belt DODGE NEON 1999 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 920 of 1200

bolt requires removal to allow the coolant tube

to be moved out of the way for access to the

power steering pump mounting bolt. The cool-

ant tube does not need to be removed or the

cooling system drained.

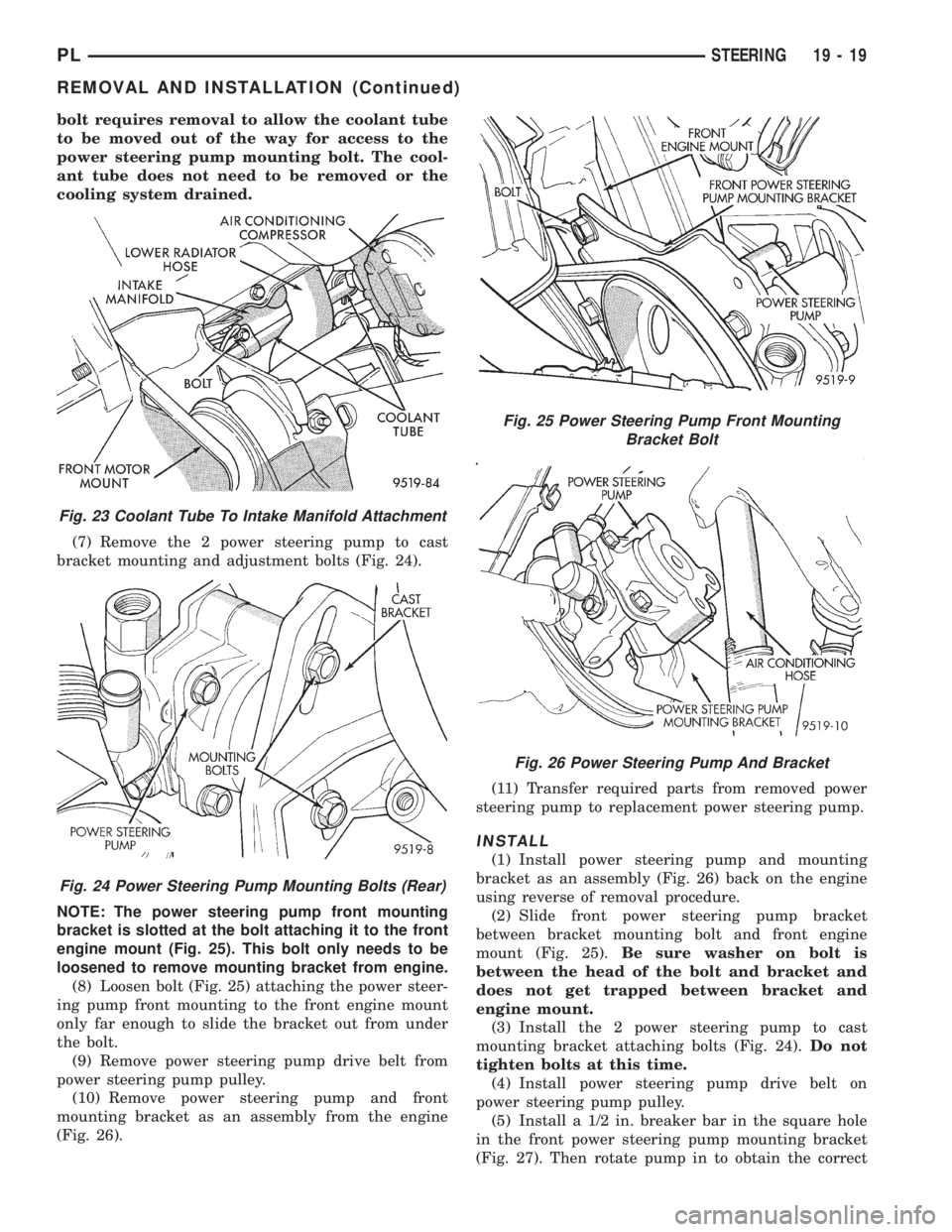

(7) Remove the 2 power steering pump to cast

bracket mounting and adjustment bolts (Fig. 24).

NOTE: The power steering pump front mounting

bracket is slotted at the bolt attaching it to the front

engine mount (Fig. 25). This bolt only needs to be

loosened to remove mounting bracket from engine.

(8) Loosen bolt (Fig. 25) attaching the power steer-

ing pump front mounting to the front engine mount

only far enough to slide the bracket out from under

the bolt.

(9) Remove power steering pump drive belt from

power steering pump pulley.

(10) Remove power steering pump and front

mounting bracket as an assembly from the engine

(Fig. 26).(11) Transfer required parts from removed power

steering pump to replacement power steering pump.

INSTALL

(1) Install power steering pump and mounting

bracket as an assembly (Fig. 26) back on the engine

using reverse of removal procedure.

(2) Slide front power steering pump bracket

between bracket mounting bolt and front engine

mount (Fig. 25).Be sure washer on bolt is

between the head of the bolt and bracket and

does not get trapped between bracket and

engine mount.

(3) Install the 2 power steering pump to cast

mounting bracket attaching bolts (Fig. 24).Do not

tighten bolts at this time.

(4) Install power steering pump drive belt on

power steering pump pulley.

(5) Install a 1/2 in. breaker bar in the square hole

in the front power steering pump mounting bracket

(Fig. 27). Then rotate pump in to obtain the correct

Fig. 23 Coolant Tube To Intake Manifold Attachment

Fig. 24 Power Steering Pump Mounting Bolts (Rear)

Fig. 25 Power Steering Pump Front Mounting

Bracket Bolt

Fig. 26 Power Steering Pump And Bracket

PLSTEERING 19 - 19

REMOVAL AND INSTALLATION (Continued)

Page 921 of 1200

drive belt tension. See Accessory Drive Belts in

Group 7 Cooling System of this service manual for

the correct drive belt tension specification. When cor-

rect drive belt tension is obtained torque the 2 bolts

at the power steering pump cast mounting bracket

(Fig. 24) to 54 N´m (40 ft. lbs.). Then torque the front

power steering pump mounting bracket bolt (Fig. 25)

to 54 N´m (40 ft. lbs.).

(6) Install power steering supply hose on power

steering pump suction fitting (Fig. 22). Install hose

clamp on hose, being sure hose clamp is installed on

hose past upset bead on power steering pump tube.

(7) Using a lint free towel, wipe clean all open

power steering hose ends, and power steering pump

fittings.

(8) Install a new O-ring on the end of the power

steering pressure hose banjo fitting (Fig. 28).(9) Install a new O-ring (Fig. 29) on power steering

fluid pressure hose banjo fitting bolt.

(10) Lubricate both O-rings using fresh clean

power steering fluid.

(11) Install banjo bolt into the power steering pres-

sure hose banjo fitting.

(12) Attach power steering pressure hose on outlet

fitting of the power steering pump (Fig. 21).

(13) Position locating pin on power steering pres-

sure hose banjo fitting so it is against power steering

pump mounting bracket (Fig. 21). While holding

locating pin against power steering pump bracket,

torque pump end Banjo bolt to 34 N´m (25 ft. lbs.).

CAUTION: Do not use automatic transmission fluid

in power steering system. Only use MoparT, Power

Steering Fluid, or equivalent.

(14) Fill power steering reservoir to correct fluid

level.

(15) Connect negative cable back on negative post

of battery.

(16) Start the engine and let run for a few seconds.

Then turn the engine off.

(17) Add fluid if necessary. Repeat the above pro-

cedure until the fluid level remains constant after

running the engine.

(18) Raise front wheels of vehicle off the ground.

