ignition DODGE NEON 1999 Service Owners Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 378 of 1200

SERVICE PROCEDURES

VEHICLE IMMOBILIZER SYSTEM

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO GROUP 8M - PASSIVE

RESTRAINT SYSTEMS BEFORE ATTEMPTING ANY

STEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

NOTE: The following tests may not prove conclu-

sive in the diagnosis of this system. The most reli-

able, efficient, and accurate means to diagnose the

Vehicle Immobilizer System involves the use of a

DRB scan tool. Refer to the Vehicle Theft Security

System menu item on the DRB scan tool for the

procedures.

The vehicle immobilizer system and the Chrysler

Collision Detection (CCD) data bus network should

be diagnosed using the DRB scan tool. The DRB will

allow confirmation that the CCD data bus is func-

tional, that the immobilizer receiver is placing the

proper messages on the CCD data bus, and that the

Powertrain Control Module (PCM) is receiving the

CCD data bus messages. Refer to the Vehicle Theft

Security System menu item on the DRB scan tool for

the procedures. Refer to 8W-39 - Vehicle Theft Secu-

rity System in Group 8W - Wiring Diagrams for com-

plete circuit descriptions and diagrams.

(1) With the ignition switch in the Off position,

depress the Lock or Unlock button of the immobilizer

transmitter. Listen for the immobilizer receiver to

issue an audible chirp (Unlock) or chirps (Lock). If

OK, go to Step 2. If not OK, replace the transmitter

batteries with known good units and repeat Step 1. If

still not OK, go to Step 2.

(2) Check the fuse in the Power Distribution Cen-

ter (PDC). If OK, go to Step 3. If not OK, repair the

shorted circuit or component as required and replace

the faulty fuse.

(3) Disconnect and isolate the battery negative

cable. Unplug the wire harness connector at the

immobilizer receiver. Check for continuity between

the ground circuit cavity of the immobilizer receiver

wire harness connector and a good ground. There

should be continuity. If OK, go to Step 4. If not OK,

repair the open circuit to ground as required.

(4) Connect the battery negative cable. Check for

battery voltage at the fused B(+) circuit cavity of the

immobilizer receiver wire harness connector. If OK,

refer to the Vehicle Theft Security System menu itemon the DRB scan tool for further diagnosis. If not

OK, repair the open circuit to the PDC fuse as

required.REMOVAL AND INSTALLATION

IMMOBILIZER RECEIVER

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO GROUP 8M - PASSIVE

RESTRAINT SYSTEMS BEFORE ATTEMPTING ANY

STEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

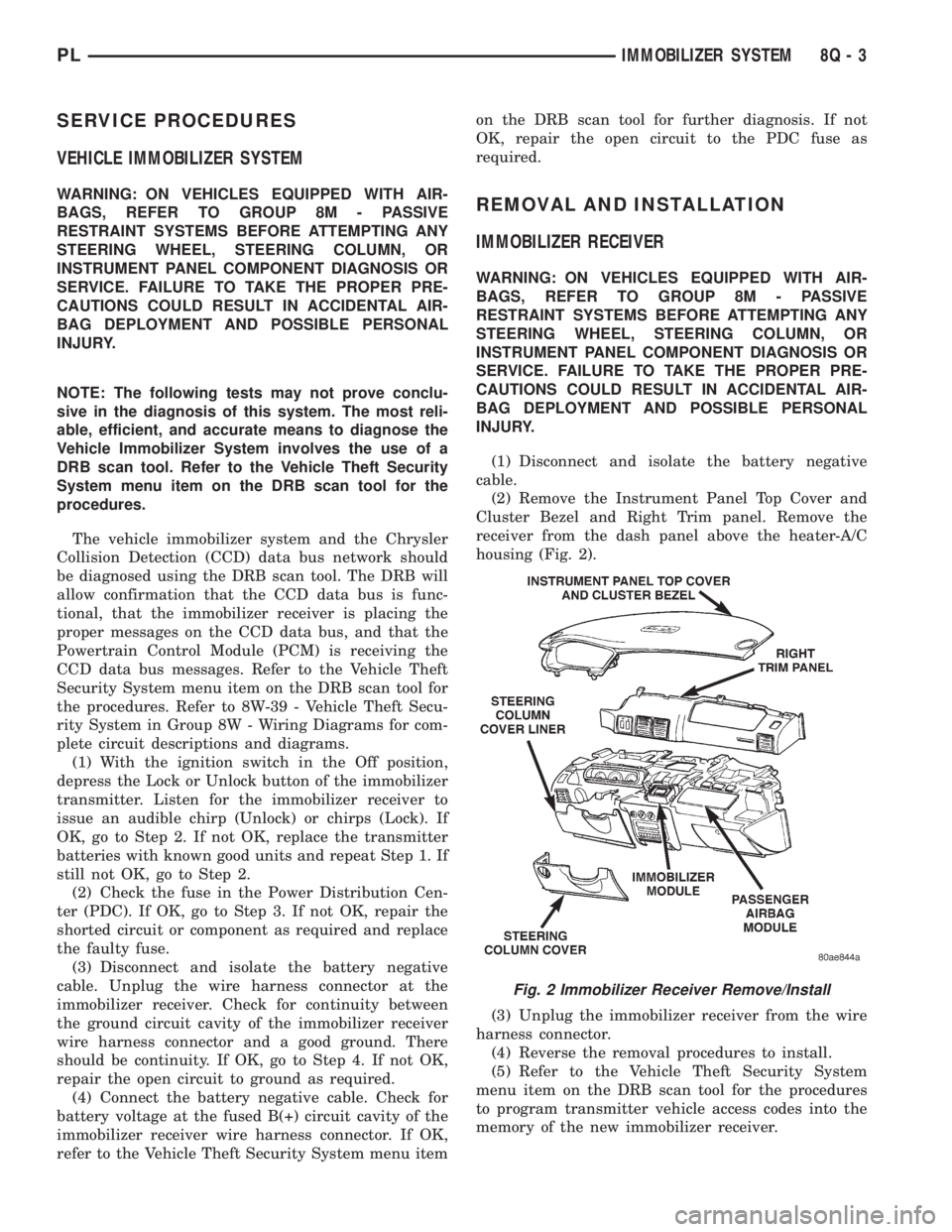

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the Instrument Panel Top Cover and

Cluster Bezel and Right Trim panel. Remove the

receiver from the dash panel above the heater-A/C

housing (Fig. 2).

