engine oil DATSUN PICK-UP 1977 Manual PDF

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 179 of 537

Condition

Engine

Electrical

System

Probable

cause

Starting

motor

cranks

slowly

Dirty

or

worn

commutator

Armature

rubs

field

coil

Damaged

solenoid

switch

Starting

motor

operates

but

does

not

crank

engine

Worn

pinion

Locked

pinion

guide

Worn

ring

gear

Starting

motor

will

not

disengage

even

if

ignition

switch

is

turned

off

Damaged

solenoid

switch

Damaged

gear

teeth

The

charging

circuit

consists

of

the

battery

alternator

regulator

and

necessary

wiring

to

connect

these

parts

The

purpose

of

this

system

is

to

convert

mechanical

energy

from

the

engine

into

electrical

energy

which

is

used

to

operate

all

electrically

operat

ed

units

and

to

keep

the

battery

fully

charged

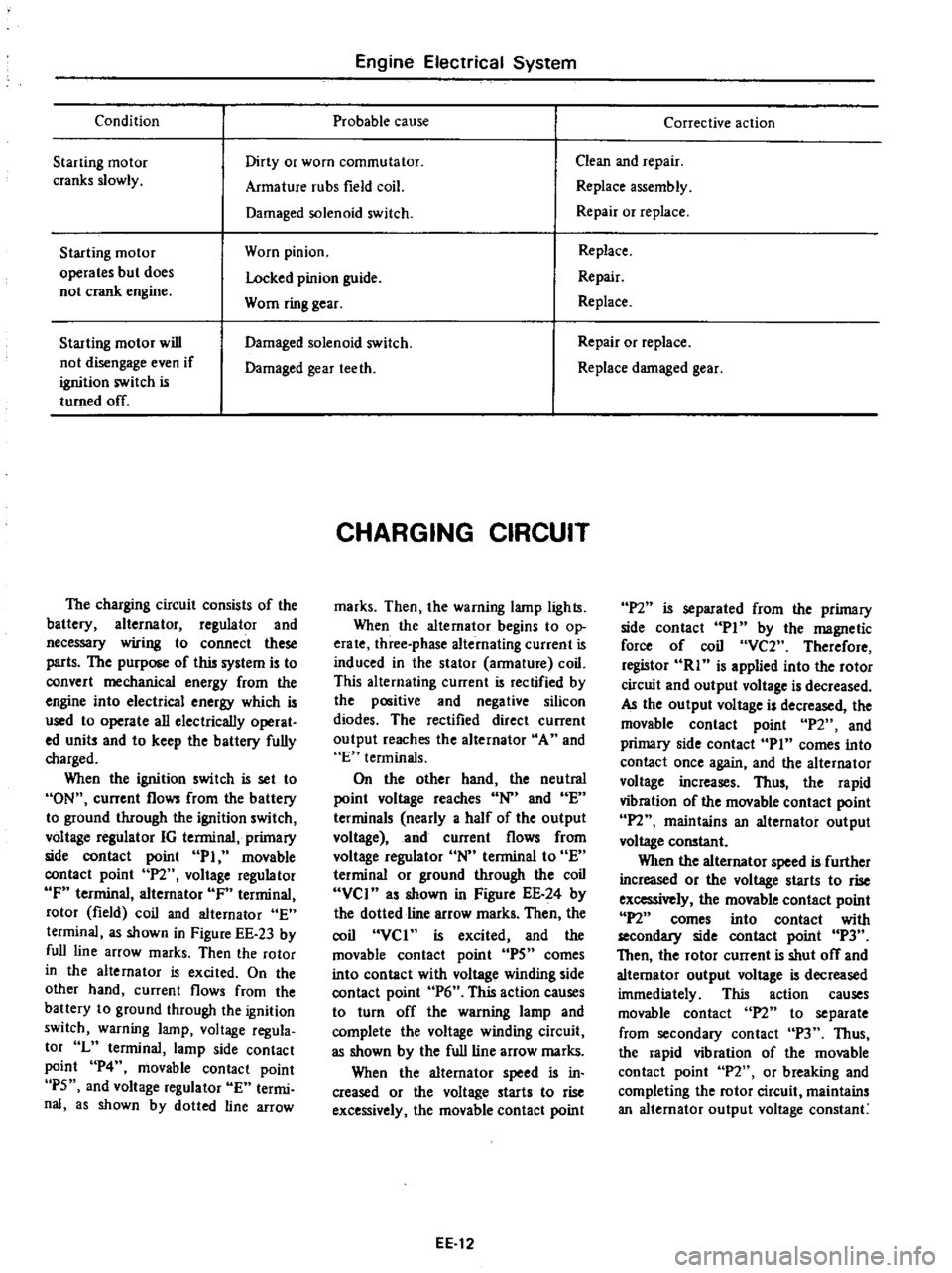

When

the

ignition

switch

is

set

to

ON

current

flows

from

the

battery

to

ground

through

the

ignition

switch

voltage

regulator

IG

terminal

primary

side

contact

point

PI

movable

contact

point

P2

voltage

regulator

IF

terminal

alternator

IF

terminal

rotor

field

coil

and

alternator

E

terminal

as

shown

in

Figure

EE

23

by

full

line

arrow

marks

Then

the

rotor

in

the

alternator

is

excited

On

the

other

hand

current

flows

from

the

battery

to

ground

through

the

ignition

switch

warning

lamp

voltage

regula

tor

L

terminal

lamp

side

contact

point

P4

movable

contact

point

P5

and

voltage

regulator

E

termi

nal

as

shown

by

dotted

line

arrow

CHARGING

CIRCUIT

marks

Then

the

warning

lamp

lights

When

the

alternator

begins

to

op

erate

three

phase

alternating

current

is

induced

in

the

stator

armature

coil

This

alternating

current

is

rectified

by

the

positive

and

negative

silicon

diodes

The

rectified

direct

current

output

reaches

the

alternator

A

and

E

terminals

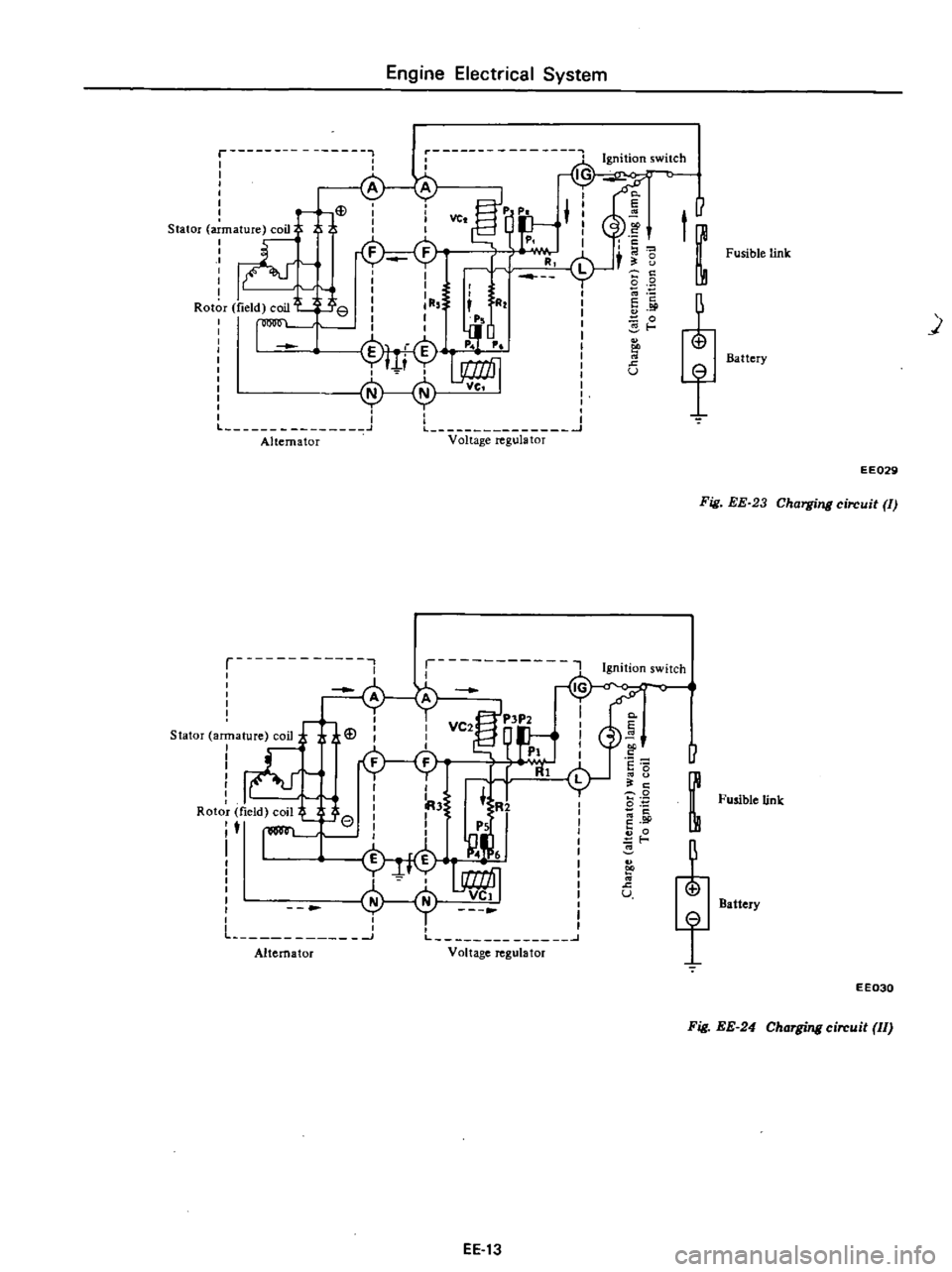

On

the

other

hand

the

neutral

point

voltage

reaches

N

and

E

terminals

nearly

a

half

of

the

output

voltage

and

current

flows

from

voltage

regulator

N

terminal

to

E

terminal

or

ground

through

the

coil

VCI

as

shown

in

Figure

EE

24

by

the

dotted

line

arrow

marks

Then

the

coil

VCI

is

excited

and

the

movable

contact

point

IPS

comes

into

contact

with

voltage

winding

side

contact

point

P6

This

action

causes

to

turn

off

the

warning

lamp

and

complete

the

voltage

winding

circuit

as

shown

by

the

full

line

arrow

marks

When

the

alternator

speed

is

in

creased

or

the

voltage

