engine DATSUN PICK-UP 1977 Manual PDF

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 80 of 537

Engine

Mechanical

SPECIAL

SERVICE

TOOL

No

Tool

number

tool

name

Description

Unit

mm

in

Engine

stand

assembly

This

engine

stand

assembly

is

used

for

disassembling

or

assembling

engine

block

or

differential

carrier

throughout

3600

in

all

directions

ST050lS000

ST050

11000

Engine

stand

ST050

12000

Base

For

use

on

Reference

page

or

Figure

No

All

Fig

EM

II

models

SE184

2

ST0526oo0l

This

engine

attachment

is

installed

to

engine

stand

Ll6

Fig

EM

II

ST0501S000

in

disassembling

or

assembling

engine

Ll8

Engine

attachment

L20B

Q

li

SE185

3

STl

0120000

Special

hollow

set

bolts

are

used

in

tightening

cylinder

heads

All

Fig

EM

18

in

L

series

engines

This

wrench

is

used

to

torque

cylinder

L

series

Cylinder

head

bolt

head

bolts

and

its

head

can

be

inserted

into

the

torque

1

rench

wrench

10

0

39

SE186

4

STl

064000

I

This

tool

is

used

togetller

with

a

torque

wrench

in

tightening

pivot

lock

nut

for

valve

clearance

adjustment

Pivot

adjuster

SE187

EM

33

All

Fig

EM

105

L

series

Page 81 of 537

Engine

Mechanical

Tool

number

For

Referenl

t

No

Description

use

page

or

tool

name

Unit

mm

in

on

Figure

No

S

KV10

1039S0

Valve

guide

reamer

This

guide

is

used

for

All

Fig

EM

44

set

o

Pressing

used

guide

out

of

place

L

series

0

Driving

a

new

guide

into

place

and

STIlO81000

0

Finishing

the

bore

of

new

guide

A

series

Reamer

12

2

mm

dia

STlI

032000

Reamer

8

0

mm

dia

STl1320000

Drift

V

SE192

6

STll6S0001