(3) Unplug the immobilizer receiver from the wire

harness connector.

(4) Reverse the removal procedures to install.

(5) Refer to the Vehicle Theft Security System

menu item on the DRB scan tool for the procedures

to program transmitter vehicle access codes into the

memory of the new immobilizer receiver.

Fig. 2 Immobilizer Receiver Remove/Install

PLIMMOBILIZER SYSTEM 8Q - 3

Page 380 of 1200

POWER WINDOWS

CONTENTS

page page

GENERAL INFORMATION

INTRODUCTION......................... 1

DIAGNOSIS AND TESTING

WINDOW MOTOR TEST................... 1

WINDOW SWITCH TEST.................. 1WIRING TEST........................... 1

REMOVAL AND INSTALLATION

2 DOOR WINDOW MOTOR................ 2

4 DOOR WINDOW MOTOR................ 3

WINDOW SWITCH....................... 2

GENERAL INFORMATION

INTRODUCTION

The window lift motors are of the permanent mag-

net type. A battery positive and negative connection

to either of the two motor terminals will cause the

motor to rotate in one direction. Reversing current

through these same two connections will cause the

motor to rotate in the opposite direction.

Each individual motor is grounded through the

master switch.

DIAGNOSIS AND TESTING

WIRING TEST

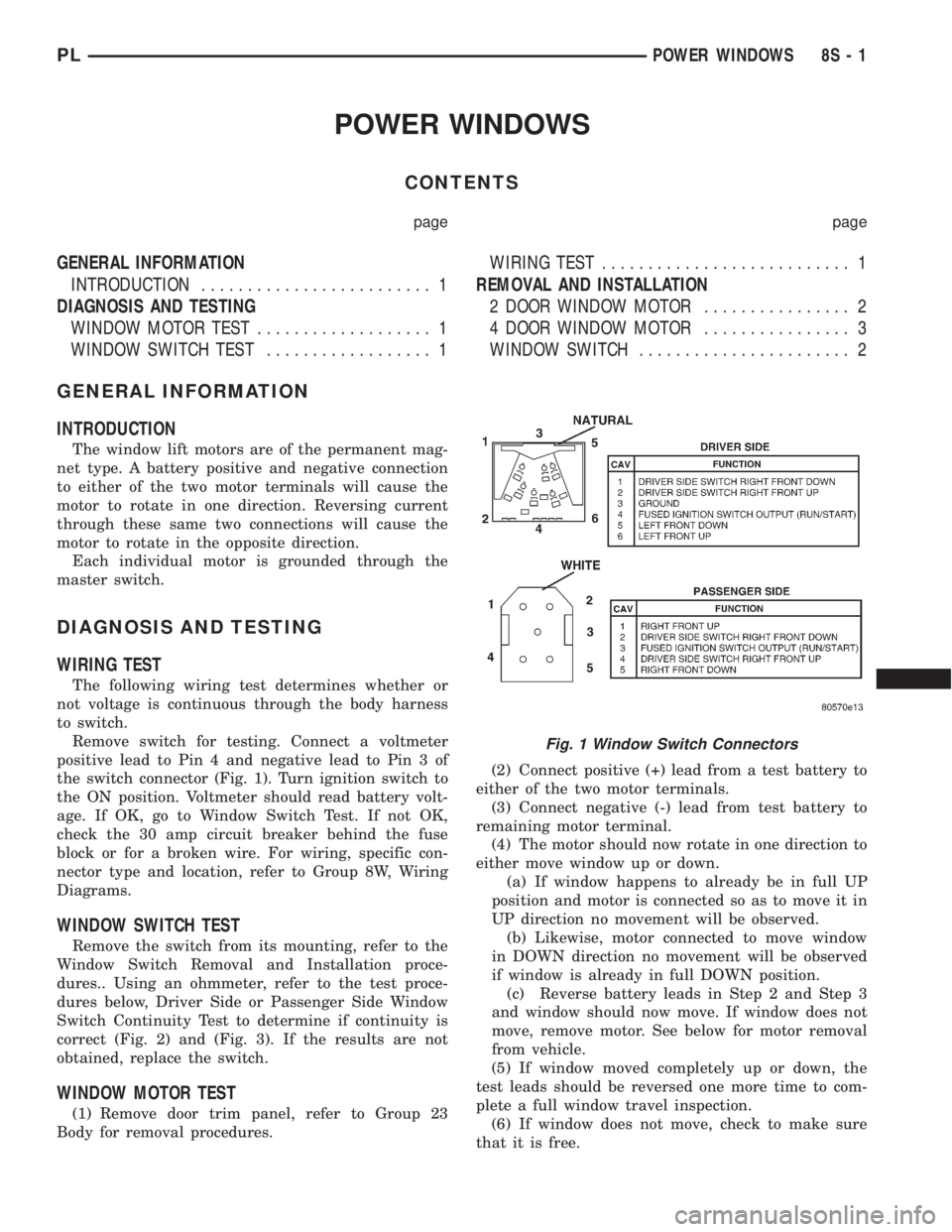

The following wiring test determines whether or

not voltage is continuous through the body harness

to switch.

Remove switch for testing. Connect a voltmeter

positive lead to Pin 4 and negative lead to Pin 3 of

the switch connector (Fig. 1). Turn ignition switch to

the ON position. Voltmeter should read battery volt-

age. If OK, go to Window Switch Test. If not OK,

check the 30 amp circuit breaker behind the fuse

block or for a broken wire. For wiring, specific con-

nector type and location, refer to Group 8W, Wiring

Diagrams.

