engine DATSUN PICK-UP 1977 Owner's Guide

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 38 of 537

r

Engine

Tune

up

A

T

C

air

cleaner

Operating

temperature

OC

OF

30

to

54

86

to

129

Tightening

torque

Cylinder

head

bolts

1st

turn

2nd

turn

3rd

turn

Spark

plugs

kg

m

ft

b

kg

lll

ft

lb

kg

m

ft

lb

kg

m

ft

lb

kg

m

ft

lb

kg

m

ft

lb

4

0

29

6

0

43

6

5

to

8

5

47

to

61

1

2

to

1

6

8

7

to

11

6

0

5

to

1

0

3

6

to

7

2

1

5

to

2

0

II

to

14

Manifold

nuts

Carburetor

nuts

ET

26

Page 39 of 537

Engine

Tune

up

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Condition

Probable

cause

CANNOT

CRANK

ENGINE

OR

SLOW

CRANKING

Improper

grade

oil

Discharged

battery

Faulty

battery

Loose

fan

belt

Malfunction

in

charge

system

Wiring

connection

loose

in

starting

circuit

Faulty

ignition

switch

Faulty

starler

motor

Trouble

shooting

procedure

on

starting

circuit

Switch

on

the

starting

motor

with

light

ON

When

light

goes

off

or

dims

considerably

a

Check

battery

b

Check

connection

and

cable

c

Check

starter

motor

When

light

stays

bright

Corrective

action

Replace

with

proper

grade

oiL

Charge

battery

Replace

Adjust

Inspect

Correct

Repair

or

replace

Repair

or

replace

a

Check

wiring

connection

between

battery

and

starter

motor

b

Check

ignition

switch

c

Check

starter

motor

ENGINE

WILL

CRANK

NORMALLY

BUT

WILL

NOT

START

In

this

case

the

following

trouble

causes

may

exist

but

in

many

cases

ignition

system

or

fuel

system

is

in

trouble

Ignition

system

in

trouble

Fuel

system

in

troubk

Valve

mechanism

does

not

work

properly

Low

compussion

Trouble

shooting

procedure

Check

spark

plug

firstly

by

following

procedure

Disconnect

high

tension

cable

from

one

spark

plug

and

hold

it

about

10

mm

0

39

in

from

the

engine

metal

part

and

crank

the

engine

Good

spark

occurs

Check

spark

plug

b

Check

ignition

timing

c

Check

fuel

system

d

Check

cylinder

compression

Check

the

current

f10

in

primary

circuit

Very

high

current

Inspect

primary

circuit

for