starts

to

rise

excessively

the

movable

contact

point

EE

12

Corrective

action

Clean

and

repair

Replace

assembly

Repair

or

replace

Replace

Repair

Replace

Repair

or

replace

Replace

damaged

gear

P2

is

separated

from

the

primary

side

contact

PI

by

the

magnetic

force

of

coil

VC2

Therefore

registor

RI

is

applied

into

the

rotor

circuit

and

output

voltage

is

decreased

AJ

the

output

voltage

is

decreased

the

movable

contact

point

P2

and

primary

side

contact

Pin

comes

into

contact

once

again

and

the

alternator

voltage

increases

Thus

the

rapid

vibration

of

the

movable

contact

point

IPl

maintains

an

alternator

output

voltage

constant

When

the

alternator

speed

is

further

increased

or

the

voltage

starts

to

rise

excessively

the

movable

contact

point

P2

comes

into

contact

with

secondllJ

side

contact

point

P3

Then

the

rotor

current

is

shut

off

and

alternator

output

voltage

is

decreased

immediately

This

action

causes

movable

contact

n

to

separate

from

secondary

contact

P3

Thus

the

rapid

vibration

of

the

movable

contact

point

P2

or

breaking

and

completing

the

rotor

circuit

maintains

an

alternator

output

voltage

constant

Page 180 of 537

Engine

Electrical

System

r

l

I

I

I

i

r

Ye

Ff

p

Stator

ma

ture

coiJ

FF

vw

I

I

RI

L

Rot

r

field

C

oil

e

R

I

I

I

I

I

J

1

J

Alternator

Voltage

regulator

11

t

c

I

Fusible

link

t

8

c

J

5

9

i

c

c

0

Battery

t

u

J

EE029

Fig

EE

23

Charging

circuit

II

p

ns

1

Slator

ar

ature

coil

teJ

U

2iI

I

r

R

l

I

I

A3

R2

0

Fusible

link

Roto

field

coil

e

I

I

t

I

I

PS

M

g

j

t

i

H

U

Battery

Lh

A

l

a

o

J

L

V

It

g

t

f

EE030

Fig

EE

24

Charging

circuit

II

EE

13

Page 182 of 537

DESCRIPTION

REMOVAL

DISASSEMBLY

INSPECTION

AND

REPAIR

ROTOR

INSPECTION

INSPECTION

OF

STATOR

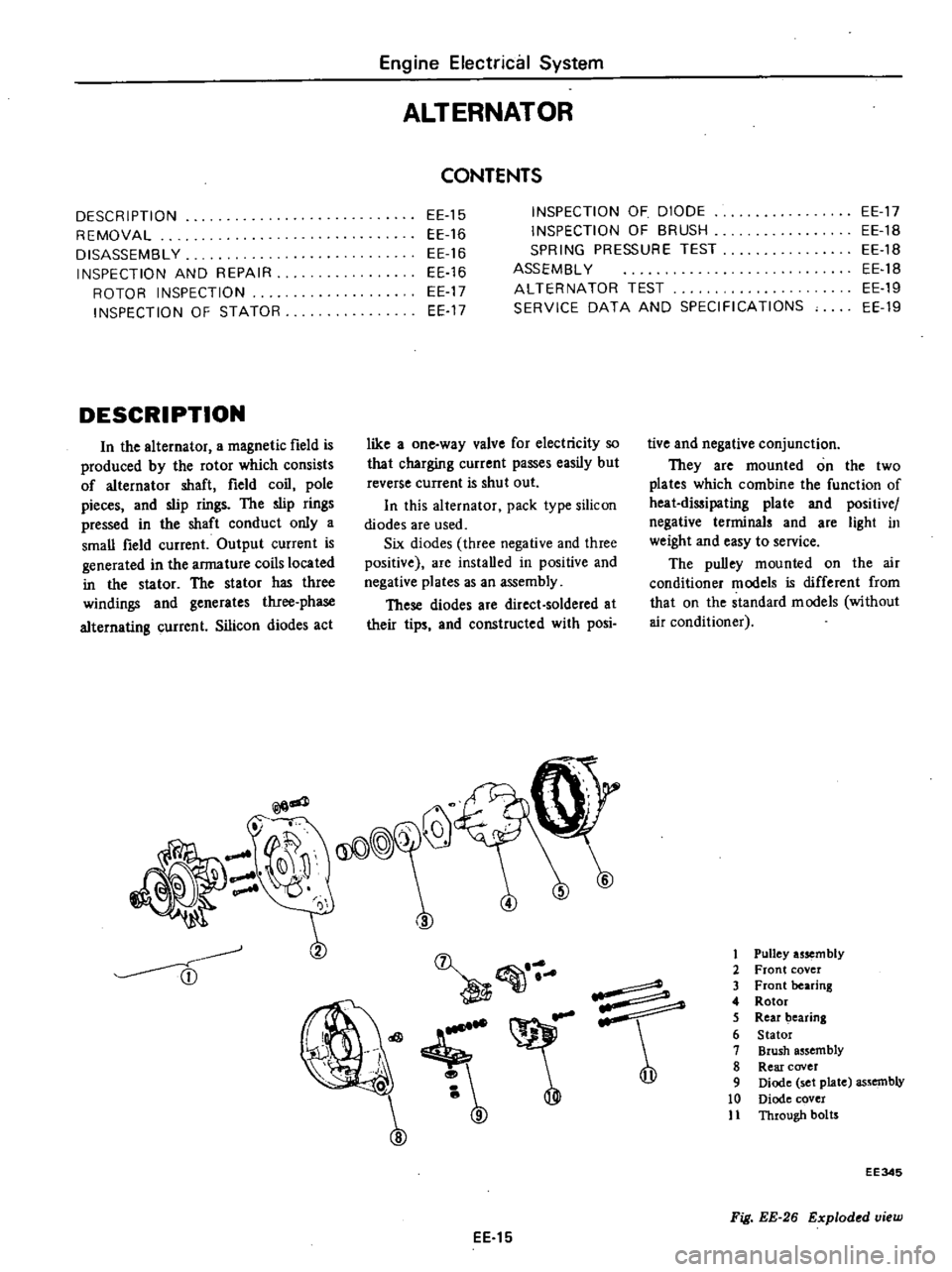

DESCRIPTION

In

the

alternator

a

magnetic

field

is

produced

by

the

rotor

which

consists

of

alternator

shaft

field

coil

pole

pieces

and

slip

rings

The

slip

rings

pressed

in

the

shaft

conduct

only

a

small

field

current

Output

current

is

generated

in

the

armature

coils

located

in

the

stator

The

stator

has

three

windings

and

generates

three

phase

alternating

current

Silicon

diodes

act

@God

A

tfff

Engine

Electrical

System

ALTERNATOR

CONTENTS

EE

15

EE

16

EE

16

EE

16

EE

17

EE

17

INSPECTION

OF

DIODE

INSPECTION

OF

BRUSH

SPRING

PRESSURE

TEST

ASSEMBL

Y

ALTERNATOR

TEST

SERVICE

DATA

AND

SPECIFICATIONS

EE

17

EE

1B

