lock DODGE NEON 1999 Service Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 164 of 1200

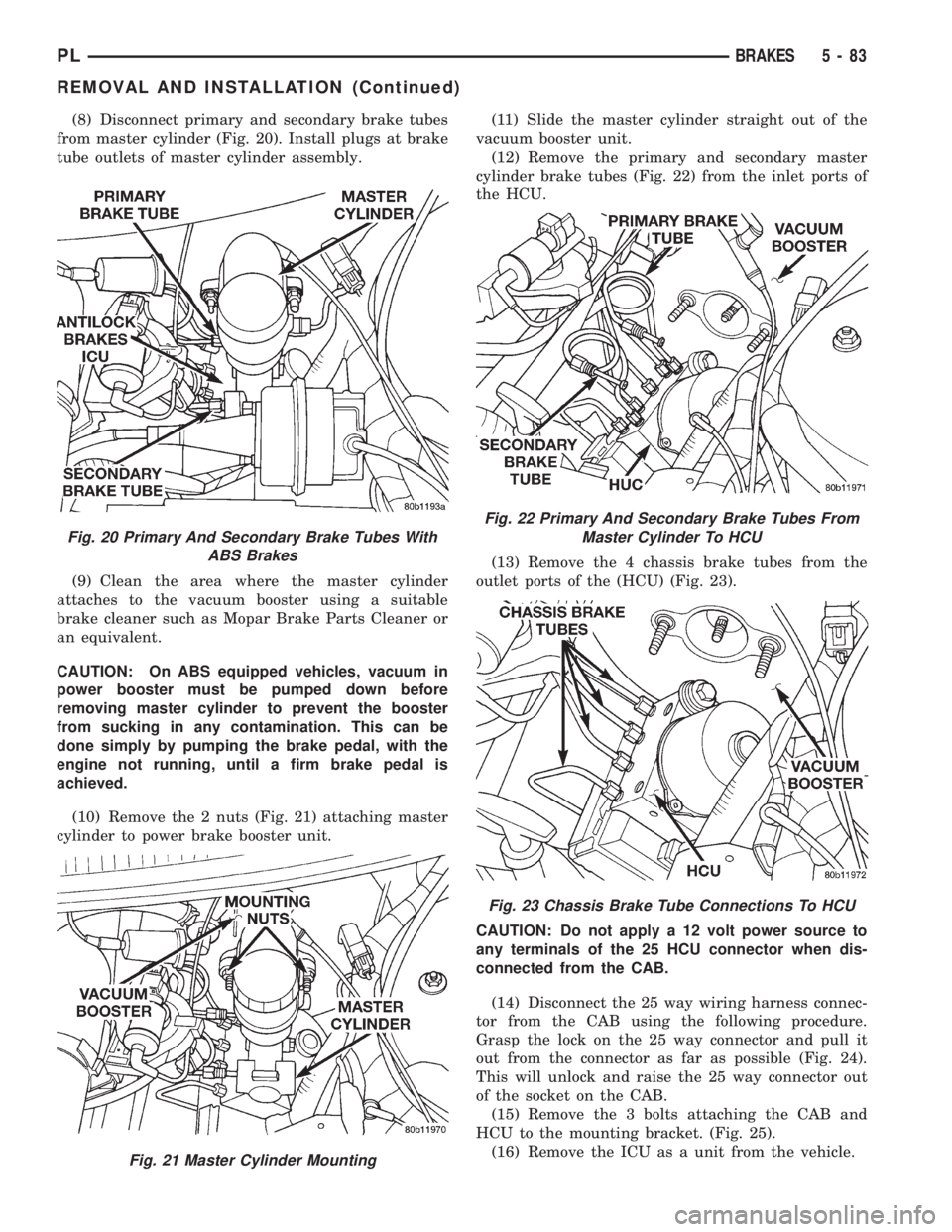

(8) Disconnect primary and secondary brake tubes

from master cylinder (Fig. 20). Install plugs at brake

tube outlets of master cylinder assembly.

(9) Clean the area where the master cylinder

attaches to the vacuum booster using a suitable

brake cleaner such as Mopar Brake Parts Cleaner or

an equivalent.

CAUTION: On ABS equipped vehicles, vacuum in

power booster must be pumped down before

removing master cylinder to prevent the booster

from sucking in any contamination. This can be

done simply by pumping the brake pedal, with the

engine not running, until a firm brake pedal is

achieved.

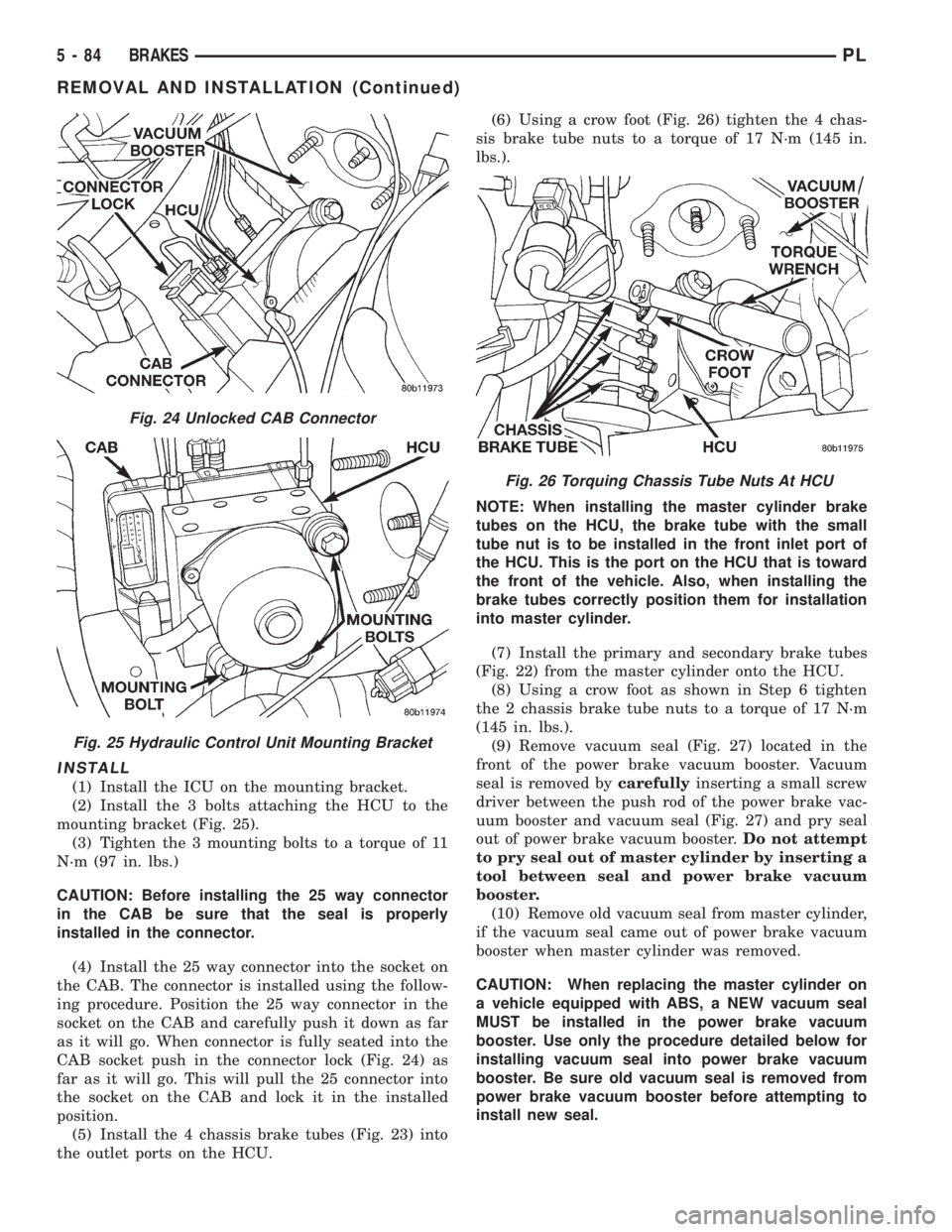

(10) Remove the 2 nuts (Fig. 21) attaching master

cylinder to power brake booster unit.(11) Slide the master cylinder straight out of the

vacuum booster unit.

