lock DODGE NEON 1999 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 779 of 1200

(18) Lower vehicle. Remove air cleaner assembly.

(19) Remove power steering pump and reservoir,

Set them aside.

(20) Remove A/C compressor.

(21) Remove ground straps to body.

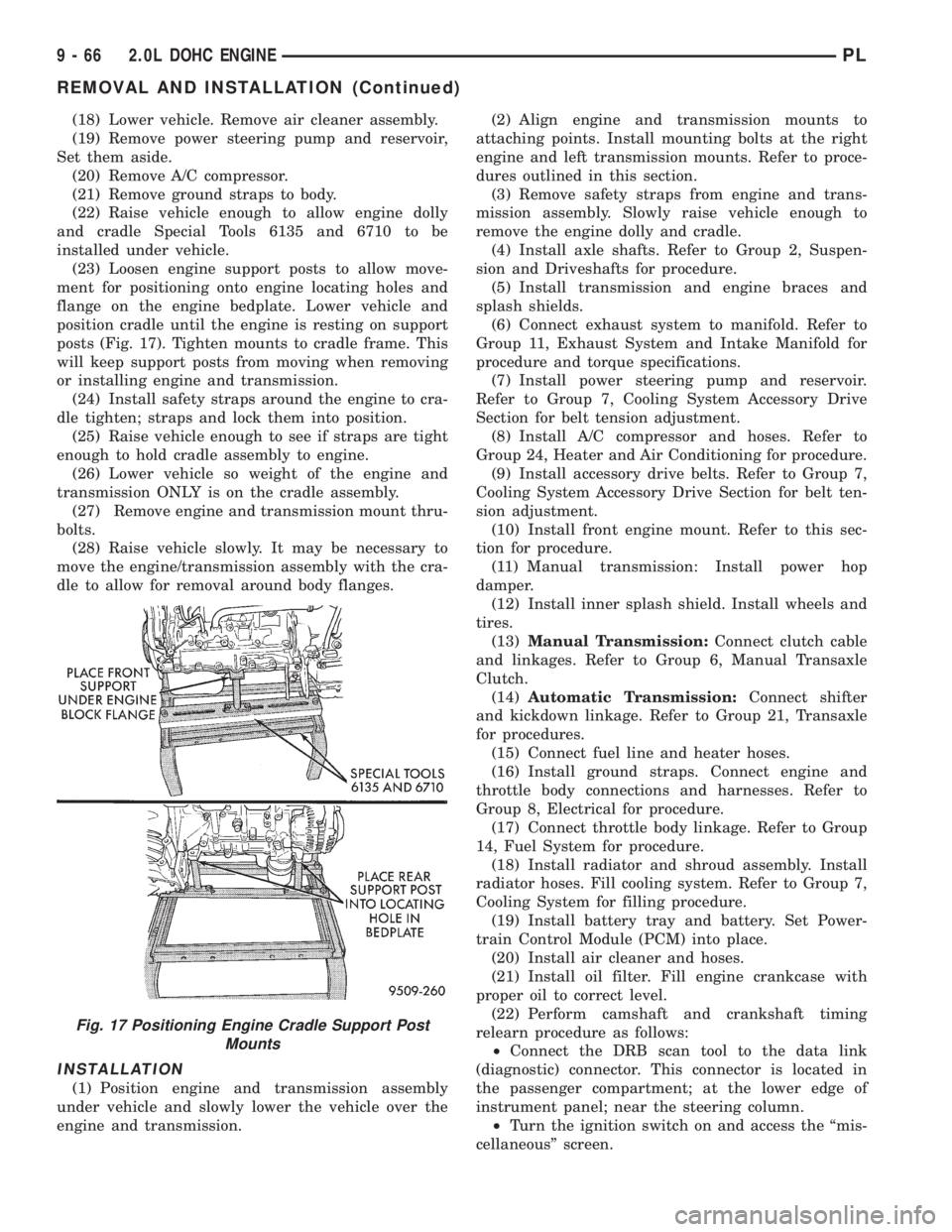

(22) Raise vehicle enough to allow engine dolly

and cradle Special Tools 6135 and 6710 to be

installed under vehicle.

(23) Loosen engine support posts to allow move-

ment for positioning onto engine locating holes and

flange on the engine bedplate. Lower vehicle and

position cradle until the engine is resting on support

posts (Fig. 17). Tighten mounts to cradle frame. This

will keep support posts from moving when removing

or installing engine and transmission.

(24) Install safety straps around the engine to cra-

dle tighten; straps and lock them into position.

(25) Raise vehicle enough to see if straps are tight

enough to hold cradle assembly to engine.

(26) Lower vehicle so weight of the engine and

transmission ONLY is on the cradle assembly.

(27) Remove engine and transmission mount thru-

bolts.

(28) Raise vehicle slowly. It may be necessary to

move the engine/transmission assembly with the cra-

dle to allow for removal around body flanges.

INSTALLATION

(1) Position engine and transmission assembly

under vehicle and slowly lower the vehicle over the

engine and transmission.(2) Align engine and transmission mounts to

attaching points. Install mounting bolts at the right

engine and left transmission mounts. Refer to proce-

dures outlined in this section.

(3) Remove safety straps from engine and trans-

mission assembly. Slowly raise vehicle enough to

remove the engine dolly and cradle.

(4) Install axle shafts. Refer to Group 2, Suspen-

sion and Driveshafts for procedure.

(5) Install transmission and engine braces and

splash shields.

(6) Connect exhaust system to manifold. Refer to

Group 11, Exhaust System and Intake Manifold for

procedure and torque specifications.

(7) Install power steering pump and reservoir.

Refer to Group 7, Cooling System Accessory Drive

Section for belt tension adjustment.

(8) Install A/C compressor and hoses. Refer to

Group 24, Heater and Air Conditioning for procedure.

(9) Install accessory drive belts. Refer to Group 7,

Cooling System Accessory Drive Section for belt ten-

sion adjustment.

(10) Install front engine mount. Refer to this sec-

tion for procedure.

(11) Manual transmission: Install power hop

damper.

(12) Install inner splash shield. Install wheels and

tires.

(13)Manual Transmission:Connect clutch cable

and linkages. Refer to Group 6, Manual Transaxle

Clutch.

(14)Automatic Transmission:Connect shifter

and kickdown linkage. Refer to Group 21, Transaxle

for procedures.

(15) Connect fuel line and heater hoses.

(16) Install ground straps. Connect engine and

throttle body connections and harnesses. Refer to

Group 8, Electrical for procedure.

(17) Connect throttle body linkage. Refer to Group

14, Fuel System for procedure.

(18) Install radiator and shroud assembly. Install

radiator hoses. Fill cooling system. Refer to Group 7,

Cooling System for filling procedure.

(19) Install battery tray and battery. Set Power-

train Control Module (PCM) into place.

(20) Install air cleaner and hoses.

(21) Install oil filter. Fill engine crankcase with

proper oil to correct level.

(22) Perform camshaft and crankshaft timing

relearn procedure as follows:

²Connect the DRB scan tool to the data link

(diagnostic) connector. This connector is located in

the passenger compartment; at the lower edge of

instrument panel; near the steering column.

²Turn the ignition switch on and access the ªmis-

cellaneousº screen.

Fig. 17 Positioning Engine Cradle Support Post

Mounts

9 - 66 2.0L DOHC ENGINEPL

REMOVAL AND INSTALLATION (Continued)

Page 782 of 1200

(5) Install cylinder head cover using procedure out-

lined in this section.