short

Check

breaker

poiIit

operation

except

tran

sistor

ignition

system

No

spark

occurs

ET

27

Page 40 of 537

Engine

Tune

up

Condition

Probable

cause

Low

or

no

current

Ign

tion

system

out

of

order

Burned

distributor

point

Improper

point

gap

Faulty

condenser

Leak

at

rotor

cap

and

rotor

Faulty

spark

plug

Improper

ignition

timing

Faulty

ignition

coil

Disconnection

of

high

tension

cable

Loose

connection

or

disconnection

in

primary

circuit

Fuel

system

out

of

order

Lack

offuel

Dirty

fuel

strainer

Dirty

or

clogged

fuel

pipe

Fuel

pump

will

not

work

properly

Carburetor

choke

will

not

work

properly

Improper

adjustment

of

float

level

Improper

idling

Dirty

or

clogged

carburetor

Clogged

breather

pip

of

fuel

tank

Malfunctioning

an

ti

dieseling

solenoid

valve

Incorrect

sparle

plug

tightening

or

faulty

gasket

Improper

grade

engine

oil

or

low

viscosity

Incorrect

valve

clearance

Compression

leak

from

valve

seat

Sticky

valve

stem

Weak

or

damaged

valve

springs

Compression

leak

at

cylinder

head

gasket

Sticking

or

damaged

piston

ring

Worn

piston

ring

or

cylinder

Trouble

ooting

procedure

Pour

the

engine

oil

from

plug

hole

and

then

measure

cylinder

compression

Compression

increases

Compression

does

not

change

Low

comp

ion

ET

28

Corrective

action

Check

for

loose

terminal

or

disconnection

in

primary

circuit

Check

for

burned

points

Repair

or

replace

Adjust

Replace

Clean

or

replace

aean

adjust

plug

gap

or

replace

Adjust

Replace

Replace

Repair

or

replace

Supply

Replace

Clean

Repair

or

replace

Check

and

adjust

Correct

Adjust

Disassemble

and

clean

Repair

and

clean

Check

for

loose

terminal

or

wire

harness

Tighten

to

normal

torque

or

replace

gasket

Replace

with

proper

grade

oil

Adjust

Remove

cyljnder

head

and

lap

valves

Correct

or

replace

valve

and

valve

guide

Replace

valve

springs

Replace

gasket

Replace

piston

rings

Overhaul

engine

Malfunctiong

cylinder

or

piston

ring

Compression

leaks

from

valve

cylinder

head

or

head

gasket

Except

transistor

ignition

