check oil DATSUN PICK-UP 1977 Manual PDF

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 268 of 537

1st

2nd

shift

valve

FSV

The

FSV

is

a

transfer

valve

which

shifts

gears

from

low

to

second

When

Ihe

vehicle

is

stopped

the

FSV

is

depressed

to

the

right

side

by

force

of

a

spring

located

on

the

left

side

putting

the

FSV

is

in

the

low

position

When

vehicle

speed

increases

the

governor

pressure

15

is

applied

to

Ihe

right

side

of

the

FSV

and

the

FSV

is

forced

toward

the

left

Contrarily

the

line

pressure

I

togelher

with

the

spring

force

force

the

FSV

toward

the

right

opposing

the

governor

pressure

15

When

the

vehide

speed

exceeds

a

certain

level

the

governor

pressure

15

exceeds

the

sum

of

the

throttle

pressure

and

Ihe

spring

force

and

the

FSV

is

forced

toward

the

left

When

the

FSV

is

depressed

10

a

certain

position

the

lire

pressure

I

is

closed

and

only

the

spring

depresses

the

FSV

toward

the

right

and

it

is

depressed

to

the

end

for

a

moment

As

a

resull

the

line

p

ressure

lJ

is

for

warded

to

8

the

band

servo

is

engaged

through

the

SLY

and

the

speed

is

shifted

to

2nd

With

the

accelerator

pedal

depressed

the

FSV

remains

iIi

the

Low

position

unless

the

governor

pressure

IS

increases

to

a

high

leVel

corresponding

to

the

line

pressure

I

since

the

line

pressure

I

increase

when

the

accelerator

pedal

is

depresse9

Contrarily

when

vehicle

speed

de

creases

the

governor

pressure

15

decrease

Howeve

f

the

gear

is

not

shifted

to

Low

nless

the

governor

pressure

15

becomes

zero

since

the

force

depressing

the

FSV

toward

the

right

is

being

delivered

only

by

the

spring

Low

in

range

I

is

led

to

the

low

and

reverse

clutch

from

line

pres

sure

5

through

line

prbssure

12

2nd

is

simultaneousi

y

led

to

the

ieft

end

spring

unit

Consequently

al

thougp

the

goverflor

pressure

in

creases

the

valve

is

still

forced

toward

the

right

and

the

SFV

is

fixedjn

the

Low

position

When

kicked

down

to

the

2nd

speed

the

SDV

operates

and

the

line

pressure

13

forces

the

FSV

toward

the

right

Although

the

Automatic

Transmission

governor

pressure

15

is

considerably

high

the

valve

is

forced