(6) Perform camshaft and crankshaft timing

relearn procedure as follows:

²Step 1: Connect the DRB scan tool to the data

link (diagnostic) connector. This connector is located

in the passenger compartment; at the lower edge of

instrument panel; near the steering column.

²Step 2: Turn the ignition switch on and access

the ªmiscellaneousº screen.

²Step 3: Select re-learn cam/crank option and fol-

low directions on DRB screen.

CAM FOLLOWER AND HYDRAULIC LASH

ADJUSTER ASSEMBLY

REMOVAL

(1) Remove cylinder head cover using procedure

outlined in this section.

(2) Remove timing belt, sprockets and covers using

procedure outlined in this section.

(3) Remove camshaft. Refer to procedure previ-

ously outline this section.

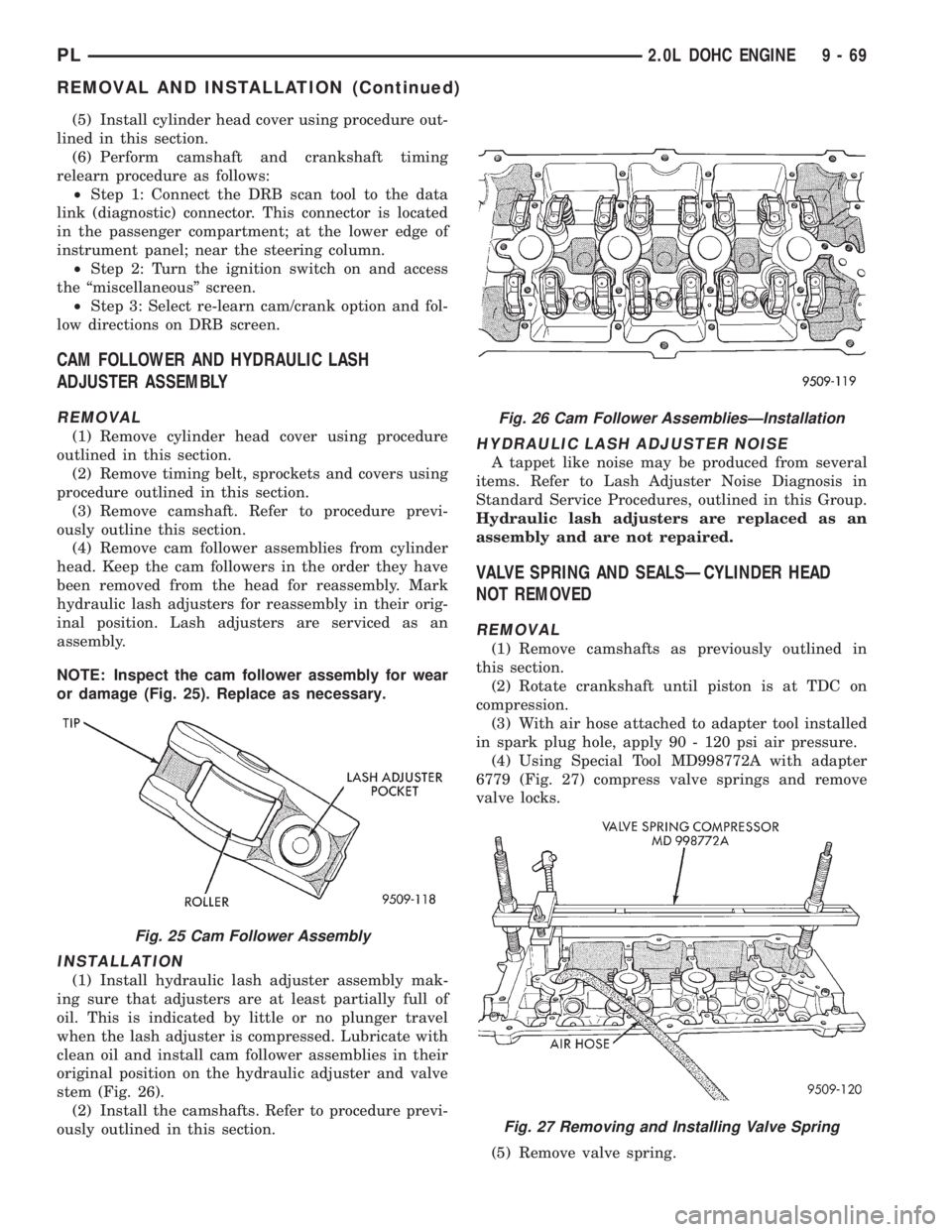

(4) Remove cam follower assemblies from cylinder

head. Keep the cam followers in the order they have

been removed from the head for reassembly. Mark

hydraulic lash adjusters for reassembly in their orig-

inal position. Lash adjusters are serviced as an

assembly.

NOTE: Inspect the cam follower assembly for wear

or damage (Fig. 25). Replace as necessary.

INSTALLATION

(1) Install hydraulic lash adjuster assembly mak-

ing sure that adjusters are at least partially full of

oil. This is indicated by little or no plunger travel

when the lash adjuster is compressed. Lubricate with

clean oil and install cam follower assemblies in their

original position on the hydraulic adjuster and valve

stem (Fig. 26).

(2) Install the camshafts. Refer to procedure previ-

ously outlined in this section.

HYDRAULIC LASH ADJUSTER NOISE

A tappet like noise may be produced from several

items. Refer to Lash Adjuster Noise Diagnosis in

Standard Service Procedures, outlined in this Group.

Hydraulic lash adjusters are replaced as an

assembly and are not repaired.