Valve

seat

cutter

set

This

valve

seat

cutter

set

is

used

to

or

refinish

a

valve

seat

All

Fig

EM

4S

L

series

7

STl2070000

Valve

lifter

SE193

This

t

ol

is

used

to

compress

valve

spring

by

the

combined

action

of

its

eam

and

lever

thereby

facilitating

the

removal

or

installation

of

valve

collet

for

general

use

All

models

Fig

EM

32

Fig

EM

8l

SE194

EM

34

Page 82 of 537

Engine

Mechanical

Tool

number

For

Reference

No

Description

use

page

or

tool

name

Unit

mm

in

on

Figure

No

8

ST13030001

This

tool

is

used

with

a

press

to

drive

pin

into

or

out

of

All

Fig

EM

29

connecting

rod

L

series

Fig

EM

84

Piston

pin

press

stand

1

20

0

79

I

8

M

e

120

4

722

0

SE1BS

9

ST153

10000

This

tool

is

used

to

push

a

lip

type

rear

oil

seal

for

L

series

All

Fig

EM

9l

Crankshaft

rear

oil

engine

into

place

by

giving

hammer

blows

L

series

seal

drift

SE189

10

KVI01041S0

This

tool

is

used

to

remove

the

cap

from

main

bearing

All

Fig

EM

25

When

using

thds

tool

turn

its

adapter

into

the

threaded

hole

L

series

Crankshaft

main

in

main

bearing

cap

bearing

cap

puller

KVI0104110

Body

250

9

8

ST165

12001

l

Adapter

se1g0

II

ST166

10001

This

tool

is

used

to

pull

pilot

bushing

out

of

place

All

Fig

EM

66

Pilot

bushing

puller

L

series

SE191

EM

35

Page 83 of 537

r

Engine

Mechanical

Tool

number

For

Reference

No

Description

use

page

or

tool

name

Unit

mm

in

on

Figure

No

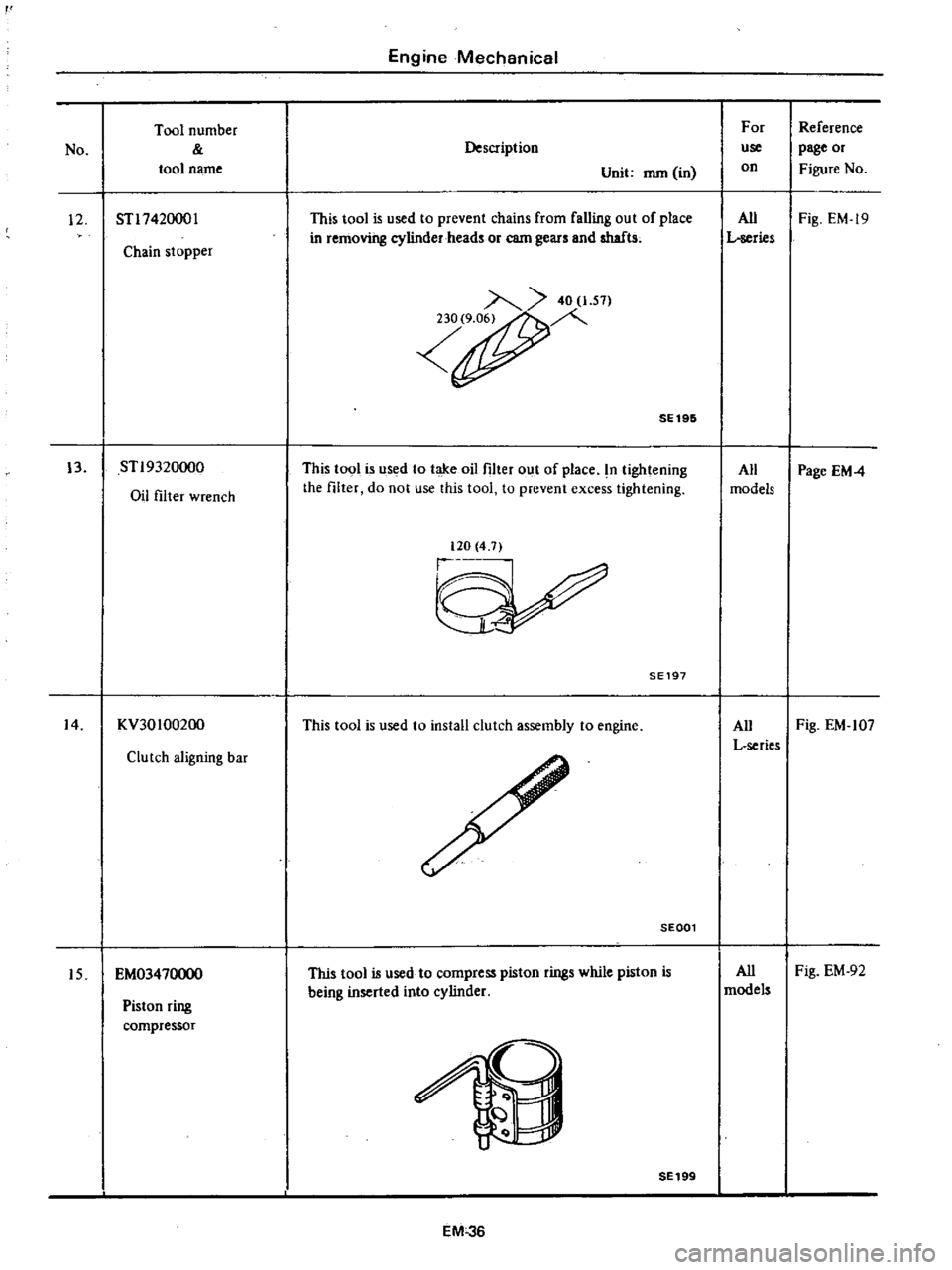

12

STl742000l

This

tool

is

used

to

prevent

chains

from

falling

out

of

place

