warning DATSUN PICK-UP 1977 User Guide

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 157 of 537

4

E

G

R

warning

system

EC251

Detector

drive

counter

Detecfor

drive

counter

is

secured

on

the

top

of

R

H

hoodledge

panel

in

engine

room

To

remove

detector

drive

counter

disconnect

w

COJUlector

and

loosen

two

bolts

securing

detector

drive

counter

to

hoodledge

panel

2

E

G

R

warning

lamp

E

G

R

warning

lamp

is

mounted

at

the

top

cen

ter

of

instrument

pad

To

remove

E

G

R

warning

lamp

proceed

as

follows

1

Remove

masking

panel

On

models

equipped

with

radio

remove

warning

lamp

from

under

in

strument

panel

2

E

G

R

warning

lamp

is

a

twist

type

Remove

lamp

and

socket

as

an

assembly

Push

and

twist

lamp

off

can

EC554

Fig

EC

60

Removing

E

G

R

warning

lamp

Emission

Control

System

3

Odometer

switch

Odometer

switch

is

mounted

on

the

back

side

of

speedometer

Cam

in

the

odometer

switch

is

rotated

by

the

speedometer

To

dismount

odometer

switch

proceed

as

follows

I

Dismount

combination

meter

as

sembly

2

Remove

meter

front

cover

and

take

off

clips

and

screws

to

dismount

shadow

plate

3

Loosen

screws

securing

speed

ometer

to

printed

circuit

housing

then

remove

speedometer

4

Remove

two

screws

securing

odomete

switch

to

the

back

side

of

speedometer

and

detach

odometer

switch

EC239

Fig

EC

61

Removing

odometer

switch

InstaUatlon

To

install

reverse

the

removal

pro

cedure

EC24

V

r

CID

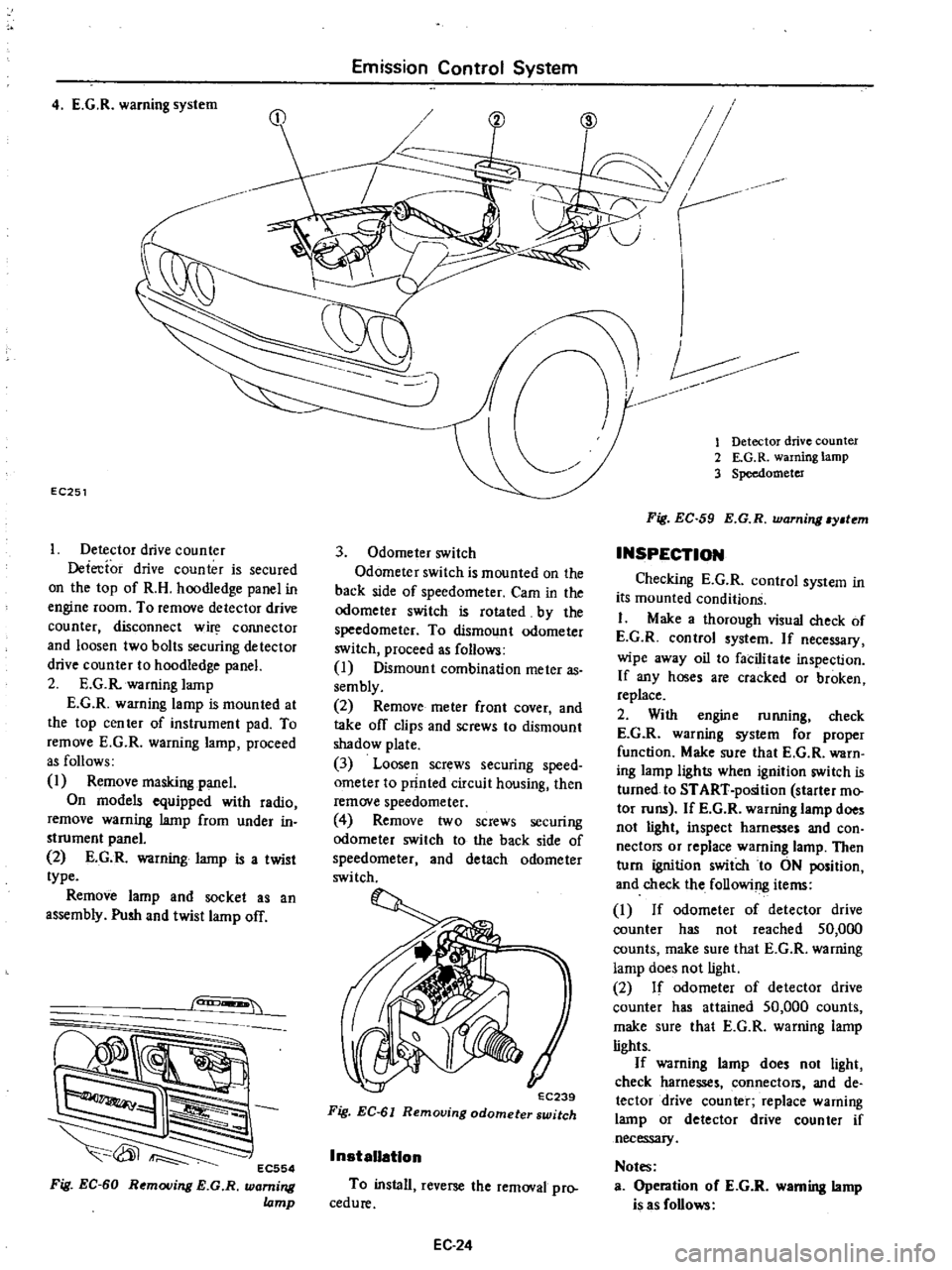

1

Detector

drive

counter

2

E

G

R

warning

lamp

3

Speedometer

Fig

EC

59

E

G

R

warning

y

tem

INSPECTION

Checking

E

G

R

control

system

in

its

mounted

conditionS

I

Make

a

thorough

visual

check

of

E

G

R

control

system

If

necessary

wipe

away

oil

to

facilitate

inspection

If

any

hoses

are

cracked

or

broken

replace

2

With

engine

running

check

E

G

R

warning

system

for

proper

function

Make

sure

that

E

G

R

warn

ing

lamp

lights

when

ignition

switch

is

turned

to

START

position

starter

mo

tor

runs

If

E

G

R

wanung

lamp

does

not

light

inspect

harnesses

and

con

nectors

or

replace

warning

lamp

Then

turn

ignition

switch

to

ON

position

and

check

the

following

items

I

If

odometer

of

detector

drive

counter

has

not

reached

50

000

counts

make

sure

that

E

G

R

warning

lamp

does

not

light

2

If

odomete

of

detector

drive

counter

has

attained

50

000

counts

make

sure

that

E

G

R

warning

lamp

lights

If

warning

lamp

does

not

light

check

harnesses

connectors

and

de

tector

drive

counter

replace

warning

lamp

or

detector

drive

counter

if

necessary

Notes

Operation

oC

E

G

R

warning

lamp

is

as

Collows

Page 158 of 537

Ignition

Switch

Position

START

Detector

Drive

Counter

E

G

R

Warning

Lamp

ON

b

After

completing

inspection

of

E

G

R

control

system

be

sure

to

reset

odometer

of

detector

drive

counter

to

zero

c

This

item

applies

to

all

620

models

except

those

bound

for

California

and

Canada

3

With

engine

stopped

inspect

E

G

R

control

valve

for

any