WINDOW SWITCH TEST

Remove the switch from its mounting, refer to the

Window Switch Removal and Installation proce-

dures.. Using an ohmmeter, refer to the test proce-

dures below, Driver Side or Passenger Side Window

Switch Continuity Test to determine if continuity is

correct (Fig. 2) and (Fig. 3). If the results are not

obtained, replace the switch.

WINDOW MOTOR TEST

(1) Remove door trim panel, refer to Group 23

Body for removal procedures.(2) Connect positive (+) lead from a test battery to

either of the two motor terminals.

(3) Connect negative (-) lead from test battery to

remaining motor terminal.

(4) The motor should now rotate in one direction to

either move window up or down.

(a) If window happens to already be in full UP

position and motor is connected so as to move it in

UP direction no movement will be observed.

(b) Likewise, motor connected to move window

in DOWN direction no movement will be observed

if window is already in full DOWN position.

(c) Reverse battery leads in Step 2 and Step 3

and window should now move. If window does not

move, remove motor. See below for motor removal

from vehicle.

(5) If window moved completely up or down, the

test leads should be reversed one more time to com-

plete a full window travel inspection.

(6) If window does not move, check to make sure

that it is free.

Fig. 1 Window Switch Connectors

PLPOWER WINDOWS 8S - 1

Page 384 of 1200

POWER MIRRORS

CONTENTS

page page

GENERAL INFORMATION

INTRODUCTION......................... 1

DIAGNOSIS AND TESTING

MIRROR MOTOR........................ 2

MIRROR SWITCH TEST................... 1REMOVAL AND INSTALLATION

INSIDE MIRROR/READING LAMPS

ASSEMBLY............................ 2

INSIDE MIRROR/READING LAMPS

BULB/LENS........................... 2

MIRROR ASSEMBLY..................... 2

MIRROR SWITCH........................ 2

GENERAL INFORMATION

INTRODUCTION

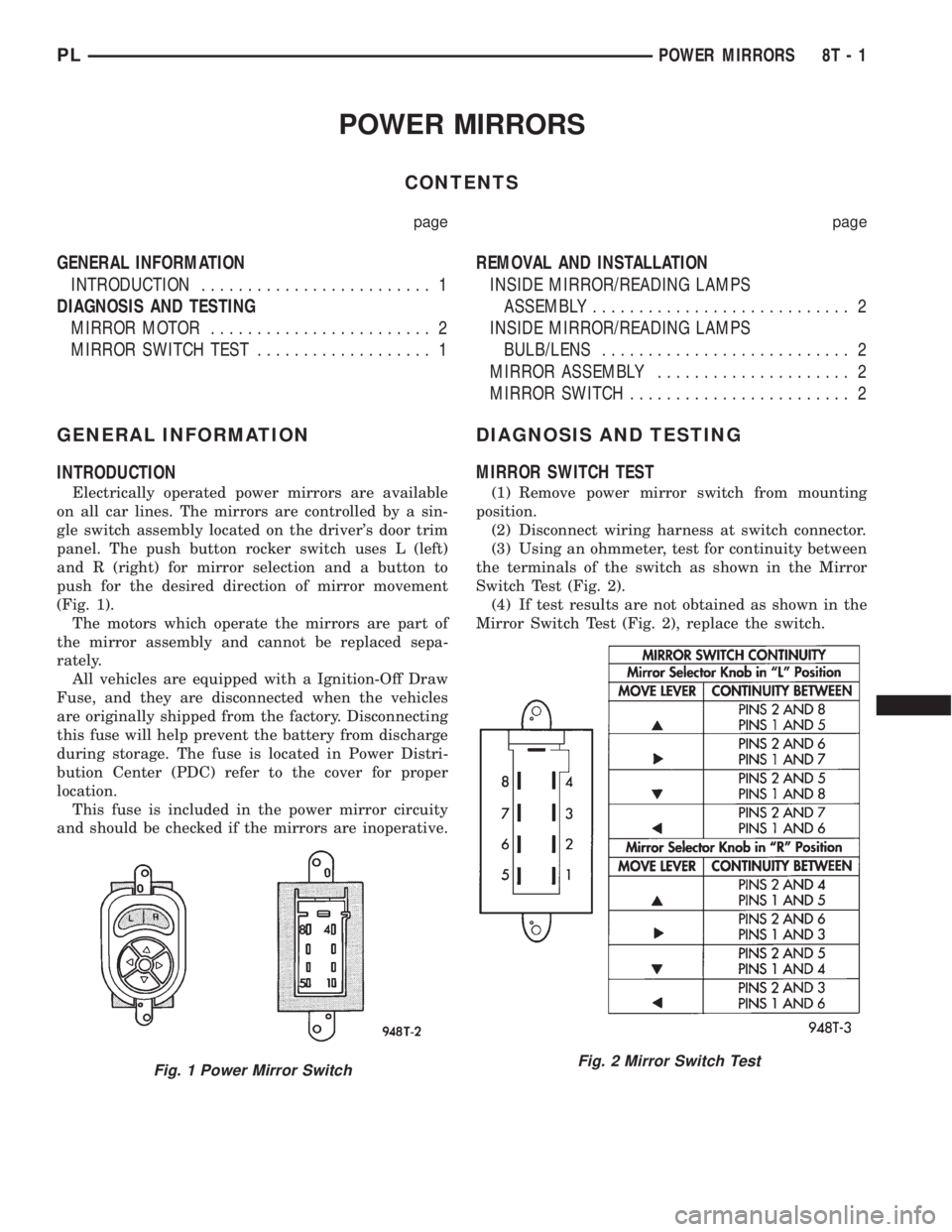

Electrically operated power mirrors are available

on all car lines. The mirrors are controlled by a sin-

gle switch assembly located on the driver's door trim

panel. The push button rocker switch uses L (left)

and R (right) for mirror selection and a button to

push for the desired direction of mirror movement

(Fig. 1).

The motors which operate the mirrors are part of

the mirror assembly and cannot be replaced sepa-

rately.