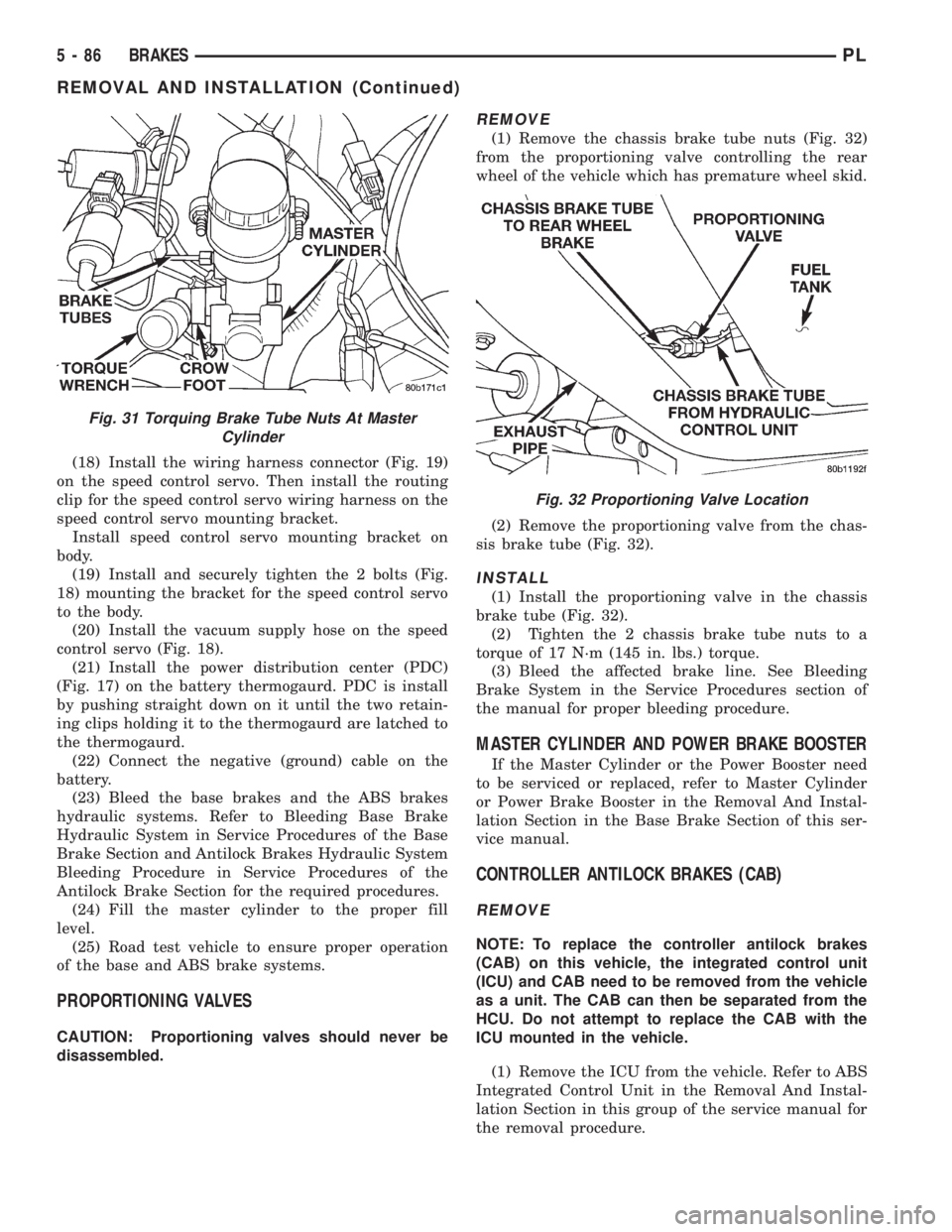

(12) Remove the primary and secondary master

cylinder brake tubes (Fig. 22) from the inlet ports of

the HCU.

(13) Remove the 4 chassis brake tubes from the

outlet ports of the (HCU) (Fig. 23).

CAUTION: Do not apply a 12 volt power source to

any terminals of the 25 HCU connector when dis-

connected from the CAB.

(14) Disconnect the 25 way wiring harness connec-

tor from the CAB using the following procedure.

Grasp the lock on the 25 way connector and pull it

out from the connector as far as possible (Fig. 24).

This will unlock and raise the 25 way connector out

of the socket on the CAB.

(15) Remove the 3 bolts attaching the CAB and

HCU to the mounting bracket. (Fig. 25).

(16) Remove the ICU as a unit from the vehicle.

Fig. 20 Primary And Secondary Brake Tubes With

ABS Brakes

Fig. 21 Master Cylinder Mounting

Fig. 22 Primary And Secondary Brake Tubes From

Master Cylinder To HCU

Fig. 23 Chassis Brake Tube Connections To HCU

PLBRAKES 5 - 83

REMOVAL AND INSTALLATION (Continued)

Page 165 of 1200

INSTALL

(1) Install the ICU on the mounting bracket.

(2) Install the 3 bolts attaching the HCU to the

mounting bracket (Fig. 25).

(3) Tighten the 3 mounting bolts to a torque of 11

N´m (97 in. lbs.)

CAUTION: Before installing the 25 way connector

in the CAB be sure that the seal is properly

installed in the connector.

(4) Install the 25 way connector into the socket on

the CAB. The connector is installed using the follow-

ing procedure. Position the 25 way connector in the

socket on the CAB and carefully push it down as far

as it will go. When connector is fully seated into the

CAB socket push in the connector lock (Fig. 24) as

far as it will go. This will pull the 25 connector into

the socket on the CAB and lock it in the installed

position.

(5) Install the 4 chassis brake tubes (Fig. 23) into

the outlet ports on the HCU.(6) Using a crow foot (Fig. 26) tighten the 4 chas-

sis brake tube nuts to a torque of 17 N´m (145 in.

lbs.).

NOTE: When installing the master cylinder brake

tubes on the HCU, the brake tube with the small

tube nut is to be installed in the front inlet port of

the HCU. This is the port on the HCU that is toward

the front of the vehicle. Also, when installing the

brake tubes correctly position them for installation

into master cylinder.

(7) Install the primary and secondary brake tubes

(Fig. 22) from the master cylinder onto the HCU.

(8) Using a crow foot as shown in Step 6 tighten

the 2 chassis brake tube nuts to a torque of 17 N´m

(145 in. lbs.).

(9) Remove vacuum seal (Fig. 27) located in the

front of the power brake vacuum booster. Vacuum

seal is removed bycarefullyinserting a small screw

driver between the push rod of the power brake vac-

uum booster and vacuum seal (Fig. 27) and pry seal

out of power brake vacuum booster.Do not attempt

to pry seal out of master cylinder by inserting a

tool between seal and power brake vacuum

booster.

(10) Remove old vacuum seal from master cylinder,

if the vacuum seal came out of power brake vacuum

booster when master cylinder was removed.

