ECU DATSUN PICK-UP 1977 Owner's Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 150 of 537

EC540

Fig

EC

38

Install

carbon

shoe

Notes

a

Carbon

shoe

A

is

1

mm

0

039

in

wider

than

B

Do

not

confuse

them

b

If

carbon

shoes

are

exposed

beyond

the

rotor

end

face

remove

carbon

shoes

and

clean

shoe

grooves

Reassemble

carbon

shoes

6

Vane

1

Pack

vane

bearing

with

high

melting

point

grease

MIL

G

3545

A

Esso

ANDOK260

or

equivalent

and

insert

dummy

shaft

into

the

Vane

bearing

STl9900000

EC563

Fig

EC

39

Vane

assembly

2

Install

vane

in

place

on

rotor

using

Dummy

Shaft

STl9900000

as

a

guide

Note

The

vanes

may

require

6

to

16

km

4

to

10

miles

wear

in

running

time

In

the

event

a

slight

squeaking

still

remains

drive

the

car

about

64

to

80

km

h

40

to

50

MPH

In

most

cases

6

to

16

km

4

to

10

miles

will

be

sufficient

for

wear

in

7

Shoe

spring

Place

shoe

springs

in

deeper

groove

of

shoe

Emission

Control

System

i

111

11

EC123

Fig

EC

40

Installing

shoe

spring

Note

When

instaUing

a

shoe

spring

make

sure

that

the

outward

bend

ing

side

faces

in

shoe

and

that

both

ends

of

spring

face

in

the

wall

of

shoe

groove

Be

sure

to

push

spring

in

so

that

spring

end

face

is

flush

with

rotor

8

Rotor

ring

Install

rotor

ring

by

correctly

align

ing

the

rear

end

face

of

rotor

with

the

0

mark

in

rotor

ring

and

tighten

four

screws

to

the

specified

torque

with

Hexagonal

Wrench

ST19810000

Tightening

torque

0

5

to

0

7

kg

m

3

6

to

5

1

ft

lb

5T19810000

EC124

Fig

EC

41

In8talling

rotor

ring

9

Removal

of

dummy

shaft

Carefuny

withdraw

dummy

shaft

from

vane

10

Vane

shaft

Pack

rear

bearing

with

high

melting

point

grease

MIL

G

3545

A

so

ANDOK

260

or

equivalent

Apply

thin

coating

of

grease

to

vane

shaft

and

rotor

ring

and

insert

vane

shaft

into

its

bearing

EC

17

Notes

a

Do

not

apply

an

u

tue

stress

to

vane

shaft

when

inserting

b

If

two

vanes

are

dislocated

when

inserting

vane

shaft

correctly

align

vanes

by

inserting

dummy

shaft

Then

draw

out

dummy

shaft

and

insert

vane

shaft

c

When

wear

occurs

on

vane

shaft

or

when

replacement

of

rear

bearing

is

necessary

replace

rear

cover

as

sembly

Jl

End

cover

Position

end

cover

in

place

Snugly

tighten

the

bolt

close

to

the

dowel

Then

tighten

four

bolts

to

the

speci

fied

torque

Tightening

torque

0

7

to

0

9

kg

m

5

1

t06

5

ft4b

EC302

Fig

EC

42

Insla

ling

end

cover

12

Pulley

Tighten

four

pulley

securing

bolts

to

the

specified

torque

Tightening

torque

0

7

to

0

9

kg

m

5

lt06

5

ft

lb

INSPECTION

Air

InJection

system

hosas

Check

air

system

hoses

for

loose

connections

cracks

or

deterioration

Retighten

or

replace

if

necessary

Air

ystem

manifold

Check

air

gaUery

pipe

and

injection

