check engine DATSUN PICK-UP 1977 Owner's Guide

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 54 of 537

Engine

Mechanical

Valve

head

diameter

I

In

42

0

to

42

2

1

654

to

1

661

VALVE

SPRING

H

1

Check

valve

spring

for

squareness

mm

in

Ex

35

0

to

35

2

1

378

to

1

386

using

a

steel

square

and

surface

plate

In

114

9

to

115

2

4

524

to

4

535

If

spring

is

out

of

square

more

than

Valve

length

1

6

mm

0

063

in

replace

L

mm

in

2

Measure

lhe

free

length

and

ten

Ex

1157

to

116

0

4

555

to

4

567

sion

of

each

spring

If

the

measured

Valve

stem

diameter

In

7

965

to

7

980

0

3136

to

0

3142

value

exceeds

specified

limit

replace

D

mm

in

spring

Ex

7

945

to

7

960

0

3128

to

0

3134

Valve

seat

angle

In

45030

a

Intake

and

Exhaust

Ex

45030

EM110

Fig

EM

37

Checking

valve

tern

diameter

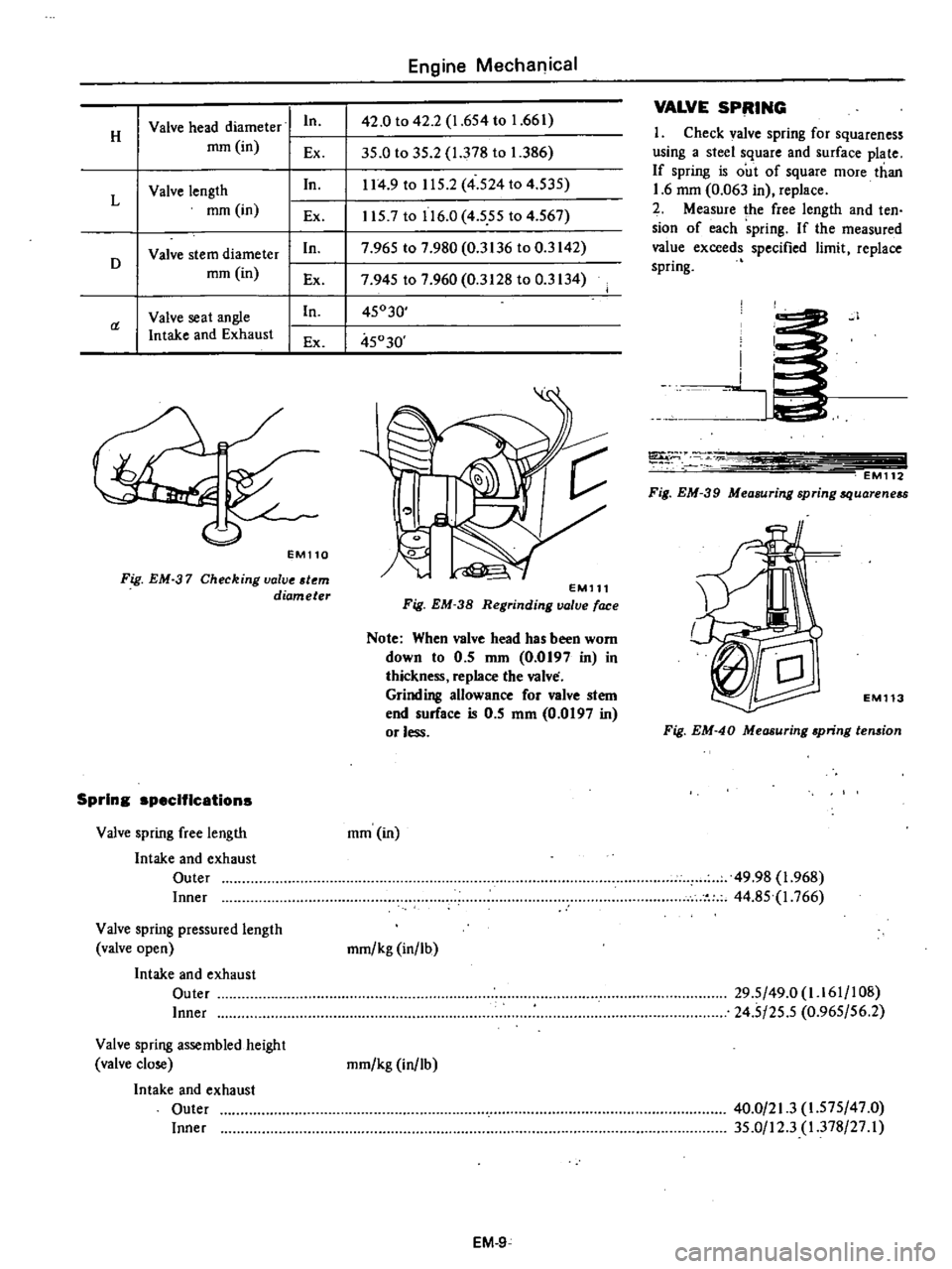

Spring

specifications

Valve

spring

free

length

Intake

and

exhaust

Outer

Inner

Valve

spring

pressured

length

valve

open

Intake

and

exhaust

Outer

Inner

Valve

spring

assembled

height

valve

close

Intake

and

exhaust

Outer

Inner

EMll1

Fig

EM

38

Regrinding

valve

face

Note

When

valve

head

has

been

worn

down

to

0

5

nun

0

0197

in

in

thickness

replace

the

valve

Grinding

allowance

for

valve

stem

end

surface

is

0

5

mm

0

0197

in

or

less

mm

in

mmlkg

in

lb

mmlkg

in

lb

EM

9

I

i

J

T

EM112

Fig

EM

39

Measuring

spring

quareneu

1

EM113

Fig

EM

40

Measuring

apring

ten

ion

49

98

1

968

44

85

1

766

29

5

49

0

1

161

108

24

5

25

5

0

965156

2

40

0

21

3

1

575

47

0

35

0

12

3

1

378

27

I

Page 55 of 537

rr

ROCKER

ARM

AND

VALVE

ROCKER

PIVOT

Check

pivot

head

and

cam

contact

and

pivot

contact

surfaces

of

rocker

arm

for

damage

or

wear

If

damage

is

found

replace

them

A

faulty

pivot

must

be

replaced

together

with

its

corresponding

rocker

arm

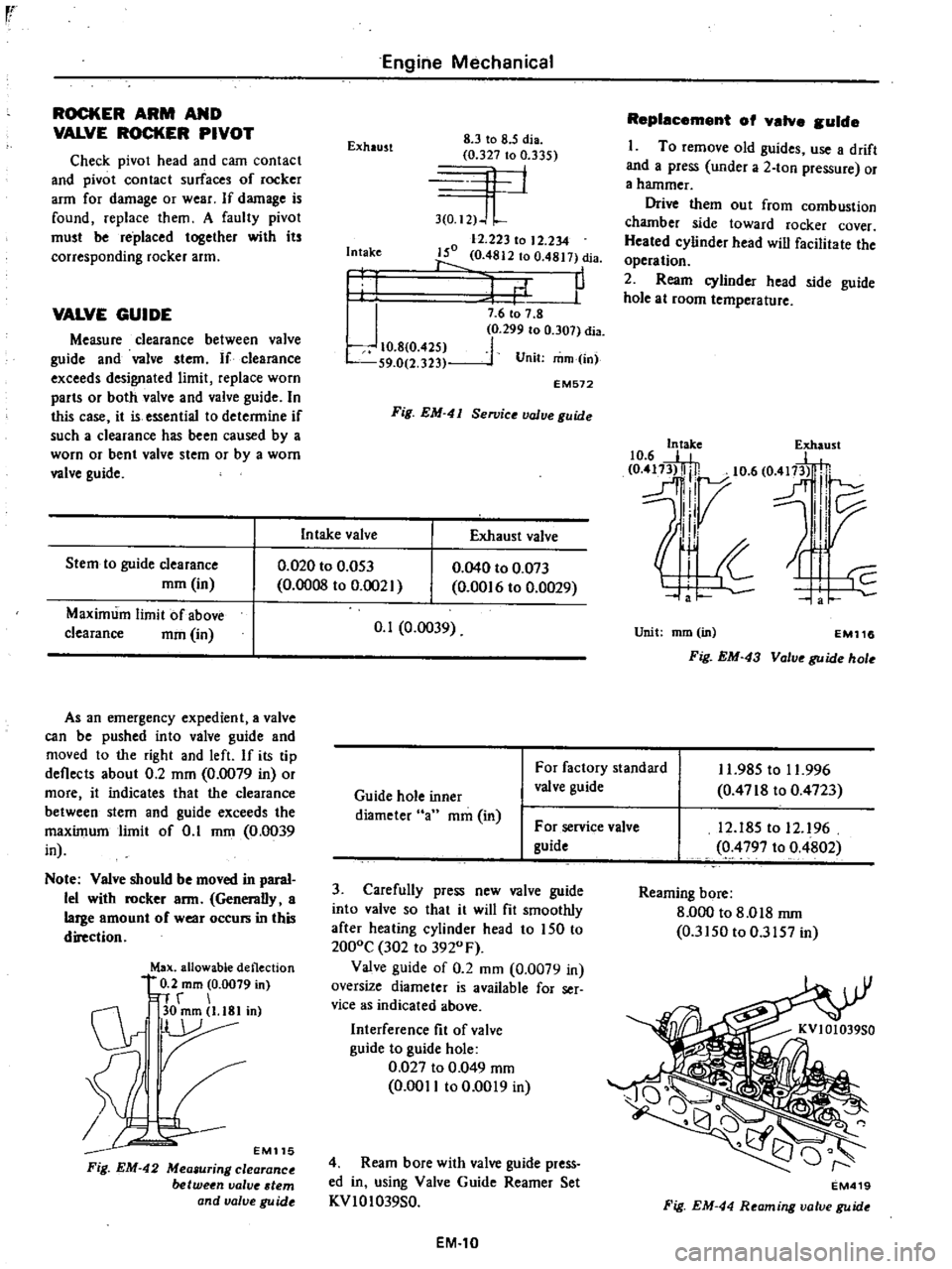

VALVE

GUIDE

Measure

clearance

between

valve

guide

and

valve

stem

If

clearance

exceeds

designated

limit

replace

worn

parts

or

both

valve

and

valve

guide

In

this

case

it

is

essential

to

determine

if

such

a

clearance

has

been

caused

by

a

worn

or

bent

valve

stem

or

by

a

worn

valve

guide

Stem

to

guide

clearance

mm

in

Maximum

limit

of

above

clearance

mm

in

Engine

Mechanical

Exhaust

8

3

to

8

5

dia

0

327

to

0

335

4

1

3

0

I2

J

L

12

223

to

12

234

150

0

4812

to

0

4817

dia

1

P

Intake

I

I

J

10

8

0

425

S9

0

2

323

7

6

to

7

8

0

299

to

0

307

dia

1

Unit

mm

in

EM572

Fig

EM

41

Se11Jice

value

guide

