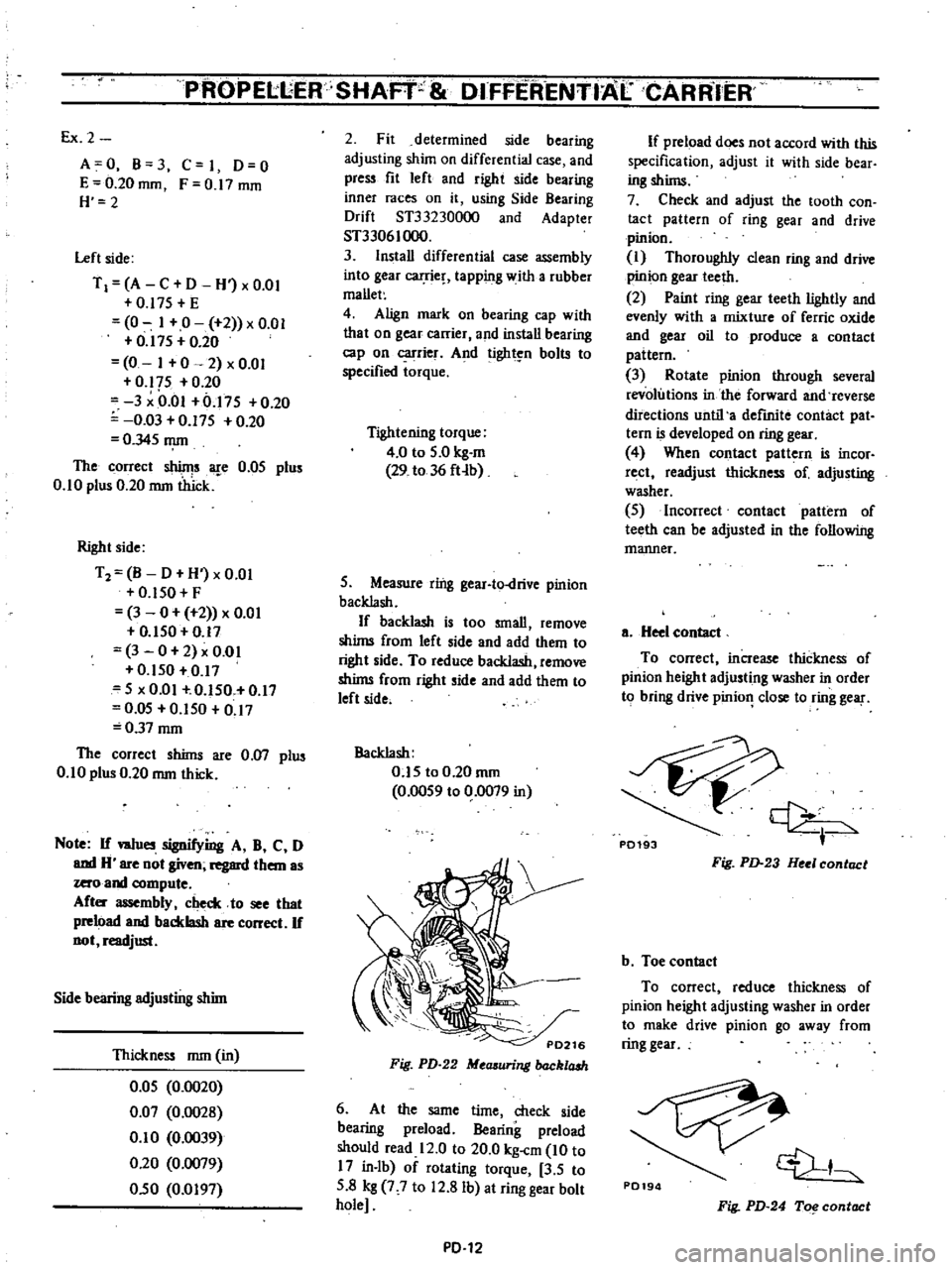

S

Measure

ring

gear

to

drive

pinion

backlash

If

backlash

is

too

small

remove

shims

from

left

side

and

add

them

to

right

side

To

reduce

backlash

remove

shims

from

right

side

and

add

them

to

left

side

Backlash

O

1S

to

0

20

mrn

0

00S9

to

0

0079

in

Fig

PD

22

Mccuuring

back1aah

6

At

the

same

time

check

side

bearing

preload

Bearing

preload

should

read

12

0

to

20

0

kg

cm

10

to

17

in

lb

of

rotating

torque

3

S

to

S

8

kg

7

7

to

12

8

Ib

at

ring

gear

bolt

hole

PD

12

If

preload

does

not

accord

with

this

specification

adjust

it

with

side

bear

ing

shims

7

Check

and

adjust

the

tooth

con

tact

pattern

of

ring

gear

and

drive

pinion

I

Thoroughly

clean

ring

and

drive

pinion

gear

teeth

2

Paint

ring

gear

teeth

lightly

and

evenly

with

a

mixture

of

ferric

oxide

and

gear

oil

to

produce

a

contact

pattern

3

Rotate

pinion

through

several

revolutions

in

the

forward

and

reverse

directions

until

a

defmite

contact

pat

tern

is

developed

on

ring

gear

4

When

contact

pattern

is

incor

rect

readjust

thickness

of

adjusting

washer

S

Incorrect

contact

pattern

of

teeth

can

be

adjusted

in

the

following

manner

a

Heel

contact

To

correct

increase

thickness

of

pinion

height

adjusting

washer

in

order

to

bring

drive

pinio

close

to

ring

gear

P0193

Fig

PD

23

Hul

contact

b

Toe

contact

To

correct

reduce

thickness

of

pinion

height

adjusting

washer

in

order

to

make

drive

pinion

go

away

from

ring

gear

P0194

1

Fig

PD

24

To

contact

Page 357 of 537

SHOCK

ABSORBER

REMOVAL

AND

INSTAUATION

1

Raise

vehicle

on

a

hoist

or

stands

2

Remove

wheel

3

Hold

the

upper

stem

of

shock

absorber

and

remove

outs

washer

and

rubber

bushing

4

Remove

bolt

from

the

lower

end

of

shock

absorber

FA232

Fig

FA

13

Shock

absorber

S

Retain

lower

rubber

bushing

in

position

install

the

lower

end

of

shock

absorber

to

the

bracket

of

lower

link

and

torque

the

bolt

to

3

1

to

4

1

kg

m

23

to

30

ft

lb

Note

Insert

the

bolt

from

the

front

side

of

vehicle

6

Install

the

upper

end

of

shock

absorber

to

body

bracket

and

tighten

lock