system

Page 41 of 537

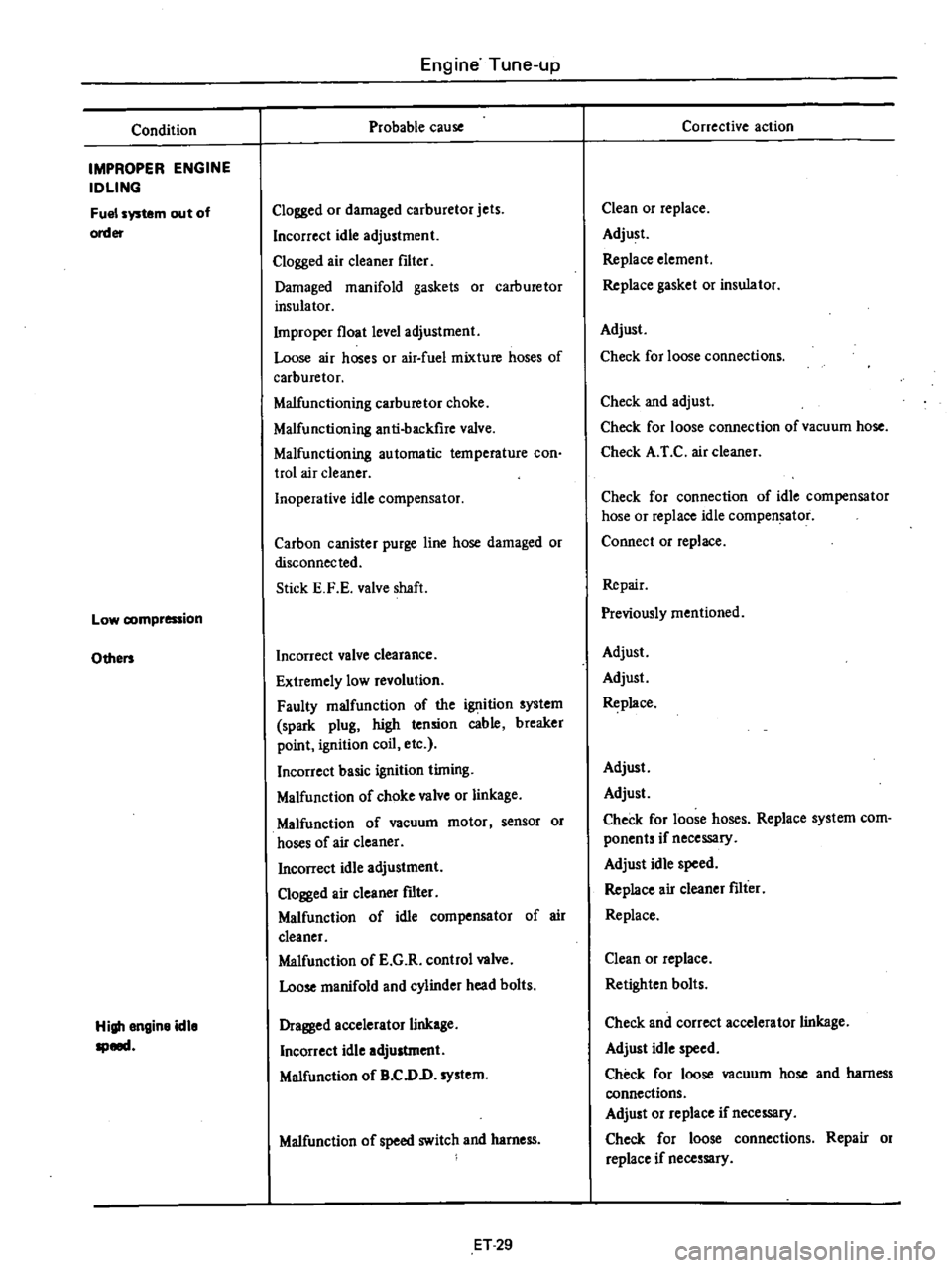

Condition

IMPROPER

ENGINE

IDLING

Fuel

system

out

of

order

Low

compression

Others

High

engine

idle

speed

Engine

Tune

up

Probable

cause

Clogged

or

damaged

carburetor

jets

Incorrect

idle

adjustment

Clogged

air

cleaner

filter

Damaged

manifold

gaskets

or

carburetor

insulator

Improper

float

level

adjustment

Loose

air

hoses

or

air

fuel

mixture

hoses

of

carburetor

Malfunctioning

carburetor

choke

Malfunctioning

anti

backfire

valve

Malfunctioning

automatic

temperature

con

trol

air

cleaner

Inoperative

idle

compensator

Carbon

canister

purge

line

hose

damaged

or

disconnected

Stick

E

F

E

valve

shaft

Incorrect

valve

clearance

Extremely

low

revolution

Faulty

malfunction

of

the

ignition

system

spark

plug

high

tension

cable

breaker

point

ignition

coil

etc

Incorrect

basic

ignition

timing

Malfunction

of

choke

valve

or

linkage

Malfunction

of

vacuum

motor

sensor

or

hoses

of

air

cleaner

Incorrect

idle

adjustment

Clogged

air

cleaner

fdter

Malfunction

of

idle

compensator

of

air

cleaner

Malfunction

of

E

G

R

control

valve

Loose

manifold

and

cylinder

head

bolts

Dragged

accelerator

linkage

Incorrect

idle

adjustment

Malfunction

of

B

CDD

system

Malfunction

of

speed

switch

and

harness

ET

29

Corrective

action

Clean

or

replace

Adjust

Replace

element

Replace

gasket

or

insulator

Adjust

Check

for

loose

connections

Check

and

adjust

Check

for

loose

connection

of

vacuum

hose

Check

A

r

C

air

cleaner

Check

for

connection

of

idle

compensator

hose

or

replace

idle

compen

tor

Connect

or

replace

Repair

Previously

mentioned

Adjust

Adjust

Replace

Adjust

Adjust

Check

for

loose

hoses

Replace

system

com

ponents

if

necessary

Adjust

idle

speed

Replace

air

cleaner

fdter

Replace

Clean

or

replace

Retighten

bolts

Check

and

correct

accelerator

linkage

Adjust

idle

speed

Check

for

loose

vacuum

hose

and

harness

connections

Adjust

or

replace

if

necessary

Check

for

loose

connections

Repair

or

replace

if

necessary

Page 42 of 537

