lock DODGE NEON 1999 Service Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 87 of 1200

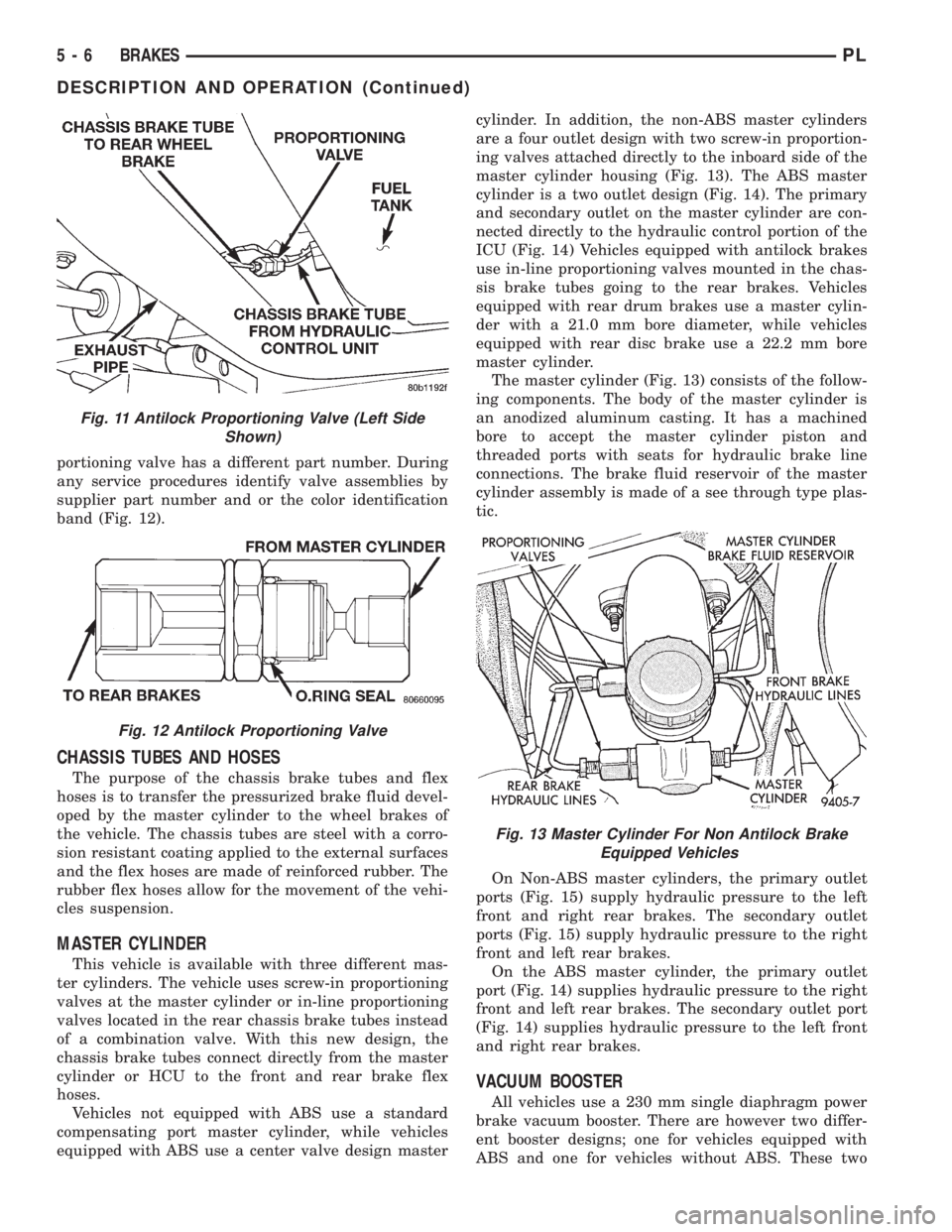

portioning valve has a different part number. During

any service procedures identify valve assemblies by

supplier part number and or the color identification

band (Fig. 12).

CHASSIS TUBES AND HOSES

The purpose of the chassis brake tubes and flex

hoses is to transfer the pressurized brake fluid devel-

oped by the master cylinder to the wheel brakes of

the vehicle. The chassis tubes are steel with a corro-

sion resistant coating applied to the external surfaces

and the flex hoses are made of reinforced rubber. The

rubber flex hoses allow for the movement of the vehi-

cles suspension.

MASTER CYLINDER

This vehicle is available with three different mas-

ter cylinders. The vehicle uses screw-in proportioning

valves at the master cylinder or in-line proportioning

valves located in the rear chassis brake tubes instead

of a combination valve. With this new design, the

chassis brake tubes connect directly from the master

cylinder or HCU to the front and rear brake flex

hoses.

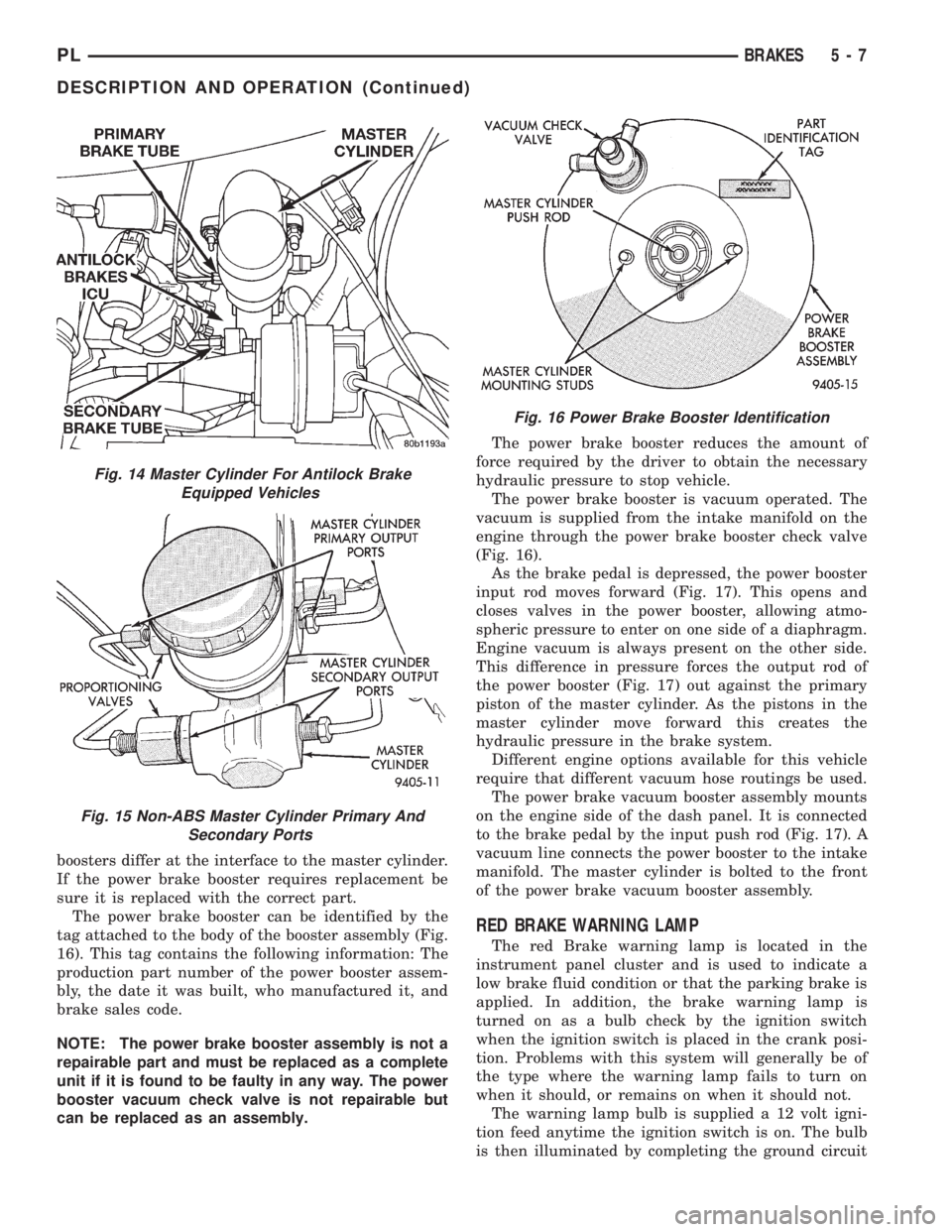

Vehicles not equipped with ABS use a standard

compensating port master cylinder, while vehicles

equipped with ABS use a center valve design mastercylinder. In addition, the non-ABS master cylinders