n

Jt

to

the

specifjcations

Tightening

torque

1

6

to

2

2

kg

m

121016

ft

lb

INSPECTION

I

Check

shock

absorber

for

visible

defects

and

oil

leaks

Place

shock

absorber

vertically

in

a

vise

and

hand

stroke

shock

absorber

as

outlined

be

low

Extend

and

compress

shock

ab

sorber

as

faI

as

possible

travelling

as

long

as

possible

If

smooth

hydraulic

resistance

is

not

present

in

bqth

Iirection

replace

absorber

2

Replace

rubber

bushing

if

crack

or

deterioration

is

detected

Front

Axle

Front

Suspension

Specifications

for

shock

absorber

Model

Item

Piston

stroke

mm

in

Damping

force

kg

lb

0

3

m

sec

0

98

ft

sec

j

Rebound

Compression

STABILIZER

REMOVAL

AND

INSTAUATION

I

Raise

vehicle

on

a

hoist

or

stands

2

Remove

wheel

3

Loosen

secUring

nut

at

the

lower

link

side

of

stabilizer

4

Remove

bolt

securing

stabilizer

mounting

bracket

to

chassis

frame

Install

stabilizer

in

the

reverse

se

quence

to

removal

noting

the

follow

ing

instructions

S

Attach

stabilizer

mounting

brack

et

to

chassis

frame

tightening

bolt

to

1

6

to

2

2

kg

m

12

to

16

ft

lb

torque

6

Install

stabilizer

lower

link

side

to

connecting

rod

and

tighten

nut

to

the

specifications

as

shown

in

Figure

FA

14

Then

torque

lock

nut

toJ

6

to

2

2

kg

m

12

to

16

ft

lb

F

A233

Fig

FA

14

Stabilizer

detail

INSPECTION

Check

stabilizer

for

deformation

FA

S

All

models

110

4

3

76

168

38

84

and

rubber

bushings

for

crack

wear

and

deterioration

Replace

if

ne

cessary

TENSION

POD

REMOVAL

AND

INSTALLATION

I

Raise

vehicle

on

a

hoist

or

stands

2

Remove

wheel

3

Remove

nuts

CD

from

both

ends

of

tension

rod

4

Remove

bracket

bolt

@

from

the

front

end

of

tension

rod

and

remove

tension

rod

with

bracket

CD

@

f

A234

Fig

FA

15

Ten

ion

rod

Install

tension

rod

in

reverse

00

qunce

to

removal

noting

the

following

instructions

Page 360 of 537

Note

When

installing

fulcrum

pin

insert

it

from

rearward

of

vehicle

12

Install

tension

rod

shock

ab

sorber

I

stabilizer

torsion

bar

spring

and

knuckle

arm

referring

to

the

related

paragraphs

13

Install

brake

disc

to

knuckle

spindle

and

torque

securing