VALVE SPRING AND SEALSÐCYLINDER HEAD

NOT REMOVED

REMOVAL

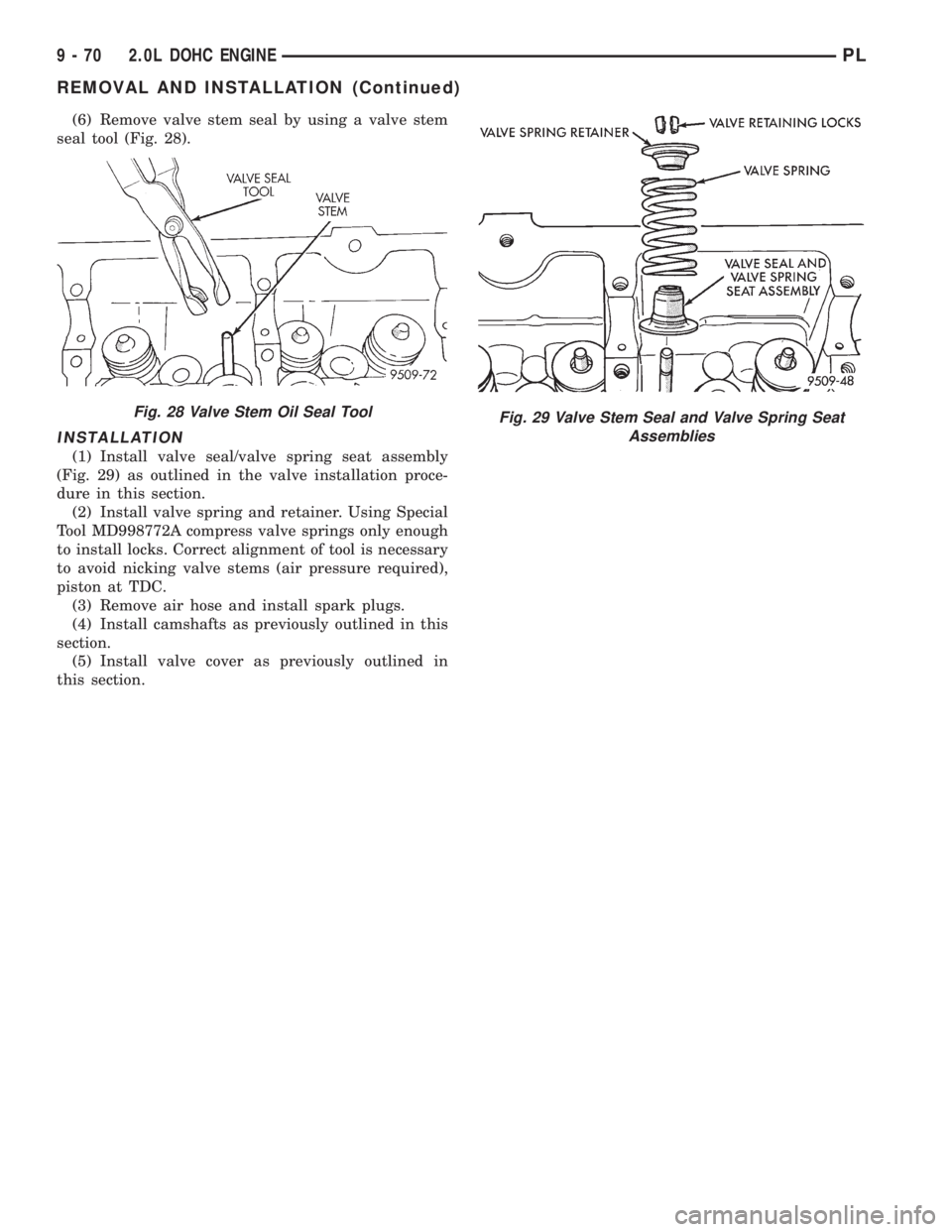

(1) Remove camshafts as previously outlined in

this section.

(2) Rotate crankshaft until piston is at TDC on

compression.

(3) With air hose attached to adapter tool installed

in spark plug hole, apply 90 - 120 psi air pressure.

(4) Using Special Tool MD998772A with adapter

6779 (Fig. 27) compress valve springs and remove

valve locks.

(5) Remove valve spring.

Fig. 25 Cam Follower Assembly

Fig. 26 Cam Follower AssembliesÐInstallation

Fig. 27 Removing and Installing Valve Spring

PL2.0L DOHC ENGINE 9 - 69

REMOVAL AND INSTALLATION (Continued)

Page 783 of 1200

(6) Remove valve stem seal by using a valve stem

seal tool (Fig. 28).

INSTALLATION

(1) Install valve seal/valve spring seat assembly

(Fig. 29) as outlined in the valve installation proce-

dure in this section.

(2) Install valve spring and retainer. Using Special

Tool MD998772A compress valve springs only enough

to install locks. Correct alignment of tool is necessary

to avoid nicking valve stems (air pressure required),

piston at TDC.

(3) Remove air hose and install spark plugs.

(4) Install camshafts as previously outlined in this

section.

(5) Install valve cover as previously outlined in

this section.

Fig. 28 Valve Stem Oil Seal ToolFig. 29 Valve Stem Seal and Valve Spring Seat

Assemblies

9 - 70 2.0L DOHC ENGINEPL

REMOVAL AND INSTALLATION (Continued)

Page 785 of 1200

REMOVAL

(1) Perform fuel system pressure release procedure

before attempting any repairs.Refer to Group 14,

Fuel System.

(2) Disconnect negative battery cable. Drain cool-

ing system. Refer to Group 7, Cooling System.

(3) Remove air cleaner duct and air cleaner, dis-

connect all vacuum lines, electrical wiring and fuel

line from fuel rail and throttle body.

(4) Remove throttle linkage.

(5) Remove accessory drive belts. Refer to Group 7,

Cooling System for procedure.

(6) Remove power brake vacuum hose from intake

manifold.

(7) Raise vehicle and remove exhaust pipe from

manifold.

(8) Remove power steering pump assembly and set

aside.

(9) Disconnect coil pack wiring connector and

remove coil pack from engine.

(10) Remove cam sensor and fuel injectors wiring

connectors.

(11) Remove timing belt, timing belt tensioner, and

camshaft sprocket. Refer to procedure outlined in

this section.

(12) Remove inner timing belt cover.

(13) Remove cylinder head cover.

(14) Remove camshaft and cam follower assem-

blies. Refer to Camshaft Service for removal proce-

dure outlined in this section.

(15) Remove cylinder head bolts.

CAUTION: Use only a plastic scraper to remove

gasket material on the aluminum head sealing sur-

faces to prevent damage to cylinder head.