In

take

valve

Exhaust

valve

0

020

to

0

053

0

0008

to

0

002

As

an

emergency

expedient

a

valve

can

be

pushed

into

valve

guide

and

moved

to

the

right

and

left

If

its

tip

deflects

about

0

2

mm

0

0079

in

or

more

it

indicates

that

the

clearance

between

stem

and

guide

exceeds

the

maximum

limit

of

0

1

mm

0

0039

in

Note

Valve

should

be

moved

in

paral

lel

with

rocker

arm

Generally

a

large

amount

of

wear

occurs

in

this

direction

Max

allowable

deflection

0

2

mm

0

0079

in

n

r

C1r

30mm

l

18Iin

r

EM115

Fig

EM

42

Mea

uring

clearance

between

valve

tern

and

valve

gu

ide

0

040

to

0

073

0

00

6

to

0

0029

0

1

0

0039

Replacement

of

valve

guide

I

To

remove

old

guides

use

a

drift

and

a

press

under

a

2

ton

pressure

or

a

hammer

Drive

them

out

from

combustion

chamber

side

toward

rocker

cover

Heated

cylinder

head

will

facilitate

the

operation

2

Ream

cylinder

head

side

guide

hole

at

room

temperature

10

6

E

e

417

5t

0

m3l

lj

10

6

O

fl

H

dl7

l

IV

II

Unit

mm

in

EM116

Fig

EM

43

Valve

guide

hole

Guide

hole

inner

diameter

an

mm

in

For

factory

standard

valve

guide

11

985

to

11

996

0

4718

to

0

4723

For

service

valve

guide

3

Carefully

press

new

valve

guide

into

valve

so

that

it

will

fit

smoothly

after

heating

cylinder

head

to

150

to

2000C

302

to

3920

F

Valve

guide

of

0

2

mm

0

0079

in

oversize

diameter

is

available

for

ser

vice

as

indicated

above

Interference

fit

of

valve

guide

to

guide

hole

0

027

to

0

049

mm

0

0011

to

0

0019

in

4

Ream

bore

with

valve

guide

press

ed

in

using

Valve

Guide

Reamer

Set

KVIOI039S0

EM

10

12

185

to

12

96

0

4797

to

0

4802

Reaming

bore

8

000

to

8

018

rnm

0

3150

to

0

3157

in

EM419

Fig

EM

44

Reaming

valve

guide

Page 56 of 537

q

1

I

k

k

lO

i

I

37

9

to

38

1

eel

1

492

to

1

500

dis

co

q

0

45

597

to

45

613

1

795

to

1

796

dia

5

Correct

valve

seat

surface

with

new

valve

guide

as

the

axis

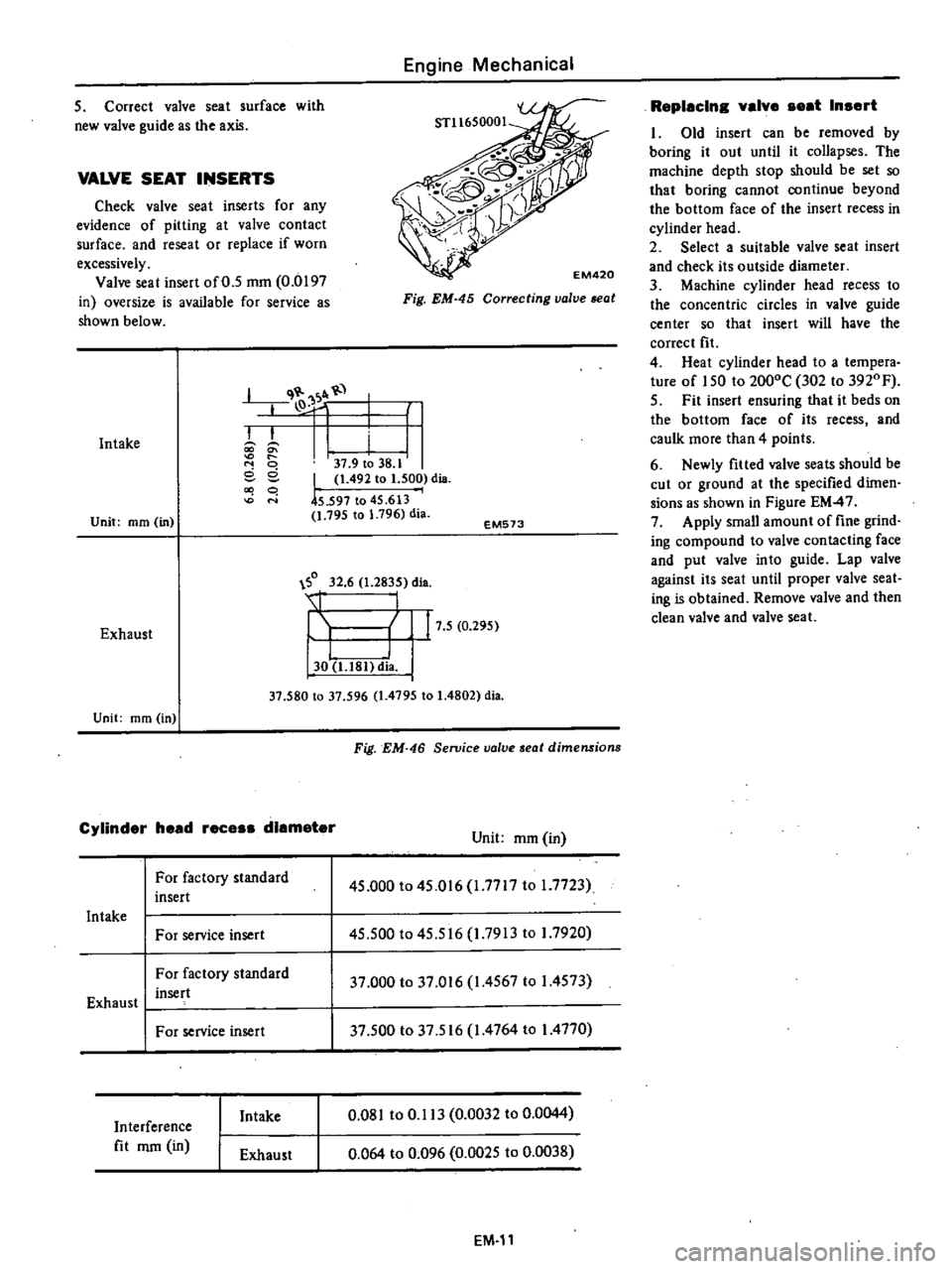

VALVE

SEAT

INSERTS

Check

valve

seat

inserts

for

any

evidence

of

pitting

at

valve

contact

surface

and

reseat

or

replace

if

worn

excessively

Valve

seat

insert

of

0

5

mm

0

0197

in

oversize

is

available

for

service

as

shown

below

Intake

Unit

mm

in

Engine

Mechanical

Fig

EM

45

Correcting

valve

seat

EM573

0

32

6

1

2835

dia

Exhaust

I

I

30

U81

dia

17

5

0

295

Unit

mm

in

37

580

to

37

596

1

4795

to

1

4802

dia

Cylinder

head

rece

diameter

For

factory

standard

insert

Intake

For

service

insert

For

factory

standard