EE1B

EE

1B

EE19

EE

19

like

a

one

way

valve

for

electricity

so

that

charging

current

passes

easily

but

reverse

current

is

shut

out

In

this

alternator

pack

type

silicon

di

odes

are

used

Six

diodes

three

negative

and

three

positive

are

installed

in

positive

and

negative

plates

as

an

assembly

These

diodes

are

direct

soldered

at

their

tips

and

constructed

with

posi

3

2

I

4

e

o

e

9

tive

and

negative

conjunction

They

are

mounted

on

the

two

plates

which

combine

the

function

of

heat

dissipating

plate

and

positive

negative

terminals

and

are

light

in

weight

and

easy

to

service

The

pulley

mounted

on

the

air

conditioner

models

is

different

from

that

on

the

standard

models

without

air

conditioner

1

Pulley

usem

bly

2

Front

cover

3

Front

bearing

4

Rotor

5

Rear

bearing

6

Stator

7

Brush

assembly

8

Rear

cover

9

Diode

set

plate

assembly

10

Diode

cover

11

Through

botrs

EE

15

EE345

Fig

EE

26

Exploded

view

Page 183 of 537

REMOVAL

1

Disconnect

negative

battery

ter

minaL

2

Disconnect

two

lead

wires

and

connector

from

alternator

3

loosen

adjusting

bolt

4

Remove

alternator

drive

belt

5

Remove

parts

associated

with

alternator

from

engine

6

Remove

alternator

from

vehicle

DISASSEMBLY

1

Remove

pulley

nut

and

pulley

assembly

11

C

@@@

EE033

Fig

EE

27

Removing

pulley

ond

fan

2

Remove

brush

holder

fIxing

screws

and

remove

brush

holder

cover

Pull

brush

holder

fOIWard

and

remove

brushes

together

with

brush

holder

Note

Do

not

disconnect

N

tenninaJ

from

stator

coil

lead

wire

EE346

1

N

terminal

2

Brush

holder

3

Brush

holder

co

r

Fig

EE

28

Remouing

brush

Engine

Electrical

System

3

Remove

through

bolts

Separate

front

cover

with

rotor

from

rear

cover

with

stator

by

lightly

tapping

front

bracket

with

a

wooden

mallet

J

J

4

C

EE035

Fig

EE

29

Separating

front

cover

with

rotor

from

rear

cover

4

Remove

three

set

screws

from

bearing

retainer

and

separate

rotor

from

front

cover

DO

Q

EE036

Fig

EE

3D

Removing

rotor

5

Pull

rear

bearing

out

from

rotor

assembly

with

a

press

or

bearing

puller

L

I

EE037

Fig

EE

3I

Pulling

out

of

roar

bearing

EE

16

6

Remove

diode

cover

fIXing

screw

and

remove

diode

cover

Disconnect

three

stator

coil

lead

wires

from

diode

terminal

with

a

soldering

iron

7

Remove

A

tenninaJ

nut

and

diode

installation

nut

and

remove

diode

assembly

CD

AJ

f

e

ecA

O

1

Diode

assembly

o

2

Diode

cover

o

EE039

Fig

EE

32

Removing

diode

