engine oil DATSUN PICK-UP 1977 Repair Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 157 of 537

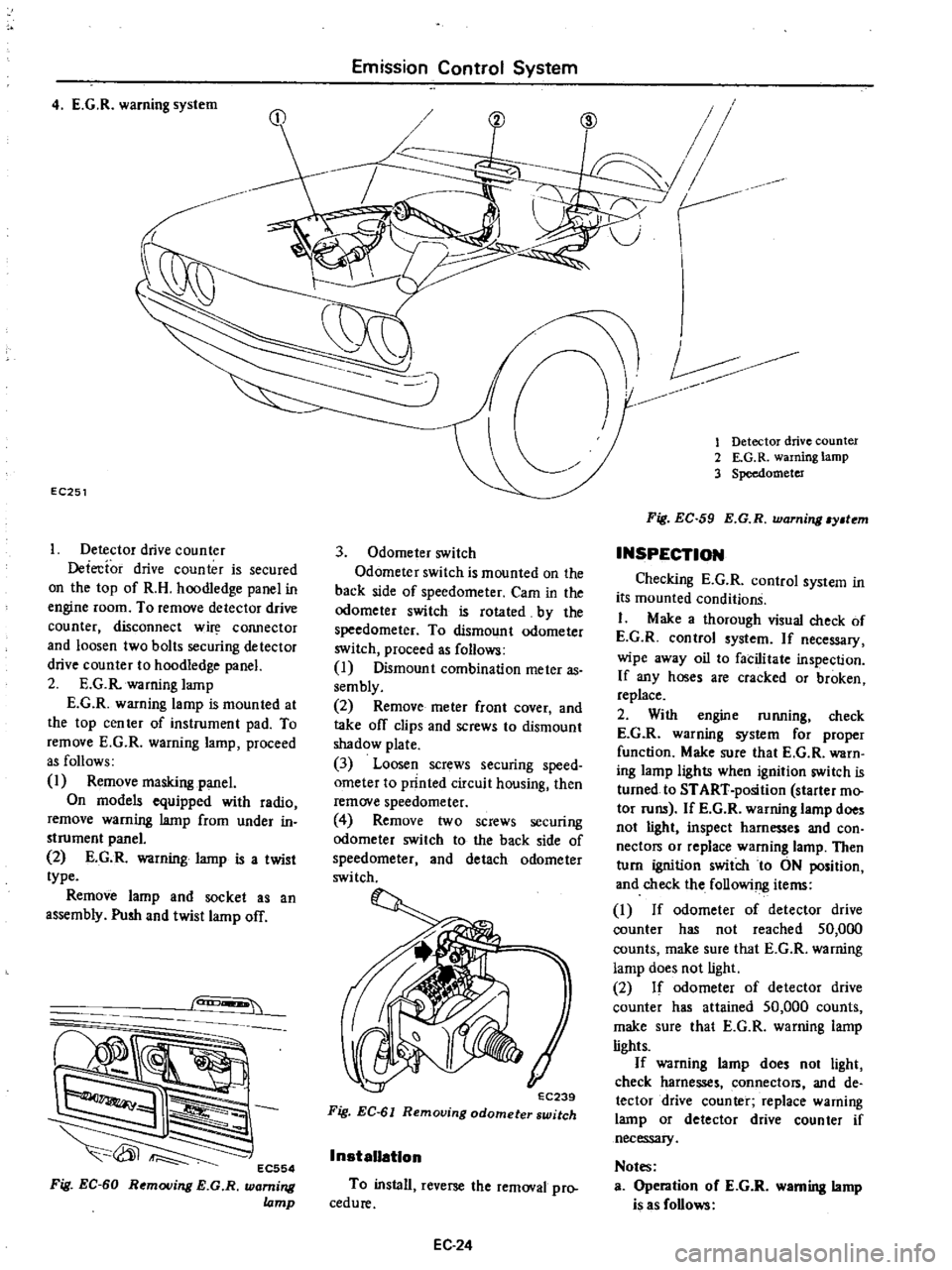

4

E

G

R

warning

system

EC251

Detector

drive

counter

Detecfor

drive

counter

is

secured

on

the

top

of

R

H

hoodledge

panel

in

engine

room

To

remove

detector

drive

counter

disconnect

w

COJUlector

and

loosen

two

bolts

securing

detector

drive

counter

to

hoodledge

panel

2

E

G

R

warning

lamp

E

G

R

warning

lamp

is

mounted

at

the

top

cen

ter

of

instrument

pad

To

remove

E

G

R

warning

lamp

proceed

as

follows

1

Remove

masking

panel

On

models

equipped

with

radio

remove

warning

lamp

from

under

in

strument

panel

2

E

G

R

warning

lamp

is

a

twist

type

Remove

lamp

and

socket

as

an

assembly

Push

and

twist

lamp

off

can

EC554

Fig

EC

60

Removing

E

G

R

warning

lamp

Emission

Control

System

3

Odometer

switch

Odometer

switch

is

mounted

on

the

back

side

of

speedometer

Cam

in

the

odometer

switch

is

rotated

by

the

speedometer

To

dismount

odometer

switch

proceed

as

follows

I

Dismount

combination

meter

as

sembly

2

Remove

meter

front

cover

and

take

off

clips

and

screws

to

dismount

shadow

plate

3

Loosen

screws

securing

speed

ometer

to

printed

circuit

housing

then

remove

speedometer

4

Remove

two

screws

securing

odomete

switch

to

the

back

side

of

speedometer

and

detach

odometer

switch

EC239

Fig

EC

61

Removing

odometer

switch

InstaUatlon

To

install

reverse

the

removal

pro

cedure

EC24

V

r

CID

1

Detector

drive

counter

2

E

G

R

warning

lamp

3

Speedometer

Fig

EC

59

E

G

R

warning

y

tem

INSPECTION

Checking

E

G

R

control

system

in

its

mounted

conditionS

I

Make

a

thorough

visual

check

of

E

G

R

control

system

If

necessary

wipe

away

oil

to

facilitate

inspection

If

any

hoses

are

cracked

or

broken

replace

2

With

engine

running

check

E

G

R

warning

system

for

proper

function

Make

sure

that

E

G

R

warn

ing

lamp

lights

when

ignition

switch

is

turned

to

START

position

starter

mo

tor

runs

If

E

G

R

wanung

lamp

does

not

light

inspect

harnesses

and

con

nectors

or

replace

warning

lamp

Then

turn

ignition

switch

to

ON

position

and

check

the

following

items

I

If

odometer

of

detector

drive

counter

has

not

reached

50

000

counts

make

sure

that

E

G

R

warning

lamp

does

not

light

2

If

odomete

of