All

Fig

EM

19

in

removing

cylinder

heads

or

earn

gears

and

shafts

L

series

Chain

stopper

40

1

S1

r

SE196

13

STl9320oo0

This

tool

is

used

to

take

oil

filter

out

of

place

n

tightening

All

Page

EM4

Oil

filter

wrench

the

filter

do

not

use

this

tool

to

prevent

excess

tightening

models

120

4

7

SE197

14

KV30100200

This

tool

is

used

to

install

clutch

assembly

to

engine

All

Fig

EM

107

L

series

Clutch

aligning

bar

SEGOl

Piston

ring

compressor

This

tool

is

used

to

compress

piston

rings

while

piston

is

being

inserted

into

cylinder

All

Fig

EM

92

models

15

EM03470000

2

SE199

EM

36

Page 84 of 537

DATSUN

PICK

UP

MODEL

620

SERIES

I

NISSAN

J

NISSAN

MOTOR

CO

LTD

TOKYO

JAPAN

SECTION

EL

ENGINE

LUBRICATION

SYSTEM

ENGINE

LUBRICATION

SYSTEM

EL

2

SERVICE

DATA

AND

EL

5

SPECIFICATIONS

TROUBLE

DIAGNOSES

AND

EL

5

CORRECTIONS

SPECIAL

SERVICE

TOOLS

EL

6

Page 85 of 537

ENGINE

LUBRICATION

SYSTEM

ENGINE

LUBRICATION

SYSTEM

CONTENTS

LUBRICATION

CIRCUIT

01

L

PUMP

Removal

Installation

Disassembly

and

assembly

EL

2

EL

2

EL

2

EL

2

EL

3

Inspection

OIL

PRESSURE

REGULATOR

VALVE

OIL

FILTER

RELIEF

VALVE

EL

3

EL

4

EL

4

EL

4

E

L049

Fig

Elr

I

Lubricating

circuit

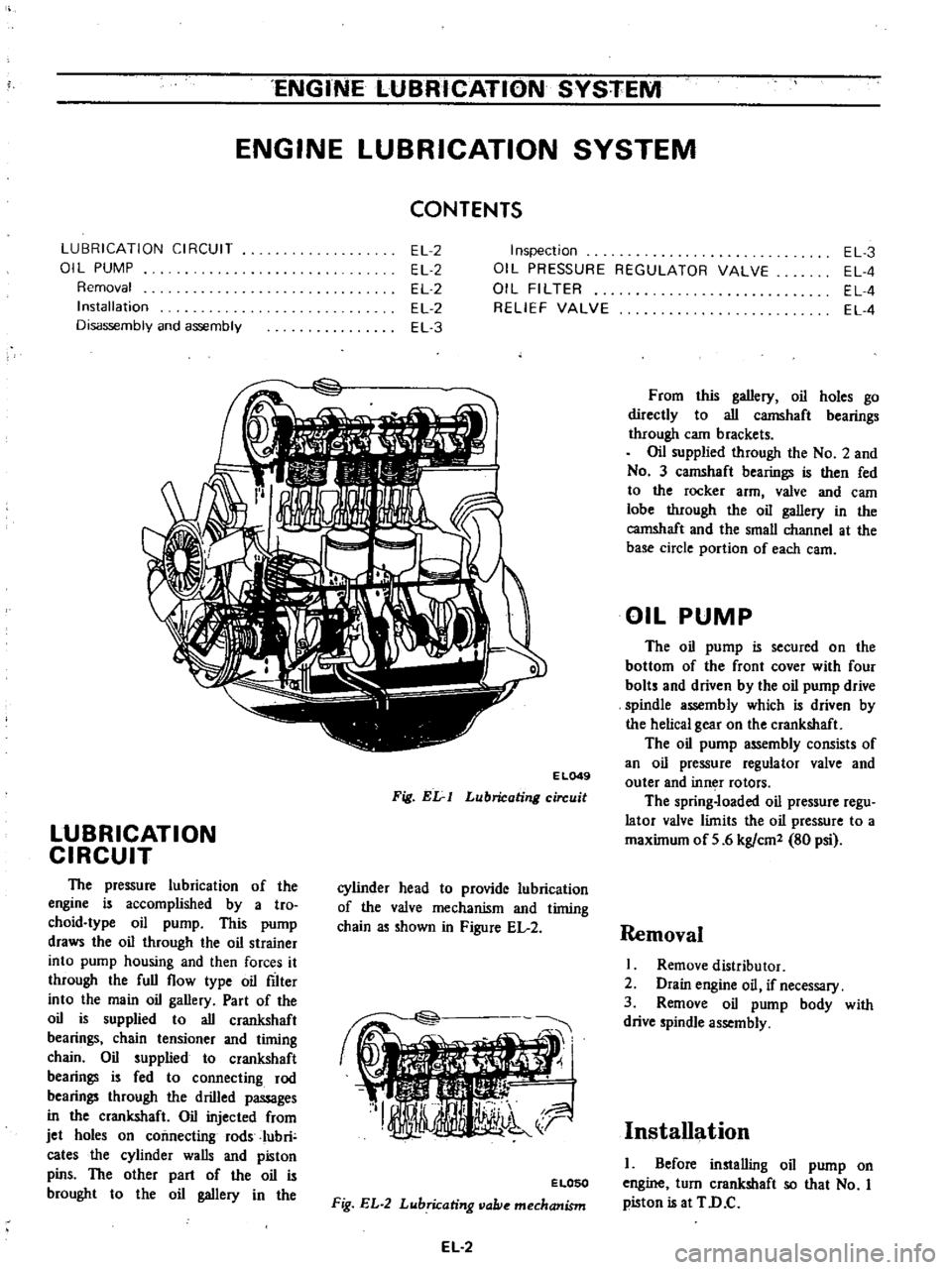

LUBRICATION

CIRCUIT

The

pressure

lubrication

of

the

engine

is

accomplished

by

a

tro

choid

type

oil

pump

This

pump

draws

the

oil

through

the

oil

strainer

into

pump

housing

and

then

forces

it

through

the

full

flow

type

oil

filter

into

the

main

oil

gallery

Part

of

the

oil

is

supplied

to

all

crankshaft

bearings

