lock DODGE NEON 1999 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 941 of 1200

(13) Remove steering wheel assembly from steer-

ing column shaft using Puller, Special Tool C-3428-B

or equivalent.

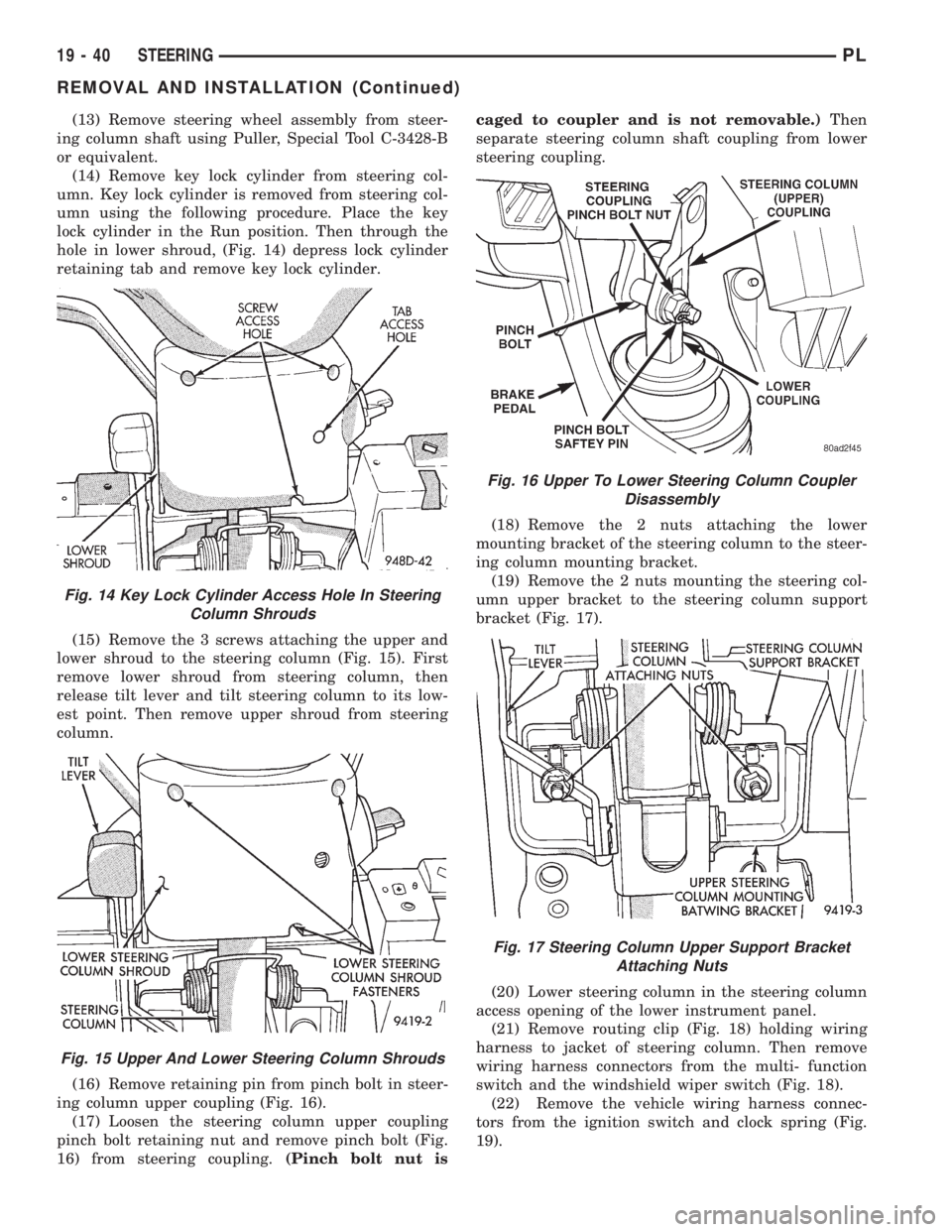

(14) Remove key lock cylinder from steering col-

umn. Key lock cylinder is removed from steering col-

umn using the following procedure. Place the key

lock cylinder in the Run position. Then through the

hole in lower shroud, (Fig. 14) depress lock cylinder

retaining tab and remove key lock cylinder.