088embly

Note

Use

care

in

assembly

to

on

it

handling

diode

an

undue

st

INSPECTION

AND

REPAIR

Remove

alternator

from

car

and

connect

a

circuit

tester

between

F

tenninal

and

E

terminal

When

the

resistance

is

approxi

mately

5il

the

condition

of

brush

and

fIeld

coil

is

satisfactory

When

no

continuity

exists

in

brush

or

fIeld

coil

or

when

resistance

differs

significantly

between

those

parts

dis

assemble

and

inspect

A

o

E

O

1

ld

Q

EE040

Fig

EE

33

Inspecting

alternator

Page 184 of 537

ROTOR

INSPECTION

1

Continuity

test

of

rotor

coil

Apply

tester

between

slip

rings

of

rotor

as

shown

in

Figure

EE

34

If

there

is

no

continuity

field

coil

is

open

Replace

rotor

assembly

EE041

Fig

EE

34

Continuity

test

of

rotor

coil

2

Ground

test

of

rotor

coil

Check

continuity

between

slip

ring

and

rotor

core

If

continuity

exists

replace

rotor

assembly

because

rotor

coil

or

slip

ring

may

be

grounded

Fig

EE

35

Testing

rotor

coil

for

round

INSPECTION

OF

STATOR

1

Continuity

test

Stator

is

normal

when

there

is

continuity

between

individual

stator

coil

tenninals

When

there

is

no

conti

nuity

between

individual

terminals

cable

is

broken

Replace

with

stator

assembly

EE043

Fig

EE

36

Testing

stator

for

continuity

Engine

Electrical

System

2

Ground

test

If

each

lead

wire

of

stator

coil

including

neutral

wire

is

not

conduc

tive

with

stator

core

condition

is

satisfactory

If

there

is

continuity

stator

coil

is

grounded

EE045

Stator

core

Fig

EE

37

Ee044

Teding

stator

for

P

Ound

Conductive

direction

I

Diode

installed

on

EEl

plate

is

a

positive

diode

which

allows

current

flowing

from

terminal

to

EEl

plate

only

In

other

words

current

does

not

flow

from

EEl

plate

to

terminal

v

1

ptate

2

Terminal

EE046

INSPECTION

OF

DIODE

Perform

a

continuity

test

on

diodes

in

both

directions

using

an

ohmmeter

A

total

of

six

diodes

are

used

three

are

mounted

on

the

positive

EEl

plate

and

other

three

are

on

the

negative

e

plate

The

continuity

test

should

be

performed

on

each

diode

between

the

terminal

and

plate

I

plate

2

ptate

3

Diode

Fig

EE

38

Conductive

direction

of

diode

Diode

installed

on

e

plate

is

a

negative

diode

which

allows

current

flowing

from

e

plate

to

terminal

only

In

other

words

current

does

not

flow

from

terminal

to

e

plate

I

plate

2

Terminal

EE047

Fig

EE

39

Inspecting

positive

diode

Fig

EE

40

Insp

cting

negative

diode

EE

17

Page 185 of 537

If

current