indication

of

binding

or

sticking

by

moving

dia

phragm

of

control

valve

upwards

with

a

finger

2

When

engine

coolant

tempera

ture

is

high

I

Make

sure

that

E

G

R

control

valve

operates

when

engine

speed

is

in

creased

from

idling

to

3

000

to

3

500

rpm

Place

a

fmger

on

the

diaphragm

of

E

G

R

control

valve

to

check

for

valve

operation

2

If

E

G

R

control

valve

does

not

operate

check

as

follows

Disconnect

one

end

E

G

R

control

valve

side

of

vacuum

hose

connect

ing

thermal

vacuum

valve

to

E

G

R

Emission

Control

System

ON

Below

50

000

counts

Above

50

000

counts

OFF

ON

4

With

engine

running

inspect

E

G

R

control

valve

and

thermal

vacuo

um

valve

for

normal

operation

1

When

engine

coolant

tempera

ture

is

low

Make

sure

that

E

G

R

control

valve

does

not

operate

when

engine

speed

is

increased

from

idling

to

3

000

to

3

500

rpm

Place

a

fmger

on

the

diaphragm

of

E

G

R

control

valve

to

check

for

valve

operation

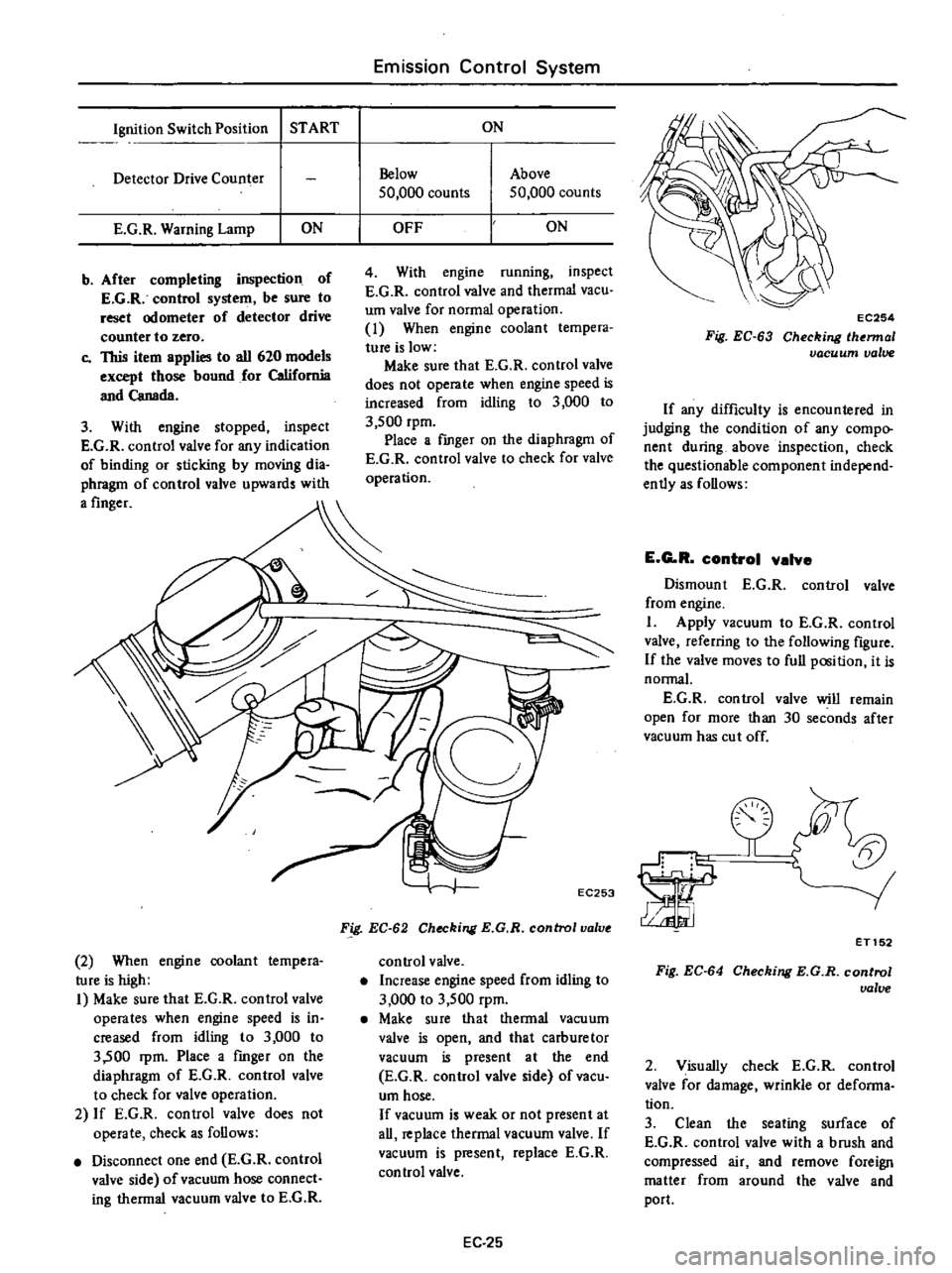

EC253

Fig

EC

62

Checking

E

G

R

control

valve

control

valve

Increase

engine

speed

from

idling

to

3

000

to

3

500

rpm

Make

su

re

that

thermal

vacu

um

valve

is

open

and

that

carburetor

vacuum

is

present

at

the

end

E

G

R

control

valve

side

of

vacu

um

hose

If

vacuum

is

weak

or

not

present

at

all

replace

thermal

vacuum

valve

If

vacuum

is

present

replace

E

G

R

control

valve

EC

25

EC254

Fig

EC

63

Checking

lhermal

vacuum

valve

If

any

difficulty

is

encountered

in

judging

the

condition

of

any

compo

nent

during

above

inspection

check

the

questionable

component

independ

ently

as

follows

E

G

R

control

valve

Dismount

E

G

R

control

valve

from

engine

I

Apply

vacuum

to

E

G

R

control

valve

referring

to

the

following

figure

If

the

valve

moves

to

full

position

it

is

normal

E

G

R

control

valve

will

remain

open

for

more

than

30

seconds

after

vacuum

has

cut

off

la

ET152

Fig

EC

64

Checking

E

G

R

control

ualue

2

Visually

check

E

G

R

control

valve

for

damage

wrinkle

or

defonna

tion

3

Clean

the

seating

surface

of

E

G

R

control

valve

with

a

brush

and

compressed

air

and

remove

foreign

matter

from

around

the

valve

and

port

Page 160 of 537

REMOVAL

AND

INSPECTION

Removal

and

inspection

can

be

done

as

follows

Removal

Catalytic

converter

1

Apply

parking

brake

2

Place

wheel

lock

under

each

tire

3

Jack

up

the

vehicle

4

Remove

lower

shelter

of

catalytic

converter

5

Dismount

catalytic

converter

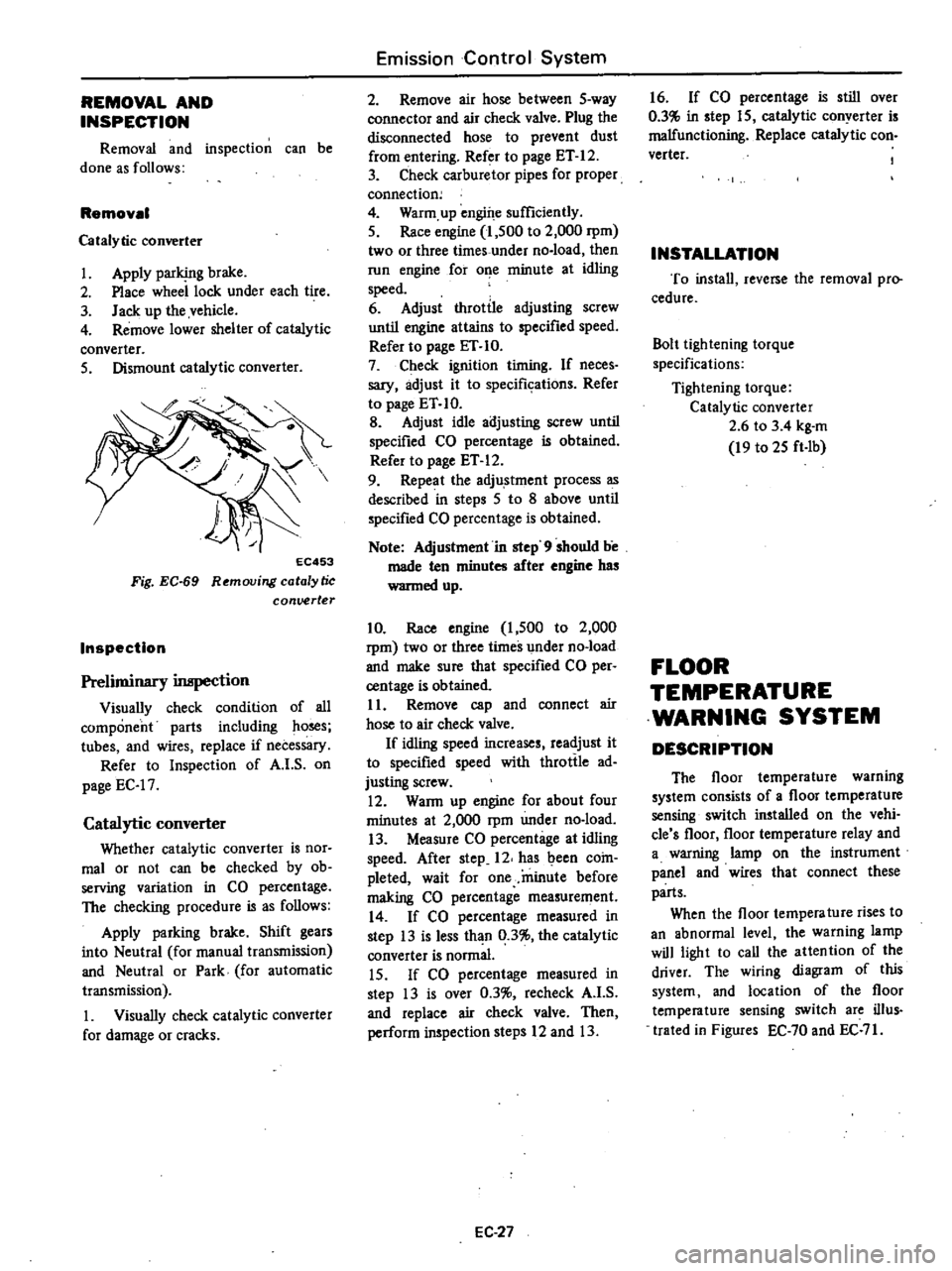

EC453

Fig

EC

69

Removing

catalytic

conuerter

Inspection

Preliminary

inspection

Visually

check

condition

of

all

component

parts

including

ho

s

tubes

and

wires

replace

if

necessary

Refer

to

Inspection

of

A

I

S

on

page

EC

17

Catalytic

converter

Whether

catalytic

converter

is

nor

mal

or

not

can

be

checked

by

ob

serving

variation

in

CO

percentage

The

checking

procedure

is

as

follows

Apply

parking

brake

Shift

gears

into

Neutral

for

manual

transmission

and

Neutral

or

