belt DODGE NEON 1999 Service Owners Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 801 of 1200

OIL PUMP

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove Timing Belt. Refer to procedure in this

section.

(3) Remove Oil Pan. Refer to procedure in this sec-

tion.

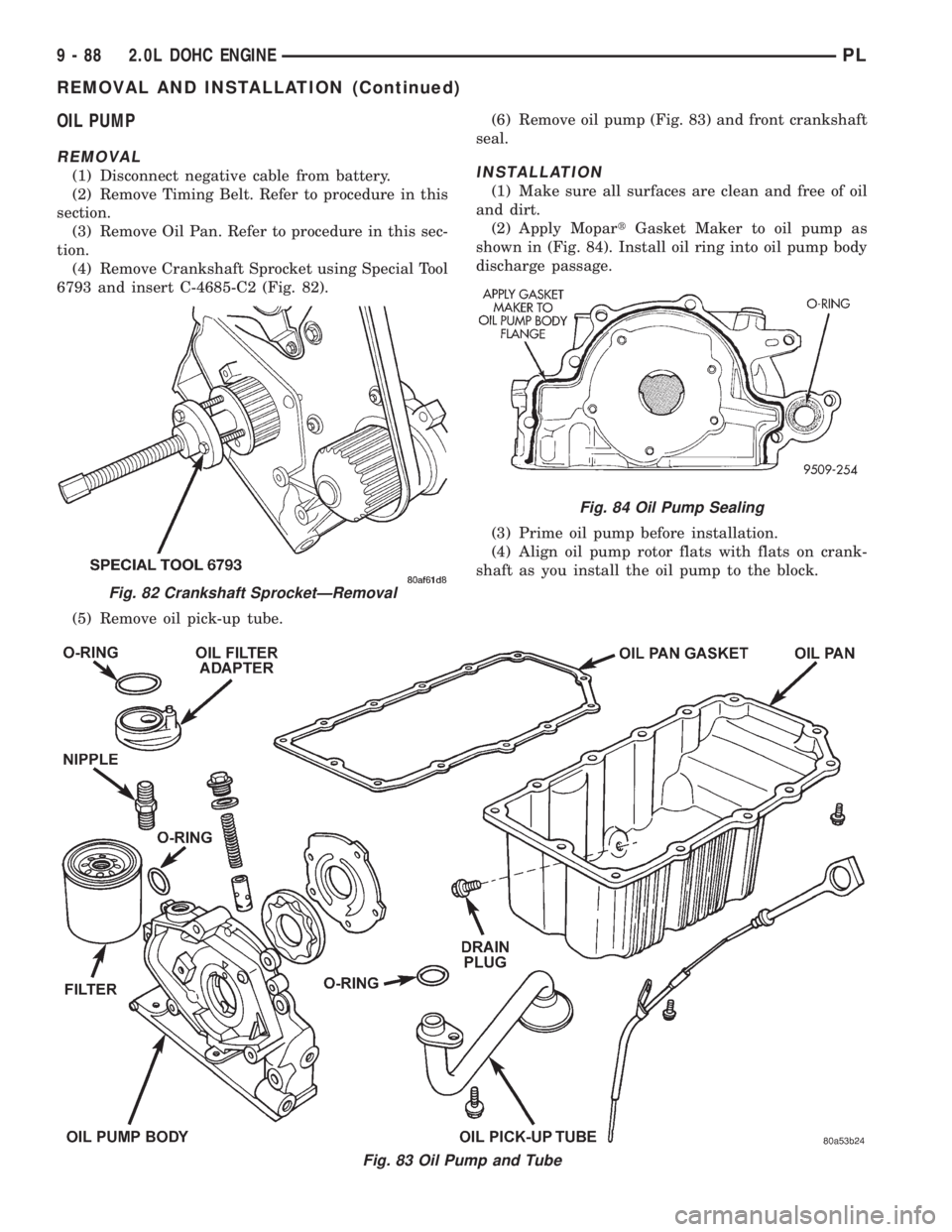

(4) Remove Crankshaft Sprocket using Special Tool

6793 and insert C-4685-C2 (Fig. 82).

(5) Remove oil pick-up tube.(6) Remove oil pump (Fig. 83) and front crankshaft

seal.INSTALLATION

(1) Make sure all surfaces are clean and free of oil

and dirt.

(2) Apply MopartGasket Maker to oil pump as

shown in (Fig. 84). Install oil ring into oil pump body

discharge passage.

(3) Prime oil pump before installation.

(4) Align oil pump rotor flats with flats on crank-

shaft as you install the oil pump to the block.

Fig. 83 Oil Pump and Tube

Fig. 82 Crankshaft SprocketÐRemoval

Fig. 84 Oil Pump Sealing

9 - 88 2.0L DOHC ENGINEPL

REMOVAL AND INSTALLATION (Continued)