CAUTION: When replacing the master cylinder on

a vehicle equipped with ABS, a NEW vacuum seal

MUST be installed in the power brake vacuum

booster. Use only the procedure detailed below for

installing vacuum seal into power brake vacuum

booster. Be sure old vacuum seal is removed from

power brake vacuum booster before attempting to

install new seal.

Fig. 24 Unlocked CAB Connector

Fig. 25 Hydraulic Control Unit Mounting Bracket

Fig. 26 Torquing Chassis Tube Nuts At HCU

5 - 84 BRAKESPL

REMOVAL AND INSTALLATION (Continued)

Page 167 of 1200

(18) Install the wiring harness connector (Fig. 19)

on the speed control servo. Then install the routing

clip for the speed control servo wiring harness on the

speed control servo mounting bracket.

Install speed control servo mounting bracket on

body.

(19) Install and securely tighten the 2 bolts (Fig.

18) mounting the bracket for the speed control servo

to the body.

(20) Install the vacuum supply hose on the speed

control servo (Fig. 18).

(21) Install the power distribution center (PDC)

(Fig. 17) on the battery thermogaurd. PDC is install

by pushing straight down on it until the two retain-

ing clips holding it to the thermogaurd are latched to

the thermogaurd.

(22) Connect the negative (ground) cable on the

battery.

(23) Bleed the base brakes and the ABS brakes

hydraulic systems. Refer to Bleeding Base Brake

Hydraulic System in Service Procedures of the Base

Brake Section and Antilock Brakes Hydraulic System

Bleeding Procedure in Service Procedures of the

Antilock Brake Section for the required procedures.

(24) Fill the master cylinder to the proper fill

level.

(25) Road test vehicle to ensure proper operation

of the base and ABS brake systems.

PROPORTIONING VALVES

CAUTION: Proportioning valves should never be

disassembled.

REMOVE

(1) Remove the chassis brake tube nuts (Fig. 32)

from the proportioning valve controlling the rear

wheel of the vehicle which has premature wheel skid.

(2) Remove the proportioning valve from the chas-

sis brake tube (Fig. 32).

INSTALL

(1) Install the proportioning valve in the chassis

brake tube (Fig. 32).

(2) Tighten the 2 chassis brake tube nuts to a

torque of 17 N´m (145 in. lbs.) torque.

(3) Bleed the affected brake line. See Bleeding

Brake System in the Service Procedures section of

the manual for proper bleeding procedure.

MASTER CYLINDER AND POWER BRAKE BOOSTER

If the Master Cylinder or the Power Booster need

to be serviced or replaced, refer to Master Cylinder

or Power Brake Booster in the Removal And Instal-

lation Section in the Base Brake Section of this ser-

vice manual.

CONTROLLER ANTILOCK BRAKES (CAB)

REMOVE

NOTE: To replace the controller antilock brakes

(CAB) on this vehicle, the integrated control unit

(ICU) and CAB need to be removed from the vehicle

as a unit. The CAB can then be separated from the

HCU. Do not attempt to replace the CAB with the

ICU mounted in the vehicle.

(1) Remove the ICU from the vehicle. Refer to ABS

Integrated Control Unit in the Removal And Instal-

lation Section in this group of the service manual for

the removal procedure.

Fig. 31 Torquing Brake Tube Nuts At Master

Cylinder

Fig. 32 Proportioning Valve Location

5 - 86 BRAKESPL

REMOVAL AND INSTALLATION (Continued)

Page 173 of 1200

The clutch cable has a unique self-adjuster mecha-

nism built into the cable which compensates for

clutch disc wear. The cable requires no maintenance

or lubrication. There are no serviceable components

on the cable assembly.

The clutch pedal is connected to the cable through

a plastic spacer. The upper end of the clutch pedal

pivots in the pedal bracket on two nylon bushings

and a shaft. These bushings are greased at assembly

and do not require periodic lubrication.

CLUTCH DISC AND COVER APPLICATION

The 2.0 single overhead cam engine uses a 216 mm

(8.5 in.) clutch disc. The manual transaxle is avail-

able only with the 2.0 liter engine.

CLUTCH REPLACEMENT

The transaxle must be removed to service the

clutch disc, pressure plate, flywheel/drive plate,

and/or clutch release bearing and lever.

DESCRIPTION AND OPERATION

CLUTCH CABLE

The manual transaxle clutch release system has a

unique self-adjusting mechanism to compensate for

clutch disc wear. This adjuster mechanism is located

within the clutch cable assembly. The preload spring

maintains tension on the cable. This tension keeps

the clutch release bearing continuously loaded

against the fingers of the clutch cover assembly.

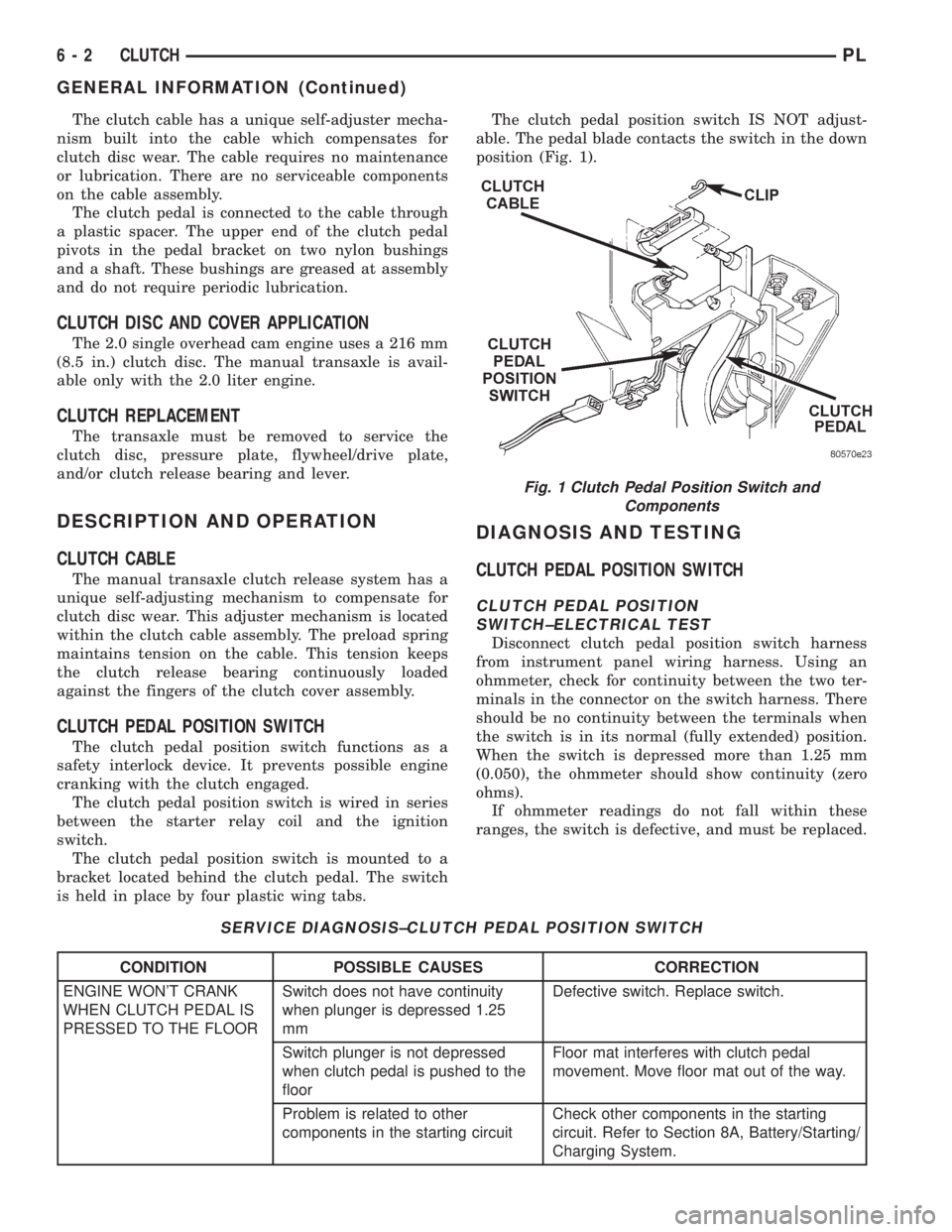

CLUTCH PEDAL POSITION SWITCH

The clutch pedal position switch functions as a

safety interlock device. It prevents possible engine

cranking with the clutch engaged.