flows

in

both

positive

and

negative

directions

diode

is

short

circuited

If

current

flows

in

one

direc

tion

only

diode

is

in

good

condition

Test

probe

of

a

circuit

t

ter

e

Gl

terminal

EEl

plate

EJ

plate

terminal

terminal

e

plate

e

plate

terminal

e

plate

@

plate

Xl

plate

e

plate

INSPECTION

OF

BRUSH

Check

movement

of

brush

and

if

movement

is

not

smooth

check

brush

holder

and

clean

if

necessary

Check

brush

for

wear

If

it

is

worn

down

to

less

than

the

specified

limit

replace

brush

assembly

Check

brush

pig

tail

and

if

dam

aged

replace

Brush

wear

limiting

line

EE127

Fig

EE

41

Bnlsh

wear

limil

Engine

Electrical

System

If

there

is

a

faulty

diode

replace

all

diodes

ix

diode

as

an

assembly

See

table

below

These

diodes

are

unserviceable

Conduction

o

o

o

SPRING

PRESSURE

TEST

With

brush

projected

approximate

ly

2

mm

0

079

in

from

brush

holder

measure

brush

spring

pressure

by

the

use

of

a

pring

balance

Normally

the

rated

pressure

of

a

new

brush

spring

is

255

to

345

gr

9

0

to

12

202

Morevover

when

brush

is

worn

pressure

decrease

approximately

20

g

0

7

02

per

1

mm

0

0039

in

wear

t

m

0

079

in

or

f

EEO

9

Fig

EE

42

M

CJ

uring

pring

preaure

EE

lB

ASSEMBLY

Reassemble

alternator

in

the

reverse

sequence

of

disassembly

noting

the

following

I

When

soldering

each

stator

coil

lead

wire

to

diode

assembly

terminal

carry

out

the

operation

as

fast

as

pas

sible

2

When

installing

diode

A

terminal

install

insulating

bush

correctly

1

Imulating

bush

2

A

terminal

bolt

3

Diode

cover

4

Rear

cover

5

Diode

a

sembly

EE347

Fig

EE

43

Sectional

view

of

diode

and

A

term

inal

3

Tighten

pulley

nut

with

tighten

ing

torque

of

3

5

to

4

0

kg

m

25

3

to

29

0

ft

Ib

When

pulley

is

tightened

make

sure

that

deflection

of

V

groove

is

less

than

0

3

mm

0

01

IS

in

q

ffl

t

EE051

Fig

EE

44

Tightening

pulley

nut

Page 187 of 537

DESCRIPTION

MEASUREMENT

OF

REGULATOR

VOLTAGE

ADJUSTMENT

VOLTAGE

REGULATOR

DESCRIPTION

The

regulator

consists

basically

of

a

voltage

regulator

and

a

charge

relay

The

voltage

regulator

has

two

sets

of

contact

points

a

lower

set

and

an

upper

set

to

control

alternator

volt

age

An

armature

plate

placed

between

the

two

sets

of

contacts

moves

upward

or

downward

or

vibrates

The

lower

contacts

when

closed

complete

the

jCV

ID@

@

GJ

I

@

@

@

Engine

Electrical

System

REGULATOR

CONTENTS

EE

20

CHARGING

RELAY

SERVICE

DATA