insert

Exhaust

I

For

service

insert

Interference

fit

mm

in

Intake

Exhaust

Fig

EM

46

Seroice

valve

seat

dimensions

Unit

mm

in

45

000

to

45

016

1

7717

to

1

7723

45

500

to

45

516

1

7913

to

I

7920

37

000

to

37

016

1

4567

to

I

4573

37

500

to

37

516

1

4764

to

I

4770

0

081

to

0

113

0

0032

to

0

0044

0

064

to

0

096

0

0025

to

0

0038

EM

11

Replacln

valve

eat

In

ert

1

Old

insert

can

be

removed

by

boring

it

out

until

it

collapses

The

machine

depth

stop

should

be

set

so

that

boring

cannot

continue

beyond

the

bottom

face

of

the

insert

recess

in

cylinder

head

2

Select

a

suitable

valve

seat

insert

and

check

its

outside

diameter

3

Machine

cylinder

head

recess

to

the

concentric

circles

in

valve

guide

center

so

that

insert

will

have

the

correct

fit

4

Heat

cylinder

head

to

a

tempera

ture

of

150

to

2000C

302

to

3920

F

5

Fit

insert

ensuring

that

it

beds

on

the

bottom

face

of

its

recess

and

caulk

more

than

4

points

6

Newly

fitted

valve

seats

should

be

cut

or

ground

at

the

specified

dimen

sions

as

shown

in

Figure

EM

47

7

Apply

small

amount

of

fine

grind

ing

compound

to

valve

contacting

face

and

put

valve

into

guide

Lap

valve

against

its

seat

until

proper

valve

seat

ing

is

obtained

Remove

valve

and

then

clean

valve

and

valve

sea

1

Page 57 of 537

Intake

Engine

Mechanical

I

600

38

1

496I

dia

W

39

6

I

559Ildia

1

8

1

6457

dia

45

1

71l1

Unit

mm

in

Exhaust

30

30

1

l811

di

I

32

6

2835

dia

34

6

1

3622

dia

137

1

4567

dia

Unit

mm

m

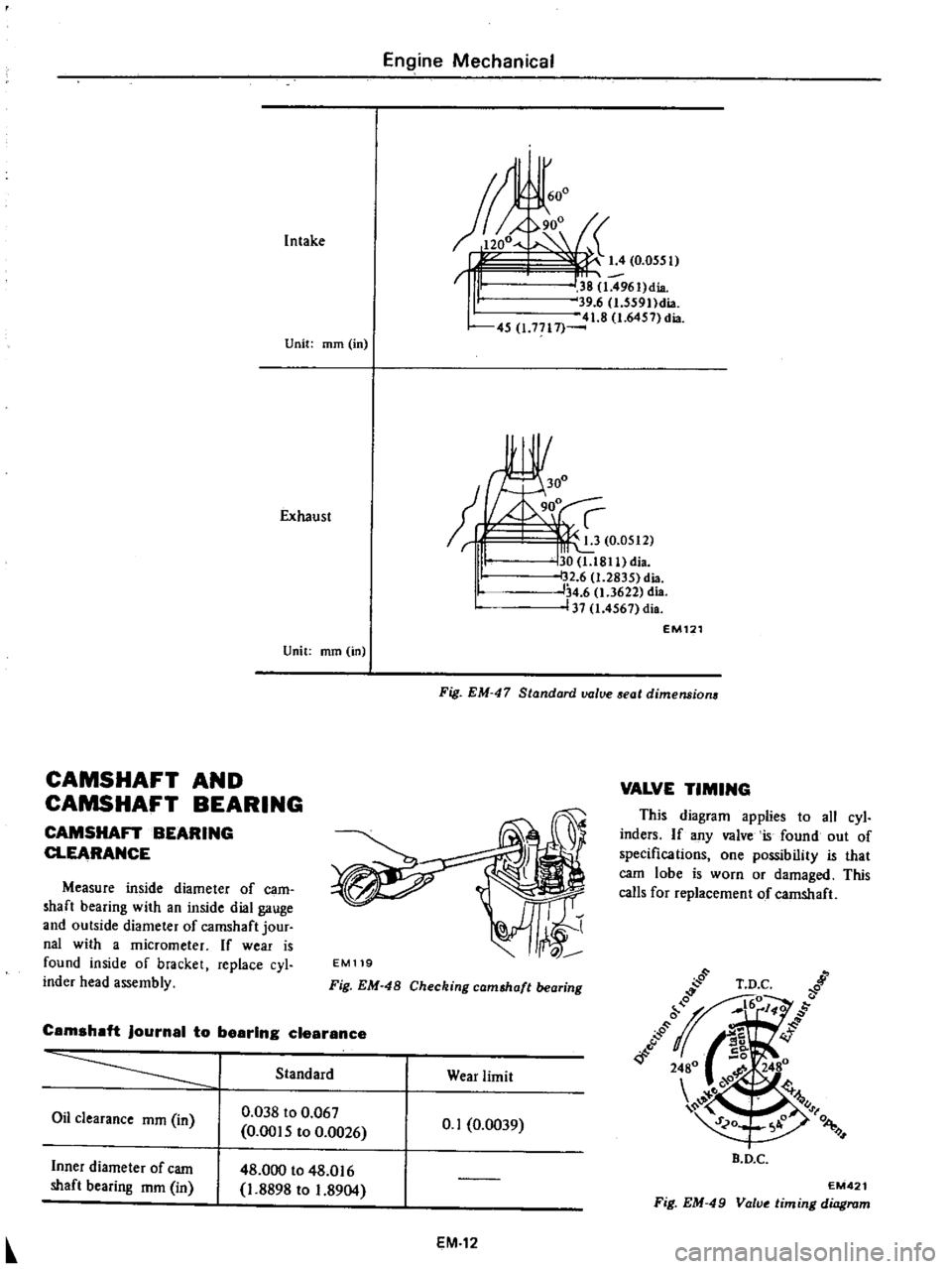

CAMSHAFT

AND

CAMSHAFT

BEARING

CAMSHAnBEARING

CLEARANCE

Measure

inside

diameter

of

earn

haft

beating

with

an

inside

dial

gauge

and

outside

diameter

of

camshaft

jour

nal

with

a

micrometer

If

wear

is

found

inside

of

bracket

replace

cyl

inder

head

assembly

EM121

Fig

EM

47

Standard

value

aeat

dimensions

EM119

Fig

EM

48

Checking

cam

haft

bearing

Camshaft

journal

to

bearing

clearance

Standard

Wear

limit

Oil

clearance

mm

in

0

038

to

0

067

0

0015

to

0

0026

0

1

0

0039

Inner

diameter

of

earn

shaft

bearing

mm

in

48

000

to

48

016

1

8898

to

1

8904

EM

12

VALVE

TIMING

This

diagram

applies

to

all

cyl

inders

If

any

valve

is

found

out

of

specifications

one

possibility

that

carn

lobe

is

worn

or

damaged

This

calls

for

replacement

of

camshaft

B

D

C

EM421

Fig

EM

49

Value

timing

diagram

Page 58 of 537

Standard

Camshaft

bend

mm

in

0

02

0

0008

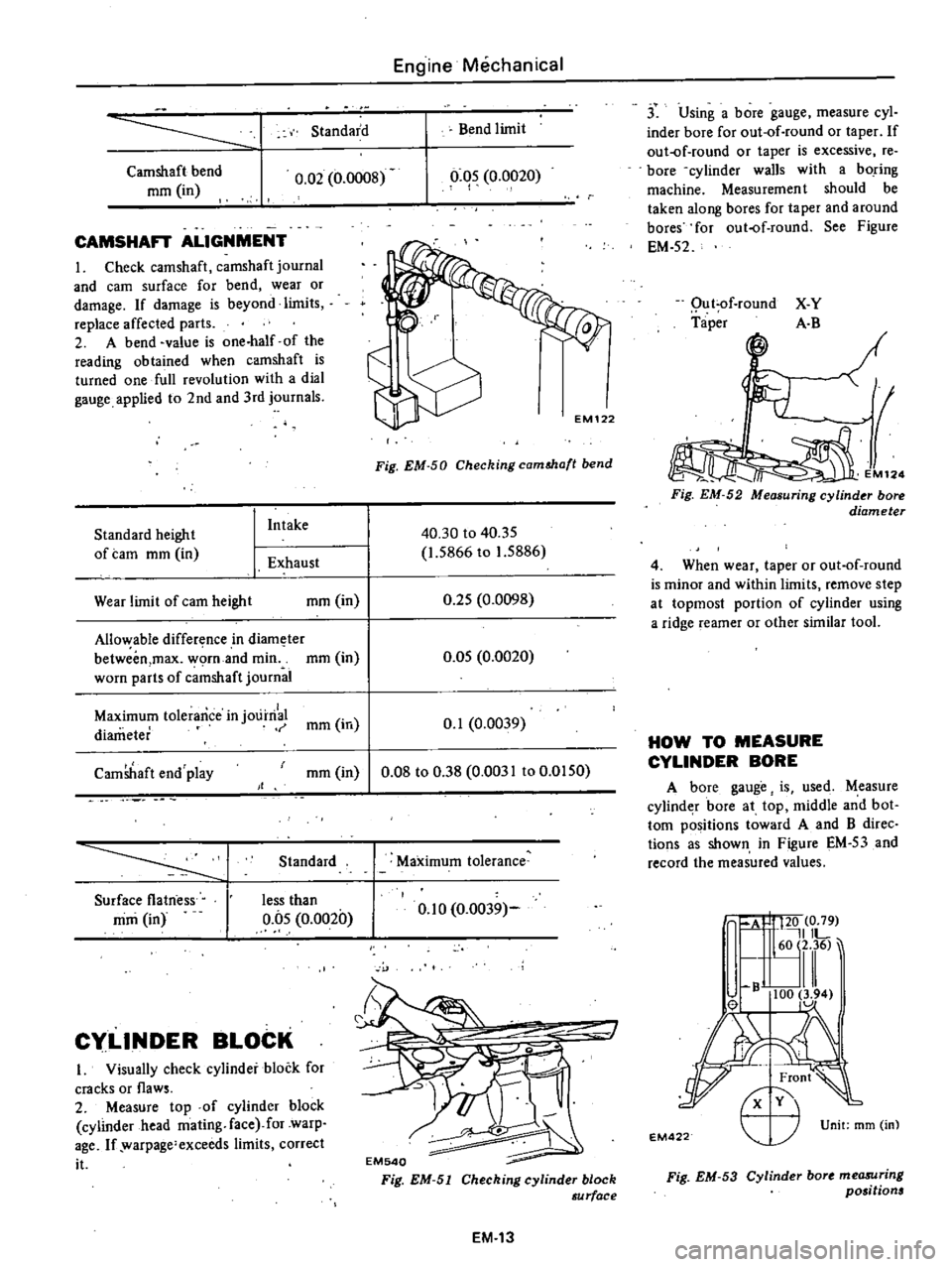

CAMSHAFT

ALIGNMENT

I

Check

