check engine DATSUN PICK-UP 1977 Workshop Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 92 of 537

The

pump

shaft

is

supported

by

a

double

row

of

ball

bearings

press

fit

in

an

aluminum

die

cast

pump

body

The

bearings

are

permanently

lubricated

and

sealed

to

prevent

loss

of

lubricant

and

entry

of

dirt

The

pump

is

provided

with

an

impeller

which

turns

on

a

steel

shaft

The

steel

shaft

rotates

together

with

the

torque

coupling

wheeL

The

volute

chamber

is

built

in

the

engine

front

cover

assembly

The

inlet

of

the

pump

is

connected

to

the

radiator

s

lower

tank

by

a

hose

i

o

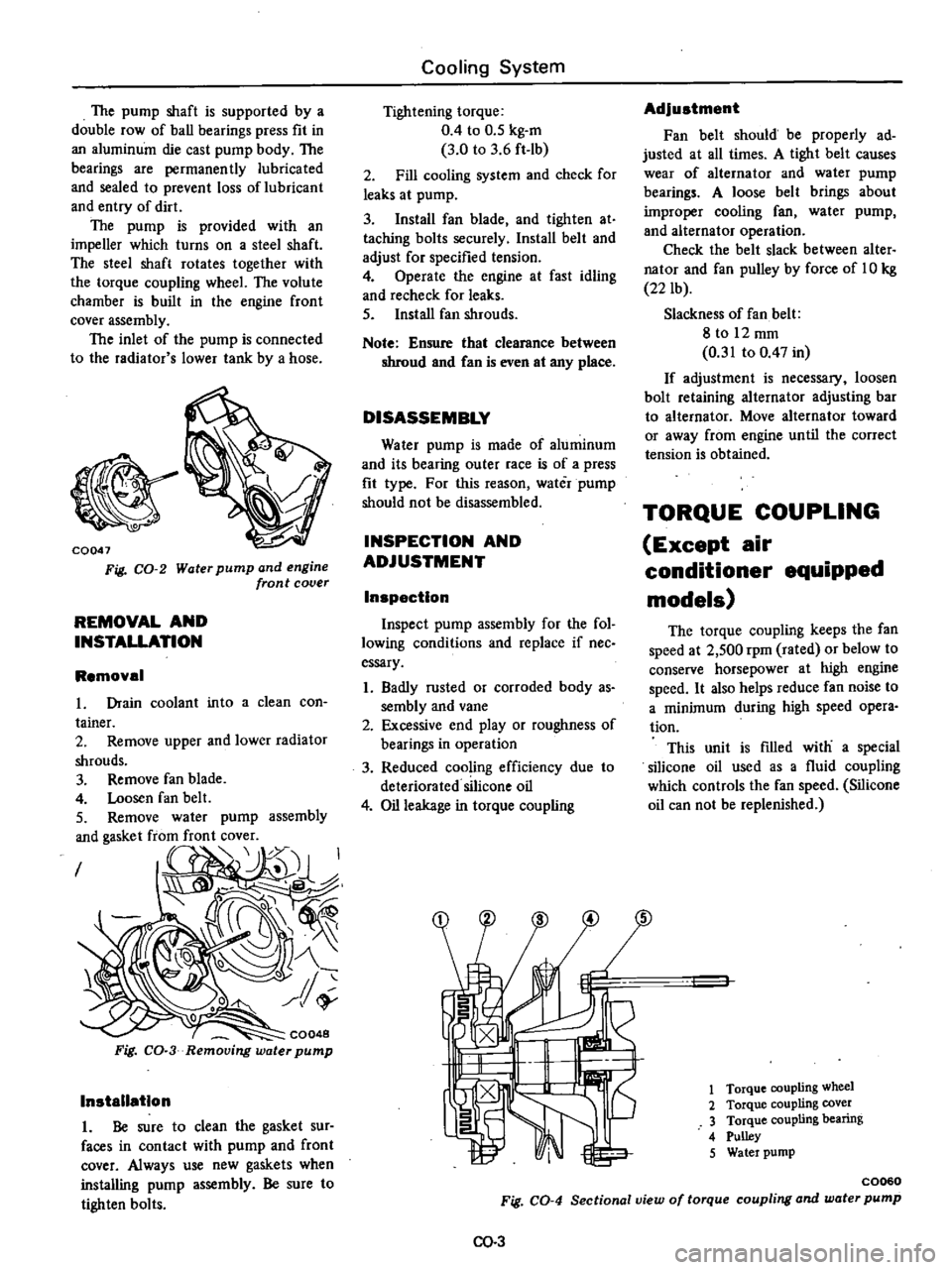

CQ047

Fig

CO

2

Water

pump

and

engine

front

cover

REMOVAL

AND

INSTALLATION

Removal

in

to

a

clean

con

assembly

I

CQ048

Fig

CO

3

Removing

water

pump

Installation

1

Be

sure

to

clean

the

gasket

sur

faces

in

contact

with

pump

and

front

cover

Always

use

new

gaskets

when

installing

pump

assembly

Be

sure

to

tighten

bolts

Cooling

System

Tightening

torque

0

4

to

0

5

kg

m

3

0

to

3

6

ft

lb

2

Fill

cooling

system

and

check

for

leaks

at

pump

3

Install

fan

blade

and

tighten

at

taching

bolts

securely

Install

belt

and

adjust

for

specified

tension

4

Operate

the

engine

at

fast

idling

and

recheck

for

leaks

5

Install

fan

shrouds

Note

Ensure

that

clearance

between

shroud

and

Can

is

even

at

any

place

DISASSEMBLY

Water

pump

is

made

of

aluminum

and

its

bearing

outer

race

is

of

a

press

fit

type

For

this

reason

water

pump

should

not

be

disassembled

INSPECTION

AND

ADJUSTMENT

Inspection

Inspect

pump

assembly

for

the

fol

lowing

conditions

and

replace

if

nee

essary

1

Badly

rusted

or

corroded

body

as

sembly

and

vane

2

Excessive

end

play

or

roughness

of

bearings

in

operation

3

Reduced

cooling

efficiency

due

to

deteriorated

silicone

oil

4

Oil

leakage

in

torque

coupling

Adjustment

Fan

belt

should

be

properly

ad

justed

at

all

times

A

tight

belt

causes

wear

of

alternator

and

water

pump

bearings

A

loose

belt

brings

about

improper

cooling

fan

water

pump

and

alternator

operation

Check

the

belt

slack

between

alter

nator

and

fan

pulley

by

force

of

10

kg

22

lb

Slackness

of

fan

belt

8

to

12

mm

0

31

to

0

47

in

If

adjustment

is

necessary

loosen

bolt

retaining

alternator

adjusting

bar

to

alternator

Move

alternator

toward

or

away

from

engine

until

the

correct

tension

is

obtained

TORQUE

COUPLING

Except

air

conditioner

equipped

models

The

torque

coupling

keeps

the

fan

speed

at

2

500

rpm

rated

or

below

to

conserve

horsepower

at

high

engine

speed

It

also

helps

reduce

fan

noise

to

a

minimum

during

high

speed

opera

tion

This

unit

is

filled

with

a

special

silicone

oil

used

as

a

fluid

coupling

which

controls

the

fan

speed

Silicone

oil

can

not

be

replenished

1

Torque

coupling

wheel

2

Torque

coupling

cover

3

Torque

coupling

bearing

4

Pulley

5

Water

pump

C0060

Fig

CO

4

Sectional

view

of

torque

coupling

and

water

pump

00

3

Page 94 of 537

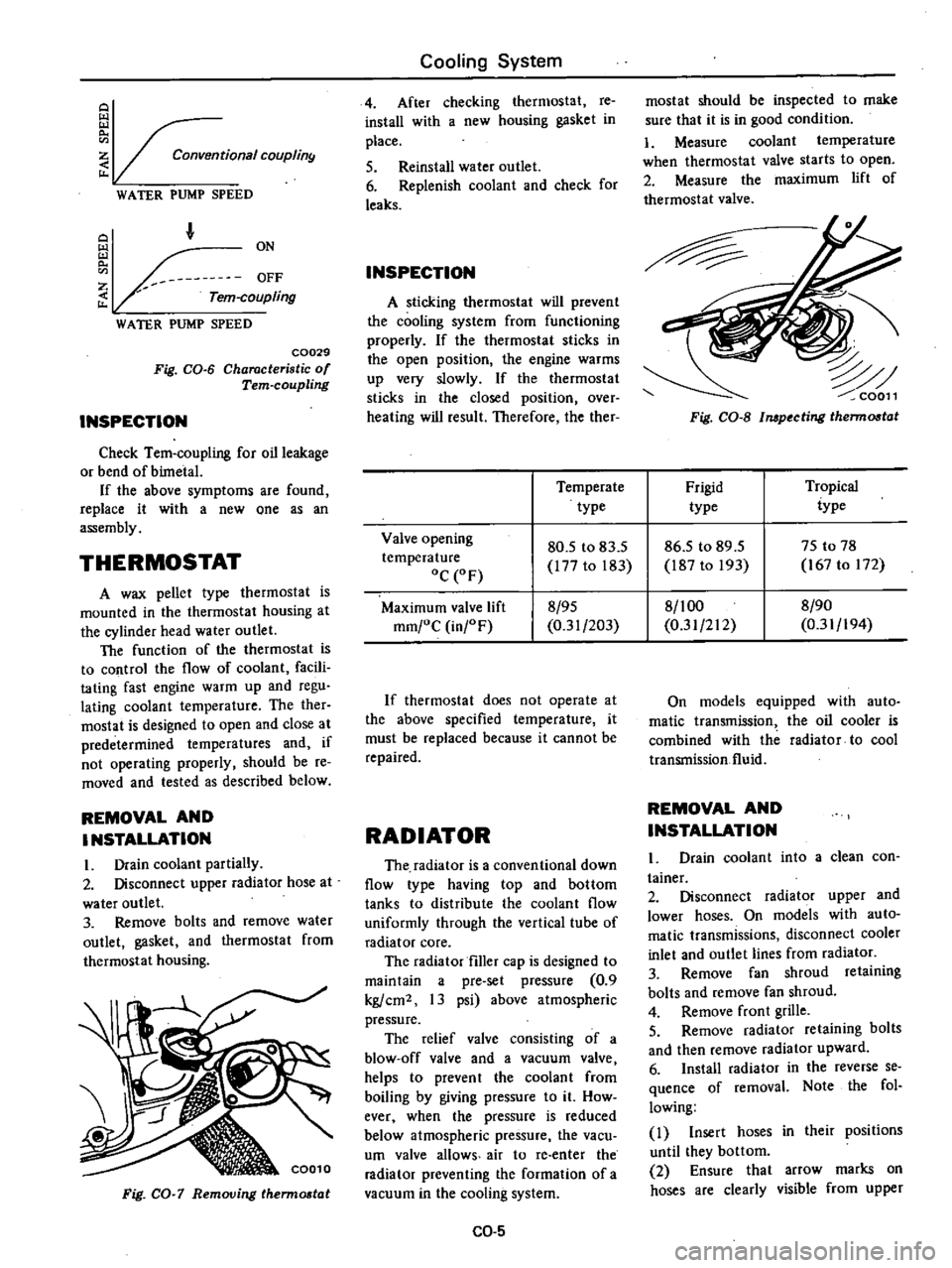

Conventional

COUplin9

WATER

PUMP

SPEED

F

Z

Tern

coupling

WATER

PUMP

SPEED

C0029

Fig

CO

6

Characteristic

of

Tern

coupling

INSPECTION

Check

Tem

coupling

for

oil

leakage

or

bend

of

bimetal

If

the

above