Page 802 of 1200

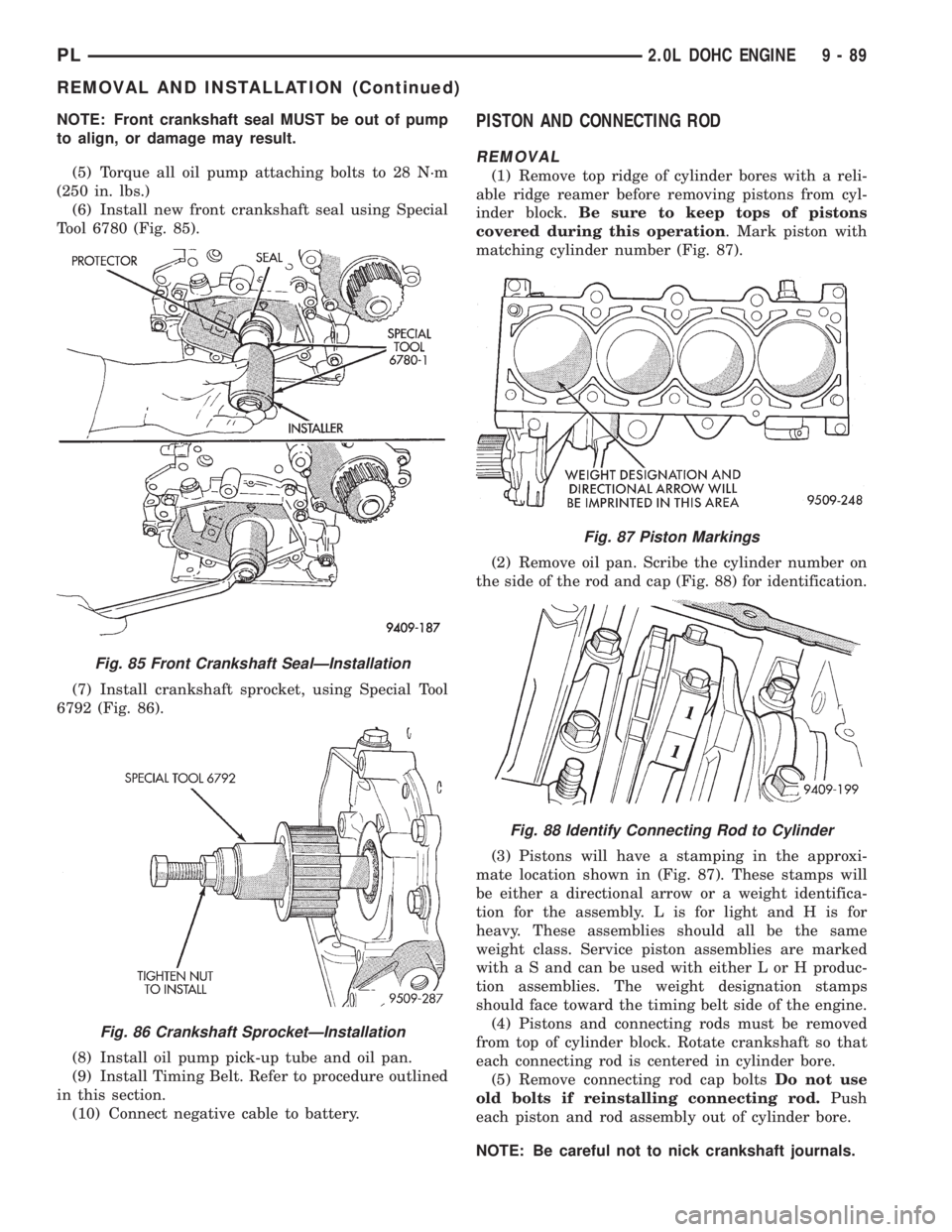

NOTE: Front crankshaft seal MUST be out of pump

to align, or damage may result.

(5) Torque all oil pump attaching bolts to 28 N´m

(250 in. lbs.)

(6) Install new front crankshaft seal using Special

Tool 6780 (Fig. 85).

(7) Install crankshaft sprocket, using Special Tool

6792 (Fig. 86).

(8) Install oil pump pick-up tube and oil pan.

(9) Install Timing Belt. Refer to procedure outlined

in this section.

(10) Connect negative cable to battery.PISTON AND CONNECTING ROD

REMOVAL

(1) Remove top ridge of cylinder bores with a reli-

able ridge reamer before removing pistons from cyl-

inder block.Be sure to keep tops of pistons

covered during this operation. Mark piston with

matching cylinder number (Fig. 87).

(2) Remove oil pan. Scribe the cylinder number on

the side of the rod and cap (Fig. 88) for identification.

(3) Pistons will have a stamping in the approxi-

mate location shown in (Fig. 87). These stamps will

be either a directional arrow or a weight identifica-

tion for the assembly. L is for light and H is for

heavy. These assemblies should all be the same

weight class. Service piston assemblies are marked

with a S and can be used with either L or H produc-

tion assemblies. The weight designation stamps

should face toward the timing belt side of the engine.

(4) Pistons and connecting rods must be removed

from top of cylinder block. Rotate crankshaft so that

each connecting rod is centered in cylinder bore.

(5) Remove connecting rod cap boltsDo not use

old bolts if reinstalling connecting rod.Push

each piston and rod assembly out of cylinder bore.

NOTE: Be careful not to nick crankshaft journals.

Fig. 85 Front Crankshaft SealÐInstallation

Fig. 86 Crankshaft SprocketÐInstallation

Fig. 87 Piston Markings

Fig. 88 Identify Connecting Rod to Cylinder

PL2.0L DOHC ENGINE 9 - 89

REMOVAL AND INSTALLATION (Continued)

Page 811 of 1200

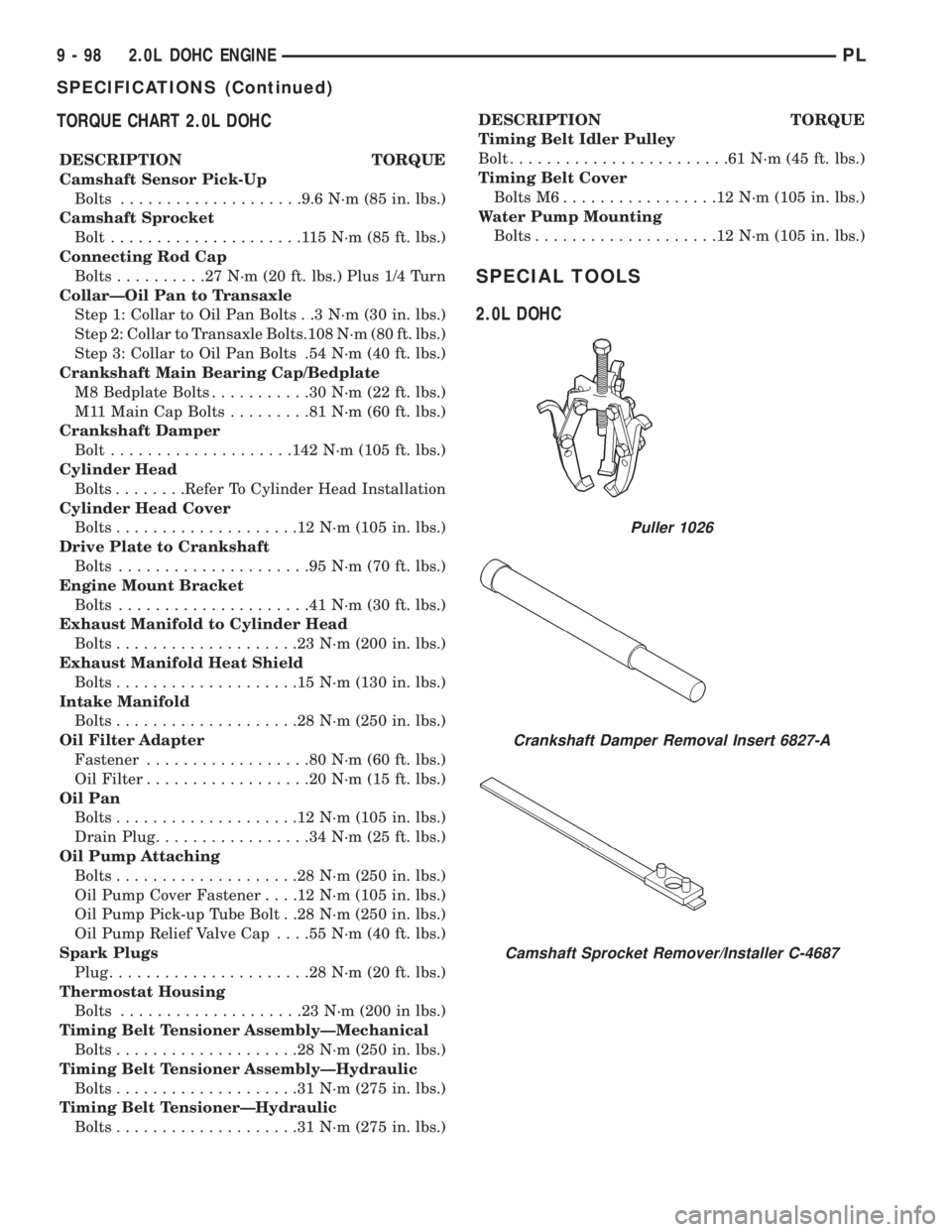

TORQUE CHART 2.0L DOHC

DESCRIPTION TORQUE

Camshaft Sensor Pick-Up

Bolts....................9.6 N´m (85 in. lbs.)