completely

toward

the

right

and

the

FSV

is

returned

to

the

Low

position

This

operation

is

alled

Kickdown

shift

15

j

13

1

c5

I

0

t

r

I

I

q

1

AT091

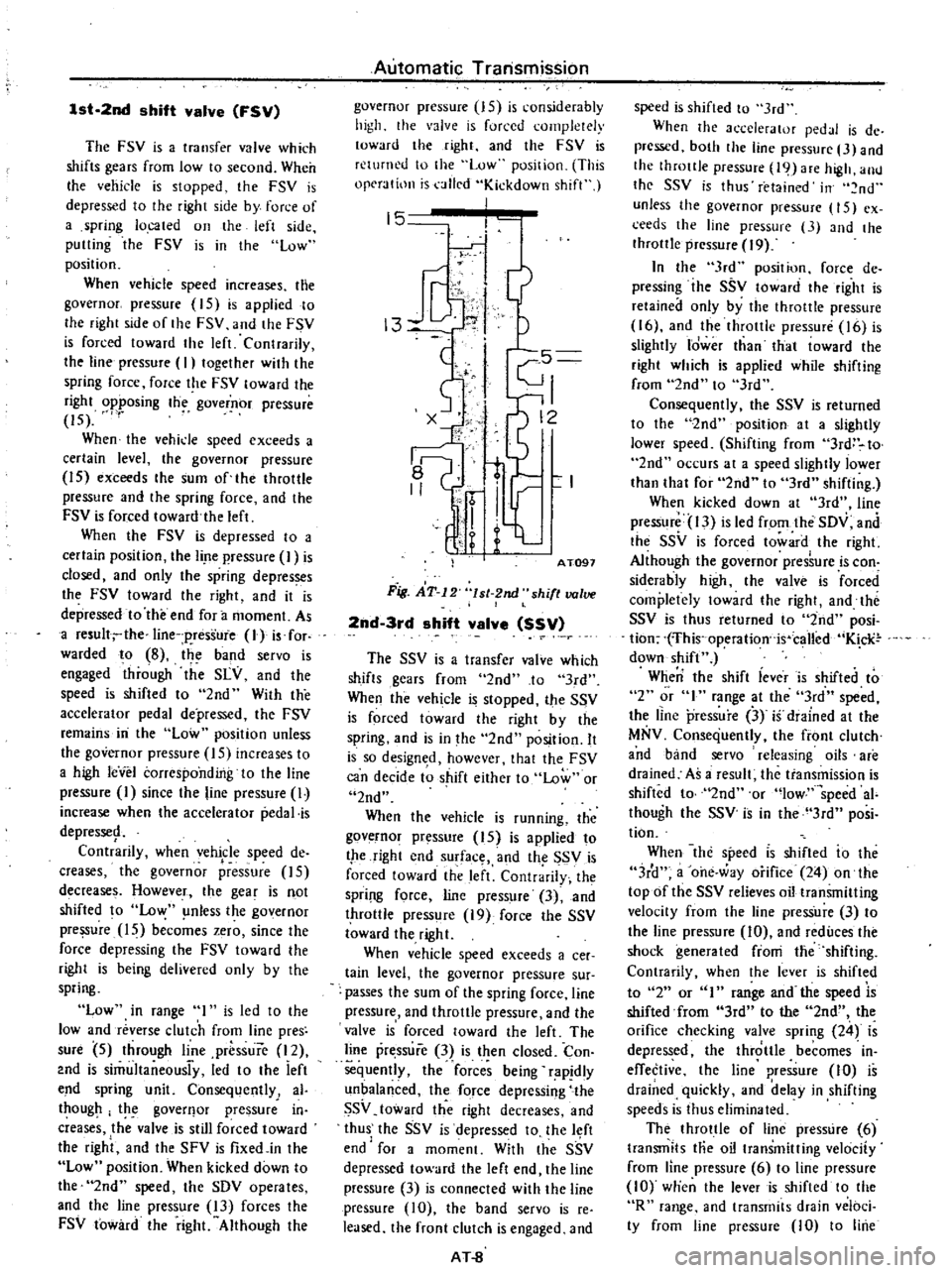

Fig

AT

12

lsl

2nd

shift

valve

2nd

3rd

shift

valve

SSV

The

SSV

is

a

transfer

valve

which

shifts

gears

from

2nd

to

3rd

When

the

vehicle

is

stopped

the

SSV

is

forced

toward

the

right

by

the

spring

and

is

in

the

2nd

position

It

is

so

design

d

however

that

the

FSV

can

decide

to

shift

either

to

Low

or

2nd

When

the

vehicle

is

running

the

governor

pressure

15

is

applied

to

the

right

end

surface

and

th

SSV

is

forced

toward

the

left

Contrarily

the

Spri

l

force

line

pressure

3

and

throttle

press

re

19

force

the

SSV

toward

the

right

When

vehicle

speed

exceeds

a

cee

tain

level

the

governor

pressure

sur

passes

the

sum

of

the

spring

force

line

pressure

and

throttle

pressure

and

the

valve

is

forced

toward

the

left

The

line

pressure

3

is

then

closed

Con

sequently

the

forces

being

rapjdly

unbalanced

the

force

depressing

the

SSV

toward

the

right

decreases

and

thus

the

SSV

is

depressed

to

the

l

ft

end

for

a

moment

With

Ihe

SSV

depressed

toward

the

left

end

lhe

line

pressure

3

is

connected

with

the

line

pressure

10

the

band

servo

is

re

leased

the

front

clutch

is

engaged

and

AT

8

speed

is

shifted

to

3rd

When

the

accelerator

pedJI

is

de

prcssed

both

the

line

pressure

3

and

the

throttle

pressure

19

are

high

allll

the

SSV

is

thus

retained

in

nd

unless

the

governor

pressure

15

ex

ceeds

the

line

pressure

3

and

the

throttle

pressure

19

In

the

3rd

position

force

de

pressing

ihe

SSV

toward

the

right

is

retained

only

by

the

throttle

pressure

16

and

the

throttle

pressure

16

is

slightly

Idwer

than

that

toward

the

right

which

is

applied

while

shifting

from

2nd

to

3rd

Consequently

the

SSV

is

returned

to

the

2nd

position

at

a

slightly

lower

speed

Shifting

from

3rd

to

2nd

occurs

at

a

speed

slightly

lower

than

that

for

2nd

to

3rd

shifting

When

kicked

down

at

3rd

line

pressure

13

is

led

from

the

SDV

and

the

SSV

is

forced

toward

the

right

Although

the

governor

pres

ure