symptoms

are

found

replace

it

with

a

new

one

as

an

assembly

THERMOSTAT

A

wax

pellet

type

thermostat

is

mounted

in

the

thermostat

housing

at

the

cylinder

head

water

outlet

The

function

of

the

thermostat

is

to

control

the

flow

of

coolant

facili

tating

fast

engine

warm

up

and

regu

lating

coolant

temperature

The

ther

mostat

is

designed

to

open

and

close

at

predetermined

temperatures

and

if

not

operating

properly

should

be

re

moved

and

tested

as

described

below

REMOVAL

AND

INSTALLATION

I

Drain

coolant

partially

2

Disconnect

upper

radiator

hose

at

water

outlet

3

Remove

bolts

and

remove

water

outlet

gasket

and

thermostat

from

thermostat

housing

Fig

CO

7

Removing

therm06t

t

Cooling

System

4

After

checking

thermostat

re

install

with

a

new

housing

gasket

in

place

5

Reinstall

water

outlet

6

Replenish

coolant

and

check

for

leaks

INSPECTION

A

sticking

thermostat

will

prevent

the

cooling

system

from

functioning

properly

If

the

thermostat

sticks

in

the

open

position

the

engine

warms

up

very

slowly

If

the

thermostat

sticks

in

the

closed

position

over

heating

will

result

Therefore

the

ther

mostat

should

be

inspected

to

make

sure

that

it

is

in

good

condition

1

Measure

coolant

temperature

when

thermostat

valve

starts

to

open

2

Measure

the

maximum

lift

of

thermostat

valve

Fig

CO

S

Impecting

therm06t

t

Temperate

Frigid

Tropical

type

type

iype

Valve

opening

80

5

to

83

5

86

5

to

89

5

75

to

78

temperature

177

to

183

187

to

193

167

to

172

oC

OF

Maximum

valve

lift

8

95

8

1

00

8

90

mm

oC

in

F

0

31

203

0

31

212

0

31

194

If

thermostat

does

not

operate

at

the

above

specified

temperature

it

must

be

replaced

because

it

cannot

be

repaired

RADIATOR

The

radiator

is

a

conventional

down

flow

type

having

top

and

bottom

tanks

to

distribute

the

coolant

flow

uniformly

through

the

vertical

tube

of

radiator

core

The

radiator

filler

cap

is

designed

to

maintain

a

pre

set

pressure

0

9

kg

cm2

13

psi

above

atmospheric

pressure

The

relief

valve

consisting

of

a

blow

off

valve

and

a

vacuum

valve

helps

to

prevent

the

coolant

from

boiling

by

giving

pressure

to

it

How

ever

when

the

pressure

is

reduced

below

atmospheric

pressure

the

vacu

um

valve

allows

air

to

re

enter

the

radiator

preventing

the

formation

of

a

vacuum

in

the

cooling

system

CO

5

On

models

equipped

with

auto

matic

transmission

the

oil

cooler

is

combined

with

the

radiator

to

cool

transmission

fluid

REMOVAL

AND

INSTALLATION

Drain

coolant

into

a

clean

con

tainer

2

Disconnect

radiator

upper

and

lower

hoses

On

models

with

auto

matic

transmissions

disconnect

cooler

inlet

and

outlet

lines

from

radiator

3

Remove

fan

shroud

retaining

bolts

and

remove

fan

shroud

4

Remove

front

grille

5

Remove

radiator

retaining

bolts

and

then

remove

radiator

upward

6

Install

radiator

in

the

reverse

se

quence

of

removal

Note

the

fol

lowing

I

Insert

hoses

in

their

positions

until

they

bottom

2

Ensure

that

arrow

marks

on

hoses

are

clearly

visible

from

upper

Page 96 of 537

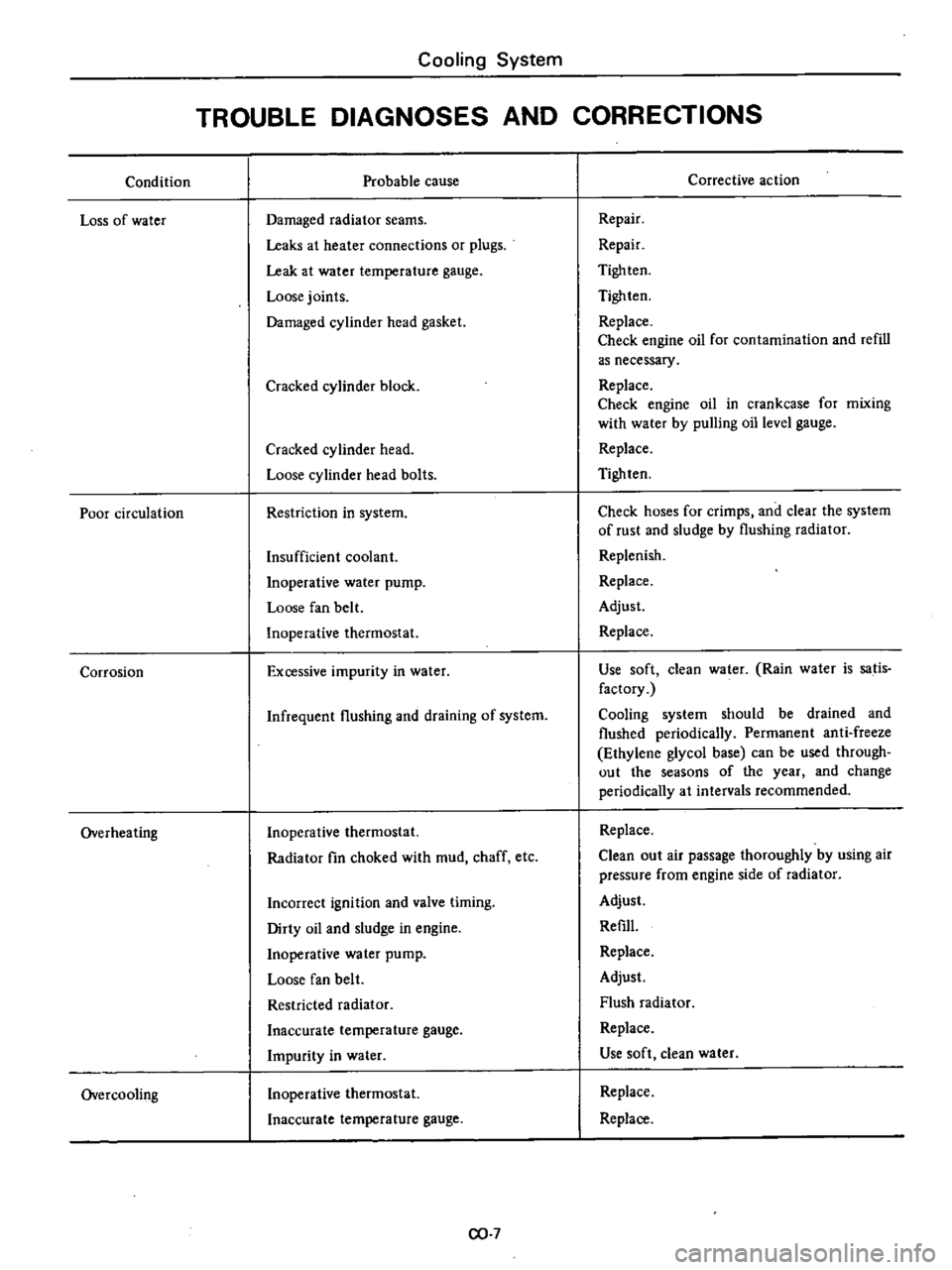

Condition

Loss

of

water

Poor

circulation

Corrosion

Overheating

Overcooling

Cooling

System

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Probable