are a four outlet design with two screw-in proportion-

ing valves attached directly to the inboard side of the

master cylinder housing (Fig. 13). The ABS master

cylinder is a two outlet design (Fig. 14). The primary

and secondary outlet on the master cylinder are con-

nected directly to the hydraulic control portion of the

ICU (Fig. 14) Vehicles equipped with antilock brakes

use in-line proportioning valves mounted in the chas-

sis brake tubes going to the rear brakes. Vehicles

equipped with rear drum brakes use a master cylin-

der with a 21.0 mm bore diameter, while vehicles

equipped with rear disc brake use a 22.2 mm bore

master cylinder.

The master cylinder (Fig. 13) consists of the follow-

ing components. The body of the master cylinder is

an anodized aluminum casting. It has a machined

bore to accept the master cylinder piston and

threaded ports with seats for hydraulic brake line

connections. The brake fluid reservoir of the master

cylinder assembly is made of a see through type plas-

tic.

On Non-ABS master cylinders, the primary outlet

ports (Fig. 15) supply hydraulic pressure to the left

front and right rear brakes. The secondary outlet

ports (Fig. 15) supply hydraulic pressure to the right

front and left rear brakes.

On the ABS master cylinder, the primary outlet

port (Fig. 14) supplies hydraulic pressure to the right

front and left rear brakes. The secondary outlet port

(Fig. 14) supplies hydraulic pressure to the left front

and right rear brakes.

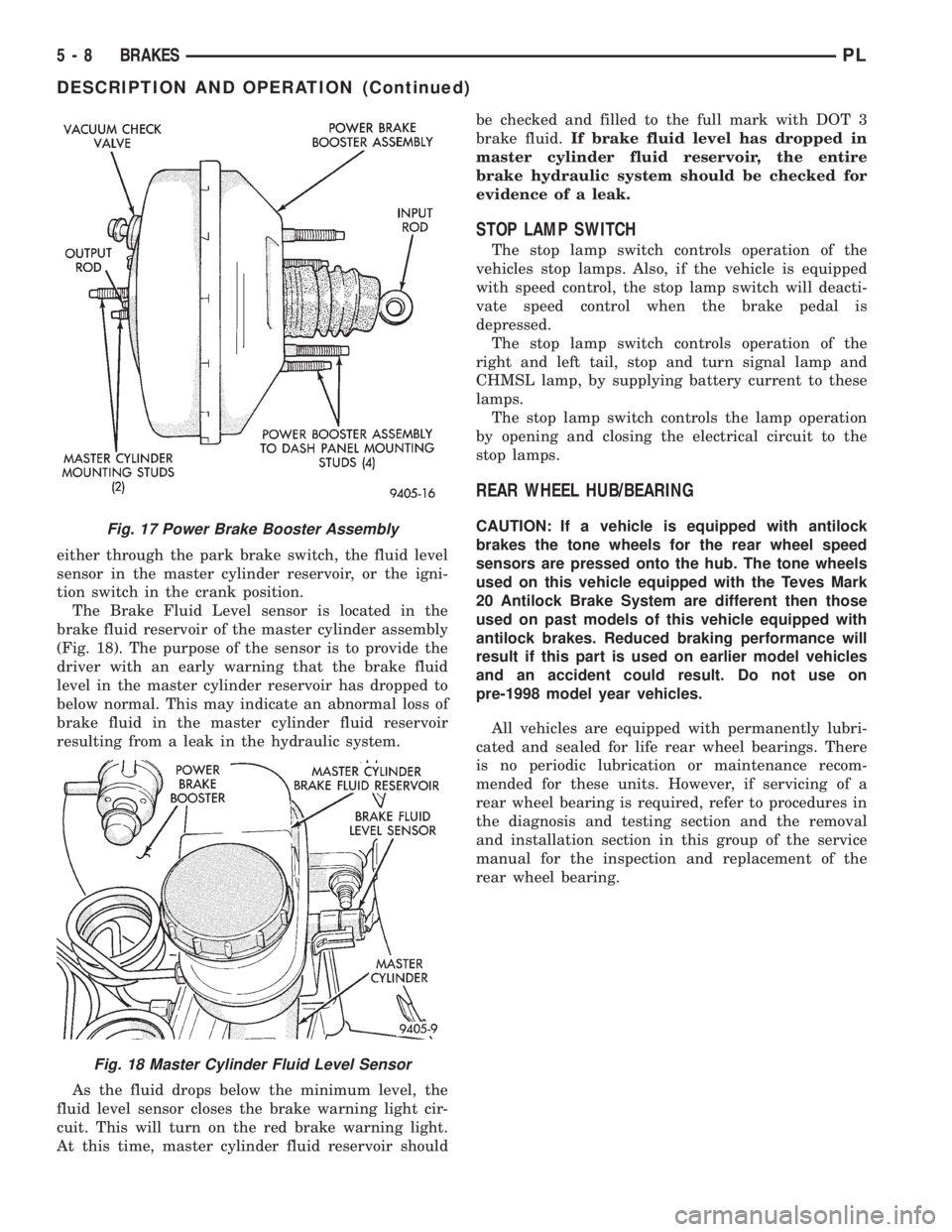

VACUUM BOOSTER

All vehicles use a 230 mm single diaphragm power

brake vacuum booster. There are however two differ-

ent booster designs; one for vehicles equipped with

ABS and one for vehicles without ABS. These two

Fig. 11 Antilock Proportioning Valve (Left Side

Shown)

Fig. 12 Antilock Proportioning Valve

Fig. 13 Master Cylinder For Non Antilock Brake

Equipped Vehicles

5 - 6 BRAKESPL

DESCRIPTION AND OPERATION (Continued)

Page 88 of 1200

boosters differ at the interface to the master cylinder.

If the power brake booster requires replacement be

sure it is replaced with the correct part.

The power brake booster can be identified by the

tag attached to the body of the booster assembly (Fig.

16). This tag contains the following information: The

production part number of the power booster assem-

bly, the date it was built, who manufactured it, and

brake sales code.

NOTE: The power brake booster assembly is not a

repairable part and must be replaced as a complete

unit if it is found to be faulty in any way. The power

booster vacuum check valve is not repairable but

can be replaced as an assembly.The power brake booster reduces the amount of

force required by the driver to obtain the necessary

hydraulic pressure to stop vehicle.