detector

drive

counter

has

attained

50

000

counts

make

sure

that

E

G

R

warning

lamp

lights

If

warning

lamp

does

not

light

check

harnesses

connectors

and

de

tector

drive

counter

replace

warning

lamp

or

detector

drive

counter

if

necessary

Notes

Operation

oC

E

G

R

warning

lamp

is

as

Collows

Page 163 of 537

3

Check

ignition

system

with

regard

to

the

following

items

Refer

to

Inspection

of

Ignition

System

1

Ignition

AMP

2

Distributor

Emission

Control

System

3

Ignition

coil

4

High

tension

code

5

Spark

plug

4

Check

idle

CO

adjustment

Refer

to

Inspection

of

Idle

CO

Adjustment

Note

Even

if

there

is

nothing

wrong

with

engine

the

warning

lamp

may

come

on

if

vebicle

is

being

driven

on

a

steep

slope

continuously

in

lower

gears

at

high

engine

speeds

EVAPORATIVE

EMISSION

CONTROL

SYSTEM

CONTENTS

DESCRIPTION

OPERATION

INSPECTION

FUEL

TANK

VAPOR

LIQUID

SEPARATOR

AND

VAPOR

VENT

LINE

DESCRIPTION

The

evaporative

emission

control

system

is

used

to

reduce

hydrocarbons

emitted

to

the

atmosphere

from

the

fuel

system

This

reduction

of

hydro

EC

30

EC

30

EC

31

CARBON

CANISTER

PURGE

CONTROL

VALVE

CARBON

CANISTER

FILTER

FUEL

TANK

VACUUM

RELIEF

VALVE

IEC

32

IEC

32

EC

32

EC

31

carbons

is

accomplished

by

activated

charcoals

in

the

carbon

canister

This

system

is

made

up

to

the

following

I

Fuel

tank

with

positive

sealing

filler

cap

@

2

Vapor

liquid

separator

3

Vapor

vent

line

4

Carbon

canister

5

Vacuum

signal

line

6

Canister

purge

line

5

OPERATION

Fuel

vapors

from

the

sealed

fuel

tank

are

led

into

the

carbon

canister

1

Fuel

tank

2

Fuel

nIler

cap

with

vacuum

relief

valve

3

liquid

vapor

separator

4

Vapor

vent

line

5

Canister

purge

line

6

Vacuum

signal

line

7

Carbon

canister

EF274

Fig

EC

76

Schematic

drawing

of

l

Iaporotive

emiaion

control6ydem

The

canister

is

fined

with

activated

charcoals

to

absorb

the

fuel

vapors

EC

30

when

the

engirie

is

at

rest

or

at

idlin

ll

See

Figure

EC

77

Page 168 of 537

DATSUN

PICK

UP

MODEL

620

SERIES

I

NISSAN

I

NISSAN

MOTOR

CO

LTD

TOKYO

JAPAN

SECTION

EE

ENGINE

ELECTRICAL

SYSTEM

BATTERY

EE

2

STARTING

MOTOR

EE

4

CHARGING

CIRCUIT

EE

12

ALTERNATOR

EE

15

REGULATOR

EE

20

IGNITION

CIRCUIT

EE

26

DISTRIBUTOR

EE

30

Non

California

models

DISTRIBUTOR

California

models

EE

33

TRANSISTOR