cause

Damaged

radiator

seams

Leaks

at

heater

connections

or

plugs

Leak

at

water

temperature

gauge

Loose

joints

Damaged

cylinder

head

gasket

Cracked

cylinder

block

Cracked

cylinder

head

Loose

cylinder

head

bolts

Restriction

in

system

Insufficient

coolant

Inoperative

water

pump

Loose

fan

belt

Inoperative

thermostat

Excessive

impurity

in

water

Infrequent

flushing

and

draining

of

system

Inoperative

thermostat

Radiator

fin

choked

with

mud

chaff

etc

Incorrect

ignition

and

valve

timing

Dirty

oil

and

sludge

in

engine

Inoperative

water

pump

Loose

fan

belt

Restricted

radiator

Inaccurate

temperature

gauge

Impurity

in

water

Inoperative

thermostat

Inaccurate

temperature

gauge

CO

7

Corrective

action

Repair

Repair

Tigh

ten

Tighten

Replace

Check

engine

oil

for

contamination

and

refill

as

necessary

Replace

Check

engine

oil

in

crankcase

for

mixing

with

water

by

pulling

oil

level

gauge

Replace

Tighten

Check

hoses

for

crimps

and

clear

the

system

of

rust

and

sludge

by

flushing

radiator

Replenish

Replace

Adjust

Replace

Use

soft

clean

water

Rain

water

is

satis

factory

Cooling

system

should

be

drained

and

flushed

periodically

Permanent

anti

freeze

Ethylene

glycol

base

can

be

used

through

out

the

seasons

of

the

year

and

change

periodically

at

intervals

recommended

Replace

Clean

out

air

passage

thoroughly

by

using

air

pressure

from

engine

side

of

radiator

Adjust

Refill

Replace

Adjust

Flush

radiator

Replace

Use

soft

clean

water

Replace

Replace

Page 102 of 537

r

AIR

CLEANER

1

Loosen

bolts

securing

air

cleaner

to

air

cleaner

bracket

2

Loosen

air

cleaner

lock

bolt

and

remove

air

cleaner

from

carburetor

Disconnect

the

following

hoses

when

dismounting

air

cleaner

Under

hood

air

inlet

hose

Hot

air

inlet

hose

Vacuum

hose

Sensor

to

intake

manifold

Vacuum

hose

Sensor

to

vacuum

motor

Vacuum

hose

Idle

compensator

to

intake

manifold

Hose

Air

pump

to

air

cleaner

Hose

AB

valve

to

air

cleaner

Hose

Carburetor

to

air

cleaner

Blow

by

hose

Air

cleaner

to

rocker

cover

Hose

Air

control

vaive

to

air

cleaner

California

models

only

3

To

install

reverse

the

removal

procedure

INSPECTION

1

AIR

CLEANER

ELEMENT

Viscous

paper

type

air

cleaner

ele

ment

does

not

require

any

cleaning

operation

until

it

is

replaced

periodi

cally

Brushing

or

blasting

operation

will

cause

clogging

and

result

in

enrich

ment

of

carburetor

mixture

and

should

never

be

conducted

For

reo

placement

interval

of

air

cleaner

ele

ment

refer

to

Maintenance

Sched

ule

2

HOT

AIR

CONTROL

SYSTEM

In

warm

weather

it

is

difficult

to

find

out

malfunction

of

hot

air

control

system

In

cold

wea

thee

however

malfunction

of

air

control

valve

due

to

disconnection

or

deterioration

of

vacu

um

hose

between

intake

manifold

and

vacuum

motor

and

insufficient

dura

bility

of

air

control

valve

will

cause

insufficient

automatic

control

opera

tion

for

intake

air

and

result

in

engine

disorder

including

I

Stall

or

hesitation

of

engine

oper

ation

2

Increase

in

fuel

consumption

3

uck

of

power

Engine

Fuel

These

phenomena

reveal

malfunc

tion

of

hot

air

control

system

If

these

phenomena

should

occur

check

hot

air

control

system

as

described

in

the

following

before

carrying