The clutch pedal position switch is wired in series

between the starter relay coil and the ignition

switch.

The clutch pedal position switch is mounted to a

bracket located behind the clutch pedal. The switch

is held in place by four plastic wing tabs.The clutch pedal position switch IS NOT adjust-

able. The pedal blade contacts the switch in the down

position (Fig. 1).

DIAGNOSIS AND TESTING

CLUTCH PEDAL POSITION SWITCH

CLUTCH PEDAL POSITION

SWITCH±ELECTRICAL TEST

Disconnect clutch pedal position switch harness

from instrument panel wiring harness. Using an

ohmmeter, check for continuity between the two ter-

minals in the connector on the switch harness. There

should be no continuity between the terminals when

the switch is in its normal (fully extended) position.

When the switch is depressed more than 1.25 mm

(0.050), the ohmmeter should show continuity (zero

ohms).

If ohmmeter readings do not fall within these

ranges, the switch is defective, and must be replaced.

SERVICE DIAGNOSIS±CLUTCH PEDAL POSITION SWITCH

CONDITION POSSIBLE CAUSES CORRECTION

ENGINE WON'T CRANK

WHEN CLUTCH PEDAL IS

PRESSED TO THE FLOORSwitch does not have continuity

when plunger is depressed 1.25

mmDefective switch. Replace switch.

Switch plunger is not depressed

when clutch pedal is pushed to the

floorFloor mat interferes with clutch pedal

movement. Move floor mat out of the way.

Problem is related to other

components in the starting circuitCheck other components in the starting

circuit. Refer to Section 8A, Battery/Starting/

Charging System.

Fig. 1 Clutch Pedal Position Switch and

Components

6 - 2 CLUTCHPL

GENERAL INFORMATION (Continued)

Page 179 of 1200

REMOVAL

(1) Remove transaxle. See Group 21, Manual Tran-

saxle, for procedure.

(2) Mark clutch cover and flywheel, to maintain

their same relative positions when installing clutch

assembly.

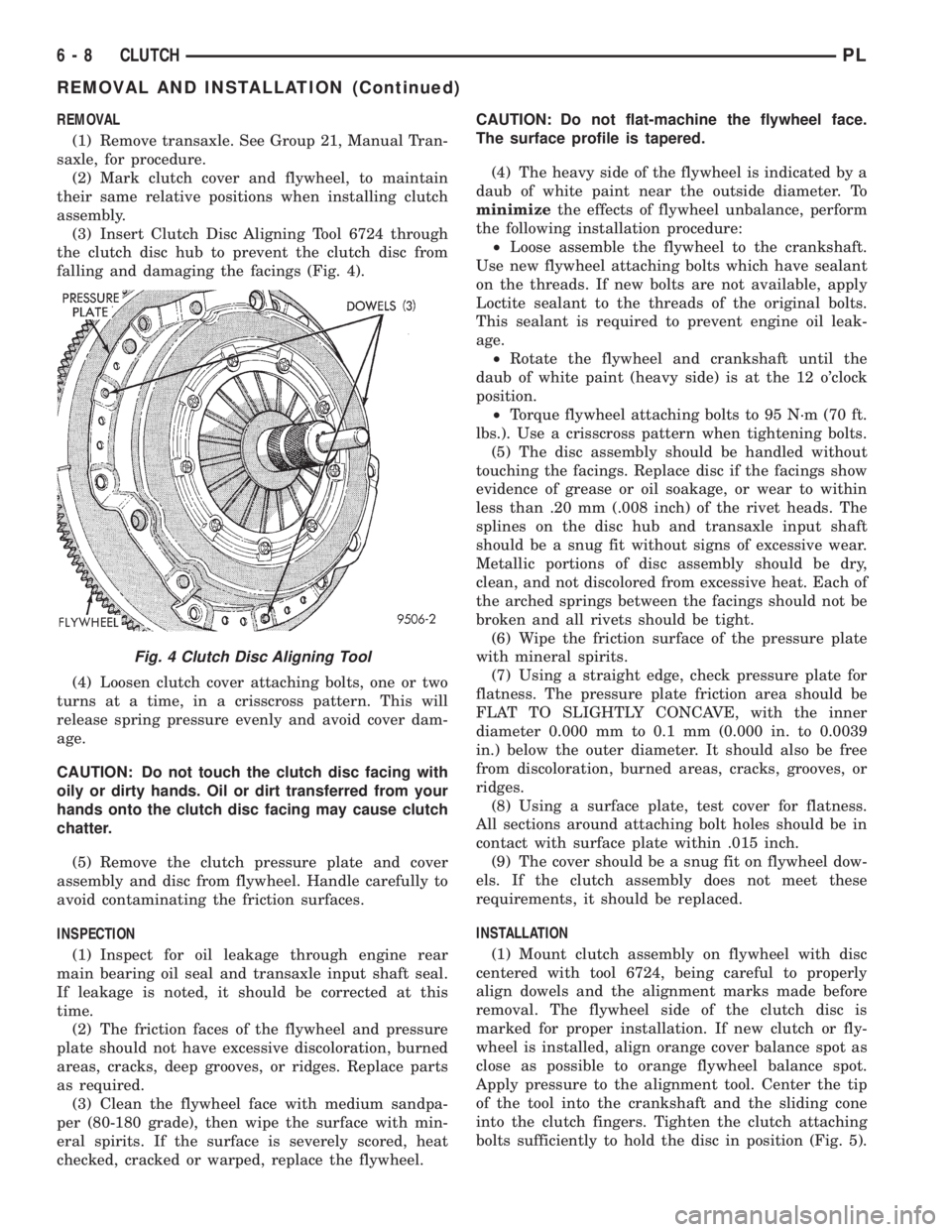

(3) Insert Clutch Disc Aligning Tool 6724 through

the clutch disc hub to prevent the clutch disc from

falling and damaging the facings (Fig. 4).

(4) Loosen clutch cover attaching bolts, one or two

turns at a time, in a crisscross pattern. This will

release spring pressure evenly and avoid cover dam-

age.

CAUTION: Do not touch the clutch disc facing with

oily or dirty hands. Oil or dirt transferred from your

hands onto the clutch disc facing may cause clutch

chatter.

(5) Remove the clutch pressure plate and cover

assembly and disc from flywheel. Handle carefully to

avoid contaminating the friction surfaces.

INSPECTION

(1) Inspect for oil leakage through engine rear

main bearing oil seal and transaxle input shaft seal.

If leakage is noted, it should be corrected at this

time.

(2) The friction faces of the flywheel and pressure

plate should not have excessive discoloration, burned

areas, cracks, deep grooves, or ridges. Replace parts

as required.