camshaft

camshaft

journal

and

earn

surface

for

bend

wear

or

damage

If

damage

is

beyond

limits

replace

affected

parts

2

A

bend

value

is

one

half

of

the

reading

obtained

when

camshaft

is

turned

one

full

revolution

with

a

dial

gauge

applied

to

2nd

and

3rd

journals

Standard

height

of

tam

mm

in

I

Intake

1

Exhaust

Wear

limit

of

earn

height

mm

in

Allo

able

difference

in

diam

ter

betweim

max

worn

and

min

mm

in

worn

parts

of

c

mshaft

journal

Engine

Mechanical

Bend

limit

0

05

0

0020

I

Fig

EM

50

Checking

camMa

t

bend

40

30

to

40

35

1

5866

to

1

5886

0

25

0

0098

0

05

0

0020

Maximum

tolerance

in

j01

irri

mm

in

0

1

0

0039

diameter

CamShaft

end

play

mm

in

0

08

to

0

38

0

0031

to

0

0150

Standard

Surface

flatness

mm

in

less

than

0

05

0

0020

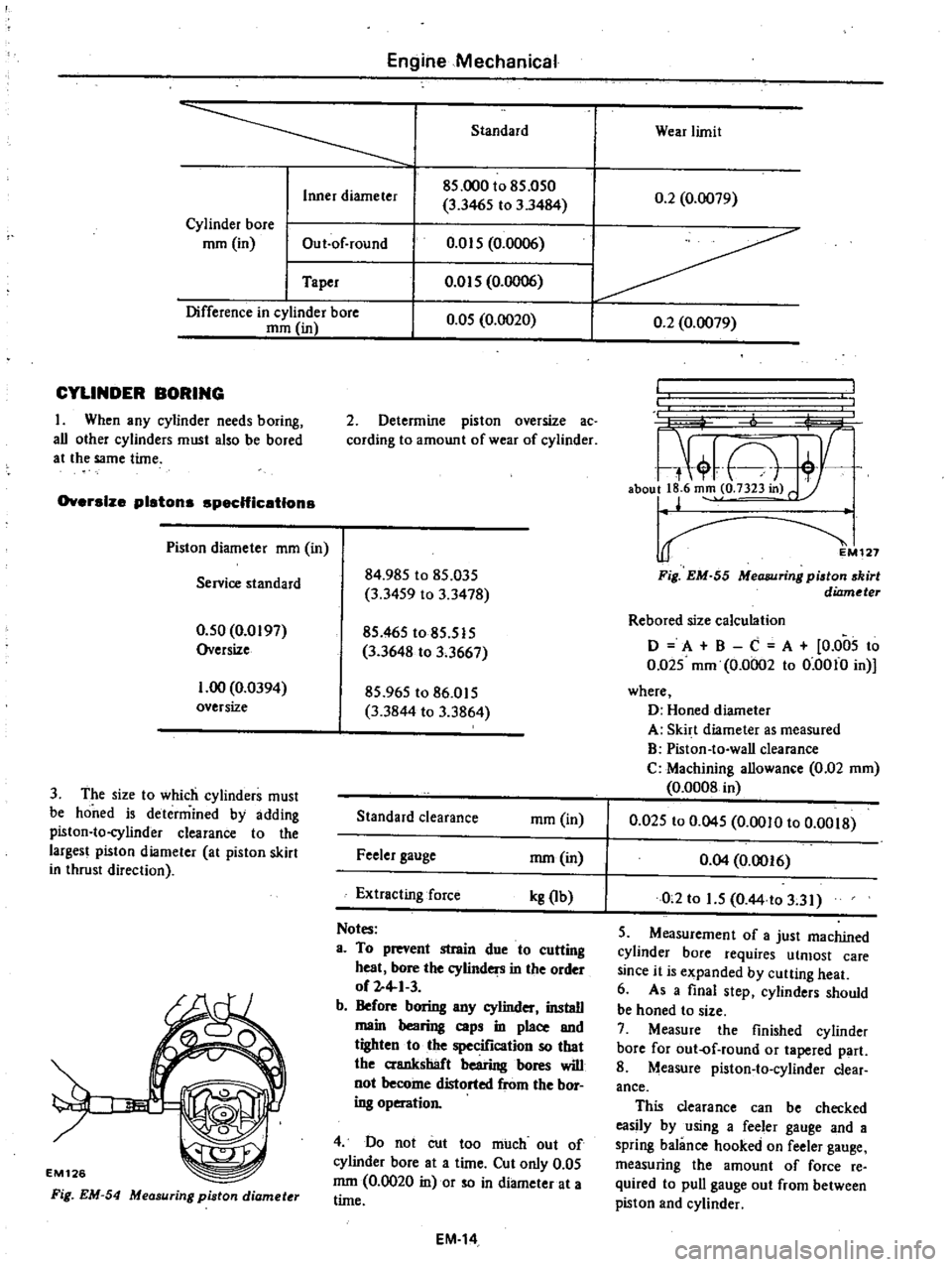

Cy

LlNDER

BLOCK

I

Visually

check

cylinder

block

for

cracks

or

flaws

2

Measure

top

of

cylinder

block

cylinder

head

mating

face

for

warp

age

If

warpage

exceeds

limits

correct

it

Maximum

tolerance

0

10

0

0039

EM540

Fig

EM

51

Cheching

cylinder

block

au

rface

EM

13

j

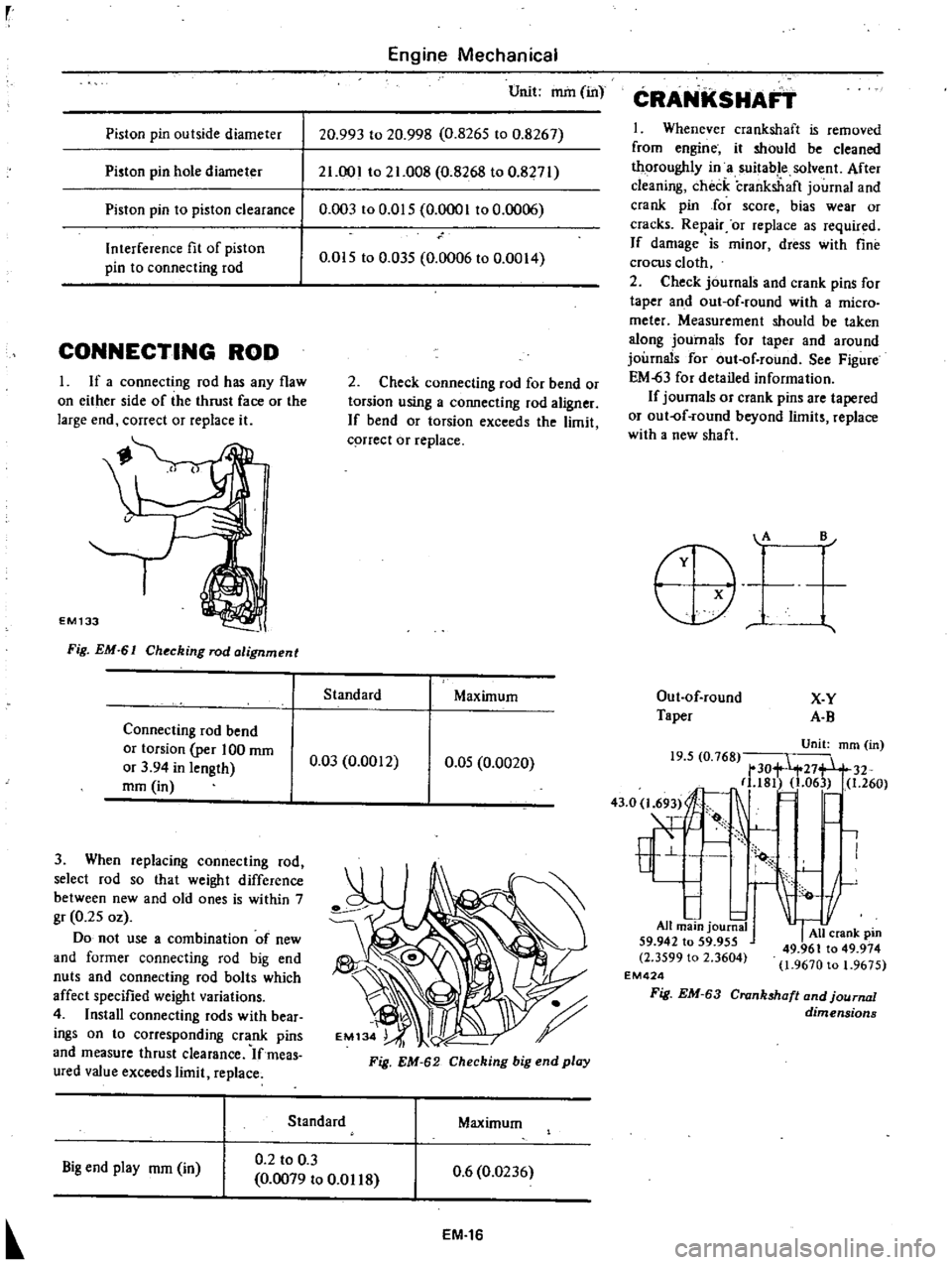

Using

a

bore

gauge

measure

cyl

inder

bore

for

out

of

round

or

taper

If

out

of

round

or

taper

is

excessive

re

bore

cylinder

walls

with

a

boring

machine

Measuremen

t

should

be

taken

along

bores

for

taper

and

around

bores

for

out

of

round

See

Figure

EM

52

Qu

t

of

round

Taper

X

Y

A

B

M12

Fig

EM

52

Measuring

cylinder

bore

diameter

4

When

wear

taper

or

out

of

round

is

minor

and

within

limits

remove

step

at

topmost

portion

of

cylinder

using

a

ridge

reamer

or

other

similar

tool

HOW

TO

MEASURE

CYLINDER

BORE

A

bore

gauge

is

used

Measure

cylind

r

bore

at

top

middle

and

bot

tom

positions

toward

A

and

B

direc

tions

as

shown

in

Figure

EM

53

and

record

the

measured

values

A

I

120

0

79

IlL

60

2

36

lll

B

100

3

94

el

1

Unit

mm

m

EM

22

r

Fig

EM

53

Cylinder

bort

me08Uring

positions

Page 59 of 537

Engine

Mechanical

Standard

Wear

limit

Inner

diameter

85

000

to

85

050

0

2

0

0079

3

3465

to

3

3484

Cylinder

bore

mm

in

Out

of

round

O

ot5

0

0006

Taper

0

015

0

0006

Difference

in

cylinder

bore

0

05

0

0020

0

2

0

0079

mm

in

CYLINDER

BORING

I

When

any

cylinder

needs

boring

all

other

cylinders

must

also

be

bored

at

the

same

time

Oversize

pistons

spec

Hic

etlons

Piston

diameter

mm

in

Servioe

standard

0

50

0

0197

Oversize

1

00

0

0394

oversize

3

The

size

to

which

cylinders

must

be

honed

is

determined