out

inspec

tion

of

carburetor

2

1

Vacuum

hose

Intake

manifold

to

3

way

connec

tor

3

way

connector

to

temperature

sensor

3

way

connector

to

idle

com

pensator

temperature

sensor

to

vacu

um

motor

I

Check

that

vacuum

hoses

are

se

curely

connected

in

correct

postion

2

Check

each

hose

for

cracks

or

distortion

hose

clip

for

condition

Note

Vacuum

hose

position

R

H

side

of

Nissan

mark

on

the

top

of

sensor

is

for

intake

manifold

L

U

side

of

the

mark

is

for

vacuum

motor

2

2

Vacuum

motor

I

With

engine

stopped

disconnect

fresh

air

duct

Place

a

mirror

at

the

end

of

air

cleaner

inlet

pipe

as

shown

and

check

to

see

if

air

con

trol

valve

is

in

correct

position

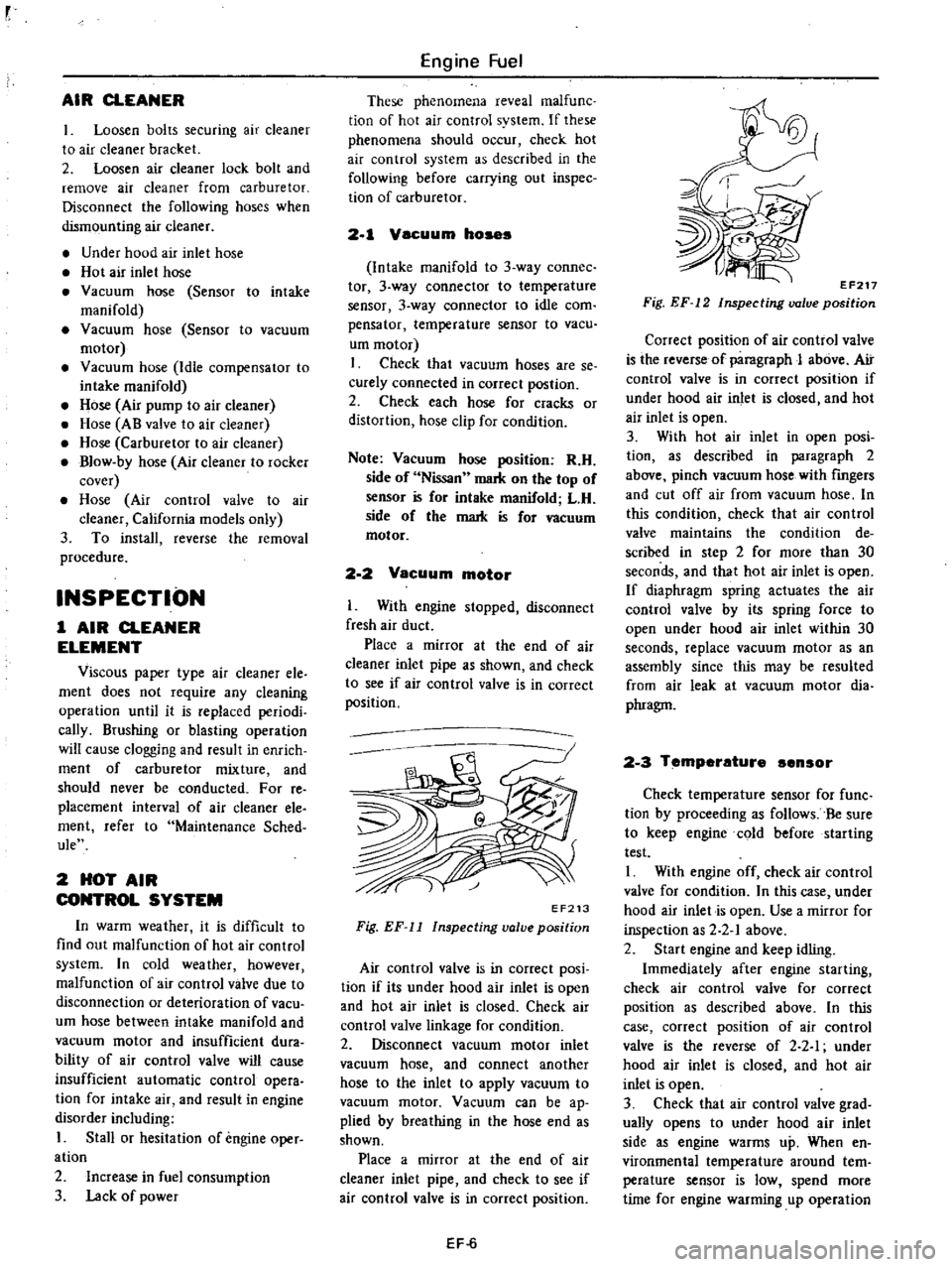

EF213

Fig

EF

11

Inspecting

valve

position

Air

control

valve

is

in

correct

posi

tion

if

its

under

hood

air

inlet

is

open

and

hot

air

inlet

is

closed

Check

air

control

valve

linkage

for

condition

2

Disconnect

vacuum

motor

inlet

vacuum

hose

and

connect

another

hose

to

the

inlet

to

apply

vacuum

to

vacuum

motor

Vacuum

can

be

ap

plied

by

breathing

in

the

hose

end

as

shown

Place

a

mirror

at

the

end

of

air

cleaner

inlet

pipe

and

check

to

see

if

air

control

valve

is

in

correct

position

EF

6

EF217

Fig

EF

12

Inspecting

valve

position

Correct

position

of

air

control

valve

is

the

reverse

of

paragraph

J

above

Air

control

valve

is

in

correct

position

if

under

hood

air

inlet

is

closed

and

hot

air

inlet

is

open

3

With

hot

air

inlet

in

open

posi

tion

as

described

in

paragraph

2

above

pinch

vacuum

hose

with

fingers

and

cut

off

air

from

vacuum

hose

In

this

condition

check

that

air

control

valve

maintains

the

condition

de

scribed

in

step

2

for

more

than

30

seconds

and

that

hot

air

inlet

is

open

If

diaphragm

spring

actuates

the

air

control

valve

by

its

spring

force

to

open

under

hood

air

inlet

within

30

seconds

replace

vacuum

motor

as

an

assembly

since

this

may

be

resulted

from

air

leak

at

vacuum

motor

dia

phragm

2

3

Temperature

ensor

Check

temperature

sensor

for

func

tion

by

proceeding

as

follows

Be

sure

to

keep

engine

cold

before

starting

test

I

With

engine

off

check

air

control

valve

for

condition

In

this

case

under

hood

air

inlet

is

open

Use

a

mirror

for

inspection

as

2

2

1

above

2

Start

engine

and

keep

idling

Immediately

after

engine

starting

check

air

control

valve

for

correct

position

as

described

above

In

this

case

correct

position

of

air

control

valve

is

the

reverse

of

2

2

I

under

hood

air

inlet

is

closed

and

hot

air

inlet

is

open

3

Check

that

air

control

valve

grad

ually

opens

to

under

hood

air

inlet

side

as

engine

warms

up

When

en

vironmental

temperature

around

tern

perature

sensor

is

low

spend

more

time

for

engine

warming

up

operation

Page 103 of 537

to

facilitate

smooth

operation

of

air

control

valve

If

the

above

test

reveals

any

prob

lem

in

the

operation

of

air

control

valve

carry

out

the

following

test

4

Remove

air

cleaner

cover

Set

temperature

sensing

element

of

ther

mistor

or

thermometer

to

a

position

where

temperature

around

sensor

can

be

measured

In

this

case

fIx

wiring

of

thermistor

or

thermometer

on

the

bottom

surface