The power brake booster is vacuum operated. The

vacuum is supplied from the intake manifold on the

engine through the power brake booster check valve

(Fig. 16).

As the brake pedal is depressed, the power booster

input rod moves forward (Fig. 17). This opens and

closes valves in the power booster, allowing atmo-

spheric pressure to enter on one side of a diaphragm.

Engine vacuum is always present on the other side.

This difference in pressure forces the output rod of

the power booster (Fig. 17) out against the primary

piston of the master cylinder. As the pistons in the

master cylinder move forward this creates the

hydraulic pressure in the brake system.

Different engine options available for this vehicle

require that different vacuum hose routings be used.

The power brake vacuum booster assembly mounts

on the engine side of the dash panel. It is connected

to the brake pedal by the input push rod (Fig. 17). A

vacuum line connects the power booster to the intake

manifold. The master cylinder is bolted to the front

of the power brake vacuum booster assembly.

RED BRAKE WARNING LAMP

The red Brake warning lamp is located in the

instrument panel cluster and is used to indicate a

low brake fluid condition or that the parking brake is

applied. In addition, the brake warning lamp is

turned on as a bulb check by the ignition switch

when the ignition switch is placed in the crank posi-

tion. Problems with this system will generally be of

the type where the warning lamp fails to turn on

when it should, or remains on when it should not.

The warning lamp bulb is supplied a 12 volt igni-

tion feed anytime the ignition switch is on. The bulb

is then illuminated by completing the ground circuit

Fig. 14 Master Cylinder For Antilock Brake

Equipped Vehicles

Fig. 15 Non-ABS Master Cylinder Primary And

Secondary Ports

Fig. 16 Power Brake Booster Identification

PLBRAKES 5 - 7

DESCRIPTION AND OPERATION (Continued)

Page 89 of 1200

either through the park brake switch, the fluid level

sensor in the master cylinder reservoir, or the igni-

tion switch in the crank position.

The Brake Fluid Level sensor is located in the

brake fluid reservoir of the master cylinder assembly

(Fig. 18). The purpose of the sensor is to provide the

driver with an early warning that the brake fluid

level in the master cylinder reservoir has dropped to

below normal. This may indicate an abnormal loss of

brake fluid in the master cylinder fluid reservoir

resulting from a leak in the hydraulic system.

As the fluid drops below the minimum level, the

fluid level sensor closes the brake warning light cir-

cuit. This will turn on the red brake warning light.

At this time, master cylinder fluid reservoir shouldbe checked and filled to the full mark with DOT 3

brake fluid.If brake fluid level has dropped in

master cylinder fluid reservoir, the entire

brake hydraulic system should be checked for

evidence of a leak.

STOP LAMP SWITCH

The stop lamp switch controls operation of the

vehicles stop lamps. Also, if the vehicle is equipped

with speed control, the stop lamp switch will deacti-

vate speed control when the brake pedal is

depressed.

The stop lamp switch controls operation of the

right and left tail, stop and turn signal lamp and

CHMSL lamp, by supplying battery current to these

lamps.

The stop lamp switch controls the lamp operation

by opening and closing the electrical circuit to the

stop lamps.

REAR WHEEL HUB/BEARING

CAUTION: If a vehicle is equipped with antilock

brakes the tone wheels for the rear wheel speed

sensors are pressed onto the hub. The tone wheels

used on this vehicle equipped with the Teves Mark

20 Antilock Brake System are different then those

used on past models of this vehicle equipped with

antilock brakes. Reduced braking performance will

result if this part is used on earlier model vehicles

and an accident could result. Do not use on

pre-1998 model year vehicles.

All vehicles are equipped with permanently lubri-

cated and sealed for life rear wheel bearings. There

is no periodic lubrication or maintenance recom-

mended for these units. However, if servicing of a

rear wheel bearing is required, refer to procedures in

the diagnosis and testing section and the removal

and installation section in this group of the service

manual for the inspection and replacement of the

rear wheel bearing.Fig. 17 Power Brake Booster Assembly

Fig. 18 Master Cylinder Fluid Level Sensor

5 - 8 BRAKESPL

DESCRIPTION AND OPERATION (Continued)

Page 90 of 1200

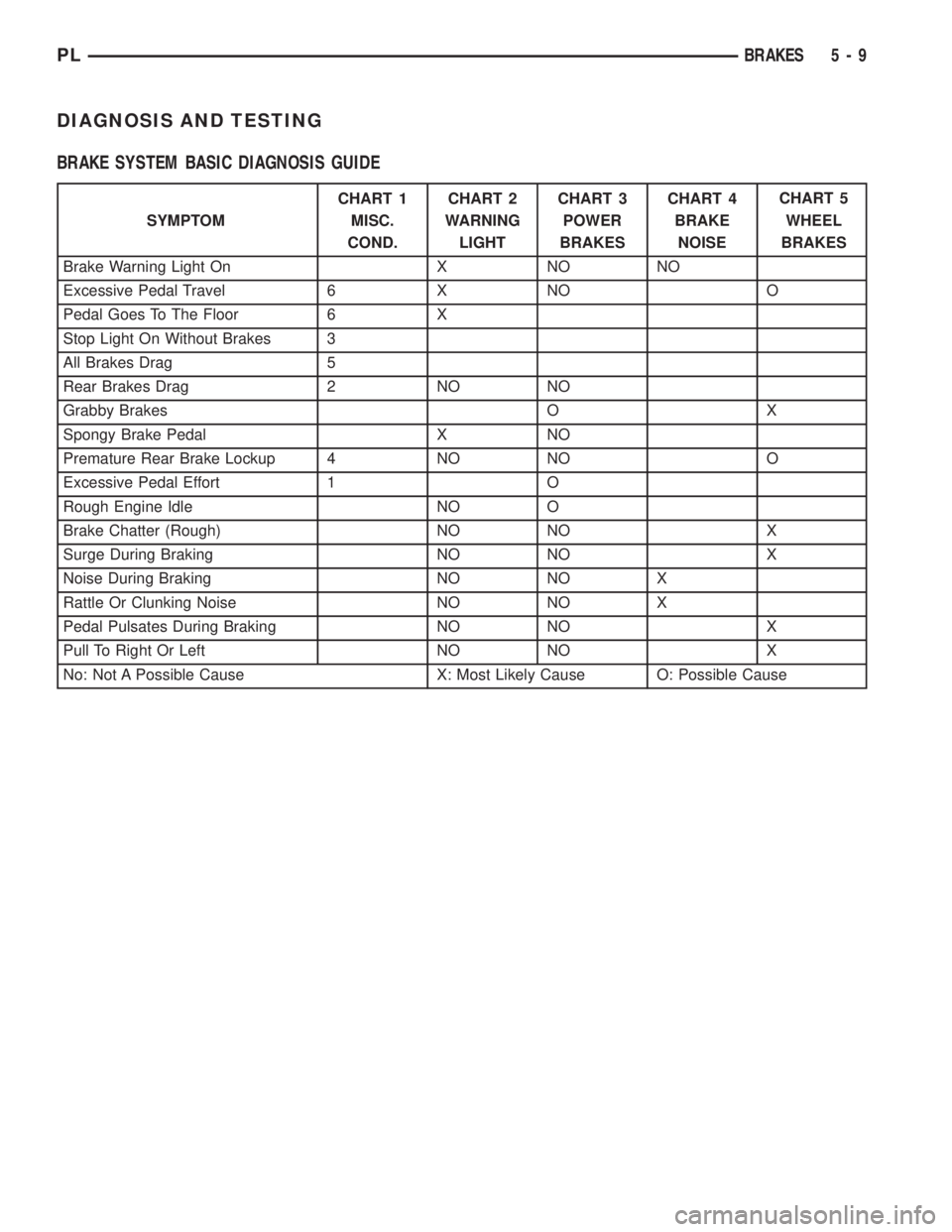

DIAGNOSIS AND TESTING

BRAKE SYSTEM BASIC DIAGNOSIS GUIDE

SYMPTOMCHART 1

MISC.