Park

for

automatic

transmission

1

Visually

check

catalytic

converter

for

damage

or

cracks

Emission

Control

System

2

Remove

air

hose

between

5

way

connector

and

air

check

valve

Plug

the

disconnected

hose

to

prevent

dust

from

entering

Refer

to

page

ET

12

3

Check

carburetor

pipes

for

proper

connection

4

Warm

up

engine

sufficiently

5

Race

engine

1

500

to

2

000

rpm

two

or

three

times

under

no

load

then

run

engine

for

o

e

minute

at

idling

speed

6

Adjust

throttle

adjusting

screw

until

engine

attains

to

specified

speed

Refer

to

page

ET

10

7

Check

ignition

timing

If

neces

sary

adjust

it

to

specifkations

Refer

to

page

ET

10

B

Adjust

idle

adjusting

screw

until

specified

CO

percentage

is

obtained

Refer

to

page

ET

12

9

Repeat

the

adju

stment

process

as

described

in

steps

5

to

8

above

until

specified

CO

percentage

is

obtained

Note

Adjustment

in

step

9

should

be

made

ten

minutes

after

engine

has

wanned

up

10

Race

engine

1

500

to

2

000

rpm

two

or

three

times

under

no

load

and

make

sure

that

specified

CO

per

centage

is

obtained

11

Remove

cap

and

connect

air

hose

to

air

check

valve

If

idling

speed

increases

readjust

it

to

specified

speed

with

throttle

ad

justing

screw

12

WaRn

up

engine

for

about

four

minutes

at

2

000

rpm

under

no

load

13

Measure

CO

percentage

at

idling

speed

After

step

12

has

been

coin

pleted

wait

for

one

minute

before

making

CO

percentage

measurement

14

If

CO

percentage

measured

in

step

13

is

less

than

0

3

the

catalytic

converter

is

normal

15

If

CO

percentage

measured

in

step

13

is

over

0

3

recheck

A

I

S

and

replace

air

check

valve

Then

perform

inspection

steps

12

and

13

EC

27

16

If

CO

percentage

is

still

over

0

3

in

step

15

catalytic

conyerter

is

malfunctioning

Replace

catalytic

con

verter

INSTALLATION

To

install

reverse

the

removal

pro

cedure

Bolt

lightening

torque

specifications

Tightening

torque

Catalytic

converter

2

6

to

3

4

kg

m

19

to

25

ft

Ib

FLOOR

TEMPERATURE

WARNING

SYSTEM

DESCRIPTION

The

floor

temperature

warning

system

consists

of

a

floor

temperature

sensing

switch

installed

on

the

vehi

cle

s

floor

floor

temperature

relay

and

a

warning

lamp

on

the

instrument

panel

and

wires

that

connect

these

parts

When

the

floor

tempera

ture

rises

to

an

abnormal

level

the

warning

lamp

will

light

to

call

the

attention

of

the

driver

The

wiring

diagram

of

this

system

and

location

of

the

floor

temperature

sensing

switch

are

ilIus

trated

in

Figures

EC

70

and

EC

71

Page 161 of 537

I

Emission

Control

System

Ignition

switch

Ignition

key

Off

T

I

I

I

Battery

I

J

77

77

Relay

J

Floor

temperature

sensing

swi

tch

Floor

temperature

warning

lamp

77

77

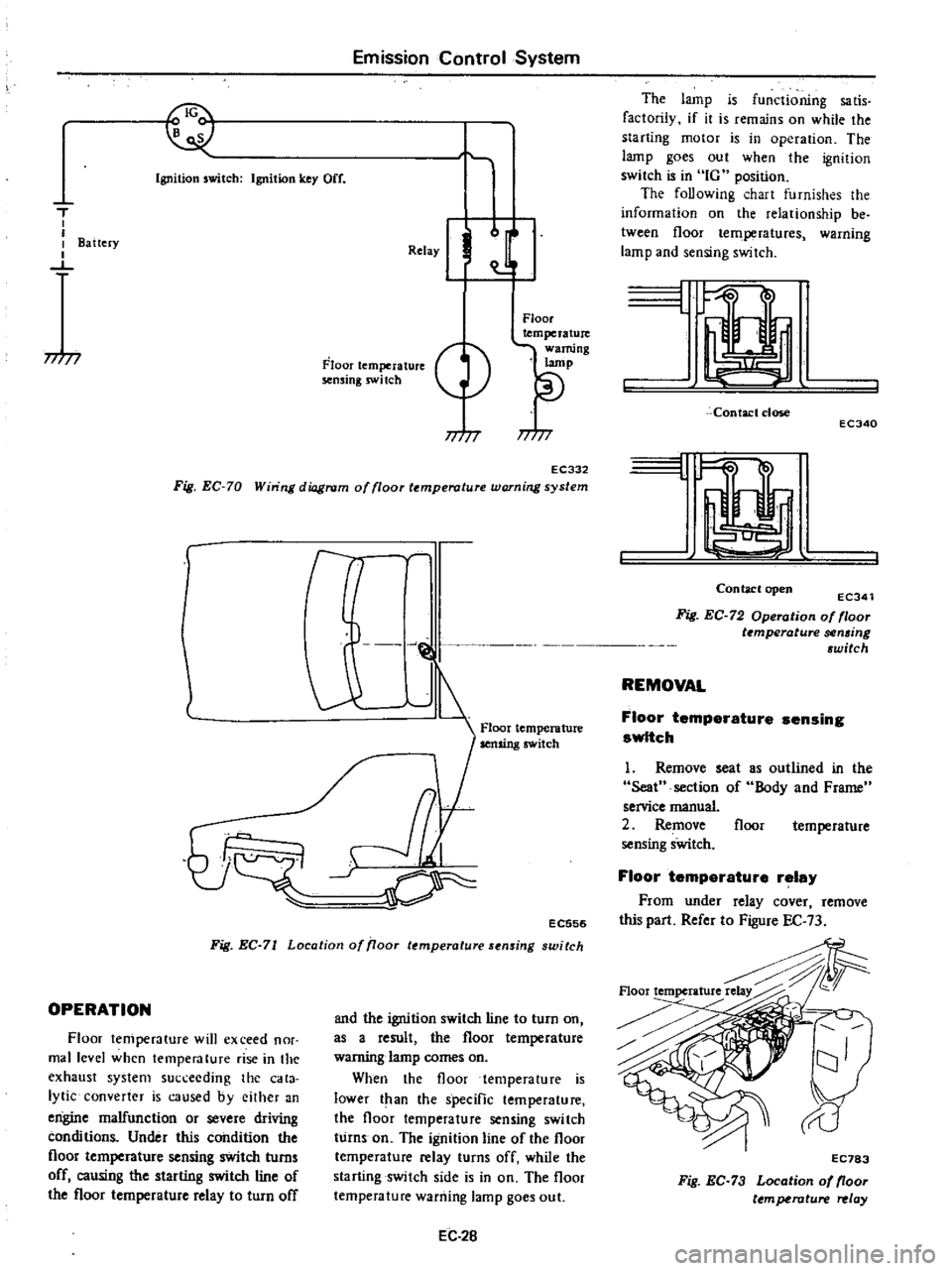

EC332

Fig

EC

70

Win

ng

diagram

of

floor

temperature

warning

system

r

l

J

@

1

Floor

temperature

Ij

cr

EC556

Fig

EC

71

Location

of

iJoor

temperature

sensing

switch

OPERATION

Floor

temperature

will

exceed

nor

mal

level