of

air

cleaner

with

adhesive

tape

in

such

a

manner

that

the

set

position

of

temperature

sensing

DESCRIPTION

OPERATION

DESCRIPTION

The

idle

compensator

is

basically

a

thermostatic

valve

which

functions

to

introduce

the

air

directly

from

the

air

cleaner

to

the

intake

manifold

to

compensate

for

abnormal

enrichment

of

mixture

in

high

idle

temperature

The

bi

metal

attached

to

the

idle

compensator

detects

the

temperature

of

intake

air

and

opens

or

closes

the

valve

Two

idle

compensators

having

different

temperature

characteristics

are

installed

one

opens

at

an

intake

air

temperature

of

60

to

700C

140

to

l580F

and

the

other

at

70

to

900C

158

to

1940F

OPERATION

The

construction

of

the

idle

com

pensator

is

shown

in

the

following

Engine

Fuel

element

will

not

be

affected

by

air

flow

Then

install

air

cleaner

cover

Fig

EF

13

Checking

temperature

sensor

IDLE

COMPENSATOR

CONTENTS

5

Carry

out

test

as

described

in

steps

I

2

and

3

above

When

air

control

valve

begins

to

open

to

under

hood

air

inlet

side

several

minutes

after

engine

starting

read

the

indica

tion

of

thermistor

or

thermometer

If

reading

falls

within

the

working

tern

perature

range

of

temperature

sensor

the

sensor

is

normal

If

reading

ex

ceeds

the

range

replace

the

sensor

with

new

one

Note

Before

replacing

temperature

sensor

check

idle

compensator

as

described

in

Idle

compensator

EF

7

EF

7

REMOVAL

AND

INSTALLATION

INSPECTION

EF

B

EF

8

q

EF222

1

Orifice

2

Bi

metal

3

Rubber

valve

Fig

EF

14

Structure

of

idle

compensator

Bi

metal

Intake

air

temperature

No

1

Below

600C

1400F

60

to

70

C

140

to

l580F

Above

700C

158

OF

Below

700C

1580F

70

to

900C

158

to

1940F

Above

900C

1940F

No

2

EF

7

The

idle

compensator

operates

in

response

to

the

under

hood

air

temper

ature

as

shown

below

Idle

compensator

operation

Fully

closed

Close

to

open

Fully

open

Fully

closed

Close

to

open

Fully

open

Page 104 of 537

Engine

Fuel

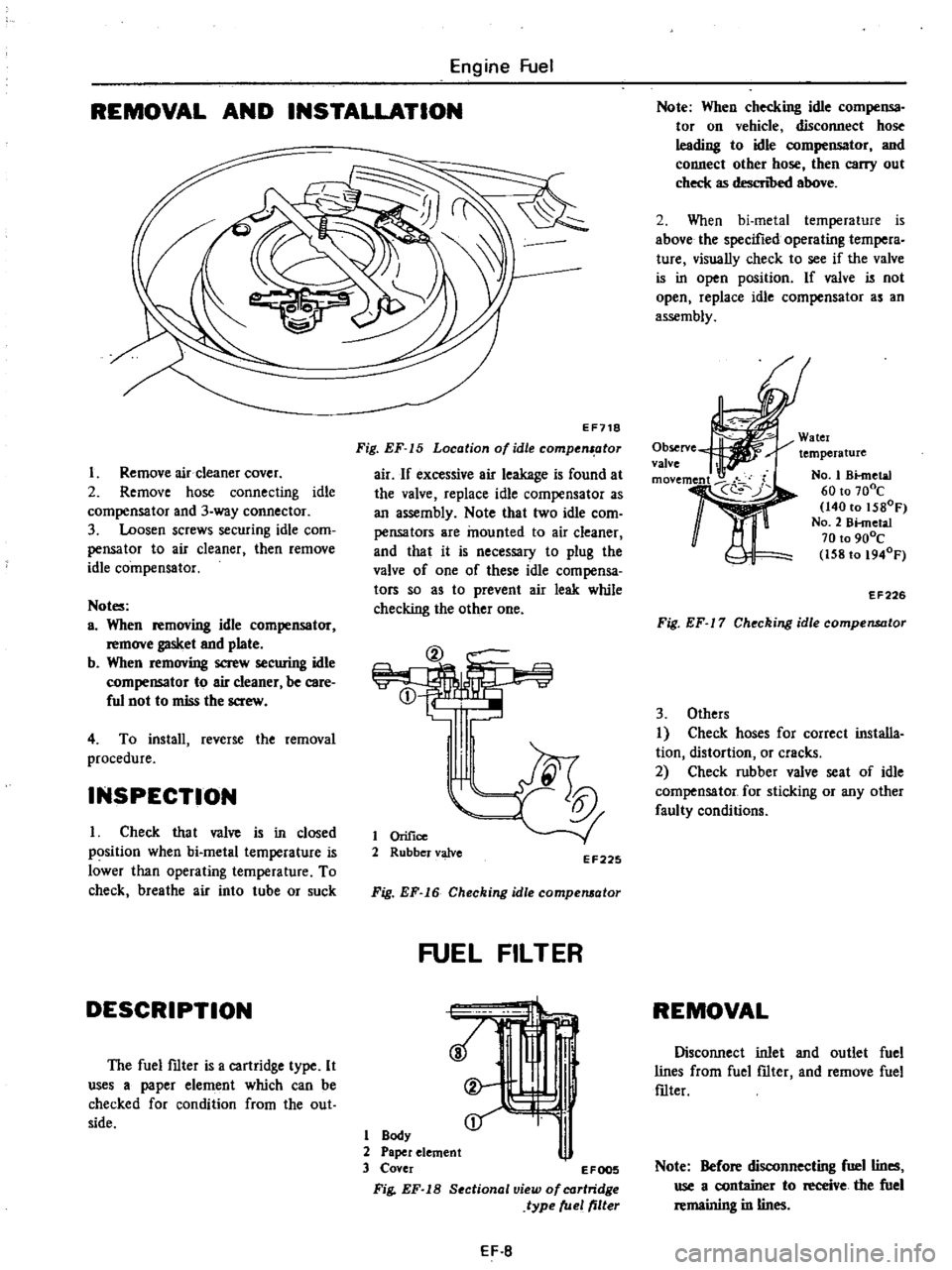

REMOVAL

AND

INSTALLATION

Remove

air

cleaner

cover

2

Remove

hose

connecting

idle

compensator

and

3

way

connector

3

Loosen

screws

securing

idle

com

pensator

to

air

cleaner

then

remove

idle

compensator

Notes

a

When

removing

idle

compensator

remove

gasket

and

plate

b

When

removing

screw

securing

idle

compensator

to

air

cleaner

be

care

ful

not

to

miss

the

saew

4

To

install

reverse

the

removal

procedure

INSPECTION

I

Check

tha

t

valve

IS

m

closed

position

when

bi

metal

temperature

is

lower

than

operating

temperature

To

check

breathe

air

into

tube

or

suck

DESCRIPTION

The

fuel

fJlter

is

a

cartridge

type

It

uses

a

paper

element

which

can

be

checked

for

condition

from

the

out

side

EF718

Fig

EF

15

Location

of

idle

compenl

otor

air

If

excessive

air

leakage

is

found

at

the

valve

replace

idle

compensator

as

an

assembly

Note

that

two

idle

com

pensators

are

mounted

to

air

cleaner

and

that

it

is

necessary

to

plug

the

valve

of

one

of

these

idle

compensa

tors

so

as

to

prevent

air

leak

while

checking

the

other

one

@

CD

I

tl

1

Orifice

2

Rubber

valve

EF225

Fig

EF

16

Checking

idle

compelll

lor

FUEL

FILTER

1

Body

2

Paper

element

3

Cover

1

EFOO5

Fig

EF

18

Sectional