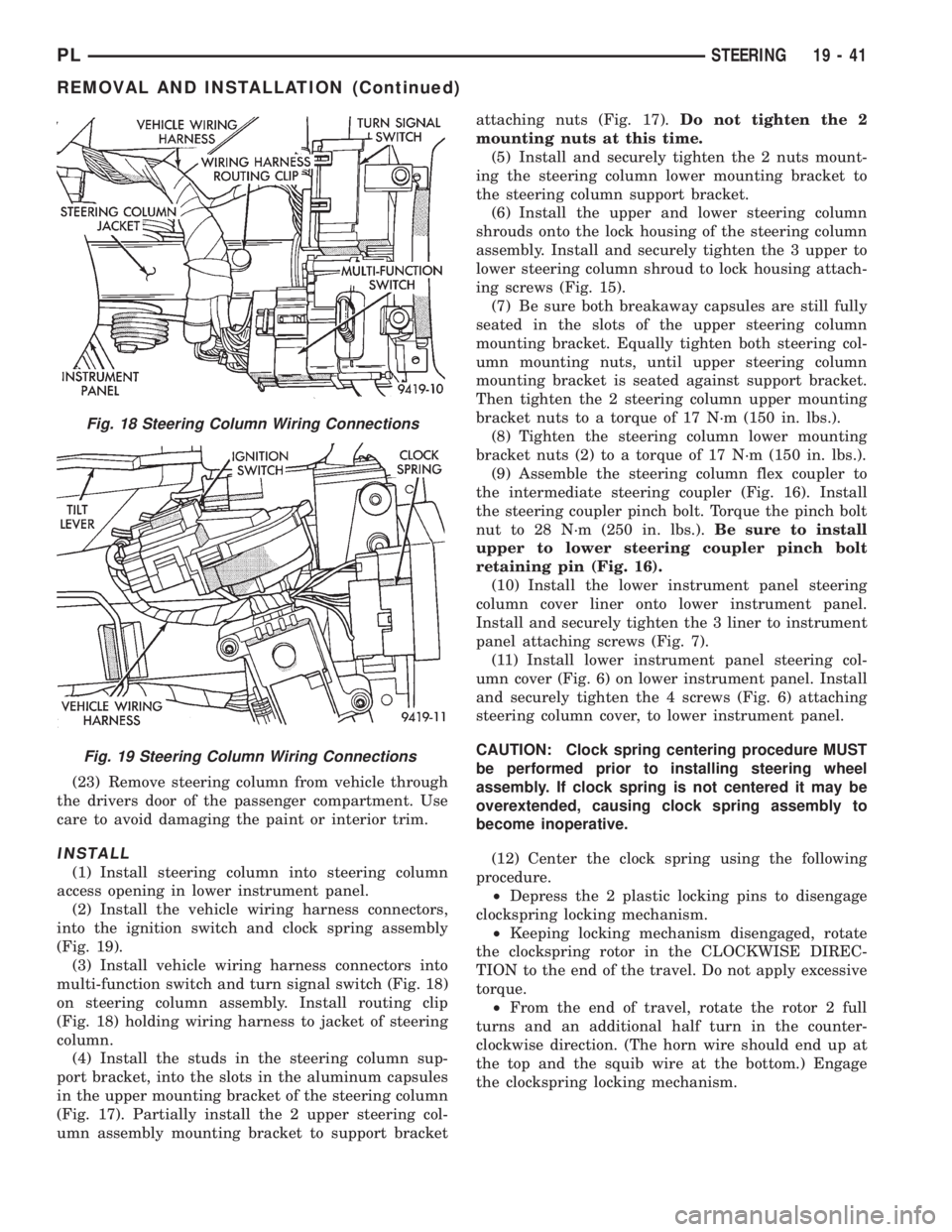

(15) Remove the 3 screws attaching the upper and

lower shroud to the steering column (Fig. 15). First

remove lower shroud from steering column, then

release tilt lever and tilt steering column to its low-

est point. Then remove upper shroud from steering

column.

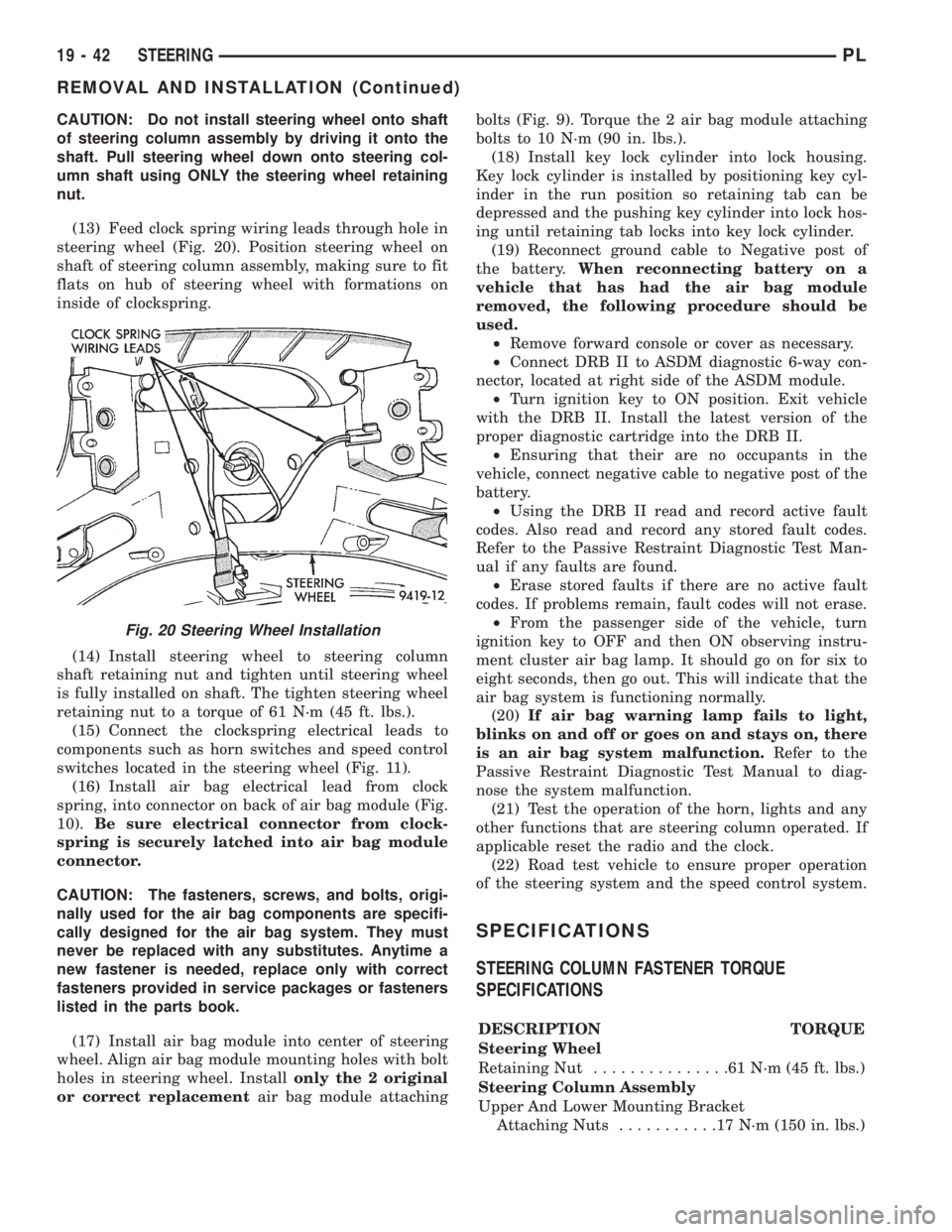

(16) Remove retaining pin from pinch bolt in steer-

ing column upper coupling (Fig. 16).

(17) Loosen the steering column upper coupling

pinch bolt retaining nut and remove pinch bolt (Fig.

16) from steering coupling.(Pinch bolt nut iscaged to coupler and is not removable.)Then

separate steering column shaft coupling from lower

steering coupling.

(18) Remove the 2 nuts attaching the lower

mounting bracket of the steering column to the steer-

ing column mounting bracket.