by

adding

piston

to

cylinder

clearance

to

the

largest

piston

diameter

at

piston

skirt

in

thrust

direction

EM126

Fig

EM

54

Measuring

piston

diamet

r

2

Determine

piston

oversize

ac

cording

to

amount

of

wear

of

cylinder

84

985

to

85

035

3

3459

to

3

3478

85

465

to

85

515

3

3648

to

3

3667

85

965

to

86

015

3

3844

to

3

3864

Standard

clearance

ffim

in

Feeler

gauge

mm

in

Extracting

force

kg

Ib

Notes

a

To

prevent

strain

due

to

cutting

heat

bore

the

cylinders

in

the

order

of

2

4

1

3

b

Before

boring

any

cylinder

install

main

bearing

caps

in

place

and

tighten

to

the

specification

so

that

the

crankshaft

bearing

bores

will

not

become

distorted

from

the

bor

ing

operation

4

Do

not

cut

too

much

out

of

cylinder

bore

at

a

time

Cut

only

0

05

mm

0

0020

in

or

so

in

diameter

at

a

time

EM

14

L

7

A

aboull

6

m

o

7323in

r

127

Fig

EM

55

MeCUJlJring

piston

skirt

diameter

Rebored

size

calculation

o

A

B

C

A

0

005

to

0

Q25

mm

0

0002

to

0

0010

in

where

D

Honed

diameter

A

Skirt

diameter

as

measured

B

Piston

to

wall

clearance

C

Machining

allowance

0

02

mm

0

0008

in

0

025

to

0

045

0

0010

to

0

0018

0

04

0

0016

0

2

to

1

5

O

44

to

3

31

5

Measurement

of

a

just

machined

cylinder

bore

requires

utmost

care

since

it

is

expanded

by

cutting

heat

6

As

a

final

step

cylinders

should

be

honed

to

size

7

Measure

the

finished

cylinder

bore

for

out

of

round

or

tapered

part

8

Measure

piston

to

cylinder

clear

ance

This

clearance

can

be

checked

easily

by

using

a

feeler

gauge

and

a

spring

balance

hooked

on

feeler

gauge

measuring

the

amount

of

force

re

quired

to

pull

gauge

out

from

between

piston

and

cylinder

Page 60 of 537

Engine

Mechanical

Notes

a

When

measuring

clearance

slowly

pull

feeier

gaUge

siraight

upward

b

It

Is

reConUnended

that

piston

and

cylinder

be

hel

ted

to

200C

680F

PISTONS

PISTON

PINS

AND

PISTON

RINGS

I

Remove

carbon

from

piston

and

ring

grooves

with

a

ca

bon

scraper

and

a

curved

steel

wire

Clean

out

oil

slots

in

bottom

land

of

oil

ring

groove

2

Check

for

damage

scratches

and

wear

Replace

if

necessary

3

Meas1

1re

side

clearance

of

rings

in

ring

grooves

as

each

ring

is

installed

Side

clearance

should

be

as

follows

00

I

EM542

Fig

EM

58

Measuring

ring

gap

Notes

a

When

piston

ring

only

is

to

be

replaced

without

cylinder

bore

being

corrected

measure

gap

at

bottom

of

cylinder

where

wear

is

minor

b

Oversize

piston

rings

are

available

for

serv

ce

Oversize

0

5

mm

0

0197