IGNITION

UNIT

California

models

IGNITION

COIL

SPARK

PLUG

EE

36

EE

46

EE

47

Page 171 of 537

DESCRIPTION

OPERATION

CONSTR

UCTI

ON

REMOVAL

DISASSEMBL

Y

CLEANING

AND

INSPECTION

TERMINAL

FIELD

COIL

BRUSHES

AND

BRUSH

LEAD

WIRE

BRUSH

SPRING

TENSION

ARMATURE

ASSEMBLY

DESCRIPTION

The

function

of

the

starting

system

which

consists

of

the

battery

ignition

switch

starting

motor

and

solenoid

is

to

crank

the

engine

The

electrical

energy

is

supplied

from

the

battery

the

solenoid

completes

the

circuit

to

operate

the

starling

motor

and

then

the

motor

carries

out

the

actual

crank

ing

of

the

engine

Engine

Electrical

System

STARTING

MOTOR

CONTENTS

EE

4

EE

6

EE

7

EE

7

EE

7

EE

8

EE

8

EE

B

EE

B

EE

B

EE

B

OVERRUNNING

CLUTCH

ASSEMBLY

BRUSH

HOLDER

TEST

FOR

GROUND

BEARING

METAL

MAGNETIC

SWITCH

ASSEMBLY

ASSEMBLY

TEST

PERFORMANCE

TEST

MAGNETIC

SWITCH

ASSEMBLY

TEST

SERVICE

DATA

AND

SPECIFICATIONS

TROUBLE

DIAGNOSES

AND

CORRECTIONS

5

@

EE

9

EE

9

EE

9

EE

9

EE

9

EE

9

EE

9

EE

O

EE

EE

11

I

Brush

2

Field

coil

3

Magnetic

switch

4

Pludgcr

5

Torsion

spring

6

Shifll

r

7

Overrunning

clutch

8

Pinion

9

Armature

9

EE315

Fig

EE

5

Sectioool

view

of

slarting

motor

Sl14

180B

EE

4

Page 173 of 537

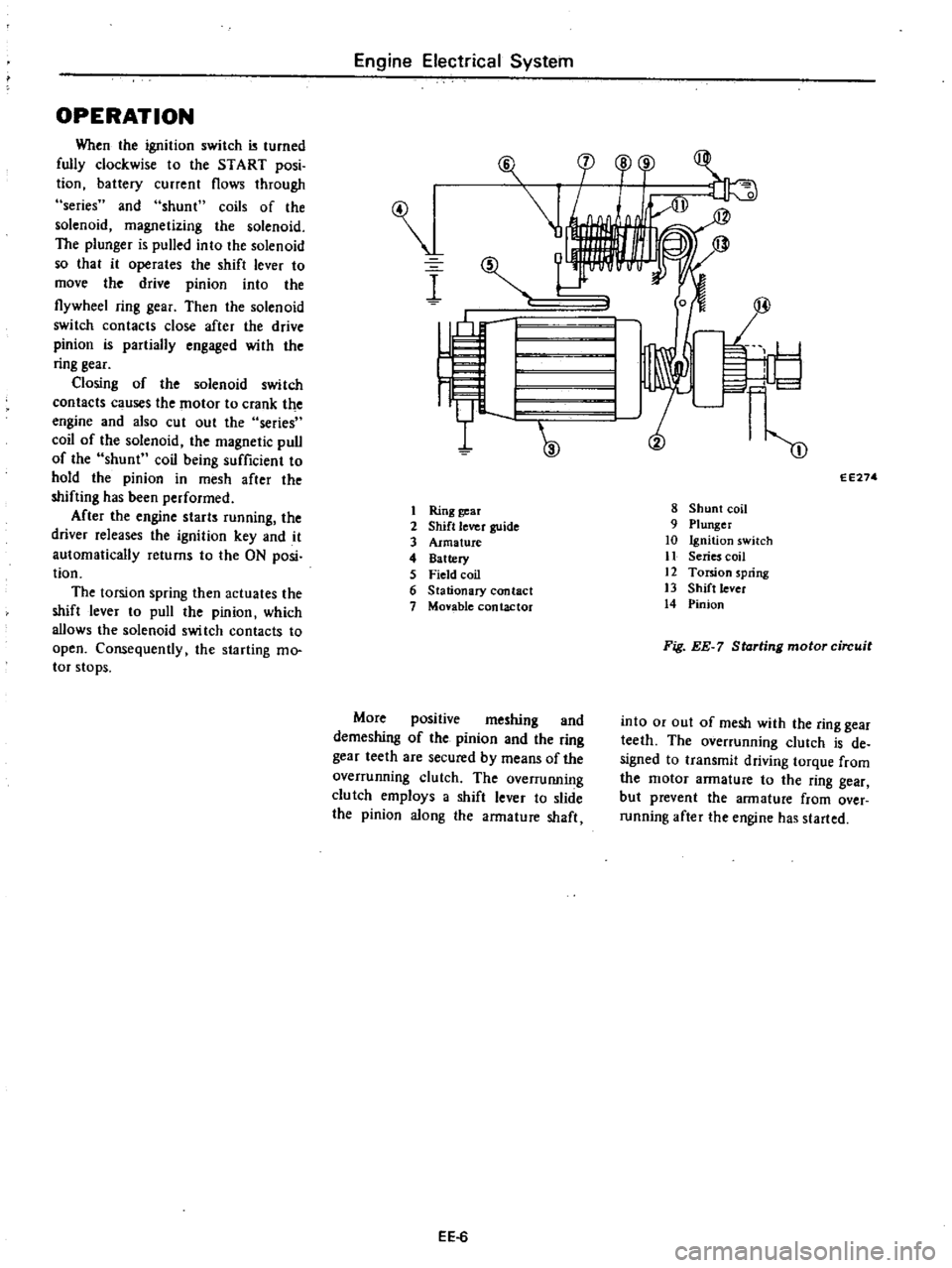

OPERATION

When

the

ignition

switch

turned

fully

clockwise

to

the

START

posi

tion

battery

current

flows

through

series

and

shunt

coils

of

the

solenoid

magnetizing

the

solenoid

The

plunger

is

pulled

into

the

solenoid

so

that

it

operates

the

shift

lever

to

move

the

drive

pinion

into

the

flywheel

ring

gear

Then

the

solenoid

switch

contacts

close

after

the

drive

pinion

is

partially

engaged

with

the

ring

gear

Closing

of

the

solenoid

switch

contacts

c

uses

the

motor

to

crank

the

engine

and

also

cut

out

the

series

coil

of

the

solenoid

the

magnetic

pull

of

the

shunt

coil

being

sufficient

to

hold

the

pinion

in

mesh

after

the

shifting

has

been

performed

After

the

engine

starts

running

the

driver

releases

the

ignition

key

and

it

automatically

returns

to

the

ON

posi

tion

The

torsion

spring

then

actuates

the

shift

lever

to

pull

the

pinion

which

allows

the

solenoid

swi

tch

contacts

to

open

Consequently

the

starting

mo

tor

stops

Engine

Electrical

System

I

I

Ring

gear

2

Shift

lever

guide

3

Armature

4