(19) Start engine, then slowly turn steering wheel

right and left several times until lightly contacting

the wheel stops. Then turn the engine off.

(20) Add power steering fluid if necessary.

(21) Lower the vehicle. Start engine again and

turn the steering wheel slowly from lock to lock.

(22) Stop the engine. Check the fluid level and

refill as required.

Fig. 27 Setting Power Steering Pump Drive Belt

Tension

Fig. 28 O-Ring Installed On Power Steering Hose

Banjo Fitting

Fig. 29 O-Ring Installed On Banjo Fitting Bolt

19 - 20 STEERINGPL

REMOVAL AND INSTALLATION (Continued)

Page 927 of 1200

STEERING GEAR

INDEX

page page

DESCRIPTION AND OPERATION

STEERING GEAR........................ 26

DIAGNOSIS AND TESTING

POWER STEERING SYSTEM

TEST PROCEDURE.................... 27

REMOVAL AND INSTALLATION

MANUAL AND POWER STEERING GEAR..... 28DISASSEMBLY AND ASSEMBLY

OUTER TIE ROD........................ 32

SPECIFICATIONS

STEERING GEAR FASTENER

TORQUE SPECIFICATIONS.............. 34

SPECIAL TOOLS

POWER STEERING GEAR................. 34

DESCRIPTION AND OPERATION

STEERING GEAR

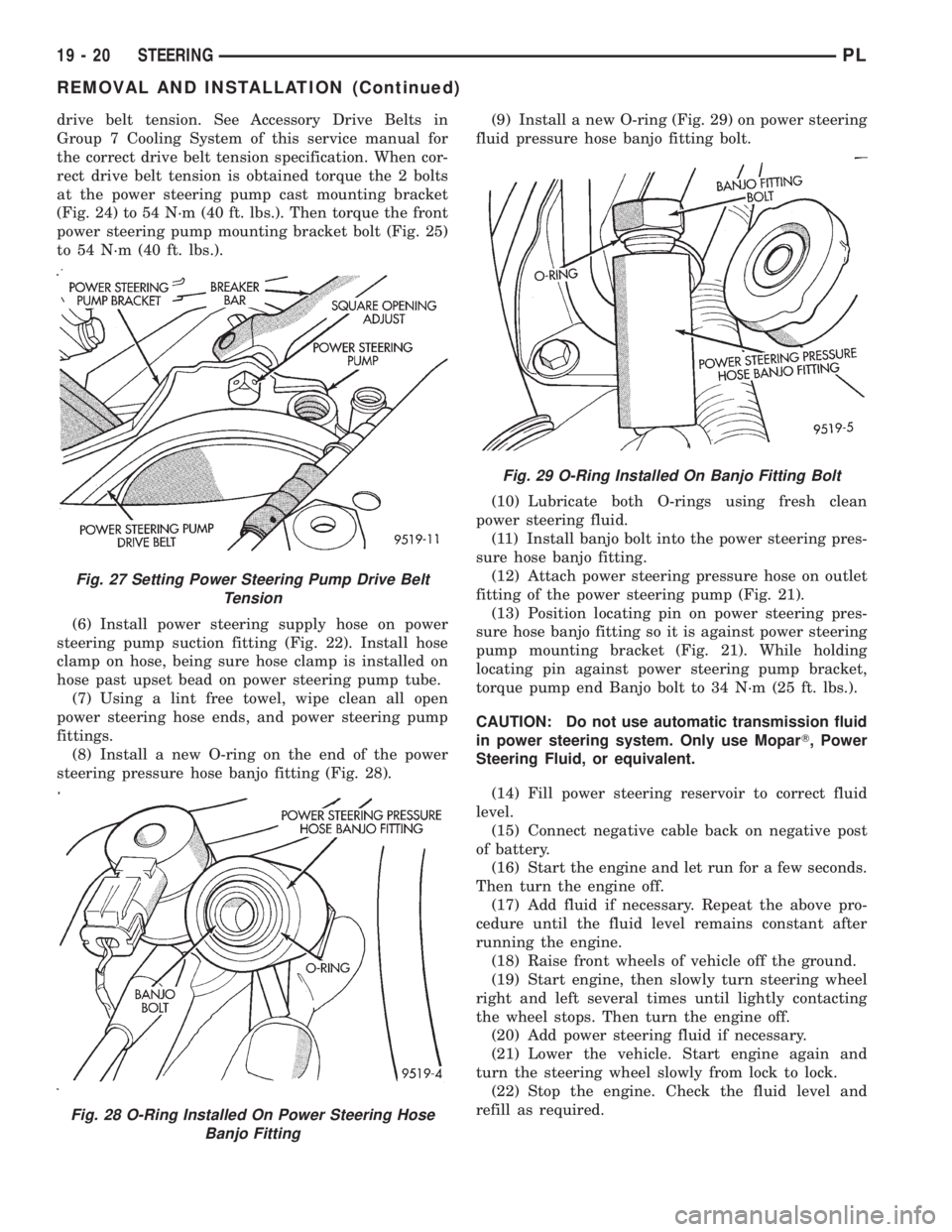

The power steering system consists of these four

major components. Power Steering Gear (Fig. 1),

Power Steering Pump, Pressure Hose, and Return

Line. Turning of the steering wheel is converted into

linear travel through the meshing of the helical pin-

ion teeth with the rack teeth. Power assist steering is

provided by an open center, rotary type control valve

which directs oil from the pump to either side of the

integral rack piston.Road feel is controlled by the diameter of a torsion

bar which initially steers the vehicle. This movement

directs oil behind the integral rack piston, which, in

turn, builds up hydraulic pressure and assists in the

turning effort.

The drive tangs on the pinion of the power steering

pump mate loosely with a stub shaft. This is to per-

mit manual steering control to be maintained if the

drive belt on the power steering pump should break.

Fig. 1 Power Steering Gear Assembly

19 - 26 STEERINGPL

Page 928 of 1200

However, under these conditions, steering effort will

be increased.

NOTE: The power steering gear (Fig. 1) should NOT

be serviced or adjusted. If a malfunction or oil leak

occurs with the steering gear, the complete steering

gear needs to be replaced.