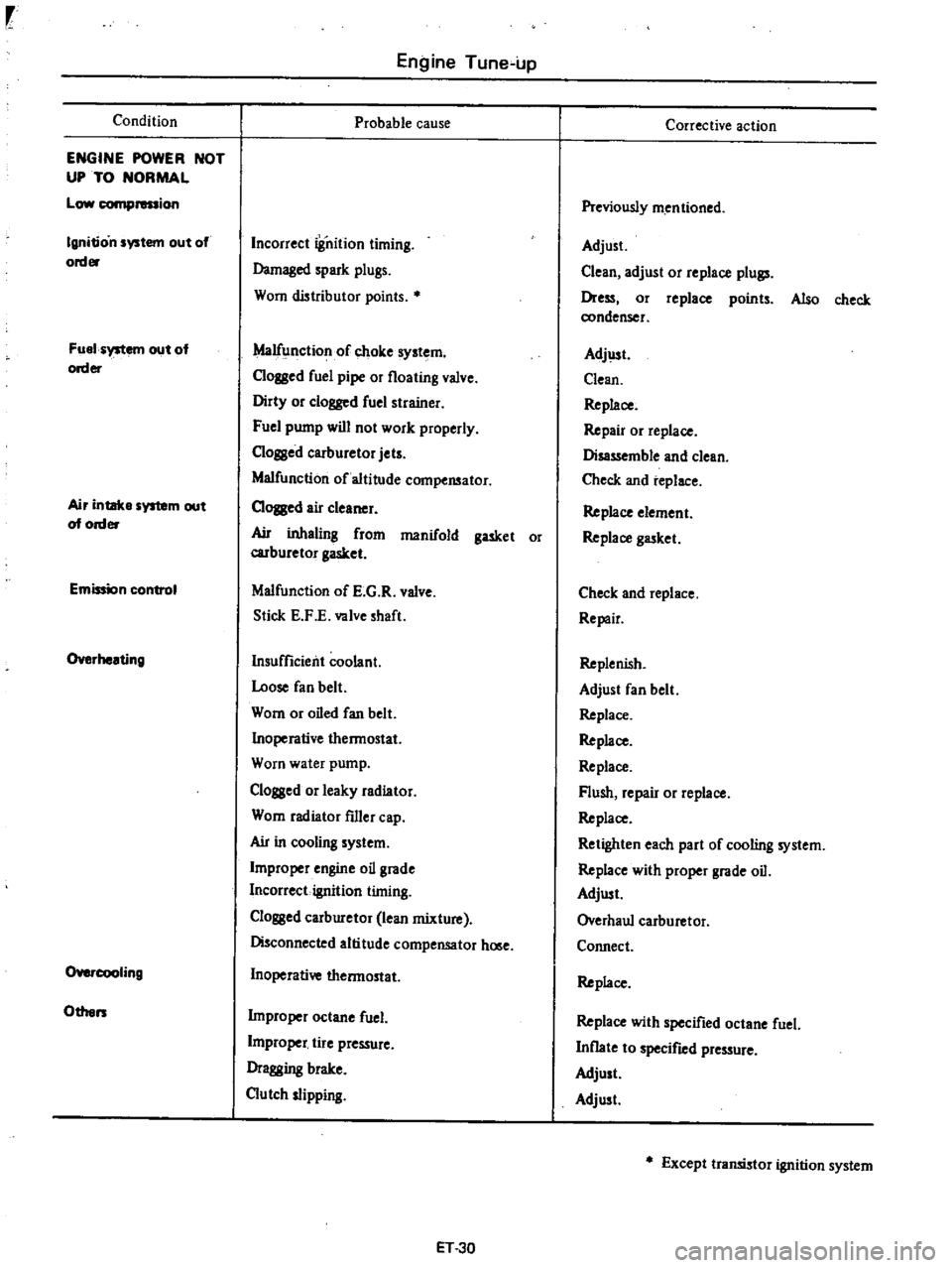

Condition

ENGINE

POWER

NOT

UP

TO

NORMAL

Low

compression

Ignition

system

out

of

order

Fuel

system

out

of

order

Air

intake

system

out

of

order

Emission

control

Overheating

O

cooIing

Others

Engine

Tune

up

Probable

cause

Incorrect

iSnition

timing

Damaged

spark

plugs

Worn

distributor

points

Malfunction

of

choke

system

Clogged

fuel

pipe

or

floating

valve

Dirty

or

clogged

fuel

strainer

Fuel

pump

will

not

work

properly

C10ssed

carburetor

jets

Malfunction

of

altitude

compensator

CIOJBed

air

cleaner

Ail

inhaling

from

manifold

gasket

or

carburetor

gasket

Malfunction

of

E

G

R

valve

Stick

E

F

E

valve

shaft

Insufficient

coolant

Loose

fan

belt

Worn

or

oiled

fan

belt

Inoperative

thermostat

Worn

water

pump

Clogged

or

leaky

radiator

Worn

radiator

filler

cap

Ail

in

cooling

system

Improper

engine

oil

grade

Incorrect

ignition

timing

Clossed

carburetor

lean

mixture

Disconnected

altitude

compensator

hOlle

Inoperative

thermostat

Improper

octane

fuel

L

j

tire

pressure

Dragging

brake

Clutch

slipping

ET

30

Corrective

action

Previously

mentioned

Adjust

Clean

adjust

or

replace

plull

Dress

or

replace

points

Also

check

condenser

Adj

lst

Clean

Replace

Repair

or

replace

Disassemble

and

clean

Check

and

replace

Replace

element

Replace

gasket

Check

and

replace

Repair

Replenish

Adjust

fan

belt

Replace

Replace

Replace

Flush

repair

or

replace

Replace

Retighten

each

part

of

cooling

system

Replace

with

proper

grade

oil

Adjust

Overhaul

carburetor

Connect

Replace

Replace

with

specified

octane

fuel

Inflate

to

specified

pressure

Adjust

Adjust

Except

transistor

ignition

system

Page 43 of 537

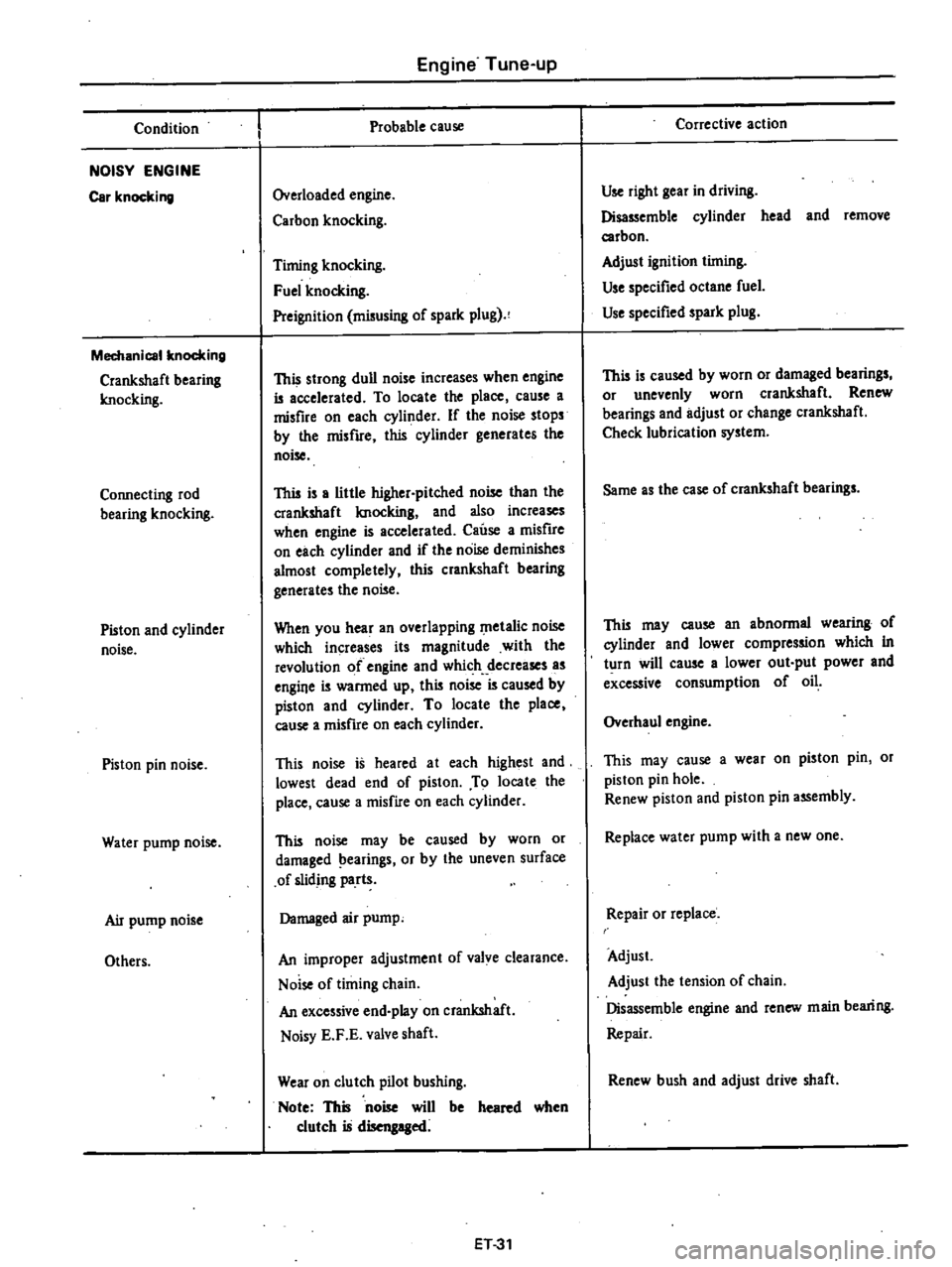

Condition

NOISY

ENGINE

Car

knocking

Mechanical

knocking

Crankshaft

bearing

Imocking

Connecting

rod

bearing

knocking

Piston

and

cylinder

noise

Piston

pin

noise

Water

pump

noise

Air

pump

noise

Others

Engine

Tune

up

Probable

cause

Overloaded

engine

Carbon

knocking

Timing

knocking

Fuel

knocking

Preignition

misusing