chain

tensioner

and

timing

chain

Oil

supplied

to

crankshaft

bearings

is

fed

to

connecting

rod

bearings

through

the

drilled

passages

in

the

crankshaft

Oil

injected

from

jet

holes

on

connecting

rods

Iubri

cates

the

cylinder

walls

and

piston

pins

The

other

part

of

the

oil

is

brought

to

the

oil

gallery

in

the

cylinder

head

to

provide

lubrication

of

the

valve

mechanism

and

timing

chain

as

shown

in

Figure

EL

2

ELOSO

Fig

EL

2

Lubricating

vallie

mechanism

EL

2

From

this

gallery

oil

holes

go

directly

to

all

camshaft

bearings

through

cam

brackets

Oil

supplied

through

the

No

2

and

No

3

camshaft

bearings

is

then

fed

to

the

rocker

arm

valve

and

eam

lobe

through

the

oil

gallery

in

the

camshaft

and

the

small

channel

at

the

base

circle

portion

of

each

earn

OIL

PUMP

The

oil

pump

is

secured

on

the

bottom

of

the

front

cover

with

four

bolts

and

driven

by

the

oil

pump

drive

spindle

assembly

which

is

driven

by

the

helical

gear

on

the

crankshaft

The

oil

pump

assembly

consists

of

an

oil

pressure

regulator

valve

and

outer

and

inn

r

rotors

The

spring

loaded

oil

pressure

regu

lator

valve

limits

the

oil

pressure

to

a

maximum

of

5

6

kg

em

80

psi

Removal

I

Remove

distributor

2

Drain

engine

oil

if

necessary

3

Remove

oil

pump

body

with

drive

spindle

assembly

Installation

I

Before

installing

oil

pump

on

engine

turn

crankshaft

so

that

No

I

piston

is

at

TD

C

Page 86 of 537

ENGINE

LUBRICATION

SYSTEM

2

Fill

pump

housing

with

engine

oil

then

align

punch

mark

of

spindle

with

hole

in