Camshaft Sprocket

Bolt.....................115N´m(85ft.lbs.)

Connecting Rod Cap

Bolts..........27N´m(20ft.lbs.) Plus 1/4 Turn

CollarÐOil Pan to Transaxle

Step 1: Collar to Oil Pan Bolts . .3 N´m (30 in. lbs.)

Step 2: Collar to Transaxle Bolts.108 N´m (80 ft. lbs.)

Step 3: Collar to Oil Pan Bolts .54 N´m (40 ft. lbs.)

Crankshaft Main Bearing Cap/Bedplate

M8 Bedplate Bolts...........30N´m(22ft.lbs.)

M11 Main Cap Bolts.........81N´m(60ft.lbs.)

Crankshaft Damper

Bolt....................142 N´m (105 ft. lbs.)

Cylinder Head

Bolts........Refer To Cylinder Head Installation

Cylinder Head Cover

Bolts....................12N´m(105 in. lbs.)

Drive Plate to Crankshaft

Bolts.....................95N´m(70ft.lbs.)

Engine Mount Bracket

Bolts.....................41N´m(30ft.lbs.)

Exhaust Manifold to Cylinder Head

Bolts....................23N´m(200 in. lbs.)

Exhaust Manifold Heat Shield

Bolts....................15N´m(130 in. lbs.)

Intake Manifold

Bolts....................28N´m(250 in. lbs.)

Oil Filter Adapter

Fastener..................80N´m(60ft.lbs.)

Oil Filter..................20N´m(15ft.lbs.)

Oil Pan

Bolts....................12N´m(105 in. lbs.)

Drain Plug.................34N´m(25ft.lbs.)

Oil Pump Attaching

Bolts....................28N´m(250 in. lbs.)

Oil Pump Cover Fastener. . . .12 N´m (105 in. lbs.)

Oil Pump Pick-up Tube Bolt . .28 N´m (250 in. lbs.)

Oil Pump Relief Valve Cap. . . .55 N´m (40 ft. lbs.)

Spark Plugs

Plug......................28N´m(20ft.lbs.)

Thermostat Housing

Bolts....................23N´m(200 in lbs.)

Timing Belt Tensioner AssemblyÐMechanical

Bolts....................28N´m(250 in. lbs.)

Timing Belt Tensioner AssemblyÐHydraulic

Bolts....................31N´m(275 in. lbs.)

Timing Belt TensionerÐHydraulic

Bolts....................31N´m(275 in. lbs.)DESCRIPTION TORQUE

Timing Belt Idler Pulley

Bolt........................61N´m(45ft.lbs.)

Timing Belt Cover

Bolts M6.................12N´m(105 in. lbs.)

Water Pump Mounting

Bolts....................12N´m(105 in. lbs.)

SPECIAL TOOLS

2.0L DOHC

Puller 1026

Crankshaft Damper Removal Insert 6827-A

Camshaft Sprocket Remover/Installer C-4687

9 - 98 2.0L DOHC ENGINEPL

SPECIFICATIONS (Continued)

Page 879 of 1200

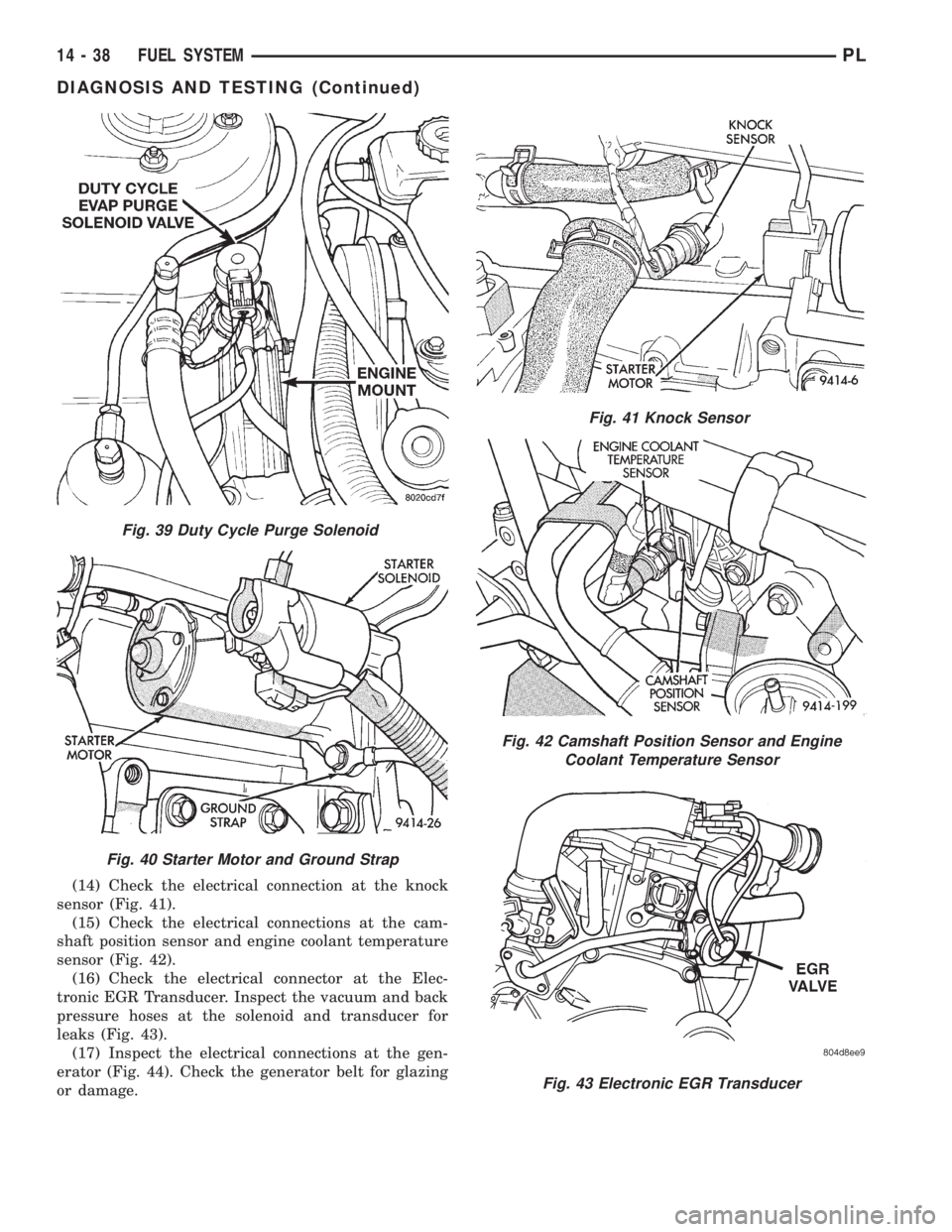

(14) Check the electrical connection at the knock

sensor (Fig. 41).

(15) Check the electrical connections at the cam-

shaft position sensor and engine coolant temperature

sensor (Fig. 42).

(16) Check the electrical connector at the Elec-

tronic EGR Transducer. Inspect the vacuum and back

pressure hoses at the solenoid and transducer for

leaks (Fig. 43).

(17) Inspect the electrical connections at the gen-

erator (Fig. 44). Check the generator belt for glazing

or damage.