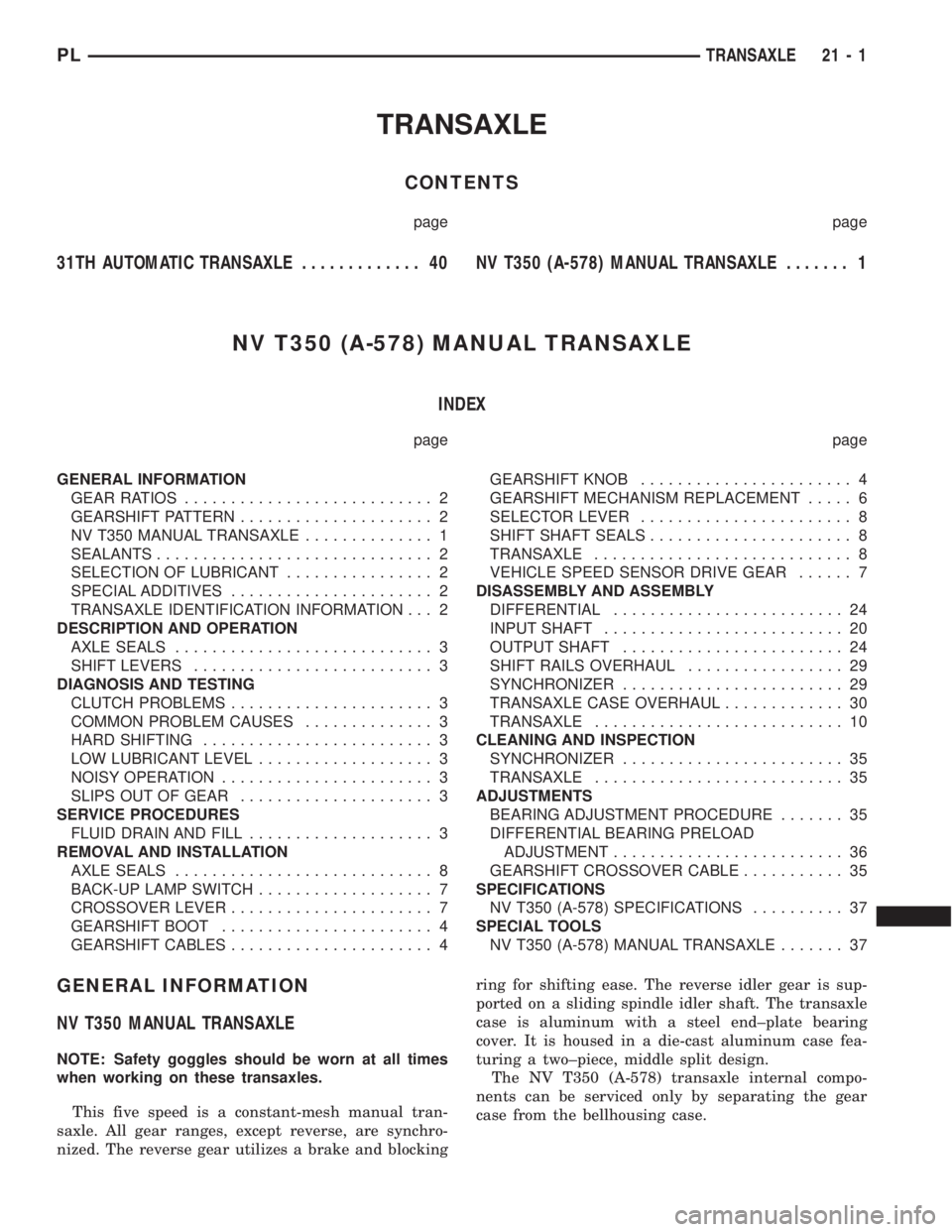

(19) Remove the 2 nuts mounting the steering col-

umn upper bracket to the steering column support

bracket (Fig. 17).

(20) Lower steering column in the steering column

access opening of the lower instrument panel.

(21) Remove routing clip (Fig. 18) holding wiring

harness to jacket of steering column. Then remove

wiring harness connectors from the multi- function

switch and the windshield wiper switch (Fig. 18).

(22) Remove the vehicle wiring harness connec-

tors from the ignition switch and clock spring (Fig.

19).

Fig. 14 Key Lock Cylinder Access Hole In Steering

Column Shrouds

Fig. 15 Upper And Lower Steering Column Shrouds

Fig. 16 Upper To Lower Steering Column Coupler

Disassembly

Fig. 17 Steering Column Upper Support Bracket

Attaching Nuts

19 - 40 STEERINGPL

REMOVAL AND INSTALLATION (Continued)

Page 942 of 1200

(23) Remove steering column from vehicle through

the drivers door of the passenger compartment. Use

care to avoid damaging the paint or interior trim.

INSTALL

(1) Install steering column into steering column

access opening in lower instrument panel.

(2) Install the vehicle wiring harness connectors,

into the ignition switch and clock spring assembly

(Fig. 19).

(3) Install vehicle wiring harness connectors into

multi-function switch and turn signal switch (Fig. 18)

on steering column assembly. Install routing clip

(Fig. 18) holding wiring harness to jacket of steering

column.

(4) Install the studs in the steering column sup-

port bracket, into the slots in the aluminum capsules

in the upper mounting bracket of the steering column

(Fig. 17). Partially install the 2 upper steering col-

umn assembly mounting bracket to support bracketattaching nuts (Fig. 17).Do not tighten the 2

mounting nuts at this time.

(5) Install and securely tighten the 2 nuts mount-

ing the steering column lower mounting bracket to

the steering column support bracket.

(6) Install the upper and lower steering column

shrouds onto the lock housing of the steering column

assembly. Install and securely tighten the 3 upper to

lower steering column shroud to lock housing attach-

ing screws (Fig. 15).

(7) Be sure both breakaway capsules are still fully

seated in the slots of the upper steering column

mounting bracket. Equally tighten both steering col-

umn mounting nuts, until upper steering column

mounting bracket is seated against support bracket.

Then tighten the 2 steering column upper mounting

bracket nuts to a torque of 17 N´m (150 in. lbs.).

(8) Tighten the steering column lower mounting

bracket nuts (2) to a torque of 17 N´m (150 in. lbs.).

(9) Assemble the steering column flex coupler to

the intermediate steering coupler (Fig. 16). Install

the steering coupler pinch bolt. Torque the pinch bolt

nut to 28 N´m (250 in. lbs.).Be sure to install

upper to lower steering coupler pinch bolt

retaining pin (Fig. 16).

(10) Install the lower instrument panel steering

column cover liner onto lower instrument panel.

Install and securely tighten the 3 liner to instrument

panel attaching screws (Fig. 7).

(11) Install lower instrument panel steering col-

umn cover (Fig. 6) on lower instrument panel. Install

and securely tighten the 4 screws (Fig. 6) attaching

steering column cover, to lower instrument panel.

CAUTION: Clock spring centering procedure MUST

be performed prior to installing steering wheel

assembly. If clock spring is not centered it may be

overextended, causing clock spring assembly to

become inoperative.

(12) Center the clock spring using the following

procedure.

²Depress the 2 plastic locking pins to disengage

clockspring locking mechanism.

²Keeping locking mechanism disengaged, rotate

the clockspring rotor in the CLOCKWISE DIREC-

TION to the end of the travel. Do not apply excessive

torque.

²From the end of travel, rotate the rotor 2 full

turns and an additional half turn in the counter-

clockwise direction. (The horn wire should end up at

the top and the squib wire at the bottom.) Engage

the clockspring locking mechanism.

Fig. 18 Steering Column Wiring Connections

Fig. 19 Steering Column Wiring Connections

PLSTEERING 19 - 41

REMOVAL AND INSTALLATION (Continued)

Page 943 of 1200

CAUTION: Do not install steering wheel onto shaft

of steering column assembly by driving it onto the

shaft. Pull steering wheel down onto steering col-

umn shaft using ONLY the steering wheel retaining

nut.

(13) Feed clock spring wiring leads through hole in

steering wheel (Fig. 20). Position steering wheel on

shaft of steering column assembly, making sure to fit

flats on hub of steering wheel with formations on

inside of clockspring.

(14) Install steering wheel to steering column

shaft retaining nut and tighten until steering wheel

is fully installed on shaft. The tighten steering wheel

retaining nut to a torque of 61 N´m (45 ft. lbs.).

(15) Connect the clockspring electrical leads to

components such as horn switches and speed control

switches located in the steering wheel (Fig. 11).

(16) Install air bag electrical lead from clock

spring, into connector on back of air bag module (Fig.