oil

pump

as

shown

in

Figure

EL

3

Punch

mark

EL009

Fig

EL

3

Aligning

punch

mark

and

oil

hole

3

Using

a

new

gasket

install

oil

pump

and

drive

spindle

assembly

so

that

the

projection

on

its

top

is

located

in

II

25

a

m

position

at

this

time

the

smaller

bow

shape

will

be

placed

toward

the

front

as

shown

in

Figure

EL

4

JI

I

c

J

V

Front

J

@

9@

tr

i

d

L

It

I

I

EL010

Fig

EL

4

Setting

drive

pindle

o

EL011

Fig

EL

5

Imtalling

oil

pump

Ascertain

whether

or

not

the

en

gagement

is

in

order

by

checking

the

top

of

spindle

through

distributor

fit

ting

hole

4

Tighten

bolts

securing

oil

pump

to

front

cover

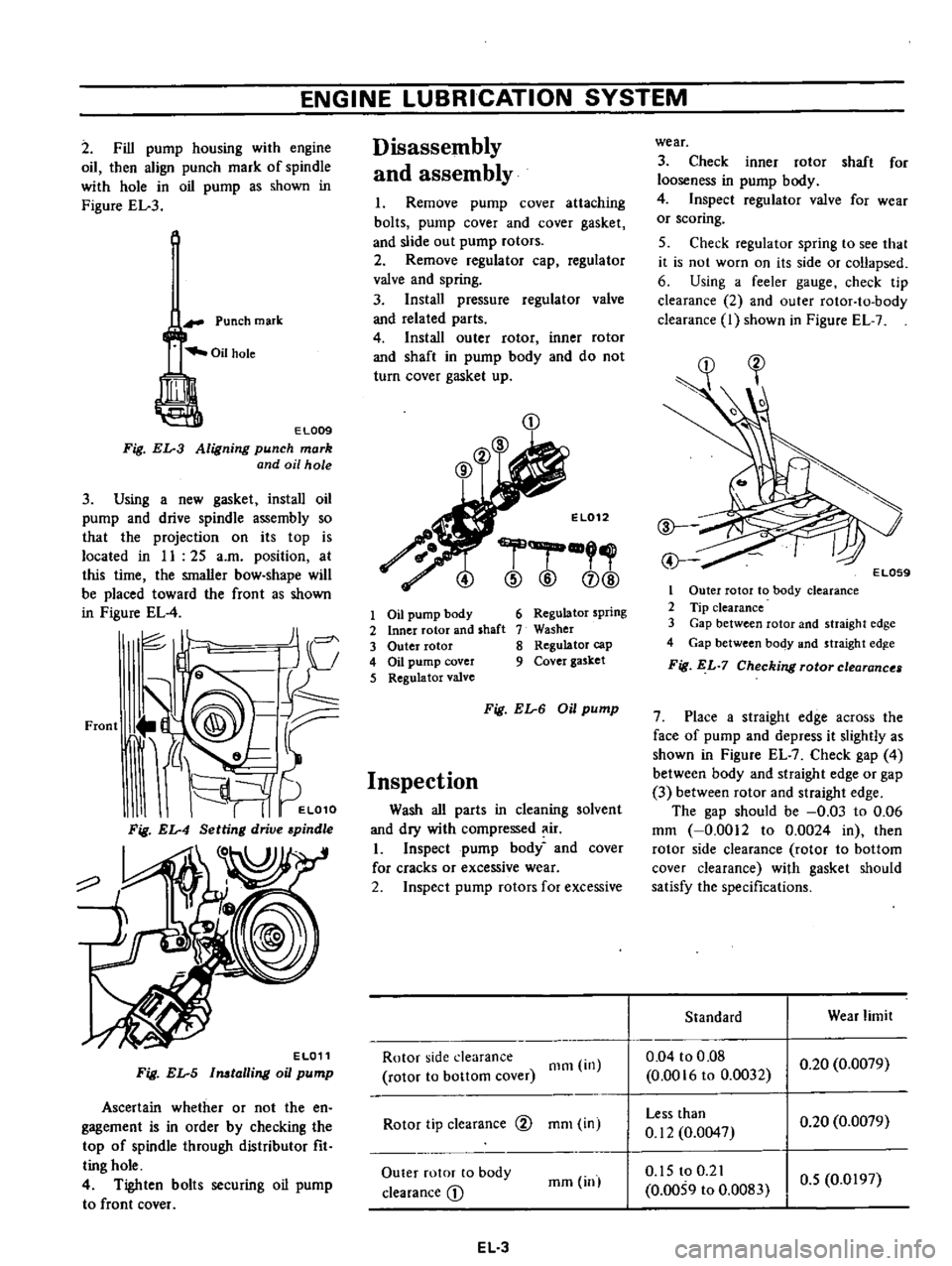

Disassembly

and

assembly

I

Remove

pump

cover

attaching

bolts

pump

cover

and

cover

gasket

and

slide

out

pump

rotors

2

Remove

regulator

cap

regulator

valve

and

spring

3

Install

pressure

regulator

valve

and

related

parts

4

Install

outer

rotor

inner

rotor

and

shaft

in

pump

body

and

do

not

turn

cover

gasket

up

CD

El012

r

@

@

CD@

1

Oil

pump

body

2

Inner

rotor

and

shaft

3

Outer

rotor

4

Oil

pump

cover

5

Regulator

valve

6

Regulator

spring

7

Washer

8

Regulator

cap

9

Cover

gasket

Fig

EL

6

Oil

pump

Inspection

Wash

all

parts

in

cleaning

solvent

and

dry

with

compressed

ir

I

Inspect

pump

body

and

cover

for

cracks

or

excessive

wear

2

Inspect

pump

rotors

for

excessive

Rotor

side

clearance

rotor

to

bottom

cover

Olm

in

Rotor

tip

clearance

@

mOl

in

Outer

rotor

to

body

clearance

D

mm

inl

EL

3

wear

3

Check

inner

rotor

shaft

for