bolt

to

4

2

to

5

0

kg

m

30

to

36

ft

Ib

14

Install

wheel

and

brake

drum

as

an

assembly

and

torque

knuckle

spin

dle

nut

to

8

0

to

9

0

kg

m

58

to

65

ft

Ib

DISASSEMBLY

AND

ASSEMBLY

Upper

link

I

Detach

upper

link

spindle

from

upper

links

and

remove

clamp

dust

cover

and

dust

seal

Secure

upper

link

in

a

vise

and

loosen

screw

bushing

Assemble

link

spindle

in

reverse

sequence

to

disassembling

noting

the

following

instructions

2

Torque

screw

bushing

on

upper

link

to

3S

to

55

kg

m

253

to

398

ft

Ib

Install

new

dust

seal

and

dust

cover

and

secure

them

with

clamp

3

Coat

grease

to

screw

bushing

in

side

and

the

thread

portion

of

upper

link

spindle

liberally

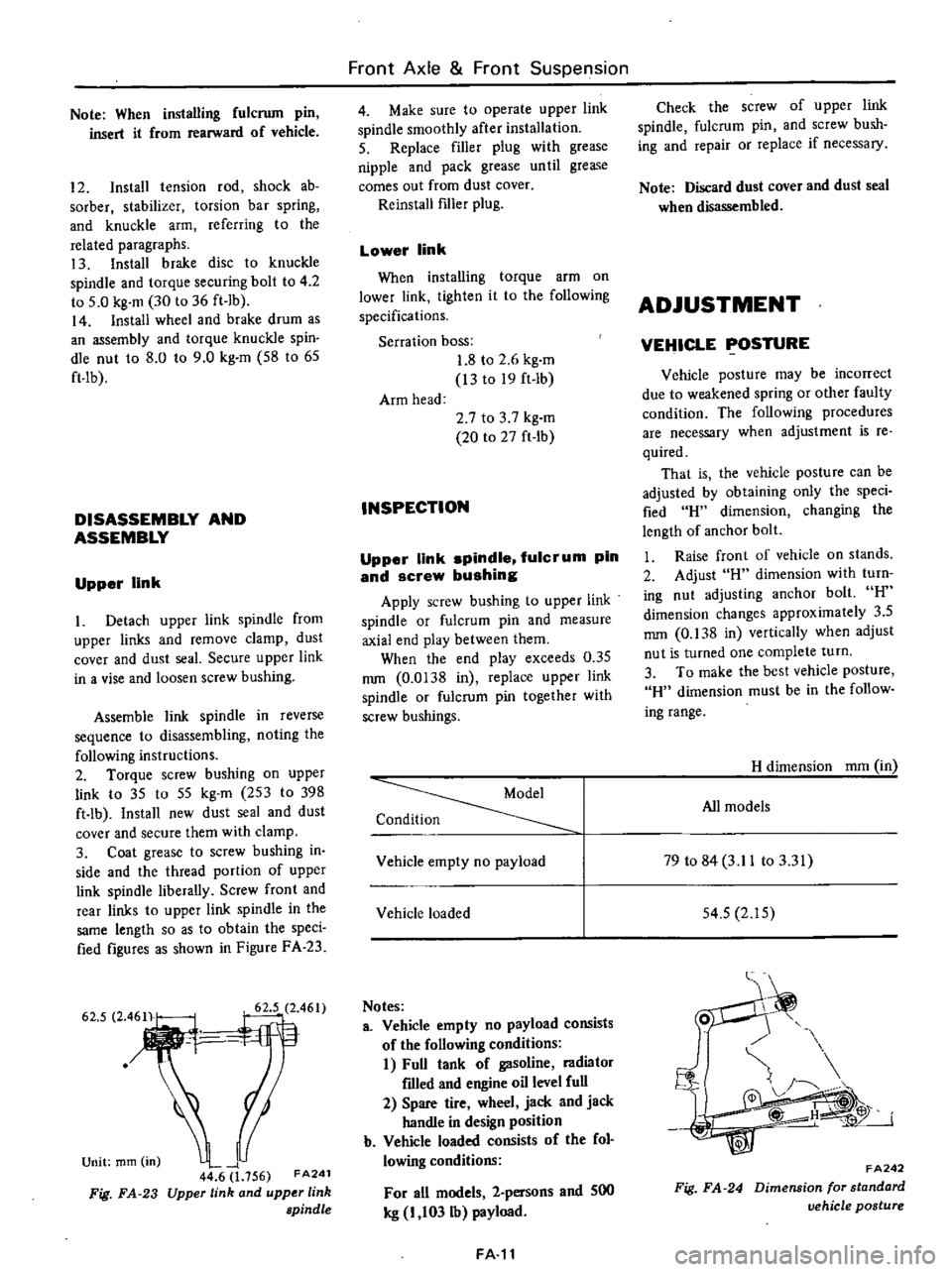

Screw

front

and

rear

links

to

upper

link

spindle

in

the

same

length

so

as

to

obtain

the

speci

fied

figures

as

shown

in

Figure

FA

23

Unit

mm

in

I

44

6

1

156

FA2

Upper

link

and

upper

link

spindle

Fig

FA

23

Front

Axle

Front

Suspension

4

Make

sure

to

operate

upper

link

spindle

smoothly

after

installation

5

Replace

filler

plug

with

grease

nipple

and

pack

grease

until

grease

comes

out

from

dust

cover

Reinstall

f1ller

plug

Lower

link

When

installing

torque

arm

on

lower

link

tighten

it

to

the

following

specifications

Serration

boss

1

8

to

2

6

kg

m

13

to

19

ft

Ib

Arm

head

2

7

to

3

7

kg

m

20

to

27

ft

tb

INSPECTION

Upper

link

spindle

fulcrum

pin

and

screw

bushing

Apply

screw

bushing

to

upper

link

spindle

or

fulcrum

pin

and

measure

axial

end

play

between

them

When

the

end

play

exceeds

0

35

mm

0

0138

in

replace

upper

link

spindle

or

fulcrum

pin

together

with

screw

bushings

Condition

Vehicle

empty

no

payload

Vehicle

loaded

Notes

a

Vehicle

empty

no

payload

consists

of

the

following

conditions

I

Full

tank

of

gasoline

radiator

f1lled

and

engine

oil

level

full

2

Spare

tire

wheel

jack

and

jack

handle

in

design

position

b

Vehicle

loaded

consists

of

the

fol

lowing

conditions

For

all

models

2

persons

and

SIlO

leg

I

103lb

payload

FA

Check

the

screw

of

upper

link

spindle

fulcrum

pin

and

screw

bush

ing

and