Battery

5

Field

coil

6

Stationary

contact

7

Monble

contactor

More

positive

meshing

and

demeshing

of

the

pinion

and

the

ring

gear

teeth

are

secured

by

means

of

the

overrunning

clutch

The

overruIUling

clutch

employs

a

shift

lever

to

slide

the

pinion

along

the

armature

shaft

EE

6

F

l

cp

o

r

1

I

I

W

m

EE274

8

Shunt

coil

9

Plunger

10

Ignition

switch

11

Series

coil

12

Torsion

spring

13

Shift

lever

14

Pinion

Fig

EE

7

Starting

motor

circuit

into

or

out

of

mesh

with

the

ring

gear

teeth

The

overrunning

clutch

is

de

signed

to

transmit

driving

torque

from

the

motor

armature

to

the

ring

gear

but

prevent

the

armature

from

over

running

after

the

engine

has

started

Page 174 of 537

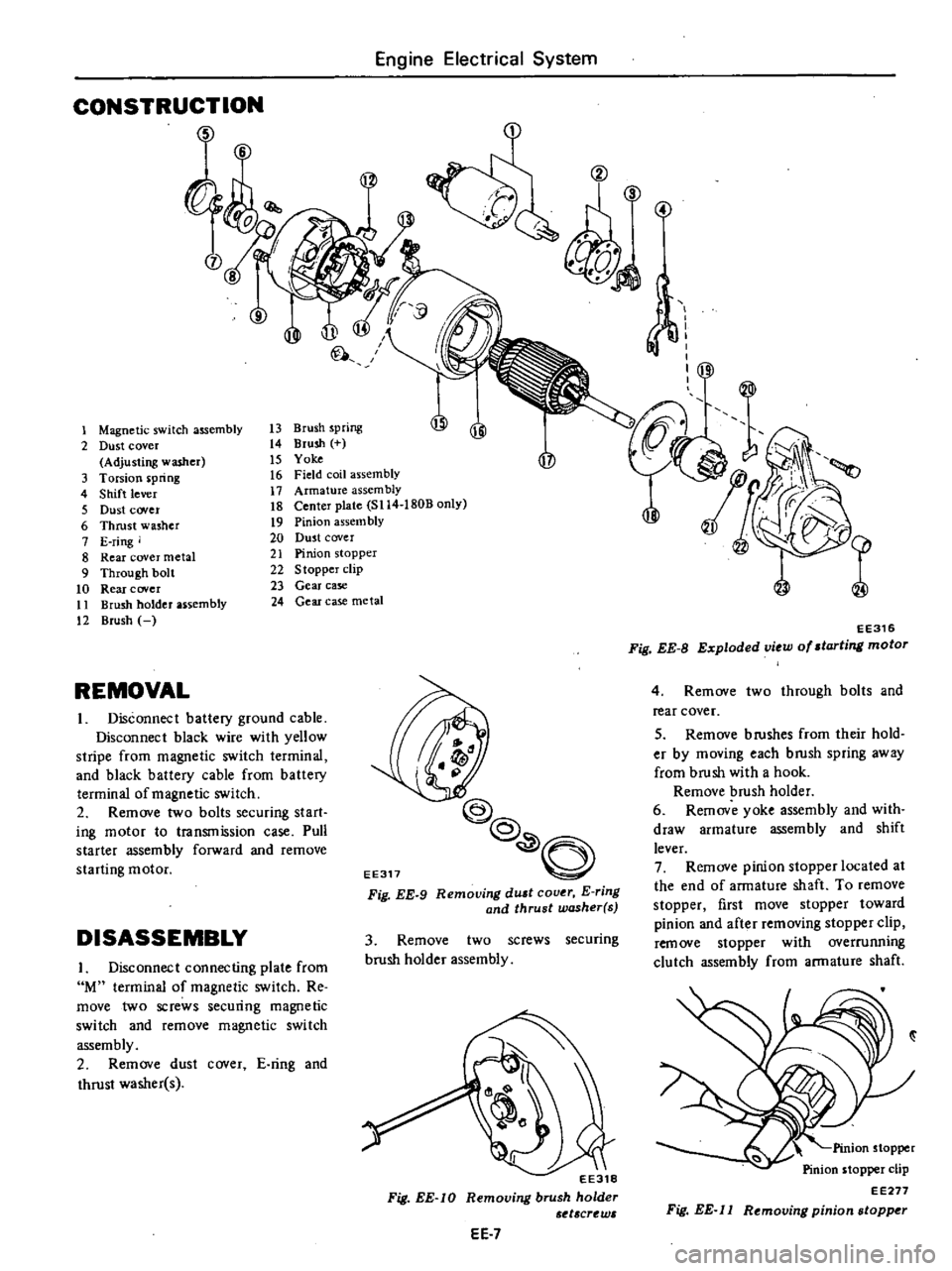

CONSTRUCTION

O

o

8

w

il

Engine

Electrical

System

V

1

Magnetic

switch

assembly

13

Brush

spring

jj

JI

2

Dust

cover

t4

Brush

Adjusting

washer

15

Yoke

P

3

Torsion

pring

t6

Field

coil

assembly

4

Shift

lever

17

Armature

assembly

5

Dust

cover

18

Center

plate

SI14

1808

only

6

Thrust

washer

19

Pinion

assem

bly

7

E

ring

20

Dust

cover

8

Rear

cover

metal

21

Pinion

stopper

9

Through

bolt

22

Stopper

clip

10

Rear

cover

23

Gear

case

tl

Brush

holder

assembly

24

Gear

case

metal

12

Brush

REMOVAL

Disconnect

battery

ground

cable

Disconnect

black

wire

with

yellow

stripe

from

magnetic

switch

terminal

and

black

battery

cable

from

battery

terminal

of

magnetic

switch

2

Remove

two

bolts

securing

start

ing

motor

to

transmission

case

Pull

starter

assembly

forward

and

remove

starting

motor

DISASSEMBLY

I

Disconnect

connecting

plate

from

M

terminal

of

magnetic

switch

Re

move

two

screws

securing

magnetic

switch

and

remove

magnetic

switch

assembly

2

Remove

dust

cover

E

ring

and

thrust

washer

s

EE317

@

@

O

Fig

EE

9

Remouing

dUlt

cover

E

ring

and

thrust

washer

s

3

Remove

two

screws

securing

brush

holder

assembly

EE318

Fig

EE

IO

Removing

brush

holder

d

crt

w

EE

7

S

4

f

I

jl

I

EE316

Fig

EE

B

Exploded

view

of

starting

motor

4

Remove

two

through

bolts

and

rear

cover

5

Remove

b

rushes

from

their

hold

er

by

moving

each

brush

spring

away

from

brush

with

a

hook

Remove

brush

holder

6

Remov

yoke

assembly

and

with

draw

armature

assembly

and

shift

lever

7

Remove

pinion

stopper

located

at

the

end

of