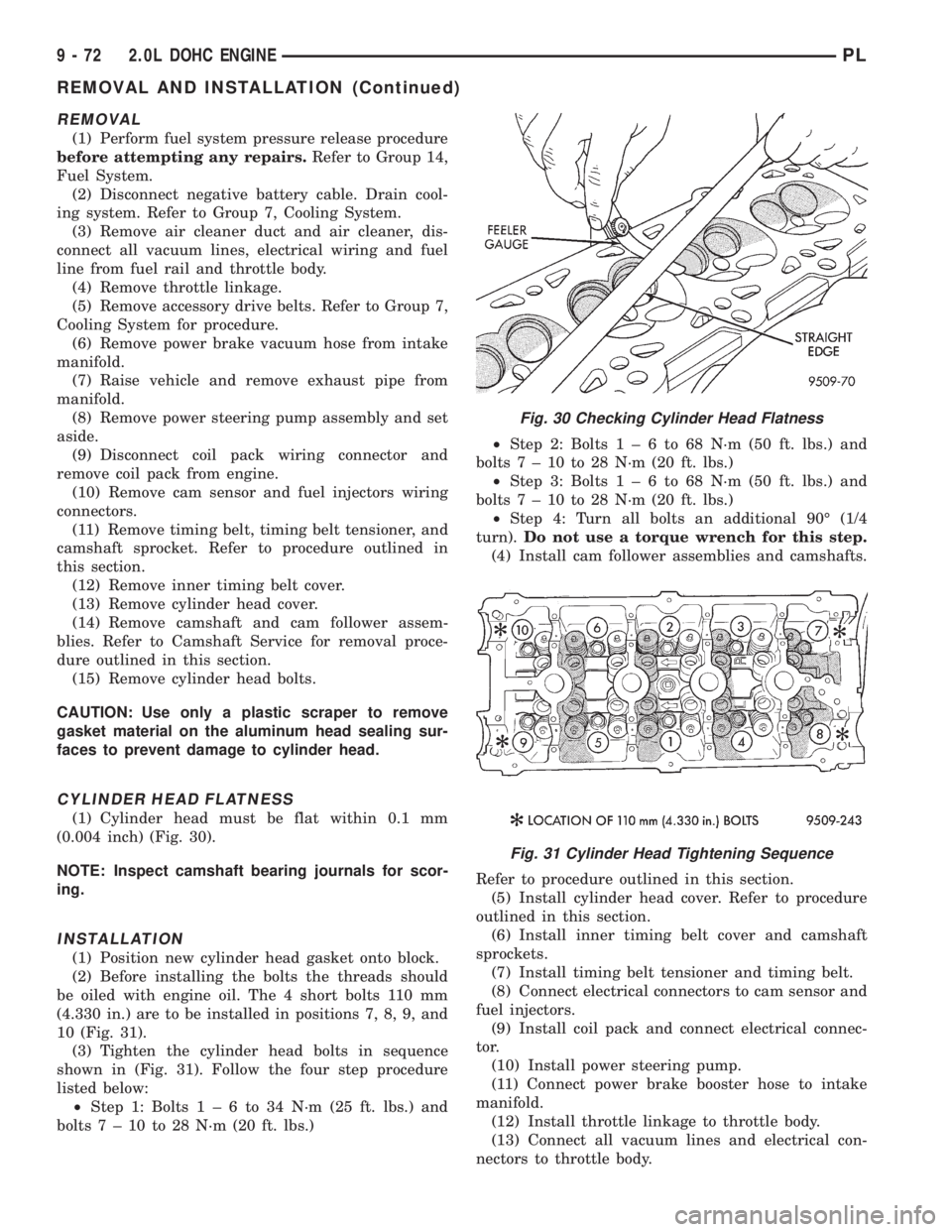

CYLINDER HEAD FLATNESS

(1) Cylinder head must be flat within 0.1 mm

(0.004 inch) (Fig. 30).

NOTE: Inspect camshaft bearing journals for scor-

ing.

INSTALLATION

(1) Position new cylinder head gasket onto block.

(2) Before installing the bolts the threads should

be oiled with engine oil. The 4 short bolts 110 mm

(4.330 in.) are to be installed in positions 7, 8, 9, and

10 (Fig. 31).

(3) Tighten the cylinder head bolts in sequence

shown in (Fig. 31). Follow the four step procedure

listed below:

²Step 1: Bolts1±6to34N´m(25ft.lbs.) and

bolts7±10to28N´m(20ft.lbs.)²Step 2: Bolts1±6to68N´m(50ft.lbs.) and

bolts7±10to28N´m(20ft.lbs.)

²Step 3: Bolts1±6to68N´m(50ft.lbs.) and

bolts7±10to28N´m(20ft.lbs.)

²Step 4: Turn all bolts an additional 90É (1/4

turn).Do not use a torque wrench for this step.

(4) Install cam follower assemblies and camshafts.

Refer to procedure outlined in this section.

(5) Install cylinder head cover. Refer to procedure

outlined in this section.

(6) Install inner timing belt cover and camshaft

sprockets.

(7) Install timing belt tensioner and timing belt.

(8) Connect electrical connectors to cam sensor and

fuel injectors.

(9) Install coil pack and connect electrical connec-

tor.

(10) Install power steering pump.

(11) Connect power brake booster hose to intake

manifold.

(12) Install throttle linkage to throttle body.

(13) Connect all vacuum lines and electrical con-

nectors to throttle body.

Fig. 30 Checking Cylinder Head Flatness

Fig. 31 Cylinder Head Tightening Sequence

9 - 72 2.0L DOHC ENGINEPL

REMOVAL AND INSTALLATION (Continued)

Page 789 of 1200

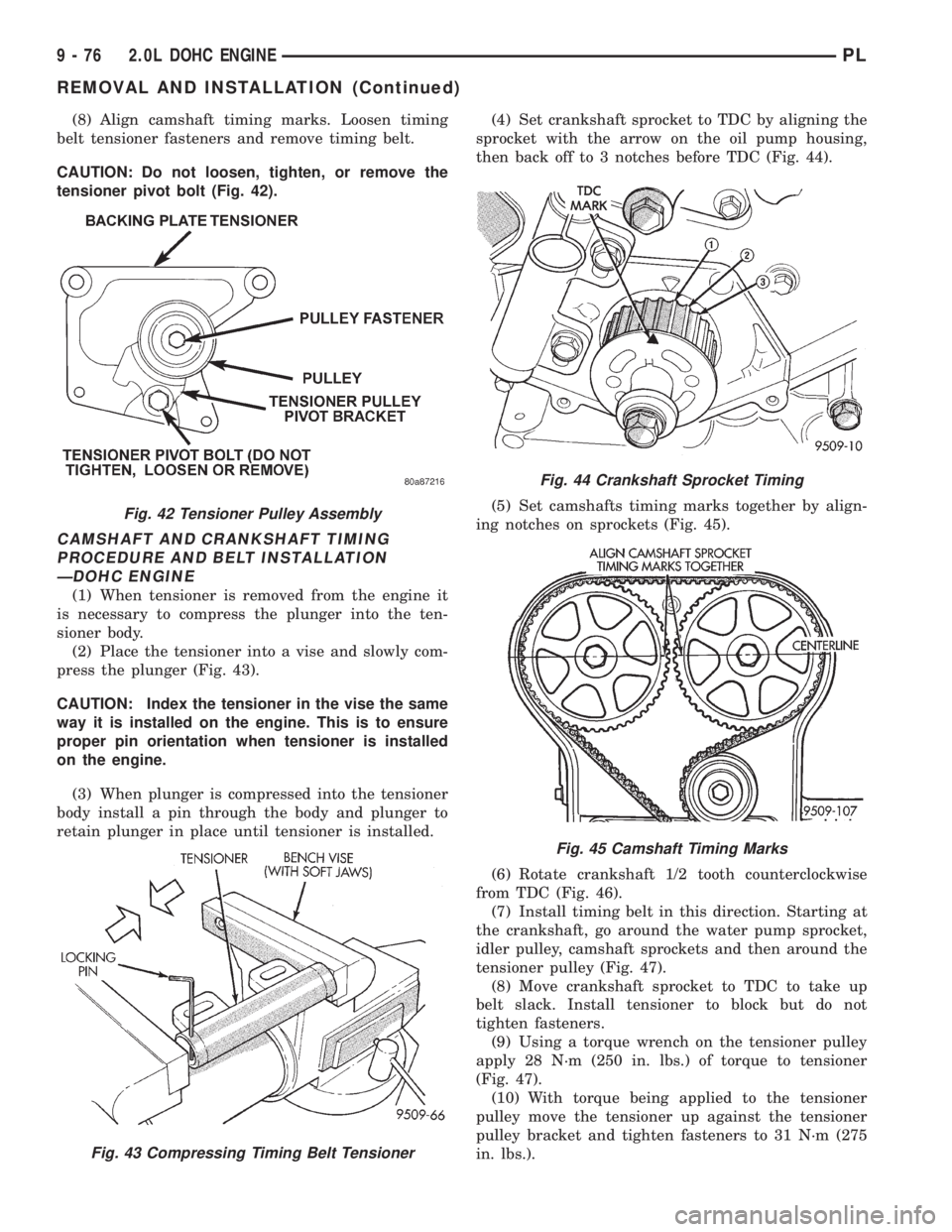

(8) Align camshaft timing marks. Loosen timing

belt tensioner fasteners and remove timing belt.

CAUTION: Do not loosen, tighten, or remove the

tensioner pivot bolt (Fig. 42).

CAMSHAFT AND CRANKSHAFT TIMING

PROCEDURE AND BELT INSTALLATION

ÐDOHC ENGINE

(1) When tensioner is removed from the engine it

is necessary to compress the plunger into the ten-

sioner body.

(2) Place the tensioner into a vise and slowly com-

press the plunger (Fig. 43).