repair

or

replace

if

necessary

Note

Discard

dust

cover

and

dust

seal

when

disassembled

ADJUSTMENT

VEHICLE

POSTURE

Vehicle

posture

may

be

incorrect

due

to

weakened

spring

or

other

faulty

condition

The

following

procedures

are

necessary

when

adjustment

is

Ie

quired

That

is

the

vehicle

posture

can

be

adjusted

by

obtaining

only

the

speci

fied

H

dimension

changing

the

length

of

anchor

bolt

I

Raise

front

of

vehicle

on

stands

2

Adjust

H

dimension

with

turn

ing

nut

adjusting

anchor

bolt

H

dimension

changes

approximately

3

5

mm

0

J38

in

vertically

when

adjust

nut

is

turned

one

complete

turn

3

To

make

the

best

vehicle

posture

H

dimension

must

be

in

the

follow

ing

range

H

dimension

mOl

in

All

models

79

to

84

3

11

to

3

31

54

5

2

15

o

i

Fig

FA

24

FA242

Dimension

for

standard

vehicle

postl4re

Page 364 of 537

Condition

Vehicle

puBes

to

right

or

left

Instability

of

vehicle

Stiff

steeirng

wheel

Excessive

steering

wheel

play

Noise

Front

Axle

Front

Suspension

Probable

cause

Deformed

of

steering

linkage

and

suspension

link

Unbalanced

vehicle

level

Improper

air

pressure

of

tire

Worn

or

loose

suspension

link

screw

bushing

Incorrect

wheel

alignment

Worn

or

deformed

steering

linkage

and

suspension

link

Incorrect

adjustment

of

steering

gear

Deformed

unbalanced

wheel

Check

and

correct

in

the

following

manner

Jack

up

front

wheels

detach

the

steering

gear

and

operate

the

steering

wheel

and

a

If

it

is

light

check

steering

linkage

and

suspension

groups

b

If

it

is

heavy

check

steering

gear

and

steering

column

groups

Improper

air

pressure

of

tire

Insufficient

lubricants

or

mixing

impurities

in

steering

linkage

or

excessively

worn

steering

linkage

Insufficient

lubricant

in

gear

box

or

contaminated

lubricant

Unsmooth

king

pin

damaged

part

Or

insufficient

lubrication

Worn

or

incorrectly

adjusted

wheel

bearing

Worn

damaged

steering

gear

and

bearing

Incorrectly

adjusted

steering

gear

Deformed

steering

linkage

Incorrect

wheel

alignment

Interference

of

steering

column

with

turn

signal

switch

Incorrectly

adjusted

steering

gear

Worn

steering

linkage

idler

arm