nozzles

for

loose

connections

and

cracks

Retighten

or

replace

if

neces

sary

Page 151 of 537

Air

pump

I

Operate

engine

until

it

reaches

normal

operating

temperature

2

Inspect

all

hose

hose

connec

tions

and

air

gallery

for

leaks

and

correct

if

necessary

before

checking

air

injection

pump

3

Check

air

injection

pump

belt

tension

and

adjust

to

specifications

if

necessary

4

Disconnect

air

supply

hose

at

check

valve

5

Disconnect

vacuum

hose

from

the

air

control

valve

California

type

only

6

Insert

open

pipe

end

of

Air

Pump

Test

Gauge

Adapter

STl9870000

in

air

supply

hose

Clamp

hose

securely

to

adapter

to

prevent

it

from

blowing

out

Position

adapter

and

test

lli

uge

so

that

air

blast

emitted

through

drilled

pipe

plug

will

be

harmlessly

dissipated

7

Install

a

tachometer

on

engine

With

engine

speed

at

2

600

rpm

ob

serve

pressure

produced

at

test

gauge

Air

pressure

should

be

100

mmHg

3

94

inHg

or

more

8

If

air

pressure

does

not

meet

above

specifications

proceed

as

fol

lows

I

Repeat

2

and

3

above

2

Disconnect

air

supply

hose

at

anti

backfire

valve

Plug

air

hose

open

ing

and

screw

with

a

clamp

Repeat

pressure

test

3

With

engine

speed

at

1

500

rpm

close

hole

of

test

gauge

with

finger

If

a

leaking

sound

is

heard

or

leaking

air

is

felt

by

ftnger

at

relief

valve

relief

valve

is

malfunctioning

Relief

valve

should

be

replaced

or

repaired

4

If

air

injection

pump

does

not

meet

minimum

requirement

of

pres

sure

test

it

should

be

replaced

Control

valve

The

following

procedures

are

reo

commended

for

checking

and

or

as

certaining

that

the

various

components

of

the

exhaust

emission

con

Irol

system

are

operating

properly

The

engine

and

all

components

must

be

at

normal

operating

tempera

tures

when

the

tests

are

performed

Prior

to

performing

any

extensive

diag

nosis

of

the

exhaust

control

system

it

Emission

Control

System

must

be

determined

that

the

engine

as

a

unit

is

functioning

properly

Check

valva

Warm

up

engine

thoroughly

2

Disconnect

hose

leading

to

check

valve

from

air

hose

COJUlector

3

Check

hose

opening

for

any

indi

cation

of

exhaust

gas

leaks

Ifleaks

are

detected

replace

check

valve

4

Race

the

engine

lightly

at

about

2

000

cpm

and

then

return

it

to

idling

VisuaDy

check

the

hose

for

any

indication

of

exhaust

gas

leaks

before

the

engine

returns

to

idling

speed

If

leaks

are

detected

replace

check

valve

EC310

Fig

EC

43

Checking

check

valve

Air

pump

raIle

valve

After

completing

inspection

of

air

pump

check

air

pump

relief

valve

in

the

following

steps

J

Disconnect

hoses

leading

to

check

valve

and

air

control

valve

from

air

hose

connector

and

install

blind

cap

to

the

connector

2

With

engine

running

at

about

3

000