Fig. 39 Duty Cycle Purge Solenoid

Fig. 40 Starter Motor and Ground Strap

Fig. 41 Knock Sensor

Fig. 42 Camshaft Position Sensor and Engine

Coolant Temperature Sensor

Fig. 43 Electronic EGR Transducer

14 - 38 FUEL SYSTEMPL

DIAGNOSIS AND TESTING (Continued)

Page 884 of 1200

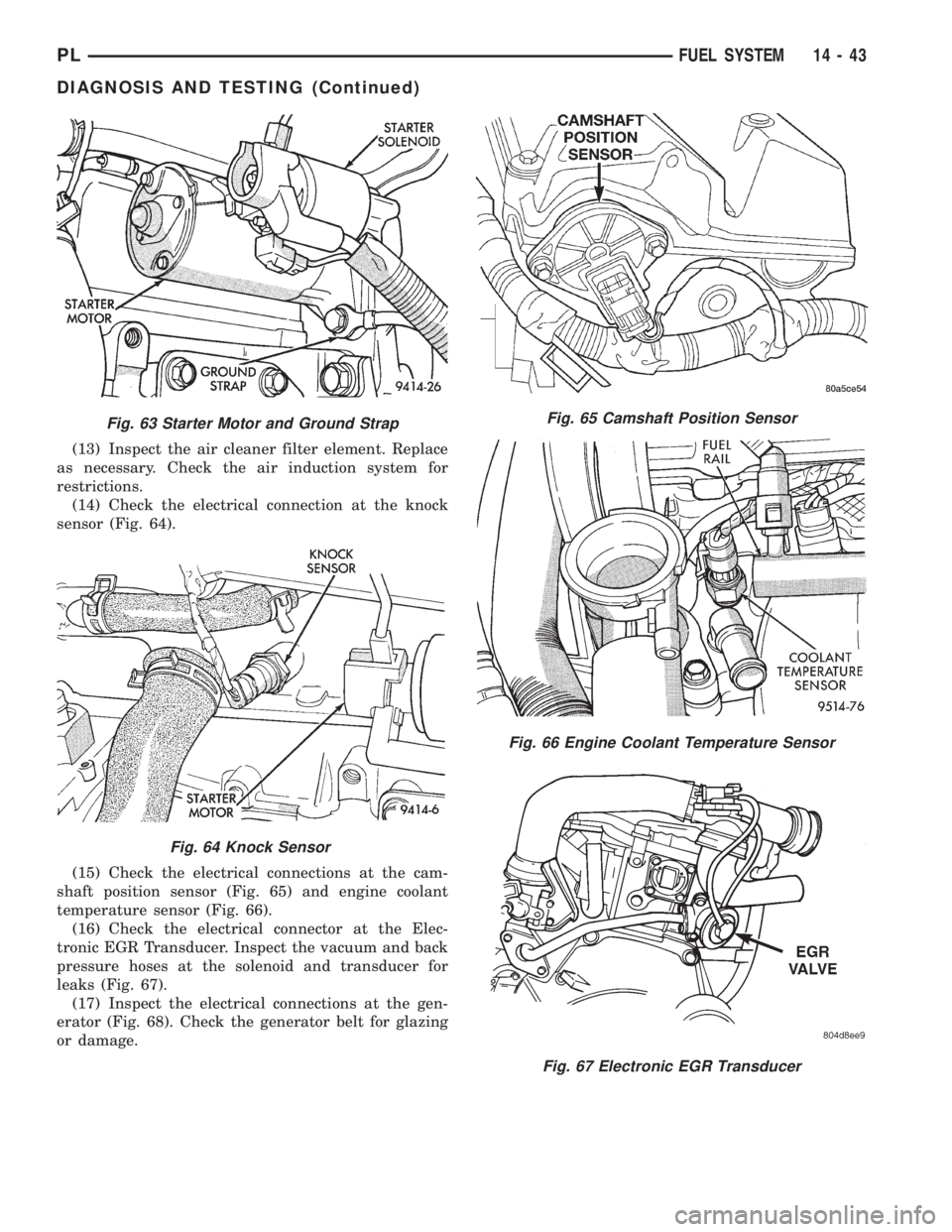

(13) Inspect the air cleaner filter element. Replace

as necessary. Check the air induction system for

restrictions.

(14) Check the electrical connection at the knock

sensor (Fig. 64).

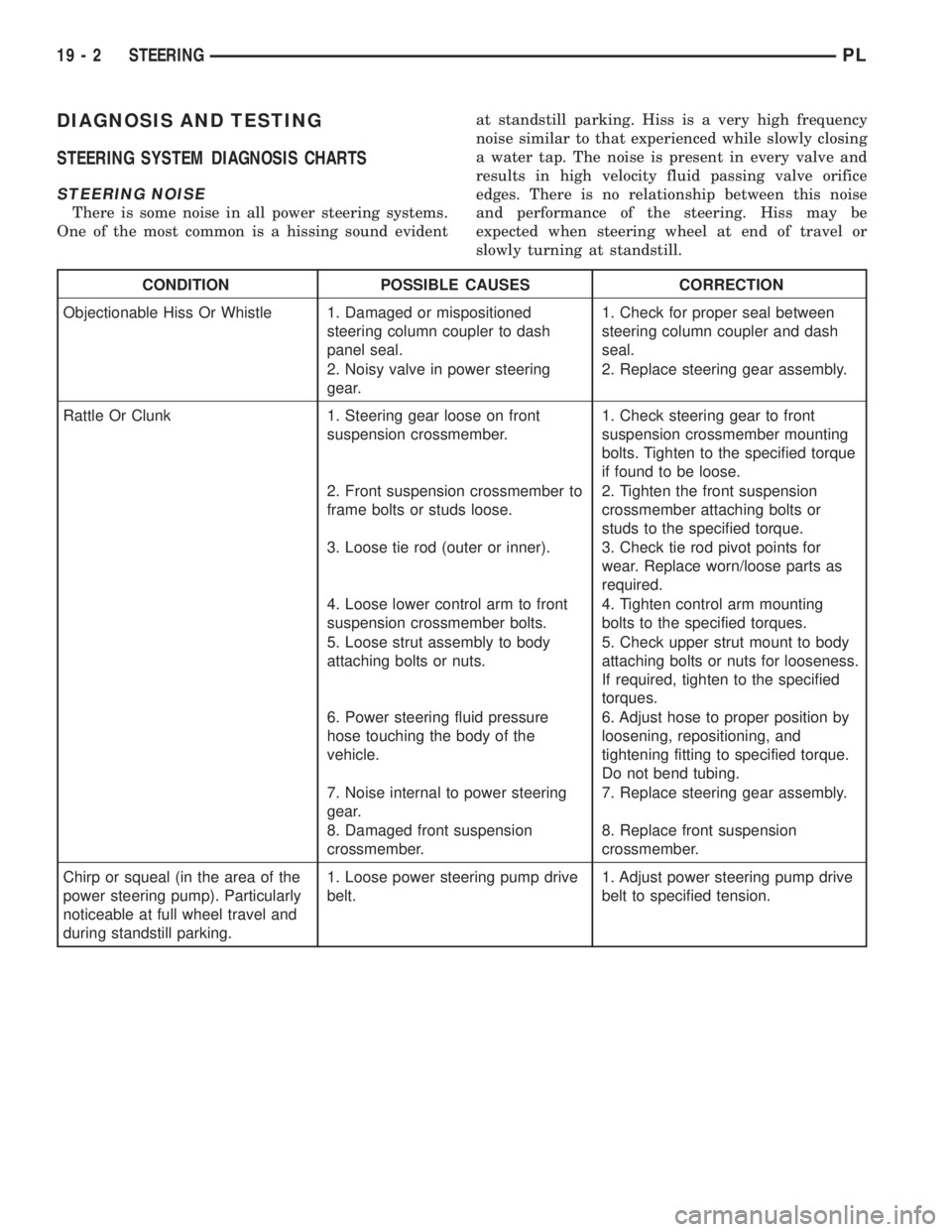

(15) Check the electrical connections at the cam-

shaft position sensor (Fig. 65) and engine coolant

temperature sensor (Fig. 66).