10).Be sure electrical connector from clock-

spring is securely latched into air bag module

connector.

CAUTION: The fasteners, screws, and bolts, origi-

nally used for the air bag components are specifi-

cally designed for the air bag system. They must

never be replaced with any substitutes. Anytime a

new fastener is needed, replace only with correct

fasteners provided in service packages or fasteners

listed in the parts book.

(17) Install air bag module into center of steering

wheel. Align air bag module mounting holes with bolt

holes in steering wheel. Installonly the 2 original

or correct replacementair bag module attachingbolts (Fig. 9). Torque the 2 air bag module attaching

bolts to 10 N´m (90 in. lbs.).

(18) Install key lock cylinder into lock housing.

Key lock cylinder is installed by positioning key cyl-

inder in the run position so retaining tab can be

depressed and the pushing key cylinder into lock hos-

ing until retaining tab locks into key lock cylinder.

(19) Reconnect ground cable to Negative post of

the battery.When reconnecting battery on a

vehicle that has had the air bag module

removed, the following procedure should be

used.

²Remove forward console or cover as necessary.

²Connect DRB II to ASDM diagnostic 6-way con-

nector, located at right side of the ASDM module.

²Turn ignition key to ON position. Exit vehicle

with the DRB II. Install the latest version of the

proper diagnostic cartridge into the DRB II.

²Ensuring that their are no occupants in the

vehicle, connect negative cable to negative post of the

battery.

²Using the DRB II read and record active fault

codes. Also read and record any stored fault codes.

Refer to the Passive Restraint Diagnostic Test Man-

ual if any faults are found.

²Erase stored faults if there are no active fault

codes. If problems remain, fault codes will not erase.

²From the passenger side of the vehicle, turn

ignition key to OFF and then ON observing instru-

ment cluster air bag lamp. It should go on for six to

eight seconds, then go out. This will indicate that the

air bag system is functioning normally.

(20)If air bag warning lamp fails to light,

blinks on and off or goes on and stays on, there

is an air bag system malfunction.Refer to the

Passive Restraint Diagnostic Test Manual to diag-

nose the system malfunction.

(21) Test the operation of the horn, lights and any

other functions that are steering column operated. If

applicable reset the radio and the clock.

(22) Road test vehicle to ensure proper operation

of the steering system and the speed control system.

SPECIFICATIONS

STEERING COLUMN FASTENER TORQUE

SPECIFICATIONS

DESCRIPTION TORQUE

Steering Wheel

Retaining Nut...............61N´m(45ft.lbs.)

Steering Column Assembly

Upper And Lower Mounting Bracket

Attaching Nuts...........17N´m(150 in. lbs.)

Fig. 20 Steering Wheel Installation

19 - 42 STEERINGPL

REMOVAL AND INSTALLATION (Continued)

Page 944 of 1200

TRANSAXLE

CONTENTS

page page

31TH AUTOMATIC TRANSAXLE............. 40 NVT350 (A-578) MANUAL TRANSAXLE....... 1

NV T350 (A-578) MANUAL TRANSAXLE

INDEX

page page

GENERAL INFORMATION

GEAR RATIOS........................... 2

GEARSHIFT PATTERN..................... 2

NV T350 MANUAL TRANSAXLE.............. 1

SEALANTS.............................. 2

SELECTION OF LUBRICANT................ 2

SPECIAL ADDITIVES...................... 2

TRANSAXLE IDENTIFICATION INFORMATION . . . 2

DESCRIPTION AND OPERATION

AXLE SEALS............................ 3

SHIFT LEVERS.......................... 3

DIAGNOSIS AND TESTING

CLUTCH PROBLEMS...................... 3

COMMON PROBLEM CAUSES.............. 3

HARD SHIFTING......................... 3

LOW LUBRICANT LEVEL................... 3

NOISY OPERATION....................... 3

SLIPS OUT OF GEAR..................... 3

SERVICE PROCEDURES

FLUID DRAIN AND FILL.................... 3

REMOVAL AND INSTALLATION

AXLE SEALS............................ 8

BACK-UP LAMP SWITCH................... 7

CROSSOVER LEVER...................... 7

GEARSHIFT BOOT....................... 4

GEARSHIFT CABLES...................... 4GEARSHIFT KNOB....................... 4

GEARSHIFT MECHANISM REPLACEMENT..... 6

SELECTOR LEVER....................... 8

SHIFT SHAFT SEALS...................... 8

TRANSAXLE............................ 8

VEHICLE SPEED SENSOR DRIVE GEAR...... 7

DISASSEMBLY AND ASSEMBLY

DIFFERENTIAL......................... 24

INPUT SHAFT.......................... 20

OUTPUT SHAFT........................ 24

SHIFT RAILS OVERHAUL................. 29

SYNCHRONIZER........................ 29

TRANSAXLE CASE OVERHAUL............. 30

TRANSAXLE........................... 10

CLEANING AND INSPECTION

SYNCHRONIZER........................ 35

TRANSAXLE........................... 35

ADJUSTMENTS

BEARING ADJUSTMENT PROCEDURE....... 35

DIFFERENTIAL BEARING PRELOAD

ADJUSTMENT......................... 36

GEARSHIFT CROSSOVER CABLE........... 35

SPECIFICATIONS

NV T350 (A-578) SPECIFICATIONS.......... 37

SPECIAL TOOLS

NV T350 (A-578) MANUAL TRANSAXLE....... 37

GENERAL INFORMATION

NV T350 MANUAL TRANSAXLE

NOTE: Safety goggles should be worn at all times

when working on these transaxles.

This five speed is a constant-mesh manual tran-

saxle. All gear ranges, except reverse, are synchro-

nized. The reverse gear utilizes a brake and blockingring for shifting ease. The reverse idler gear is sup-

ported on a sliding spindle idler shaft. The transaxle

case is aluminum with a steel end±plate bearing

cover. It is housed in a die-cast aluminum case fea-

turing a two±piece, middle split design.

The NV T350 (A-578) transaxle internal compo-

nents can be serviced only by separating the gear

case from the bellhousing case.