DIAGNOSIS AND TESTING

POWER STEERING SYSTEM TEST PROCEDURE

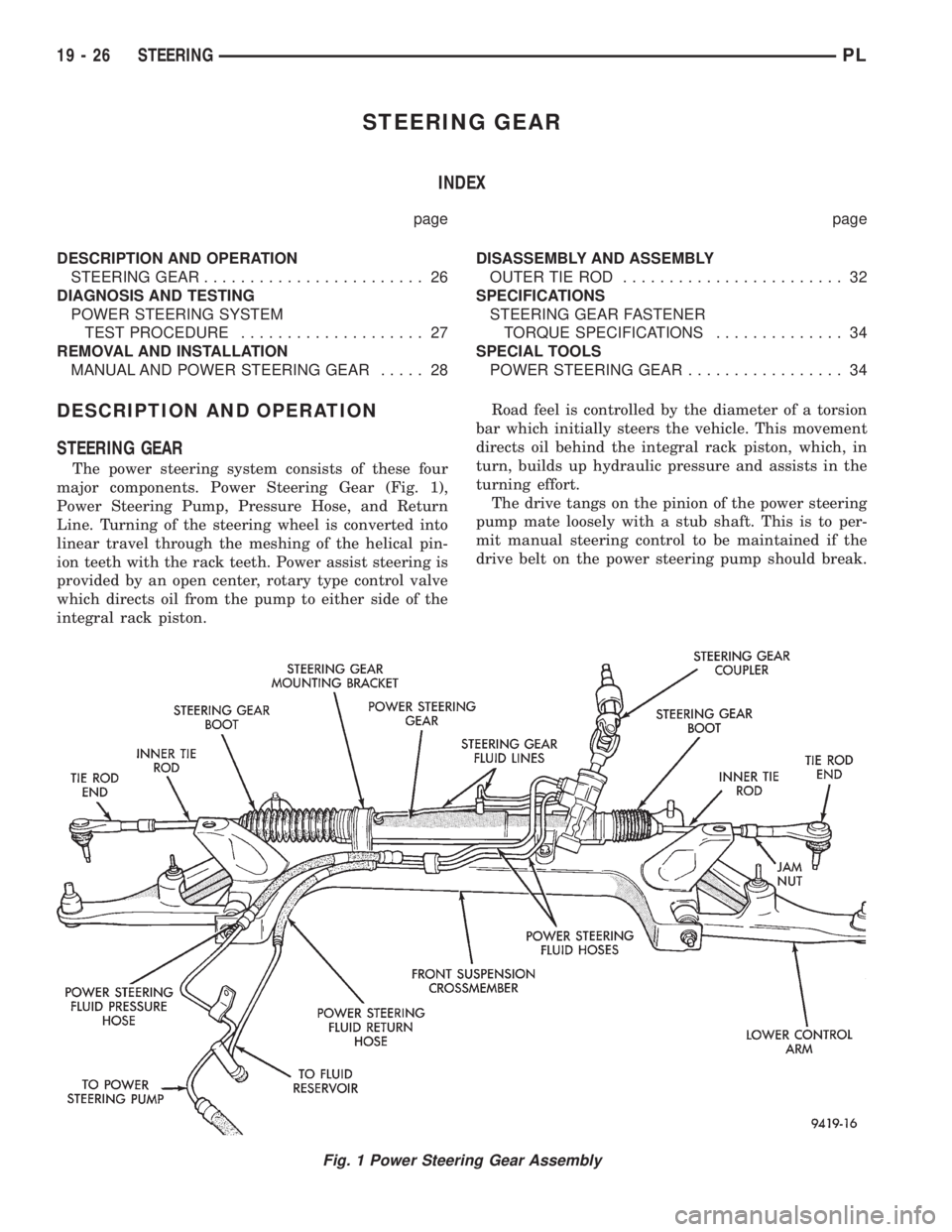

The following procedure can be used to test the

operation of the power steering system on the vehi-

cle. This test will provide the flow rate of the power

steering pump along with the maximum relief pres-

sure. This test is to be performed any time a power

steering system problem is present to determine if

the power steering pump or power steering gear is

not functioning properly. The following pressure and

flow test is performed using Pressure/Flow Tester,

Special Tool 6815 (Fig. 2).

POWER STEERING PUMP FLOW AND

PRESSURE TEST PROCEDURE

(1) Check power steering pump drive belt tension

and adjust as necessary.

(2) Disconnect power steering fluid pressure hose,

at power steering pump. Use a container for dripping

fluid.

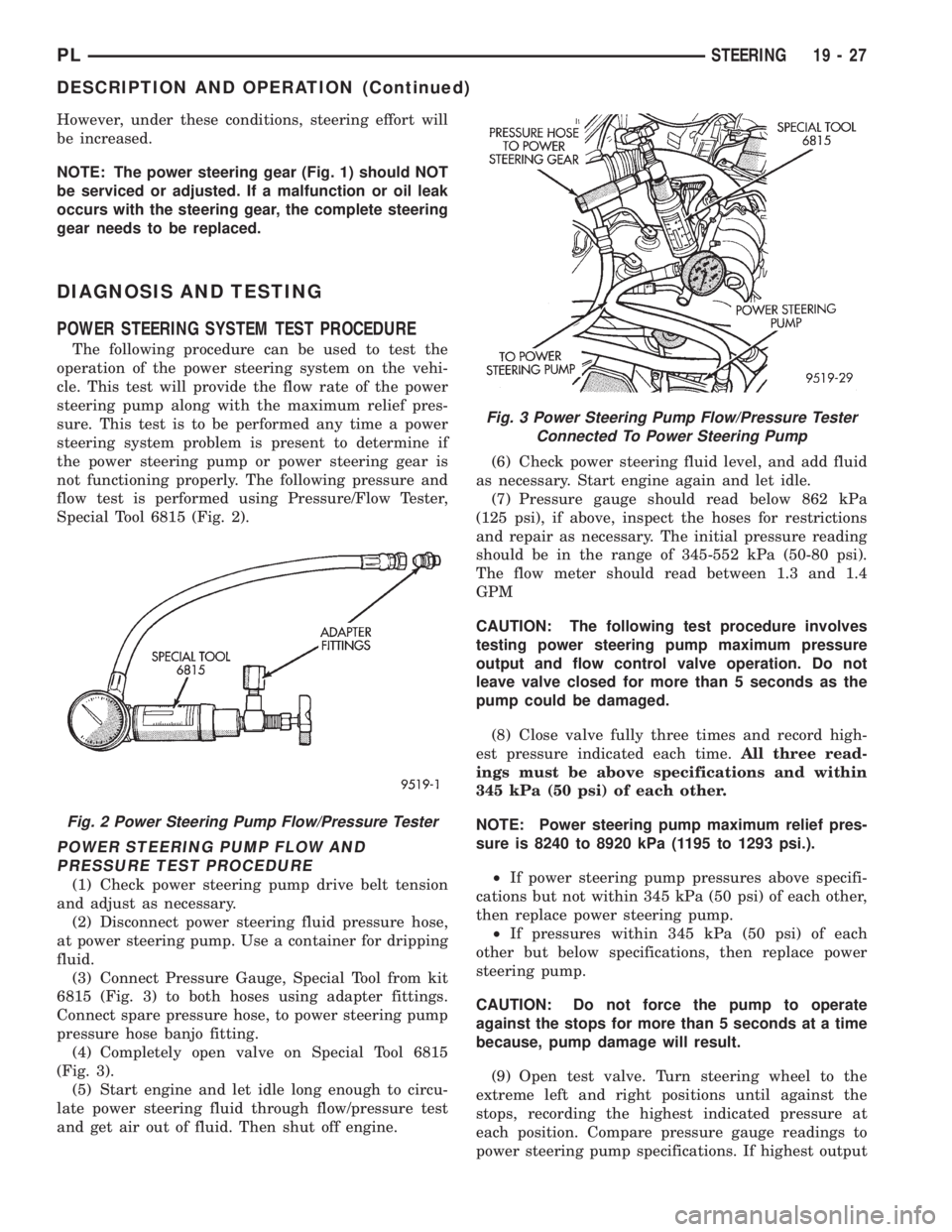

(3) Connect Pressure Gauge, Special Tool from kit

6815 (Fig. 3) to both hoses using adapter fittings.

Connect spare pressure hose, to power steering pump

pressure hose banjo fitting.

(4) Completely open valve on Special Tool 6815

(Fig. 3).

(5) Start engine and let idle long enough to circu-

late power steering fluid through flow/pressure test

and get air out of fluid. Then shut off engine.(6) Check power steering fluid level, and add fluid

as necessary. Start engine again and let idle.

(7) Pressure gauge should read below 862 kPa

(125 psi), if above, inspect the hoses for restrictions

and repair as necessary. The initial pressure reading

should be in the range of 345-552 kPa (50-80 psi).

The flow meter should read between 1.3 and 1.4

GPM

CAUTION: The following test procedure involves

testing power steering pump maximum pressure

output and flow control valve operation. Do not

leave valve closed for more than 5 seconds as the

pump could be damaged.