view

of

cartridge

type

fuel

filter

EF

8

Note

When

checking

idle

compensa

tor

on

vehicle

disconnect

hose

leading

to

idle

compensator

and

connect

other

hose

then

carry

out

check

as

descn

bed

above

2

When

bi

metal

temperature

is

above

the

specified

operating

tempera

ture

visually

check

to

see

if

the

valve

is

in

open

position

If

valve

is

not

open

replace

idle

compensator

as

an

assembly

Watcr

temperature

Observe

valve

11t

No

1

Bknctal

60

to

70De

140

to

1580F

NO

2

Bi

metal

70

to

900C

158to

1940F

EF226

Fig

EF

17

Checking

idle

compensator

3

Others

I

Check

hoses

for

correct

installa

tion

distortion

or

cracks

2

Check

rubber

valve

seat

of

idle

compensator

for

sticking

or

any

other

faulty

conditions

REMOVAL

Disconnect

inlet

and

outlet

fuel

lines

from

fuel

fJlter

and

remove

fuel

fJlter

Note

Before

disconnecting

fuel

lines

use

a

container

to

receive

the

fuel

remaining

in

lines

Page 106 of 537

4

Run

the

engine

at

varying

speeds

5

The

pressure

gauge

indicates

static

fuel

pressure

in

the

line

The

gauge

reading

should

be

within

the

following

range

0

21

to

0

27

kg

em2

3

0

to

3

8

psi

Note

If

the

fuel

in

carburetor

float

chamber

has

run

out

and

engine

has

stopped

clip

and

pour

fuel

into

carburetor

Fasten

clip

secure

ly

and

repe

1

static

pressure

test

Pressure

below

the

lower

limit

indi

cates

extreme

wear

on

one

part

or

a

small

amount

of

wear

on

each

working

part

It

also

indicates

ruptured

dia

phragm

worn

warped

dirty

or

gum

ming

valves

and

seats

or

a

weak

diaphragm

return

spring

Pressure

above

the

upper

limit

indicates

an

excessively

strong

tension

of

dia

phragm

return

spring

or

a

diaphragm

that

is

too

tight

Both

of

these

condi

tions

require

the

removal

of

pump

assembly

for

replacement

or

repair

CAPACITY

TEST

The

capacity

test

is

made

only

when

static

pressure

is

within

the

specifications

To

make

this

test

pro

ceed

as

follows

1

Disconnect

pressure

gauge

from

T

connector

and

in

its

vacant

place

install

a

suitable

container

as

a

fuel

sump

2

Run

engine

at

1

000

rpm

3

The

pump

should

deliver

1

000

cc

2

11

US

pt

of

fuel

in

one

minute

or

less

If

little

or

no

fuel

flows

from

the

open

end

of

pipe

it

is

an

indication

that

fuel

line

is

clogged

or

pump

is

malfunctioning

REMOVAL

AND

DISASSEMBLY

Remove

fuel

pump

assembly

by

unscrewing

two

mounting

nuts

and

disassemble

in

the

following

order

1

Separate

upper

body

and

lower

body

by

unscrewing

body

set

screws

Engine

Fuel

2

Take

off

cap

and

cap

gasket

by

removing

cap

screws

3

Unscrew

elbow

and

connector

4

Take

off

valve

retainer

by

un

screwing

two

retainer

screws

and

re

move

two

valves

5

To

remove

diaphragm

press

down

its

center

against

spring

force

With

diaphragm

pressed

down

tilt

it

until

the

end

of

pull

rod

touches

the

inne

wall

of

body

Then

release

diaphragm

to

unhook

push

rod

Be

careful

during

this

operation

not

to

damage

diaphragm

or

oil

se

L

i

J

EFOO7

Fig

EF

20

Remouing

pull

rod

6

Drive

rocker

arm

pin

out

with

a

press

or

hammer

8

o

6

7

8

@

INSPECTION

I

Check

upper

body

and

lower

body

for

cracks

EF

10

I

fuel

pump

cap

2

Cap

gasket

3

Valve

packing

4

fuel

pump

val

e

