engine oil DATSUN PICK-UP 1977 Manual Online

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 194 of 537

FUSIBLE

LtNK

m

Engine

Electrical

System

E

CJI2t

Bf

o

00

00

fOl

R

BL

I

ti

L

oj

L

C

J

RESISTOR

IGNITION

COIL

COLOR

CODE

B

Black

OW

Black

with

white

stripe

DR

Black

with

red

stripe

aL

Black

with

blue

stripe

W

White

W

R

Wj

BW

BR

IGNITION

SWtTCH

DISTRtBUTOR

jjj

SPARK

PLUGS

EE493

EE

27

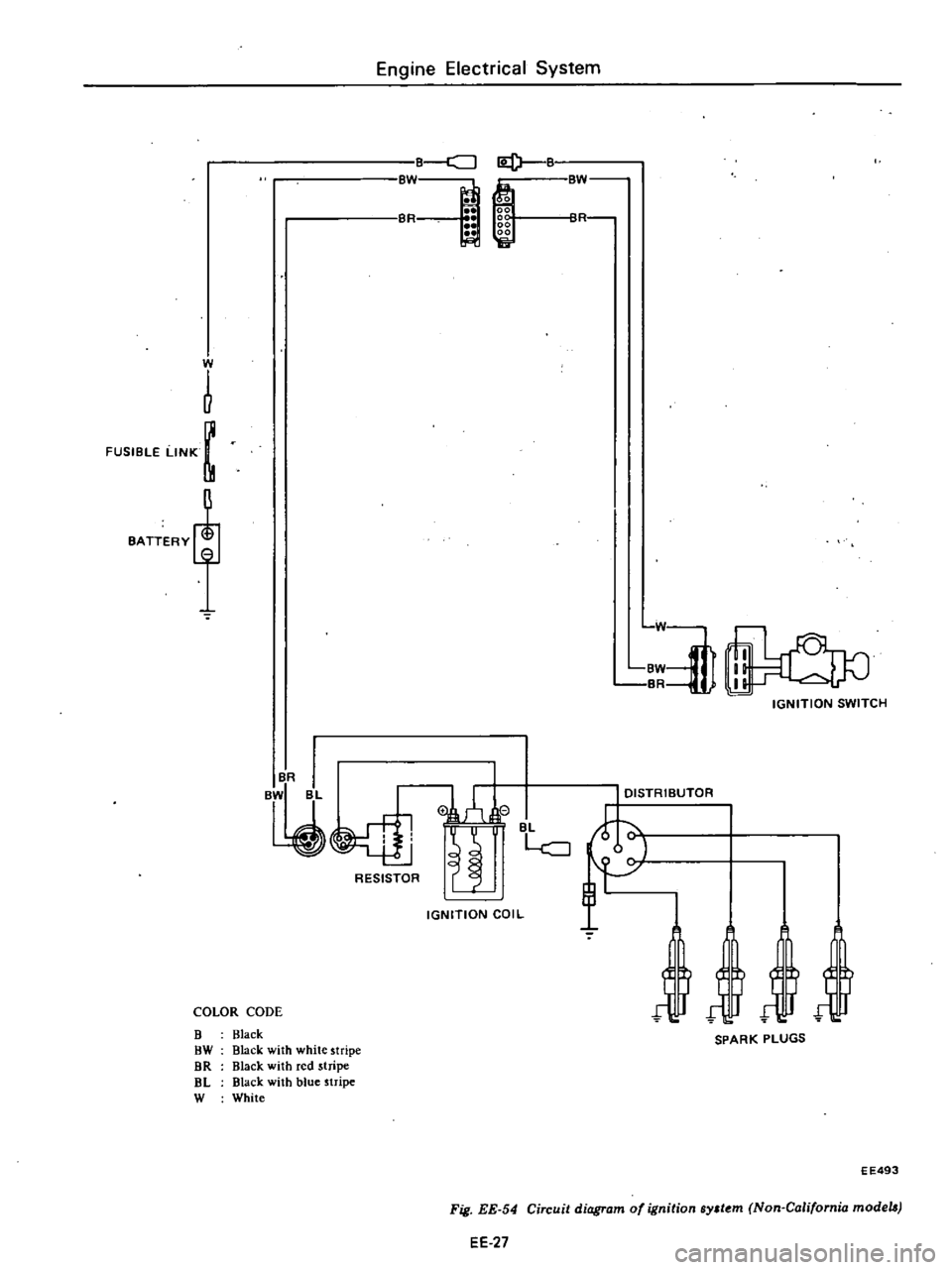

Fig

EE

54

Circuit

diagram

of

ignition

ByJt

m

Non

California

models

Page 195 of 537

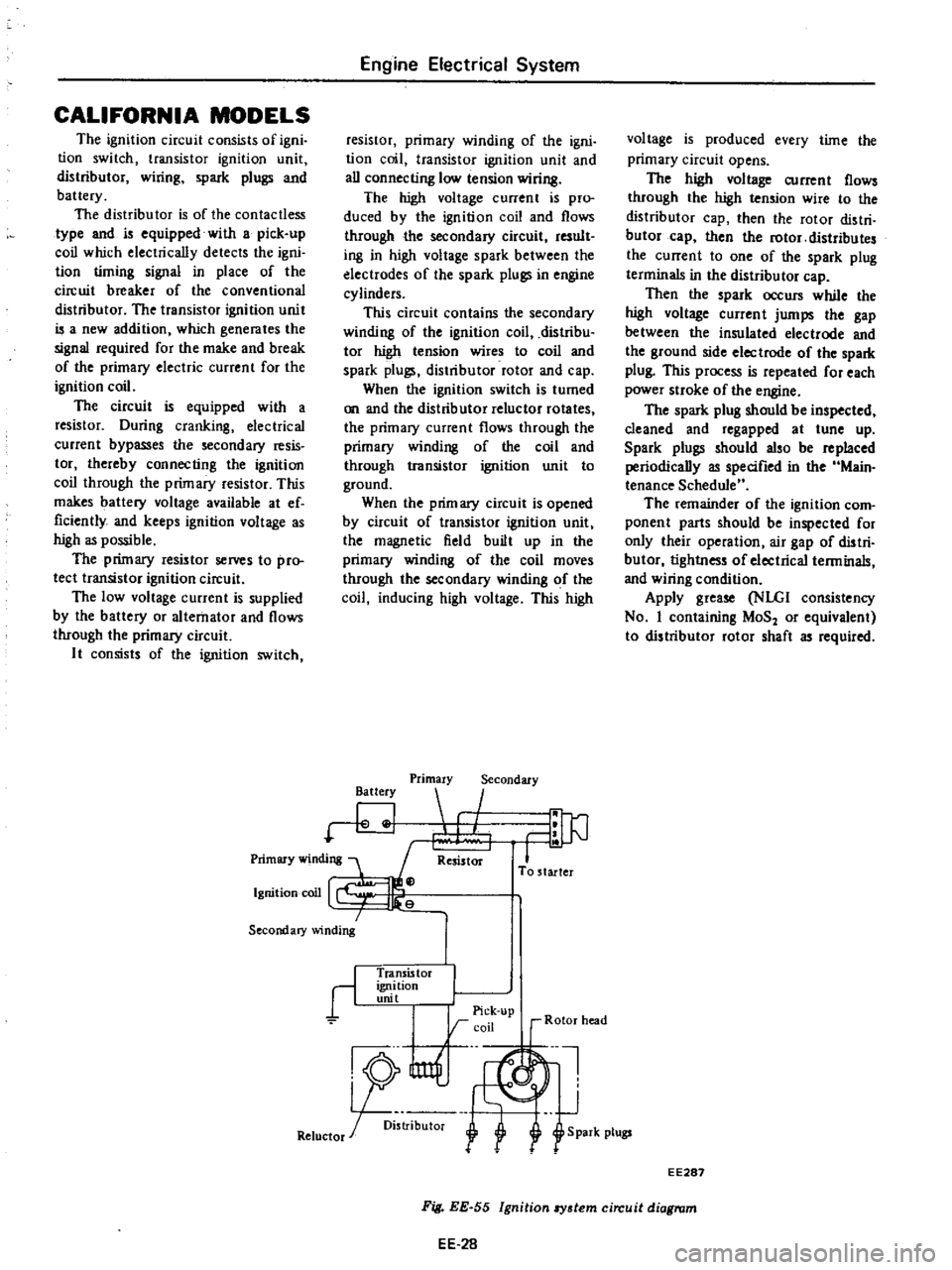

Primary

winding

1

Ignition

coo

I

Secondary

winding

CALIFORNIA

MODELS

The

ignition

circuit

consists

of

igni

tion

switch

transistor

ignition

unit

distributor

wiring

spark

plugs

and

battery

The

distributor

is

of

the

contactless

type

and

is

equipped

with

a

pick

up

coil

which

electrically

detects

the

igni

tion

timing

signal

in

place

of

the

circuit

breaker

of

the

conventional

distributor

The

transistor

ignition

unit

is

a

new

addition

which

generates

the

signal

required

for

the

make

and

break

of

the

primary

electric

current

for

the

ignition

coil

The

circuit

is

equipped

with

a

resistor

During

cranking

electrical

current

bypasses

the

secondary

resis

tor

thereby

connecting

the

ignition

coil

through

the

primary

resistor

This

makes

battery

voltage

available

at

ef

ficiently

and

keeps

ignition

voltage

as

high

as

possible

The

primary

resistor

selVeS

to

pro

tect

transistor

ignition

circuit

The

low

voltage

current

is

supplied

by

the

battery

or

alternator

and

flows

through

the

primary

circuit

It

consists

of

the

ignition

switch

Engine

Electrical

System

resistor

primary

winding

of

the

igni

tion

coil

transistor

ignition

unit

and

all

connecting

low

tension

wiring

The

high

voltage

current

is

pro

duced

by

the

ignition

coil

and

flows

through

the

secondary

circuit

result

ing

in

high

voltage

spark

between

the

electrodes

of

the

spark

plugs

in

engine

cylinders

This

circuit

contains

the

secondary

winding

of

the

ignition

coil

distribu

tor

high

tension

wires

to

coil

and

spark

plugs

distributor

rotor

and

cap

When

the

ignition

switch

is

turned

on

and

the

distributor

reluctor

rotates

the

primary

current

flows

through

the

primary

winding

of

the

coil

and

through

transistor

ignition

unit

to

ground

When

the

prim

ary

circuit

is

opened

by

circuit

of

transistor

ignition

unit

the

magnetic

field

built

up

in

the

primary

winding

of

the

coil

moves

through

the

secondary

winding

of

the

coil

inducing

high

voltage

This

high

Battery

Primary

Secondary

I

Resistor

To

starter

r

Transis

tor

ignition

unit

I

I

Pick

up

rcoil

r

Rotor

head

nl

J

R5

U1f