(8) Close valve fully three times and record high-

est pressure indicated each time.All three read-

ings must be above specifications and within

345 kPa (50 psi) of each other.

NOTE: Power steering pump maximum relief pres-

sure is 8240 to 8920 kPa (1195 to 1293 psi.).

²If power steering pump pressures above specifi-

cations but not within 345 kPa (50 psi) of each other,

then replace power steering pump.

²If pressures within 345 kPa (50 psi) of each

other but below specifications, then replace power

steering pump.

CAUTION: Do not force the pump to operate

against the stops for more than 5 seconds at a time

because, pump damage will result.

(9) Open test valve. Turn steering wheel to the

extreme left and right positions until against the

stops, recording the highest indicated pressure at

each position. Compare pressure gauge readings to

power steering pump specifications. If highest output

Fig. 3 Power Steering Pump Flow/Pressure Tester

Connected To Power Steering Pump

Fig. 2 Power Steering Pump Flow/Pressure Tester

PLSTEERING 19 - 27

DESCRIPTION AND OPERATION (Continued)

Page 1083 of 1200

BODY COMPONENTS

INDEX

page page

DIAGNOSIS AND TESTING

WATER LEAKS.......................... 3

WIND NOISE............................ 4

SERVICE PROCEDURES

HEAT STAKING.......................... 4

REMOVAL AND INSTALLATION

WINDOW REGULATORÐ4 DOOR........... 36

A-PILLAR TRIM.......................... 4

B-PILLAR APPLIQUEÐ2 DOOR.............. 5

B-PILLAR APPLIQUEÐ4 DOOR.............. 5

B-PILLAR TRIMÐ4 DOOR.................. 6

B-PILLAR WEATHERSTRIP CHANNEL......... 6

BODY VENT............................. 6

CARPET............................... 7

CHILD RESTRAINT SEAT BACK............. 8

CHILD SEAT MODULE..................... 8

COWL COVER........................... 7

DOOR HINGE........................... 9

DOOR LOCK CYLINDER.................. 10

DOOR OPENING TRIM WELT.............. 10

DOOR SILL TRIM........................ 10

DOOR................................. 9

FLOOR CONSOLE LATCH................. 11

FLOOR CONSOLE....................... 11

FRONT DOOR CHECK STOP............... 11

FRONT DOOR GLASSÐ2 DOOR............ 12

FRONT DOOR GLASSÐ4 DOOR............ 13

FRONT DOOR INNER BELT WEATHERSTRIP . . 13

FRONT DOOR LATCH STRIKER............ 14

FRONT DOOR LATCH.................... 13

FRONT DOOR OUTER BELT WEATHERSTRIP . 14

FRONT DOOR OUTSIDE HANDLE........... 14

FRONT DOOR TRIM PANEL................ 14

FRONT DOOR WATER SHIELD............. 16

FRONT DOOR WEATHERSTRIP............ 16

FRONT OUTBOARD SEAT BELT............ 17

FRONT SEAT BELT BUCKLE............... 18

FRONT SEAT BELT RETRACTOR........... 18

FRONT SEAT........................... 17

FRONT SHOULDER BELT ADJUSTER........ 18

FRONT VERTICAL GUIDE BAR............. 18

GRILLE............................... 19

HEADLINING........................... 19

HOOD HINGE.......................... 20

HOOD LATCH.......................... 21

HOOD RELEASE CABLE.................. 21

HOOD................................ 20

LOCK BUTTON BELL-CRANK.............. 21

LOWER QUARTER TRIMÐ4 DOOR.......... 22PARCEL SHELF TRIM.................... 22

QUARTER TRIM PANELÐ2 DOOR........... 22

REAR DOOR GLASS..................... 23

REAR DOOR INNER BELT WEATHERSTRIP . . . 23