CAUTION: Index the tensioner in the vise the same

way it is installed on the engine. This is to ensure

proper pin orientation when tensioner is installed

on the engine.

(3) When plunger is compressed into the tensioner

body install a pin through the body and plunger to

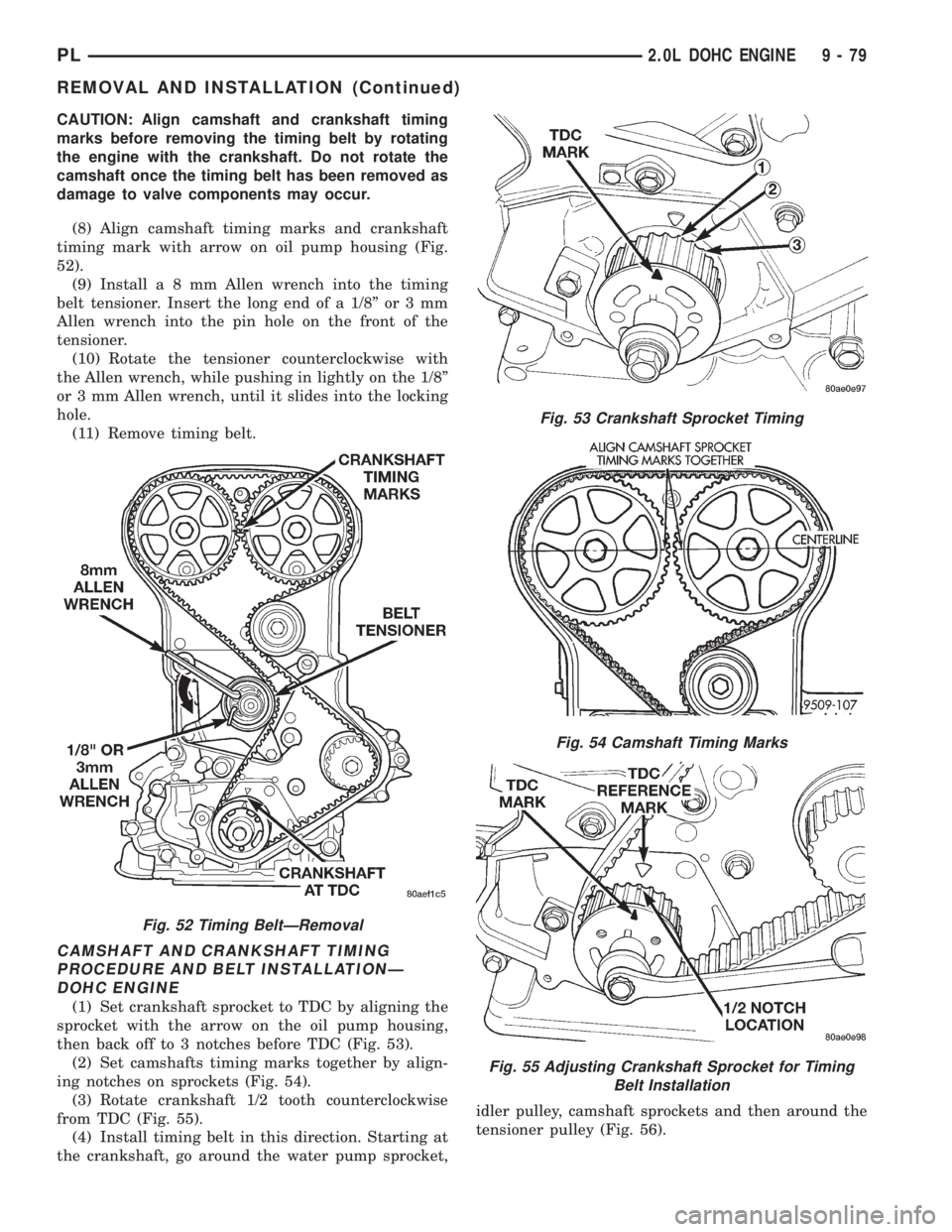

retain plunger in place until tensioner is installed.(4) Set crankshaft sprocket to TDC by aligning the

sprocket with the arrow on the oil pump housing,

then back off to 3 notches before TDC (Fig. 44).

(5) Set camshafts timing marks together by align-

ing notches on sprockets (Fig. 45).

(6) Rotate crankshaft 1/2 tooth counterclockwise

from TDC (Fig. 46).

(7) Install timing belt in this direction. Starting at

the crankshaft, go around the water pump sprocket,

idler pulley, camshaft sprockets and then around the

tensioner pulley (Fig. 47).

(8) Move crankshaft sprocket to TDC to take up

belt slack. Install tensioner to block but do not

tighten fasteners.

(9) Using a torque wrench on the tensioner pulley

apply 28 N´m (250 in. lbs.) of torque to tensioner

(Fig. 47).

(10) With torque being applied to the tensioner

pulley move the tensioner up against the tensioner

pulley bracket and tighten fasteners to 31 N´m (275

in. lbs.).

Fig. 42 Tensioner Pulley Assembly

Fig. 43 Compressing Timing Belt Tensioner

Fig. 44 Crankshaft Sprocket Timing

Fig. 45 Camshaft Timing Marks

9 - 76 2.0L DOHC ENGINEPL

REMOVAL AND INSTALLATION (Continued)

Page 792 of 1200

CAUTION: Align camshaft and crankshaft timing

marks before removing the timing belt by rotating

the engine with the crankshaft. Do not rotate the

camshaft once the timing belt has been removed as

damage to valve components may occur.

(8) Align camshaft timing marks and crankshaft

timing mark with arrow on oil pump housing (Fig.

52).

(9) Installa8mmAllen wrench into the timing

belt tensioner. Insert the long end of a 1/8º or 3 mm

Allen wrench into the pin hole on the front of the

tensioner.

(10) Rotate the tensioner counterclockwise with

the Allen wrench, while pushing in lightly on the 1/8º

or 3 mm Allen wrench, until it slides into the locking

hole.

(11) Remove timing belt.

CAMSHAFT AND CRANKSHAFT TIMING

PROCEDURE AND BELT INSTALLATIONÐ

DOHC ENGINE

(1) Set crankshaft sprocket to TDC by aligning the

sprocket with the arrow on the oil pump housing,

then back off to 3 notches before TDC (Fig. 53).

(2) Set camshafts timing marks together by align-

ing notches on sprockets (Fig. 54).

(3) Rotate crankshaft 1/2 tooth counterclockwise

from TDC (Fig. 55).

(4) Install timing belt in this direction. Starting at

the crankshaft, go around the water pump sprocket,idler pulley, camshaft sprockets and then around the

tensioner pulley (Fig. 56).

Fig. 52 Timing BeltÐRemoval

Fig. 53 Crankshaft Sprocket Timing

Fig. 54 Camshaft Timing Marks

Fig. 55 Adjusting Crankshaft Sprocket for Timing

Belt Installation

PL2.0L DOHC ENGINE 9 - 79

REMOVAL AND INSTALLATION (Continued)

Page 794 of 1200

INSTALLATION

(1) Install timing belt tensioner assembly. Tighten

attaching bolts to 28 N´m (250 in. lbs.).

(2) Install timing belt. Refer to procedure outlined

in this section.