1

Retuctor

r

oi

l

f

S

park

plugs

voltage

is

produced

every

time

the

primary

circuit

opens

The

high

voltage

current

flows

through

the

high

tension

wire

to

the

distributor

cap

then

the

rotor

distri

butor

cap

then

the

rotor

distributes

the

current

to

one

of

the

spark

plug

terminals

in

the

distributor

cap

Then

the

spark

occurs

while

the

high

voltage

current

jumps

the

gap

between

the

insulated

electrode

and

the

ground

side

electrode

of

the

spark

plug

This

process

is

repeated

for

each

power

stroke

of

the

engine

The

spark

plug

should

be

inspected

cleaned

and

regapped

at

tune

up

Spark

plugs

should

also

be

replaced

periodically

as

specified

in

the

Main

tenance

Schedule

The

remainder

of

the

ignition

com

ponent

parts

should

be

inspected

for

only

their

operation

air

gap

of

distri

butor

tightness

of

electrical

terminals

and

wiring

condition

Apply

grease

NLGI

consistency

No

I

containing

MoS

or

equivalent

to

distributor

rotor

shaft

as

required

EE287

EE

28

Fig

EE

55

Ignition

8Y3tem

circuit

diagram

Page 196 of 537

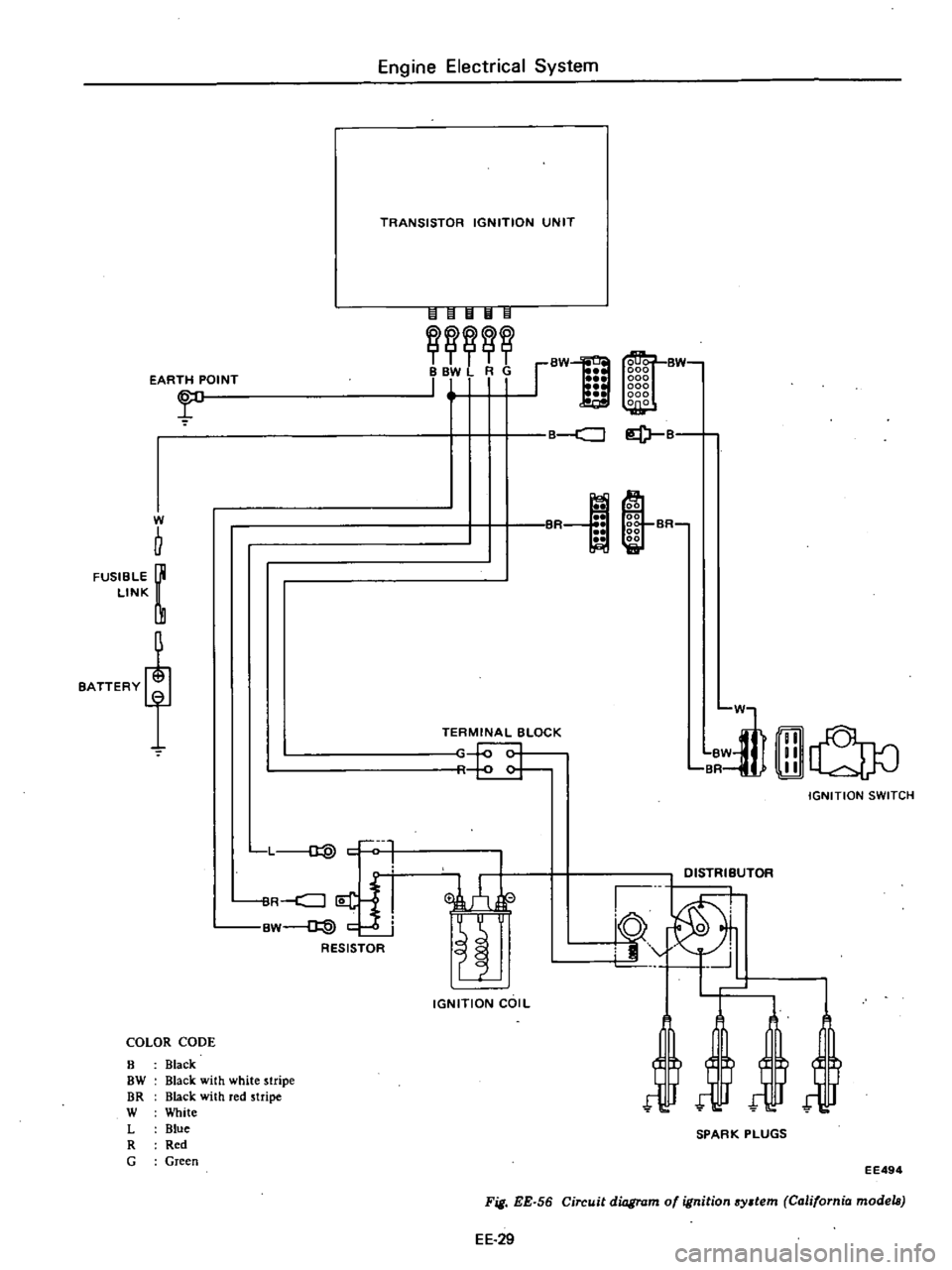

EARTH

POINT

r

W

b

FUSIBLE

LINK

BATTERY

L

d

l

ilR

j

i

BW

@

c

RESISTOR

COLOR

CODE

8

Black

OW

Black

with

white

stripe

DR

Black

with

red

stripe

W

White

L

Blue

R

Red

G

Green

Engine

Electrical

System

TRANSISTOR

IGNITION

UNIT

IHIIl

II

II

BW

BBV

RG

111

I

I

TERMINAL

BLOCK

r

c

IGNITION

COIL

BW

B

ml

BR

lliJ

LldJ0

IGNITION

SWITCH

EE

29

Fig

EE

56

Circuit

diagram

of

ignition

system

California

models

EE494

a

B

lof1

@

00

00

00

SR

00

00

Et

liiI

in

D1STRliUTOR

10

0

i9

J

SPARK

PLUGS

Page 198 of 537

CHECKING

AND

ADJUSTMENT

CAP

AND

ROTOR

HEAD

Cap

and

rotor

head

should

be

in

spected

periodically

as

specified

in

the

Maintenance

Schedule

Remove

cap

and

clean

all

dust

and

carbon

deposits

from

cap

and

rotor

If

cap

is

cracked

or

is

leaking

replace

with

a

De

one

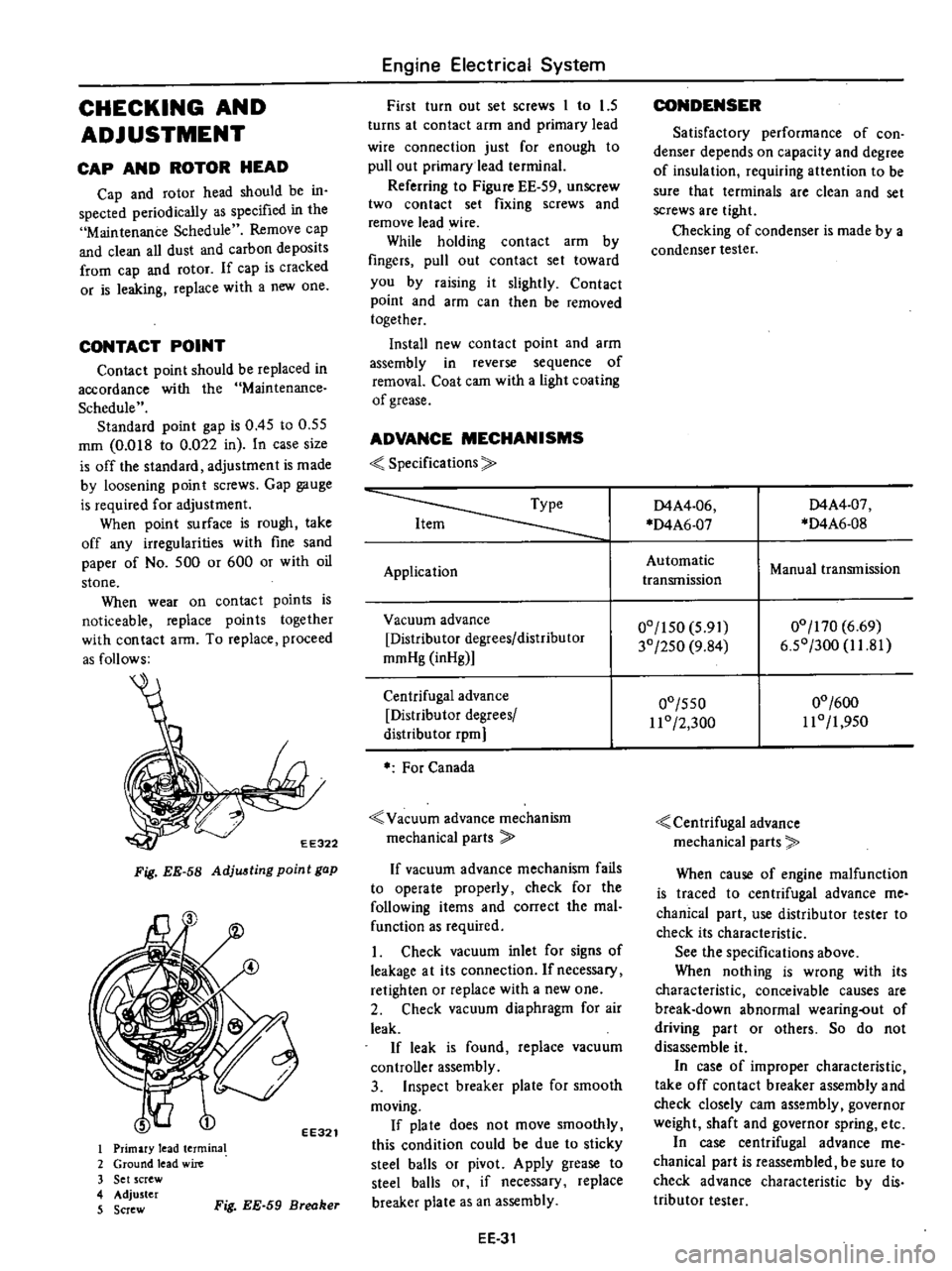

CONTACT

POINT

Contact

point

should

be

replaced

in

accordance

with

the

Maintenance

Schedule

Standard

point

gap

is

0

45

to

0

55

mm

O

OIS

to

0

022

in

In

case

size

is

off

the

standard

adjustment

is

made

by

loosening

point

screws

Gap

gauge

is

required

for

adjustment

When

point

surface

is

rough

take

off

any

irregularities

with

fine

sand

paper

of

No

500

or

600

or

with

oil

stone

When

wear

on

contact

points

is

noticeable

replace

points

together

with

contact

arm

To

replace

proceed

as

follows

EE322

Fig

EE

58

Adju

ting

point

gap

EE321

I

Primary

lead

termina

2

Ground

lead

wire

3

Set

screw

4

Adjuster

5

Screw

Fig

EE

59

Breaker

Engine

Electrical

System

First

turn

out

set

screws

1

to

1

5

turns

at