(3) Clean the flywheel face with medium sandpa-

per (80-180 grade), then wipe the surface with min-

eral spirits. If the surface is severely scored, heat

checked, cracked or warped, replace the flywheel.CAUTION: Do not flat-machine the flywheel face.

The surface profile is tapered.

(4) The heavy side of the flywheel is indicated by a

daub of white paint near the outside diameter. To

minimizethe effects of flywheel unbalance, perform

the following installation procedure:

²Loose assemble the flywheel to the crankshaft.

Use new flywheel attaching bolts which have sealant

on the threads. If new bolts are not available, apply

Loctite sealant to the threads of the original bolts.

This sealant is required to prevent engine oil leak-

age.

²Rotate the flywheel and crankshaft until the

daub of white paint (heavy side) is at the 12 o'clock

position.

²Torque flywheel attaching bolts to 95 N´m (70 ft.

lbs.). Use a crisscross pattern when tightening bolts.

(5) The disc assembly should be handled without

touching the facings. Replace disc if the facings show

evidence of grease or oil soakage, or wear to within

less than .20 mm (.008 inch) of the rivet heads. The

splines on the disc hub and transaxle input shaft

should be a snug fit without signs of excessive wear.

Metallic portions of disc assembly should be dry,

clean, and not discolored from excessive heat. Each of

the arched springs between the facings should not be

broken and all rivets should be tight.

(6) Wipe the friction surface of the pressure plate

with mineral spirits.

(7) Using a straight edge, check pressure plate for

flatness. The pressure plate friction area should be

FLAT TO SLIGHTLY CONCAVE, with the inner

diameter 0.000 mm to 0.1 mm (0.000 in. to 0.0039

in.) below the outer diameter. It should also be free

from discoloration, burned areas, cracks, grooves, or

ridges.

(8) Using a surface plate, test cover for flatness.

All sections around attaching bolt holes should be in

contact with surface plate within .015 inch.

(9) The cover should be a snug fit on flywheel dow-

els. If the clutch assembly does not meet these

requirements, it should be replaced.

INSTALLATION

(1) Mount clutch assembly on flywheel with disc

centered with tool 6724, being careful to properly

align dowels and the alignment marks made before

removal. The flywheel side of the clutch disc is

marked for proper installation. If new clutch or fly-

wheel is installed, align orange cover balance spot as

close as possible to orange flywheel balance spot.

Apply pressure to the alignment tool. Center the tip

of the tool into the crankshaft and the sliding cone

into the clutch fingers. Tighten the clutch attaching

bolts sufficiently to hold the disc in position (Fig. 5).

Fig. 4 Clutch Disc Aligning Tool

6 - 8 CLUTCHPL

REMOVAL AND INSTALLATION (Continued)

Page 190 of 1200

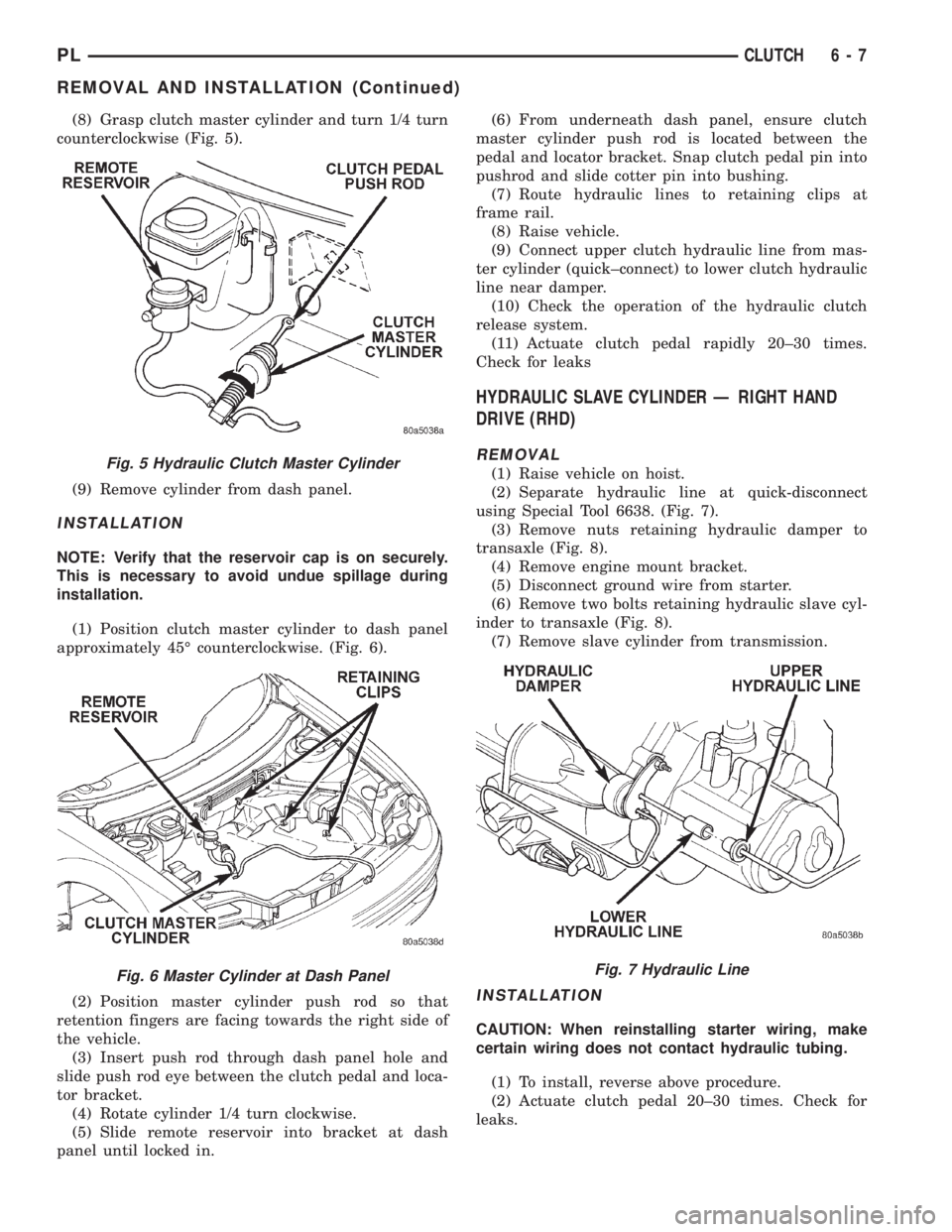

(8) Grasp clutch master cylinder and turn 1/4 turn

counterclockwise (Fig. 5).

(9) Remove cylinder from dash panel.

INSTALLATION

NOTE: Verify that the reservoir cap is on securely.

This is necessary to avoid undue spillage during

installation.

(1) Position clutch master cylinder to dash panel

approximately 45É counterclockwise. (Fig. 6).

(2) Position master cylinder push rod so that

retention fingers are facing towards the right side of

the vehicle.

(3) Insert push rod through dash panel hole and

slide push rod eye between the clutch pedal and loca-

tor bracket.

(4) Rotate cylinder 1/4 turn clockwise.

(5) Slide remote reservoir into bracket at dash

panel until locked in.(6) From underneath dash panel, ensure clutch

master cylinder push rod is located between the

pedal and locator bracket. Snap clutch pedal pin into

pushrod and slide cotter pin into bushing.

(7) Route hydraulic lines to retaining clips at

frame rail.

(8) Raise vehicle.

(9) Connect upper clutch hydraulic line from mas-

ter cylinder (quick±connect) to lower clutch hydraulic

line near damper.

(10) Check the operation of the hydraulic clutch

release system.

(11) Actuate clutch pedal rapidly 20±30 times.