AND

SPECIFICATIONS

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Including

alternatorl

EE

25

EE

23

EE

24

EE

20

EE

23

EE

23

field

circuit

direct

to

ground

and

the

upper

contacts

when

closed

complete

the

field

circuit

to

ground

through

a

resistance

field

coil

and

produce

alternator

output

The

charge

relay

i

similar

in

construction

to

the

voltage

regulator

When

the

upper

contacts

are

closed

charge

warning

lamp

goes

on

v

1

Charge

relay

2

Voltage

regulator

EE285

Fig

EE

46

View

of

removing

cover

As

regards

the

construction

the

voltage

regulator

is

very

similar

to

the

charge

relay

as

shown

in

Figure

EE47

@

r

J

CD

@

@

@

Q

@

ID@

ID@

J

t

L

T

@

r

b

r

CD

L

@

j

1

g

f

@

@

EEJ97

J

I1Jlccting

spring

2

Y

kt

g

p

3

Armaturc

4

Core

go

5

Low

Sllccd

lnlacl

h

Point

ap

7

High

speed

conlat

t

8

Contact

c

9

3111111

0

118

ill

di

10

41l1I11W

157in

c1ia

few

II

Cuil

12

lock

nut

J3

Adjllslin

screw

14

Adjll

sting

sprin

15

Yoke

9

Adjusting

screw

10

Lock

nut

11

Coil

12

4mm

0

157

in

dia

screw

13

3mm

0

118

in

dla

crew

14

Contact

iet

15

Voltage

cgulatm

contact

a

Cnl1

Tlll

tion

f

lltagl

l

j

llIOltllT

I

Point

gilp

2

Charge

relay

contllct

3

Core

gap

4

ArlllatlJre

5

Connecting

sprin

6

Yoke

gap

7

Yoh

B

Adjusting

pring

b

Construction

of

charge

relay

Fig

EE

47

Structural

vi

w

EE

20

Page 190 of 537

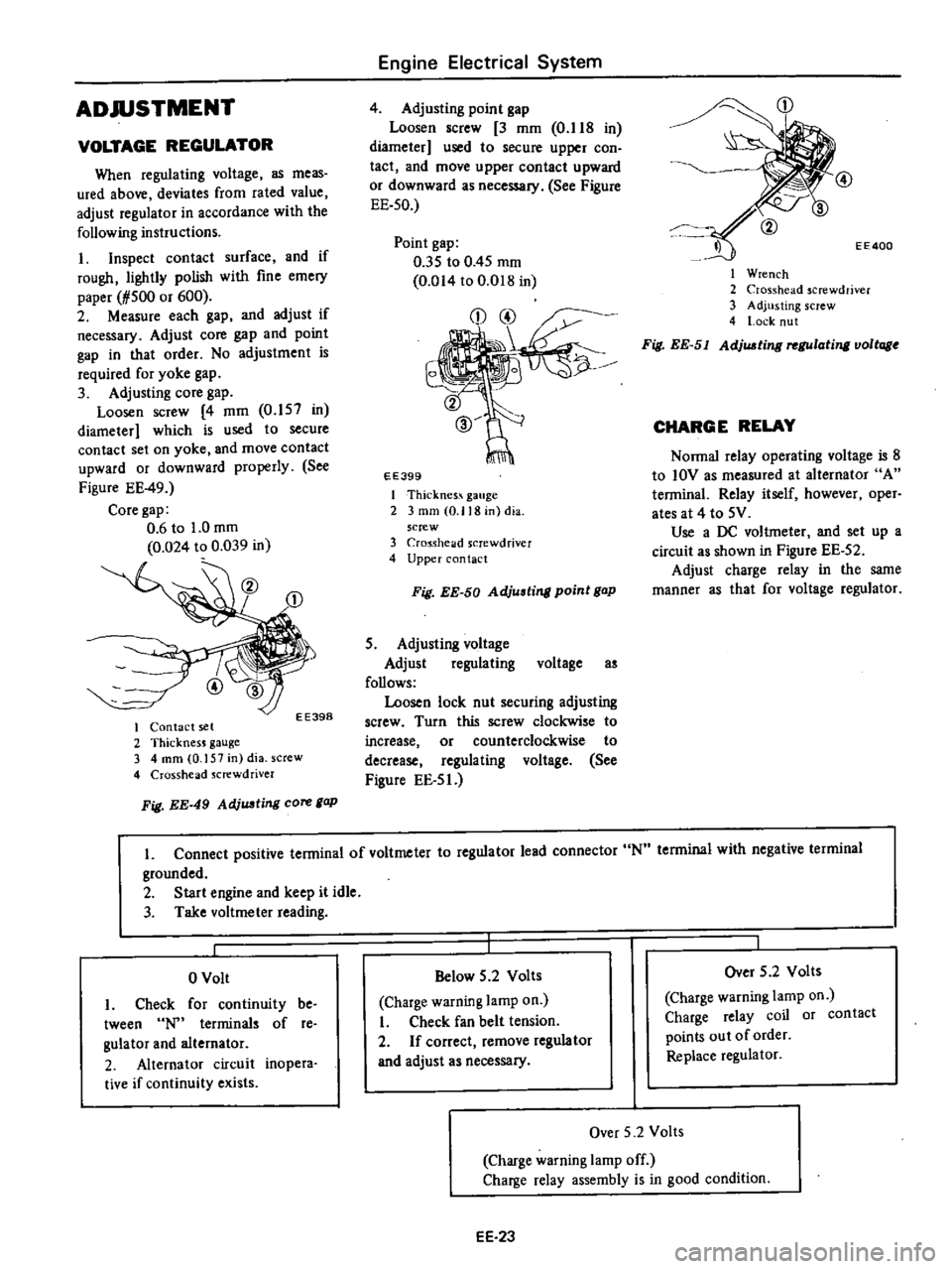

ADJUSTMENT

VOLTAGE

REGULATOR

When

regulating

voltage

as

meas

ured

above

deviates

from

rated

value

adjust

regulator

in

accordance

with

the

following

instructions

I

Inspect

contact

surface

and

if

rough

lightly

polish

with

fine

emery

paper

1

500

or

600

2

Measure

each

gap

and

adjust

if

necessary

Adjust

core

gap

and

point

gap

in

that

order

No

adjustment

is

required

for

yoke

gap

3

Adjusting

core

gap

Loosen

screw

4

mm

0

157

in

diameter

which

is

used

to

secure

contact

set

on

yoke

and

move

contact

upward

or

downward

properly

See

Figure

EE

49

Core

gap

0

6

to

1

0

mm

0

024

to

0

039

in

EE398

I

Contact

set

2

ThicknesJ

gauge

3

4

mm

0

157

in

dia

screw

4

Crosshead

Jcrewdriver

Fig

EE

49

AdjUJJting

core

gap

Engine

Electrical

System

4

Adjusting

point

gap

Loosen

screw

3

mm

O

lIS

in

diameter

used

to

secure

upper

con

tact

and

move

upper

contact

upward

or

downward

as

necessary

See

Figure

EE

50

Point

gap

035

to

0

45

mm

0

014

to

O

D1S

in

EE399

I

Thicknes

gauge

2

3

mm

0

118

in

dia

screw