PLTRANSAXLE 21 - 1

Page 953 of 1200

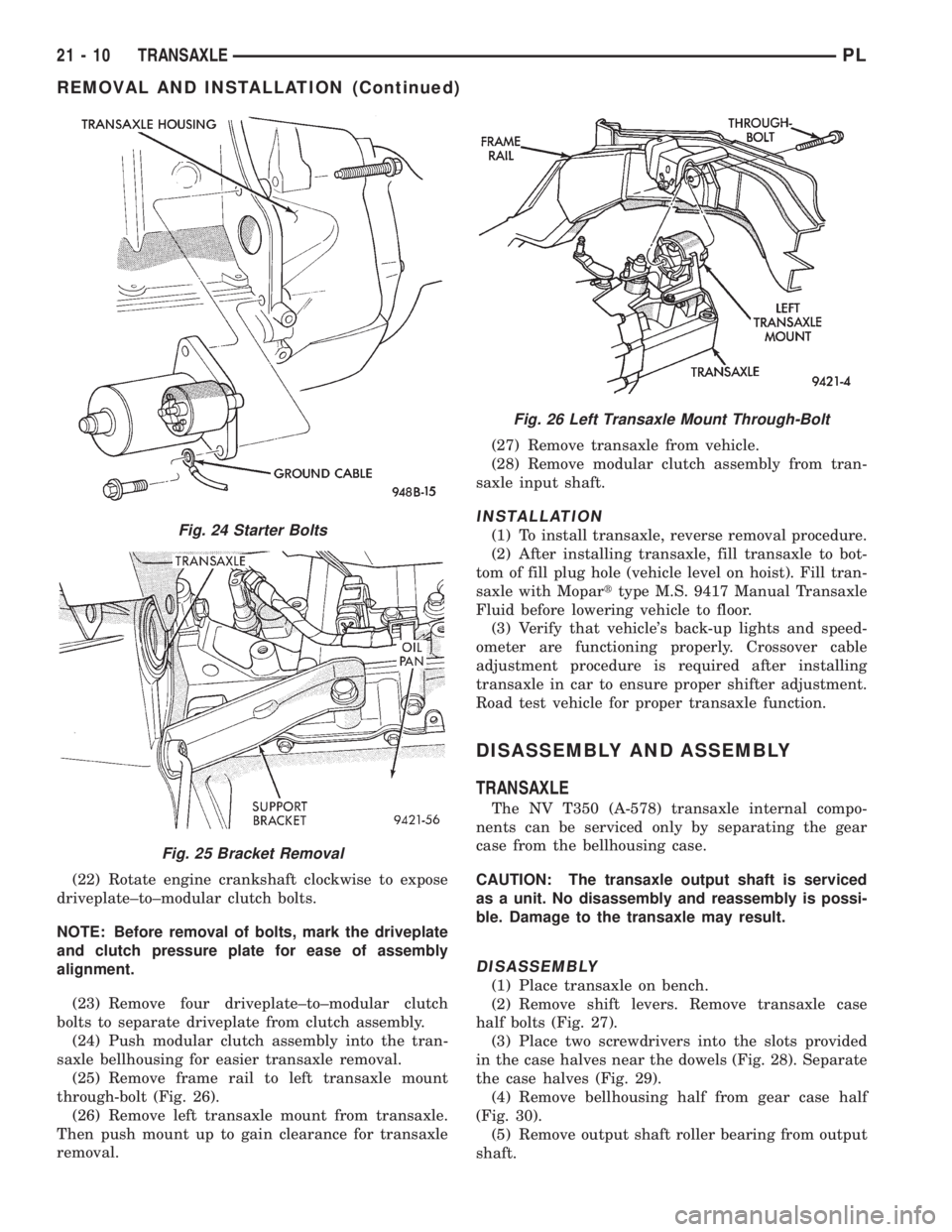

(22) Rotate engine crankshaft clockwise to expose

driveplate±to±modular clutch bolts.

NOTE: Before removal of bolts, mark the driveplate

and clutch pressure plate for ease of assembly

alignment.

(23) Remove four driveplate±to±modular clutch

bolts to separate driveplate from clutch assembly.

(24) Push modular clutch assembly into the tran-

saxle bellhousing for easier transaxle removal.

(25) Remove frame rail to left transaxle mount

through-bolt (Fig. 26).

(26) Remove left transaxle mount from transaxle.

Then push mount up to gain clearance for transaxle

removal.(27) Remove transaxle from vehicle.

(28) Remove modular clutch assembly from tran-

saxle input shaft.

INSTALLATION

(1) To install transaxle, reverse removal procedure.

(2) After installing transaxle, fill transaxle to bot-

tom of fill plug hole (vehicle level on hoist). Fill tran-

saxle with Moparttype M.S. 9417 Manual Transaxle

Fluid before lowering vehicle to floor.

(3) Verify that vehicle's back-up lights and speed-

ometer are functioning properly. Crossover cable

adjustment procedure is required after installing

transaxle in car to ensure proper shifter adjustment.

Road test vehicle for proper transaxle function.

DISASSEMBLY AND ASSEMBLY

TRANSAXLE

The NV T350 (A-578) transaxle internal compo-

nents can be serviced only by separating the gear

case from the bellhousing case.

CAUTION: The transaxle output shaft is serviced

as a unit. No disassembly and reassembly is possi-

ble. Damage to the transaxle may result.

DISASSEMBLY

(1) Place transaxle on bench.

(2) Remove shift levers. Remove transaxle case

half bolts (Fig. 27).

(3) Place two screwdrivers into the slots provided

in the case halves near the dowels (Fig. 28). Separate

the case halves (Fig. 29).

(4) Remove bellhousing half from gear case half

(Fig. 30).

(5) Remove output shaft roller bearing from output

shaft.

Fig. 24 Starter Bolts

Fig. 25 Bracket Removal

Fig. 26 Left Transaxle Mount Through-Bolt

21 - 10 TRANSAXLEPL

REMOVAL AND INSTALLATION (Continued)