Check for leaks

HYDRAULIC SLAVE CYLINDER Ð RIGHT HAND

DRIVE (RHD)

REMOVAL

(1) Raise vehicle on hoist.

(2) Separate hydraulic line at quick-disconnect

using Special Tool 6638. (Fig. 7).

(3) Remove nuts retaining hydraulic damper to

transaxle (Fig. 8).

(4) Remove engine mount bracket.

(5) Disconnect ground wire from starter.

(6) Remove two bolts retaining hydraulic slave cyl-

inder to transaxle (Fig. 8).

(7) Remove slave cylinder from transmission.

INSTALLATION

CAUTION: When reinstalling starter wiring, make

certain wiring does not contact hydraulic tubing.

(1) To install, reverse above procedure.

(2) Actuate clutch pedal 20±30 times. Check for

leaks.

Fig. 5 Hydraulic Clutch Master Cylinder

Fig. 6 Master Cylinder at Dash PanelFig. 7 Hydraulic Line

PLCLUTCH 6 - 7

REMOVAL AND INSTALLATION (Continued)

Page 194 of 1200

COOLING

CONTENTS

page page

GENERAL INFORMATION

ACCESSORY DRIVE BELTS................ 2

AUTOMATIC TRANSMISSION OIL COOLER.... 3

COOLANT RECOVERY SYSTEM (CRS)....... 2

COOLANT.............................. 3

COOLING SYSTEM PRESSURE CAP......... 3

COOLING SYSTEM....................... 1

ENGINE BLOCK HEATER.................. 3

ENGINE THERMOSTAT.................... 3

RADIATOR............................. 3

WATER PUMP.......................... 3

DESCRIPTION AND OPERATION

COOLANT PERFORMANCE................. 4

COOLING SYSTEM PRESSURE CAP......... 5

ENGINE BLOCK HEATER.................. 5

ENGINE THERMOSTAT.................... 4

RADIATOR HOSES AND CLAMPS........... 5

WATER PUMP.......................... 6

DIAGNOSIS AND TESTING

ACCESSORY DRIVEBELT DIAGNOSIS....... 13

COOLING SYSTEM DIAGNOSIS............. 7

COOLING SYSTEM FLOW CHECK.......... 14

DEAERATION.......................... 15

ELECTRIC FAN MOTOR TEST.............. 14

ENGINE THERMOSTAT TESTING........... 13

LOW COOLANT LEVEL AERATION.......... 15

PRESSURE CAP TO FILLER NECK SEAL

PRESSURE RELIEF CHECK.............. 15

PRESSURE TESTING COOLING SYSTEM

PRESSURE CAP...................... 15

RADIATOR FAN CONTROL................ 14

TEMPERATURE GAUGE INDICATION........ 16

TESTING COOLING SYSTEM FOR LEAKS.... 14WATER PUMP DIAGNOSIS............... 14

SERVICE PROCEDURES

COOLANT LEVEL CHECKÐROUTINE........ 16

COOLANT LEVELÐSERVICING............ 16

COOLANTÐADDING ADDITIONAL......... 16

COOLING SYSTEMÐDRAINING............ 16

COOLING SYSTEMÐREFILLING........... 17

REMOVAL AND INSTALLATION

ACCESSORY DRIVE BELTS............... 21

ENGINE BLOCK HEATER................. 21

ENGINE THERMOSTAT................... 18

RADIATOR DRAINCOCK.................. 20

RADIATOR FANS AND MOTOR............ 20

RADIATOR............................ 19

WATER PUMP INLET TUBE............... 18

WATER PUMP......................... 17

CLEANING AND INSPECTION

ACCESSORY DRIVE BELT INSPECTION...... 22

CHEMICAL CLEANING................... 23

CLEANING COOLING SYSTEM............. 22

COOLING SYSTEM CAP.................. 22

RADIATOR FLUSHING................... 23

REVERSE FLUSHING.................... 23

WATER PUMP......................... 21

ADJUSTMENTS

BELT TENSION GAUGE METHOD........... 24

PROPER BELT TENSION................. 23

SPECIFICATIONS

COOLING SYSTEM CAPACITY............. 24

TORQUE.............................. 24

SPECIAL TOOLS

COOLING............................. 24

GENERAL INFORMATION

COOLING SYSTEM

The cooling system consists of an engine cooling

module, thermostat, coolant, and a water pump to

circulate the coolant. The engine cooling module may

consist of a radiator, electric fan motor, fan, shroud,

coolant reserve system, transmission oil cooler, hoses,

clamps, air condition condenser and transmission oil lines.

²When the Engine is cold: The thermostat is

closed; the cooling system has no flow through the

radiator. The coolant flows through the engine,

heater system and bypass.

²When the Engine is warm: Thermostat is open;

the cooling system has flow through radiator, engine,

heater system and bypass.

Coolant flow circuit for the 2.0L engine is shown in

(Fig. 1).

PLCOOLING 7 - 1

Page 196 of 1200

ENGINE THERMOSTAT

The engine thermostat is located on the front of

the engine (radiator side) in the thermostat housing/

engine outlet connector. The thermostat has an air

bleed (vent) located in the flange and a O-ring for

sealing incorporate on it. There is a relief in the ther-

mostat housing/outlet connector for the O-ring.