(16) Check the electrical connector at the Elec-

tronic EGR Transducer. Inspect the vacuum and back

pressure hoses at the solenoid and transducer for

leaks (Fig. 67).

(17) Inspect the electrical connections at the gen-

erator (Fig. 68). Check the generator belt for glazing

or damage.

Fig. 63 Starter Motor and Ground Strap

Fig. 64 Knock Sensor

Fig. 65 Camshaft Position Sensor

Fig. 66 Engine Coolant Temperature Sensor

Fig. 67 Electronic EGR Transducer

PLFUEL SYSTEM 14 - 43

DIAGNOSIS AND TESTING (Continued)

Page 903 of 1200

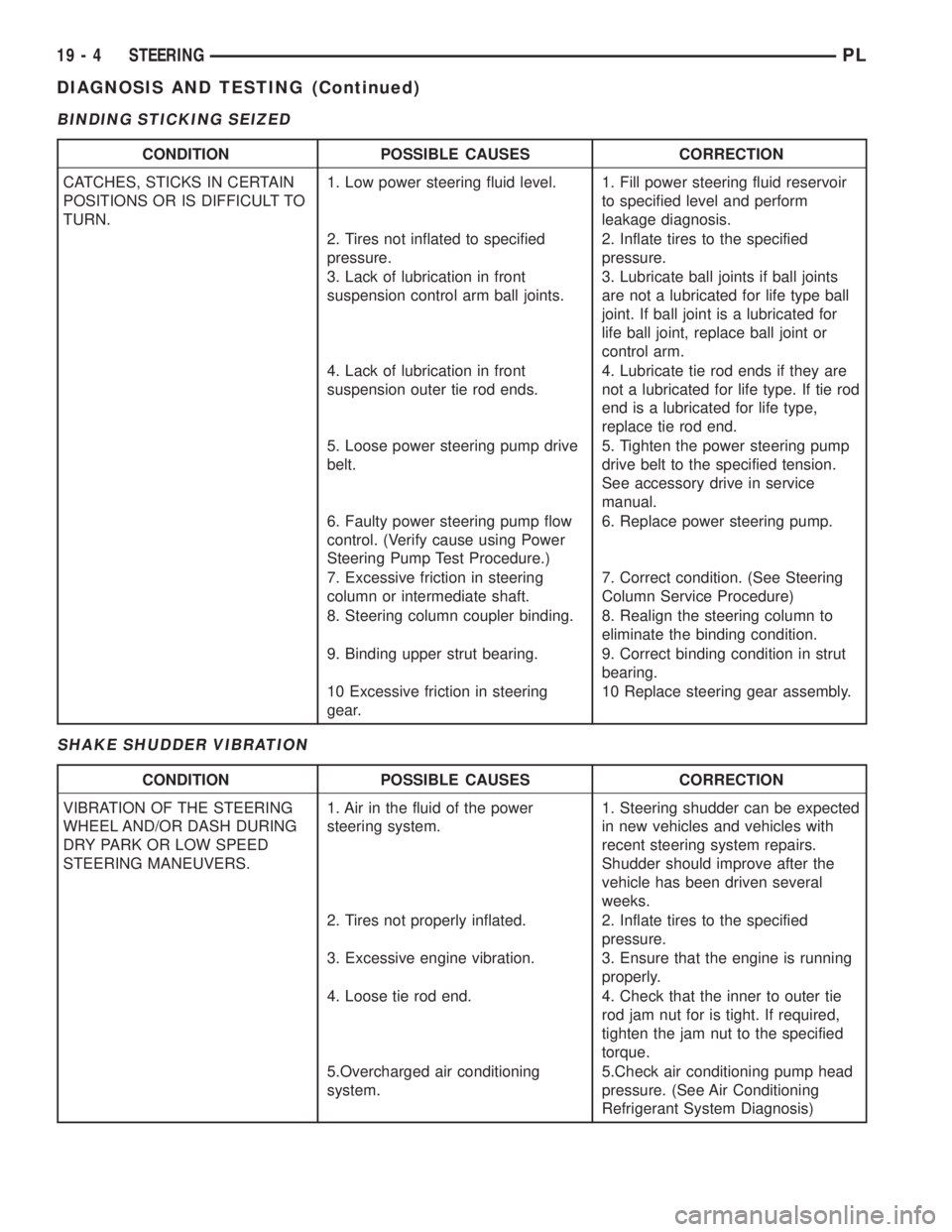

DIAGNOSIS AND TESTING

STEERING SYSTEM DIAGNOSIS CHARTS

STEERING NOISE

There is some noise in all power steering systems.

One of the most common is a hissing sound evidentat standstill parking. Hiss is a very high frequency

noise similar to that experienced while slowly closing

a water tap. The noise is present in every valve and

results in high velocity fluid passing valve orifice

edges. There is no relationship between this noise

and performance of the steering. Hiss may be

expected when steering wheel at end of travel or

slowly turning at standstill.

CONDITION POSSIBLE CAUSES CORRECTION

Objectionable Hiss Or Whistle 1. Damaged or mispositioned

steering column coupler to dash

panel seal.1. Check for proper seal between

steering column coupler and dash

seal.

2. Noisy valve in power steering

gear.2. Replace steering gear assembly.

Rattle Or Clunk 1. Steering gear loose on front

suspension crossmember.1. Check steering gear to front

suspension crossmember mounting

bolts. Tighten to the specified torque

if found to be loose.

2. Front suspension crossmember to

frame bolts or studs loose.2. Tighten the front suspension

crossmember attaching bolts or

studs to the specified torque.

3. Loose tie rod (outer or inner). 3. Check tie rod pivot points for

wear. Replace worn/loose parts as

required.

4. Loose lower control arm to front

suspension crossmember bolts.4. Tighten control arm mounting

bolts to the specified torques.

5. Loose strut assembly to body

attaching bolts or nuts.5. Check upper strut mount to body

attaching bolts or nuts for looseness.

If required, tighten to the specified

torques.

6. Power steering fluid pressure

hose touching the body of the

vehicle.6. Adjust hose to proper position by

loosening, repositioning, and

tightening fitting to specified torque.

Do not bend tubing.

7. Noise internal to power steering

gear.7. Replace steering gear assembly.