COND.CHART 2

WARNING

LIGHTCHART 3

POWER

BRAKESCHART 4

BRAKE

NOISECHART 5

WHEEL

BRAKES

Brake Warning Light On X NO NO

Excessive Pedal Travel 6 X NO O

Pedal Goes To The Floor 6 X

Stop Light On Without Brakes 3

All Brakes Drag 5

Rear Brakes Drag 2 NO NO

Grabby Brakes O X

Spongy Brake Pedal X NO

Premature Rear Brake Lockup 4 NO NO O

Excessive Pedal Effort 1 O

Rough Engine Idle NO O

Brake Chatter (Rough) NO NO X

Surge During Braking NO NO X

Noise During Braking NO NO X

Rattle Or Clunking Noise NO NO X

Pedal Pulsates During Braking NO NO X

Pull To Right Or Left NO NO X

No: Not A Possible Cause X: Most Likely Cause O: Possible Cause

PLBRAKES 5 - 9

Page 100 of 1200

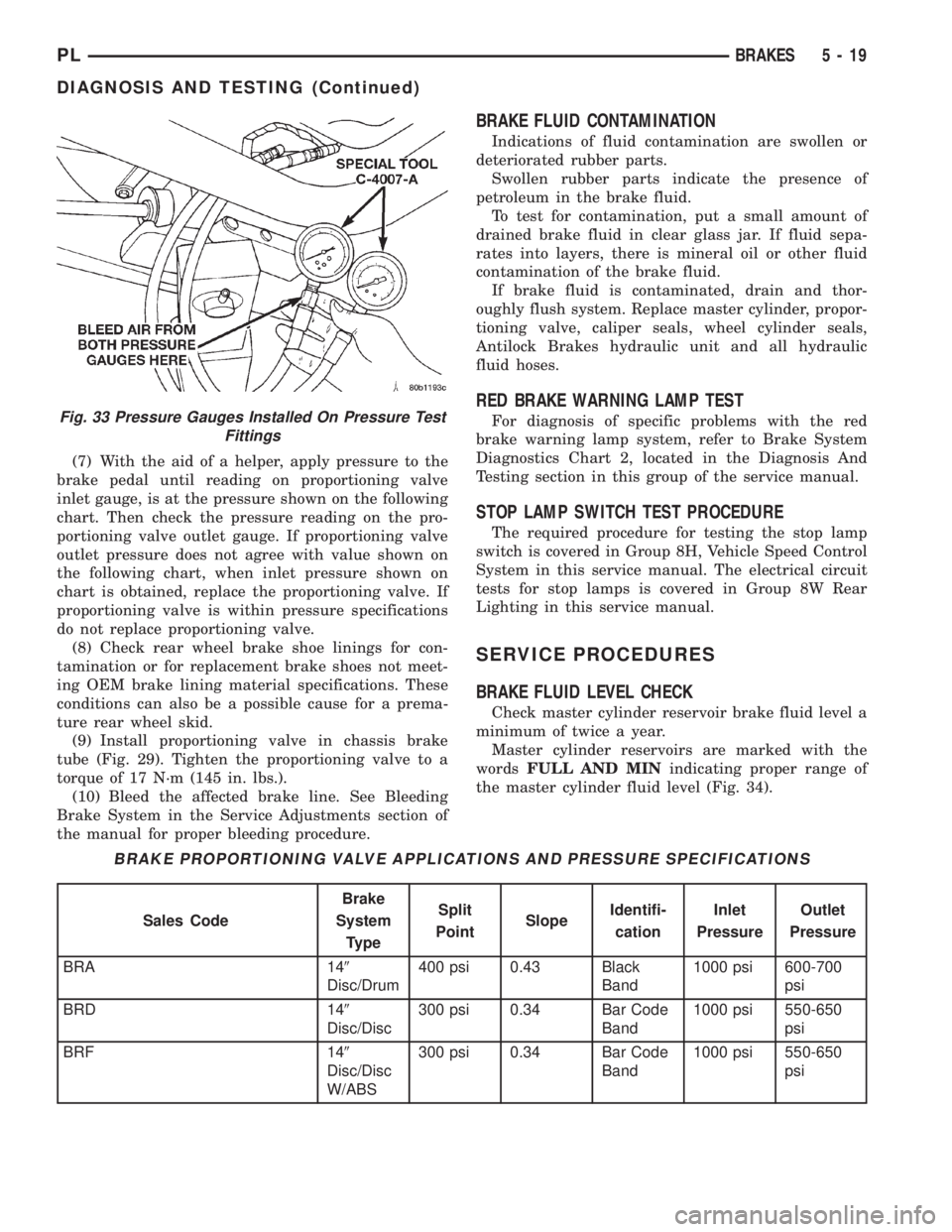

(7) With the aid of a helper, apply pressure to the

brake pedal until reading on proportioning valve

inlet gauge, is at the pressure shown on the following

chart. Then check the pressure reading on the pro-

portioning valve outlet gauge. If proportioning valve

outlet pressure does not agree with value shown on

the following chart, when inlet pressure shown on

chart is obtained, replace the proportioning valve. If

proportioning valve is within pressure specifications

do not replace proportioning valve.

(8) Check rear wheel brake shoe linings for con-

tamination or for replacement brake shoes not meet-

ing OEM brake lining material specifications. These

conditions can also be a possible cause for a prema-

ture rear wheel skid.

(9) Install proportioning valve in chassis brake

tube (Fig. 29). Tighten the proportioning valve to a

torque of 17 N´m (145 in. lbs.).

(10) Bleed the affected brake line. See Bleeding

Brake System in the Service Adjustments section of

the manual for proper bleeding procedure.

BRAKE FLUID CONTAMINATION

Indications of fluid contamination are swollen or

deteriorated rubber parts.

Swollen rubber parts indicate the presence of

petroleum in the brake fluid.

To test for contamination, put a small amount of

drained brake fluid in clear glass jar. If fluid sepa-

rates into layers, there is mineral oil or other fluid

contamination of the brake fluid.

If brake fluid is contaminated, drain and thor-

oughly flush system. Replace master cylinder, propor-

tioning valve, caliper seals, wheel cylinder seals,

Antilock Brakes hydraulic unit and all hydraulic

fluid hoses.

RED BRAKE WARNING LAMP TEST

For diagnosis of specific problems with the red

brake warning lamp system, refer to Brake System

Diagnostics Chart 2, located in the Diagnosis And

Testing section in this group of the service manual.

STOP LAMP SWITCH TEST PROCEDURE

The required procedure for testing the stop lamp

switch is covered in Group 8H, Vehicle Speed Control

System in this service manual. The electrical circuit

tests for stop lamps is covered in Group 8W Rear

Lighting in this service manual.

SERVICE PROCEDURES

BRAKE FLUID LEVEL CHECK

Check master cylinder reservoir brake fluid level a

minimum of twice a year.

Master cylinder reservoirs are marked with the

wordsFULL AND MINindicating proper range of

the master cylinder fluid level (Fig. 34).