rpm

under

no

load

place

your

hand

on

the

air

outlet

of

air

pump

relief

valve

to

check

for

discharged

air

If

no

air

is

felt

replace

the

air

pump

relief

valve

EC311

Fig

EC

44

Checking

air

pump

relief

valve

EC

18

Air

control

valve

C

U

ornla

models

I

Warm

up

engine

thoroughly

2

Before

checking

air

control

valve

check

all

hoses

for

loose

connection

leaks

etc

and

repair

or

correct

if

necessary

3

With

engine

idling

disconnect

the

outlet

side

hose

of

the

air

control

valve

and

place

your

hand

on

the

air

hose

outlet

to

check

for

air

If

no

air

is

felt

replace

the

air

control

valve

4

Pull

vacuum

hose

off

from

air

con

trol

valve

If

discharge

of

air

from

air

hose

stops

the

air

con

trol

valve

is

normaL

If

discharge

is

still

felt

replace

the

valve

Plug

up

the

removed

vacuum

hose

to

stabilize

engine

running

EC312

Fig

EC

45

Checking

air

control

valve

Emarsancy

air

rella

valve

E

A

R

Valve

lCalHornla

models

L

Warm

up

engine

thoroughly

2

Before

checking

air

control

valve

check

all

hoses

for

loose

connection

leaks

etc

and

repair

or

correct

if

necessary

3

Race

engine

approximately

2

000

rpm

under

no

load

Place

your

hand

on

air

outlet

of

E

A

R

valve

to

check

for

presence

of

discharged

air

If

no

air

is

felt

E

A

R

valve

is

normal

4

Disconnect

vacuum

hose

from

B

A

R

valve

as

shown

in

Figure

EC

46

Page 157 of 537

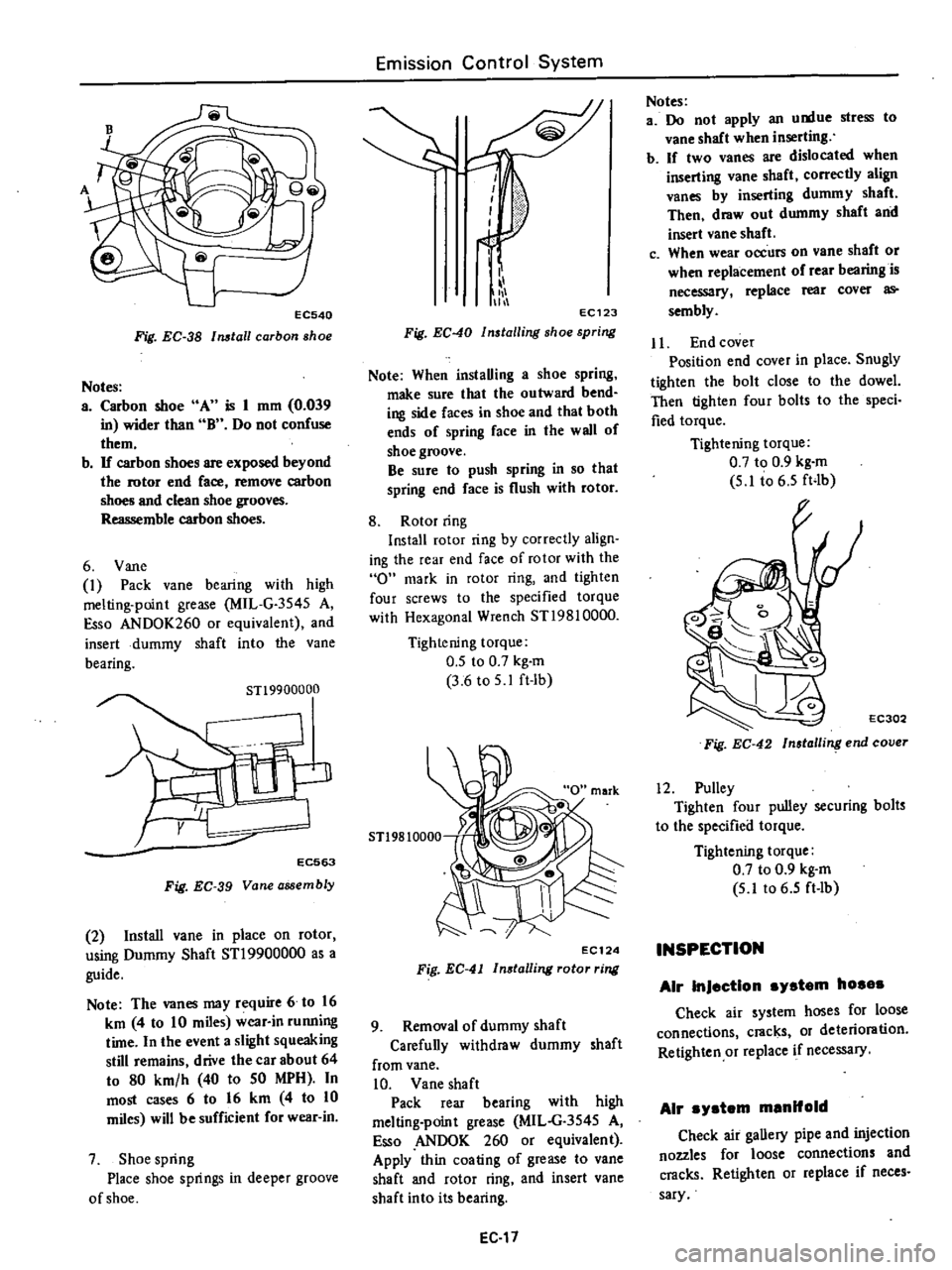

4

E

G

R

warning

system

EC251

Detector

drive

counter

Detecfor

drive

counter

is

secured

on

the

top

of

R

H

hoodledge

panel

in

engine

room

To

remove

detector

drive

counter

disconnect

w

COJUlector

and

loosen

two

bolts

securing

detector

drive

counter

to

hoodledge

panel

2

E

G

R

warning

lamp

E

G

R

warning

lamp

is

mounted

at

the

top

cen

ter

of

instrument

pad

To

remove

E

G

R

warning

lamp

proceed

as

follows

1

Remove

masking

panel

On

models

equipped

with

radio

remove

warning

lamp

from

under

in

strument

panel

2

E

G

R

warning

lamp

is

a

twist

type

Remove

lamp

and

socket

as

an

assembly

Push

and

twist

lamp

off

can

EC554

Fig

EC

60

Removing

E

G

R

warning

lamp

Emission

Control

System

3

Odometer

switch

Odometer

switch

is

mounted

on

the

back

side

of

speedometer

Cam

in

the

odometer

switch

is

rotated

by

the

speedometer

To

dismount

odometer

switch

proceed

as

follows

I

Dismount

combination

meter

as

sembly

2

Remove

meter

front

cover

and

take

off

clips

and

screws

to

dismount

shadow

plate

3

Loosen

screws

securing

speed

ometer

to

printed

circuit

housing

then

remove

speedometer

4

Remove

two

screws

securing

odomete

switch

to

the

back

side

of

speedometer

and

detach

odometer

switch

EC239

Fig

EC

61

Removing

odometer

switch

InstaUatlon

To

install

reverse

the

removal

pro

cedure