All vehicles are equipped with a Ignition-Off Draw

Fuse, and they are disconnected when the vehicles

are originally shipped from the factory. Disconnecting

this fuse will help prevent the battery from discharge

during storage. The fuse is located in Power Distri-

bution Center (PDC) refer to the cover for proper

location.

This fuse is included in the power mirror circuity

and should be checked if the mirrors are inoperative.

DIAGNOSIS AND TESTING

MIRROR SWITCH TEST

(1) Remove power mirror switch from mounting

position.

(2) Disconnect wiring harness at switch connector.

(3) Using an ohmmeter, test for continuity between

the terminals of the switch as shown in the Mirror

Switch Test (Fig. 2).

(4) If test results are not obtained as shown in the

Mirror Switch Test (Fig. 2), replace the switch.

Fig. 1 Power Mirror SwitchFig. 2 Mirror Switch Test

PLPOWER MIRRORS 8T - 1

Page 386 of 1200

POWER MIRRORS

CONTENTS

page page

GENERAL INFORMATION

INTRODUCTION........................ 1

DIAGNOSIS AND TESTING

MIRROR MOTOR....................... 2MIRROR SWITCH TEST.................. 1

GENERAL INFORMATION

INTRODUCTION

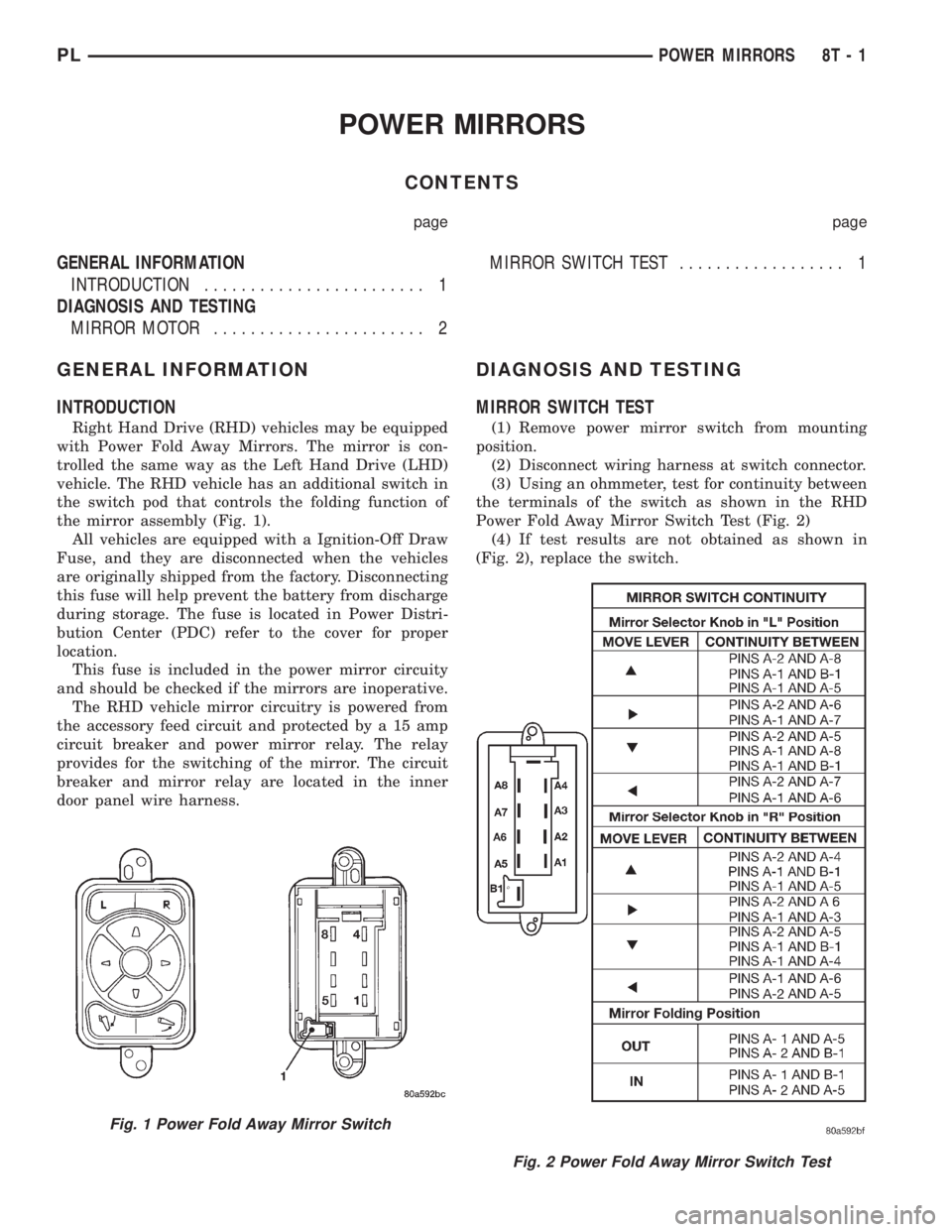

Right Hand Drive (RHD) vehicles may be equipped

with Power Fold Away Mirrors. The mirror is con-

trolled the same way as the Left Hand Drive (LHD)

vehicle. The RHD vehicle has an additional switch in

the switch pod that controls the folding function of

the mirror assembly (Fig. 1).

All vehicles are equipped with a Ignition-Off Draw

Fuse, and they are disconnected when the vehicles

are originally shipped from the factory. Disconnecting

this fuse will help prevent the battery from discharge

during storage. The fuse is located in Power Distri-

bution Center (PDC) refer to the cover for proper

location.

This fuse is included in the power mirror circuity

and should be checked if the mirrors are inoperative.

The RHD vehicle mirror circuitry is powered from

the accessory feed circuit and protected by a 15 amp

circuit breaker and power mirror relay. The relay

provides for the switching of the mirror. The circuit

breaker and mirror relay are located in the inner

door panel wire harness.

DIAGNOSIS AND TESTING

MIRROR SWITCH TEST

(1) Remove power mirror switch from mounting

position.

(2) Disconnect wiring harness at switch connector.