is

con

siderably

high

the

valve

is

forced

completely

loward

the

right

and

tht

SSV

is

thus

returned

to

2nd

posi

tion

fhis

operation

is

called

K

cli

down

shift

When

the

shift

iever

is

shifted

to

2

or

I

range

at

the

3rd

speed

the

line

pressure

3

if

diained

at

the

MNV

Consequently

the

front

clutch

and

band

servo

releasing

oils

are

drained

As

a

result

the

transmission

is

shifted

to

2nd

or

low

speed

ai

though

the

SSV

is

in

the

3rd

posi

tion

When

the

specd

IS

shifted

io

the

3r

1

a

one

way

orifice

24

on

the

topof

the

SSV

relieves

oil

transmitting

velocity

from

the

line

pressure

3

to

the

line

pressure

10

and

reduces

the

shock

generated

fioni

the

shifting

Contrarily

when

the

lever

is

shifted

to

2

or

I

range

and

the

speed

is

shifted

from

3rd

to

the

2nd

the

orifice

checking

valve

spring

24

is

depressed

the

throttle

becomes

in

effective

the

line

pressure

10

is

drained

quickly

and

delay

in

shifting

speeds

is

thus

eliminated

The

throttle

of

line

pressure

6

transmits

Hie

oil

transmitting

velocity

from

line

pressure

6

to

line

pressurc

10

wtien

the

lever

is

shifted

to

the

R

range

and

transmits

drain

veloci

ty

from

line

pressure

10

to

line

Page 277 of 537

R

range

Reverse

Torq

Con

Oil

Cool

r

A

r

Lubt

lcetlon

0

II

iL

Vel

o

Front

or

ln

l

n

jL

r

x

Q

A

uletor

Val

NIJte

kld

Automatic

Transmission

@

2nd

3n

l

Timl

lil

1i

II

r

U

nu

r

l3

ni

II

15

15

Front

Cll

ltc

Il

Low

a

Aev

Br

k

B

k

II

I

LJ

2f

ID

p

Mc

e

lf

v

If

I

I

CID

VEL

1

Thrc

r

V

I

I

11

1

IU

T

R

Clutch

f

r

Ir

l

II

Orlflc

Check

Velve

22

n

@lnd

3rdShlft

v

D

h

III

r

r

I

I

111

L

Ll

p

O

nOl

f

t

p

r

Goy

norpreat

l

Torque

Ilrfl

r

Throttl

D

ln

v

5

1

O

eln

rmrp

Throttl

p

a

nor

v

11

J

I

t

Q

V

1ve

Fig

A

T

28

Oil

preBBure

circuit

diagram

R

range

Reverie

AT

17

Page 279 of 537

Automatic

Transmission

P

range

Park

Front

Cluteh

1

1

Brllk

ar

Bond

Torqu

Con

u

o

ID

VK

Th

o

I

V

II

IftY

all

Coo

II

I

Front

Lubrk

It

n

Orltlc

Check

V

A

L

b

k

tlon

1

e

O

ln

I

ThrOttle

D

ln

V

21

j

r

tUI

lor

V

h

@

V

hI

N01

M

rked

X

r

D

ln

5

I

I

I

X

Line

pr

Go

nor

t

d

pr

L