Page 955 of 1200

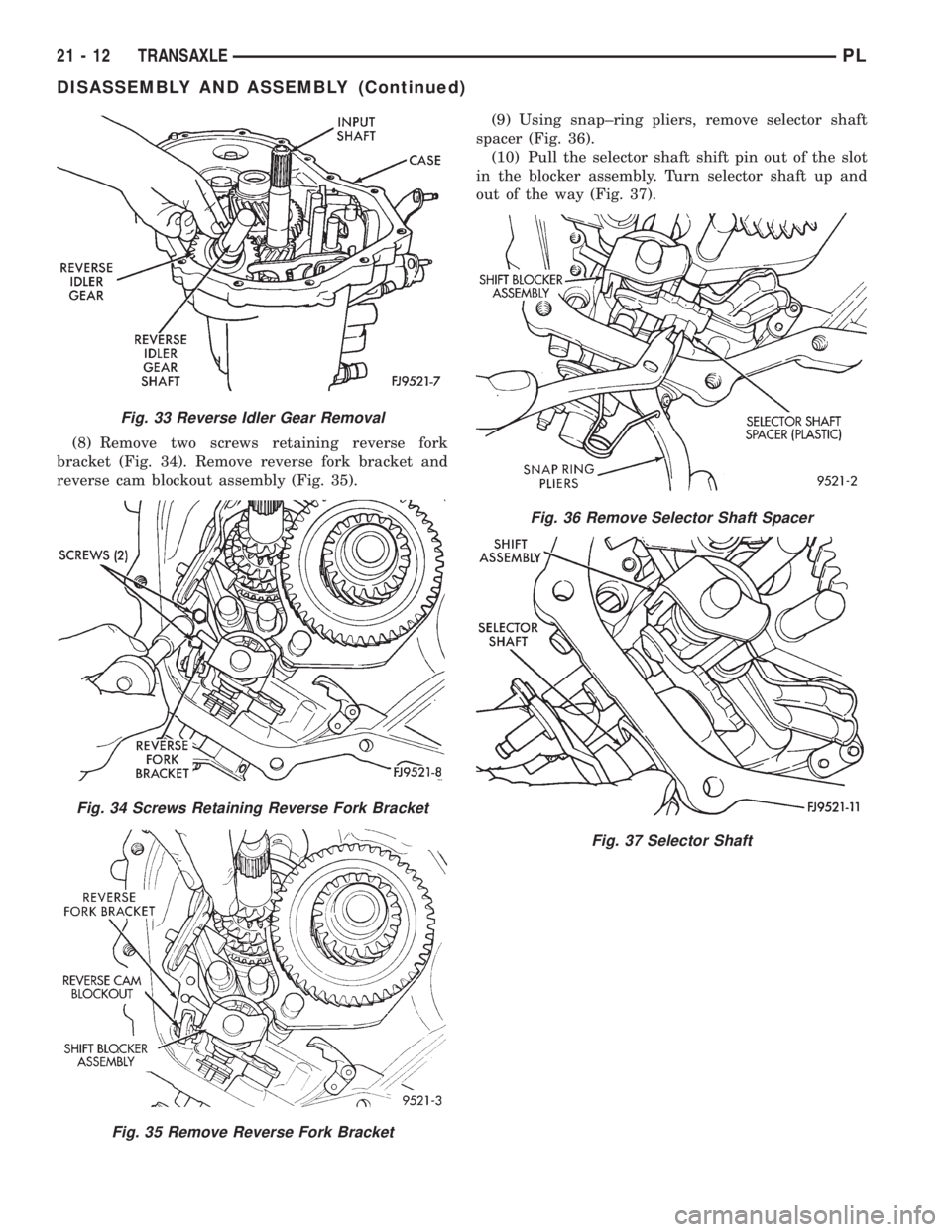

(8) Remove two screws retaining reverse fork

bracket (Fig. 34). Remove reverse fork bracket and

reverse cam blockout assembly (Fig. 35).(9) Using snap±ring pliers, remove selector shaft

spacer (Fig. 36).

(10) Pull the selector shaft shift pin out of the slot

in the blocker assembly. Turn selector shaft up and

out of the way (Fig. 37).

Fig. 33 Reverse Idler Gear Removal

Fig. 34 Screws Retaining Reverse Fork Bracket

Fig. 35 Remove Reverse Fork Bracket

Fig. 36 Remove Selector Shaft Spacer

Fig. 37 Selector Shaft

21 - 12 TRANSAXLEPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 957 of 1200

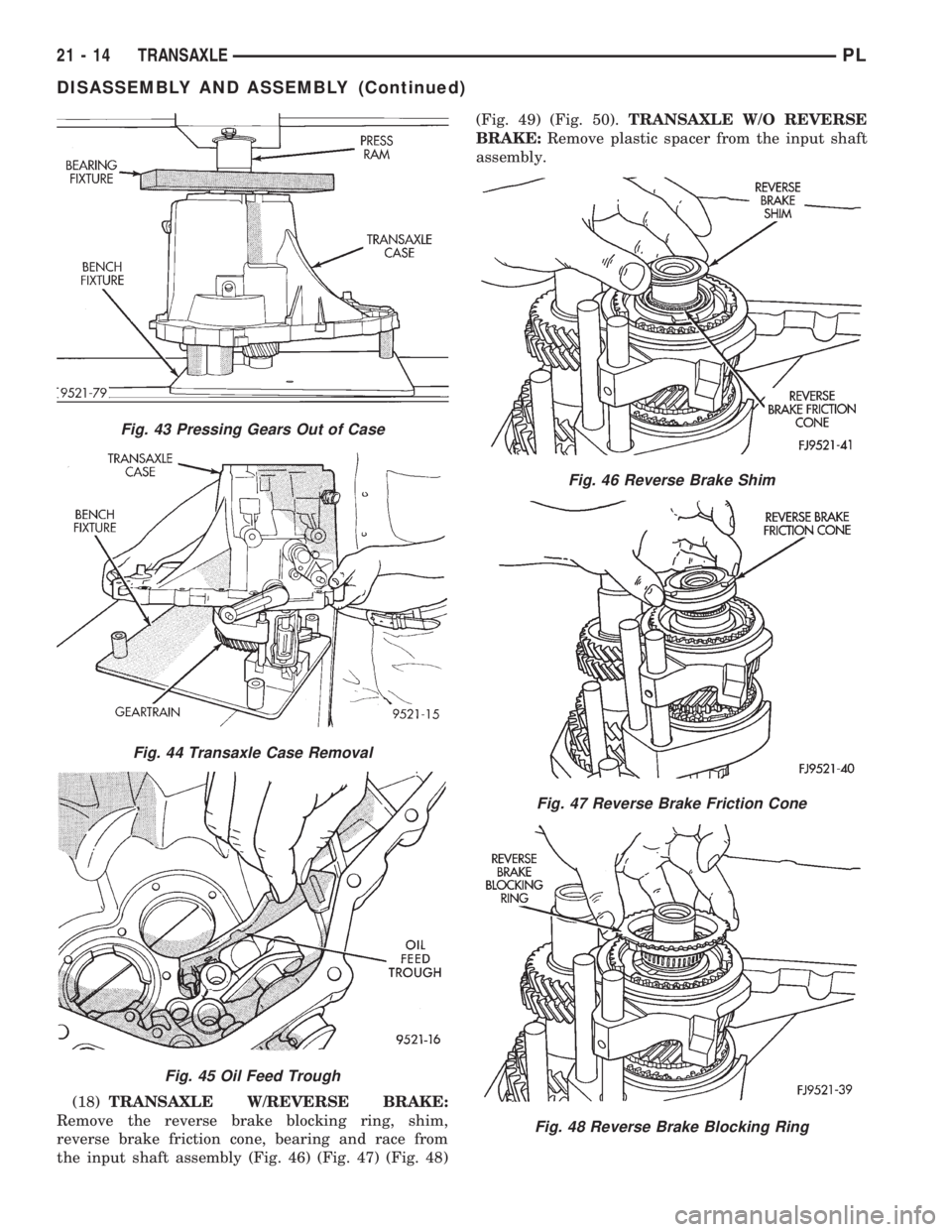

(18)TRANSAXLE W/REVERSE BRAKE:

Remove the reverse brake blocking ring, shim,

reverse brake friction cone, bearing and race from

the input shaft assembly (Fig. 46) (Fig. 47) (Fig. 48)(Fig. 49) (Fig. 50).TRANSAXLE W/O REVERSE

BRAKE:Remove plastic spacer from the input shaft

assembly.