EC24

V

r

CID

1

Detector

drive

counter

2

E

G

R

warning

lamp

3

Speedometer

Fig

EC

59

E

G

R

warning

y

tem

INSPECTION

Checking

E

G

R

control

system

in

its

mounted

conditionS

I

Make

a

thorough

visual

check

of

E

G

R

control

system

If

necessary

wipe

away

oil

to

facilitate

inspection

If

any

hoses

are

cracked

or

broken

replace

2

With

engine

running

check

E

G

R

warning

system

for

proper

function

Make

sure

that

E

G

R

warn

ing

lamp

lights

when

ignition

switch

is

turned

to

START

position

starter

mo

tor

runs

If

E

G

R

wanung

lamp

does

not

light

inspect

harnesses

and

con

nectors

or

replace

warning

lamp

Then

turn

ignition

switch

to

ON

position

and

check

the

following

items

I

If

odometer

of

detector

drive

counter

has

not

reached

50

000

counts

make

sure

that

E

G

R

warning

lamp

does

not

light

2

If

odomete

of

detector

drive

counter

has

attained

50

000

counts

make

sure

that

E

G

R

warning

lamp

lights

If

warning

lamp

does

not

light

check

harnesses

connectors

and

de

tector

drive

counter

replace

warning

lamp

or

detector

drive

counter

if

necessary

Notes

Operation

oC

E

G

R

warning

lamp

is

as

Collows

Page 170 of 537

BATTERY

FREEZING

Battery

electrolyte

freezing

point

varies

with

acid

concentration

or

its

specific

gravity

A

battery

with

an

insufficient

charge

will

freeze

at

lower

temperatures

If

specific

gravity

of

a

battery

falls

below

1

1

this

is

an

0

10

20

30

g

40

I

u

il

SO

I

0

e

60

0

E

70

Engine

Electrical

System

indication

that

battery

is

completely

discharged

and

will

freeze

readily

when

temperatures

fall

below

freezing

Note

Use

extreme

caution

to

avoid

freezing

battery

since

freezing

will

generally

ruin

the

battery

1

80

1

00

1

04

1

08

t

l2

1

16

t

20

1

24

1

28

Specific

gravity

of

electrolyte

CHARGING

I

f

electrolyte

level

is

satisfactory

battery

must

be

charged

when

electro

lyte

gravity

reading

falls

below

1

20

If

battery

on

car

is

quick

charged

to

1

32

EEOQ4

Fig

EE

4

Froezing

point

of

electrolyte

bring

it

up

to

full

charge

the

opera

tion

should

be

carried

out

with

nega

tive

cable

removed

Prior

to

charging

corroded

termi

EE

3

nals

should

be

cleaned

with

a

brush

and

common

baking

soda

solution

In

addition

the

following

items

should

be

observed

while

battery

is

being

charged

I

Be

sure

that

electrolyte

level

is

above

top

of

each

plate

2

Keep

removed

plugs

in

a

safe

place

3

Do

not

allow

electrolyte

tempera

ture

to

go

over

450C

I130F

4

After

charging

check

to

be

cer

tain

that

specific

gravity

does

not

exceed

1

260

at

200C

680P

Cor

rection

can

be

made

by

adding

dis

tilled

water

into

cells

as

necessary

5

Keep

battery

away

from

open

flame

while

it

is

being

charged

6

After

all

vent

plugs