armature

shaft

To

remove

stopper

first

move

stopper

toward

pinion

and

after

removing

stopper

clip

remove

stopper

with

overrunning

clutch

assembly

from

armature

shaft

Pinion

stopper

Pinion

stopper

clip

EE277

Fig

EE

l1

Removing

pinion

stopper

Page 175 of 537

CLEANING

AND

INSPECTION

Clean

all

disassembled

parts

but

do

not

use

grease

dissolving

solvents

for

cleaning

overrunning

clutch

annature

assembly

magnetic

switch

assembly

and

field

coils

since

such

a

solvent

would

dissolve

grease

packed

in

c1u

tch

mechanism

and

would

damage

coils

or

other

insulators

Check

them

for

excessive

damage

or

wear

and

replace

if

necessary

TERMINAL

Check

terminal

for

damage

and

wear

and

replace

magnetic

switch

assembly

if

necessary

FIELD

COIL

Check

field

coil

for

insulation

If

the

insulation

of

coil

is

damaged

or

worn

it

should

be

replaced

Testing

field

coil

for

continuity

Connect

the

probe

of

a

circuit

tester

or

an

ohmmeter

to

field

coil

positive

terminal

and

positive

brush

holder

If

tester

shows

no

continuity

field

circuit

or

coil

is

open

EE016

Fig

EE

I2

Testing

field

coil

for

continuity

TestIng

field

coD

for

ground

Place

one

probe

of

circuit

tester

onto

yoke

and

the

other

onto

field

coil

lead

positive

tenninal

If

very

little

resistance

is

read

field

coil

is

grounded

Engine

Electrical

System

EE017

Fig

EE

I3

Testing

rU

ld

coil

for

ground

BRUSHES

AND

BRUSH

LEAD

WIRE

Check

the

surface

condition

of

brush

contact

and

wear

of

brush

If

a

loose

contact

is

found

it

should

be

replaced

If

brush

is

worn

so

that

its

length

is

less

than

12

mm

0

472

in

replace

Check

the

connection

of

lead

clip

and

lead

wire

o

@

EE

8

Check

brush

holders

and

spring

cUp

to

see

if

they

are

not

deformed

or

bent

and

will

properly

hold

brushes

against

the

commutator

If

brushes

or

brush

holders

are

dirty

they

should

be

cleaned

BRUSH

SPRING

TENSION

Check

brush

spring

tension

by

a

spring

scale

as

shown

in

Figure

EE

13

The

reading

should

be

1

6

kg

3

5

Ib

Replace

spring

if

tension

is

lower

than

I

4

kg

3

1

Ib

ARMATURE

ASSEMBLY

Check

external

appearance

of

armature

and

commutator

1

Inspect

commutator

If

the

sur

face

of

commutator

is

rough

it

must

be

sanded

lightly

with

a

No

500

emery

cloth

If

the

depth

of

insulating

mica

is

less

than