REAR DOOR INTERLOCK LATCH STRIKER . . . 24

REAR DOOR LATCH STRIKER............. 24

REAR DOOR LATCH..................... 24

REAR DOOR LOCK BELL CRANK........... 24

REAR DOOR OUTER BELT WEATHERSTRIP . . 25

REAR DOOR TRIM....................... 25

REAR DOOR WINDOW REGULATOR........ 25

REAR SEAT BACK....................... 26

REAR SEAT BELT BUCKLE................ 26

REAR SEAT BELT RETRACTOR............ 26

REAR SEAT CUSHION.................... 26

REAR SPOILER......................... 27

REAR VERTICAL GUIDE BAR.............. 27

ROOF APERTURE (RAP) MOLDING.......... 28

ROOF RACK CROSS RAILS............... 28

ROOF RACK........................... 28

ROOF RAIL WEATHER-STRIP FOUR DOOR . . . 29

ROOF RAIL WEATHER-STRIP ± TWO DOOR . . . 29

SIDE COWL TRIM....................... 30

SIDE VIEW MIRROR STANCHION........... 31

SIDE VIEW MIRROR TRIM COVER.......... 31

SIDE VIEW MIRROR..................... 30

SUN VISOR SUPPORT................... 31

SUN VISOR............................ 31

TRUNK CARPET........................ 31

TRUNK LATCH STRIKER.................. 32

TRUNK LATCH.......................... 32

TRUNK LID LIFT SPRINGS................ 33

TRUNK LID............................ 32

TRUNK LOCK CYLINDER................. 33

TRUNK TRIM PANEL..................... 34

TRUNK WEATHERSTRIP.................. 34

UPPER QUARTER TRIMÐ4 DOOR.......... 34

WINDOW INNERBELT STABILIZER.......... 34

WINDOW REGULATORÐ2 DOOR........... 35

ADJUSTMENTS

FRONT DOOR GLASS ADJUSTMENT........ 37

FRONT DOOR LATCH ADJUSTMENT........ 38

REAR DOOR GLASS ADJUSTMENT......... 38

REAR DOOR LATCH ADJUSTMENT.......... 39

SPECIFICATIONS

BODY LUBRICATION SPECIFICATIONS....... 39

SPECIAL TOOLS

BODY................................. 40

23 - 2 BODYPL

Page 1087 of 1200

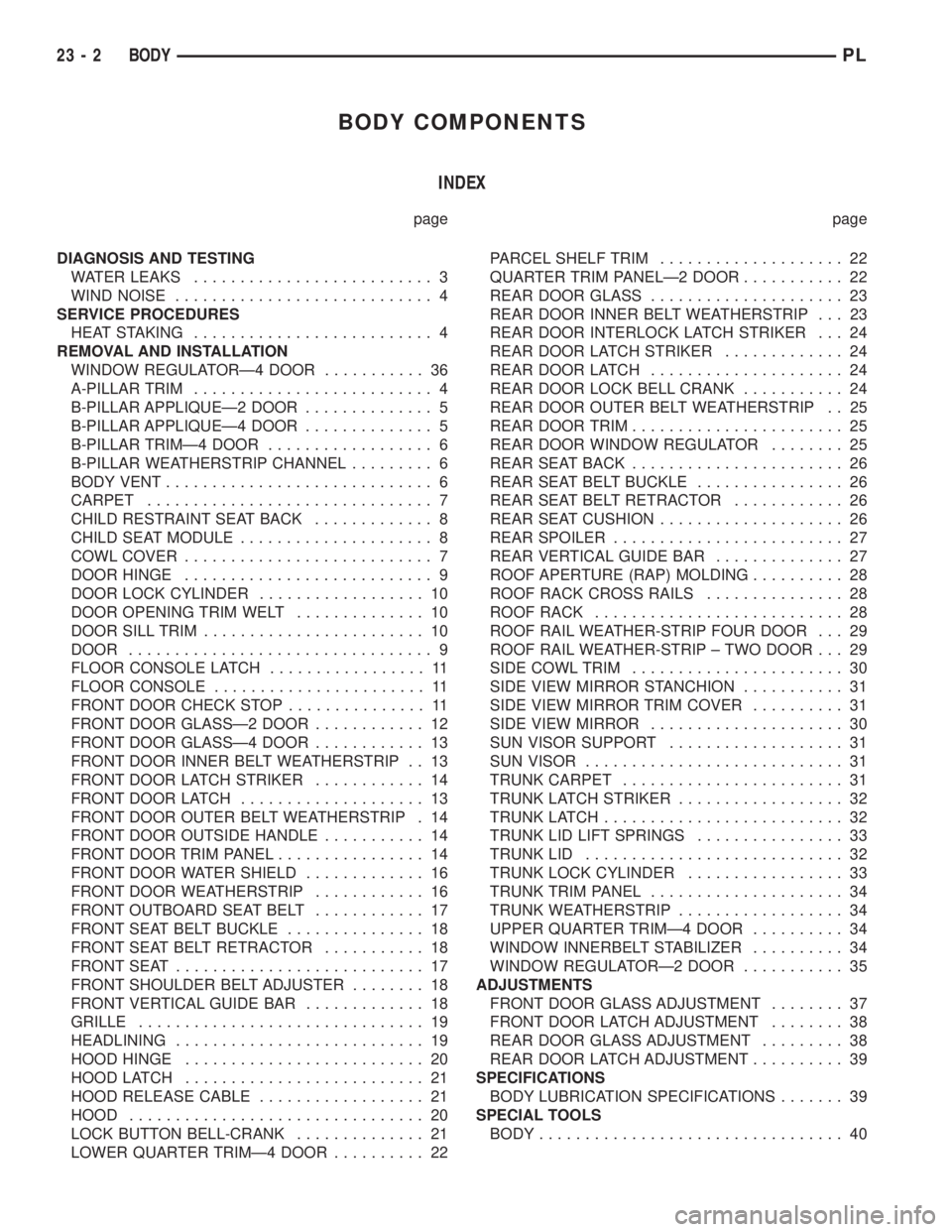

B-PILLAR TRIMÐ4 DOOR

REMOVAL

(1) Remove bolt holding lower seat belt anchor to

floor pan kick-up.

(2) Remove shoulder belt height control knob.

(3) Remove bolt holding turning loop to belt

adjuster (Fig. 4).

(4) Remove access cover from B-pillar trim.

(5) Disengage clips holding trim to B-pillar.

(6) Feed seat belt turning loop and seat belt

through trim panel.

(7) Separate B-pillar trim from vehicle.

INSTALLATION

(1) Position B±pillar trim panel near B±pillar.

(2) Feed seat belt turning loop and seat belt

through trim panel.

(3) Align locating pins on backside of trim panel to

mating holes in B±pillar.

(4) Push clips on trim panel into slots in B±pillar.

(5) Install access cover to B-pillar trim.

(6) Install bolt holding turning loop to belt

adjuster.

(7) Install shoulder belt height control knob.

(8) Install bolt holding lower seat belt anchor to

floor pan kick-up.

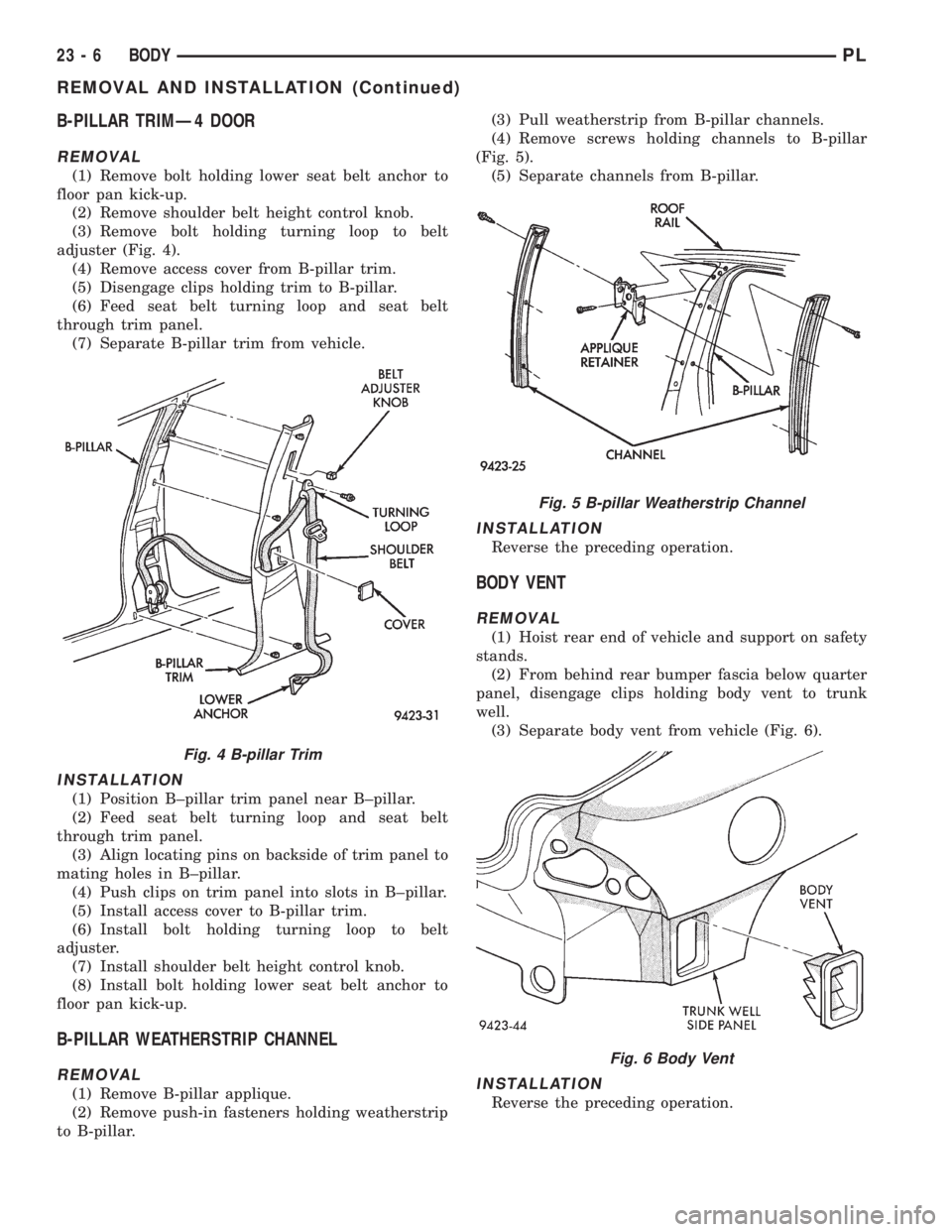

B-PILLAR WEATHERSTRIP CHANNEL

REMOVAL

(1) Remove B-pillar applique.

(2) Remove push-in fasteners holding weatherstrip

to B-pillar.(3) Pull weatherstrip from B-pillar channels.

(4) Remove screws holding channels to B-pillar

(Fig. 5).

(5) Separate channels from B-pillar.

INSTALLATION

Reverse the preceding operation.

BODY VENT

REMOVAL

(1) Hoist rear end of vehicle and support on safety

stands.

(2) From behind rear bumper fascia below quarter

panel, disengage clips holding body vent to trunk

well.