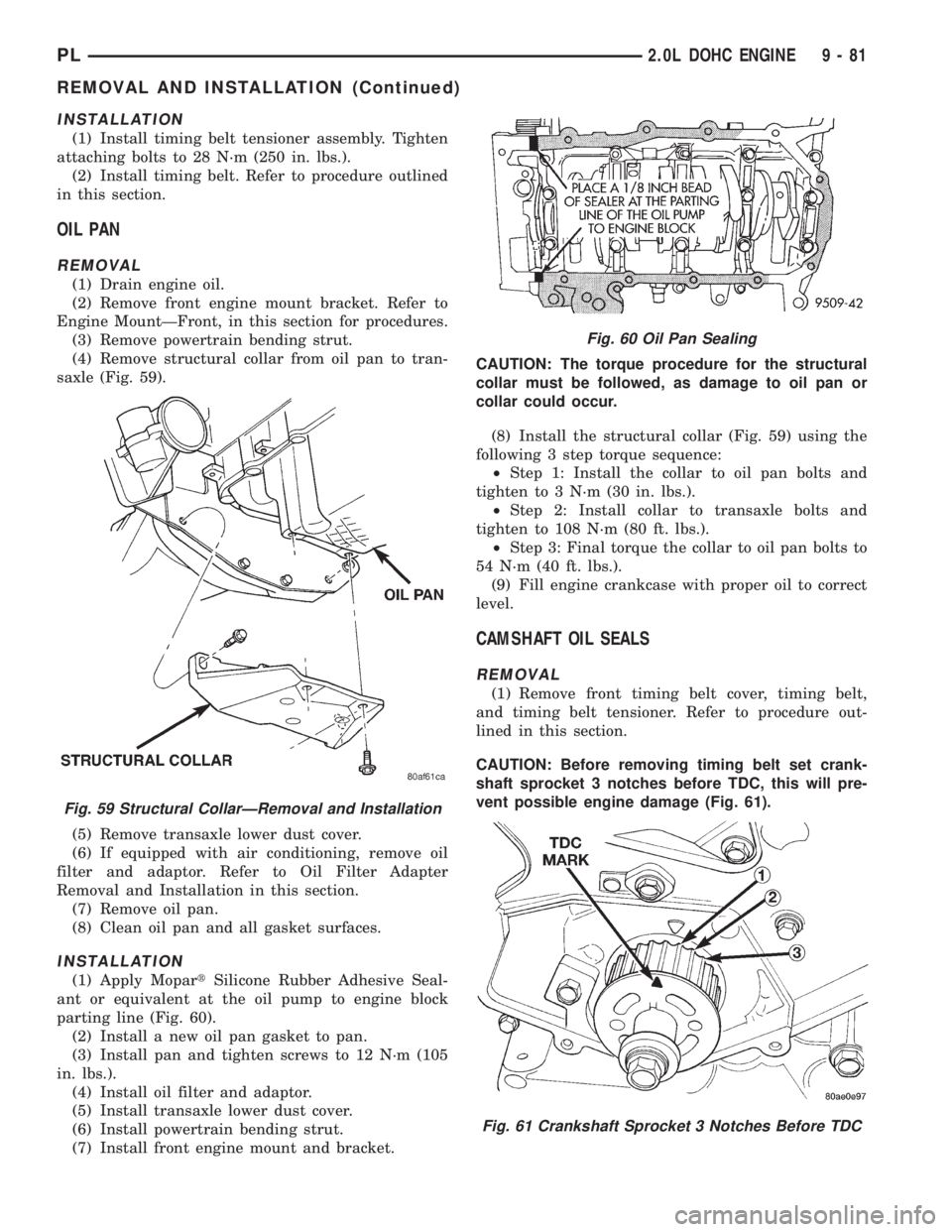

OIL PAN

REMOVAL

(1) Drain engine oil.

(2) Remove front engine mount bracket. Refer to

Engine MountÐFront, in this section for procedures.

(3) Remove powertrain bending strut.

(4) Remove structural collar from oil pan to tran-

saxle (Fig. 59).

(5) Remove transaxle lower dust cover.

(6) If equipped with air conditioning, remove oil

filter and adaptor. Refer to Oil Filter Adapter

Removal and Installation in this section.

(7) Remove oil pan.

(8) Clean oil pan and all gasket surfaces.

INSTALLATION

(1) Apply MopartSilicone Rubber Adhesive Seal-

ant or equivalent at the oil pump to engine block

parting line (Fig. 60).

(2) Install a new oil pan gasket to pan.

(3) Install pan and tighten screws to 12 N´m (105

in. lbs.).

(4) Install oil filter and adaptor.

(5) Install transaxle lower dust cover.

(6) Install powertrain bending strut.

(7) Install front engine mount and bracket.CAUTION: The torque procedure for the structural

collar must be followed, as damage to oil pan or

collar could occur.

(8) Install the structural collar (Fig. 59) using the

following 3 step torque sequence:

²Step 1: Install the collar to oil pan bolts and

tighten to 3 N´m (30 in. lbs.).

²Step 2: Install collar to transaxle bolts and

tighten to 108 N´m (80 ft. lbs.).

²Step 3: Final torque the collar to oil pan bolts to

54 N´m (40 ft. lbs.).

(9) Fill engine crankcase with proper oil to correct

level.

CAMSHAFT OIL SEALS

REMOVAL

(1) Remove front timing belt cover, timing belt,

and timing belt tensioner. Refer to procedure out-

lined in this section.

CAUTION: Before removing timing belt set crank-

shaft sprocket 3 notches before TDC, this will pre-

vent possible engine damage (Fig. 61).

Fig. 59 Structural CollarÐRemoval and Installation

Fig. 60 Oil Pan Sealing

Fig. 61 Crankshaft Sprocket 3 Notches Before TDC

PL2.0L DOHC ENGINE 9 - 81

REMOVAL AND INSTALLATION (Continued)