Fig. 43 Pressing Gears Out of Case

Fig. 44 Transaxle Case Removal

Fig. 45 Oil Feed Trough

Fig. 46 Reverse Brake Shim

Fig. 47 Reverse Brake Friction Cone

Fig. 48 Reverse Brake Blocking Ring

21 - 14 TRANSAXLEPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 958 of 1200

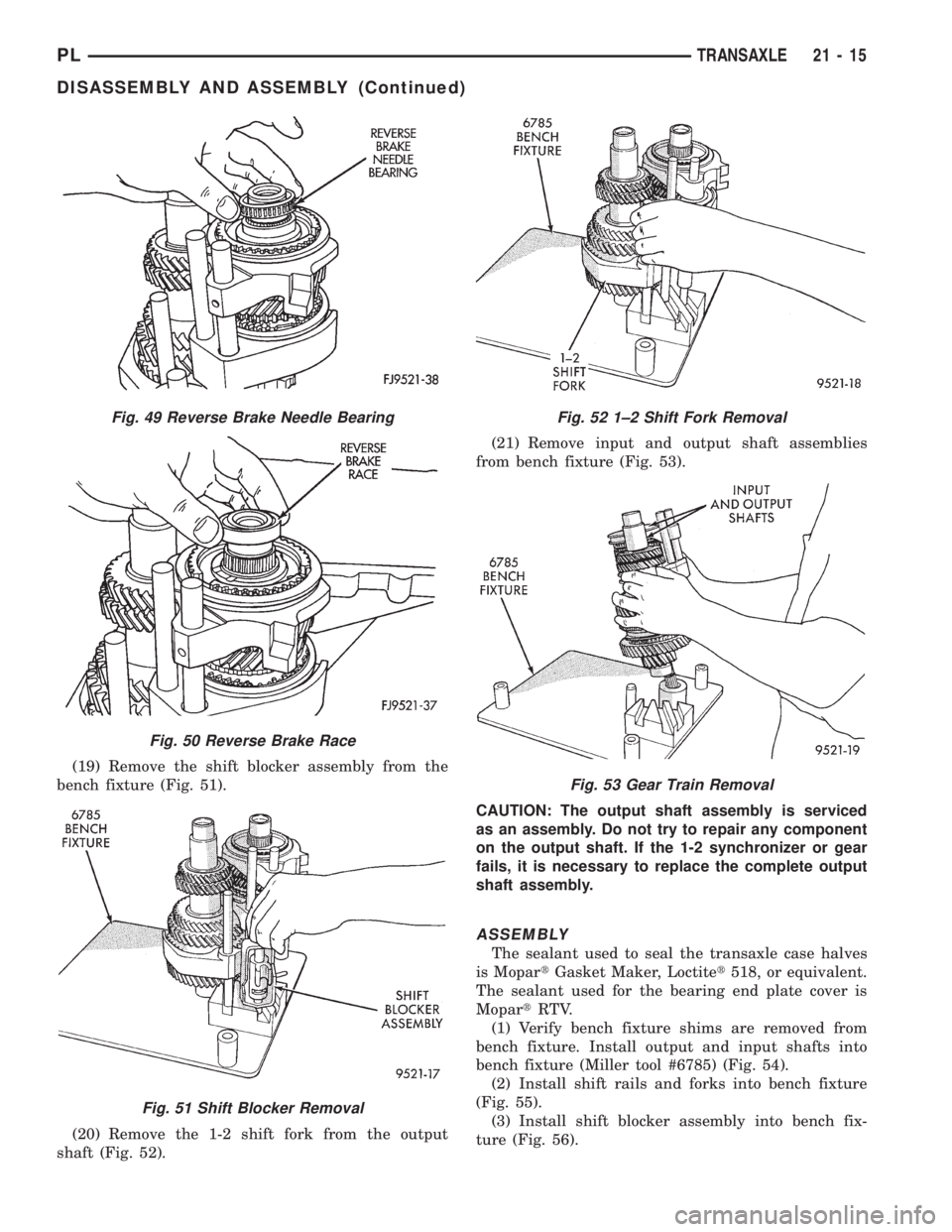

(19) Remove the shift blocker assembly from the

bench fixture (Fig. 51).

(20) Remove the 1-2 shift fork from the output

shaft (Fig. 52).(21) Remove input and output shaft assemblies

from bench fixture (Fig. 53).

CAUTION: The output shaft assembly is serviced

as an assembly. Do not try to repair any component

on the output shaft. If the 1-2 synchronizer or gear

fails, it is necessary to replace the complete output

shaft assembly.

ASSEMBLY

The sealant used to seal the transaxle case halves

is MopartGasket Maker, Loctitet518, or equivalent.

The sealant used for the bearing end plate cover is

MopartRTV.