8. Damaged front suspension

crossmember.8. Replace front suspension

crossmember.

Chirp or squeal (in the area of the

power steering pump). Particularly

noticeable at full wheel travel and

during standstill parking.1. Loose power steering pump drive

belt.1. Adjust power steering pump drive

belt to specified tension.

19 - 2 STEERINGPL

Page 905 of 1200

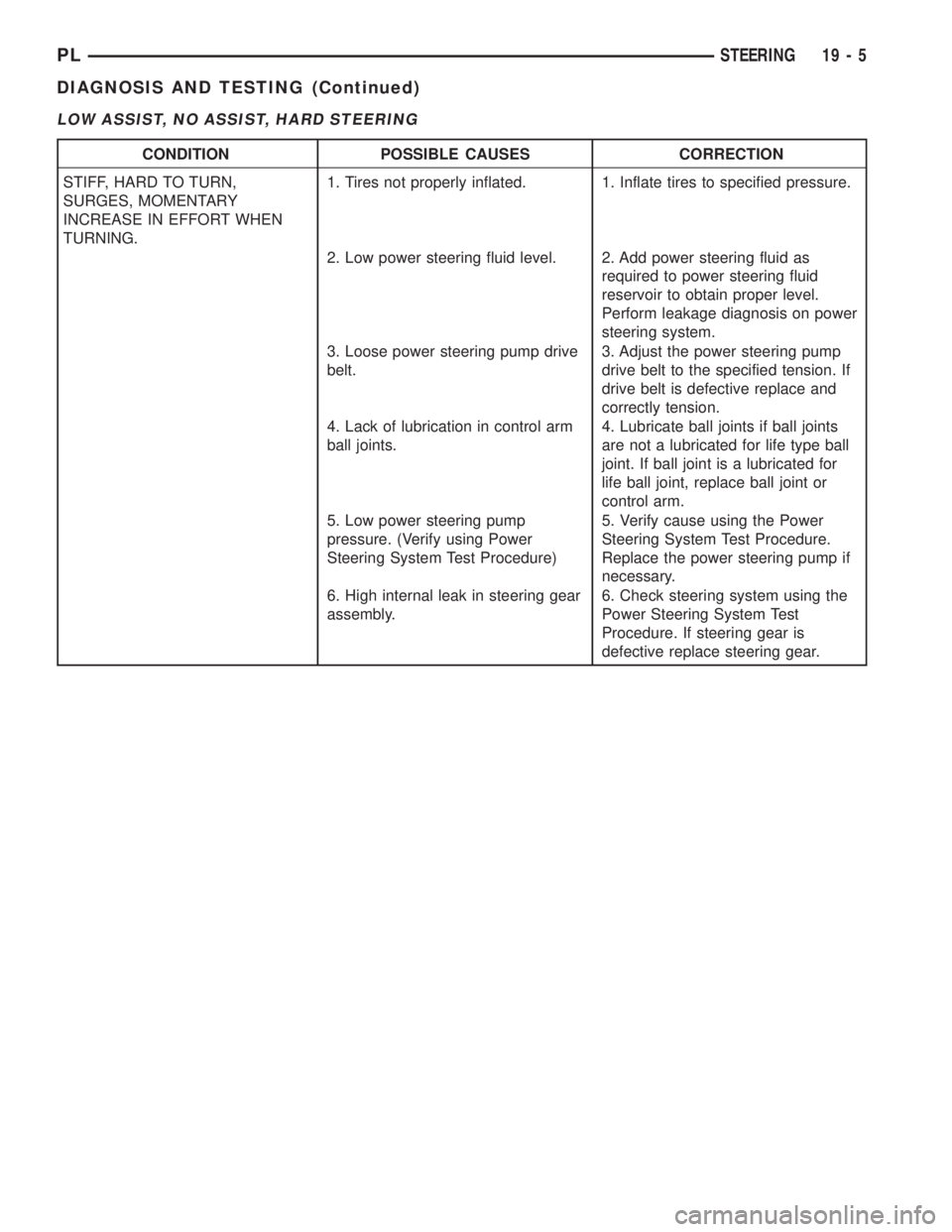

BINDING STICKING SEIZED

SHAKE SHUDDER VIBRATION

CONDITION POSSIBLE CAUSES CORRECTION

CATCHES, STICKS IN CERTAIN

POSITIONS OR IS DIFFICULT TO

TURN.1. Low power steering fluid level. 1. Fill power steering fluid reservoir

to specified level and perform

leakage diagnosis.

2. Tires not inflated to specified

pressure.2. Inflate tires to the specified

pressure.

3. Lack of lubrication in front

suspension control arm ball joints.3. Lubricate ball joints if ball joints

are not a lubricated for life type ball

joint. If ball joint is a lubricated for

life ball joint, replace ball joint or

control arm.

4. Lack of lubrication in front

suspension outer tie rod ends.4. Lubricate tie rod ends if they are

not a lubricated for life type. If tie rod

end is a lubricated for life type,

replace tie rod end.

5. Loose power steering pump drive

belt.5. Tighten the power steering pump

drive belt to the specified tension.

See accessory drive in service

manual.

6. Faulty power steering pump flow

control. (Verify cause using Power

Steering Pump Test Procedure.)6. Replace power steering pump.

7. Excessive friction in steering

column or intermediate shaft.7. Correct condition. (See Steering

Column Service Procedure)

8. Steering column coupler binding. 8. Realign the steering column to

eliminate the binding condition.

9. Binding upper strut bearing. 9. Correct binding condition in strut

bearing.

10 Excessive friction in steering

gear.10 Replace steering gear assembly.

CONDITION POSSIBLE CAUSES CORRECTION

VIBRATION OF THE STEERING

WHEEL AND/OR DASH DURING

DRY PARK OR LOW SPEED

STEERING MANEUVERS.1. Air in the fluid of the power

steering system.1. Steering shudder can be expected

in new vehicles and vehicles with

recent steering system repairs.

Shudder should improve after the

vehicle has been driven several

weeks.

2. Tires not properly inflated. 2. Inflate tires to the specified

pressure.

3. Excessive engine vibration. 3. Ensure that the engine is running

properly.

4. Loose tie rod end. 4. Check that the inner to outer tie

rod jam nut for is tight. If required,

tighten the jam nut to the specified

torque.

5.Overcharged air conditioning

system.5.Check air conditioning pump head

pressure. (See Air Conditioning

Refrigerant System Diagnosis)

19 - 4 STEERINGPL

DIAGNOSIS AND TESTING (Continued)

Page 906 of 1200

LOW ASSIST, NO ASSIST, HARD STEERING

CONDITION POSSIBLE CAUSES CORRECTION

STIFF, HARD TO TURN,

SURGES, MOMENTARY

INCREASE IN EFFORT WHEN

TURNING.1. Tires not properly inflated. 1. Inflate tires to specified pressure.

2. Low power steering fluid level. 2. Add power steering fluid as

required to power steering fluid

reservoir to obtain proper level.

Perform leakage diagnosis on power

steering system.

3. Loose power steering pump drive

belt.3. Adjust the power steering pump

drive belt to the specified tension. If

drive belt is defective replace and

correctly tension.