looseness

in

pump

body

4

Inspect

regulator

valve

for

wear

or

scoring

5

Check

regulator

spring

to

see

that

it

is

not

worn

on

its

side

or

collapsed

6

Using

a

feeler

gauge

check

tip

clearance

2

and

outer

rotor

to

body

clearance

I

shown

in

Figure

EL

7

1

Outer

rotor

to

body

clearance

2

Tip

clearance

3

Gap

between

rotor

and

straight

edge

4

Gap

between

body

and

straight

edg

e

Fig

EL

7

Checking

rotor

clearance

7

Place

a

straight

edge

across

the

face

of

pump

and

depress

it

slightly

as

shown

in

Figure

EL

7

Check

gap

4

between

body

and

straight

edge

or

gap

3

between

rotor

and

straight

edge

The

gap

should

be

0

03

to

0

06

mm

0

0012

to

0

0024

in

then

rotor

side

clearance

rotor

to

bottom

cover

clearance

with

gasket

should

satisfy

the

specifications

Standard

Wear

limit

0

04

to

0

08

0

0016

to

0

0032

0

20

0

0079

Less

than

0

12

0

0047

0

20

0

0079

0

15

to

0

21

0

0059

to

0

0083

0

5

0

0197

Page 87 of 537

ENGINE

LUBRI

CATION

SYSTEM

Note

Pump

rotors

and

body

are

not

serviced

separately

If

pump

rotors

or

body

are

damaged

or

worn

replacement

of

the

entire

oil

pump

assembly

is

necessary

Tightening

torque

Oil

pump

mounting

bolts

Oil

pump

cover

bolts

Regulator

valve

cap

nut

Specifications

Oil

pressure

at

idling

Regulator

valve

spring

Free

length

Pressured

length

Regulator

valve

opening

pressure

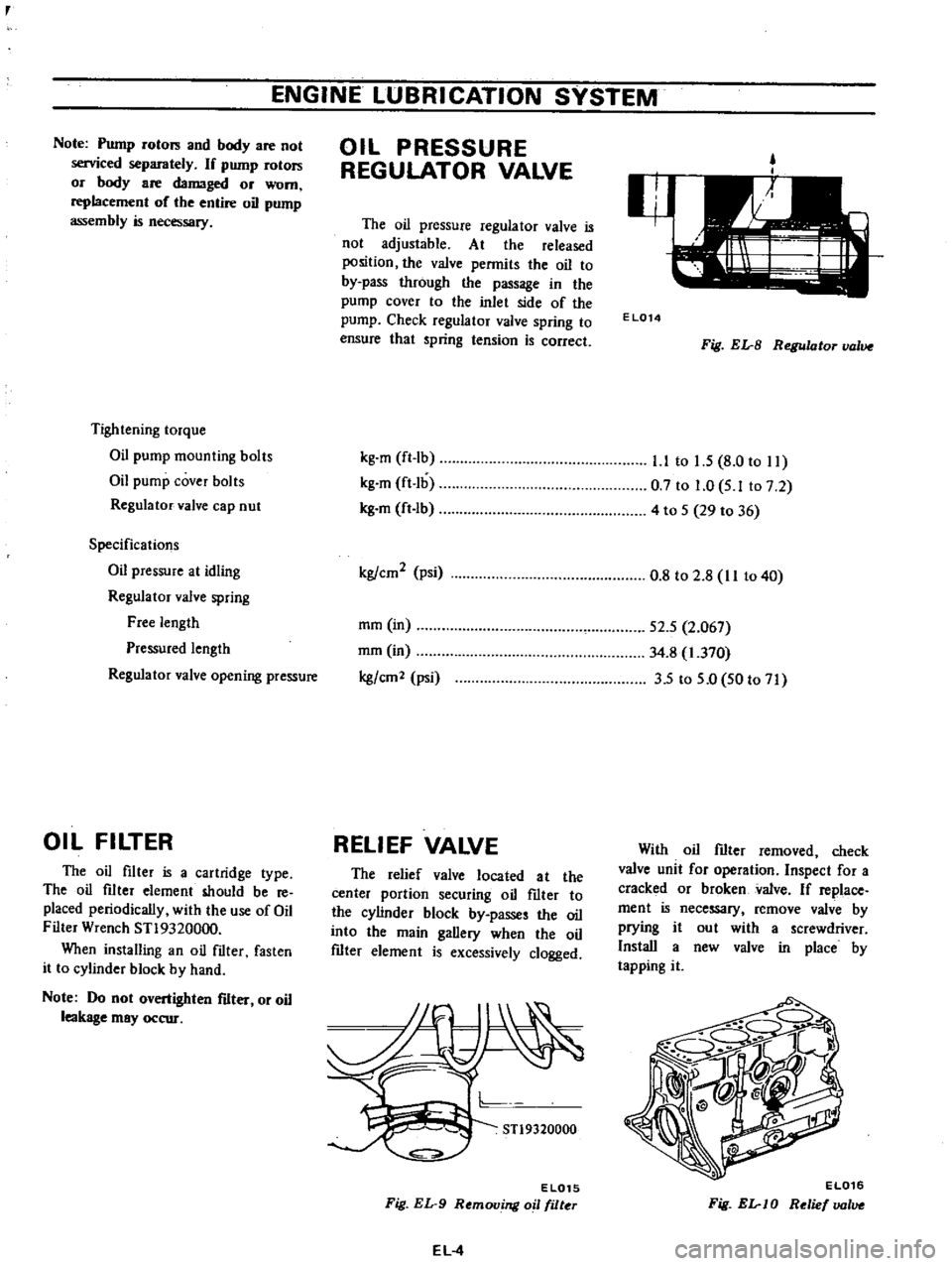

OIL

FILTER

The

oil

filter

is

a

cartridge

type

The

oil

filter

element

should

be

reo

placed

periodically

with

the

use

of

Oil

Filter

Wrench