Page 797 of 1200

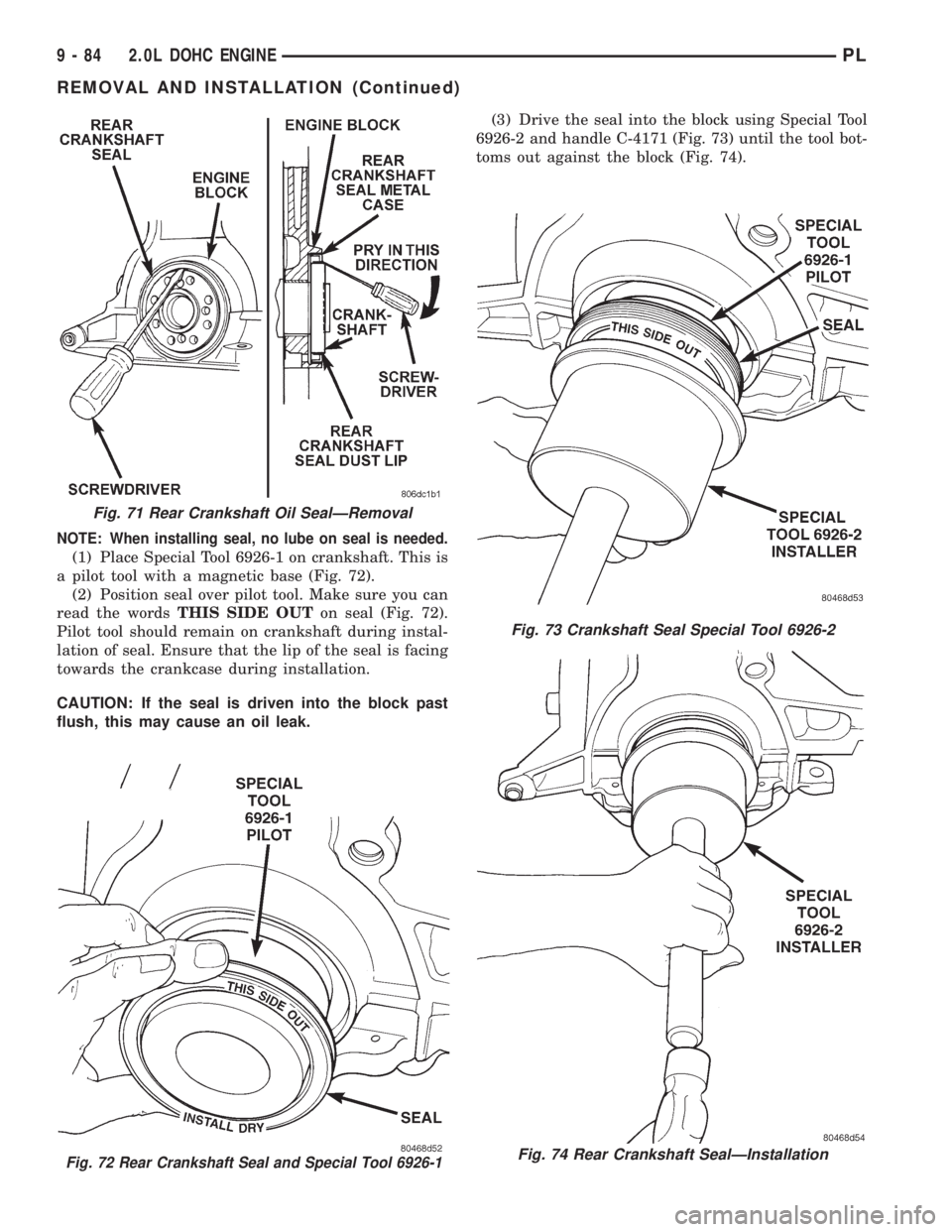

NOTE: When installing seal, no lube on seal is needed.

(1) Place Special Tool 6926-1 on crankshaft. This is

a pilot tool with a magnetic base (Fig. 72).

(2) Position seal over pilot tool. Make sure you can

read the wordsTHIS SIDE OUTon seal (Fig. 72).

Pilot tool should remain on crankshaft during instal-

lation of seal. Ensure that the lip of the seal is facing

towards the crankcase during installation.

CAUTION: If the seal is driven into the block past

flush, this may cause an oil leak.(3) Drive the seal into the block using Special Tool

6926-2 and handle C-4171 (Fig. 73) until the tool bot-

toms out against the block (Fig. 74).

Fig. 71 Rear Crankshaft Oil SealÐRemoval

Fig. 72 Rear Crankshaft Seal and Special Tool 6926-1

Fig. 73 Crankshaft Seal Special Tool 6926-2

Fig. 74 Rear Crankshaft SealÐInstallation

9 - 84 2.0L DOHC ENGINEPL

REMOVAL AND INSTALLATION (Continued)

Page 798 of 1200

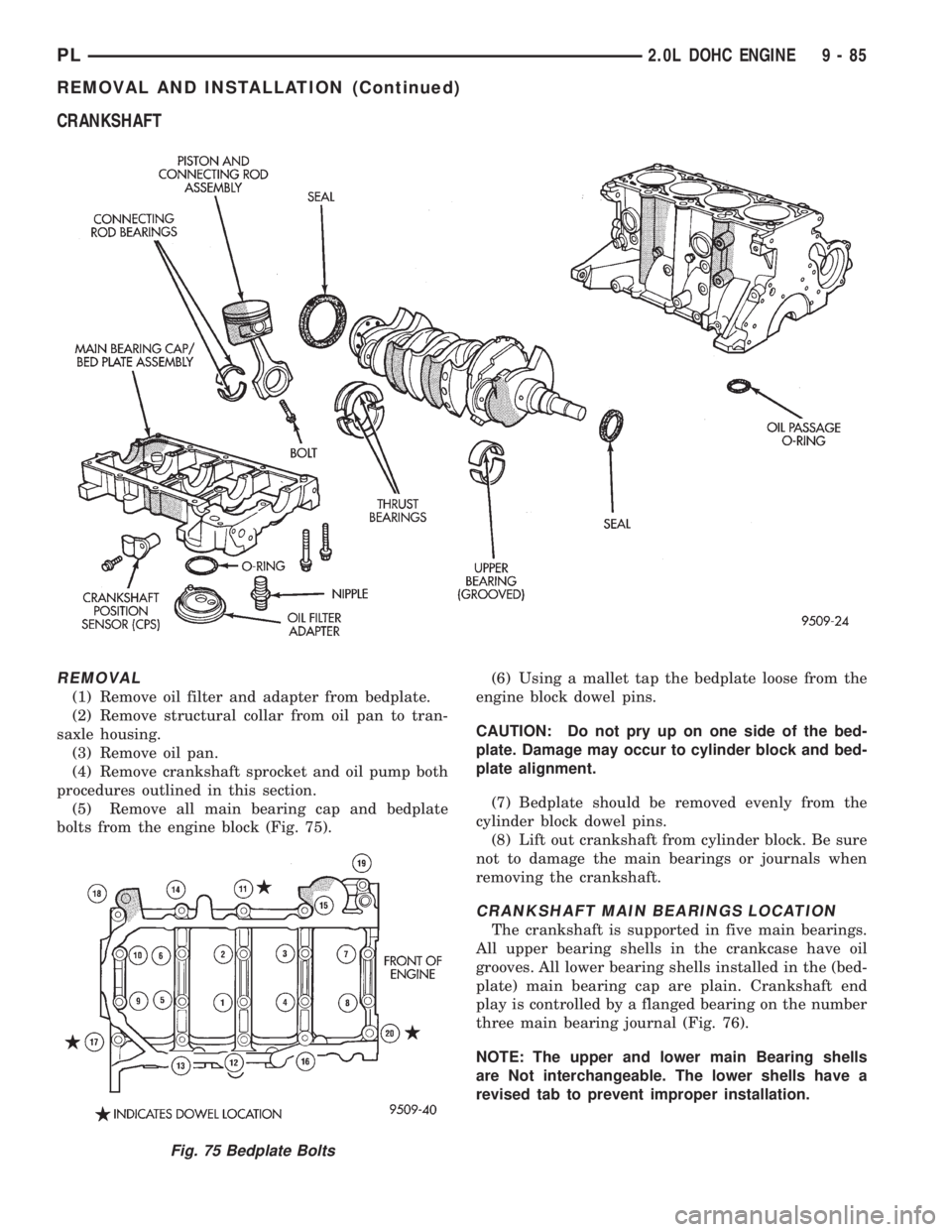

CRANKSHAFT

REMOVAL

(1) Remove oil filter and adapter from bedplate.

(2) Remove structural collar from oil pan to tran-

saxle housing.

(3) Remove oil pan.

(4) Remove crankshaft sprocket and oil pump both

procedures outlined in this section.

(5) Remove all main bearing cap and bedplate

bolts from the engine block (Fig. 75).(6) Using a mallet tap the bedplate loose from the

engine block dowel pins.