when

temperature

rise

in

the

exhaust

system

succeeding

the

cata

lytic

converter

is

caused

byeilher

an

engine

malfunction

or

severe

driving

conditions

Under

this

condition

the

floor

temperature

sensing

switch

turns

off

causing

the

starting

switch

line

of

the

floor

temperature

relay

to

turn

off

and

the

ignition

switch

line

to

turn

on

as

a

result

the

floor

temperature

warning

lamp

comes

on

When

the

floor

temperature

is

lower

t

an

the

specific

temperature

the

floor

temperature

sensing

switch

turns

on

The

ignition

line

of

the

floor

temperature

relay

turns

off

while

the

starting

switch

side

is

in

on

The

floor

temperature

warning

lamp

goes

out

EC

2B

The

lamp

is

functioning

sa

tis

factorily

if

it

is

remains

on

while

the

starting

motor

is

in

operation

The

lamp

goes

out

when

the

ignition

switch

is

in

IG

position

The

foUowing

chart

furnishes

the

information

on

the

relationship

be

tween

floor

temperatures

warning

lamp

and

sensing

switch

L

Contact

close

ECJ40

I

Contaclopen

ECJ41

Fig

EC

72

Operation

of

floor

t

mperature

sen6ing

6witch

REMOVAL

Floor

temperature

sensing

switch

1

Remove

seat

Seat

section

of

service

manual

2

Remove

sensing

sWitch

as

outlined

in

the

Body

and

Frame

floor

temperature

Floor

temperature

relay

From

under

relay

cover

remove

this

part

Refer

to

Figure

EC

73

Floortemperature

EC783

Fig

EC

73

Location

of

floor

ttmperature

relay

Page 162 of 537

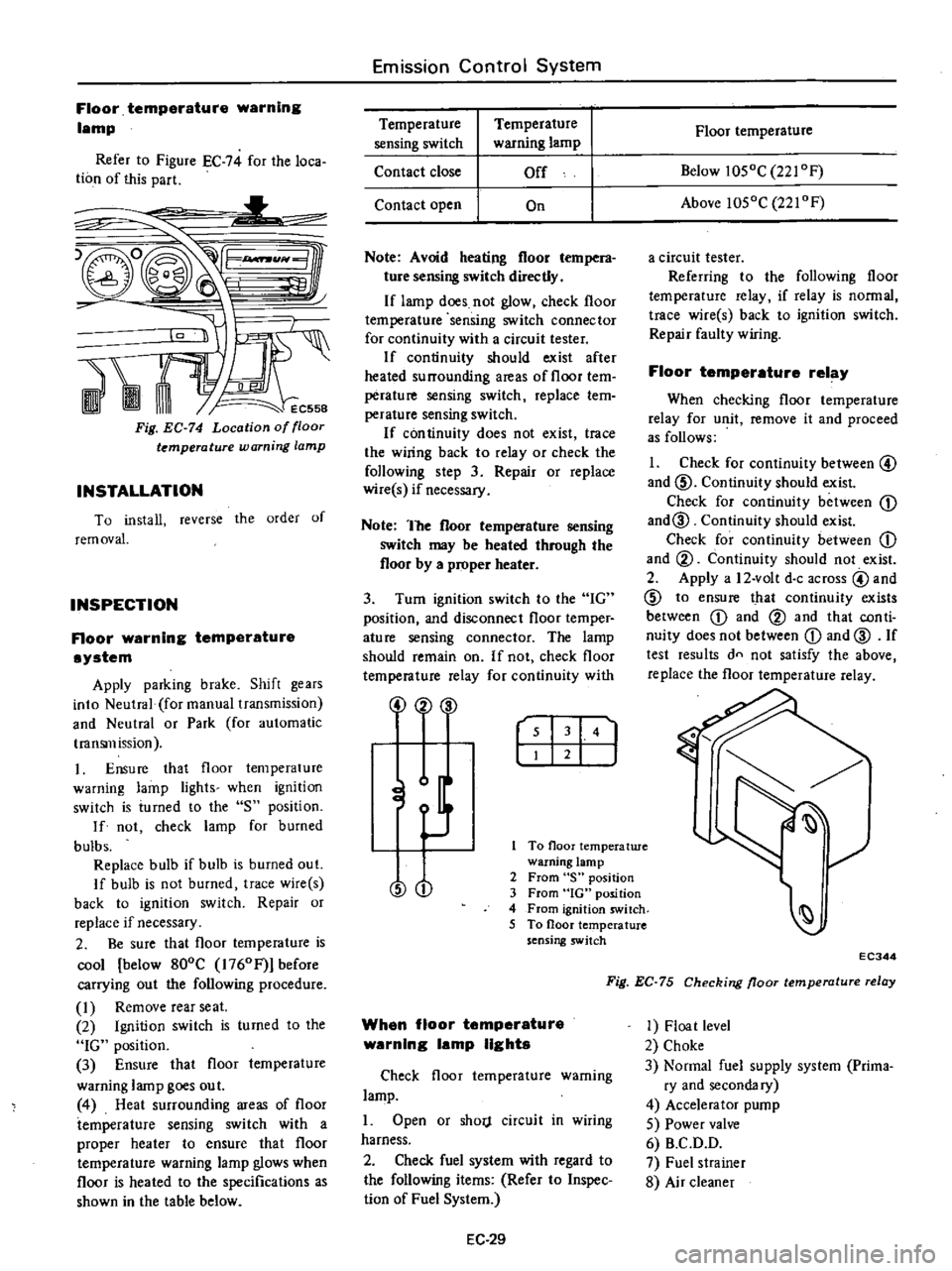

Floor

temparature

warning

lamp

Refer

to

Figure

EC

74

for

the

loca

tion

of

this

part

L

1t

1

RAt

Fig

EC

74

Location

of

floor

temperature

warning

lamp

INSTALLATION

To

install

reverse

the

order

of

rem

ovaL

INSPECTION

Floor

warning

temperature

system

Apply

parking

brake

Shift

gears

into

Neutral

foI

manual

transmission

and

Neutral

or

Park

for

automatic

transmission

1

Ensure

that

floor

temperature

warning

lamp

lights

when

ignition

switch

is

iumed

to

the

S

position

If

not

check

lamp

for

burned

bulbs

Replace

bulb

if

bulb

is

burned

out

If

bulb

is

not

burned

trace

wire

s

back

to

ignition

switch

Repair

or

replace

if

necessary

2

Be

sure

that

floor

temperature

is

cool

below

800C

1760Fj

before

carrying

out

the

following

procedure

I

Remove

rearseat

2

Ignition

switch

is

turned

to

the

IG

position

3

Ensure

that

floor

temperature

warning

lamp

goes

out

4

Heat

surrounding

areas

of

floor

temperature

sensing

switch

with

a

proper

heater

to

ensure

that

floor

temperature

warning

lamp

glows

when

floor

is

heated

to

the

specifications

as

shown

in

the

table

below

Emission

Control

System

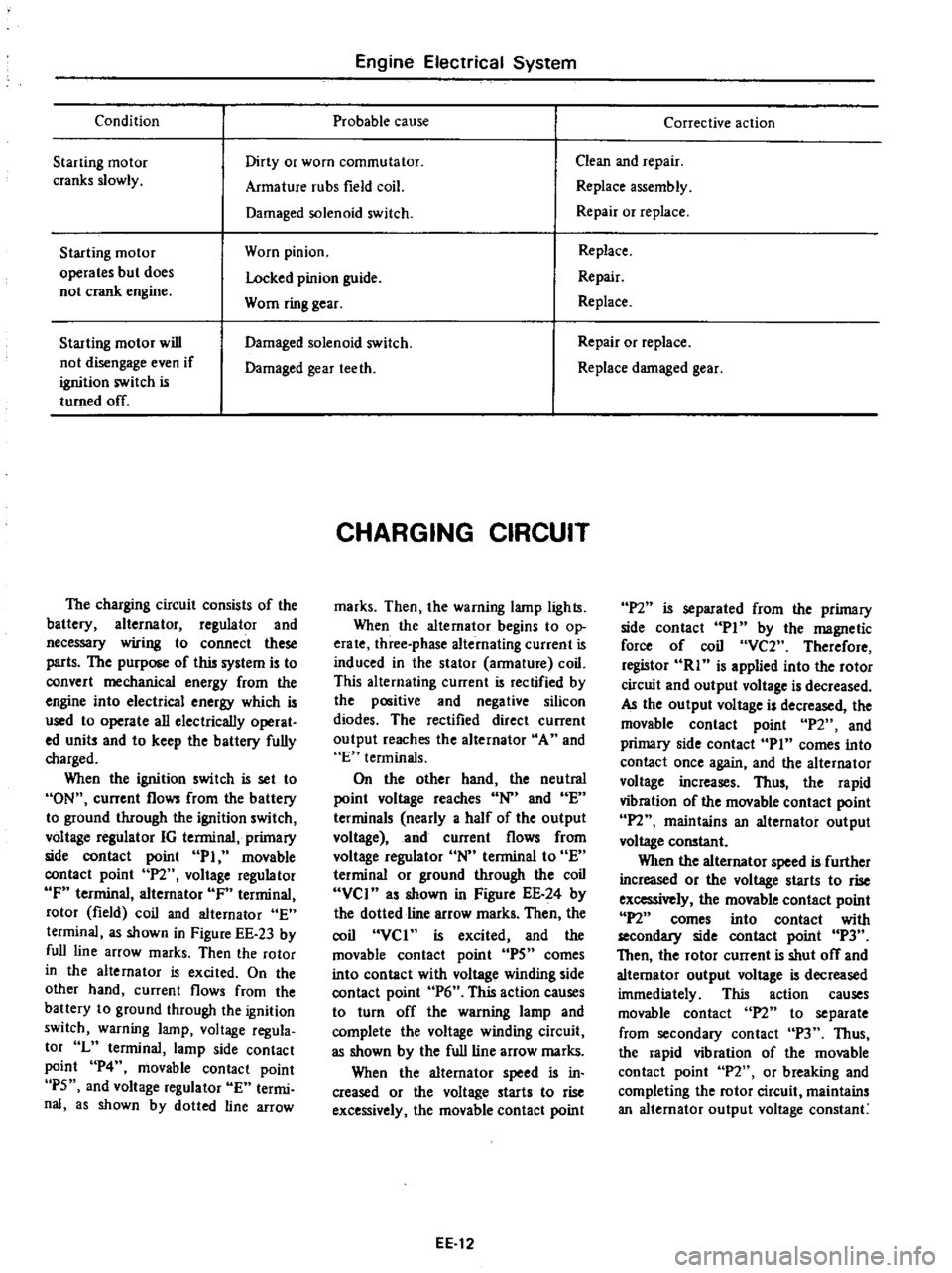

Temperature

sensing

switch

Contact

close

Temperature

warning

lamp

Off

Contact

open

On

Note

Avoid

heating

floor

tempera

ture

sensing

switch

directly

If

lamp

does

not

glow

check

floor

temperature

sensing

switch

connector

for

continuity

with

a

circuit

tester

If

continuity

should

exist

after

heated

surrounding

areas

of

floor

tem

perature

sensing

switch

replace