(3) Separate body vent from vehicle (Fig. 6).

INSTALLATION

Reverse the preceding operation.

Fig. 4 B-pillar Trim

Fig. 5 B-pillar Weatherstrip Channel

Fig. 6 Body Vent

23 - 6 BODYPL

REMOVAL AND INSTALLATION (Continued)

Page 1088 of 1200

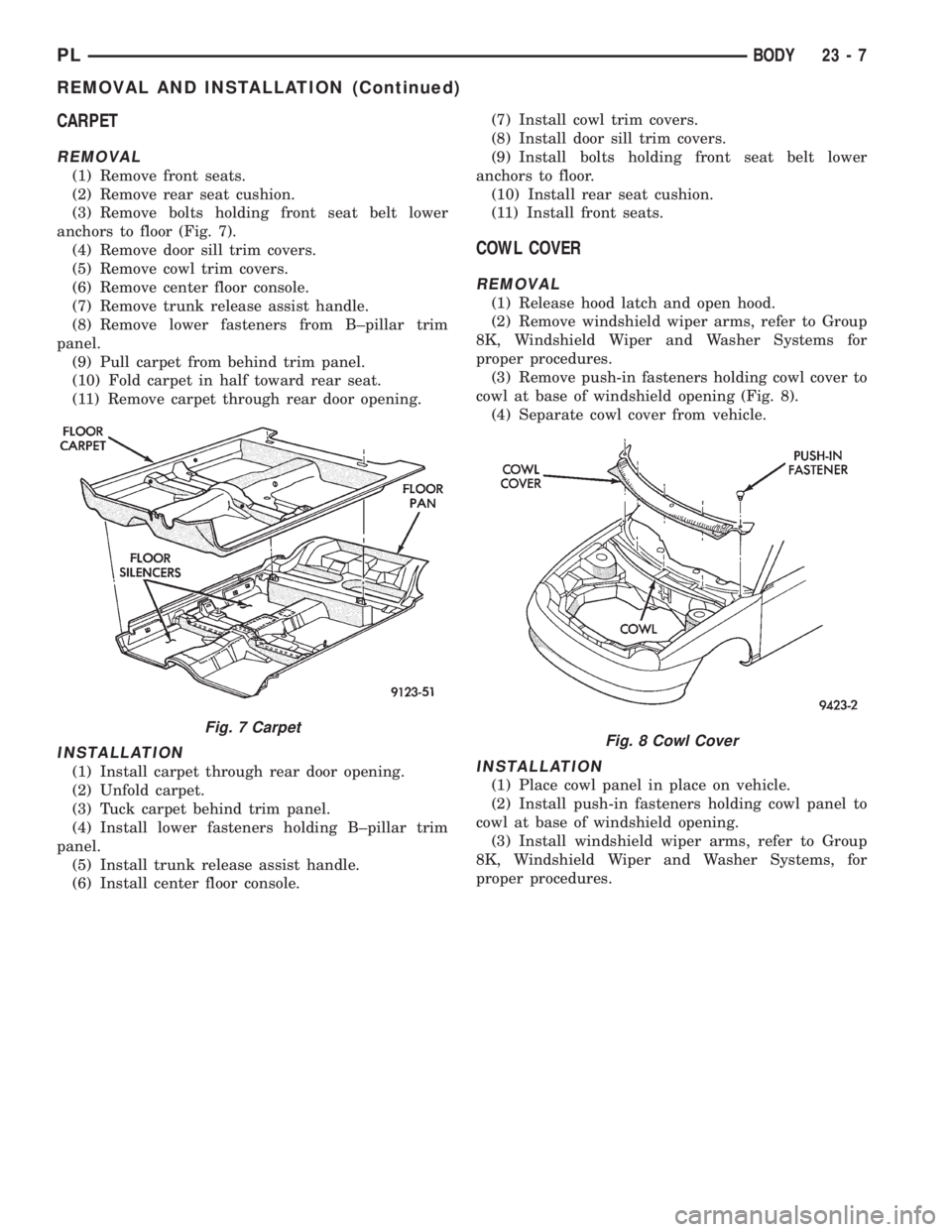

CARPET

REMOVAL

(1) Remove front seats.

(2) Remove rear seat cushion.

(3) Remove bolts holding front seat belt lower

anchors to floor (Fig. 7).

(4) Remove door sill trim covers.

(5) Remove cowl trim covers.

(6) Remove center floor console.

(7) Remove trunk release assist handle.

(8) Remove lower fasteners from B±pillar trim

panel.

(9) Pull carpet from behind trim panel.

(10) Fold carpet in half toward rear seat.

(11) Remove carpet through rear door opening.

INSTALLATION

(1) Install carpet through rear door opening.

(2) Unfold carpet.

(3) Tuck carpet behind trim panel.

(4) Install lower fasteners holding B±pillar trim

panel.

(5) Install trunk release assist handle.

(6) Install center floor console.(7) Install cowl trim covers.

(8) Install door sill trim covers.

(9) Install bolts holding front seat belt lower

anchors to floor.

(10) Install rear seat cushion.

(11) Install front seats.

COWL COVER

REMOVAL

(1) Release hood latch and open hood.

(2) Remove windshield wiper arms, refer to Group

8K, Windshield Wiper and Washer Systems for

proper procedures.

(3) Remove push-in fasteners holding cowl cover to

cowl at base of windshield opening (Fig. 8).

(4) Separate cowl cover from vehicle.

INSTALLATION

(1) Place cowl panel in place on vehicle.

(2) Install push-in fasteners holding cowl panel to

cowl at base of windshield opening.

(3) Install windshield wiper arms, refer to Group

8K, Windshield Wiper and Washer Systems, for

proper procedures.

Fig. 7 CarpetFig. 8 Cowl Cover

PLBODY 23 - 7

REMOVAL AND INSTALLATION (Continued)