have

been

tightened

clean

all

sprayed

electrolyte

off

upper

face

of

battery

INSTALLATION

1

Install

and

tighten

clamps

secure

Iy

2

After

clamps

have

been

tightened

clean

battery

cable

terminals

and

apply

grease

to

retard

formation

of

corrosion

Page 173 of 537

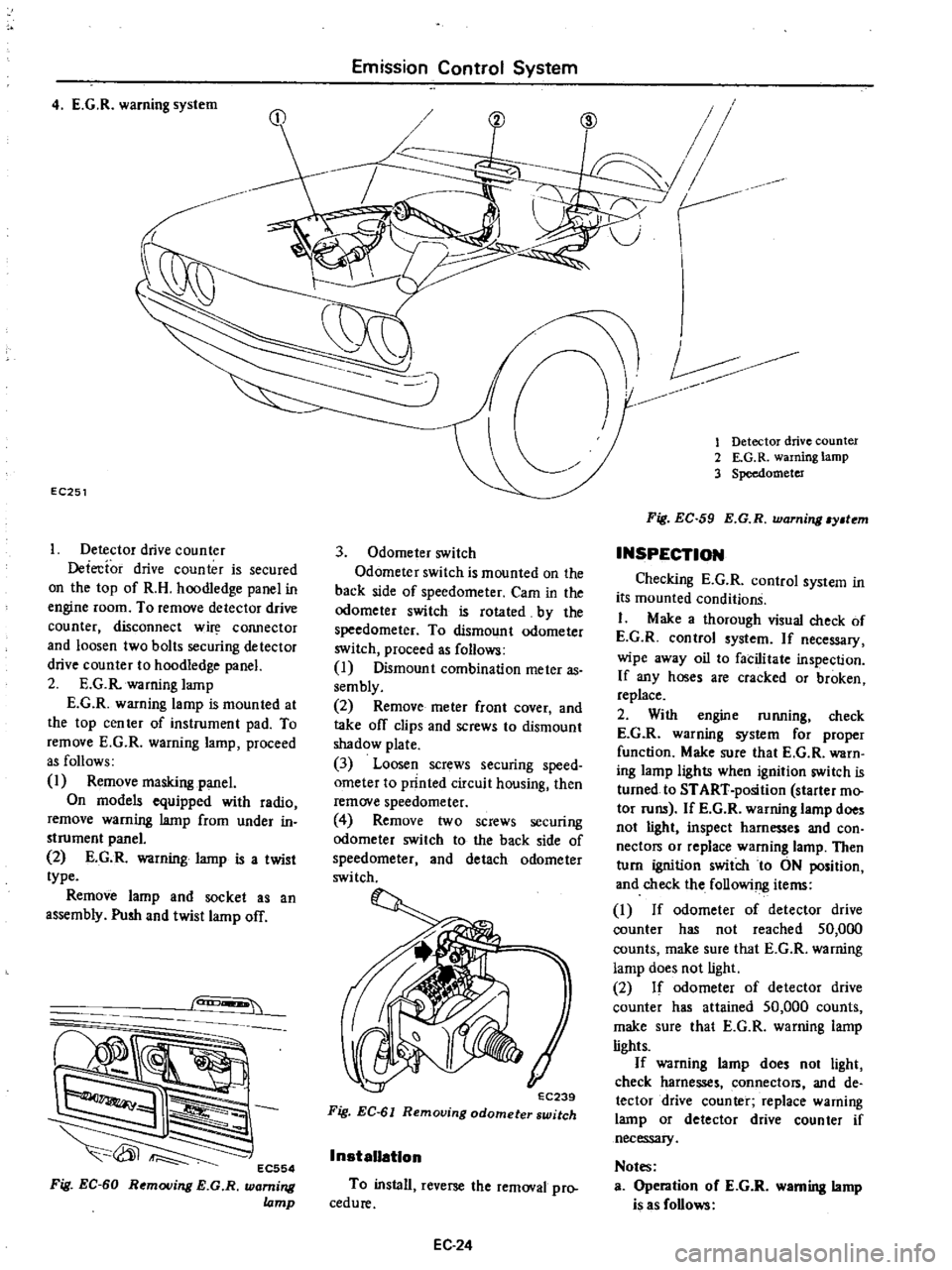

OPERATION

When

the

ignition

switch

turned

fully

clockwise

to

the

START

posi

tion

battery

current

flows

through

series

and

shunt

coils

of

the

solenoid

magnetizing

the

solenoid

The

plunger

is

pulled

into

the

solenoid

so

that

it

operates

the

shift

lever

to

move

the

drive

pinion

into

the

flywheel

ring

gear

Then

the

solenoid

switch

contacts

close

after

the

drive

pinion

is

partially

engaged

with

the

ring

gear

Closing

of

the

solenoid

switch

contacts

c

uses

the

motor

to

crank

the

engine

and

also

cut

out

the

series

coil

of

the

solenoid

the

magnetic

pull

of

the

shunt

coil

being

sufficient

to

hold

the

pinion

in

mesh

after

the

shifting

has

been

performed

After

the

engine

starts

running

the

driver

releases

the

ignition

key

and

it

automatically

returns

to

the

ON

posi

tion

The

torsion

spring

then

actuates

the

shift

lever

to

pull

the

pinion

which

allows

the

solenoid

swi

tch

contacts

to

open

Consequently

the

starting

mo

tor

stops

Engine

Electrical

System

I

I

Ring

gear

2

Shift

lever

guide

3

Armature

4

Battery

5

Field

coil

6

Stationary

contact

7

Monble

contactor

More

positive

meshing

and

demeshing

of

the

pinion

and

the

ring

gear

teeth

are

secured

by

means

of

the

overrunning

clutch

The

overruIUling

clutch

employs

a

shift

lever

to

slide

the

pinion

along

the

armature

shaft

EE

6

F

l

cp

o

r

1

I

I

W

m

EE274

8

Shunt

coil

9

Plunger

10

Ignition

switch

11

Series

coil

12

Torsion

spring

13

Shift

lever

14

Pinion

Fig

EE

7

Starting

motor

circuit

into

or

out

of

mesh

with

the

ring

gear

teeth

The

overrunning

clutch

is

de

signed

to

transmit

driving

torque

from

the

motor

armature

to

the

ring

gear

but

prevent

the

armature

from

over

running

after

the

engine

has

started

Page 174 of 537

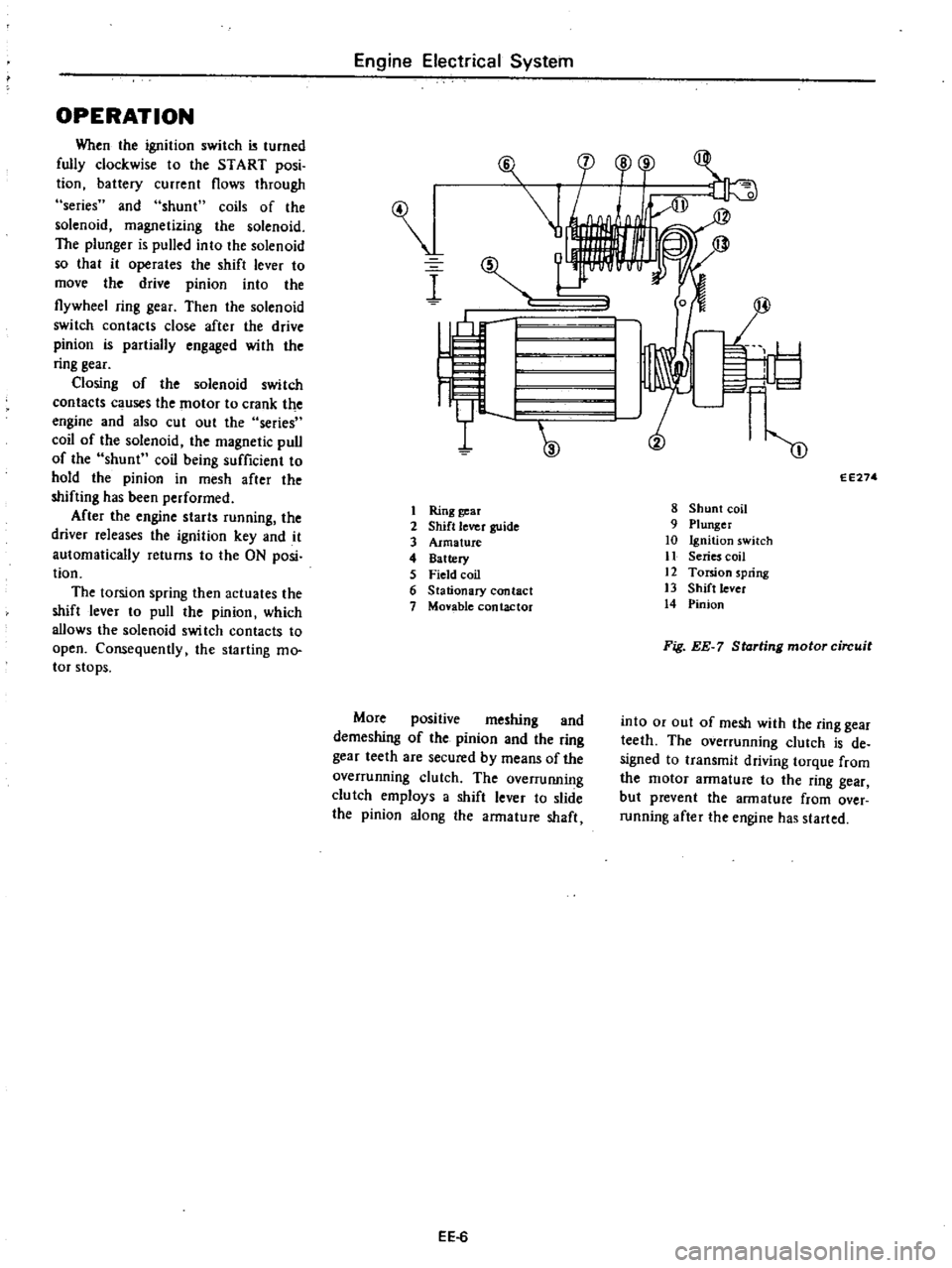

CONSTRUCTION

O

o

8

w

il

Engine

Electrical

System

V

1

Magnetic

switch

assembly

13

Brush

spring

jj

JI

2

Dust

cover

t4

Brush

Adjusting

washer

15

Yoke

P

3

Torsion

pring

t6

Field

coil

assembly

4

Shift

lever

17

Armature

assembly

5

Dust

cover

18

Center

plate

SI14

1808

only

6

Thrust

washer

19

Pinion

assem

bly

7

E

ring

20

Dust

cover

8

Rear

cover

metal

21

Pinion

stopper

9

Through

bolt

22

Stopper

clip

10

Rear

cover

23

Gear

case

tl

Brush

holder

assembly

24

Gear

case

metal

12

Brush

REMOVAL

Disconnect

battery

ground

cable

Disconnect

black

wire

with

yellow

stripe

from

magnetic

switch

terminal

and

black

battery

cable

from

battery