Fig. 33 Pressure Gauges Installed On Pressure Test

Fittings

BRAKE PROPORTIONING VALVE APPLICATIONS AND PRESSURE SPECIFICATIONS

Sales CodeBrake

System

TypeSplit

PointSlopeIdentifi-

cationInlet

PressureOutlet

Pressure

BRA 149

Disc/Drum400 psi 0.43 Black

Band1000 psi 600-700

psi

BRD 149

Disc/Disc300 psi 0.34 Bar Code

Band1000 psi 550-650

psi

BRF 149

Disc/Disc

W/ABS300 psi 0.34 Bar Code

Band1000 psi 550-650

psi

PLBRAKES 5 - 19

DIAGNOSIS AND TESTING (Continued)

Page 104 of 1200

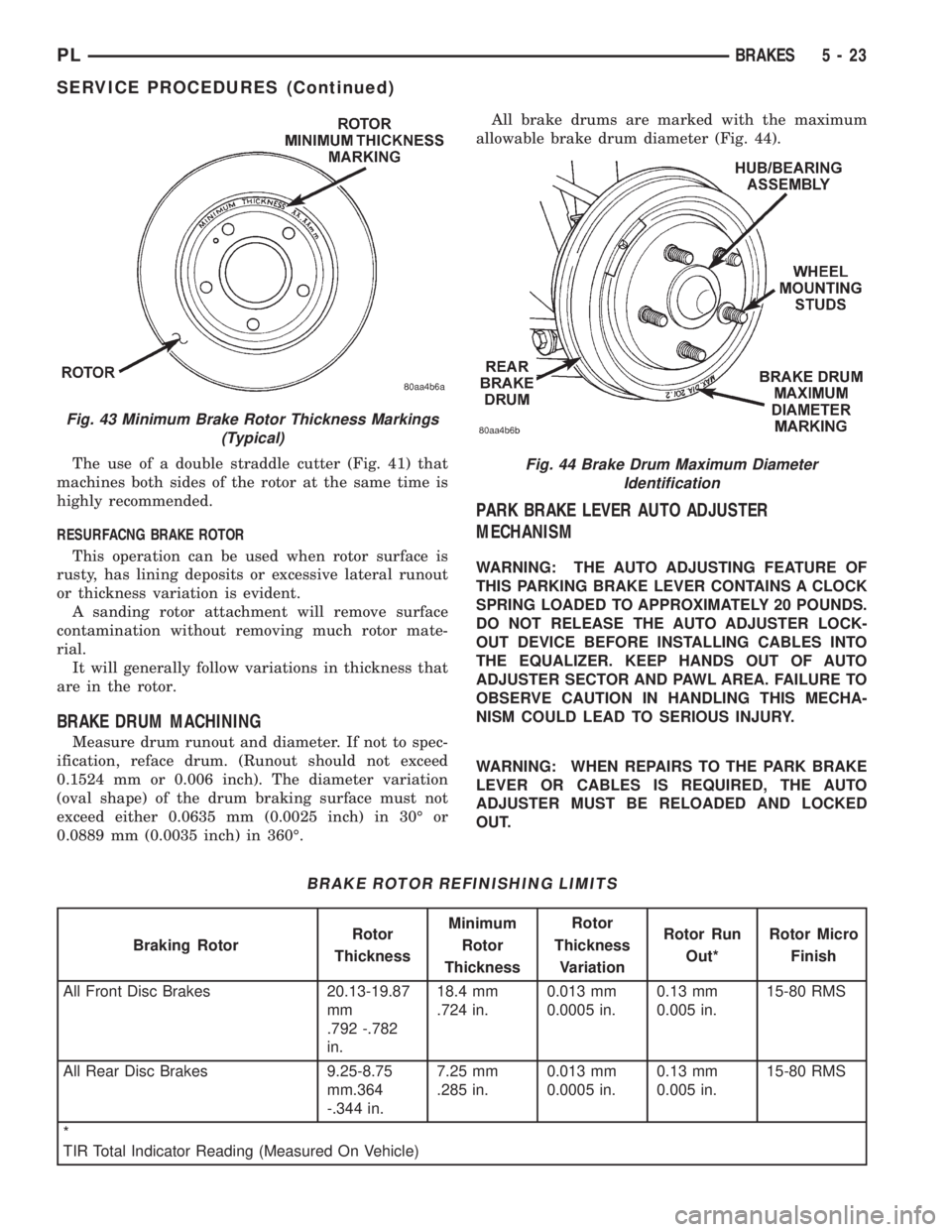

The use of a double straddle cutter (Fig. 41) that

machines both sides of the rotor at the same time is

highly recommended.

RESURFACNG BRAKE ROTOR

This operation can be used when rotor surface is

rusty, has lining deposits or excessive lateral runout

or thickness variation is evident.

A sanding rotor attachment will remove surface

contamination without removing much rotor mate-

rial.

It will generally follow variations in thickness that

are in the rotor.

BRAKE DRUM MACHINING

Measure drum runout and diameter. If not to spec-

ification, reface drum. (Runout should not exceed

0.1524 mm or 0.006 inch). The diameter variation

(oval shape) of the drum braking surface must not

exceed either 0.0635 mm (0.0025 inch) in 30É or

0.0889 mm (0.0035 inch) in 360É.All brake drums are marked with the maximum

allowable brake drum diameter (Fig. 44).

PARK BRAKE LEVER AUTO ADJUSTER

MECHANISM

WARNING: THE AUTO ADJUSTING FEATURE OF

THIS PARKING BRAKE LEVER CONTAINS A CLOCK

SPRING LOADED TO APPROXIMATELY 20 POUNDS.

DO NOT RELEASE THE AUTO ADJUSTER LOCK-

OUT DEVICE BEFORE INSTALLING CABLES INTO

THE EQUALIZER. KEEP HANDS OUT OF AUTO

ADJUSTER SECTOR AND PAWL AREA. FAILURE TO

OBSERVE CAUTION IN HANDLING THIS MECHA-

NISM COULD LEAD TO SERIOUS INJURY.

WARNING: WHEN REPAIRS TO THE PARK BRAKE

LEVER OR CABLES IS REQUIRED, THE AUTO

ADJUSTER MUST BE RELOADED AND LOCKED

OUT.

Fig. 43 Minimum Brake Rotor Thickness Markings

(Typical)

BRAKE ROTOR REFINISHING LIMITS

Braking RotorRotor

ThicknessMinimum

Rotor

ThicknessRotor

Thickness

VariationRotor Run

Out*Rotor Micro

Finish

All Front Disc Brakes 20.13-19.87

mm

.792 -.782

in.18.4 mm

.724 in.0.013 mm

0.0005 in.0.13 mm

0.005 in.15-80 RMS

All Rear Disc Brakes 9.25-8.75

mm.364

-.344 in.7.25 mm

.285 in.0.013 mm

0.0005 in.0.13 mm

0.005 in.15-80 RMS

*

TIR Total Indicator Reading (Measured On Vehicle)

Fig. 44 Brake Drum Maximum Diameter

Identification

PLBRAKES 5 - 23

SERVICE PROCEDURES (Continued)