assembly

S

Valve

retainer

6

Diaphragm

assembly

7

Diaphragm

spring

8

PuRro

9

Lower

body

seal

washer

10

Lower

body

seal

11

Inkl

connector

12

Outlet

connector

13

Rocker

arm

spring

14

Rocker

arm

I

S

Rocker

artyl

side

pin

16

Fuel

pump

packing

17

Spacer

fuel

pump

fo

cylinder

block

EF510

Fig

EF

21

Slruc

ure

of

fuel

pump

2

Check

valve

assembly

for

wear

on

valve

and

valve

spring

Blow

valve

assembly

with

brea

th

to

examine

its

function

Page 107 of 537

3

Check

diaphragm

for

small

holes

carcks

or

wear

4

Check

rocker

arm

for

wear

at

the

mating

portion

with

camshaft

5

Check

rocker

arm

pin

for

wear

A

worn

pin

may

cause

oil

leakage

6

Check

all

other

components

for

any

abnormalities

and

replace

if

neces

sary

DESCRIPTION

INSPECTION

REMOVAL

AND

INSTALLATION

DESCRIPTION

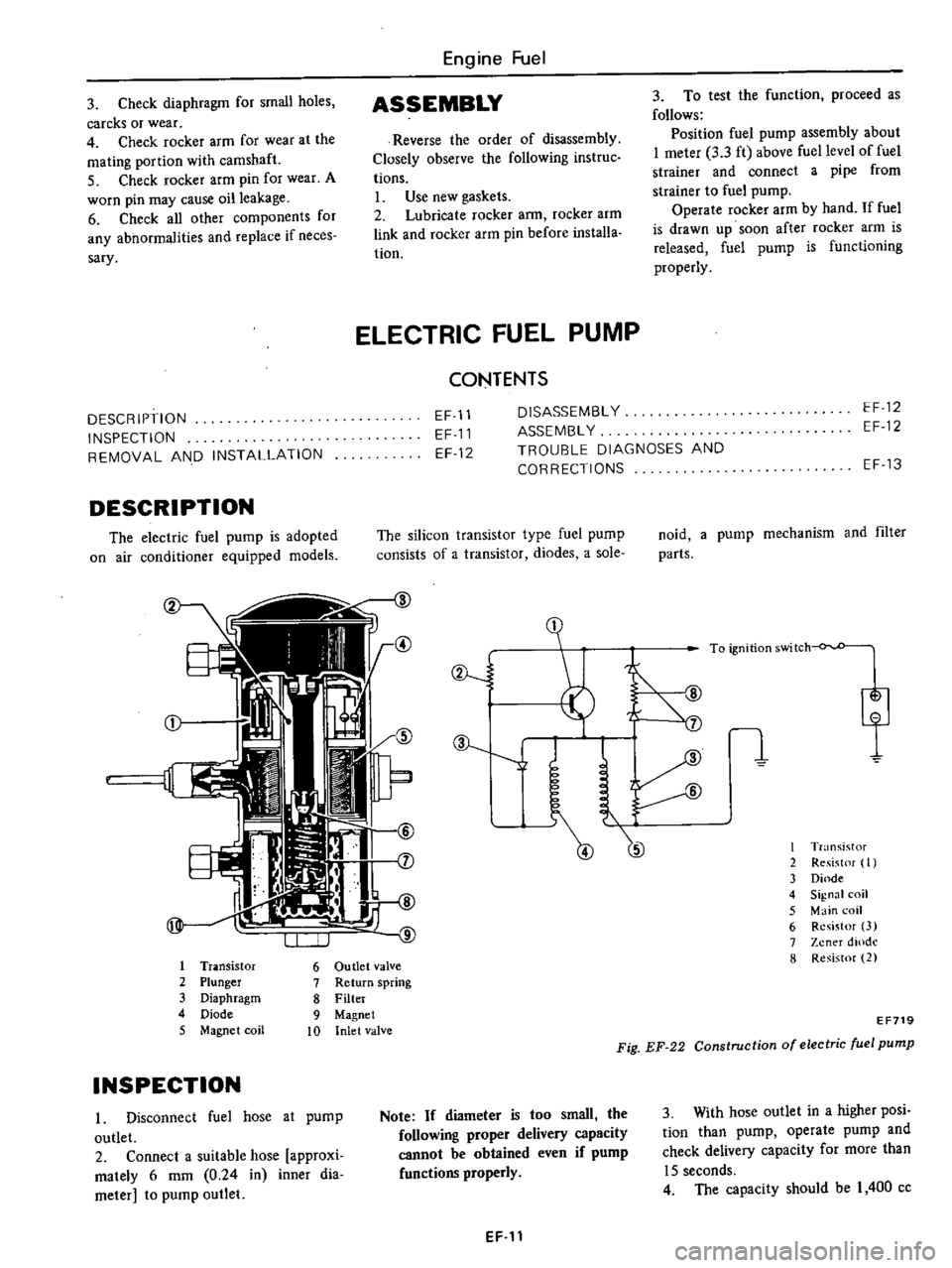

The

electric

fuel

pump

is

adopted

on

air

conditioner

equipped

models

Engine

Fuel

ASSEMBLY

Reverse

the

order

of

disassembly

Closely

observe

the

following

instruc

tions

L

Use

new

gaskets

2

Lubricate

rocker

ann

rocker

arm

link

and

rocker

arm

pin

before

installa

tion

3

To

test

the

function

proceed

as

follows

Position

fuel

pump

assembly

about

I

meter

3

3

ft

above

fuel

level

of

fuel

strainer

and

connect

a

pipe

from

strainer

to

fuel

pump

Operate

rocker

arm

by

hand

If

fuel

is

drawn

up

soon

after

rocker

arm

is

released

fuel

pump

is

functioning

properly

ELECTRIC

FUEL

PUMP

CONTENTS

EF

11

EF

11

EF

12

DISASSEMBL

Y

ASSEMBL

Y

TROUBLE

DIAGNOSES

AND

CORRECTIONS

EF

12

EF

12

The

silicon

transistor

type

fuel

pump

consists

of

a

transistor

diodes

a

sole

I

Tr

lOsistor

6

Ou

tIet

valve

2

Plunger

7

Return

spring

3

Diaphragm

8

Filter

4

Diode

9

Magnet

5

Magnet

coil

10

Inlet

valve

INSPECTION

I

Disconnect

fuel

hose

at

pump

outlet

2

Connect

a

suitable

hose

approxi

mately

6

mm

0

24

in

inner

dia

meter

to

pump

outlet

ev

J

J

Note

If

diameter

is

too

small

the

following

proper

delivery

capacity

cannot

be

obtained

even

if

pump

functions

properly

EF

11

EF

13

noid

a

pump

mechanism

and

filter

parts

I

T

nsistor

2

Re

ist

f

I

3

Dinde

4

Signal

coil

5

Main

coil

6

Resistor

3

7

Zener

dlOdl

8

Resistor

2

EF719

Fig

EF

22

Construction

of

electric

fuel

pump

3

With

hose

outlet

in

a

higher

posi

tion

than

pump

operate

pump

and

check

delivery

capacity

for

more

than

15

seconds

4

The

capacity

should

be

I

400

cc

Page 108 of 537

854

co

in

in

one

minute

or

less

If

no

gasoline

or

only

a

little

flows

from

open

end

of

pipe

with

pump

operated

or

if

pump

does

not

work

perform

the

following

diagnosis

Notes

3

Do

not

connect

battery

in

reverse

polarity

which

if

left

for

a

long

time

would

damage

transitor

circuit

and

disable

pump

Engine

Fuel

b

Do

not

let

fall

pump

as

it

may

damage

electronic

components

c

Do

not

apply

overvoitage

max

l

8Y

Overvoltage

starting

by

quick

charge

or

tage

running

would

deteriorate

or

damage

elec

tronic

components

Fuel

pressure

maximum

0

32

kg

cm

4

6

psi

REMOVAL

AND

INSTALLATION

Flom

fuel

tank

Electric

fuel

pump

is

installed

on

bracket

with

two

bolts

This

bracket

is

located

on

R

H

side

member

adjacent

to

fuel

tank

I

Remove

inlet

hose

from

fuel

pump