J

Q

RO

p

c

J

Torq

co

p

f

Th

ottl

p

Iecond

y

Ocw

no

V

Gover

V

Fig

A

T

25

Oil

pressure

circuit

diagram

P

range

Park

AT

IS

Page 281 of 537

R

range

Reverse

Automatic

Transmission

TOl

QuaConverter

o

IIi

0

ou

14

Q

FI

Lu

IUt

O

Front

Lub

lc

O

lnV

ly

R

MO

V

l

Front

Clutdt

LowaoA

B

k

e

k

B

Clutch

ID

VK

n

V

lv

@

ftV

1

I

j

Throttle

O

in

V

Otlflce

Check

V

III

@lnd

3rdShih

V

zz

@

2nd

rd

TIm

If

V

Iy

Second

Lock

V

3

I

Zl

Not

M

k

d

X

er

0

1

LI

p

O

nOf

f

P

G

preau

I

J

Torqu

0

0

pr

Throttl

p

1

s

co

O

V

0

O

V

Fig

A

T

28

AT

17

Oil

pressure

circuit

diagram

n

II

range

Reverse

Page 283 of 537

Automatic

Transmission

N

ranee

Neutral

I

a

a

8

nd

011

Coolei

VK

Th

o

Vtlv

J

@

Vtlv

I

I

D

ln

Ol

v

Lubrlc

tlon

11

I

OIIt

Lubrlut

O

lfIC

Check

Vtlv

D

lnV

I

T

uott

O

in

v

8Jl

12

ht

2nd

Shift

y

tve

5

CD

Rl9UlttO

Vtlv

Nott

M

rked

X

r

D

in

liia

1

or

IOo

nOf

fNd

IH

oov

no

p

c

z

Torqu

con

er

pr

Throttl

p

s

cond

y

a

Ol

V

o

V

tve

Fig

AT

29

AT

19

Oil

pressure

circuit

diagram

N

range

Neutral

Page 289 of 537

Automatic

Transmission

0

range

Top

gear

Low

A

lI

eke

B

e

I

mf

D

J

J

V

va

I

011

COO

VK

Thro

V

o

Ot

al

oi

v

L

R

Lubfkatlon

y

Front

Lubric

1

n

Oriliu

Check

1

1

O

nV

Th

onla

O

eln

Vah

2

P

M

lflM

V

I

5

22

x

i2J

3

1n

2nd

Shift

v

1Ye

5

Manue

Val

PRND2

j

Pr

R

I

Of

1

1

5

Nota

Marked

r

Dr

ln

rs

ond

y

l

y

G

nor

Val

Goy

rnor

Val

1

1

IOo

no

feold

P

Oo

no

p

Torq

c

on

n

p

Th

onl

pr

Fig

A

T

38

Oil

pressure

circuit

diagram

uD

J

range

Top

gear

AT

25

Page 291 of 537

Automatic

Transmission

I

M

nual

f4fL

J

0

I

1

r

PR

0

range

kickdown

Shift

valves

In

2nd

gear

position

To

queeO

t

Front

Clutch

Low

a

A

8

8

e

e

a

o

14

0

Oil

COO

R

L

ubrication

n

0

Drain

1

4

j

v

I

Front

Lub

icet

p

n

o

I

Thron

p

ain

V

I

j

R

gu

ato

V

I

Not

Ma

ked

X

r

p

n

Li

pr

IGo

no

f

d

p

l

Governor

p

c

Torque

CO

I

1

p

ThrOWepr

VK

Th

o

V

lv

7

1

iftV

8

Throttle

BKk

up

V

hl

ID

So

e

COw

P

Ifk

Check

V

I

1

24

5

Mod

Yo

I

@2nCl

3rdSl

lilr

V

12

3

ht

2nd

Shih

V

5

L

I

X

S

COnd

Primary

G

rw

Va

Gov

nor