ST19320000

When

installing

an

oil

filter

fasten

it

to

cylinder

block

by

hand

Note

Do

not

overtighten

filter

or

oil

leakage

may

occur

OIL

PRESSURE

REGULATOR

VALVE

The

oil

pressure

regulator

valve

is

not

adjustable

At

the

released

position

the

valve

permits

the

oil

to

by

pass

through

the

passage

in

the

pump

cover

to

the

inlet

side

of

the

pump

Check

regulator

valve

spring

to

ensure

that

spring

tension

is

correct

kg

m

ft

Ib

kg

m

ft

lb

kg

m

ft

lb

kg

cm2

psi

mm

in

mm

in

kg

em

2

psi

RELIEF

VALVE

The

relief

valve

located

at

the

center

portion

securing

oil

fIlter

to

the

cylinder

block

by

passes

the

oil

into

the

main

gallery

when

the

oil

fIlter

element

is

excessively

clogged

STl9320000

EL015

Fig

EL

9

Removing

oil

filter

EL

4

EL014

Fig

EL

B

Regulator

value

l

l

to

1

5

8

0

to

11

0

7

to

1

0

5

Ito

7

2

4

to

5

29

to

36

0

8

to

2

8

II

to

40

52

5

2

067

34

8

1

370

35

to

5

0

50

to

71

With

oil

fIlter

removed

check

valve

unit

for

operation

Inspect

for

a

cracked

or

broken

valve

If

replace

ment

is

necessary

remove

valve

by

prying

it

out

with

a

screwdriver

Install

a

new

valve

in

place

by

tapping

it

EL016

Fig

EL

JO

Relief

lJOlue

Page 88 of 537

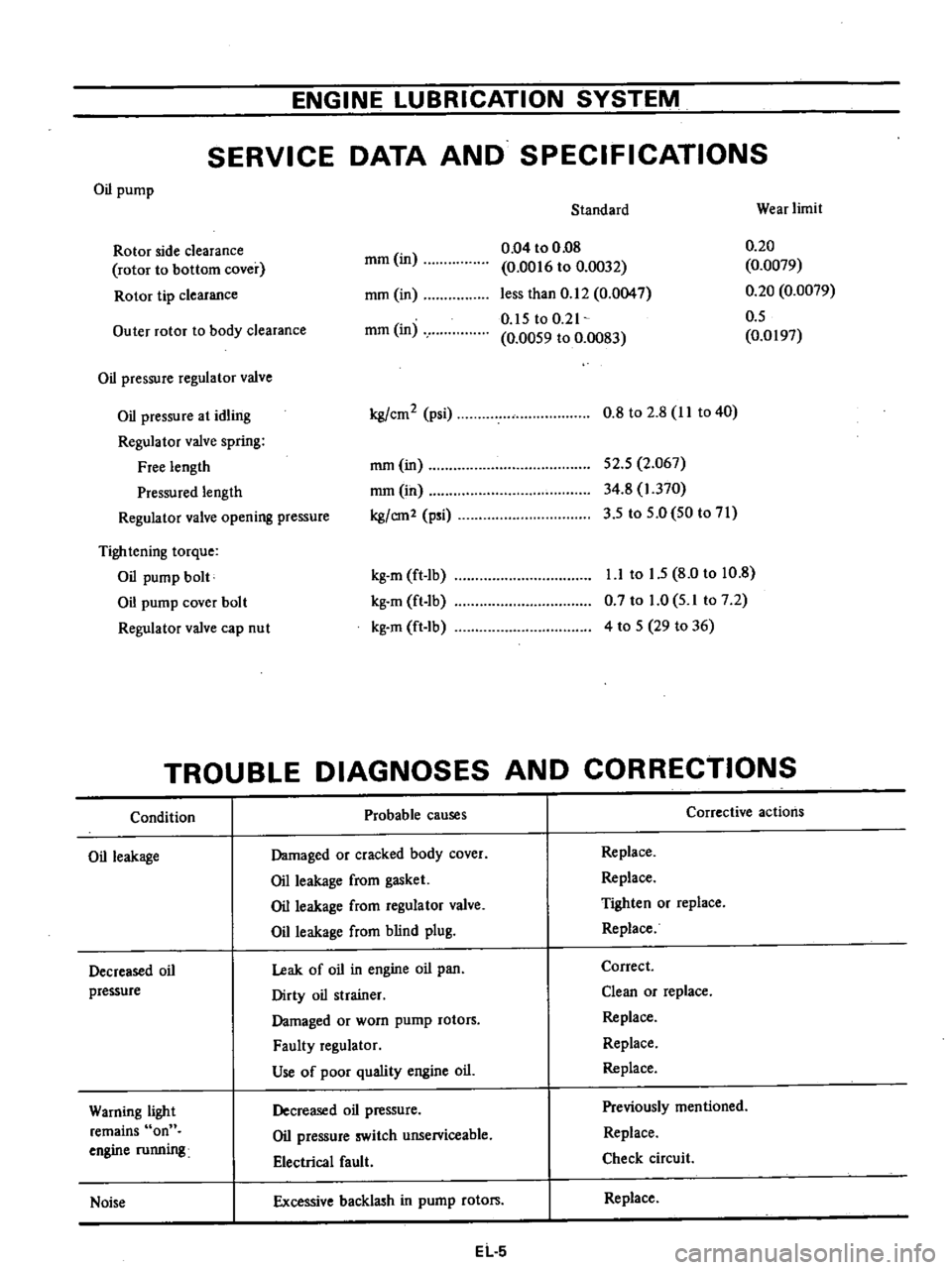

ENGINE

LUBRICATION

SYSTEM

SERVICE

DATA

AND

SPECIFICATIONS

Oil

pump

Standard

Wear

limit

mm

in

0

04

to

0

08

0

0016

to

0

0032

less

than

0

12

0

0047

0

15

toO

21

0

0059

to

0

0083

0

20

0

0079

0

20

0

0079

0

5

0

0197

Rotor

side

clearance

rotor

to

bottom

cover

Rotor

tip