CAUTION: Do not pry up on one side of the bed-

plate. Damage may occur to cylinder block and bed-

plate alignment.

(7) Bedplate should be removed evenly from the

cylinder block dowel pins.

(8) Lift out crankshaft from cylinder block. Be sure

not to damage the main bearings or journals when

removing the crankshaft.

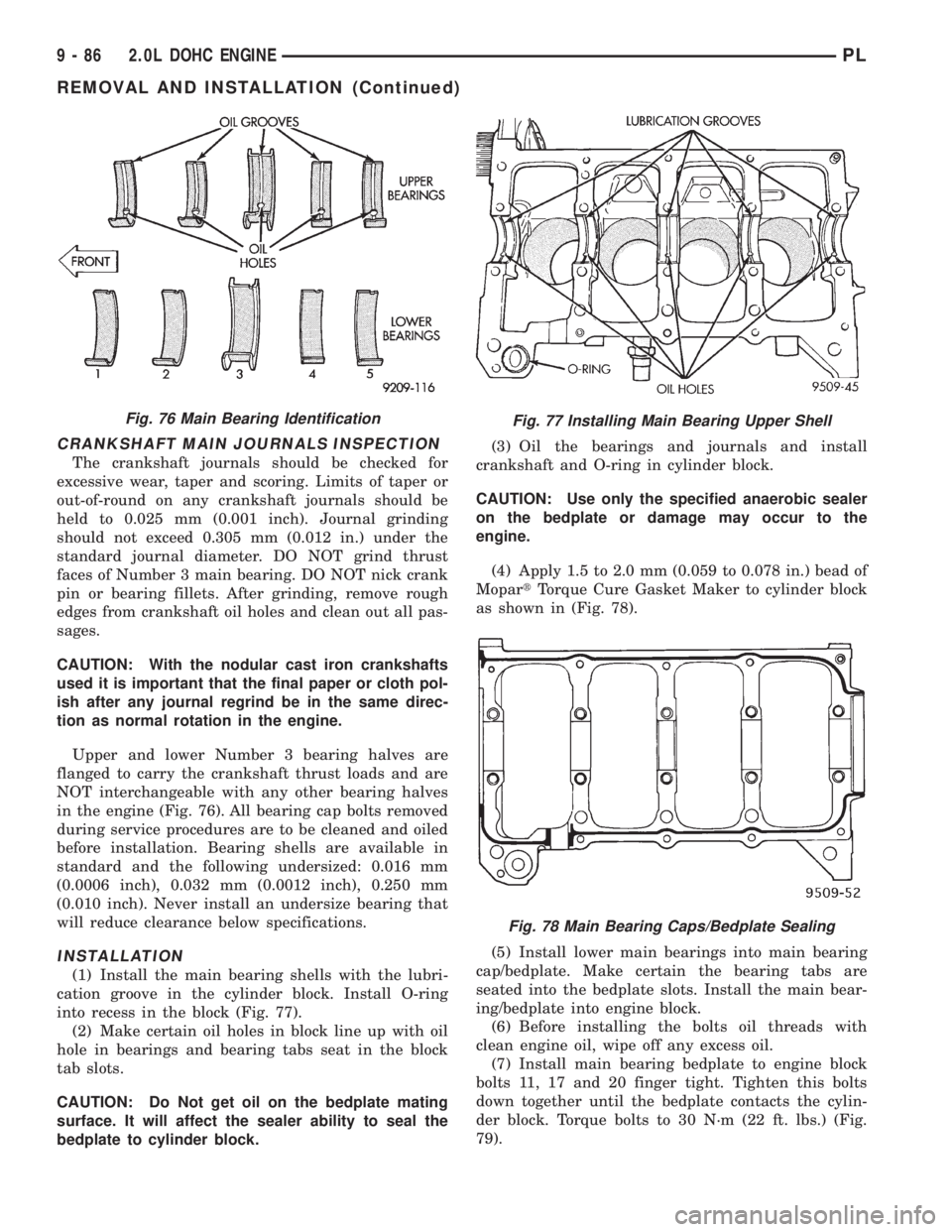

CRANKSHAFT MAIN BEARINGS LOCATION

The crankshaft is supported in five main bearings.

All upper bearing shells in the crankcase have oil

grooves. All lower bearing shells installed in the (bed-

plate) main bearing cap are plain. Crankshaft end

play is controlled by a flanged bearing on the number

three main bearing journal (Fig. 76).

NOTE: The upper and lower main Bearing shells

are Not interchangeable. The lower shells have a

revised tab to prevent improper installation.

Fig. 75 Bedplate Bolts

PL2.0L DOHC ENGINE 9 - 85

REMOVAL AND INSTALLATION (Continued)

Page 799 of 1200

CRANKSHAFT MAIN JOURNALS INSPECTION

The crankshaft journals should be checked for

excessive wear, taper and scoring. Limits of taper or

out-of-round on any crankshaft journals should be

held to 0.025 mm (0.001 inch). Journal grinding

should not exceed 0.305 mm (0.012 in.) under the

standard journal diameter. DO NOT grind thrust

faces of Number 3 main bearing. DO NOT nick crank

pin or bearing fillets. After grinding, remove rough

edges from crankshaft oil holes and clean out all pas-

sages.

CAUTION: With the nodular cast iron crankshafts

used it is important that the final paper or cloth pol-

ish after any journal regrind be in the same direc-

tion as normal rotation in the engine.

Upper and lower Number 3 bearing halves are

flanged to carry the crankshaft thrust loads and are

NOT interchangeable with any other bearing halves

in the engine (Fig. 76). All bearing cap bolts removed

during service procedures are to be cleaned and oiled

before installation. Bearing shells are available in

standard and the following undersized: 0.016 mm

(0.0006 inch), 0.032 mm (0.0012 inch), 0.250 mm

(0.010 inch). Never install an undersize bearing that

will reduce clearance below specifications.

INSTALLATION

(1) Install the main bearing shells with the lubri-

cation groove in the cylinder block. Install O-ring

into recess in the block (Fig. 77).

(2) Make certain oil holes in block line up with oil

hole in bearings and bearing tabs seat in the block

tab slots.

CAUTION: Do Not get oil on the bedplate mating

surface. It will affect the sealer ability to seal the

bedplate to cylinder block.(3) Oil the bearings and journals and install

crankshaft and O-ring in cylinder block.

CAUTION: Use only the specified anaerobic sealer

on the bedplate or damage may occur to the

engine.

(4) Apply 1.5 to 2.0 mm (0.059 to 0.078 in.) bead of

MopartTorque Cure Gasket Maker to cylinder block

as shown in (Fig. 78).

(5) Install lower main bearings into main bearing

cap/bedplate. Make certain the bearing tabs are

seated into the bedplate slots. Install the main bear-

ing/bedplate into engine block.

(6) Before installing the bolts oil threads with

clean engine oil, wipe off any excess oil.

(7) Install main bearing bedplate to engine block

bolts 11, 17 and 20 finger tight. Tighten this bolts

down together until the bedplate contacts the cylin-

der block. Torque bolts to 30 N´m (22 ft. lbs.) (Fig.

79).

Fig. 76 Main Bearing IdentificationFig. 77 Installing Main Bearing Upper Shell

Fig. 78 Main Bearing Caps/Bedplate Sealing

9 - 86 2.0L DOHC ENGINEPL

REMOVAL AND INSTALLATION (Continued)