Valve

AT

27

Fig

AT

39

Oil

pressure

circuit

diagram

D

ronge

kickdown

shift

values

in

2nd

gear

position

Page 293 of 537

Automatic

Transmission

2

range

2nd

gear

Torqu

Con

Fron

Clutch

l

ow

A

B

ke

Br

I

12

011

Cool

i

IL

12

ID

v

Th

ot

Valve

7

T

onl

Beck

up

V

ID

So

0

Id

1ft

v

Front

Lubric

t

Orltic

Check

Va

Or

lnVal

e

Throttle

Dr

in

V

l

P

Modif

Va

15

BJl

@

2nct

3rd

Tim

If

Ve

12

3

1

2nd

Stolt

21

Se

onc

l

Lock

Va

3

I

PR

02

1

s

I

Jl

J

I

r

A

ul

Gr

v

2

w

Valve

Note

Merltedl

D

a

n

I

G

v

Line

p

IOo

nOf

f

d

pr

G

no

p

r

c

o

Torque

con

pr

Thron

p

re

ond

a

nor

v

Fig

A

T

42

Oil

pressure

circuit

diagram

2

range

2nd

gear

AT

29

Page 298 of 537

Starter

should

be

brought

into

op

eration

only

when

selector

lever

is

in

P

and

N

positions

it

should

not

be

started

when

lever

is

in

D

2

I

and

R

positions

Back

up

lamp

should

also

light

when

selector

lever

is

placed

in

R

position

S

After

converter

is

installed

rotate

10

Check

level

of

oil

in

transmis

crankshaft

several

turns

and

check

to

be

sure

that

transmission

rotates

freely

sion

For

detailed

procedure

see

page

AT48

without

binding

6

Pour

recommended

automatic

II

Move

selector

lever

through

aU

positions

to

be

sure

that

transmission

transmission

fluid

up

to

correct

level

operates

correctly

through

oil

charge

pipe

verter

to

transmission

measure

dis

With

hand

brake

applied

rotate

tan

A

to

be

certain

that

they

are

7

Connect

manual

lever

to

shift

engine

at

idling

Without

disturbing

correctly

mbi

d

S

F

rod

Opeiationsliould

oecaTrie

f

bue

the

above

sclUng

ffiovTSelector

lever

AT

50

with

manual

and

selector

levers

in

through

N

to

D

to

2

to

I

Distance

A

N

and

to

R

A

slight

shock

should

be

More

than

21

5

mm

0

846

in

8

Connect

inhibitor

switch

wires

felt

by

hand

gripping

selector

each

time

transmission

is

shifted

Automatic

Transmission

4

Bolt

converter

to

drive

plate

Note

Align

chalk

marks

painted

a

cross

both

parts

during

disas

sembling

processes

AT116

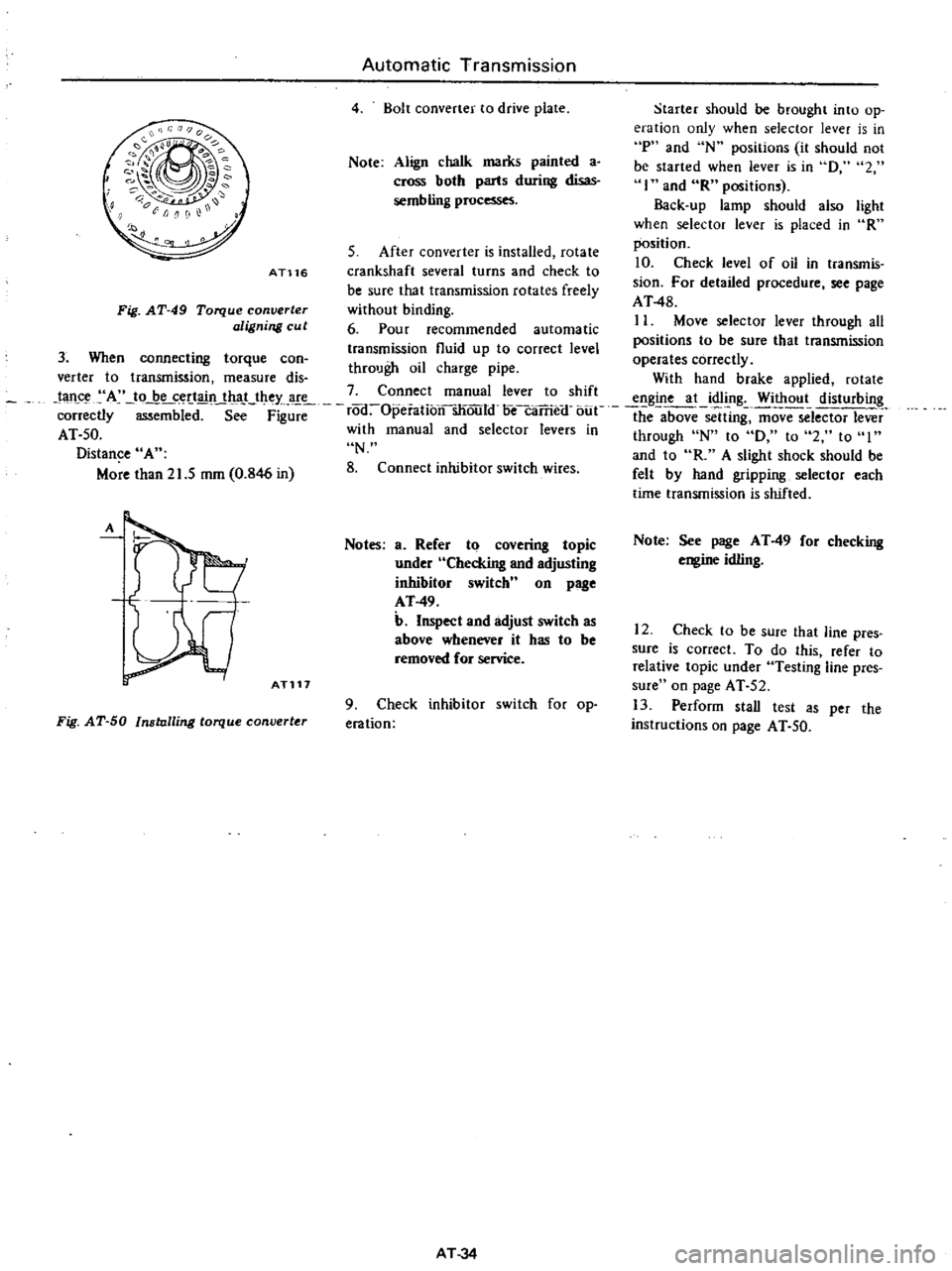

Fig

AT

49

Torque

converter

aligning

cu

t

3

When

connecting

torque

can

A

ATl17

Notes

a

Refer

to

covering