terminal

of

magnetic

switch

2

Remove

two

bolts

securing

start

ing

motor

to

transmission

case

Pull

starter

assembly

forward

and

remove

starting

motor

DISASSEMBLY

I

Disconnect

connecting

plate

from

M

terminal

of

magnetic

switch

Re

move

two

screws

securing

magnetic

switch

and

remove

magnetic

switch

assembly

2

Remove

dust

cover

E

ring

and

thrust

washer

s

EE317

@

@

O

Fig

EE

9

Remouing

dUlt

cover

E

ring

and

thrust

washer

s

3

Remove

two

screws

securing

brush

holder

assembly

EE318

Fig

EE

IO

Removing

brush

holder

d

crt

w

EE

7

S

4

f

I

jl

I

EE316

Fig

EE

B

Exploded

view

of

starting

motor

4

Remove

two

through

bolts

and

rear

cover

5

Remove

b

rushes

from

their

hold

er

by

moving

each

brush

spring

away

from

brush

with

a

hook

Remove

brush

holder

6

Remov

yoke

assembly

and

with

draw

armature

assembly

and

shift

lever

7

Remove

pinion

stopper

located

at

the

end

of

armature

shaft

To

remove

stopper

first

move

stopper

toward

pinion

and

after

removing

stopper

clip

remove

stopper

with

overrunning

clutch

assembly

from

armature

shaft

Pinion

stopper

Pinion

stopper

clip

EE277

Fig

EE

l1

Removing

pinion

stopper

Page 178 of 537

Engine

Electrical

System

SERVICE

DATA

AND

SPECIFICATIONS

Type

System

voltage

No

load

Terminal

voltage

Current

Revolution

v

V

A

rpm

Brush

length

Outer

diameter

of

commutator

mm

in

mm

in

Brush

spring

tension

kg

Ib

Clearance

between

bearing

metal

and

armature

shaft

mm

in

Clearance

L

between

pinion

front

edge

and

pinion

stopper

mm

in

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Condition

Starting

motor

will

not

operate

Noisy

starting

motor

Starting

motor

cranks

slowly

Probable

cause

Discharged

battery

Damaged

solenoid

switch

Loose

connections

of

terminal

Damaged

brushes

Starti

g

motor

inoperative

Loose

securing

bolt

Worn

pinion

gear

Poor

lubrication

Worn

commutator

Worn

brushes

Discharged

battery

Loose

connection

of

terminal

Worn

brushes

Locked

brushes

EE

ll

Manual

transmission

Automatic

transmission

Optional

for

manual

transmission

SII4

ISOB

S114

170B

12

12

Less

than

60

More

than

7

000

More

than

6

000

More

than

39

1

54

More

than

12

0

47

1

4

to

I

S

3

1

to

4

0

Less

than

0

2

O

OOS

0

3

to

1

5

0

012

to

0

059

Corrective

action

Charge

or

replace

battery

Repair

or

replace

solenoid

switch

Clean

and

tighten

terminal

Replace

brushes

Remove

starting

motor

and

make

test

Tighten

Replace

Add

oil

Replace

Replace

Charge

Clean

and

tighten

Replace

Inspect

brush

spring

tension

or

repair

brush

holder

Page 190 of 537

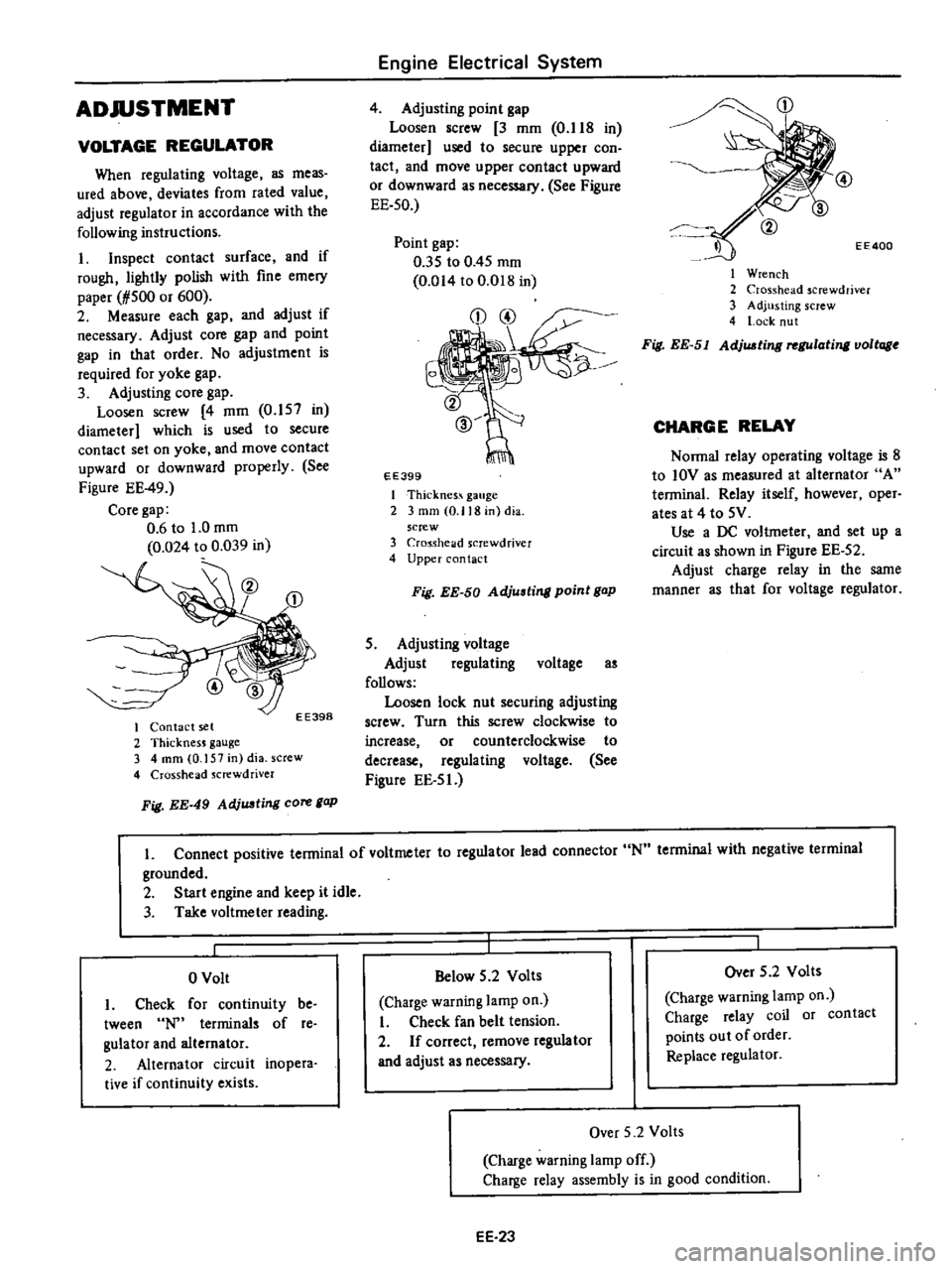

ADJUSTMENT

VOLTAGE

REGULATOR

When

regulating

voltage

as

meas

ured

above

deviates

from

rated

value

adjust

regulator

in

accordance

with

the

following

instructions

I

Inspect

contact