(3) Using an ohmmeter, test for continuity between

the terminals of the switch as shown in the RHD

Power Fold Away Mirror Switch Test (Fig. 2)

(4) If test results are not obtained as shown in

(Fig. 2), replace the switch.

Fig. 1 Power Fold Away Mirror Switch

Fig. 2 Power Fold Away Mirror Switch Test

PLPOWER MIRRORS 8T - 1

Page 390 of 1200

CHIME WARNING/REMINDER SYSTEM

CONTENTS

page page

GENERAL INFORMATION

INTRODUCTION......................... 1

DIAGNOSIS AND TESTING

CHIME SYSTEM CONDITIONS.............. 1

FASTEN SEAT BELTS..................... 1

HEADLAMPS LEFT ON.................... 1KEY LEFT IN IGNITION SWITCH............ 1

REMOVAL AND INSTALLATION

CHIME................................. 2

HEADLAMP SWITCH..................... 2

KEY-IN SWITCH......................... 2

SEAT BELT BUCKLE...................... 2

GENERAL INFORMATION

INTRODUCTION

WARNING: ON VEHICLES EQUIPPED WITH AN

AIRBAG, REFER TO THE AIRBAG PORTION OF

THIS SECTION FOR STEERING WHEEL OR SWITCH

REMOVAL AND INSTALLATION PROCEDURES.

The seat belt reminder system uses both visual

and audible signals. A combined seat belt and key

reminder chime with a red light on the instrument

panel.

The system will always illuminate the seat belt

reminder lamp for four to eight seconds when the

ignition switch is turned to the ON position. The

CHIME will sound during the same time interval if

the driver's seat belt is not fastened. Passenger belts

are not connected to the system. The chime will acti-

vate if the drivers door is opened and:

²The key is in the ignition switch, with the igni-

tion switch in either the OFF or accessory (ACC)

position

²The head lamps are ON.

The chime is part of the instrument cluster.

NOTE: This group covers both Left-Hand Drive

(LHD) and Right-Hand Drive (RHD) versions of this

model. Whenever required and feasible, the RHD

versions of affected vehicle components have been

constructed as mirror-image of the LHD versions.

While most of the illustrations used in this group

represent only the LHD version, the diagnostic and

service procedures outlined can generally be

applied to either version. Exceptions to this rule

have been clearly identified as LHD, RHD, or Export

if a special illustration or procedure is required.

DIAGNOSIS AND TESTING

FASTEN SEAT BELTS

To test the fasten seat belts function, turn the igni-

tion switch to the ON position with the driver's seat

belt unbuckled and fully retracted. The seat belt

warning lamp should light for four to eight seconds

and the tone should sound three to five times.

HEADLAMPS LEFT ON

To test the headlamps left on function:

²Turn headlamps

²Driver's door open

²Key removed from the ignition switch

Chime should sound until headlamps are turned

off or driver's door is closed.

KEY LEFT IN IGNITION SWITCH

To test the key left in ignition function, insert key

into the ignition and open driver's door. Chime

should sound until key is removed from ignition or

driver's door is closed.

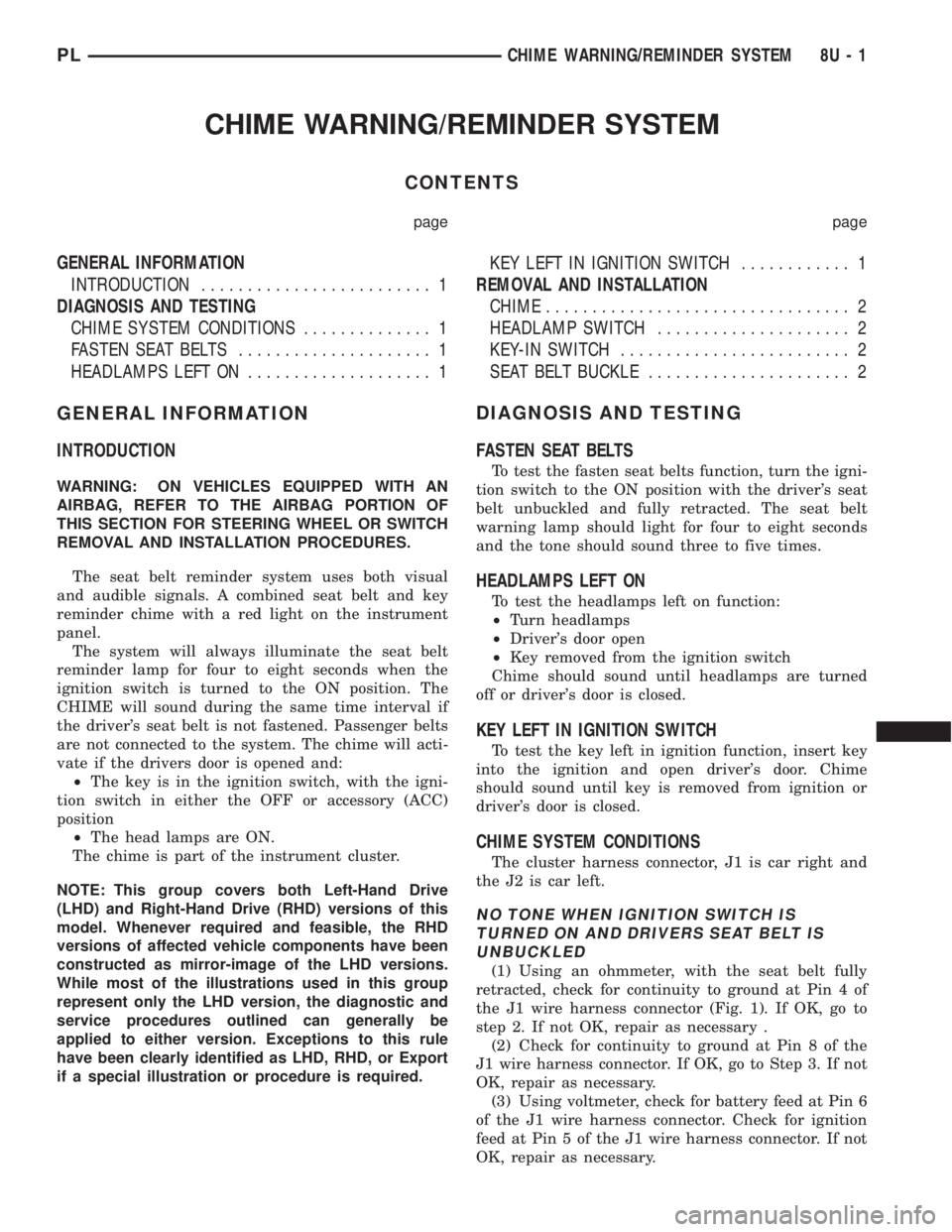

CHIME SYSTEM CONDITIONS

The cluster harness connector, J1 is car right and

the J2 is car left.