4. Lack of lubrication in control arm

ball joints.4. Lubricate ball joints if ball joints

are not a lubricated for life type ball

joint. If ball joint is a lubricated for

life ball joint, replace ball joint or

control arm.

5. Low power steering pump

pressure. (Verify using Power

Steering System Test Procedure)5. Verify cause using the Power

Steering System Test Procedure.

Replace the power steering pump if

necessary.

6. High internal leak in steering gear

assembly.6. Check steering system using the

Power Steering System Test

Procedure. If steering gear is

defective replace steering gear.

PLSTEERING 19 - 5

DIAGNOSIS AND TESTING (Continued)

Page 910 of 1200

POWER STEERING PUMP

INDEX

page page

DESCRIPTION AND OPERATION

POWER STEERING PUMP................. 9

DIAGNOSIS AND TESTING

POWER STEERING SYSTEM TEST

PROCEDURE......................... 10

SERVICE PROCEDURES

POWER STEERING PUMP

FLOW CONTROL VALVE SEAL............ 11

POWER STEERING PUMP

INITIAL OPERATION.................... 11

POWER STEERING PUMP

SUCTION PORT SEAL.................. 12

POWER STEERING SYSTEM

FLUID LEVEL CHECK................... 11

REMOVAL AND INSTALLATION

POWER STEERING FLUID PRESSURE HOSE . . 13

POWER STEERING FLUID RESERVOIR...... 21POWER STEERING FLUID RETURN HOSE.... 15

POWER STEERING FLUID SUPPLY HOSE

RESERVOIR TO POWER STEERING PUMP . . 17

POWER STEERING PRESSURE SWITCH..... 12

POWER STEERING PUMP (ALL ENGINES).... 18

DISASSEMBLY AND ASSEMBLY

POWER STEERING PUMP DRIVE PULLEY.... 22

POWER STEERING PUMP MOUNTING

BRACKET............................ 23

SPECIFICATIONS

POWER STEERING PUMP FASTENER

TORQUE SPECIFICATIONS.............. 25

POWER STEERING PUMP FLOW

SPECIFICATIONS...................... 25

SPECIAL TOOLS

POWER STEERING PUMP................. 25

DESCRIPTION AND OPERATION

POWER STEERING PUMP

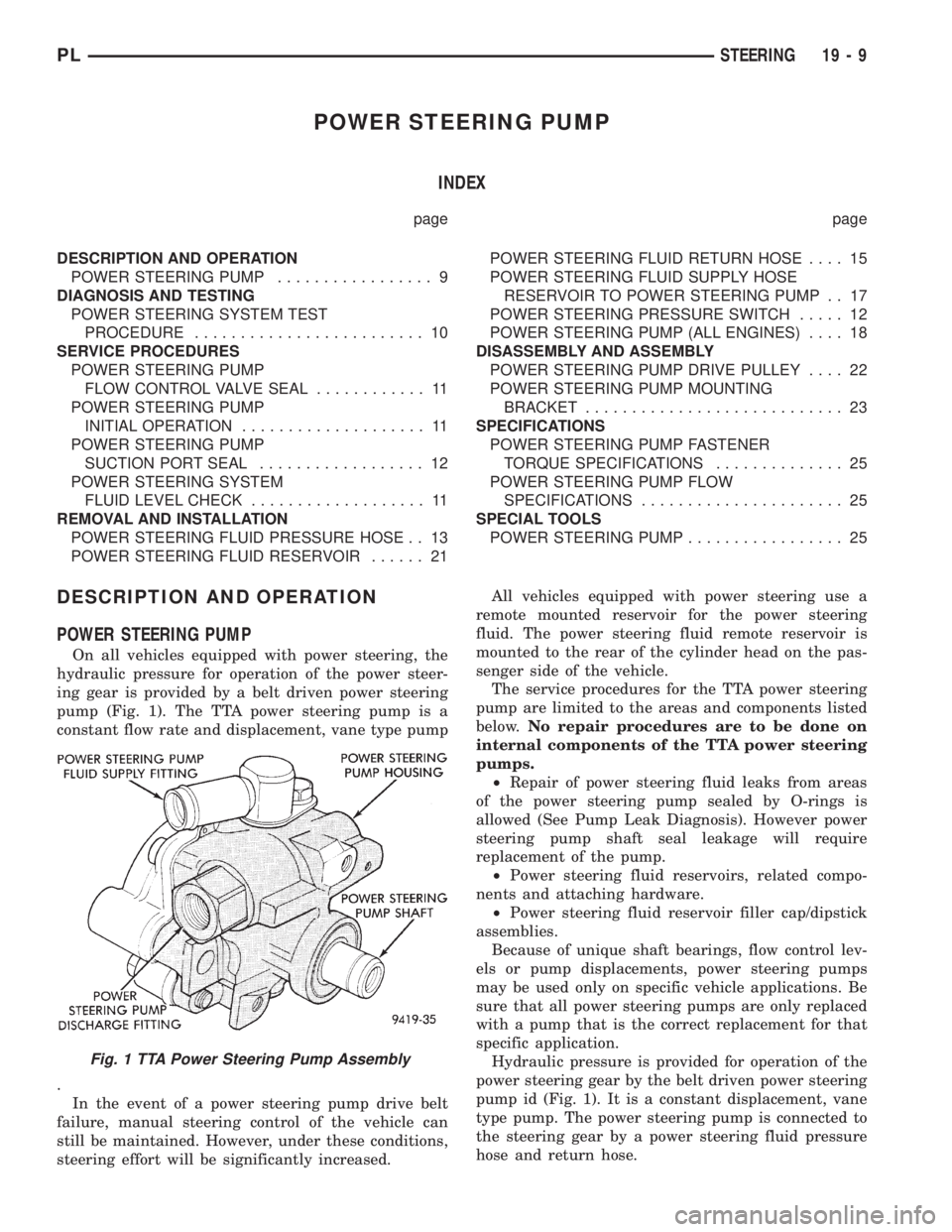

On all vehicles equipped with power steering, the

hydraulic pressure for operation of the power steer-

ing gear is provided by a belt driven power steering

pump (Fig. 1). The TTA power steering pump is a

constant flow rate and displacement, vane type pump

.

In the event of a power steering pump drive belt

failure, manual steering control of the vehicle can

still be maintained. However, under these conditions,

steering effort will be significantly increased.All vehicles equipped with power steering use a

remote mounted reservoir for the power steering

fluid. The power steering fluid remote reservoir is

mounted to the rear of the cylinder head on the pas-

senger side of the vehicle.

The service procedures for the TTA power steering

pump are limited to the areas and components listed

below.No repair procedures are to be done on

internal components of the TTA power steering

pumps.

²Repair of power steering fluid leaks from areas

of the power steering pump sealed by O-rings is

allowed (See Pump Leak Diagnosis). However power

steering pump shaft seal leakage will require

replacement of the pump.

²Power steering fluid reservoirs, related compo-

nents and attaching hardware.

²Power steering fluid reservoir filler cap/dipstick

assemblies.

Because of unique shaft bearings, flow control lev-

els or pump displacements, power steering pumps

may be used only on specific vehicle applications. Be

sure that all power steering pumps are only replaced

with a pump that is the correct replacement for that

specific application.