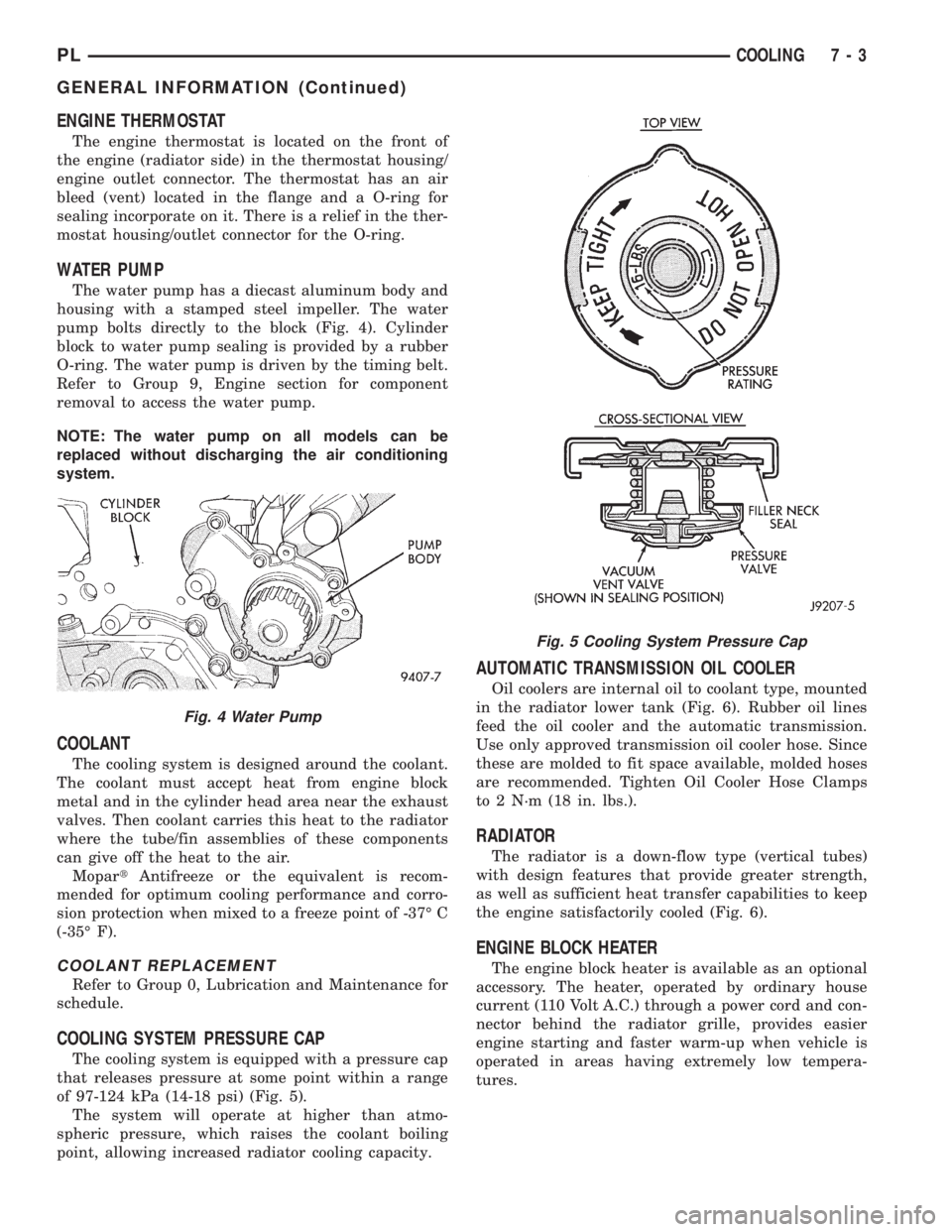

WATER PUMP

The water pump has a diecast aluminum body and

housing with a stamped steel impeller. The water

pump bolts directly to the block (Fig. 4). Cylinder

block to water pump sealing is provided by a rubber

O-ring. The water pump is driven by the timing belt.

Refer to Group 9, Engine section for component

removal to access the water pump.

NOTE: The water pump on all models can be

replaced without discharging the air conditioning

system.

COOLANT

The cooling system is designed around the coolant.

The coolant must accept heat from engine block

metal and in the cylinder head area near the exhaust

valves. Then coolant carries this heat to the radiator

where the tube/fin assemblies of these components

can give off the heat to the air.

MopartAntifreeze or the equivalent is recom-

mended for optimum cooling performance and corro-

sion protection when mixed to a freeze point of -37É C

(-35É F).

COOLANT REPLACEMENT

Refer to Group 0, Lubrication and Maintenance for

schedule.

COOLING SYSTEM PRESSURE CAP

The cooling system is equipped with a pressure cap

that releases pressure at some point within a range

of 97-124 kPa (14-18 psi) (Fig. 5).

The system will operate at higher than atmo-

spheric pressure, which raises the coolant boiling

point, allowing increased radiator cooling capacity.

AUTOMATIC TRANSMISSION OIL COOLER

Oil coolers are internal oil to coolant type, mounted

in the radiator lower tank (Fig. 6). Rubber oil lines

feed the oil cooler and the automatic transmission.

Use only approved transmission oil cooler hose. Since

these are molded to fit space available, molded hoses

are recommended. Tighten Oil Cooler Hose Clamps

to 2 N´m (18 in. lbs.).

RADIATOR

The radiator is a down-flow type (vertical tubes)

with design features that provide greater strength,

as well as sufficient heat transfer capabilities to keep

the engine satisfactorily cooled (Fig. 6).

ENGINE BLOCK HEATER

The engine block heater is available as an optional

accessory. The heater, operated by ordinary house

current (110 Volt A.C.) through a power cord and con-

nector behind the radiator grille, provides easier

engine starting and faster warm-up when vehicle is

operated in areas having extremely low tempera-

tures.

Fig. 4 Water Pump

Fig. 5 Cooling System Pressure Cap

PLCOOLING 7 - 3

GENERAL INFORMATION (Continued)

Page 198 of 1200

SELECTION AND ADDITIVES

The use of aluminum cylinder heads, intake mani-

folds DOHC, and water pumps requires special corro-

sion protection. MopartAntifreeze or the equivalent

is recommended for best engine cooling without cor-

rosion. When mixed only to a freeze point of -37ÉC

(-35ÉF) to -59ÉC (-50ÉF). If it looses color or becomes

contaminated, drain, flush, and replace with fresh

properly mixed solution.

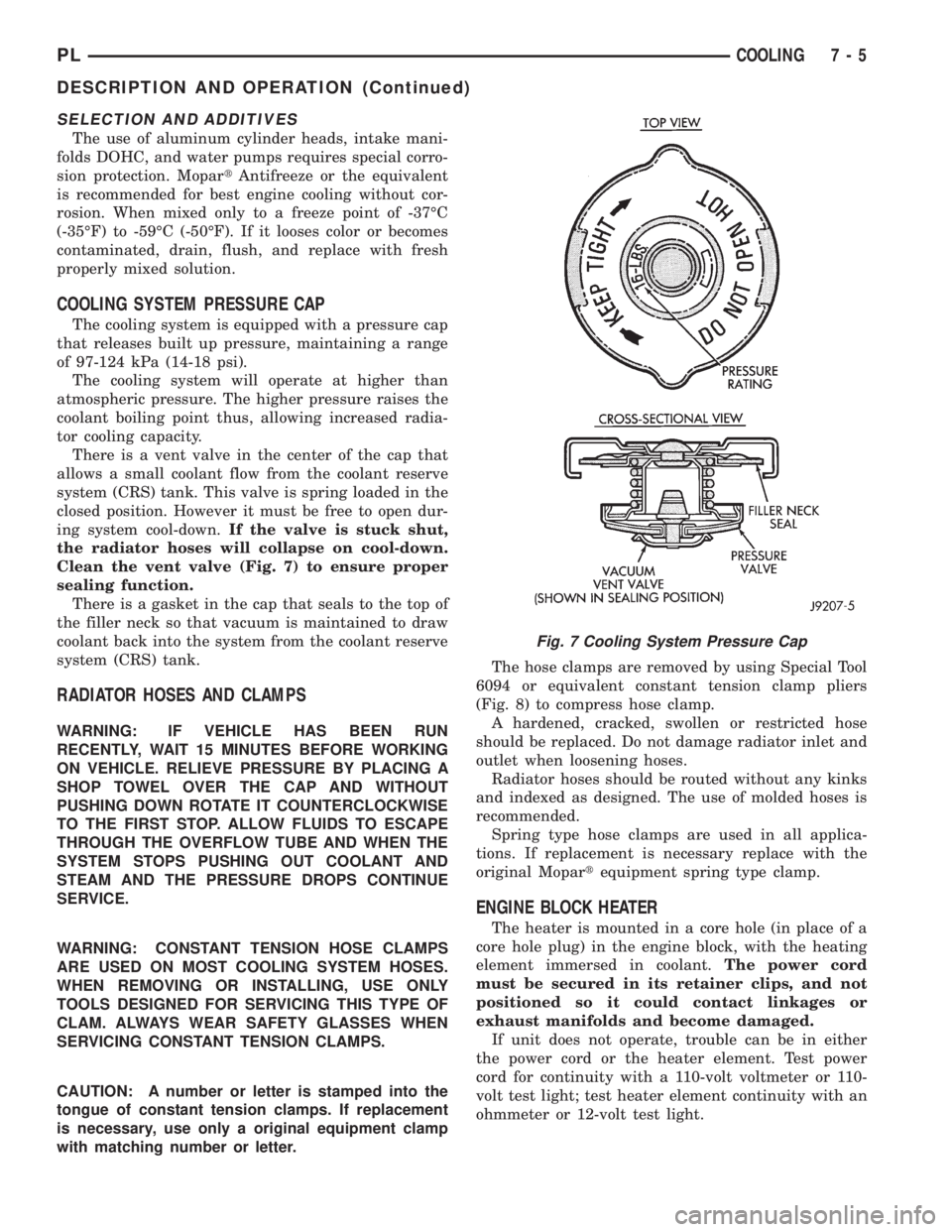

COOLING SYSTEM PRESSURE CAP

The cooling system is equipped with a pressure cap

that releases built up pressure, maintaining a range

of 97-124 kPa (14-18 psi).