topic

under

Checking

and

adjusting

inhibitor

switch

n

on

page

AT

49

b

Inspect

and

adjust

switch

as

above

whenever

it

has

to

be

removed

for

service

Fig

AT

50

Installing

torque

converter

9

Check

inhibitor

switch

for

op

eration

AT

34

Note

See

page

AT

49

for

checking

engine

idling

12

Check

to

be

sure

that

line

pres

sure

is

correct

To

do

this

refer

to

relative

topic

under

Testing

line

pres

sure

on

page

AT

52

13

Perform

stall

test

as

per

the

instructions

on

page

AT

50

Page 299 of 537

Automatic

Transmission

TRANSMISSION

CONTROL

LINKAGE

4

120N

L

B

j

p

r

4

1

Control

lever

knob

2

Pusher

3

Control

lever

assembly

4

Selector

range

lever

5

Control

lever

bracket

6

Selector

rod

REMOVAL

AND

INSTALLATION

1

Disconnect

control

knob

from

control

lever

by

removing

two

2

screws

2

Remove

console

box

3

Remove

selector

rod

selector

range

lever

and

control

lever

assembly

with

bracket

To

install

reverse

the

order

of

removal

ADJUSTMENT

The

adjustment

of

linkage

is

as

Tightening

torque

1

of

nuts

and

screw

kg

m

ft

lb

G

A

T273

@

T

0

07

to

0

13

0

5

to

0

9

@

T

1

6

to

2

2

12

to

16

T

3

to

4

22

to

29

@

T

0

35

to

0

45

2

5

to

3

3

C8i

T

0

8

to

1

1

6

to

8

important

as

Inspection

of

oil

level

for

the

automatic

transmission

Therefore

great

care

should

be

exercised

because

faulty

adjustment

will

result

in

the

breakdown

of

the

transmission

1

Prior

to

installing

control

knob

set

the

dimension

A

to

II

to

12

mm

0

43

to

0

47

in

2

Install

control

knob

on

lever

At

the

same

time

check

the

dimension

B

and

adjust

it

to

0

1

to

1

1

mm

0

004

to

0

043

in

by

turning

pusher

@

See

Figure

AT

51

AT

35

Fig

AT

51

Controlli

f

kage

sy

tem

3

Loosen

adjust

nuts

@

Set

control

lever

@

and

selector

lever

@

at

N

position

moreover

J

set

the

clearance

C

to

I

mm

0

039

in

by

turning

in

or

out

adjusting

nuts

at

trunnion

with

connects

selector

rod

@

After

adjusting

make

sure

that

control

lever

can

be

set

in

any

position

correctly

and

that

selector

lever

oper

ates

properly

without

any

binding

If

levers

do

not

operate

satisfactori

ly

readjust

or

replace

parts

as

neces

sary