tem

perature

sensing

switch

If

con

tinuity

does

not

exist

trace

the

wiring

back

to

relay

or

check

the

following

step

3

Repair

or

replace

wire

s

if

necessary

Note

The

floor

temperature

sensing

switch

may

be

heated

through

the

floor

by

a

proper

heater

3

Turn

ignition

switch

to

the

IG

position

and

disconnect

floor

temper

ature

sensing

connector

The

lamp

should

remain

on

If

not

check

floor

temperature

relay

for

continuity

with

2

00

r

I

141

J

To

floor

temperatwe

warning

lamp

2

From

S

position

3

From

IG

position

4

From

ignition

switch

5

To

floor

temperature

sensing

switch

O

When

floor

temperature

warning

lamp

lights

Check

floor

temperature

warning

lamp

1

Open

or

shorj

circuit

in

wiring

harness

2

Check

fuel

system

with

regard

to

the

following

items

Refer

to

Inspec

lion

of

Fuel

System

EC

29

Floor

temperature

Below

1050C

221

OF

Above

1050C

221

OF

a

circuit

tester

Referring

to

the

following

floor

temperature

relay

if

relay

is

normal

trace

wire

s

back

to

ignition

switch

Repair

faulty

wiring

Floor

temperature

relay

When

checking

floor

temperature

relay

for

unit

remove

it

and

proceed

as

follows

1

Check

for

continuity

between

@

and

ID

Continuity

should

exist

Check

for

continuity

between

CD

and@

Continuity

should

exist

Check

for

continuity

between

CD

and

@

Continuity

should

not

exist

2

Apply

a

12

volt

doc

across

@

and

ID

to

ensure

that

continuity

exists

between

CD

and

@

and

that

con

ti

nuity

does

not

between

CD

and

@

If

test

results

dn

not

satisfy

the

above

replace

the

floor

temperature

relay

EC344

Fig

EC

75

Checking

floor

temperature

relay

1

Float

level

2

Choke

3

Normal

fuel

supply

system

Prima

ry

and

secondary

4

Accelerator

pump

5

Power

valve

6

B

C

D

D

7

Fuel

strainer

8

Air

cleaner

Page 163 of 537

3

Check

ignition

system

with

regard

to

the

following

items

Refer

to

Inspection

of

Ignition

System

1

Ignition

AMP

2

Distributor

Emission

Control

System

3

Ignition

coil

4

High

tension

code

5

Spark

plug

4

Check

idle

CO

adjustment

Refer

to

Inspection

of

Idle

CO

Adjustment

Note

Even

if

there

is

nothing

wrong

with

engine

the

warning

lamp

may

come

on

if

vebicle

is

being

driven

on

a

steep

slope

continuously

in

lower

gears

at

high

engine

speeds

EVAPORATIVE

EMISSION

CONTROL

SYSTEM

CONTENTS

DESCRIPTION

OPERATION

INSPECTION

FUEL

TANK

VAPOR

LIQUID

SEPARATOR

AND

VAPOR

VENT

LINE

DESCRIPTION

The

evaporative

emission

control

system

is

used

to

reduce

hydrocarbons

emitted

to

the

atmosphere

from

the

fuel

system

This

reduction

of

hydro

EC

30

EC

30

EC

31

CARBON

CANISTER

PURGE

CONTROL

VALVE

CARBON

CANISTER

FILTER

FUEL

TANK

VACUUM

RELIEF

VALVE

IEC

32

IEC

32

EC

32

EC

31

carbons

is

accomplished

by

activated

charcoals

in

the

carbon

canister

This

system

is

made

up

to

the

following

I

Fuel

tank

with

positive

sealing

filler

cap

@

2

Vapor

liquid

separator

3

Vapor

vent

line

4

Carbon

canister

5

Vacuum

signal

line

6

Canister

purge

line

5

OPERATION