contact

arm

and

primary

lead

wire

connection

just

for

enough

to

pull

out

primary

lead

terminal

Referring

to

Figure

EE

59

unSCrew

two

contact

set

fixing

screws

and

remove

lead

wire

While

holding

contact

arm

by

fingers

pull

out

contact

set

toward

you

by

raising

it

slightly

Contact

point

and

afm

can

then

be

removed

together

Install

new

contact

point

and

arm

assembly

in

reverse

sequence

of

removal

Coat

cam

with

a

light

coating

of

grease

ADVANCE

MECHANISMS

Specifications

Application

Vacuum

advance

Distributor

degrees

distributor

mmHg

inHg

Centrifugal

advance

Distributor

degrees

distribu

tor

rpm

For

Canada

Vacuum

advance

mechanism

mechanical

parts

If

vacuum

advance

mechanism

fails

to

operate

properly

check

for

the

following

items

and

correct

the

mal

function

as

required

1

Check

vacuum

inlet

for

signs

of

leakage

at

its

connection

Ifnecessacy

retighten

or

replace

with

a

new

one

2

Check

vacuum

diaphragm

for

air

leak

If

leak

is

found

replace

vacuum

controller

assembly

3

Inspect

breaker

plate

for

smooth

moving

If

pia

te

does

not

move

smoothly

this

condition

could

be

due

to

sticky

steel

balls

or

pivot

Apply

grease

to

steel

balls

or

if

necessary

replace

breaker

plate

as

an

assembly

EE

31

CONDENSER

Satisfactory

performance

of

con

denser

depends

on

capacity

and

degree

of

insulation

requiring

attention

to

be

sure

that

terminals

are

clean

and

set

screws

are

tight

Checking

of

condenser

is

made

by

a

condenser

tester

D4A4

06

D4A6

07

D4A4

07

D4A6

0S

Automatic

transmission

Manual

transmission

00

150

5

91

30

250

9

S4

00

170

6

69

6

50

300

1I

S1

00

550

11

0

2

300

00

600

110

1

950

Centrifugal

advance

mechanical

parts

When

cause

of

engine

malfunction

is

traced

to

centrifugal

advance

me

chanical

part

use

distributor

tester

to

check

its

characteristic

See

the

specifications

above

When

nothing

is

wrong

with

its

characteristic

conceivable

causes

are

break

down

abnormal

wearing

out

of

driving

part

or

others

So

do

not

disassemble

it

In

case

of

improper

characteristic

take

off

contact

breaker

assembly

and

check

closely

cam

assembly

governor

weight

shaft

and

governor

spring

etc

In

case

centrifugal

advance

me

chanical

part

is

reassembled

be

sure

to

check

advance

characteristic

by

dis

tributor

tester

Page 200 of 537

Engine

Electrical

System

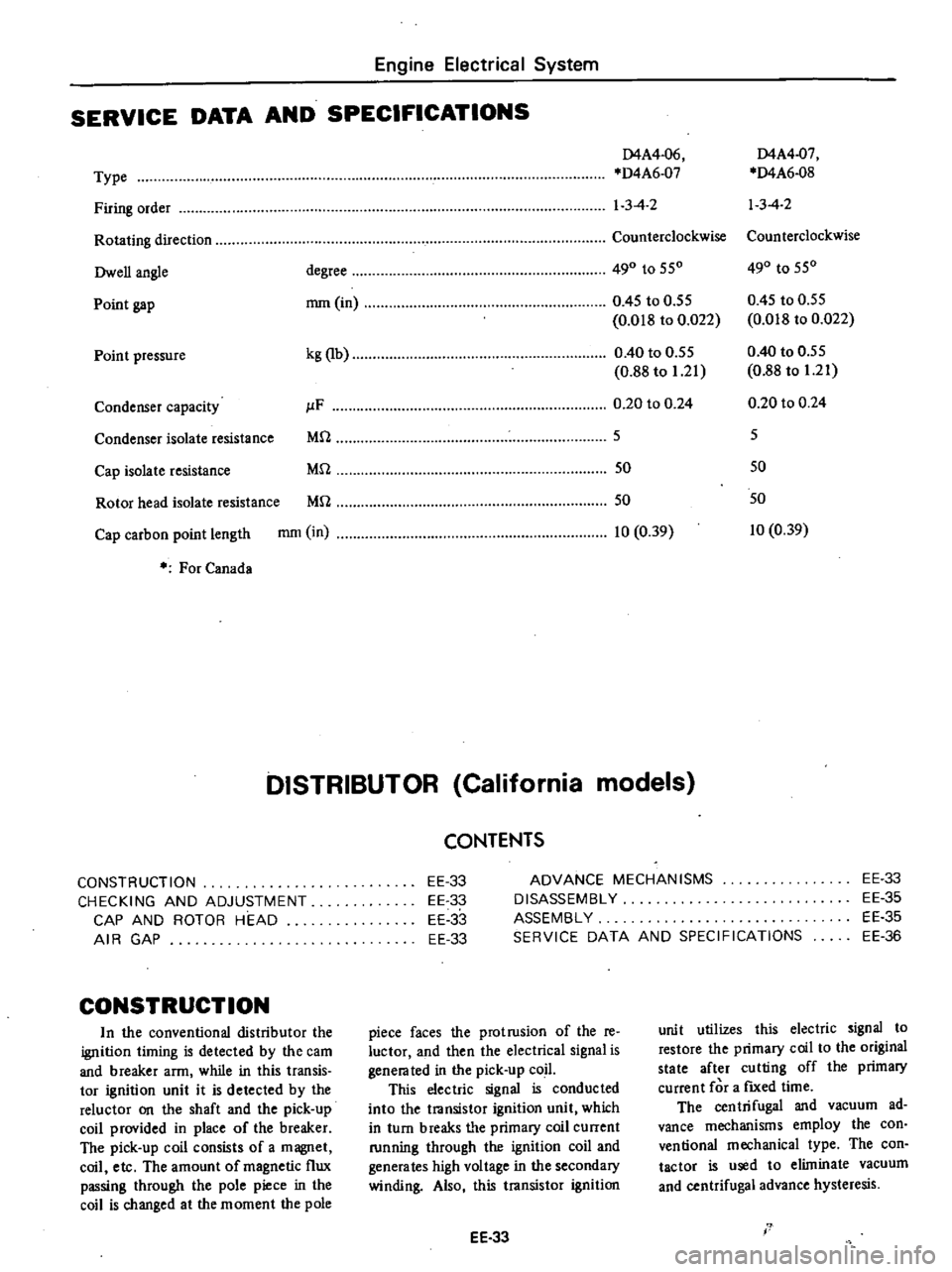

SERVICE

DATA

AND

SPECIFICATIONS

D4A4

06

D4A4

07

Type

D4A6

07

D4A6

08

Firing

order

1

3

4

2

13

4

2

Rotating

direction

Counterclockwise

Counterclockwise

Owen

angle

degree

490

to

550

490

to

550

Point

gap

mm

in

0

45

to

0

55

0

45

to

0

55

0

018

to

0

022

0

018

to

0

022

Point