0

2

mm

0

0079

in

from

commutator

surface

insulating

mica

should

also

be

undercut

so

that

its

depth

is

0

5

to

0

8

mm

0

01

97

to

0

0315

in

The

wear

limit

of

commutator

dia

meter

is

2

mm

0

0787

in

If

the

diameter

of

cammu

tator

is

less

than

31

mm

1

220

in

replace

annature

assembly

EE018

Fig

EE

14

Inspecting

brush

spring

tension

Page 176 of 537

L

0

5

to

0

8

mm

71j

Correct

2

Inspect

soldered

connection

of

armature

lead

and

commutator

If

loose

connection

is

found

solder

it

using

resin

flux

3

Armature

test

for

ground

Using

a

circuit

tester

place

one

test

probe

onto

armature

shaft

and

other

onto

each

commutator

bar

If

tester

shows

continuity

armature

is

grounded

and

must

be

replaced

EE022

Fig

EE

16

Testing

annature

for

ground

4

Check

armature

for

short

by

placing

it

on

armature

tester

growler

with

a

piece

of

iron

over

armature

core

rotating

armature

If

the

plate

vibrates

armature

is

shorted

j

l

EE023

Fig

EE

17

Testing

annature

for

ahort

Engine

Electrical

System

L

File

l

0

Commutator

Segmen

t

IWMica

Incorrect

EE021

Fig

EE

15

Undercutting

i118ulating

mica

5

Check

armature

for

continuity

by

placing

probes

of

tester

on

two

seg

ments

side

by

side

If

tester

shows

no

continuity

the

circuit

is

open

OVERRUNNING

CLUTCH

ASSEMBLY

Inspect

pinion

assembly

and

screw

sleeve

Screw

sleeve

must

slide

freely

along

armature

shaft

splines

If

damage

is

found

or

resistance

is

felt

when

sliding

it

must

be

repaired

Inspect

pinion

teeth

If

excessive

rub

bing

is

found

on

teeth

replace

Flywheel

ring

gear

also

must

be

in

spected

l

EE278

Fig

EE

18

Overrunning

clutch

auem

bly

BRUSH

HOLDER

TEST

FOR

GROUND

Using

a

circuit

tester

place

one

test

probe

onto

negative

side

of

brush

holder

and

another

onto

positive

side

If

tester

shows

continuity

brush

holder

is

shorted

to

ground

Replace

brush

holder

EE

9

Ee026

Fig

EE

19

Testing

brush

for

round

BEARING

METAL

Inspect

bearing

metal

for

wear

or

side

play

If

the

clearance

between

bearing

metal

and

armature

shaft

is

more

than

0

2

mm

0

0079

in

replace

metal

MAGNETIC

SWITCH

ASSEMBLY

1

Using

a

circuit

tester

l

check

con

tinuity

between

S

terminal

of

mag

netic

switch

and

switch

body

metal

If

continuity

does

not

exist

shunt

coit

is

opened

Replace

switch