The cooling system will operate at higher than

atmospheric pressure. The higher pressure raises the

coolant boiling point thus, allowing increased radia-

tor cooling capacity.

There is a vent valve in the center of the cap that

allows a small coolant flow from the coolant reserve

system (CRS) tank. This valve is spring loaded in the

closed position. However it must be free to open dur-

ing system cool-down.If the valve is stuck shut,

the radiator hoses will collapse on cool-down.

Clean the vent valve (Fig. 7) to ensure proper

sealing function.

There is a gasket in the cap that seals to the top of

the filler neck so that vacuum is maintained to draw

coolant back into the system from the coolant reserve

system (CRS) tank.

RADIATOR HOSES AND CLAMPS

WARNING: IF VEHICLE HAS BEEN RUN

RECENTLY, WAIT 15 MINUTES BEFORE WORKING

ON VEHICLE. RELIEVE PRESSURE BY PLACING A

SHOP TOWEL OVER THE CAP AND WITHOUT

PUSHING DOWN ROTATE IT COUNTERCLOCKWISE

TO THE FIRST STOP. ALLOW FLUIDS TO ESCAPE

THROUGH THE OVERFLOW TUBE AND WHEN THE

SYSTEM STOPS PUSHING OUT COOLANT AND

STEAM AND THE PRESSURE DROPS CONTINUE

SERVICE.

WARNING: CONSTANT TENSION HOSE CLAMPS

ARE USED ON MOST COOLING SYSTEM HOSES.

WHEN REMOVING OR INSTALLING, USE ONLY

TOOLS DESIGNED FOR SERVICING THIS TYPE OF

CLAM. ALWAYS WEAR SAFETY GLASSES WHEN

SERVICING CONSTANT TENSION CLAMPS.

CAUTION: A number or letter is stamped into the

tongue of constant tension clamps. If replacement

is necessary, use only a original equipment clamp

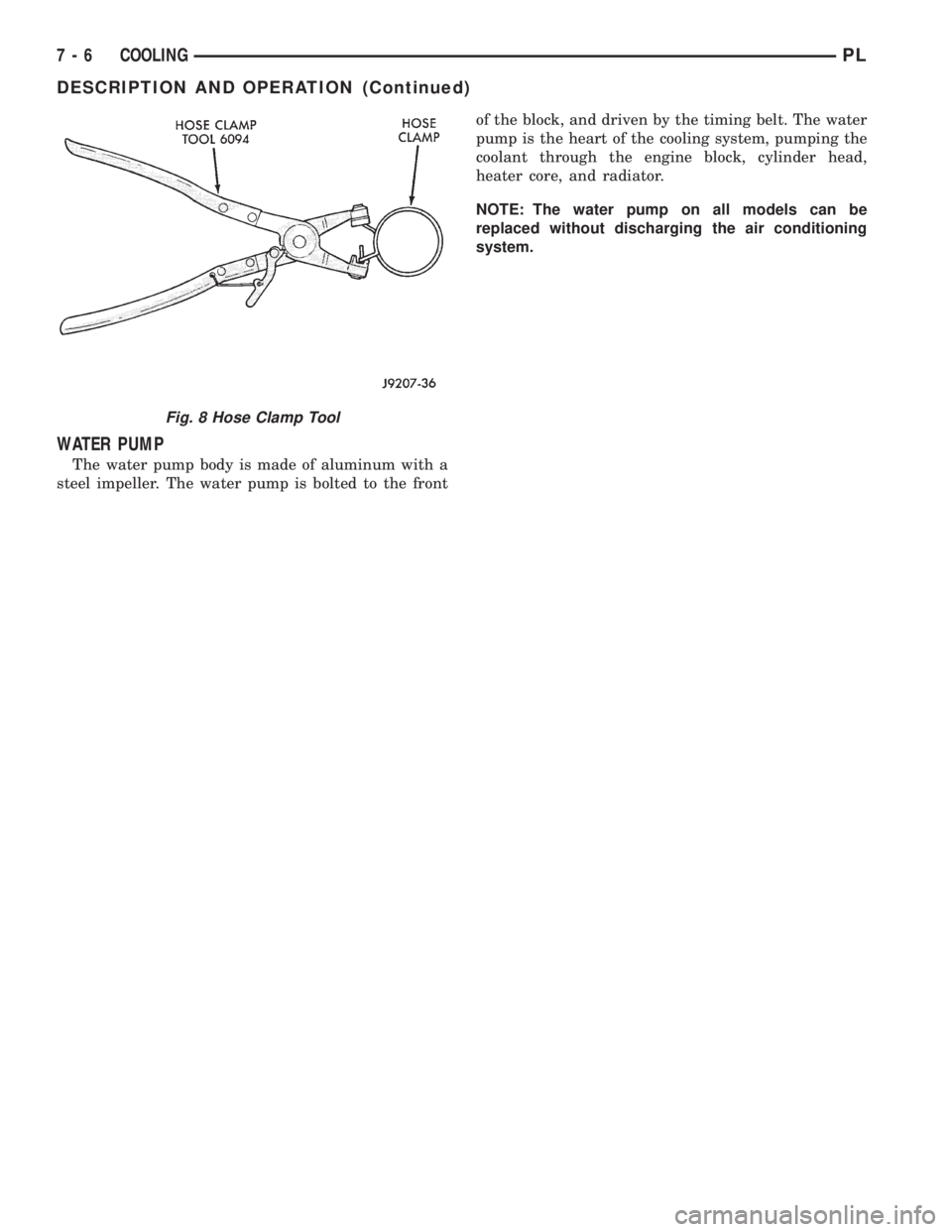

with matching number or letter.The hose clamps are removed by using Special Tool

6094 or equivalent constant tension clamp pliers

(Fig. 8) to compress hose clamp.

A hardened, cracked, swollen or restricted hose

should be replaced. Do not damage radiator inlet and

outlet when loosening hoses.

Radiator hoses should be routed without any kinks

and indexed as designed. The use of molded hoses is

recommended.

Spring type hose clamps are used in all applica-

tions. If replacement is necessary replace with the

original Mopartequipment spring type clamp.

ENGINE BLOCK HEATER

The heater is mounted in a core hole (in place of a

core hole plug) in the engine block, with the heating

element immersed in coolant.The power cord

must be secured in its retainer clips, and not

positioned so it could contact linkages or

exhaust manifolds and become damaged.

If unit does not operate, trouble can be in either

the power cord or the heater element. Test power

cord for continuity with a 110-volt voltmeter or 110-

volt test light; test heater element continuity with an

ohmmeter or 12-volt test light.

Fig. 7 Cooling System Pressure Cap

PLCOOLING 7 - 5

DESCRIPTION AND OPERATION (Continued)

Page 199 of 1200

WATER PUMP

The water pump body is made of aluminum with a

steel impeller. The water pump is bolted to the frontof the block, and driven by the timing belt. The water

pump is the heart of the cooling system, pumping the

coolant through the engine block, cylinder head,

heater core, and radiator.

NOTE: The water pump on all models can be

replaced without discharging the air conditioning

system.

Fig. 8 Hose Clamp Tool

7 - 6 COOLINGPL

DESCRIPTION AND OPERATION (Continued)