pressure

kg

lb

0

40

to

0

55

0

40

to

0

55

0

88

to

1

21

0

88

to

1

21

Condenser

capacity

JlF

0

20

to

0

24

0

20

to

0

24

Condenser

isolate

resistance

Mrl

5

5

Cap

isolate

resistance

Mrl

50

50

Rotor

head

isolate

resistance

Mrl

50

50

Cap

carbon

point

length

mm

in

10

0

39

10

0

39

For

Canada

DISTRIBUTOR

California

models

CONSTRUCTION

CHECKING

AND

ADJUSTMENT

CAP

AND

ROTOR

HEAD

AIR

GAP

CONSTRUCTION

In

the

conventional

distributor

the

ignition

liming

is

detected

by

the

cam

and

breaker

arm

while

in

this

transis

tor

ignition

unit

it

is

detected

by

the

reluctor

on

the

shaft

and

the

pick

up

coil

provided

in

place

of

the

breaker

The

pick

up

coil

consists

of

a

magnet

coil

etc

The

amount

of

magnetic

flux

passing

through

the

pole

piece

in

the

coil

is

changed

at

the

moment

the

pole

CONTENTS

EE

33

EE

33

EE

33

EE

33

ADVANCE

MECHANISMS

DISASSEMBLY

ASSEMBLY

SERVICE

DATA

AND

SPECIFICATIONS

EE

33

EE

35

EE

35

EE

36

piece

faces

the

protrusion

of

the

re

luctor

and

then

the

electrical

signal

is

genera

ted

in

the

pick

up

coil

This

electric

signal

is

conducted

into

the

transistor

ignition

unit

which

in

turn

breaks

tI

e

primary

coil

current

running

through

the

ignition

coil

and

generates

high

voltage

in

the

secondary

winding

Also

this

transistor

ignition

EE

33

unit

utilizes

this

electric

signal

to

restore

the

primary

coil

to

the

original

state

after

cutting

off

the

primary

current

for

a

fIXed

time

The

centrifugal

and

vacuum

ad

vance

mechanisms

employ

the

con

ventional

mechanical

type

The

con

tactor

is

used

to

eliminate

vacuum

and

centrifugal

advance

hysteresis

I

Page 201 of 537

t3

l

l

J

@

r

9

V

fW

@

@

CHECKING

AND

ADJUSTMENT

CAP

AND

ROTOR

HEAD

Cap

and

rotor

head

must

be

in

spected

periodically

as

specified

in

the

Maintenance

Schedule

Remove

cap

and

clean

all

dust

and

carbon

deposits

from

cap

and

rotor

from

time

to

time

If

cap

is

cracked

or

is

leaking

replace

with

a

new

one

AIR

GAP

Standard

air

gap

is

0

2

to

0

4

mm

0

008

to

0

016

in

If

the

gap

is

off

the

standard

adjustment

mould

be

made

by

loos

ening

pick

up

coil

screws

Gap

gauge

is

required

for

adjust

ment

Air

gaps

must

be

checked

from

time

to

time

Air

gap

0

2

to

0

4

mm

0

008

to

0

016

in

Engine

Electrical

System

tl

@

9

EE328

Fig

EE

67

Checking

oir

gap

To

remove

pick

up

cail

disconnect

distributor

harness

at

terminal

block

and

remove

screw

securing

pick

up

coil

ADVANCE

MECHANISMS

Specifications

Type

Item

Vacuum

advance

Distributor

degrees

Distributor

mmHg

inHg

Centrifugal

advance

Distributor

degrees

Distributor

cpm

EE34

1

Cap

assembly

2

Rotor

head

a55embly