(1) Verify bench fixture shims are removed from

bench fixture. Install output and input shafts into

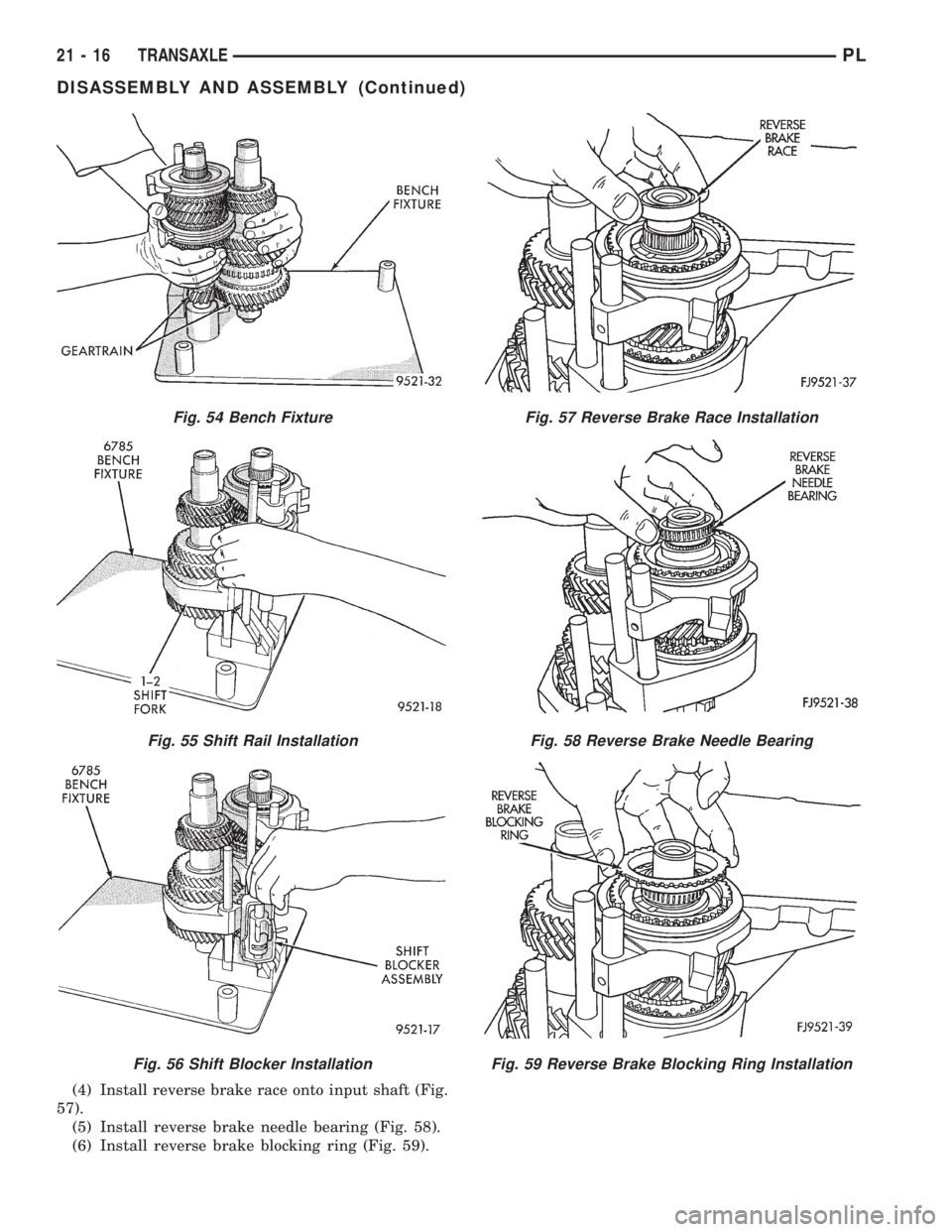

bench fixture (Miller tool #6785) (Fig. 54).

(2) Install shift rails and forks into bench fixture

(Fig. 55).

(3) Install shift blocker assembly into bench fix-

ture (Fig. 56).

Fig. 49 Reverse Brake Needle Bearing

Fig. 50 Reverse Brake Race

Fig. 51 Shift Blocker Removal

Fig. 52 1±2 Shift Fork Removal

Fig. 53 Gear Train Removal

PLTRANSAXLE 21 - 15

DISASSEMBLY AND ASSEMBLY (Continued)

Page 959 of 1200

(4) Install reverse brake race onto input shaft (Fig.

57).

(5) Install reverse brake needle bearing (Fig. 58).

(6) Install reverse brake blocking ring (Fig. 59).

Fig. 54 Bench Fixture

Fig. 55 Shift Rail Installation

Fig. 56 Shift Blocker Installation

Fig. 57 Reverse Brake Race Installation

Fig. 58 Reverse Brake Needle Bearing

Fig. 59 Reverse Brake Blocking Ring Installation

21 - 16 TRANSAXLEPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 961 of 1200

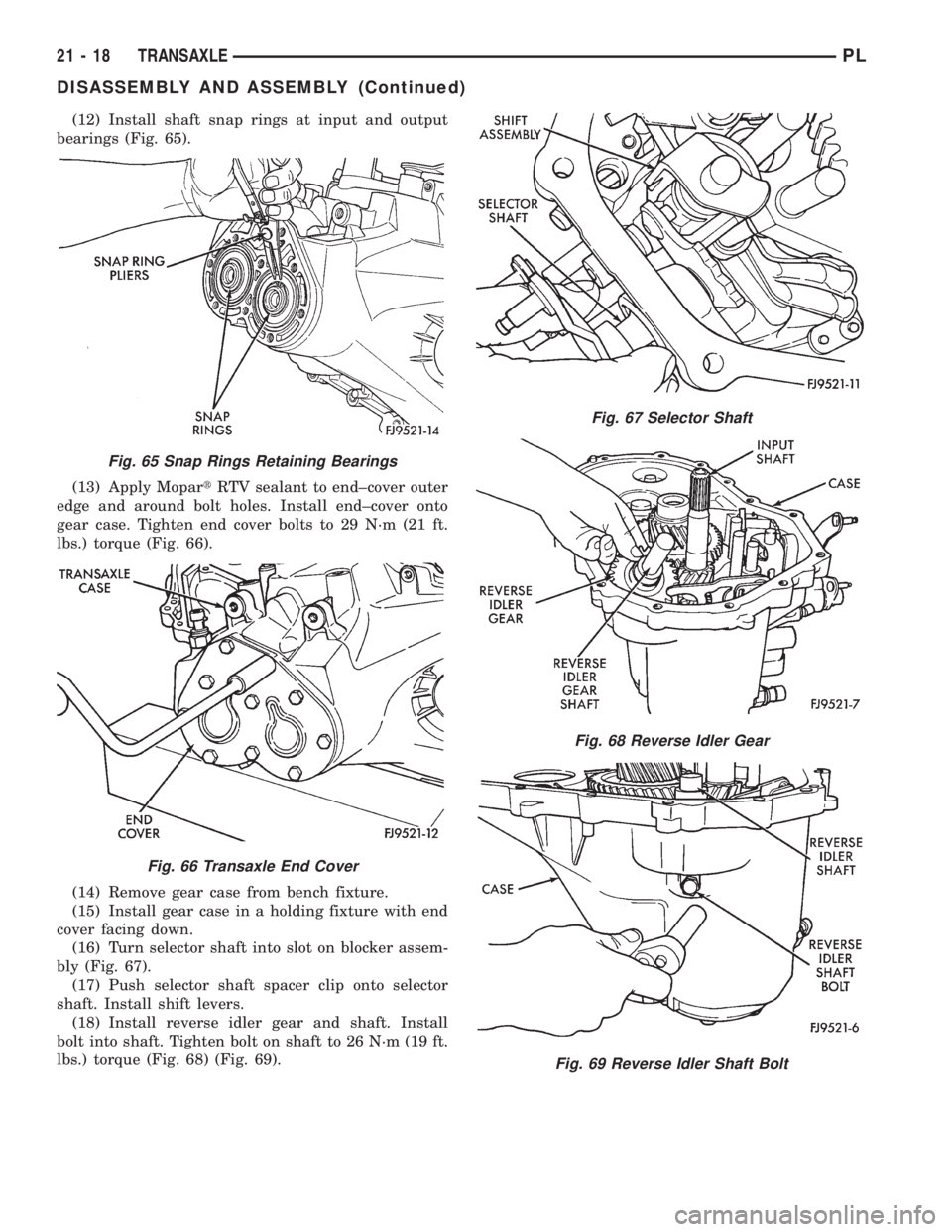

(12) Install shaft snap rings at input and output

bearings (Fig. 65).

(13) Apply MopartRTV sealant to end±cover outer

edge and around bolt holes. Install end±cover onto

gear case. Tighten end cover bolts to 29 N´m (21 ft.

lbs.) torque (Fig. 66).

(14) Remove gear case from bench fixture.

(15) Install gear case in a holding fixture with end

cover facing down.

(16) Turn selector shaft into slot on blocker assem-

bly (Fig. 67).

(17) Push selector shaft spacer clip onto selector

shaft. Install shift levers.

(18) Install reverse idler gear and shaft. Install

bolt into shaft. Tighten bolt on shaft to 26 N´m (19 ft.

lbs.) torque (Fig. 68) (Fig. 69).

Fig. 65 Snap Rings Retaining Bearings

Fig. 66 Transaxle End Cover

Fig. 67 Selector Shaft

Fig. 68 Reverse Idler Gear

Fig. 69 Reverse Idler Shaft Bolt

21 - 18 TRANSAXLEPL

DISASSEMBLY AND ASSEMBLY (Continued)