Fuel

vapors

from

the

sealed

fuel

tank

are

led

into

the

carbon

canister

1

Fuel

tank

2

Fuel

nIler

cap

with

vacuum

relief

valve

3

liquid

vapor

separator

4

Vapor

vent

line

5

Canister

purge

line

6

Vacuum

signal

line

7

Carbon

canister

EF274

Fig

EC

76

Schematic

drawing

of

l

Iaporotive

emiaion

control6ydem

The

canister

is

fined

with

activated

charcoals

to

absorb

the

fuel

vapors

EC

30

when

the

engirie

is

at

rest

or

at

idlin

ll

See

Figure

EC

77

Page 179 of 537

Condition

Engine

Electrical

System

Probable

cause

Starting

motor

cranks

slowly

Dirty

or

worn

commutator

Armature

rubs

field

coil

Damaged

solenoid

switch

Starting

motor

operates

but

does

not

crank

engine

Worn

pinion

Locked

pinion

guide

Worn

ring

gear

Starting

motor

will

not

disengage

even

if

ignition

switch

is

turned

off

Damaged

solenoid

switch

Damaged

gear

teeth

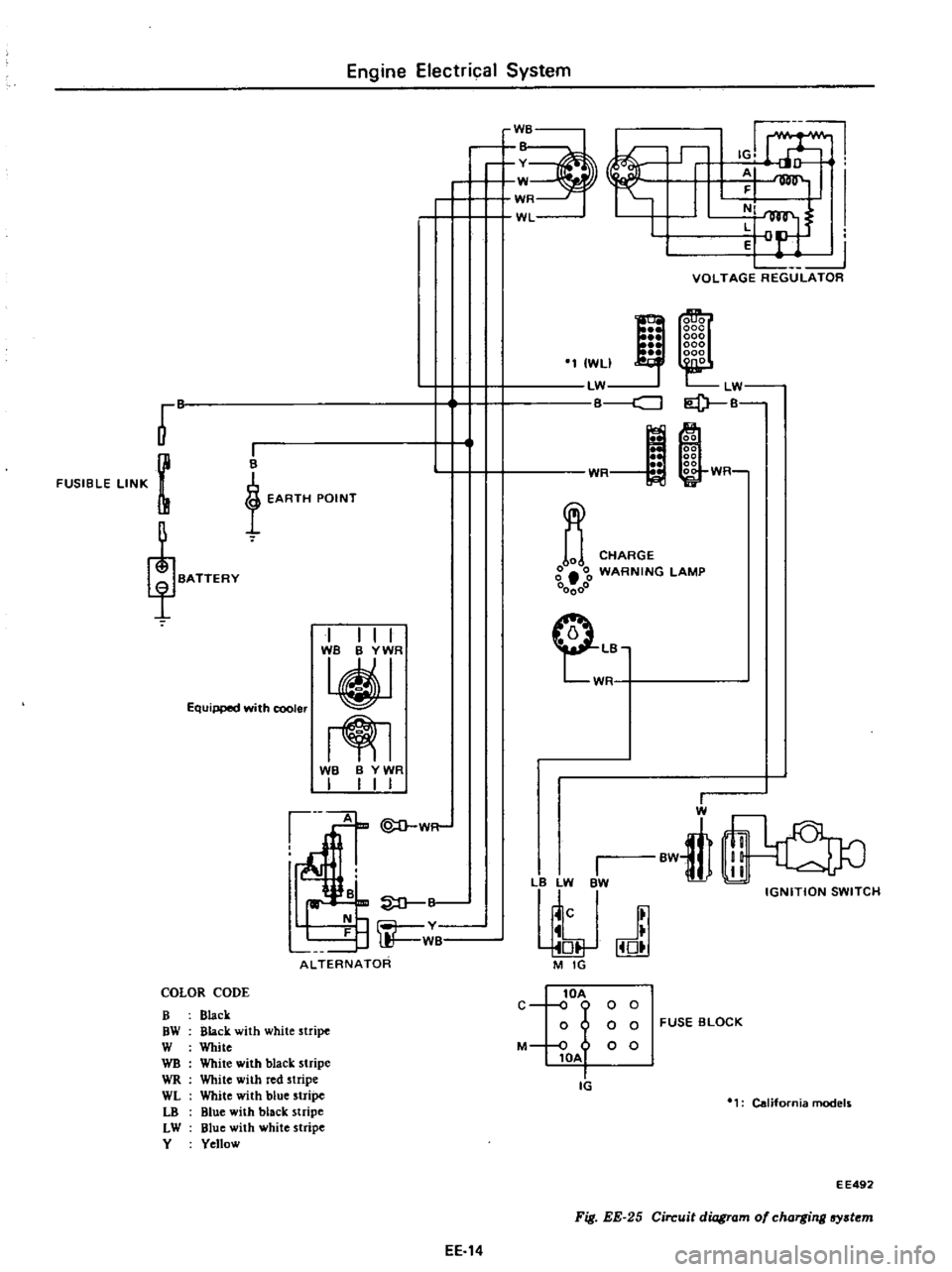

The

charging

circuit

consists

of

the

battery

alternator

regulator

and

necessary

wiring

to

connect

these

parts

The

purpose

of

this

system

is

to

convert

mechanical

energy

from

the

engine

into

electrical

energy

which

is

used

to

operate

all

electrically

operat

ed

units

and

to

keep

the

battery

fully

charged

When

the

ignition

switch

is

set

to

ON

current

flows

from

the

battery

to

ground

through

the

ignition

switch

voltage

regulator

IG

terminal

primary

side

contact

point

PI

movable

contact

point

P2

voltage

regulator

IF

terminal

alternator

IF

terminal

rotor

field

coil

and

alternator

E

terminal

as

shown

in

Figure

EE

23

by

full

line

arrow

marks

Then

the

rotor

in

the

alternator

is

excited

On

the

other

hand

current

flows

from

the

battery

to

ground

through

the

ignition

switch

warning

lamp

voltage

regula

tor

L

terminal

lamp

side

contact

point

P4

movable

contact

point

P5

and

voltage

regulator

E

termi

nal

as

shown

by

dotted

line

arrow

CHARGING

CIRCUIT

marks

Then

the

warning

lamp

lights

When

the

alternator

begins

to

op

erate

three

phase

alternating

current

is

induced

in

the

stator

armature

coil

This

alternating

current

is

rectified

by

the

positive

and

negative

silicon

diodes

The

rectified

direct

current

output

reaches

the

alternator

A

and

E

terminals

On

the

other

hand

the

neutral

point

voltage

reaches

N

and

E

terminals

nearly

a

half

of

the

output

voltage

and

current

flows

from

voltage

regulator

N

terminal

to

E

terminal

or

ground

through

the

coil

VCI

as

shown

in

Figure

EE

24

by

the

dotted

line

arrow

marks

Then

the

coil

VCI

is

excited

and

the

movable

contact

point

IPS

comes

into

contact

with

voltage

winding

side

contact

point

P6

This

action

causes

to

turn

off

the

warning

lamp

and

complete

the

voltage

winding

circuit

as

shown

by

the

full

line

arrow

marks

When

the

alternator

speed

is

in

creased

or

the

voltage

starts

to

rise

excessively

the

movable

contact

point

EE

12

Corrective

action

Clean

and

repair

Replace

assembly

Repair

or

replace

Replace

Repair

Replace

Repair

or

replace

Replace

damaged