Page 1089 of 1200

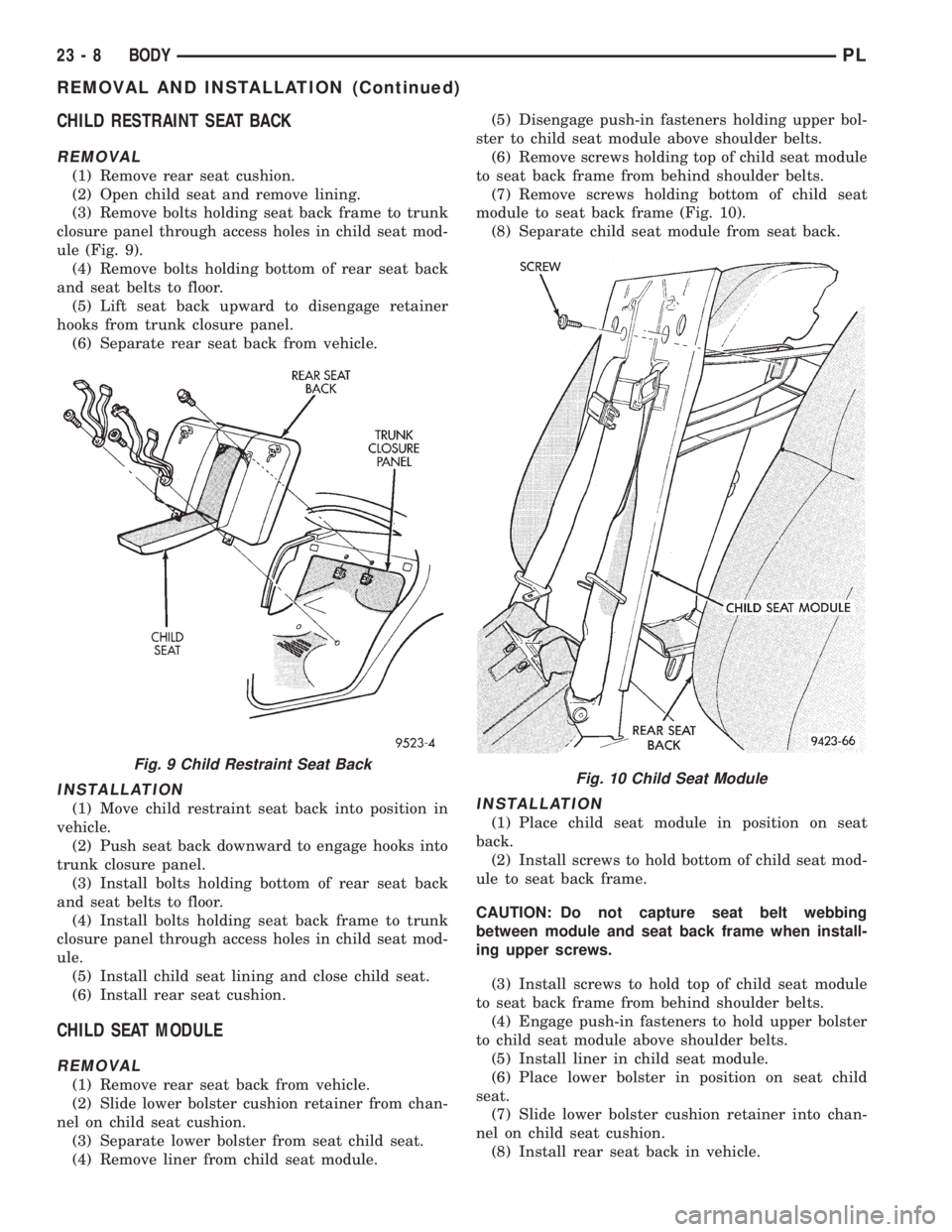

CHILD RESTRAINT SEAT BACK

REMOVAL

(1) Remove rear seat cushion.

(2) Open child seat and remove lining.

(3) Remove bolts holding seat back frame to trunk

closure panel through access holes in child seat mod-

ule (Fig. 9).

(4) Remove bolts holding bottom of rear seat back

and seat belts to floor.

(5) Lift seat back upward to disengage retainer

hooks from trunk closure panel.

(6) Separate rear seat back from vehicle.

INSTALLATION

(1) Move child restraint seat back into position in

vehicle.

(2) Push seat back downward to engage hooks into

trunk closure panel.

(3) Install bolts holding bottom of rear seat back

and seat belts to floor.

(4) Install bolts holding seat back frame to trunk

closure panel through access holes in child seat mod-

ule.

(5) Install child seat lining and close child seat.

(6) Install rear seat cushion.

CHILD SEAT MODULE

REMOVAL

(1) Remove rear seat back from vehicle.

(2) Slide lower bolster cushion retainer from chan-

nel on child seat cushion.

(3) Separate lower bolster from seat child seat.

(4) Remove liner from child seat module.(5) Disengage push-in fasteners holding upper bol-

ster to child seat module above shoulder belts.

(6) Remove screws holding top of child seat module

to seat back frame from behind shoulder belts.

(7) Remove screws holding bottom of child seat

module to seat back frame (Fig. 10).

(8) Separate child seat module from seat back.

INSTALLATION

(1) Place child seat module in position on seat

back.

(2) Install screws to hold bottom of child seat mod-

ule to seat back frame.

CAUTION: Do not capture seat belt webbing

between module and seat back frame when install-

ing upper screws.

(3) Install screws to hold top of child seat module

to seat back frame from behind shoulder belts.

(4) Engage push-in fasteners to hold upper bolster

to child seat module above shoulder belts.

(5) Install liner in child seat module.

(6) Place lower bolster in position on seat child

seat.

(7) Slide lower bolster cushion retainer into chan-

nel on child seat cushion.

(8) Install rear seat back in vehicle.

Fig. 9 Child Restraint Seat BackFig. 10 Child Seat Module

23 - 8 BODYPL

REMOVAL AND INSTALLATION (Continued)

Page 1093 of 1200

INSTALLATION

(1) Position door check on vehicle and install bolts

attaching stop to door end frame.

(2) Install door speaker, if so equipped.

(3) Install bolt holding door check stop to hinge

pillar.

(4) Install door trim panel and water shield.

FRONT DOOR GLASSÐ2 DOOR

REMOVAL

(1) Remove door trim panel and water shield.

(2) Remove inner and outer door belt weather-

strips.

(3) Loosen inner belt stabilizer.

(4) Lower door glass to bottom of travel to access

glass attachment bolts.

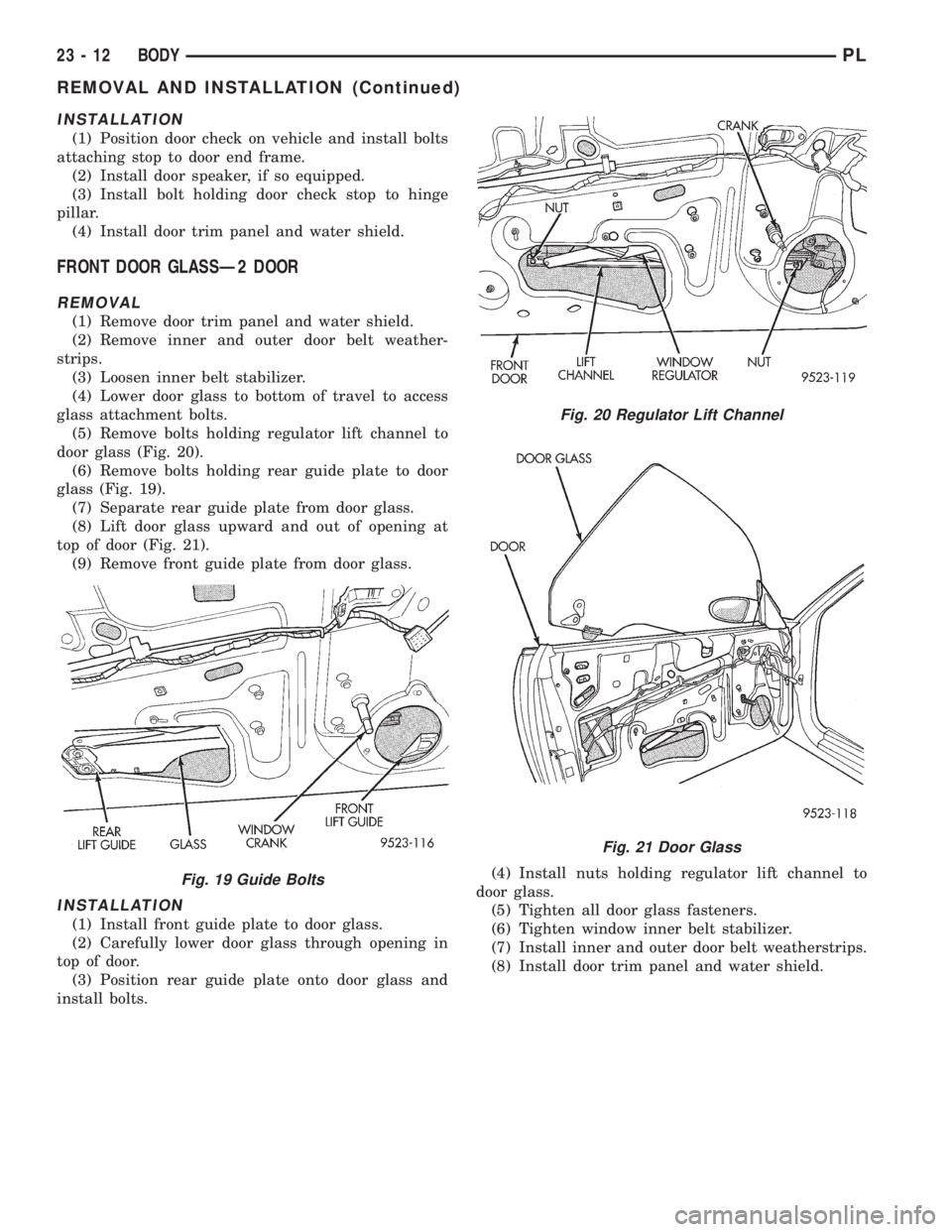

(5) Remove bolts holding regulator lift channel to

door glass (Fig. 20).