NO TONE WHEN IGNITION SWITCH IS

TURNED ON AND DRIVERS SEAT BELT IS

UNBUCKLED

(1) Using an ohmmeter, with the seat belt fully

retracted, check for continuity to ground at Pin 4 of

the J1 wire harness connector (Fig. 1). If OK, go to

step 2. If not OK, repair as necessary .

(2) Check for continuity to ground at Pin 8 of the

J1 wire harness connector. If OK, go to Step 3. If not

OK, repair as necessary.

(3) Using voltmeter, check for battery feed at Pin 6

of the J1 wire harness connector. Check for ignition

feed at Pin 5 of the J1 wire harness connector. If not

OK, repair as necessary.

PLCHIME WARNING/REMINDER SYSTEM 8U - 1

Page 391 of 1200

NO FASTEN SEAT BELT LAMP WHEN

IGNITION SWITCH IS ON.

(1) Check for burned out lamp.

(2) Check for battery feed at cluster wire harness

connector terminal J1-6 (Fig. 1).

(3) Check for ignition feed at cluster wire harness

connector terminal J1-5. Repair as necessary.

NO TONE WHEN HEADLAMPS ARE ON AND

DRIVERS DOOR IS OPEN

(1) Check left door jamb switch for good ground

when drivers door is open.

(2) Check for ground at J2-5.

(3) Check for battery feed at cluster wire harness

connector terminal J1-6 (Fig. 1).

(4) Check for NO voltage at J1-5. Ignition voltage

must not be present for the chime to work.

(5) Check headlamp switch.

NO TONE WHEN KEY IS LEFT IN IGNITION

AND DRIVERS DOOR IS OPEN

(1) Check for continuity to ground at Pin 8 of the

J1 wire harness connector. If OK, go to Step 3. If not

OK, repair as necessary.(2) Using voltmeter, check for battery feed at Pin 6

of the J1 wire harness connector. Check for NO igni-

tion feed at Pin 5 of the J1 wire harness connector. If

OK, go to Step 3. If not OK, repair as necessary.

(3) Open driver's door and ensure the ignition key

is in the OFF or ACC position. Check for continuity

to ground at Pin 5 of the J2 wire harness connector.

If ground OK, replace cluster printed circuit board. If

no ground, check key-in switch or door switch wiring

and repair as necessary.

CHIMES CONTINUE WHEN HEADLAMPS ARE

TURNED OFF AND/OR KEY IS REMOVED

FROM IGNITION

Check for ground at J2-5. If grounded the chime

should activate. Make sure the door is closed, key is

in ignition and parking lamps are OFF. If ground is

still present check door switch, key in switch, head-

lamp switch and repair as necessary.

REMOVAL AND INSTALLATION

CHIME

The chime is built into the instrument cluster print

circuit board. Refer to Group 8E, Instrument Panel

and Gauges.

SEAT BELT BUCKLE

Refer to Group 23, Body of this service manual.

HEADLAMP SWITCH

Refer to Group 8E, Instrument Panel and Systems.

KEY-IN SWITCH

The Key-in switch is built into the ignition switch

assembly. Should the Key-in switch require service,

the ignition switch assembly must be replaced. Refer

to Group 8D Ignition System of this service manual.

Fig. 1 Cluster Wire Harness Connectors

8U - 2 CHIME WARNING/REMINDER SYSTEMPL

DIAGNOSIS AND TESTING (Continued)

Page 392 of 1200

WIRING DIAGRAMS

CONTENTS

page page

AIR CONDITIONING-HEATER.......... 8W-42-1

AIRBAG SYSTEM................... 8W-43-1

ANTI-LOCK BRAKES................. 8W-35-1

AUDIO SYSTEMS................... 8W-47-1

CHARGING SYSTEM................. 8W-20-1

COMPONENT INDEX................. 8W-02-1

CONNECTOR/GROUND LOCATIONS..... 8W-90-1

CONNECTOR PIN-OUTS.............. 8W-80-1

FRONT LIGHTING................... 8W-50-1

FUEL/IGNITION SYSTEMS............ 8W-30-1

FUSE BLOCK....................... 8W-11-1

GENERAL INFORMATION............. 8W-01-1

GROUND DISTRIBUTION............. 8W-15-1

HORN/CIGAR LIGHTER............... 8W-41-1INSTRUMENT CLUSTER.............. 8W-40-1

INTERIOR LIGHTING................. 8W-44-1

POWER DISTRIBUTION.............. 8W-10-1

POWER DOOR LOCKS............... 8W-61-1

POWER MIRRORS.................. 8W-62-1

POWER SUNROOF.................. 8W-64-1

POWER WINDOWS.................. 8W-60-1

REAR LIGHTING.................... 8W-51-1

REAR WINDOW DEFOGGER........... 8W-48-1

SPLICE INFORMATION............... 8W-70-1

SPLICE LOCATIONS................. 8W-95-1

STARTING SYSTEM................. 8W-21-1

TURN SIGNALS..................... 8W-52-1

WIPERS........................... 8W-53-1

PLWIRING DIAGRAMS 8W - 1

Page 394 of 1200

8W-01 GENERAL INFORMATION

INDEX

page page

DESCRIPTION AND OPERATION

CIRCUIT FUNCTIONS..................... 4

CIRCUIT INFORMATION................... 4

CONNECTOR INFORMATION............... 7

ELECTROSTATIC DISCHARGE (ESD)