Page 105 of 1200

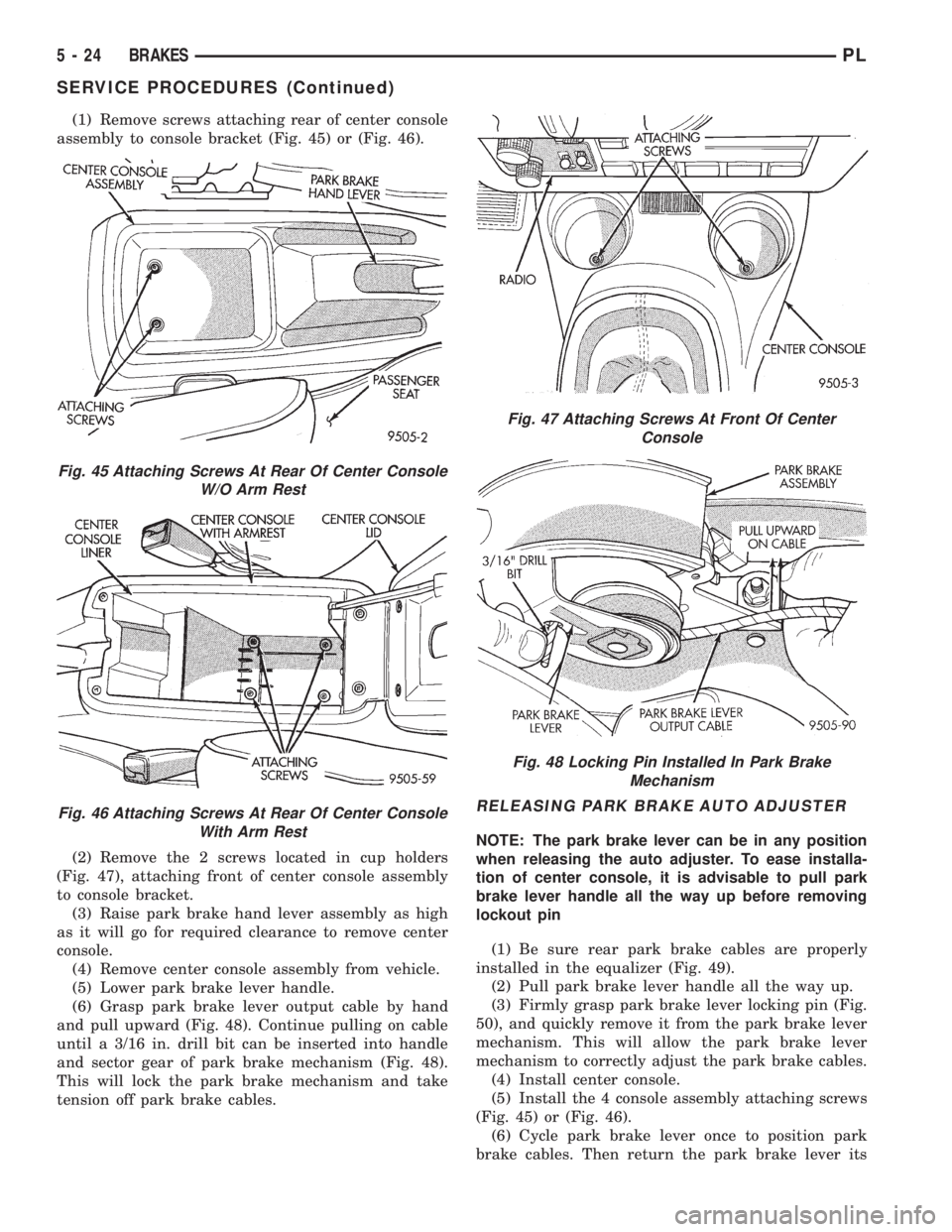

(1) Remove screws attaching rear of center console

assembly to console bracket (Fig. 45) or (Fig. 46).

(2) Remove the 2 screws located in cup holders

(Fig. 47), attaching front of center console assembly

to console bracket.

(3) Raise park brake hand lever assembly as high

as it will go for required clearance to remove center

console.

(4) Remove center console assembly from vehicle.

(5) Lower park brake lever handle.

(6) Grasp park brake lever output cable by hand

and pull upward (Fig. 48). Continue pulling on cable

until a 3/16 in. drill bit can be inserted into handle

and sector gear of park brake mechanism (Fig. 48).

This will lock the park brake mechanism and take

tension off park brake cables.

RELEASING PARK BRAKE AUTO ADJUSTER

NOTE: The park brake lever can be in any position

when releasing the auto adjuster. To ease installa-

tion of center console, it is advisable to pull park

brake lever handle all the way up before removing

lockout pin

(1) Be sure rear park brake cables are properly

installed in the equalizer (Fig. 49).

(2) Pull park brake lever handle all the way up.

(3) Firmly grasp park brake lever locking pin (Fig.

50), and quickly remove it from the park brake lever

mechanism. This will allow the park brake lever

mechanism to correctly adjust the park brake cables.

(4) Install center console.

(5) Install the 4 console assembly attaching screws

(Fig. 45) or (Fig. 46).

(6) Cycle park brake lever once to position park

brake cables. Then return the park brake lever its

Fig. 45 Attaching Screws At Rear Of Center Console

W/O Arm Rest

Fig. 46 Attaching Screws At Rear Of Center Console

With Arm Rest

Fig. 47 Attaching Screws At Front Of Center

Console

Fig. 48 Locking Pin Installed In Park Brake

Mechanism

5 - 24 BRAKESPL

SERVICE PROCEDURES (Continued)

Page 106 of 1200

released position. Check the rear wheels of the vehi-

cle, they should rotate freely without dragging.