in

and

1

0

mm

0

0394

in

5

Measure

piston

pin

hole

in

rela

tion

to

outer

diameter

of

pin

If

wear

exceeds

limit

replace

each

piston

pin

together

with

the

piston

on

which

it

is

installed

6

Determine

the

fitting

of

piston

pin

into

piston

pin

hole

to

such

an

extent

that

it

can

be

finger

pressed

at

room

temperature

This

piston

pin

must

be

a

tight

pre

s

fit

into

connect

ing

rod

t

J

f

rr

11

1

I

EM541

Fig

EM

56

Measuring

piaton

fit

in

cylinder

Fig

EM

57

Measuring

piston

ring

side

clearance

Side

clearance

Unit

mm

in

I

Second

ring

I

I

Wear

limit

Standard

0

040

to

0

073

0

0016

to

0

0029

0

030

to

0

070

I

0

0012

to

0

0028

I

Top

ring

0

1

0

0039

Oil

ring

f

feeler

gauge

Ring

should

be

placed

to

diameter

at

upper

or

lower

limit

of

ring

travel

4

Push

ring

into

cylinder

with

pis

ton

so

as

to

place

it

squarely

in

cylinder

measure

ring

gap

with

a

EM131

Ring

gap

Fig

EM

59

Piston

pin

fitting

Unit

rom

in

Standard

Wear

limit

0

25

to

0

40

0

0098

to

0

0157

0

30

to

0

50

0

0

II

8

to

0

0197

Top

ring

Second

ring

1

0

0

0394

EM132

0

30

to

0

90

0

0118

to

0

0354

Oil

ring

Fig

EM

60

Measuring

pi

ton

pin

diamet

EM

15

Page 61 of 537

r

Piston

pin

outside

diameter

Piston

pin

hole

diameter

Piston

pin

to

piston

clearance

I

Interference

fit

of

piston

pin

to

connecting

rod

CONNECTING

ROD

I

If

a

connecting

rod

has

any

flaw

on

either

side

of

the

thrust

face

or

the

large

end

correct

or

replace

it

EM133

Fig

EM

61

Ch

cking

rod

alignment

Connecting

rod

bend

or

torsion

per

100

mm

or

3

94

in

length

mm

in

3

When

replacing

connecting

rod

select

rod

so

that

weight

difference

between

new

and

old

ones

is

within

7

gr

0

25

oz

Do

not

use

a

combination

of

new

and

former

connecting

rod

big

end

nuts

and

connecting

rod

bolts

which

affect

specified

weight

variations

4

Install

connecting

rods

with

bear

ings

on

to

corresponding

crank

pins

and

measure

thrust

clearance

Ifmeas

ured

value

exceeds

limit

replace

Engine

Mechanical

Unit

mm

in

20

993

to

20

998

0

8265

to

0

8267

21

001

to

21

008

0

8268

to

0

8271

0

003

to

0

015

0

0001

to

0

006

0

015

to

0

035

0

0006

to

0

0014

2

Check

connecting

rod

for

bend

or

torsion

using

a

connecting

rod

aligner

If

bend

or

torsion

exceeds

the

limit

q

rrect

or

replace

Standard

Maximum

0

03

0

0012

0

05

0

0020

Fig

EM

62

Checking

big

end

play

Standard

Maximum

Big

end

play

mm

in

0

2

to

0

3

0

0079

to

0

01

18

0

6

0

0236

EM

16