surface

and

if

rough

lightly

polish

with

fine

emery

paper

1

500

or

600

2

Measure

each

gap

and

adjust

if

necessary

Adjust

core

gap

and

point

gap

in

that

order

No

adjustment

is

required

for

yoke

gap

3

Adjusting

core

gap

Loosen

screw

4

mm

0

157

in

diameter

which

is

used

to

secure

contact

set

on

yoke

and

move

contact

upward

or

downward

properly

See

Figure

EE

49

Core

gap

0

6

to

1

0

mm

0

024

to

0

039

in

EE398

I

Contact

set

2

ThicknesJ

gauge

3

4

mm

0

157

in

dia

screw

4

Crosshead

Jcrewdriver

Fig

EE

49

AdjUJJting

core

gap

Engine

Electrical

System

4

Adjusting

point

gap

Loosen

screw

3

mm

O

lIS

in

diameter

used

to

secure

upper

con

tact

and

move

upper

contact

upward

or

downward

as

necessary

See

Figure

EE

50

Point

gap

035

to

0

45

mm

0

014

to

O

D1S

in

EE399

I

Thicknes

gauge

2

3

mm

0

118

in

dia

screw

3

Cro

Sshelld

screwdriver

4

Upper

contact

Fig

EE

50

Adjusting

point

gap

5

Adjusting

voltage

Adjust

regulating

voltage

as

follows

Loosen

lock

nut

securing

adjusting

screw

Turn

this

screw

clockwise

to

increase

or

counterclockwise

to

decrease

regulating

voltage

See

Figure

EE

5

J

CD

EE400

I

Wrench

2

Crosshead

screwdriver

3

Adjusting

screw

4

l

ock

nut

Fig

EE

51

AdjUJJting

rel

Ulating

voltage

CHARGE

RELAY

Nonna

relay

operating

voltage

is

S

to

IOV

as

measured

at

alternator

A

tenninal

Relay

itself

however

oper

ates

at

4

to

5V

Use

a

DC

voltmeter

and

set

up

a

circuit

as

shown

in

Figure

EE

52

Adjust

charge

relay

in

the

same

manner

as

that

for

voltage

regulator

L

Connect

positive

tenninal

of

voltmeter

to

regulator

lead

connector

N

tenninal

with

negative

terminal

grounded

2

Start

engine

and

keep

it

idle

3

Take

voltmeter

reading

o

Volt

I

Check

for

continuity

be

tween

terminals

of

re

gulator

and

alternator

2

Alternator

circuit

inopera

tive

if

continuity

exists

Below

5

2

Volts

Charge

warning

lamp

on

I

Check

fan

belt

tension

2

If

correct

remove

regulator

and

adjust

as

necessary

Over

5

2

Volts

Charge

warning

lamp

on

Charge

relay

coil

or

contact

points

out

of

order

Replace

regulator

Over

5

2

Volts

Charge

warning

lamp

off

Charge

relay

assembly

is

in

good

condition

EE

23

Page 201 of 537

t3

l

l

J

@

r

9

V

fW

@

@

CHECKING

AND

ADJUSTMENT

CAP

AND

ROTOR

HEAD

Cap

and

rotor

head

must

be

in

spected

periodically

as

specified

in

the

Maintenance

Schedule

Remove

cap

and

clean

all

dust

and

carbon

deposits

from

cap

and

rotor

from

time

to

time

If

cap

is

cracked

or

is

leaking

replace

with

a

new

one

AIR

GAP

Standard

air

gap

is

0

2

to

0

4

mm

0

008

to

0

016

in

If

the

gap

is

off

the

standard

adjustment

mould

be

made

by

loos

ening

pick

up

coil

screws

Gap

gauge

is

required

for

adjust

ment

Air

gaps

must

be