SENSITIVE DEVICES.................... 8

INTRODUCTION......................... 1

NOTES, CAUTIONS, and WARNINGS......... 7

SECTION IDENTIFICATION................. 5

SPLICE LOCATIONS...................... 7

SYMBOLS.............................. 5

TAKE OUTS............................. 8

TERMINOLOGY.......................... 7

DIAGNOSIS AND TESTING

INTERMITTENT AND POOR CONNECTIONS.... 9TROUBLESHOOTING TESTS................ 9

TROUBLESHOOTING TOOLS............... 8

TROUBLESHOOTING WIRING PROBLEMS.... 10

SERVICE PROCEDURES

CONNECTOR AND TERMINAL REPLACEMENT . 12

CONNECTOR REPLACEMENT.............. 12

DIODE REPLACEMENT................... 14

TERMINAL REPLACEMENT................ 13

TERMINAL/CONNECTOR REPAIR-MOLEX

CONNECTORS........................ 10

TERMINAL/CONNECTOR REPAIRÐTHOMAS

AND BETTS CONNECTORS.............. 11

WIRING REPAIR........................ 10

SPECIAL TOOLS

WIRING/TERMINAL...................... 15

DESCRIPTION AND OPERATION

INTRODUCTION

Chrysler wiring diagrams are designed to provide

information regarding the vehicles wiring content. In

order to effectively use Chrysler wiring diagrams to

diagnose and repair a Chrysler vehicle, it is impor-

tant to understand all of their features and charac-

teristics.

Diagrams are arranged such that the power (B+)

side of the circuit is placed near the top of the page,

and the ground (B-) side of the circuit is placed near

the bottom of the page.

All switches, components, and modules are shown

in the at rest position with the doors closed and the

key removed from the ignition.Components are shown two ways. A solid line

around a component indicates that the component is

complete. A dashed line around a component indi-

cates that the component being shown is not com-

plete. Incomplete components have a reference

number to indicate the page where the component is

shown complete.

It is important to realize that no attempt is made

on the diagrams to represent components and wiring

as they appear on the vehicle. For example, a short

piece of wire is treated the same as a long one. In

addition, switches and other components are shown

as simply as possible, with regard to function only.

PL8W - 01 GENERAL INFORMATION 8W - 01 - 1

Page 397 of 1200

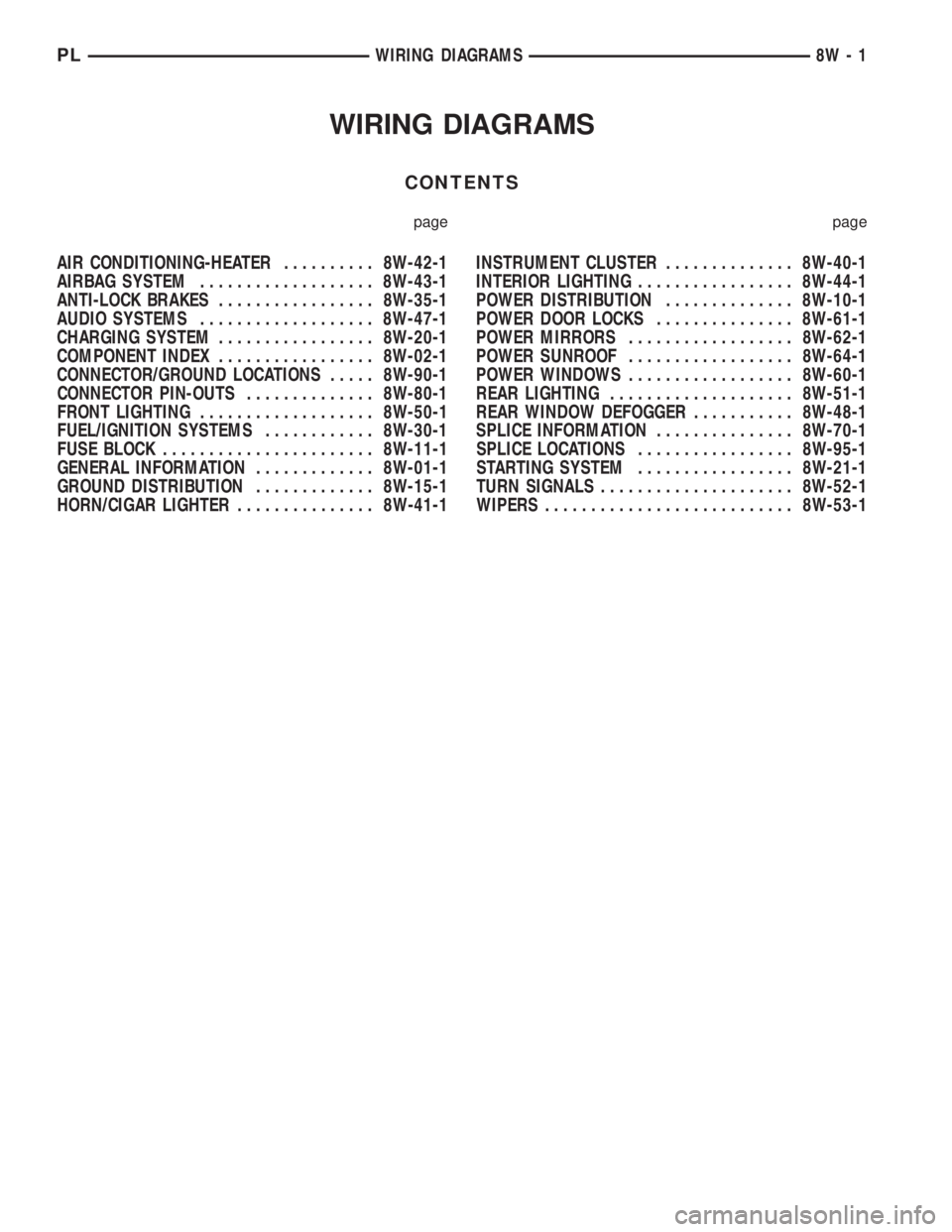

CIRCUIT INFORMATION

Each wire shown in the diagrams contains a code

which identifies the main circuit, part of the main

circuit, gage of wire, and color (Fig. 1)

CIRCUIT FUNCTIONS

All circuits in the diagrams use an alpha/numeric

code to identify the wire and its function. To identify

which circuit code applies to a system, refer to the

Circuit Identification Code Chart. This chart shows

the main circuits only and does not show the second-

ary codes that may apply to some models.