3

Roll

pin

4

ReJuctor

S

Pick

up

coil

6

Contactoi

7

Breaker

plate

assembly

8

Packing

9

Rotor

shaft

10

Governor

spring

11

Governor

weigh

t

12

Shaft

a

Jscmbly

13

Cap

setter

14

Vacuum

controller

15

Housing

16

Fixing

plate

17

O

ring

18

Collar

EE327

Fig

EE

66

Exploded

view

of

di3tributor

assembly

and

distributor

harness

to

their

positions

EE329

Fig

EE

68

Remouing

pick

up

coil

D4F4

04

D4F4

Q3

Manual

Automatic

00

150

5

91

30

250

9

84

00

550

110

2

300

00

600

110

1

950

Page 202 of 537

Vacuum

advance

mechanism

mechanical

parts

If

vacuum

advance

mechanism

fails

to

operate

properly

check

for

the

following

items

and

correct

the

prob

lem

as

required

1

Check

vacuum

inlet

for

signs

of

leakage

at

its

connection

If

necessary

retighten

or

replace

with

a

new

one

2

Check

vacuum

diaphragm

for

air

leak

If

leak

is

found

replace

vacuum

controller

assembly

3

Inspect

breaker

plate

for

smooth

moving

If

plate

does

not

move

smoothly

this

condition

could

be

due

to

sticky

steel

balls

or

pivot

Apply

grease

to

steel

balls

or

if

necessary

replace

distributor

assembly

Centrifugal

advance

mechanical

parts

When

cause

of

engine

malfunction

is

traced

to

centrifugal

advance

mecha

nical

parts

use

distributor

tester

to

check

its

characteristics

See

to

the

specifications

above

If

nothing

is

wrong

with

its

charac

teristics

conceivable

causes

are

faulty

or

abnormal

wear

of

driving

part

or

others

So

do

not

disassemble

it

In

the

event

of

improper

character

istics

check

closely

rotor

shaft

assem

bly

governor

weight

and

shaft

If

any

of

above

parts

are

malfunc

tioning

replace

distributor

assembly

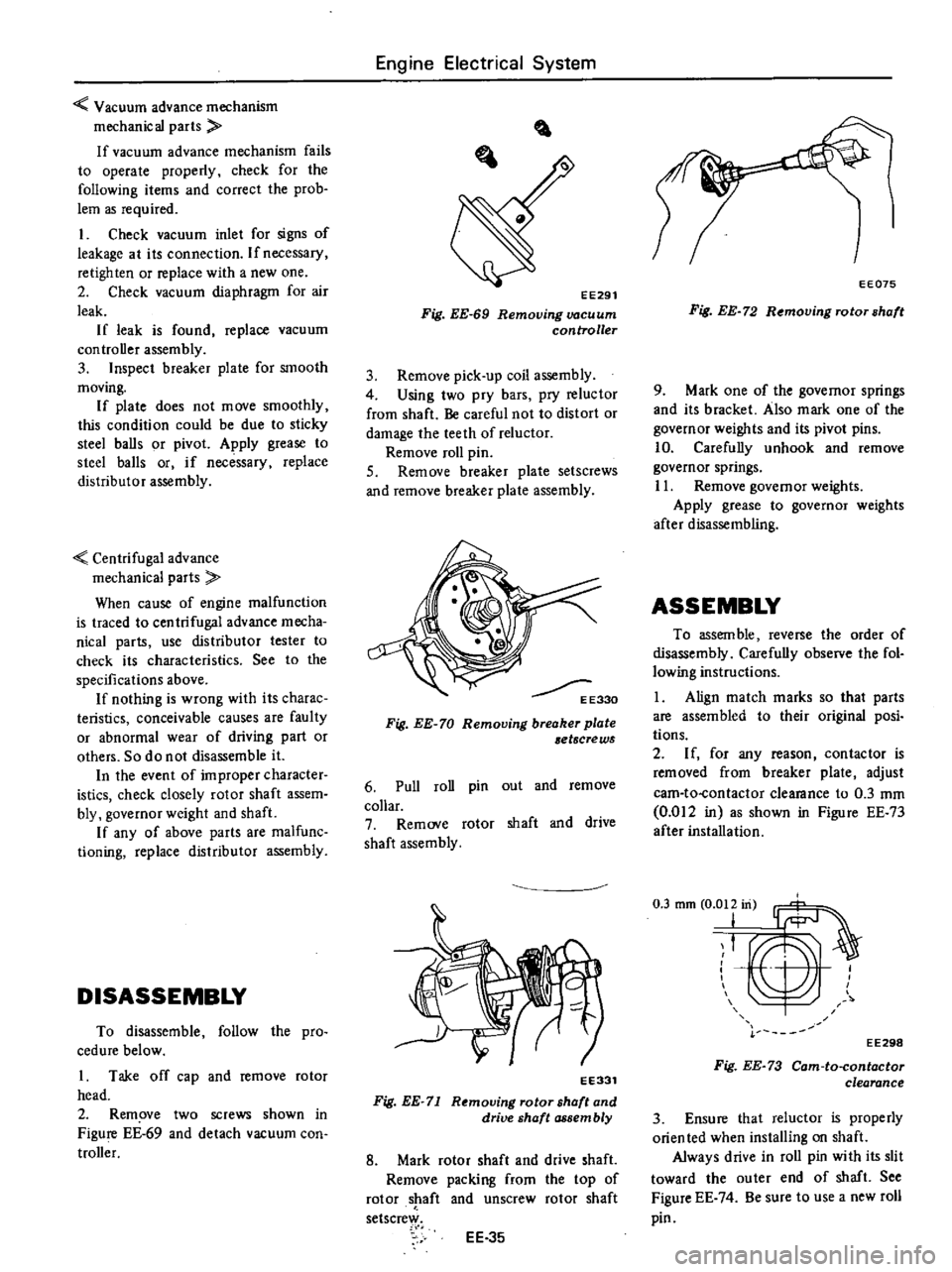

DISASSEMBLY

To

disassemble

follow

the

pro

cedure

below

1

Take

off

cap

and

remove

rotor

head

2

Remove

two

screws

shown

in

Figure

EE

69

and

detach

vacuum

con

troller

Engine

Electrical

System

EE291

Fig

EE

69

Removing

vacuum

controller

3

Remove

pick

up

coil

assembly

4

Using

two

pry

bars

pry

reluctor

from

shaft

Be

careful

not

to

distort

or

damage

the

teeth

of

reluctor

Remove

roll

pin

S

Remove

breaker

plate

setscrews

and

remove

breaker

plate

assembly

E330

Fig

EE

70

Removing

breaker

plate

etscrews

6

Pull

roll

pin

out

and

remove

collar

7

Remove

rotor

shaft

and

drive

shaft

assembly

EE331

Fig

EE

71

Removing

rotor

shaft

and

drive

shaft

assembly

8

Mark

rotor

shaft

and

drive

shaft

Remove

packing

from

the

top

of

rotor

shaft

and

unscrew

rotor

shaft

setscrew

EE

35

EE075

Fig

EE

72

Removing

rotor

shaft

9

Mark

one

of

the

governor

springs

and

its

bracket

Also

mark

one

of

the

governor

weights

and

its

pivot

pins

10

Carefully

unhook

and