Hydraulic pressure is provided for operation of the

power steering gear by the belt driven power steering

pump id (Fig. 1). It is a constant displacement, vane

type pump. The power steering pump is connected to

the steering gear by a power steering fluid pressure

hose and return hose.

Fig. 1 TTA Power Steering Pump Assembly

PLSTEERING 19 - 9

Page 911 of 1200

Rectangular pumping vanes in the shaft driven

rotor, move power steering fluid from the intake to

the cam ring pressure cavities of the power steering

pump. As the rotor begins to turn, centrifugal force

throws the vanes against the inside surface of the

cam ring to pickup residual oil. This oil is then forced

into the high pressure area. As more oil is picked up

by the vanes, the additional oil is forced into the cav-

ities of the thrust plate through two crossover holes

in the cam ring and pressure plate. The crossover

holes empty into the high pressure area between the

pressure plate and the housing end cover.

As the high pressure area is filled, oil flows under

the vanes in the rotor slots, forcing the vanes to fol-

low the inside surface of the cam ring. As the vanes

reach the restricted area of the cam ring, oil is forced

out from between the vanes. When excess oil flow is

generated during high-speed operation, a regulated

amount of oil returns to the pump intake side

through a flow control valve. The flow control valve

reduces the power required to drive the pump and

holds down temperature build-up.

When steering conditions exceed maximum pres-

sure requirements, such as when the wheels are

turned against the stops. The pressure built up in

the steering gear exerts pressure on the spring end of

the flow control valve. The high pressure lifts the

relief valve ball from its seat and allows oil to flow

through a trigger orifice located in the outlet fitting.

This reduces pressure on the spring end of the flow

control valve which then opens and allows the oil to

return to the intake side of the pump. This action

limits maximum pressure output of the pump to a

safe level.

Under normal power steering pump operating con-

ditions, pressure requirements of the pump are below

maximum, causing the pressure relief valve to

remain closed.

DIAGNOSIS AND TESTING

POWER STEERING SYSTEM TEST PROCEDURE

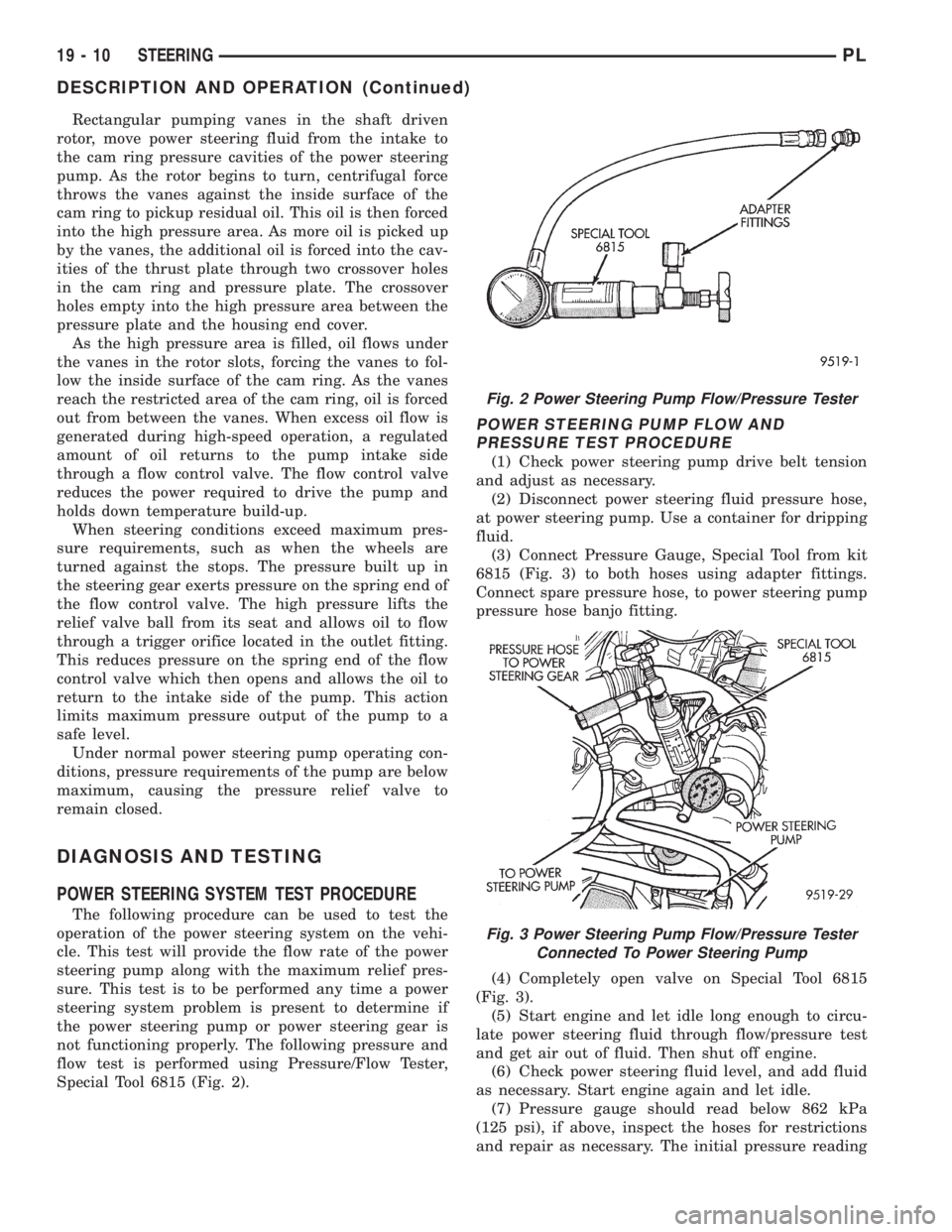

The following procedure can be used to test the

operation of the power steering system on the vehi-

cle. This test will provide the flow rate of the power

steering pump along with the maximum relief pres-

sure. This test is to be performed any time a power

steering system problem is present to determine if

the power steering pump or power steering gear is

not functioning properly. The following pressure and

flow test is performed using Pressure/Flow Tester,

Special Tool 6815 (Fig. 2).

POWER STEERING PUMP FLOW AND

PRESSURE TEST PROCEDURE

(1) Check power steering pump drive belt tension

and adjust as necessary.

(2) Disconnect power steering fluid pressure hose,

at power steering pump. Use a container for dripping

fluid.

(3) Connect Pressure Gauge, Special Tool from kit

6815 (Fig. 3) to both hoses using adapter fittings.

Connect spare pressure hose, to power steering pump

pressure hose banjo fitting.

(4) Completely open valve on Special Tool 6815

(Fig. 3).

(5) Start engine and let idle long enough to circu-

late power steering fluid through flow/pressure test

and get air out of fluid. Then shut off engine.

(6) Check power steering fluid level, and add fluid

as necessary. Start engine again and let idle.

(7) Pressure gauge should read below 862 kPa

(125 psi), if above, inspect the hoses for restrictions

and repair as necessary. The initial pressure reading

Fig. 2 Power Steering Pump Flow/Pressure Tester

Fig. 3 Power Steering Pump Flow/Pressure Tester

Connected To Power Steering Pump

19 - 10 STEERINGPL

DESCRIPTION AND OPERATION (Continued)