gear

P2

is

separated

from

the

primary

side

contact

PI

by

the

magnetic

force

of

coil

VC2

Therefore

registor

RI

is

applied

into

the

rotor

circuit

and

output

voltage

is

decreased

AJ

the

output

voltage

is

decreased

the

movable

contact

point

P2

and

primary

side

contact

Pin

comes

into

contact

once

again

and

the

alternator

voltage

increases

Thus

the

rapid

vibration

of

the

movable

contact

point

IPl

maintains

an

alternator

output

voltage

constant

When

the

alternator

speed

is

further

increased

or

the

voltage

starts

to

rise

excessively

the

movable

contact

point

P2

comes

into

contact

with

secondllJ

side

contact

point

P3

Then

the

rotor

current

is

shut

off

and

alternator

output

voltage

is

decreased

immediately

This

action

causes

movable

contact

n

to

separate

from

secondary

contact

P3

Thus

the

rapid

vibration

of

the

movable

contact

point

P2

or

breaking

and

completing

the

rotor

circuit

maintains

an

alternator

output

voltage

constant

Page 181 of 537

Engine

Electrical

System

B

v

W

WR

WL

L2

VOLTAGE

REGULATOR

co

LW

I

P

B

r

FUSIBLE

LINK

m

I

WLI

LW

cJ

I

B

t

EARTH

POINT

m

WR

WR

CHARGE

g

00

WARNING

lAMP

00000

Equipped

with

cooler

I

I

I

I

TjT

m

CLB

W

WB

B

YWR

I

I

I

I

1

W

B

rn

ALTERNATOR

I

l

LW

BW

j

J

M

IG

I

W

BwtIl

IGNITION

SWITCH

COLOR

CODE

B

Black

OW

Black

with

white

stripe

W

White

WB

White

with

black

stripe

WR

White

with

red

stripe

WL

White

with

blue

stripe

LO

Blue

with

black

stripe

LW

Blue

with

white

stripe

Y

Yellow

lOA

C

o

0

0

0

o

0

0

FUSE

BLOCK

M

0

0

0

lOA

Ii

California

models

E

E492

Fig

EE

25

Circuit

diagram

of

charging

lfY

t

m

EE

14

Page 187 of 537

DESCRIPTION

MEASUREMENT

OF

REGULATOR

VOLTAGE

ADJUSTMENT

VOLTAGE

REGULATOR

DESCRIPTION

The

regulator

consists

basically

of

a

voltage

regulator

and

a

charge

relay

The

voltage

regulator

has

two

sets

of

contact

points

a

lower

set

and

an

upper

set

to

control

alternator

volt

age

An

armature

plate

placed

between

the

two

sets

of

contacts

moves

upward

or

downward

or

vibrates

The

lower

contacts

when

closed

complete

the

jCV

ID@

@

GJ

I

@

@

@

Engine

Electrical

System

REGULATOR

CONTENTS

EE

20

CHARGING

RELAY

SERVICE

DATA

AND

SPECIFICATIONS

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Including

alternatorl

EE

25

EE

23

EE

24

EE

20

EE

23

EE

23

field

circuit

direct

to

ground

and

the

upper

contacts

when

closed

complete

the

field

circuit

to

ground

through

a

resistance

field

coil

and

produce

alternator

output

The

charge

relay

i

similar

in

construction

to

the

voltage

regulator

When

the

upper

contacts

are

closed

charge

warning

lamp

goes

on

v

1

Charge

relay

2

Voltage

regulator

EE285

Fig

EE

46

View

of

removing

cover

As

regards

the

construction

the

voltage

regulator

is

very

similar

to

the

charge

relay

as

shown

in

Figure

EE47

@

r

J

CD

@

@

@

Q

@

ID@

ID@

J

t

L

T

@

r

b

r

CD

L

@

j

1

g

f

@

@

EEJ97

J

I1Jlccting

spring

2

Y

kt

g

p

3

Armaturc

4

Core

go

5

Low

Sllccd

lnlacl