of

spark

plug

This

strong

dull

noise

increases

when

engine

is

accelerated

To

locate

the

place

cause

a

misfire

on

each

cylinder

If

the

noise

stops

by

the

misfire

this

cylinder

generates

the

noise

This

is

a

little

higher

pitched

noise

than

the

crankshaft

Imocking

and

also

increases

when

engine

is

accelerated

Cause

a

misfire

on

each

cylinder

and

if

the

noise

deminishes

almost

completely

this

crankshaft

bearing

generates

the

noise

When

you

hear

an

overlapping

metalic

noise

which

increases

its

magnitude

with

the

revolution

of

engine

and

which

decreases

as

engine

is

warmed

up

this

noise

is

caused

by

piston

and

cylinder

To

locate

the

place

cause

a

misfire

on

each

cylinder

This

noise

is

heared

at

each

highest

and

lowest

dead

end

of

piston

To

locate

the

place

cause

a

misfire

on

each

cylinder

This

noise

may

be

caused

by

worn

or

damaged

earings

or

by

the

uneven

surface

of

sliding

parts

Damaged

air

pump

An

improper

adjustment

of

valve

clearance

Noise

of

timing

chain

An

excessive

end

play

on

crankshaft

Noisy

E

F

E

valve

shaft

Wear

on

clutch

pilot

bushing

Note

This

noise

will

be

heared

when

clutch

is

disengaged

ET31

Corrective

action

Use

right

gear

in

driving

Disassemble

cylinder

head

and

remove

carbon

Adjust

ignition

timing

Use

specified

octane

fuel

Use

specified

spark

plug

This

is

caused

by

worn

or

damaged

bearings

or

unevenly

worn

crankshaft

Renew

bearings

and

adjust

or

change

crankshaft

Check

lubrication

system

Same

as

the

case

of

crankshaft

bearings

This

may

cause

an

abnormal

wearing

of

cylinder

and

lower

compression

which

in

turn

will

cause

a

lower

out

put

power

and

excessive

consumption

of

oil

Overhaul

engine

This

may

cause

a

wear

on

piston

pin

or

piston

pin

hole

Renew

piston

and

piston

pin

assembly

Replace

water

pump

with

a

new

one

Repair

or

replace

Adjust

Adjust

the

tension

of

chain

Disassemble

engine

and

renew

main

bearing

Repair

Renew

bush

and

adjust

drive

shaft

Page 44 of 537