Fig. 1 Wire Code Identification

COLOR CODE COLORSTANDARD

TRACER

COLOR

BL BLUE WT

BK BLACK WT

BR BROWN WT

DB DARK BLUE WT

DG DARK GREEN WT

GY GRAY BK

LB LIGHT BLUE BK

LG LIGHT GREEN BK

OR ORANGE BK

PK PINK BK or WT

RD RED WT

TN TAN WT

VT VIOLET WT

WT WHITE BK

YL YELLOW BK

* WITH TRACER

CIRCUIT FUNCTION

A BATTERY FEED

B BRAKE CONTROLS

C CLIMATE CONTROLS

D DIAGNOSTIC CIRCUITS

E DIMMING ILLUMINATION CIRCUITS

F FUSED CIRCUITS

G MONITORING CIRCUITS (GAUGES)

H OPEN

I NOT USED

J OPEN

K POWERTRAIN CONTROL MODULE

L EXTERIOR LIGHTING

M INTERIOR LIGHTING

N NOT USED

O NOT USED

P POWER OPTION (BATTERY FEED)

Q POWER OPTIONS (IGNITION FEED)

R PASSIVE RESTRAINT

S SUSPENSION/STEERING

T TRANSMISSION/TRANSAXLE/

TRANSFER CASE

U OPEN

V SPEED CONTROL, WIPER/WASHER

W OPEN

X AUDIO SYSTEMS

Y OPEN

Z GROUNDS

8W - 01 - 4 8W - 01 GENERAL INFORMATIONPL

DESCRIPTION AND OPERATION (Continued)

Page 401 of 1200

WARNING: BE SURE THAT THE IGNITION SWITCH

ALWAYS IS IN THE OFF POSITION, UNLESS THE

PROCEDURE REQUIRES IT TO BE ON.

WARNING: SET THE PARKING BRAKE WHEN

WORKING ON ANY VEHICLE. AN AUTOMATIC

TRANSMISSION SHOULD BE IN PARK. A MANUAL

TRANSMISSION SHOULD BE IN NEUTRAL.

WARNING: OPERATE THE ENGINE ONLY IN A

WELL-VENTILATED AREA.

WARNING: KEEP AWAY FROM MOVING PARTS

WHEN THE ENGINE IS RUNNING, ESPECIALLY THE

FAN AND BELTS.

WARNING: TO PREVENT SERIOUS BURNS, AVOID

CONTACT WITH HOT PARTS SUCH AS THE RADIA-

TOR, EXHAUST MANIFOLD(S), TAIL PIPE, CATA-

LYTIC CONVERTER, AND MUFFLER.

WARNING: DO NOT ALLOW FLAME OR SPARKS

NEAR THE BATTERY. GASES ARE ALWAYS

PRESENT IN AND AROUND THE BATTERY.

WARNING: ALWAYS REMOVE RINGS, WATCHES,

LOOSE HANGING JEWELRY, AND LOOSE CLOTH-

ING.

TAKE OUTS

The abbreviation T/O is used in the component

location section to indicate a point in which the wir-

ing harness branches out to a component.

ELECTROSTATIC DISCHARGE (ESD) SENSITIVE

DEVICES

All ESD sensitive components are solid state and a

symbol (Fig. 4) is used to indicate this. When han-

dling any component with this symbol comply with

the following procedures to reduce the possibility of

electrostatic charge build up on the body and inad-

vertent discharge into the component. If it is not

known whether the part is ESD sensitive, assume

that it is.

(1) Always touch a known good ground before han-

dling the part. This should be repeated while han-

dling the part and more frequently after sliding

across a seat, sitting down from a standing position,

or walking a distance.

(2) Avoid touching electrical terminals of the part,

unless instructed to do so by a written procedure.(3) When using a voltmeter, be sure to connect the

ground lead first.

(4) Do not remove the part from its protective

packing until it is time to install the part.

(5) Before removing the part from its package,

ground the package to a known good ground on the

vehicle.

DIAGNOSIS AND TESTING

TROUBLESHOOTING TOOLS

When diagnosing a problem in an electrical circuit

there are several common tools necessary. These tools

are listed and explained below.

²Jumper Wire - This is a test wire used to con-

nect two points of a circuit. It can be used to bypass

an open in a circuit.

WARNING: NEVER USE A JUMPER WIRE ACROSS

A LOAD, SUCH AS A MOTOR, CONNECTED

BETWEEN A BATTERY FEED AND GROUND.

²Voltmeter - Used to check for voltage on a cir-

cuit. Always connect the black lead to a known good

ground and the red lead to the positive side of the

circuit.

CAUTION: Most of the electrical components used

in today's vehicle are solid state. When checking

voltages in these circuits use a meter with a 10-me-

gohm or greater impedance rating.

²Ohmmeter - Used to check the resistance

between two points of a circuit. Low or no resistance

in a circuit means good continuity.

CAUTION: - Most of the electrical components used

in today's vehicle are Solid State. When checking

resistance in these circuits use a meter with a 10-

megohm or greater impedance rating. In addition,

make sure the power is disconnected from the cir-

cuit. Circuits that are powered up by the vehicle

electrical system can cause damage to the equip-

ment and provide false readings.

Fig. 4 Electrostatic Discharge Symbol

8W - 01 - 8 8W - 01 GENERAL INFORMATIONPL

DESCRIPTION AND OPERATION (Continued)