(6) Remove bolts holding rear guide plate to door

glass (Fig. 19).

(7) Separate rear guide plate from door glass.

(8) Lift door glass upward and out of opening at

top of door (Fig. 21).

(9) Remove front guide plate from door glass.

INSTALLATION

(1) Install front guide plate to door glass.

(2) Carefully lower door glass through opening in

top of door.

(3) Position rear guide plate onto door glass and

install bolts.(4) Install nuts holding regulator lift channel to

door glass.

(5) Tighten all door glass fasteners.

(6) Tighten window inner belt stabilizer.

(7) Install inner and outer door belt weatherstrips.

(8) Install door trim panel and water shield.

Fig. 19 Guide Bolts

Fig. 20 Regulator Lift Channel

Fig. 21 Door Glass

23 - 12 BODYPL

REMOVAL AND INSTALLATION (Continued)

Page 1094 of 1200

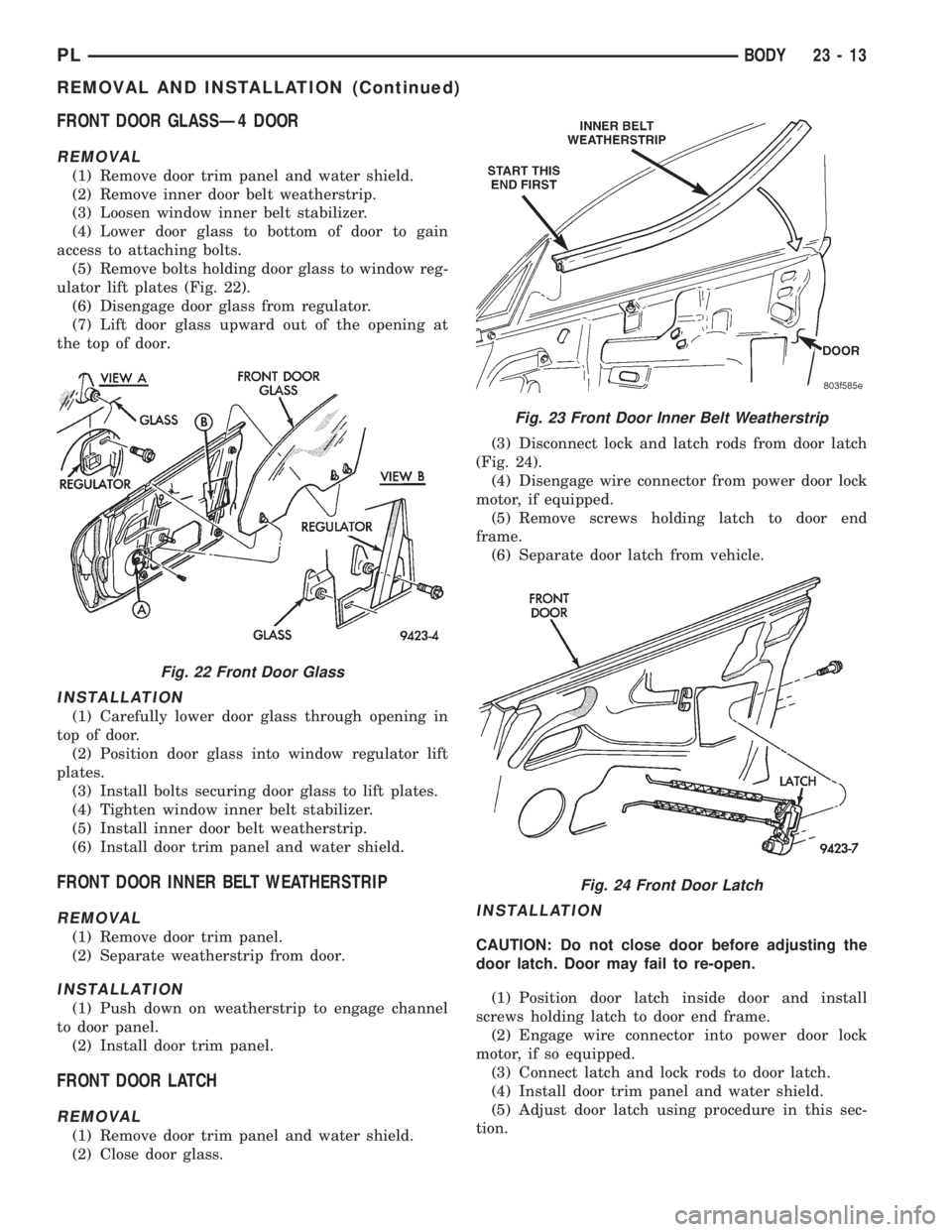

FRONT DOOR GLASSÐ4 DOOR

REMOVAL

(1) Remove door trim panel and water shield.

(2) Remove inner door belt weatherstrip.

(3) Loosen window inner belt stabilizer.

(4) Lower door glass to bottom of door to gain

access to attaching bolts.

(5) Remove bolts holding door glass to window reg-

ulator lift plates (Fig. 22).

(6) Disengage door glass from regulator.

(7) Lift door glass upward out of the opening at

the top of door.

INSTALLATION

(1) Carefully lower door glass through opening in

top of door.

(2) Position door glass into window regulator lift

plates.

(3) Install bolts securing door glass to lift plates.

(4) Tighten window inner belt stabilizer.

(5) Install inner door belt weatherstrip.

(6) Install door trim panel and water shield.

FRONT DOOR INNER BELT WEATHERSTRIP

REMOVAL

(1) Remove door trim panel.

(2) Separate weatherstrip from door.

INSTALLATION

(1) Push down on weatherstrip to engage channel

to door panel.

(2) Install door trim panel.

FRONT DOOR LATCH

REMOVAL

(1) Remove door trim panel and water shield.

(2) Close door glass.(3) Disconnect lock and latch rods from door latch

(Fig. 24).

(4) Disengage wire connector from power door lock

motor, if equipped.

(5) Remove screws holding latch to door end

frame.

(6) Separate door latch from vehicle.

INSTALLATION

CAUTION: Do not close door before adjusting the

door latch. Door may fail to re-open.

(1) Position door latch inside door and install

screws holding latch to door end frame.

(2) Engage wire connector into power door lock

motor, if so equipped.

(3) Connect latch and lock rods to door latch.

(4) Install door trim panel and water shield.

(5) Adjust door latch using procedure in this sec-

tion.

Fig. 22 Front Door Glass

Fig. 23 Front Door Inner Belt Weatherstrip

Fig. 24 Front Door Latch

PLBODY 23 - 13

REMOVAL AND INSTALLATION (Continued)