remove

governor

springs

11

Remove

governor

weights

Apply

grease

to

governor

weights

after

disassembling

ASSEMBLY

To

assem

ble

reverse

the

order

of

disassembly

Carefully

observe

the

fol

lowing

instructions

1

Align

match

marks

so

that

parts

are

assembled

to

their

original

posi

tions

2

If

for

any

reason

contactor

is

removed

from

breaker

plate

adjust

cam

to

contactor

clearance

to

0

3

mm

0

012

in

as

shown

in

Figure

EE

73

after

installation

T

EE298

Fig

EE

73

Cam

to

contactor

clearance

3

Ensure

that

reluctor

is

properly

orien

ted

when

installing

on

shaft

Always

drive

in

roll

pin

with

its

slit

toward

the

outer

end

of

shaft

See

Figure

EE

74

Be

sure

to

use

a

new

roll

pin

Page 203 of 537

EE299

Fig

EE

74

Driving

in

roll

pin

Engine

Electrical

System

4

Apply

grease

to

the

top

of

rotor

shaft

as

required

5

Check

the

operation

of

governor

before

installing

distributor

on

engine

6

Adjust

ignition

timing

after

distri

butor

is

installed

on

engine

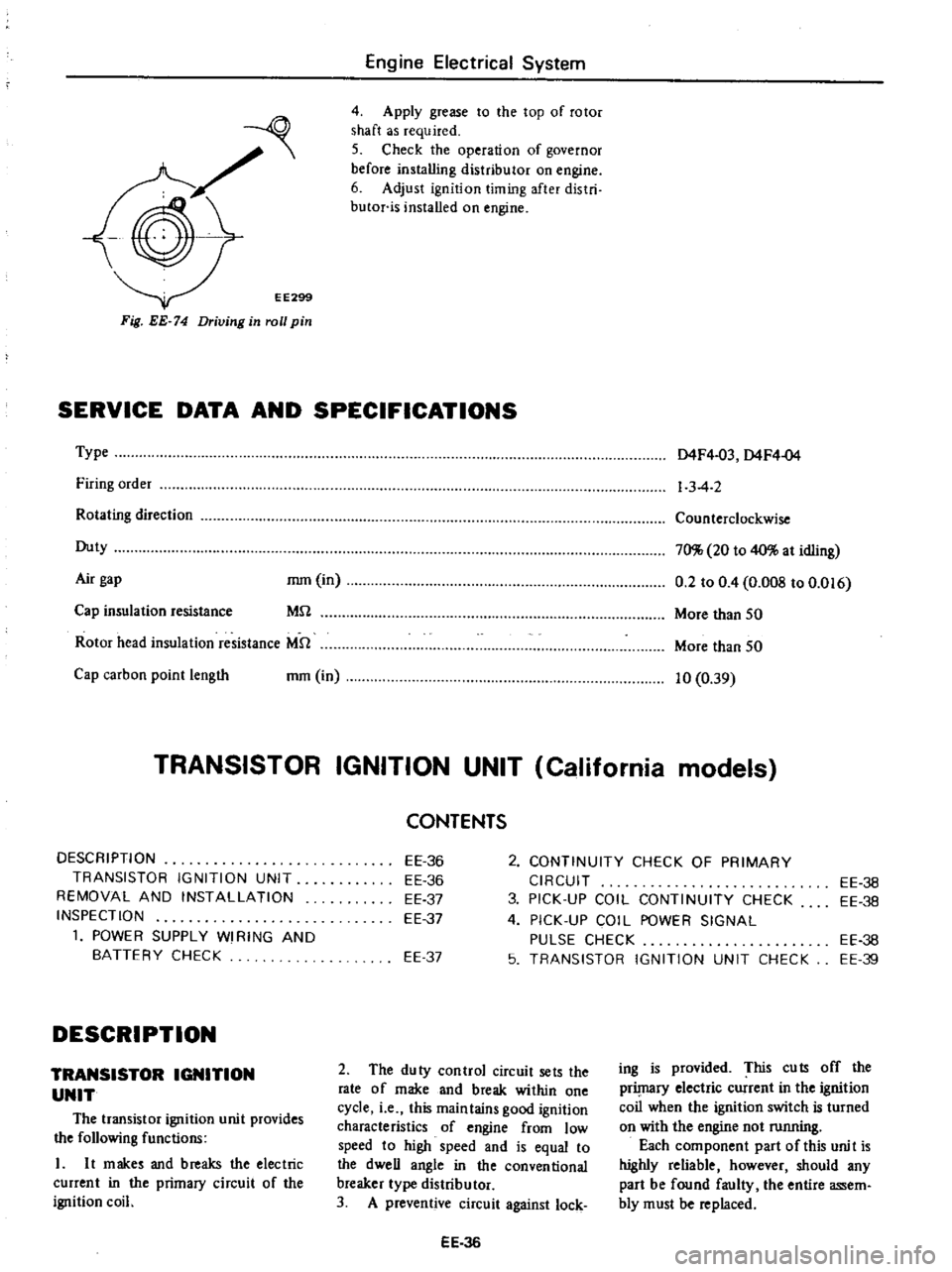

SERVICE

DATA

AND

SPECIFICATIONS

Type

Firing

order

Rotating

direction

Duty

Air

gap

mm

in

MU

Cap

insulation

resistance

Rotor

head

insulation

resistance

MU

Cap

carbon

point

length

mm

in

D4F4

03

D4F4

04

1

3

4

2

Counterclockwise

70

20

to

40

at

idling

0

2

to

0

4

O

OOS

to

0

016

More

than

50

More

than

50

10

0

39

TRANSISTOR

IGNITION

UNIT

California

models

DESCRIPTION

TRANSISTOR

IGNITION

UNIT

REMOVAL

AND

INSTALLATION

INSPECTION

1

POWER

SUPPLY

WI

RING

AND

BATTERY

CHECK

DESCRIPTION

TRANSISTOR

IGNITION

UNIT

The

transistor

ignition

unit

provides

the

following

functions

L

It

makes

and

breaks

the

electric

current

in

the

primacy

circuit

of

the

ignition

coil

2

CONTINUITY

CHECK

OF

PRIMARY

CIRCUIT

3

PICK

UP

COIL

CONTINUITY

CHECK

4

PICK

UP

COIL

POWER

SIGNAL

PULSE

CHECK

5

TRANSISTOR

IGNITION

UNIT

CHECK

CONTENTS

EE

36

EE

36

EE

37

EE

37

EE

37

2

The

duty

control

circuit

sets

the

rate

of

make

and

break

within

one

cycle

i

e

this

maintains

good

ignition

characteristics

of

engine

from

low

speed

to

high

speed

and

is

equal

to

the

dweU

angle

in

the

conventional

breaker

type

distributor

3

A

preventive

circuit

against

lock

EE

36

EE

36

EE

38

EE

38

EE

39

ing

is

provided

This

cuts

off

the

prilnaCY

electric

current

in

the

ignition

coil

when

the

ignition

switch

is

turned

on

with

the

engine

not

running

Each

component

part

of

this

unit

is

highly

reliable

however

should

any

part

be

found

faulty

the

entire

assem

bly

must

be

replaced

Page 204 of 537

Engine

Electrical

System

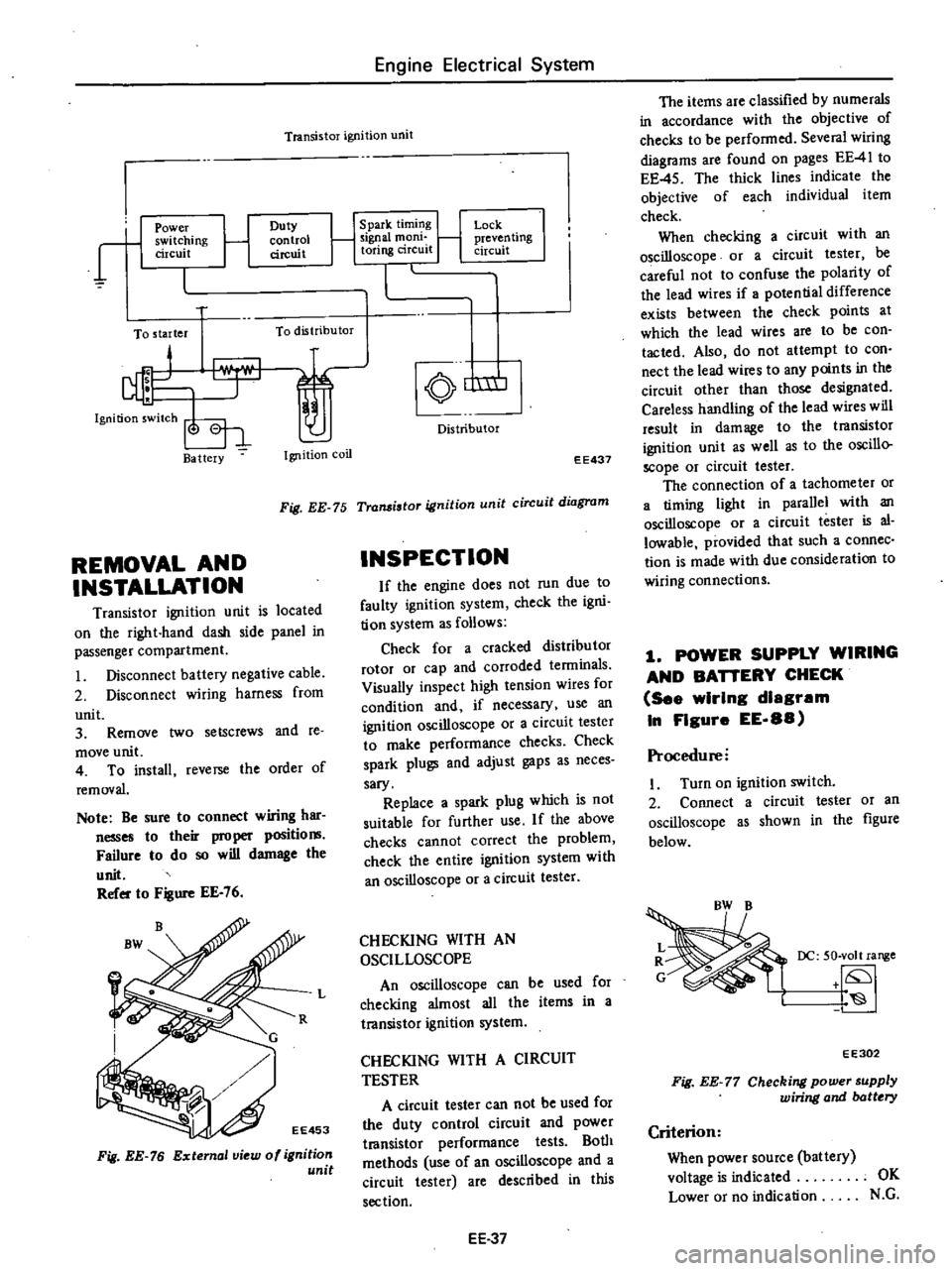

Transistor

ignition

unit

r

1

Power

switching

circuit

Duty

control

circuit