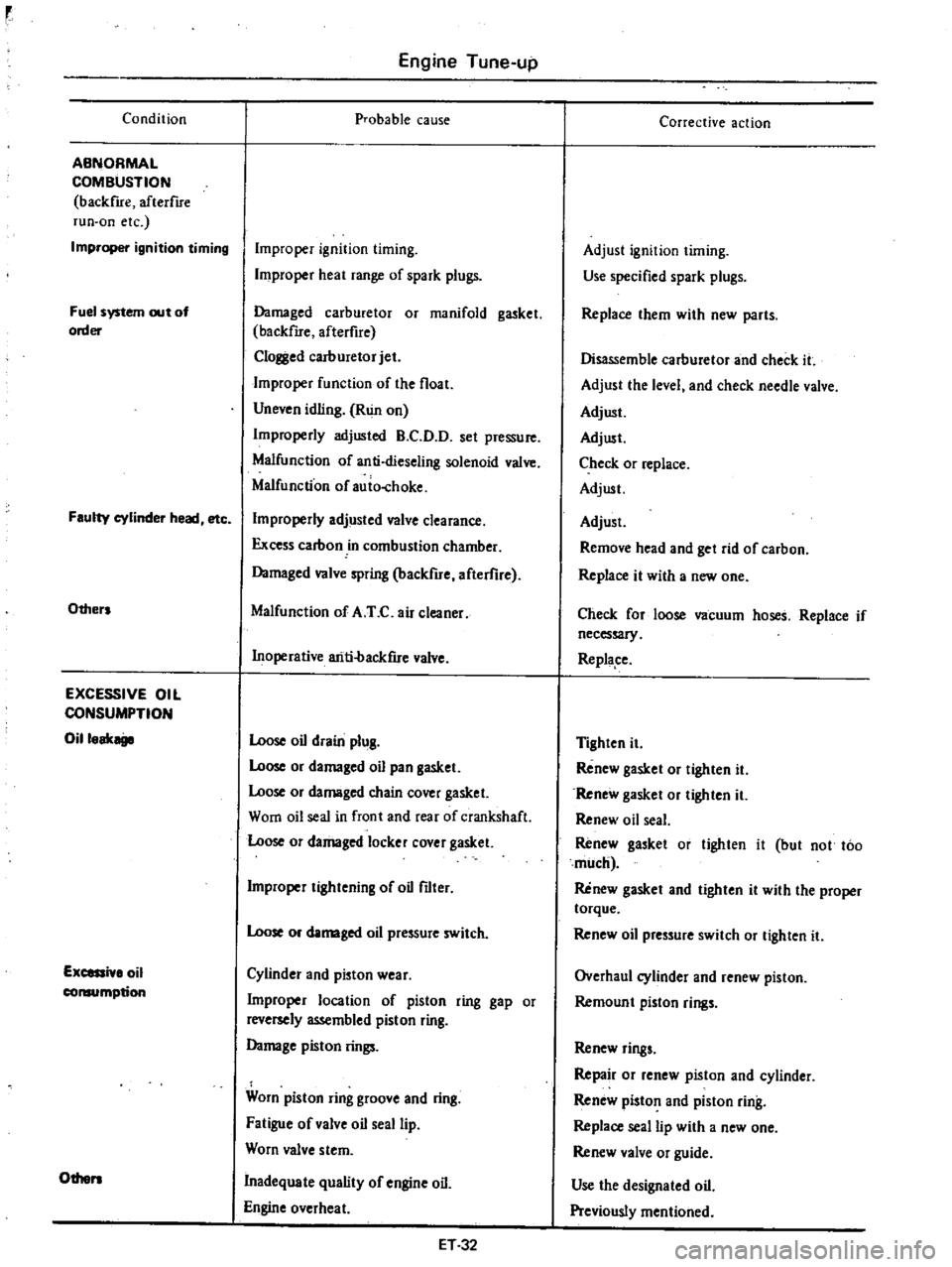

Condition

ABNORMAL

COMBUSTION

backfue

afterflre

run

on

etc

Improper

ignition

timing

Fuel

system

out

of

order

Faulty

cylinder

head

etc

Others

EXCESSIVE

OIL

CONSUMPTION

Oilloak

Excessi

lo

oil

consumption

Others

Engine

Tune

up

probable

cause

Improper

ignition

timing

Improper

heat

range

of

spark

plugs

Damaged

carburetor

or

manifold

gasket

backfue

afterfire

Clol

l

ed

carburetor

jet

Improper

function

of

the

float

Uneven

idling

Run

on

Improperly

adjusted

B

C

D

D

set

pressure

Malfunction

of

anti

dieseling

solenoid

valve

Malfunction

of

auio

choke

Improperly

adjusted

valve

clearance

Excess

carbon

in

combustion

chamber

Damaged

valve

spring

backfire

afterflre

Malfunction

of

A

T

C

air

cleaner

Inoperative

ariti

backfue

valve

Loose

oil

drain

plug

Loose

or

damaged

oil

pan

gasket

Loose

or

damaged

chain

cover

gasket

Worn

oil

seal

in

front

and

rear

of

crankshaft

Loose

or

damaged

locker

cover

gasket

Improper

tightening

of

oil

filter

Loose

or

damaged

oil

pressure

switch

Cylinder

and

pioton

wear

Improper

location

of

piston

ring

gap

or

reversely

assembled

piston

ring

Damage

piston

rings

Worn

piston

ring

groove

and

ring

Fatigue

of

valve

oil

seal

lip

Worn

valve

stem

Inadequate

quality

of

engine

oil

Engine

overheat

ET32

Corrective

action

Adjust

ignition

timing

Use

specified

spark

plugs

Replace

them

with

new

parts

Disassemble

carburetor

and

check

it

Adjust

the

level

and

check

needle

valve

Adjust

Adjust

Check

or

replace

Adjust

Adjust

Remove

head

and

get

rid

of

carbon

Replace

it

with

a

new

one

Check

for

loose

vacuum

hoses

Replace

if

necessary

Replape

Tighten

it

Renew

gasket

or

tighten

it

Renew

gasket

or

tighten

it

Renew

oil

seal

Renew

gasket

or

tighten

it

but

not

too

much

Renew

gasket

and

tighten

it

with

the

proper

torque

Renew

oil

pressure

switch

or

tighten

it

Overhaul

cylinder

and

renew

piston

Remoun

t

piston

rings

Renew

rings

Repair

or

renew

piston

and

cylinder

Renew

piston

and

piston

ring

Replace

seal

lip