assembly

2

In

the

same

manner

as

above

check

continuity

between

terminals

S

and

M

If

continuity

does

not

exist

series

coil

is

opened

Replace

switch

assembly

ASSEMBLY

Reassemble

starting

motor

in

re

verse

sequence

of

disassembly

When

assembling

be

sure

to

apply

grease

to

gear

case

and

rear

cover

bearing

metal

and

apply

oil

lightly

to

pinion

TEST

PERFORMANCE

TEST

Starter

motor

should

be

subjected

to

a

no

load

test

whenever

it

has

been

overhauled

to

ensure

that

its

performance

will

be

satisfactory

when

installed

on

engine

Starter

motor

should

also

be

subjected

to

the

test

when

the

cause

of

abnormal

operation

is

to

be

determined

A

brief

outline

of

the

test

is

given

below

Page 177 of 537

No

load

test

Connect

starting

motor

in

series

with

specified

12

volts

battery

and

an

ammeter

capable

of

indicating

1

000

amperes

Starter

motor

Diagnoses

of

test

1

Low

speed

with

no

load

and

high

current

draw

may

result

from

the

following

1

Tight

dirty

or

worn

bearings

2

Bent

armature

shaft

or

loosened

field

probe

3

Shorted

armature

Check

armature

further

4

A

grounded

armature

or

field

a

Remove

input

tenninal

b

Raise

two

negative

side

brushes

from

commutator

c

Using

a

circuit

tester

place

one

probe

onto

input

tenninal

and

the

other

onto

yoke

d

I

f

tester

indicates

continuity

raise

the

other

two

brushes

and

check

field

and

armature

separately

to

determine

whether

field

or

armature

is

grounded

2

F

allure

to

operate

with

high

current

draw

may

be

caused

by

the

Engine

Electrical

System

Specified

current

draw

and

revolu

tion

in

these

test

are

shown

in

Specifications

Switch

6

Battery

Et

Voltmeter

Ammeter

Ee026

Fig

EE

20

No

load

l

ting

following

I

A

grounded

or

open

field

coil

Inspect

the

connection

and

trace

circuit

with

a

circuit

tester

2

Armature

coil

does

not

operate

Inspect

commutator

for

excessive

burning

In

this

case

arc

may

occur

on

damaged

commutator

when

motor

is

operated

with

no

load

3

Burned

out

commutator

bar

Weak

brush

spring

tension

broken

brush

spring

rubber

bush

thrust

out

of

mica

in

commu

tat

or

or

a

loose

contact

between

biush

and

com

mutator

would

cause

commutator

bar

to

burn

3

Low

current

draw

and

low

no

load

speed

would

cause

high

internal

resistance

due

to

loose

con

nections