Improperly

fitted

of

gear

box

Incorrectly

adjusted

wheel

bearing

Worn

or

loose

suspension

link

screw

bushing

Improper

air

pressure

of

tire

Insufficient

lubricating

oil

and

grease

for

suspension

link

screw

bushing

and

steering

linkage

or

their

breakage

FA

15

Corrective

action

Replace

Correct

the

unbalance

Adjust

Replace

Adjust

Replace

Adjust

Correct

or

replace

Adjust

Replenish

grease

or

replace

the

part

Add

or

replace

gear

oil

Replace

Replace

or

adjust

Replace

Adjust

Replace

Adjust

Adjust

Adjust

Replace

Retighten

Adjust

Replace

Adjust

Replenish

lubricating

oil

and

grease

or

replace

Page 372 of 537

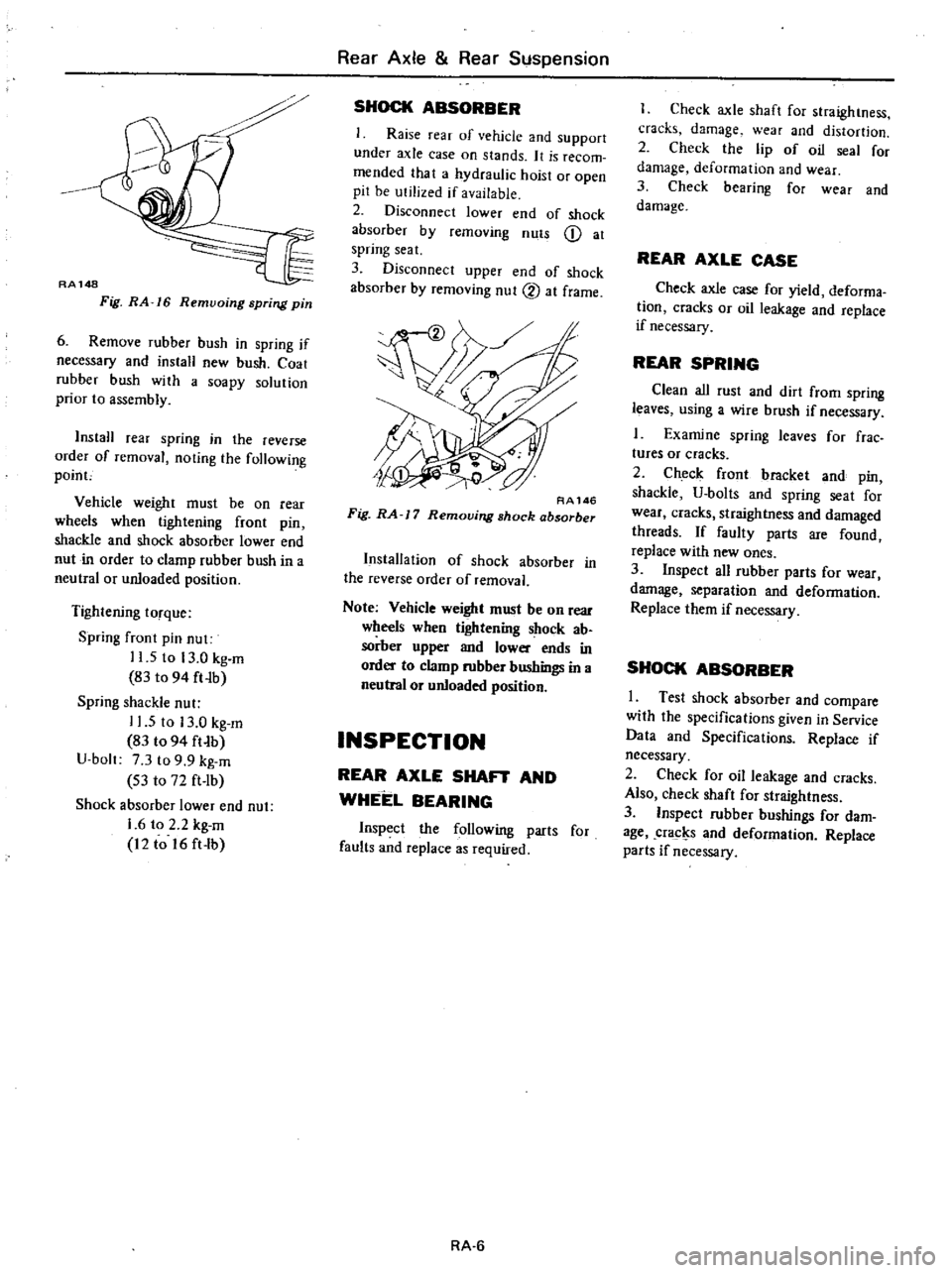

RA148

Fig

RA

16

Remvoing

spring

pin

6

Remove

rubber

bush

in

spring

if

necessary

and

install

new

bush

Coat

rubber

hush

with

a

soapy

solution

prior

to

assembly

InstaH

rear

spring

in

the

reverse

order

of

removal

noting

the

following

poinc

Vehicle

weight

must

be

on

rear

wheels

when

tightening

front

pin

shackle

and

shock

absorber

lower

end

nut

in

order

to

clamp

rubber

bush

in

a

neutral

or

unloaded

position

Tightening

torque

Spring

fTont

pin

nut

11

5

to

13

0

kg

m

83

to

94

ft

Ib

Spring

shackle

nut

11

5

to

13

0

kg

m

83

t094

ft

b

U

bolt

7

3

to

9

9

kg

m

S3

to

72

ft

lb

Shock

absorber

lower

end

nut

1

6

to

2

2

kg

m

12

to

16

ft

lb

Rear

Axle

Rear

Suspension

SHOCK

ABSORBER

Raise

rear

of

vehicle

and

support

under

axle

case

on

stands

It

is

recom

mended

that

a

hydraulic

hoist

or

open

pit

be

utilized

if

available

2

Disconnect

lower

end

of

shock

absorber

by

removing

nuts

Q

at

spring

seat

3

Disconnect

upper

end

of

shock

absorber

by

removing

nut

2

at

frame

RA146

Fig

RA

J

7

Removing

shock

absorber

Installation

of

shock

absorber

in

the

reverse

order

of

removal

Note

Vehicle

weight

must

be

on

Tear

wheels

when

tigtrtening

shock

ab

sorber

upper

and

lower

ends

in

order

to

clamp

rubber

bushings

in

a

neutral

or

unloaded

position

INSPECTION

REAR

AXLE

SHAFT

AND

WHEEL

BEARING

Inspect

the

following

parts

for

faults

and

replace

as

required

RA

6

I

Check

axle

shaft

for

straightness

cracks

damage