clearance

mm

in

Outer

rotor

to

body

clearance

mm

in

Oil

pressure

regulator

valve

Oil

pressure

at

idling

Regulator

valve

spring

Free

length

Pressured

length

Regulator

valve

opening

pressure

kg

cm2

psi

0

8

to

2

8

II

to

40

mm

in

mmOn

kg

em2

psi

52

5

2

067

34

8

1

370

3

5

to

5

0

50

to

71

Tightening

torque

Oil

pump

bolt

Oil

pump

cover

bolt

Regulator

valve

cap

nut

kg

m

ft

lb

kg

m

ft

lb

kg

m

ft

Ib

1

1

to

1

5

8

0

to

10

8

0

7

to

1

0

5

1

to

7

2

4

to

5

29

to

36

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Condition

Probable

causes

Corrective

actions

Oil

leakage

Damaged

or

cracked

body

cover

Oil

leakage

from

gasket

Oil

leakage

from

regulator

valve

Oil

leakage

from

blind

plug

Replace

Replace

Tighten

or

replace

Replace

Decreased

oil

pressure

Leak

of

oil

in

engine

oil

pan

Dirty

oil

strainer

Damaged

or

worn

pump

rotors

Faulty

regulator

Use

of

poor

quality

engine

oiL

Correct

Clean

or

replace

Replace

Replace

Replace

Warning

light

remains

on

engine

running

Decreased

oil

pressure

Oil

pressure

switch

unserviceable

Electrical

fault

Previously

mentioned

Replace

Check

circuit

Noise

Excessive

backlash

in

pump

rotors

Replace

EL

5

Page 89 of 537

No

Tool

number

tool

name

STl9320000

Oil

filter

wrench

ENGINE

LUBRICATION

SYSTEM

SPECIAL

SERVICE

TOOL

Description

Unit

nun

in

For

use

on

Reference

page

or

Figure

No

This

tool

is

used

to

take

oil

f1Iter

out

of

place

In

tightening

All

Fig

EL

9

the

f1Iter

do

not

use

this

tool

to

prevent

excess

tightening

models

I

120

4

7

SE197

EL

6