damaged

leads

dirty

corn

mutator

and

causes

listed

on

item

2

3

EE10

MAGNETIC

SWITCH

ASSEMBLY

TEST

Switch

o

Fv

IB

I

I

D

Battery

Starter

motor

EE351

FiN

EE

21

Circuit

ofmagndic

awitch

assembly

ted

If

the

starting

motor

check

is

OK

check

magnetic

switch

as

sembly

Connect

cables

between

negative

battery

tenninal

and

start

ing

motor

M

terminal

positive

battery

terminal

and

starting

motor

S

terminal

connecting

a

switch

in

series

as

shown

in

Figure

EE

21

With

the

switch

on

push

pinion

back

to

remove

all

slack

and

measure

the

clearance

l

between

pinion

front

edge

and

pinion

stopper

The

clearance

should

be

held

within

0

3

to

1

5

mm

0

012

to

0

059

in

If

neces

sary

adjust

it

by

changing

or

adding

adjusting

washer

s

Adjusting

washers

are

available

in

to

two

different

sizes

0

5

mm

0

020

in

and

O

S

mm

0

031

in

0

3

to

I

S

rom

0

012

to

0

059

in

l

EE029

Fig

EE

22

MeO

uring

clearance

t

Page 178 of 537

Engine

Electrical

System

SERVICE

DATA

AND

SPECIFICATIONS

Type

System

voltage

No

load

Terminal

voltage

Current

Revolution

v

V

A

rpm

Brush

length

Outer

diameter

of

commutator

mm

in

mm

in

Brush

spring

tension

kg

Ib

Clearance

between

bearing

metal

and

armature

shaft

mm

in

Clearance

L

between

pinion

front

edge

and

pinion

stopper

mm

in

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Condition

Starting

motor

will

not

operate

Noisy

starting

motor

Starting

motor

cranks

slowly

Probable

cause

Discharged

battery

Damaged

solenoid

switch

Loose

connections

of

terminal

Damaged

brushes

Starti

g

motor

inoperative

Loose

securing

bolt

Worn

pinion

gear

Poor

lubrication

Worn

commutator

Worn

brushes

Discharged

battery

Loose

connection

of

terminal

Worn

brushes

Locked

brushes

EE

ll

Manual

transmission

Automatic

transmission

Optional

for

manual

transmission

SII4

ISOB

S114

170B

12

12

Less

than

60

More

than

7

000

More

than

6

000

More

than

39

1

54

More

than

12

0

47

1

4

to

I

S

3

1

to

4

0

Less

than

0

2

O

OOS

0

3

to

1

5

0

012

to

0

059

Corrective

action

Charge

or

replace

battery

Repair

or

replace

solenoid

switch

Clean

and

tighten

terminal

Replace

brushes

Remove

starting

motor

and

make

test

Tighten

Replace

Add

oil

Replace

Replace

Charge

Clean

and

tighten

Replace

Inspect

brush

spring

tension

or

repair

brush

holder