wear

and

distortion

2

Check

the

lip

of

oil

seal

for

damage

deformation

and

wear

3

Check

bearing

for

wear

and

damage

REAR

AXLE

CASE

Check

axle

case

for

yield

deforma

tion

cracks

or

oil

leakage

and

replace

if

necessary

REAR

SPRING

Clean

all

rust

and

dirt

from

spring

leaves

using

a

wire

brush

if

necessary

1

Examine

spring

leaves

for

frae

tures

or

cracks

2

Check

front

bracket

and

pin

shackle

U

bolts

and

spring

seat

for

wear

cracks

straightness

and

damaged

threads

If

faulty

parts

are

found

replace

with

new

ones

3

Inspect

all

rubber

parts

for

wear

damage

separation

and

deformation

Replace

them

if

necessary

SHOCK

ABSORBER

I

Test

shock

absorber

and

compare

with

the

specifications

given

in

Service

Data

and

Specifications

Replace

if

necessary

2

Check

for

oil

leakage

and

cracks

Also

check

shaft

for

straightness

3

Inspect

rubber

bushings

for

dam

age

cracl

s

and

deformation

Replace

parts

if

necessary

Page 374 of 537

Rear

Axle

Rear

Suspension

Spring

front

pin

Spring

shackle

Bearing

cage

fIXing

bolt

Wheel

bearing

lock

nut

Air

breather

Differential

gear

carrier

to

axle

case

nut

Propeller

shaft

flange

bolt

Drain

and

filler

plug

Bumper

rubber

fixing

bolt

Wheel

nut

kg

m

ft

lb

kg

m

ft

Ib

kg

en

ft

lb

kg

m

ft

Ib

kg

m

ft

Ib

kg

m

ft

Ib

kg

en

ft

Ib

kg

m

ft

Ib

kg

m

ft

Ib

kg

m

ft

lb

11

5

to

13

0

83

to

94

11

5

to

13

0

83

to

94

S

4

to

6

4

39

to

46

IS

to

20

108

to

l4S

0

7

to

0

9

S

I

to

6

S

17

to

2

7

12

to

20

2

0

to

2

7

14

to

20

6

to

10

43

to

72

1

6

to

2

2

12

to

16

8

to

9

S8

to

6S

TROUBLE

DIAGNOSES

AND

CORRECTIONS

When

rear

axle

and

suspension

is

suspected

of

being

noisy

it

is

advisable

to

make

a

thorough

test

to

determine

whether

the

noise

originates

in

the

tires

road

surface

exhaust

propeller

shaft

engine

transmission

universal

joint

wheel

bearings

or

suspension

Noise

which

originates

in

other

places

can

not

be

corrected

by

adjust

ment

or

replacement

of

parts

in

the

rear

axle

and

rear

suspension

In

case

of

oil

leak

first

check

if

there

is

any

damage

or

restriction

in

breather