3

Cro

Sshelld

screwdriver

4

Upper

contact

Fig

EE

50

Adjusting

point

gap

5

Adjusting

voltage

Adjust

regulating

voltage

as

follows

Loosen

lock

nut

securing

adjusting

screw

Turn

this

screw

clockwise

to

increase

or

counterclockwise

to

decrease

regulating

voltage

See

Figure

EE

5

J

CD

EE400

I

Wrench

2

Crosshead

screwdriver

3

Adjusting

screw

4

l

ock

nut

Fig

EE

51

AdjUJJting

rel

Ulating

voltage

CHARGE

RELAY

Nonna

relay

operating

voltage

is

S

to

IOV

as

measured

at

alternator

A

tenninal

Relay

itself

however

oper

ates

at

4

to

5V

Use

a

DC

voltmeter

and

set

up

a

circuit

as

shown

in

Figure

EE

52

Adjust

charge

relay

in

the

same

manner

as

that

for

voltage

regulator

L

Connect

positive

tenninal

of

voltmeter

to

regulator

lead

connector

N

tenninal

with

negative

terminal

grounded

2

Start

engine

and

keep

it

idle

3

Take

voltmeter

reading

o

Volt

I

Check

for

continuity

be

tween

terminals

of

re

gulator

and

alternator

2

Alternator

circuit

inopera

tive

if

continuity

exists

Below

5

2

Volts

Charge

warning

lamp

on

I

Check

fan

belt

tension

2

If

correct

remove

regulator

and

adjust

as

necessary

Over

5

2

Volts

Charge

warning

lamp

on

Charge

relay

coil

or

contact

points

out

of

order

Replace

regulator

Over

5

2

Volts

Charge

warning

lamp

off

Charge

relay

assembly

is

in

good

condition

EE

23

Page 191 of 537

Engine

Electrical

System

RegulatoI

r

Yellow

terminal

A

W

L

WR

IG

WL

N

Y

E

B

F

WB

Voltmeter

Fig

EE

52

Tuting

charging

re

Qy

EE348

SERVICE

DATA

AND

SPECIFICATIONS

Voltage

legulator

Type

Regulating

voltage

with

fully

charged

battery

Voltage

coil

resistance

RotOI

coil

inserting

resistance

Voltage

coil

series

resistance

Smoothing

resistance

COle

gap

Point

gap

Ch

uge

lay

Release

voltage

Voltage

coil

resistance

Core

gap

Point

gap

v

fl

nun

in

nun

in

V

fl

nun

in

mID

in

TLl

Z

S5C

14

3

to

15

3

at

200C

680F

10

5

at

200C

680F

10

31

40

0

6

to

1

0

0

024

to

0

039

0

35

to

0

45

0

014

to

O

OIS

4

2

to

5

2

at

N

terminal

37

S

at

200C

680F

0

8

to

1

0

0

031

to

0

039

0

4

to

0

6

0

016

to

0

024

Standard

tempelatUIe

gIlIdient

O

OISV

oC

EE

24

Page 193 of 537

NON

CALIFORNIA

MODELS

Engine

Electrical

System

IGNITION

CIRCUIT

CONTENTS

EE

26

CALIFORNIA

MODELS

EE

2B

NON

CALIFORNIA

MODELS

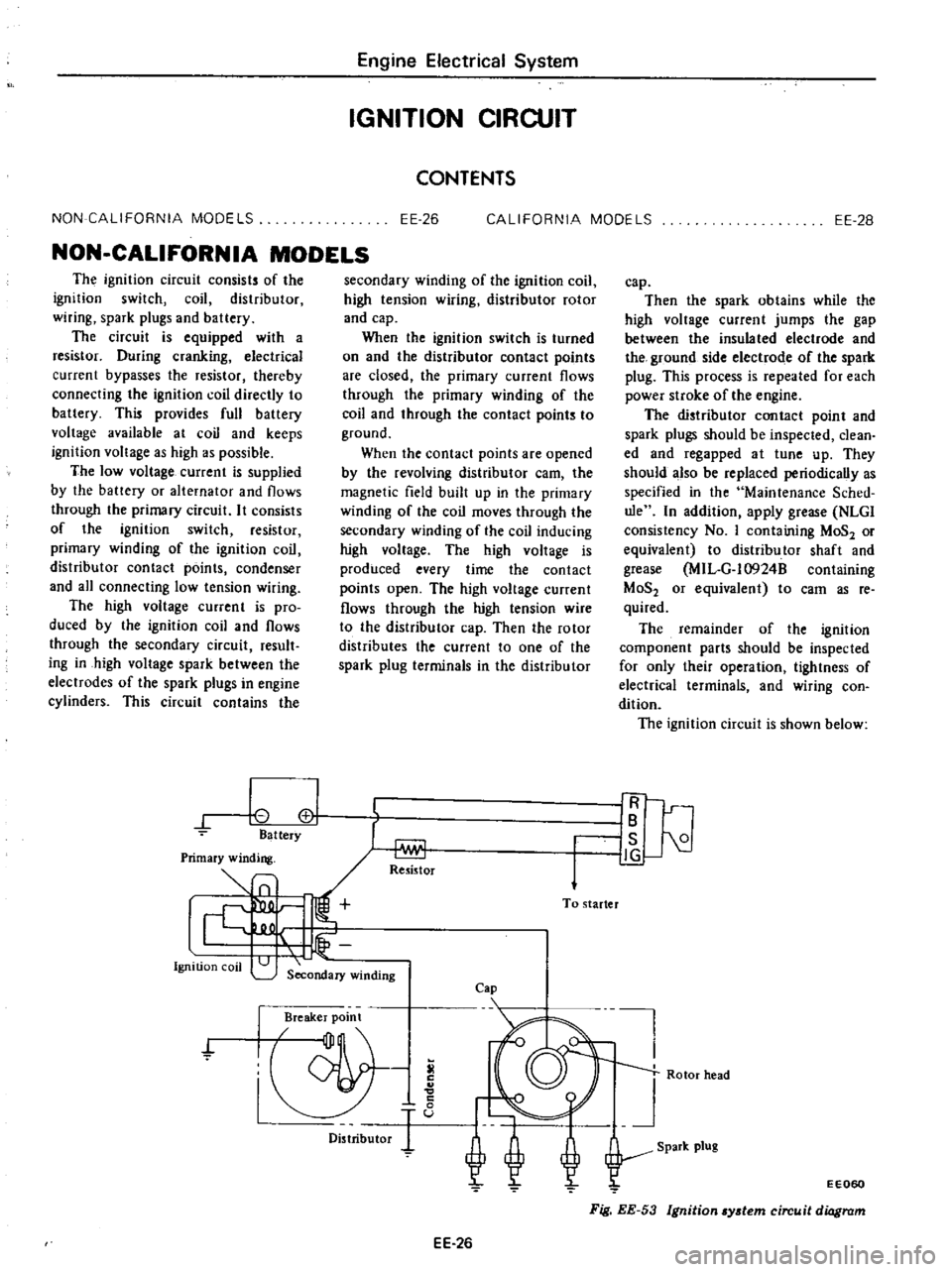

The

ignition

circuit

consists

of

the

ignition

switch

coil

distributor

wiring

spark

plugs

and

battery

The

circuit

is

equipped