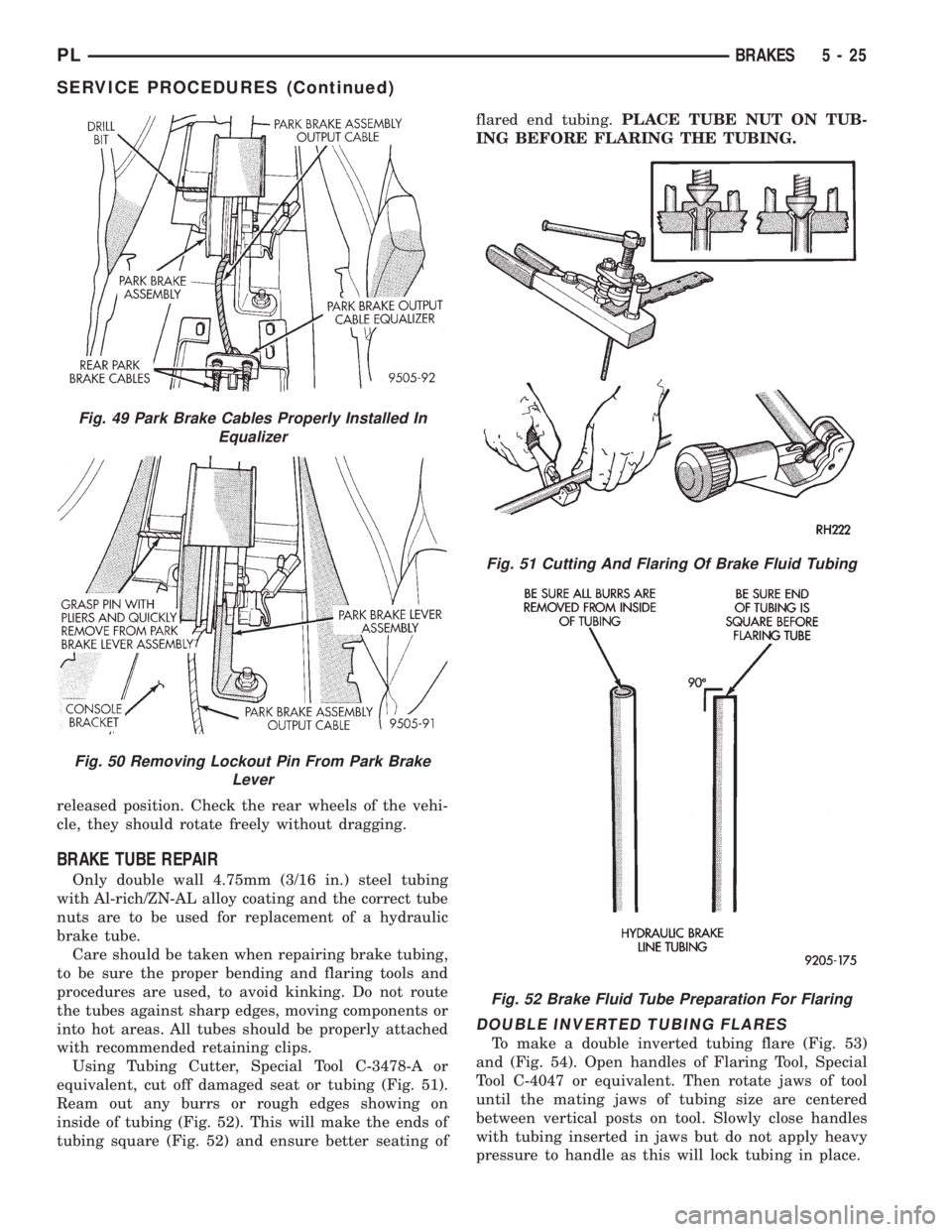

BRAKE TUBE REPAIR

Only double wall 4.75mm (3/16 in.) steel tubing

with Al-rich/ZN-AL alloy coating and the correct tube

nuts are to be used for replacement of a hydraulic

brake tube.

Care should be taken when repairing brake tubing,

to be sure the proper bending and flaring tools and

procedures are used, to avoid kinking. Do not route

the tubes against sharp edges, moving components or

into hot areas. All tubes should be properly attached

with recommended retaining clips.

Using Tubing Cutter, Special Tool C-3478-A or

equivalent, cut off damaged seat or tubing (Fig. 51).

Ream out any burrs or rough edges showing on

inside of tubing (Fig. 52). This will make the ends of

tubing square (Fig. 52) and ensure better seating offlared end tubing.PLACE TUBE NUT ON TUB-

ING BEFORE FLARING THE TUBING.

DOUBLE INVERTED TUBING FLARES

To make a double inverted tubing flare (Fig. 53)

and (Fig. 54). Open handles of Flaring Tool, Special

Tool C-4047 or equivalent. Then rotate jaws of tool

until the mating jaws of tubing size are centered

between vertical posts on tool. Slowly close handles

with tubing inserted in jaws but do not apply heavy

pressure to handle as this will lock tubing in place.

Fig. 49 Park Brake Cables Properly Installed In

Equalizer

Fig. 50 Removing Lockout Pin From Park Brake

Lever

Fig. 51 Cutting And Flaring Of Brake Fluid Tubing

Fig. 52 Brake Fluid Tube Preparation For Flaring

PLBRAKES 5 - 25

SERVICE PROCEDURES (Continued)

Page 107 of 1200

Place gauge (Form A) on edge over end of brake

tubing. Push tubing through jaws until end of tubing

contacts the recessed notch in gauge matching the

tubing size. Squeeze handles of flaring tool and lock

tubing in place. Place 3/16 inch plug of gauge (A)

down in end of tubing. Swing compression disc over

gauge and center tapered flaring screw in recess of

disc. Screw in until plug gauge has seated on jaws of

flaring tool. This action has started to invert the

extended end of the tubing. Remove gauge and con-

tinue to screw down until tool is firmly seated in tub-

ing. Remove tubing from flaring tool and inspect

seat. Refer to tube routing diagrams for proper brake

tube routing and clip locations. Replace any damaged

tube routing clips.

REMOVAL AND INSTALLATION

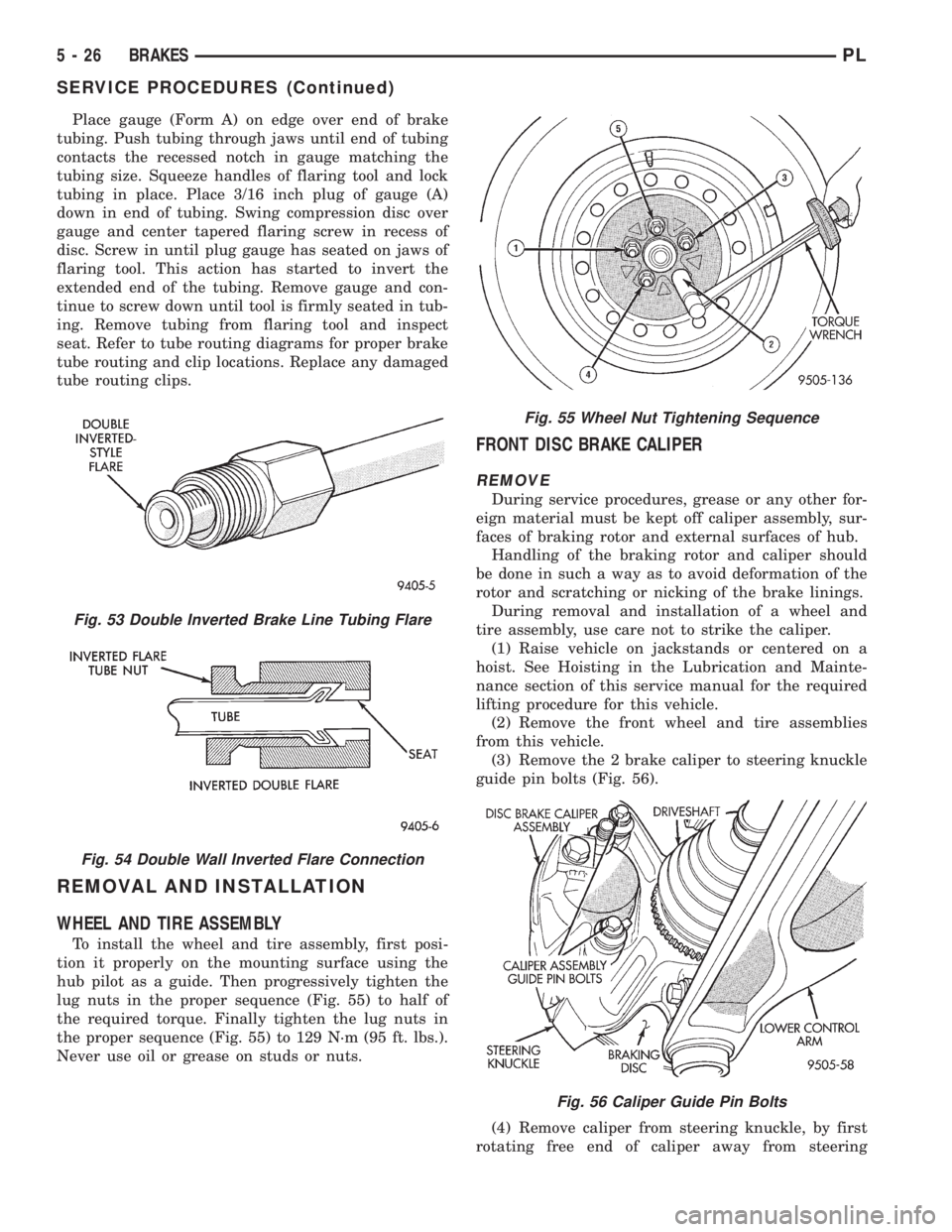

WHEEL AND TIRE ASSEMBLY

To install the wheel and tire assembly, first posi-

tion it properly on the mounting surface using the

hub pilot as a guide. Then progressively tighten the

lug nuts in the proper sequence (Fig. 55) to half of

the required torque. Finally tighten the lug nuts in

the proper sequence (Fig. 55) to 129 N´m (95 ft. lbs.).