Also

remove

outlet

hose

run

ning

to

engine

Receive

fuel

remaining

in

fuel

hose

in

a

suitable

container

2

Disconnect

harness

at

connector

3

Remove

bolts

securing

fuel

pump

to

bracket

and

detach

fuel

pump

4

Installation

is

the

reverse

order

of

removal

9

@

1

Cover

2

Magnet

3

Cover

gasket

4

Filter

5

Gasket

6

Spring

retainer

7

Washer

8

O

ring

9

Inlet

valve

10

Retutn

PIing

11

Plunger

12

Plunger

cylinder

13

Body

To

carburetor

1

Elecuic

fuel

pump

2

Mounting

bracket

3

Fuel

mter

EF72D

Fig

EF

23

Electric

fuel

pump

DISASSEMBLY

Do

not

disassemble

unless

pump

is

faulty

I

Remove

cover

with

wrench

and

take

out

cover

gasket

magnet

and

filter

from

pump

body

2

When

removing

plunger

take

out

spring

retainer

from

plunger

tube

3

Then

take

out

washer

O

ring

inlet

valve

return

spring

and

plunger

from

tube

Note

Do

not

disassemble

electronic

components

If

n

replace

with

new

ones

6

EF721

Fig

EF

24

Exploded

view

of

electric

fuel

pump

EF

12

ASSEMBLY

I

Before

assembly

clean

all

parts

with

gasoline

and

compressed

air

com

pletely

Notes

a

If

gask

t

an

d

fdterare

faulty

r

place

b

Clean

magnet

and

cover

for

fault

c

Take

care

not

to

defonn

thin

tube

d

Assemble

plunger

return

spring

inlet

valve

O

ring

washer

and

set

spring

retainer

in

that

order

e

Assemble

filter

gasket

and

cover

with

f

Tighten

cover

with

wrench

to

the

stopper

If

component

parts

are

dirty

after

disassembly

clean

as

follows

Wash

fIlter

and

strainer

with

clean

gasoline

and

blow

with

compressed

air

When

cleaning

parts

check

fllter

for

fault

If

faulty

replace

Wash

plunger

plunger

cylinder

and

inlet

valve

with

clean

gasoline

and

blow

dust

off

with

compressed

air

2

Check

c

v

m

lI

parts

for

wear

or

damage

If

they

are

found

faulty

replace

them

3

Insert

plunger

assembly

into

plunger

cylinder

of

body

and

apply

electric

current

to

it

Move

the

assembly

up

and

down

If

the

assembly

does

not

move

it

shows

that

the

electric

uuit

is

faulty

and

it

must

be

replaced

Page 109 of 537

Engine

Fuel

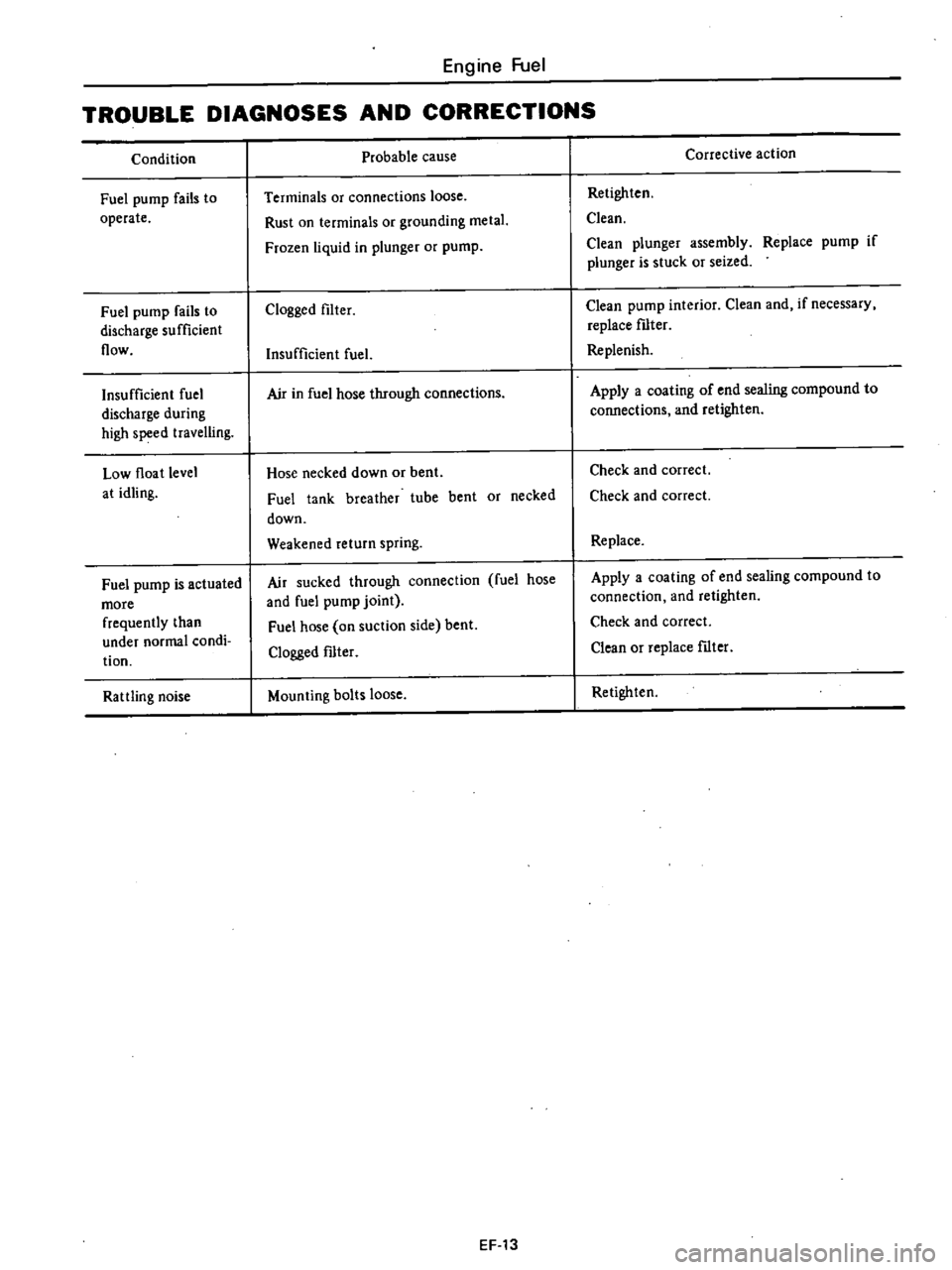

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Condition

Fuel

pump

fails

to

operate

Fuel

pump

fails

to

discharge

sufficient

flow

Insufficient

fuel

discharge

during

high

speed

travelling

Low

float

level

at

idling

Fuel

pump

is

actuated

more

frequently

than

under

normal

condi

tion

Rattling

noise

Probable

cause

Terminals

or

connections

loose

Rust

on

terminals

or

grounding

metal

Frozen

liquid

in

plunger

or

pump

Clogged

filter

Insufficient

fuel

Air

in

fuel

hose

through

connections

Hose

necked

down

or

bent

Fuel

tank

breather

tube

bent

or

necked

down

Weakened

return

spring

Air

sucked

through

connection

fuel

hose

and

fuel

pump

joint

Fuel

hose

on

suction

side

bent

Clogged

fIlter

Mounting

bolts

loose

EF

13

Corrective

action

Retighten

Clean

Clean

plunger

assembly

Replace

pump

if

plunger

is

stuck

or

seized

Clean

pump

interior

Clean

and

if

necessary

replace

fIlter

Replenish

Apply

a

coating

of

end

sealing

compound

to

connections

and

retighten

Check

and

correct

Check

and

correct

Replace

Apply

a

coating

of

end

sealing

compound

to

connection

and

retighten

Check

and

correct

Clean

or

replace

fIlter

Retighten