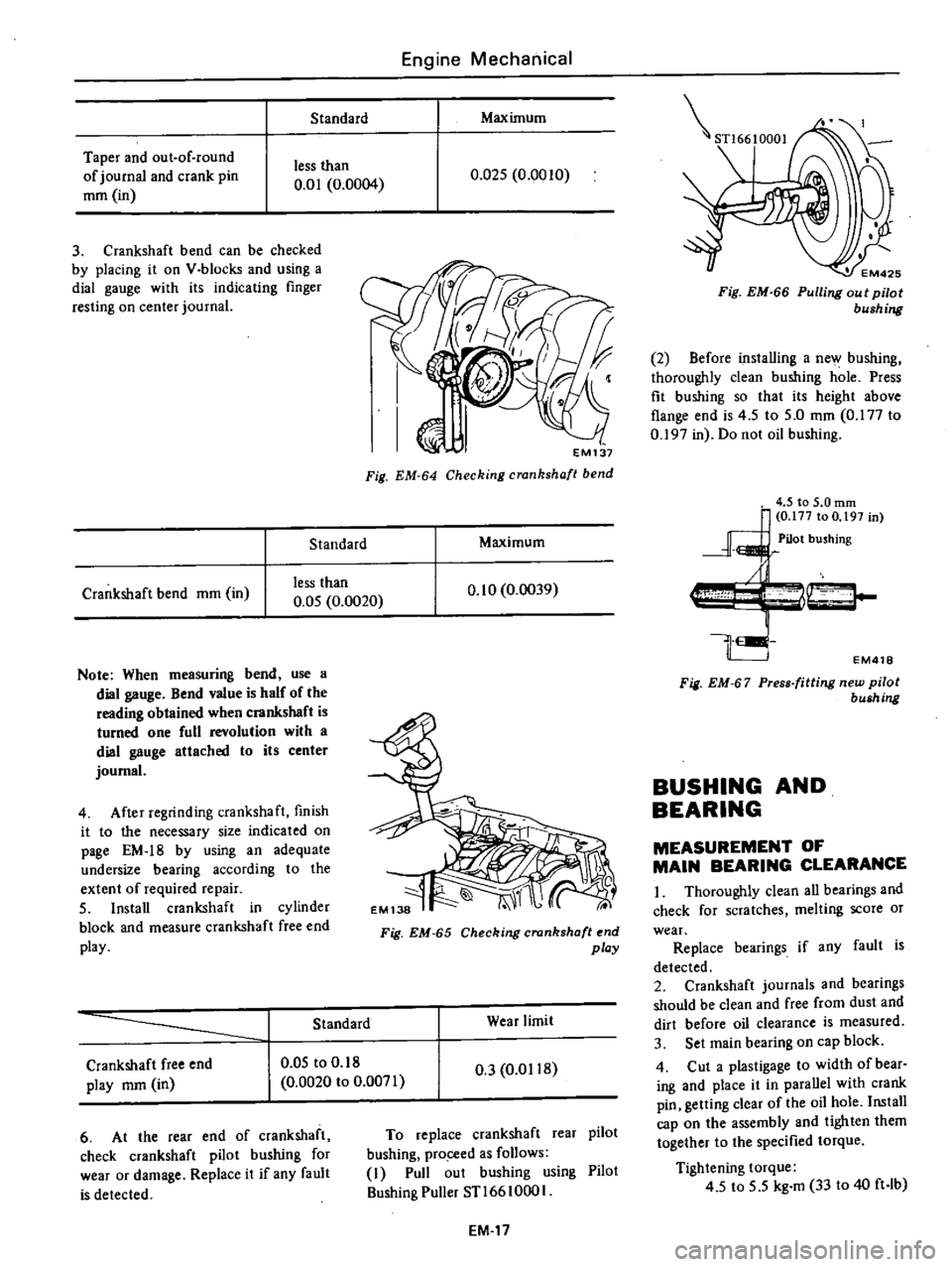

CRANKSHAFT

1

Whenever

crankshaft

is

removed

from

engine

it

should

be

cleaned

thoroughly

in

a

suitable

solvent

After

cleaning

check

crankshaft

journal

and

crank

pin

Jor

score

bias

wear

or

cracks

Rep

air

or

replace

as

required

If

damage

is

minor

dress

with

fine

crocus

cloth

2

Check

journals

and

crank

pins

for

taper

and

out

of

round

with

a

micro

meter

Measurement

should

be

taken

along

journals

for

taper

and

around

journals

for

out

of

round

See

Figure

EM

63

for

detailed

information

If

journals

or

crank

pins

are

tapered

or

out

of

round

beyond

limits

replace

with

a

new

shaft

A

B

Out

of

round

X

Y

Taper

A

B

Unit

mm

in

19

5

0

768

tt

30

27

32

181

1

06

1

260

43

O

l

69

I

E

1

All

main

journa

59

942

to

59

955

All

crank

pm

2

3599

l

2

3604

49

961

to

49

974

o

1

9670

to

1

9675

EM424

Fig

EM

63

Crankshaft

and

journal

dimensions

Page 62 of 537

Standard

Taper

and

out

of

round

of

journal

and

crank

pin

mm

in

less

than

0

01

0

0004

3

Crankshaft

bend

can

be

checked

by

placing

it

on

V

blocks

and

using

a

dial

gauge

with

its

indicating

finger

resting

on

center

journal

Standard

Crankshaft

bend

mm

in

less

than

0

05

0

0020

Note

When

measuring

bend

use

a

dial

gauge

Bend

value

is

half

of

the

reading

obtained

when

crankshaft

is

turned

one

full

revolution

with

a

dial

gauge

attached

to

its

center

journal

4

After

regrinding

crankshaft

finish

it

to

the

necessary

size

indicated

on

page

EM

18

by

using

an

adequate

undersize

bearing

according

to

the

extent

of

required

repair

5

Install

crankshaft

in

cylinder

block

and

measure

crankshaft

free

end

play

Engine

Mechanical

Maximum

0

Q25

0

0010

EM137

Fig

EM

64

Checking

crankshaft

bend

Maximum

0

10

0

0039

Fig

EM

65

Checking

crankshaft

end

play

Standard

Wear

limit

Crankshaft

free

end

play

mm

in

0

05

to

0

18

0

0020

to

0

0071

0

3

0

0118

6

At

the

rear

end

of

crankshaft

check

crankshaft

pilot

bushing

for

wear

or

damage

Replace

it

if

any

fault

is

detected

To

replace

crankshaft

rear

pilot

bushing

pro

ceed

as

follows

I

Pull

out

bushing

using

Pilot

Bushing

Puller

STl66

1000

I

EM

17

STl6610001

EM425

Fig

EM

66

Pulling

out

pilot

bushing

2

Before

installing

a

new

bushing

thoroughly

clean

bushing

hole

Press

fit

bushing

so

that

its

height

above

flange

end

is

4

5

to

5

0

mm

0

177

to

0

197

in

Do

not

oil

bushing

EM418

Fig

EM

67

Press

fitting

new

pilot

bush

ng

BUSHING

AND

BEARING

MEASUREMENT

OF

MAIN

BEARING

CLEARANCE

I

Thoroughly