Never use oil or grease on studs or nuts.

FRONT DISC BRAKE CALIPER

REMOVE

During service procedures, grease or any other for-

eign material must be kept off caliper assembly, sur-

faces of braking rotor and external surfaces of hub.

Handling of the braking rotor and caliper should

be done in such a way as to avoid deformation of the

rotor and scratching or nicking of the brake linings.

During removal and installation of a wheel and

tire assembly, use care not to strike the caliper.

(1) Raise vehicle on jackstands or centered on a

hoist. See Hoisting in the Lubrication and Mainte-

nance section of this service manual for the required

lifting procedure for this vehicle.

(2) Remove the front wheel and tire assemblies

from this vehicle.

(3) Remove the 2 brake caliper to steering knuckle

guide pin bolts (Fig. 56).

(4) Remove caliper from steering knuckle, by first

rotating free end of caliper away from steering

Fig. 53 Double Inverted Brake Line Tubing Flare

Fig. 54 Double Wall Inverted Flare Connection

Fig. 55 Wheel Nut Tightening Sequence

Fig. 56 Caliper Guide Pin Bolts

5 - 26 BRAKESPL

SERVICE PROCEDURES (Continued)

Page 126 of 1200

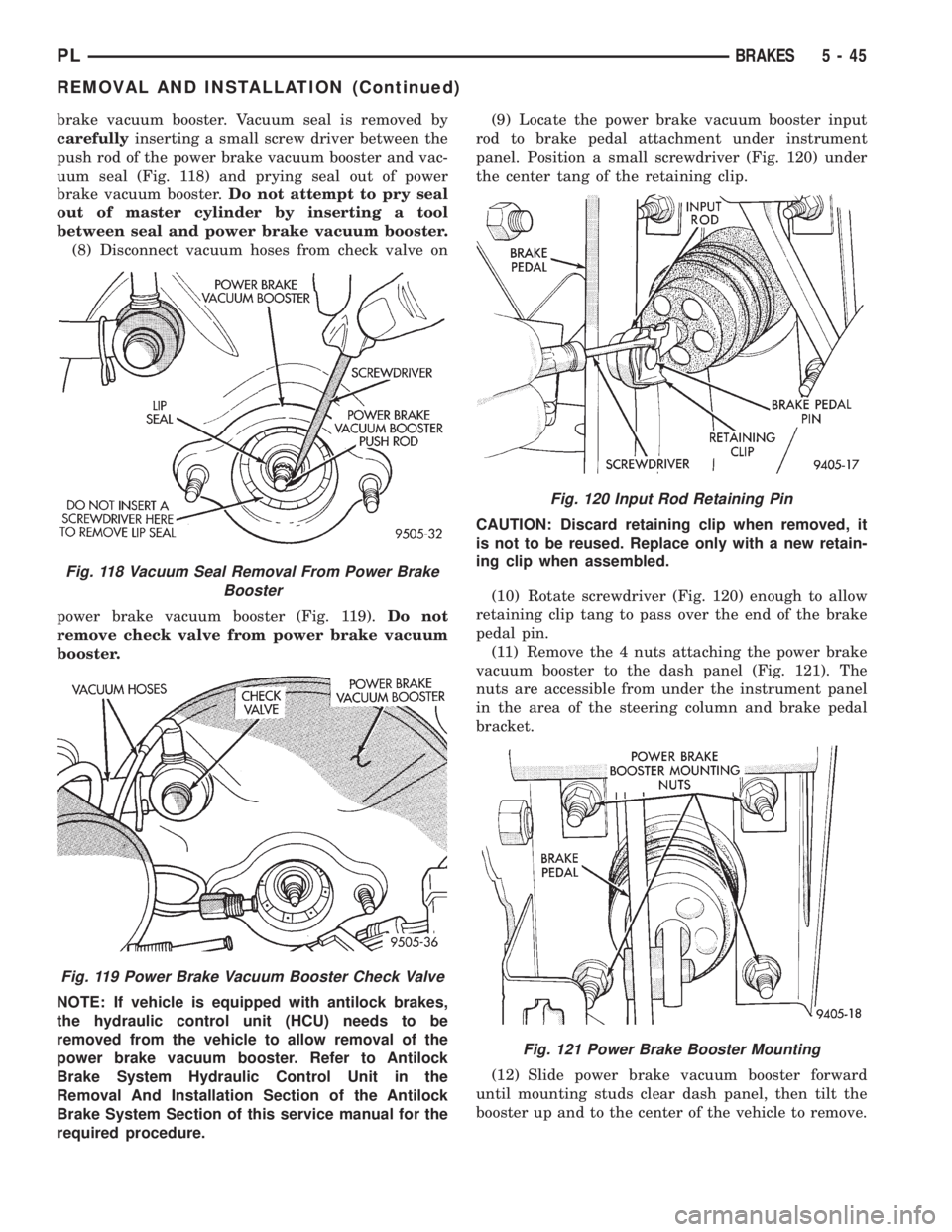

brake vacuum booster. Vacuum seal is removed by

carefullyinserting a small screw driver between the

push rod of the power brake vacuum booster and vac-

uum seal (Fig. 118) and prying seal out of power

brake vacuum booster.Do not attempt to pry seal

out of master cylinder by inserting a tool

between seal and power brake vacuum booster.

(8) Disconnect vacuum hoses from check valve on

power brake vacuum booster (Fig. 119).Do not

remove check valve from power brake vacuum

booster.

NOTE: If vehicle is equipped with antilock brakes,

the hydraulic control unit (HCU) needs to be

removed from the vehicle to allow removal of the

power brake vacuum booster. Refer to Antilock

Brake System Hydraulic Control Unit in the

Removal And Installation Section of the Antilock

Brake System Section of this service manual for the

required procedure.(9) Locate the power brake vacuum booster input

rod to brake pedal attachment under instrument

panel. Position a small screwdriver (Fig. 120) under

the center tang of the retaining clip.

CAUTION: Discard retaining clip when removed, it

is not to be reused. Replace only with a new retain-

ing clip when assembled.

(10) Rotate screwdriver (Fig. 120) enough to allow

retaining clip tang to pass over the end of the brake

pedal pin.

(11) Remove the 4 nuts attaching the power brake

vacuum booster to the dash panel (Fig. 121). The

nuts are accessible from under the instrument panel

in the area of the steering column and brake pedal

bracket.

(12) Slide power brake vacuum booster forward

until mounting studs clear dash panel, then tilt the

booster up and to the center of the vehicle to remove.

Fig. 118 Vacuum Seal Removal From Power Brake

Booster

Fig. 119 Power Brake Vacuum Booster Check Valve

Fig. 120 Input Rod Retaining Pin

Fig. 121 Power Brake Booster Mounting

PLBRAKES 5 - 45

REMOVAL AND INSTALLATION (Continued)