checked

from

time

to

time

Air

gap

0

2

to

0

4

mm

0

008

to

0

016

in

Engine

Electrical

System

tl

@

9

EE328

Fig

EE

67

Checking

oir

gap

To

remove

pick

up

cail

disconnect

distributor

harness

at

terminal

block

and

remove

screw

securing

pick

up

coil

ADVANCE

MECHANISMS

Specifications

Type

Item

Vacuum

advance

Distributor

degrees

Distributor

mmHg

inHg

Centrifugal

advance

Distributor

degrees

Distributor

cpm

EE34

1

Cap

assembly

2

Rotor

head

a55embly

3

Roll

pin

4

ReJuctor

S

Pick

up

coil

6

Contactoi

7

Breaker

plate

assembly

8

Packing

9

Rotor

shaft

10

Governor

spring

11

Governor

weigh

t

12

Shaft

a

Jscmbly

13

Cap

setter

14

Vacuum

controller

15

Housing

16

Fixing

plate

17

O

ring

18

Collar

EE327

Fig

EE

66

Exploded

view

of

di3tributor

assembly

and

distributor

harness

to

their

positions

EE329

Fig

EE

68

Remouing

pick

up

coil

D4F4

04

D4F4

Q3

Manual

Automatic

00

150

5

91

30

250

9

84

00

550

110

2

300

00

600

110

1

950

Page 213 of 537

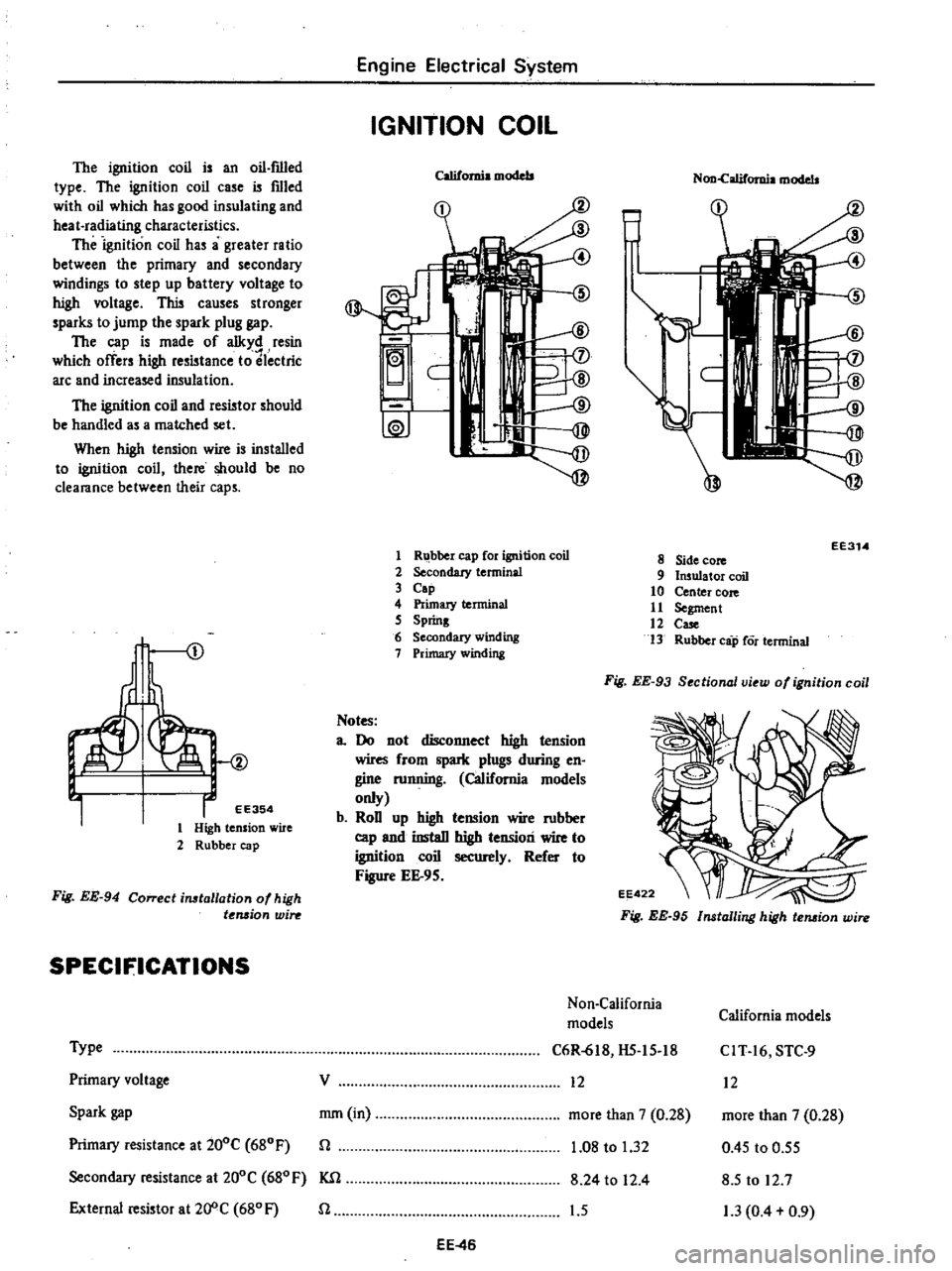

The

ignition

coil

is

an

oil

f1l1ed

type

The

ignition

coil

case

is

filled

with

oil

which

has

good

insulating

and

heat

radiating

characteristics

The

ignition

coil

has

a

greater

ratio

between

the

primary

and

secondary

windings

to

step

up

battery

voltage

t

high

voltage

This

causes

stronger

sparks

to

jump

the

spark

plug

gap

The

cap

is

made

of

alkyd

resin

which

offers

high

resistance

to

lectric

arc

and

increased

insulation

The

ignition

coil

and

resistor

should

be

handled

as

a

matched

set

When

high

tension

wire

is

installed

to

ignition

coil

there

should

be

no

clearance

between

their

caps

I

EE354

1

High

tension

wire

2

Rubber

cap

Fig

EE

94

Correcl

installation

of

high

t

Mjon

win

SPECIFICATIONS

Type

Primary

voltage

Spark

gap

Primary

resistance

at

200C

680F

Secondary

resistance

at

200C

680

F

KSl

External

resistor

at20

C

680F

n

Engine

Electrical

System

IGNITION

COIL

California

models

f

ID

@

J

C

ID

I

1W

1

R

bber

cap

for

ignition

coil

2

Secondary

terminal

3

Cap

4

Primary

terminal

5

Spring

6

Secondary

winding

7

Primary

winding

Notes

a

Do

not

disconnect

high

tension

wires

from

spark

plugs

during

en

gine

mnning

California

models

only

b

RoD

up

high

tension

wire

mbber

cap

and

instaD

high

tension

wire

to

ignition

coil

securely

Refer

to

Figure

EE

9S

Non

califomia

models

EE314

8

Side

core

9

Insulator

coil

10

Center

core

11

Segment

12

Case

13

Rubber

cap

Cor

terminal

Fig

EE

93

Sectional

view

of

ignition

coil

Fig

EE

95

Installing

high

tension

wire

Non

California

California

models

models

C6R

618

HS

15

18

CIT

16

STC

9

12

12

more

than

7

0

28

more

than

7

0

28

1

08

to

1

32

0

45

to

0

55

8

24

to

12

4

8

5

to

12

7

1

5

1

3

0

4

0

9

V

mm

in

n

EE

46