with

a

new

one

Renew

valve

or

guide

Use

the

designated

oil

Previously

mentioned

Page 45 of 537

Condition

POOR

FUEL

ECONOMY

Se

the

xplanation

of

the

pow

r

dec

Oth

n

PROBLEM

IN

OTHER

FUNCTIONS

D

cr

d

oil

p

ssure

Excessive

wear

on

the

sliding

parts

Scuffing

of

sliding

parts

Floor

temperature

too

high

California

only

Engine

Tune

up

Probable

cause

Exceeding

idling

revolution

Inoperative

acceleration

recovery

Fuel

leakage

Malfunction

of

B

C

D

D

Malfunction

of

A

r

C

air

cleaner

Inadequate

oil

quality

Overheat

Worn

oil

pump

regulator

valve

Functional

deterioration

of

oil

pump

Blocked

oil

f1lter

Increased

clearance

in

various

sliding

parts

Blocked

oil

strainer

Inoperative

oil

gauge

pressure

switch

Oil

pressure

decreases

Improper

quality

or

contamination

of

oil

Damaged

air

cleaner

Overheat

or

overcoal

Improper

fuel

mixture

Decrease

of

oil

pressure

Insufficient

clearances

Overhea

t

Improper

fuel

mixture

Problem

in

fuel

system

Refer

to

Inspec

tion

of

Fuel

System

Problem

in

ignition

system

Refer

to

In

spection

of

Ignition

System

ET33

Corrective

action

Adjust

it

to

the

designated

rpm

Adjust

it

Repair

or

tighten

the

connection

of

fuel

pipes

Adjust

Check

and

replace

Use

the

designated

oil

Previously

mentioned

Disassemble

oil

pump

and

repair

or

renew

it

Repair

or

replace

it

with

a

new

one

Renew

it

Disassemble

and

replace

the

worn

parts

with

new

ones

Oeanit

Replace

it

with

a

new

one

Previousiy

mentioned

Exchange

the

oil

with

proper

one

and

change

element

Change

elemen

t

Previously

mentioned

Check

the

fuel

system

Previously

mentioned

Readjust

to

the

designated

clearances

Previously

mentioned

Check

the

fuel

system

Check

and

repair

Check

and

repair

Page 46 of 537

DATSUN

PICK

UP

MODEL

620

SERIES

lMlSSAN

I

oJ

NISSAN

MOTOR

CO

LTD

TOKYO

JAPAN

SECTION

EM

ENGINE

MECHANICAL

GENERAL

DESCRIPTION

ENGINE

DISASSEMBLY

INSPECTION

AND

REPAIR

ENGINE

ASSEMBLY

SERVICE

DATA

AND

SPECIFICATIONS

TROUBLE

DIAGNOSES

AND

CORRECTIONS

SPECIAL

SERVICE

TOOLS

EM