Condition

Probable

cause

Noise

Loose

wheel

nuts

Loose

one

or

more

securing

bolts

Lack

of

lubricating

oil

or

grease

Faulty

shock

absorber

Incorrect

adjustment

of

rear

axle

shaft

end

play

Damaged

or

worn

wheel

bearing

Worn

spline

portion

of

rear

axle

shaft

Broken

leaf

spring

Loose

journal

connections

or

so

no

Wheel

and

tire

unbalance

Damaged

rubber

parts

such

as

leaf

spring

bush

shock

absorber

moun

ting

bush

Faulty

universal

joints

Instability

in

driving

Loose

wheel

nuts

Worn

shock

absorber

Worn

or

broken

leaf

spring

Oil

leakage

Damaged

or

restricted

air

breather

Damaged

oil

seal

in

rear

axle

case

or

differ

ential

carrier

Oil

leakage

from

between

the

differential

carrier

and

axle

case

RA

8

Corrective

action

Tighten

the

wheel

nuts

Tighten

the

bolts

to

the

specified

torque

Lubricate

as

required

Replace

the

shock

absorber

Adjust

the

rear

axle

shaft

end

play

Replace

wheel

bearing

Replace

if

necessary

Replace

leaf

spring

Tighten

to

the

given

torque

Balance

wheel

and

tire

Replace

the

required

parts

Adjust

or

replace

Tighten

to

the

given

torque

Replace

faulty

shock

absorber

Replace

leaf

spring

Clean

or

replace

air

breather

Replace

the

damaged

oil

seal

Tighten

to

the

specified

torque

or

replace

gasket

Page 381 of 537

DISASSEMBLY

AND

ASSEMBLY

1

00

11I

1

Reservoir

cap

2

Oil

mter

3

Oil

reservoir

4

Packing

5

Valve

cap

Brake

System

00

oC

1

O

b

0

1

r

r

L

BA927

6

Secondary

piston

stopper

7

Bleeder

screw

8

Secondary

return

spring

9

Secondary

piston

10

Primary

return

spring

11

Primary

piston

12

Piston

stopper

13

Piston

stopper

ring

1

Remove

reservoir

cap

and

filter

and

drain

out

brake

fluid

2

Pry

off

stopper

ring

using

a

screwdriver

3

Remove

stopper

screw

and

take

out

stopper

primary

piston

assembly

spring

and

secondary

piston

assembly

in

the

order

shown

Note

Discard

piston

cup

if

it

is

re

moved

from

piston

sembly

and

use

a

new

one

4

Unscrew

plugs

to

gain

access

to

check

valve

for

disassembling

Note

Never

detach

reservoir

tank

U

it

is

removed

for

any

reason

dis

canI

it

and

install

a

new

one

S

Assemble

master

cylinder