To

starter

To

distributor

Ba

ttery

Ignition

coil

1

Spark

timing

1

Signal

mom

toring

circuit

Lock

j

preven

ling

circuit

nm

Distributor

EE437

Fig

EE

75

Transistor

ignition

unit

circuit

diagram

REMOVAL

AND

INSTALLATION

Transistor

ignition

unit

is

located

on

the

right

hand

dash

side

panel

in

passenger

compartment

Disconnect

battery

negative

cable

2

Disconnect

wiring

harness

from

unit

3

Remove

two

setscrews

and

te

move

unit

4

To

install

reverse

the

order

of

removal

Note

Be

sure

to

connect

wiring

har

nesses

to

their

proper

positio

Failure

to

do

so

will

damage

the

unit

Refer

to

Figure

EE

76

Fig

EE

76

External

view

of

ignition

unit

INSPECTION

If

the

engine

does

not

run

due

to

faulty

ignition

system

check

the

igni

tion

system

as

follows

Check

for

a

cracked

distributor

rotor

or

cap

and

corroded

tenninals

Visually

inspect

high

tension

wires

for

condition

and

if

necessary

use

an

ignition

oscilloscope

or

a

circuit

tester

to

make

performance

checks

Check

spark

plugs

and

adjust

gaps

as

neces

sary

Replace

a

spark

plug

which

is

not

suitable

for

further

use

If

the

above

checks

cannot

correct

the

problem

check

the

entire

ignition

system

with

an

oscilloscope

or

a

circuit

tester

L

CHECKING

WITH

AN

OSCILLOSCOPE

An

oscilloscope

can

be

used

for

checking

almost

all

the

items

in

a

transistor

ignition

system

CHECKING

WITH

A

CIRCUIT

TESTER

A

circuit

tester

can

not

be

used

for

the

duty

control

circuit

and

power

t18nsistor

performance

tests

Both

methods

use

of

an

oscilloscope

and

a

circuit

tester

are

described

in

this

section

EE

37

The

items

are

classified

by

numerals

in

accordance

with

the

objective

of

checks

to

be

performed

Several

wiring

diagrams

are

found

on

pages

EE

41

to

EE

45

The

thick

lines

indicate

the

objective

of

each

individual

item

check

When

checking

a

circuit

with

an

oscilloscope

or

a

circuit

tester

be

careful

not

to

confuse

the

polarity

of

the

lead

wires

if

potential

difference

exists

between

the

check

points

at

which

the

lead

wires

are

to

be

con

tacted

Also

do

not

attempt

to

con

nect

the

lead

wires

to

any

points

in

the

circuit

other

than

those

designated

Careless

handling

of

the

lead

wires

will

result

in

damage

to

the

transistor

ignition

unit

as

well

as

to

the

oscillo

scope

or

circuit

tester

The

connection

of

a

tachometer

or

a

timing

light

in

parallel

with

an

oscilloscope

or

a

circuit

tester

is

al

lowable

provided

that

such

a

connec

tion

is

made

with

due

consideration

to

wiring

connections

1

POWER

SUPPLY

WIRING

AND

BAnERY

CHECK

See

wIrIng

diagram

In

FIgure

EE

88

Procedure

I

Turn

on

ignition

switch

2

Connect

a