2

EM

4

EM

8

EM

21

EM

2l

EM

31

EM

33

Page 47 of 537

Engine

Mechanical

GENERAL

DESCRIPTION

MODEL

L20B

ENGINE

CYLINDER

BLOCK

CRANKSHAFT

PISTON

AND

CONNECTING

ROD

CYLINDER

HEAD

CONTENTS

EM

2

EM

3

EM

3

EM

3

EM

3

CAMSHAFT

VALVE

MECHANISM

CAMSHAFT

DRIVE

MANIFOLDS

out

smooth

dependable

power

The

cylinder

block

is

cast

as

a

single

unit

and

featllres

deep

skirting

This

engine

is

equipped

with

a

single

2

barrel

downdraft

carburetor

that

in

corporates

a

special

device

to

control

emissions

MODEL

L20B

ENGINE

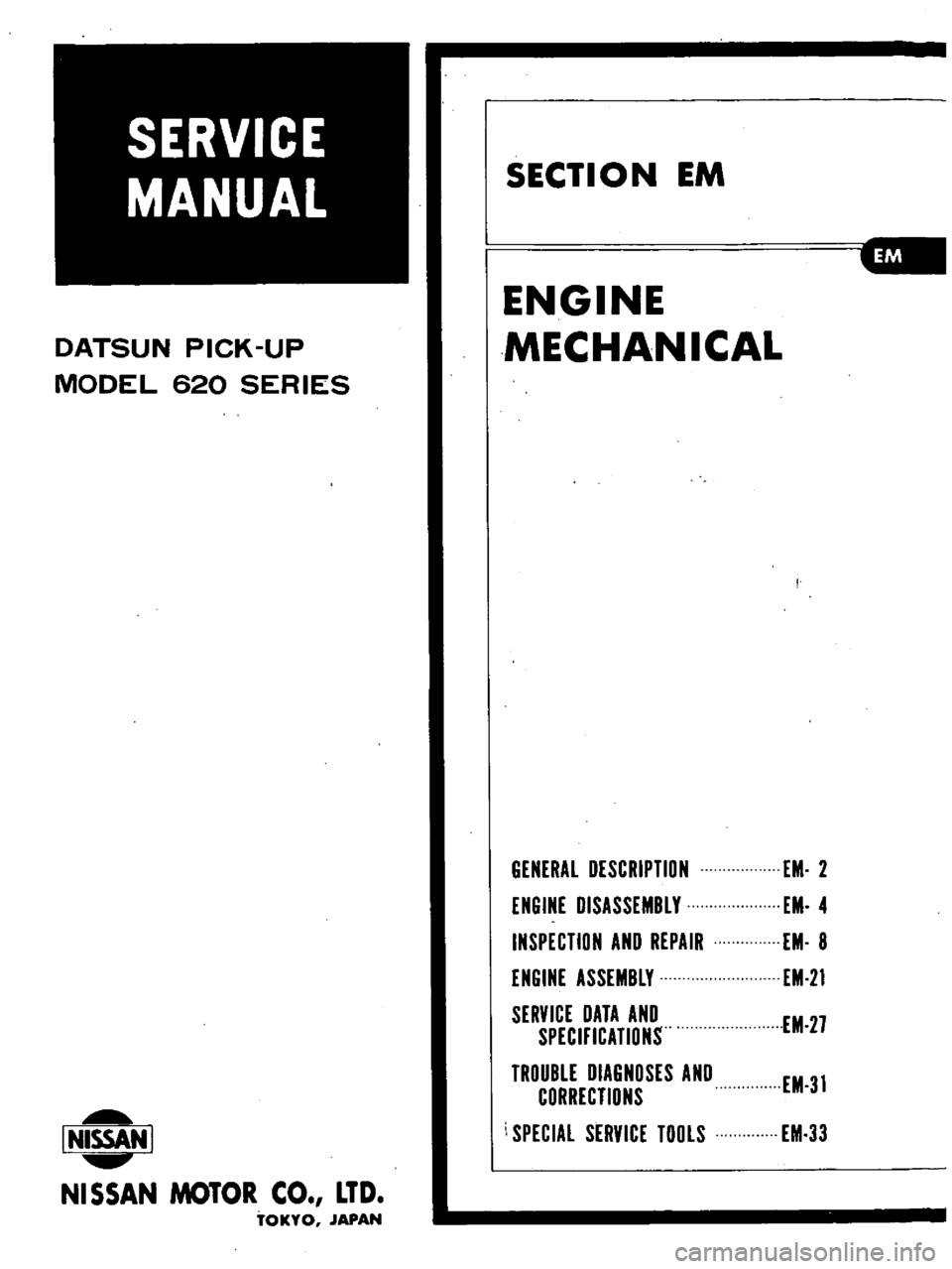

The

L20B

engine

features

O

H

C

valves

wedge

shaped

combustion

chamber

aluminum

head

and

a

fully

balanced

5

bearing

crankshaft

to

turn

Main

specifications

Oisplacemen

t

cc

cu

in

Bore

x

stroke

mm

in

Compression

ratio

Ignition

timing

Degree

B

T

O

C

rpm

MIT

AlT

MIT

Manual

Transmission

EM535

Fig

EM

Cross

sectional

view

L20B

1

952

1191

85

X

86

3

35

x

3

39

8

5

12

750

Non

California

model

10

750

California

model

12

650

in

0

position

AIT

Automatic

Transmission

EM

2

EM

3

EM

3

EM

3

EM

3

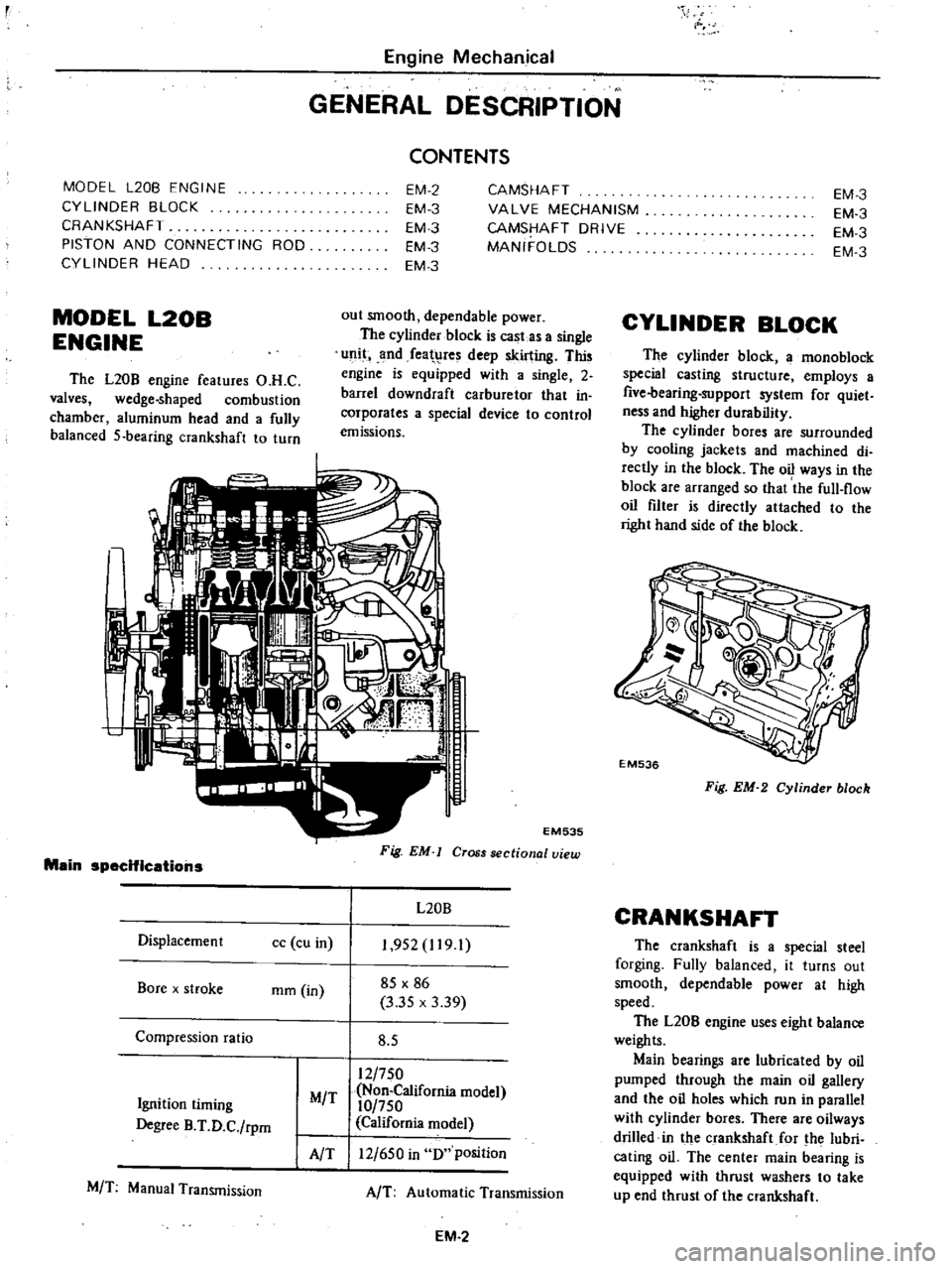

CYLINDER

BLOCK

The

cylinder

block

a

mono

block

special

casting

structure

employs

a

five

bearing

support

system

for

quiet

ness

and

higher

durability

The

cylinder

bores

are

surrounded

by

cooling

jackets

and

machined

di

rectly

in

the

block

The

oil

ways

in

the

block

are

arranged

so

that

the

full

flow

oil

filter

is

directly

attached

to

the

right

hand

side

of

the

block

EM536

Fig

EM

2

Cylinder

block

CRANKSHAFT

The

crankshaft

is

a

special

steel

forging

Fully

balanced

it

turns

out

smooth

dependable

power

at

high

speed

The

L20B

engine

uses

eight

balance

weights

Main

bearings

are

lubricated

by

oil

pumped

through

the

main

oil

gallery

and

the

oil

holes

which

run

in

parallel

with

cylinder

bores

There

are

oilways

drilled

in

the

crankshaft

for

the

lubri

cating

oil

The

center

main

bearing

is

equipped

with

thrust

washers

to

take

up

end

thrust

of

the

crankshaft