clean

all

bearings

and

check

for

scratches

melting

score

or

wear

Replace

bearings

if

any

fault

is

detected

2

Crankshaft

journals

and

bearings

should

be

clean

and

free

from

dust

and

dirt

before

oil

clearance

is

measured

3

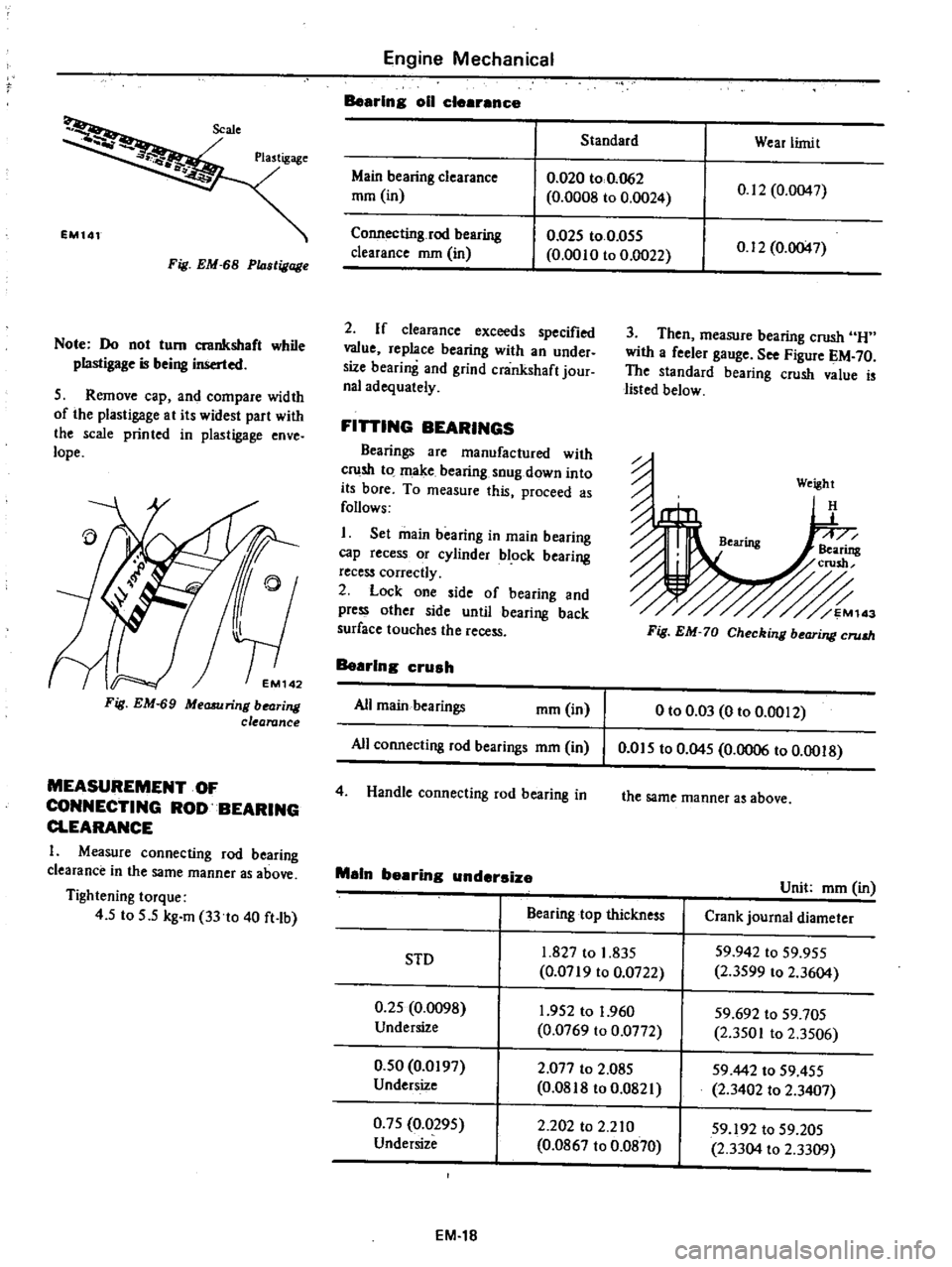

Set

main

bearing

on

cap

block

4

Cut

a

plastigage

to

width

of

bear

ing

and

place

it

in

parallel

with

crank

pin

getting

clear

of

the

oil

hole

Install

cap

on

the

assembly

and

tighten

them

together

to

the

specified

torque

Tightening

torque

4

5

to

5

5

kg

m

33

to

40

ft

lb

Page 63 of 537

Fig

EM

68

P14stigage

Note

Do

not

tum

crankshaft

while

plastigage

is

being

inserted

5

Remove

cap

and

compare

width

of

the

plastigage

at

its

widest

part

with

the

scale

printed

in

plastigage

enve

lope

Fig

EM

69

Measuring

bearing

clearance

MEASUREMENT

OF

CONNECTING

ROD

BEARING

CLEARANCE

I

Measure

connecting

rod

bearing

clearance

in

the

same

manner

as

above

Tightening

torque

4

5

to

5

5

kg

m

33

to

40

ft

lb

Engine

Mechanical

Bearing

011

clearance

Standard

Wear

limit

Main

bearing

clearance

mm

in

0

020

to

0

062

0

0008

to

0

0024

0

12

0

0047

Connecting

rod

bearing

clearance

mm

in

0

025

to

0

055

0

0010

to

0

0022

0

12

0

0047

2

If

clearance

exceeds

specified

value

replace

bearing

with

an

under

size

bearing

and

grind

crankshaft

jour

nal

adequately

FiniNG

BEARINGS

Bearings

are

manufactured

with

crush

to

make

bearing

snug

down

into

its

bore

To

measure

this

proceed

as

follows

I

Set

main

bearing

in

main

bearing

cap

recess

or

cylinder

block

bearing

recess

correctly

2

Lock

one

side

of

bearing

and

press

other

side

until

bearing

back

surface

touches

the

recess

Bearing

crush

All

main

bearings

mm

in

All

connecting

rod

bearings

mm

in

4

Handle

connecting

rod

bearing

in

3

Then

measure

bearing

crush

H

with

a

feeler

gauge

See

Figure

EM

70

The

standard

bearing

crush

value

is

listed

below

Weight

H

Fig

EM

70

Checking

bearing

crum

o

to

0

03

0

to

0

0012

0

015

to

0

045

0

0006

to

0

0018

the

same

manner

as

above

Main

bearing

undersize

Unit

mm

in

Bearing

top

thickness

Crank

journal

diameter

1

827

to

1

835

59

942

to

59

955

SID

0

0719

to

0

0722

2

3599

to

2

3604

0

25

0

0098

1

952

to

1

960

59

692

to

59

705

Undersize

0

0769

to

0

0772

2

3501

to

2

3506

0

50

0

0197

2

077

to

2

085

59442

to

59

455

Undersize

0

0818

to

0

0821

2

3402

to

2

3407

0

75

0

0295

2

202

to

2

210

59

192

to

59

205

Undersize

0

0867

to

0

0870

2

3304

to

2

3309

EM

18