circuit

tester

or

an

oscilloscope

as

shown

in

the

figure

below

DC

50

volt

range

EE302

Fig

EE

77

Checking

power

supply

wiring

and

batt

ry

Criterion

When

power

source

battery

voltage

is

indicated

OK

Lower

or

no

indication

N

G

Page 205 of 537

If

the

result

is

N

C

Take

the

following

measures

I

Check

BW

and

B

color

wire

harness

respectively

for

proper

con

ductance

2

Check

battery

terminals

for

proper

connection

3

Check

charge

condition

of

bat

tery

if

an

excessively

low

voltage

is

indicated

2

CONTINUITY

CHECK

OF

PRIMARY

CIRCUIT

2

1

CheckIng

prImary

circuit

See

wiring

diagram

In

Fig

EE

89

Proced

ure

I

Disconnect

L

color

wire

from

ignition

unit

2

Turn

on

ignition

switch

3

C

ooneet

a

cireui

t

tester

or

an

oscilloscope

as

shown

in

Figure

EE

78

DC

50

volt

range

tf

S

EE303

Fig

EE

78

Checking

primary

circuit

Criterion

When

Donnal

power

Source

battery

voltage

is

indicated

OK

Lower

or

no

indication

N

G

If

the

result

is

N

C

Take

the

following

measures

1

Check

BW

and

L

color

wire

Engine

Electrical

System

harness

respectively

for

proper

con

ductance

2

Check

resistor

and

ignition

coil

terminals

for

loose

contact

3

Check

resistor

and

ignition

coil

for

discontinuity

4

Check

WB

color

wire

harness

of

ignition

coil

assembly

for

proper

continuity

2

2

Chacklng

IgnitIon

coil

auembly

See

wiring

diagram

In

Fig

EE

90

Procedure

I

Disconnect

ignition

coil

and

dis

tributor

harness

from

ignition

coil

external

resistor

2

Connect

a

circuit

tester

as

shown

in

the

figure

below

Resistance

1

range

Q

o

fD

ro

EE336

Fig

EE

79

Checking

ignition

coil

assembly

Criterion

When

approximately

1

6

to

2

0

ohm

is

indicated

OK

More

than

2

0

ohm

N

C

If

the

result

is

N

C

Replace

ignition

coil

assembly

3

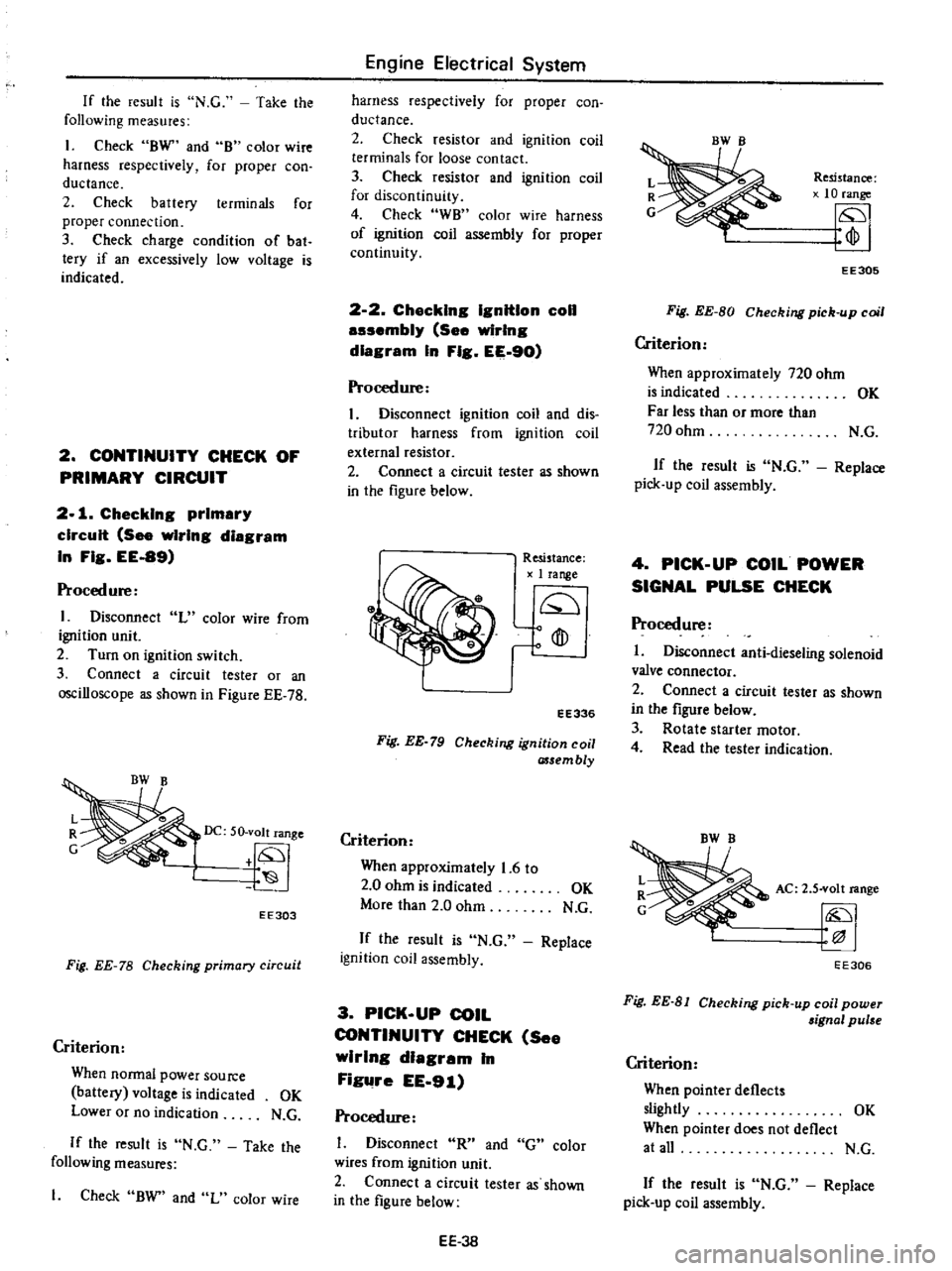

PICK

UP

COIL

CONTINUITY

CHECK

See

wirIng

dIagram

In

Figure

EE

91

Procedure

Disconnect

R

and

G

color

wires

from

ignition

unit

2

Connect

a

circuit

tester

as

shown

in

the

figure

below

EE

3B

Resistance

10

range

fp

EE305

Fig

EE

BO

Checking

pick

up

coil

Criterion

When

approximately

720

ohm

is

indicated

OK

Far

less

than

or

more

than

720

ohm

N

C

If

the

result

is

N

C

Replace

pick

up

coil

assembly

4

PICK

UP

COIL

POWER

SIGNAL

PULSE

CHECK

Procedure

I

Disconnect

anti

dieseling

solenoid

valve

connector

2

Connect

a

circuit

tester

as

shown

in

the

figure

below

3

Rotate

starter

motor

4

Read

the

tester

indication

AC

2

S

volt

range

EE306

Fig

EE

81

Checking

pick

up

coil

power

aignal

pulse

Criterion

When

pointer

deflects

slightly

OK

When

pointer

does

not

deflect

at

all

N

C

If

the

result

is

N

C

Replace

pick

up

coil

assembly