h

Point

ap

7

High

speed

conlat

t

8

Contact

c

9

3111111

0

118

ill

di

10

41l1I11W

157in

c1ia

few

II

Cuil

12

lock

nut

J3

Adjllslin

screw

14

Adjll

sting

sprin

15

Yoke

9

Adjusting

screw

10

Lock

nut

11

Coil

12

4mm

0

157

in

dia

screw

13

3mm

0

118

in

dla

crew

14

Contact

iet

15

Voltage

cgulatm

contact

a

Cnl1

Tlll

tion

f

lltagl

l

j

llIOltllT

I

Point

gilp

2

Charge

relay

contllct

3

Core

gap

4

ArlllatlJre

5

Connecting

sprin

6

Yoke

gap

7

Yoh

B

Adjusting

pring

b

Construction

of

charge

relay

Fig

EE

47

Structural

vi

w

EE

20

Page 190 of 537

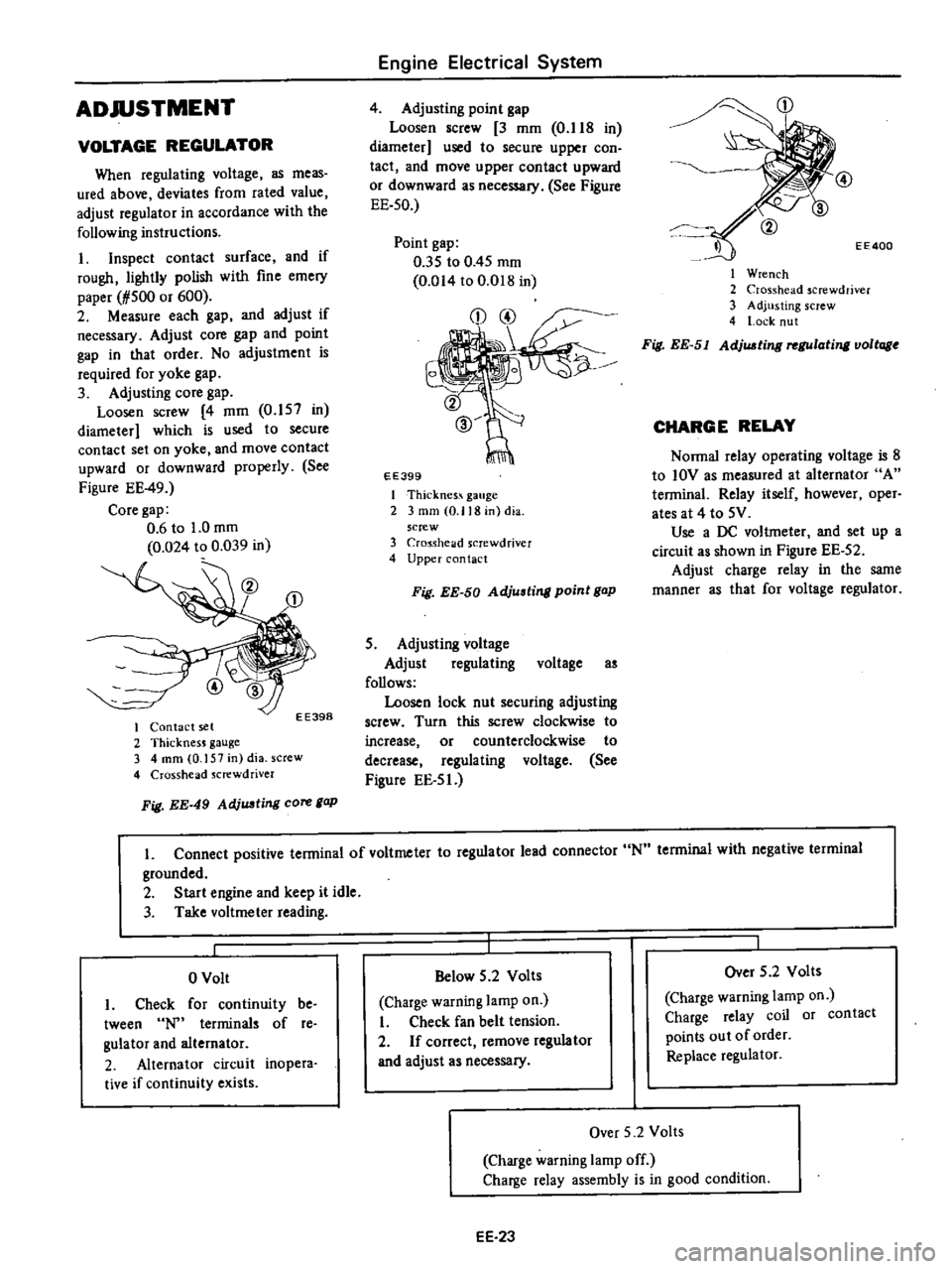

ADJUSTMENT

VOLTAGE

REGULATOR

When

regulating

voltage

as

meas

ured

above

deviates

from

rated

value

adjust

regulator

in

accordance

with

the

following

instructions

I

Inspect

contact

surface

and

if

rough

lightly

polish

with

fine

emery

paper

1

500

or

600

2

Measure

each

gap

and

adjust

if

necessary

Adjust

core

gap

and

point

gap

in

that

order

No

adjustment

is

required

for

yoke

gap

3

Adjusting

core

gap

Loosen

screw

4

mm

0

157

in

diameter

which

is

used

to

secure

contact

set

on

yoke

and

move

contact

upward

or

downward

properly

See

Figure

EE

49

Core

gap

0

6

to

1

0

mm

0

024

to

0

039

in

EE398

I

Contact

set

2

ThicknesJ

gauge

3

4

mm

0

157

in

dia

screw

4

Crosshead

Jcrewdriver

Fig

EE

49

AdjUJJting

core

gap

Engine

Electrical

System

4

Adjusting

point

gap

Loosen

screw

3

mm

O

lIS

in

diameter

used

to

secure

upper

con

tact

and

move

upper

contact

upward

or

downward

as

necessary

See

Figure

EE

50

Point

gap

035

to

0

45

mm

0

014

to

O

D1S

in

EE399

I

Thicknes

gauge

2

3

mm

0

118

in

dia

screw

3

Cro

Sshelld

screwdriver

4

Upper

contact

Fig

EE

50

Adjusting

point

gap

5

Adjusting

voltage

Adjust

regulating

voltage

as

follows

Loosen

lock

nut

securing

adjusting

screw

Turn

this

screw

clockwise

to

increase

or

counterclockwise

to

decrease

regulating

voltage

See

Figure

EE

5

J

CD

EE400

I

Wrench

2

Crosshead

screwdriver

3

Adjusting

screw

4

l

ock

nut

Fig

EE

51

AdjUJJting

rel

Ulating

voltage

CHARGE

RELAY

Nonna

relay

operating

voltage

is

S

to

IOV

as

measured

at

alternator

A

tenninal

Relay

itself

however

oper

ates

at

4

to

5V

Use

a

DC

voltmeter

and

set

up

a

circuit

as

shown

in

Figure

EE

52

Adjust

charge

relay

in

the

same

manner

as

that

for

voltage

regulator

L

Connect

positive

tenninal

of

voltmeter

to

regulator

lead

connector

N

tenninal

with

negative

terminal

grounded

2

Start

engine

and

keep

it

idle

3

Take

voltmeter

reading

o

Volt

I

Check

for

continuity

be

tween

terminals

of

re

gulator

and

alternator

2

Alternator

circuit

inopera

tive

if

continuity

exists

Below

5

2

Volts

Charge

warning

lamp

on

I

Check

fan

belt

tension

2

If

correct

remove

regulator

and

adjust

as

necessary

Over

5

2

Volts

Charge

warning

lamp

on

Charge

relay

coil

or

contact

points

out

of

order

Replace

regulator

Over

5

2

Volts

Charge

warning

lamp

off

Charge

relay

assembly

is

in

good

condition

EE

23