with

a

resistor

During

cranking

electrical

current

bypasses

the

resistor

thereby

connecting

the

ignition

coil

directly

to

battery

This

provides

full

battery

voltage

available

at

coil

and

keeps

ignition

voltage

as

high

as

possible

The

low

voltage

current

is

supplied

by

the

battery

or

alternator

and

flows

through

the

primary

circuit

It

consists

of

the

ignition

switch

resistor

primary

winding

of

the

ignition

coil

distributor

contact

points

condenser

and

all

connecting

low

tension

wiring

The

high

voltage

current

is

pro

duced

by

the

ignition

coil

and

flows

through

the

secondary

circuit

result

ing

in

high

voltage

spark

between

the

electrodes

of

the

spark

plugs

in

engine

cylinders

This

circuit

contains

the

0

cl

Battery

Ignition

coil

secondary

winding

of

the

ignition

coil

high

tension

wiring

distributor

rotor

and

cap

When

the

ignition

switch

is

turned

on

and

the

distributor

contact

points

are

closed

the

primary

current

flows

through

the

primary

winding

of

the

coil

and

through

the

contact

points

to

ground

When

the

contact

points

are

opened

by

the

revolving

distributor

earn

the

magnetic

field

built

up

in

the

primary

winding

of

the

coil

moves

through

the

secondary

winding

of

the

coil

inducing

high

voltage

The

high

voltage

is

produced

every

time

the

contact

points

open

The

high

voltage

current

flows

through

the

high

tension

wire

to

the

distributor

cap

Then

the

rotor

distributes

the

current

to

one

of

the

spark

plug

terminals

in

the

distributor

Re5istor

To

starter

Secondary

winding

Cap

Breaker

point

f

Distributor

EE

26

cap

Then

the

spark

obtains

while

the

high

voltage

current

jumps

the

gap

between

the

insulated

electrode

and

the

ground

side

electrode

of

the

spark

plug

This

process

is

repeated

for

each

power

stroke

of

the

engine

The

distributor

contact

point

and

spark

plugs

should

be

inspected

clean

ed

and

regapped

at

tune

up

They

should

also

be

replaced

periodically

as

specified

in

the

Maintenance

Sched

ule

In

addition

apply

grease

NLGl

consistency

No

I

containing

MoS2

or

equivalent

to

distributor

shaft

and

grease

MIL

G

l0924B

containing

MoS2

or

equivalent

to

cam

as

reo

quired

The

remainder

of

the

ignition

component

parts

should

be

inspected

for

only

their

operation

tightness

of

electrical

terminals

and

wiring

con

dition

The

ignition

circuit

is

shown

below

IR

IB

I

is

21

J

g

Rotor

head

EE060

Fig

EE

53

Ignition

ydem

circuit

diagram