in

the

reverse

sequence

of

disassembly

pay

ing

particular

attention

to

the

follow

ing

notes

Fig

BR

10

Master

cylinder

Tightening

torque

Valve

cap

T

okico

8

t09

kg

m

S8

to

6S

ft

Ib

Nabco

2

5

to

3

S

kg

m

18

to

2S

ft

Ib

Bleeder

0

7

to

0

9

kg

m

S

to

7

ft

lb

Notes

a

Replace

gaskets

and

packings

with

new

ones

b

Apply

brake

fluid

or

rubber

grease

to

sliding

contact

surfaces

of

parts

to

facilitate

assembly

of

master

cylinder

c

The

blllke

master

cylinder

is

avail

able

in

both

NABCO

make

and

TOKlCO

make

There

is

no

inter

changeability

of

repair

kits

or

com

ponent

parts

between

NABCO

and

TOKlCO

JIIlkes

When

replacing

the

repair

kit

or

component

parts

BR

6

ascertain

the

brand

of

the

brake

master

cylinder

body

Be

sure

to

use

parts

of

the

same

make

as

the

former

ones

INSPECTION

Thoroughly

clean

all

parts

in

a

suitable

solvent

and

check

for

WOol

or

damaged

parts

Replace

any

part

that

is

faulty

Note

Do

not

clean

robber

parts

with

minerai

oil

since

this

will

be

the

sure

way

of

deteriolllting

parts

Use

brake

fluid

or

alcohoL

When

alco

hol

is

used

for

leaning

these

parts

do

not

immerse

them

in

it

longer

than

30

seconds

After

parts

are

cIeaned

dry

with

compressed

air

I

Check

cylinder

and

position

for

evidence

of

abnonnaI

wear

or

damage

Replace

if

found

faulty

2

Check

piston

to

cylinder

clear

ance

If

it

is

more

than

O

IS

mm

0

OOS9

in

replace

either

piston

or

cylinder

Master

cylinder

inner

diameter

19

0S

mm

Yoin

3

Check

for

weakened

fatigued

or

damaged

springs

and

replace

if

neces

sary

4

When

master

cylioder

is

disassem

bled

be

sure

to

discard

cups

and

valves

Replace

any

other

part

which

shows

evidence

of

deformation

wear

or

damage

S

Replace

damaged

oil

reservoirs

and

caps

INSTALLATION

Install

master

cylinder

in

the

re

verse

sequence

of

removal

Bleed

air

out

of

master

cylinder

by

loosening

bleeder

screw

after

it

is

installed

in

its

original

position

Tightening

torque

Brake

master

cylinder

attaching

nut

0

8

to

1

1

kg

m

6

to

8

ft

Ib

Brake

tube

connector

I

S

to

1

8

kg

m

II

to

13

ft

Ib