lock DODGE NEON 1999 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 830 of 1200

FRAME AND BUMPERS

CONTENTS

page page

BUMPERS............................... 1FRAMES................................ 3

BUMPERS

INDEX

page page

REMOVAL AND INSTALLATION

FRONT BUMPER FASCIA.................. 1

FRONT BUMPER REINFORCEMENT.......... 1REAR BUMPER FASCIA................... 1

REAR BUMPER REINFORCEMENT........... 2

REMOVAL AND INSTALLATION

FRONT BUMPER FASCIA

REMOVAL

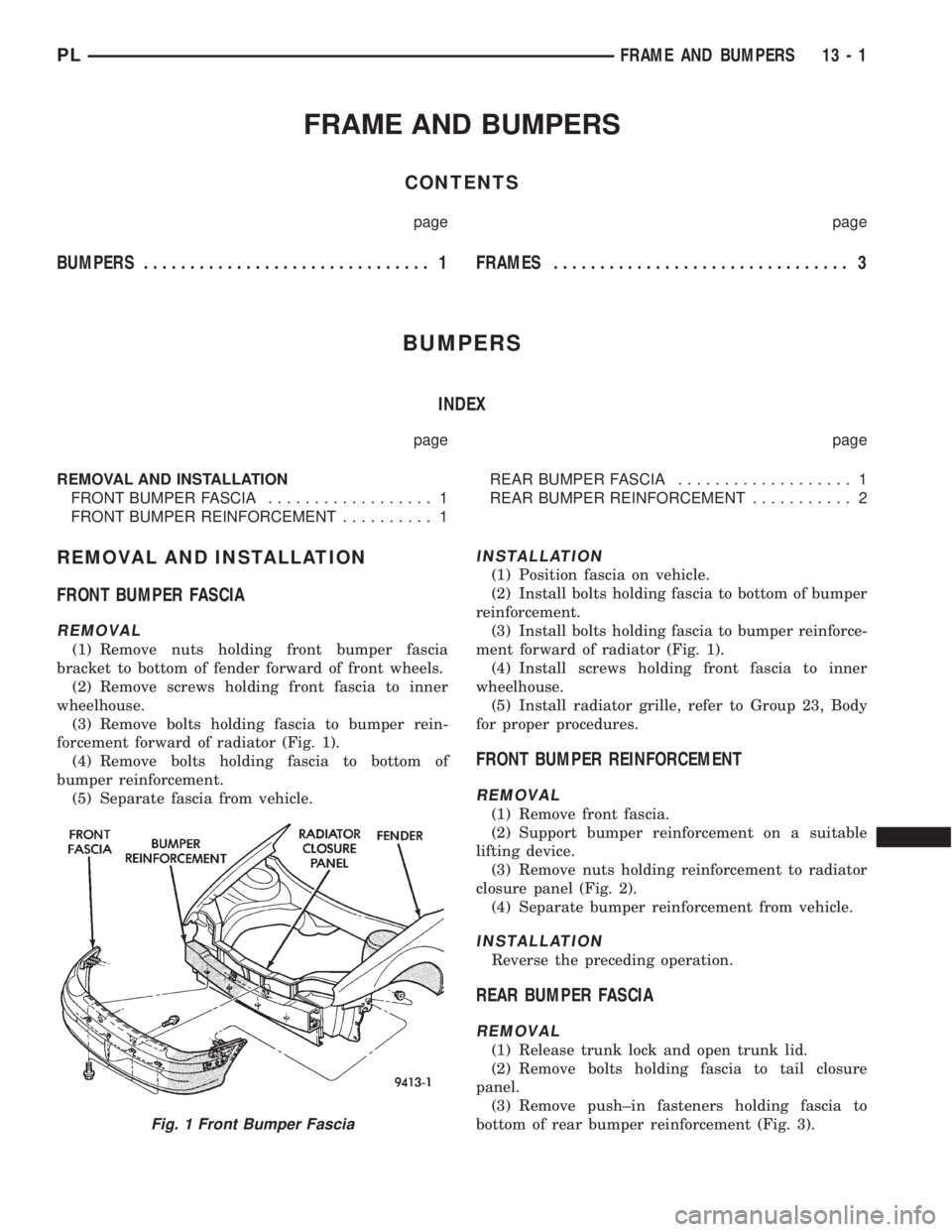

(1) Remove nuts holding front bumper fascia

bracket to bottom of fender forward of front wheels.

(2) Remove screws holding front fascia to inner

wheelhouse.

(3) Remove bolts holding fascia to bumper rein-

forcement forward of radiator (Fig. 1).

(4) Remove bolts holding fascia to bottom of

bumper reinforcement.

(5) Separate fascia from vehicle.

INSTALLATION

(1) Position fascia on vehicle.

(2) Install bolts holding fascia to bottom of bumper

reinforcement.

(3) Install bolts holding fascia to bumper reinforce-

ment forward of radiator (Fig. 1).

(4) Install screws holding front fascia to inner

wheelhouse.

(5) Install radiator grille, refer to Group 23, Body

for proper procedures.

FRONT BUMPER REINFORCEMENT

REMOVAL

(1) Remove front fascia.

(2) Support bumper reinforcement on a suitable

lifting device.

(3) Remove nuts holding reinforcement to radiator

closure panel (Fig. 2).

(4) Separate bumper reinforcement from vehicle.

INSTALLATION

Reverse the preceding operation.

REAR BUMPER FASCIA

REMOVAL

(1) Release trunk lock and open trunk lid.

(2) Remove bolts holding fascia to tail closure

panel.

(3) Remove push±in fasteners holding fascia to

bottom of rear bumper reinforcement (Fig. 3).

Fig. 1 Front Bumper Fascia

PLFRAME AND BUMPERS 13 - 1

Page 846 of 1200

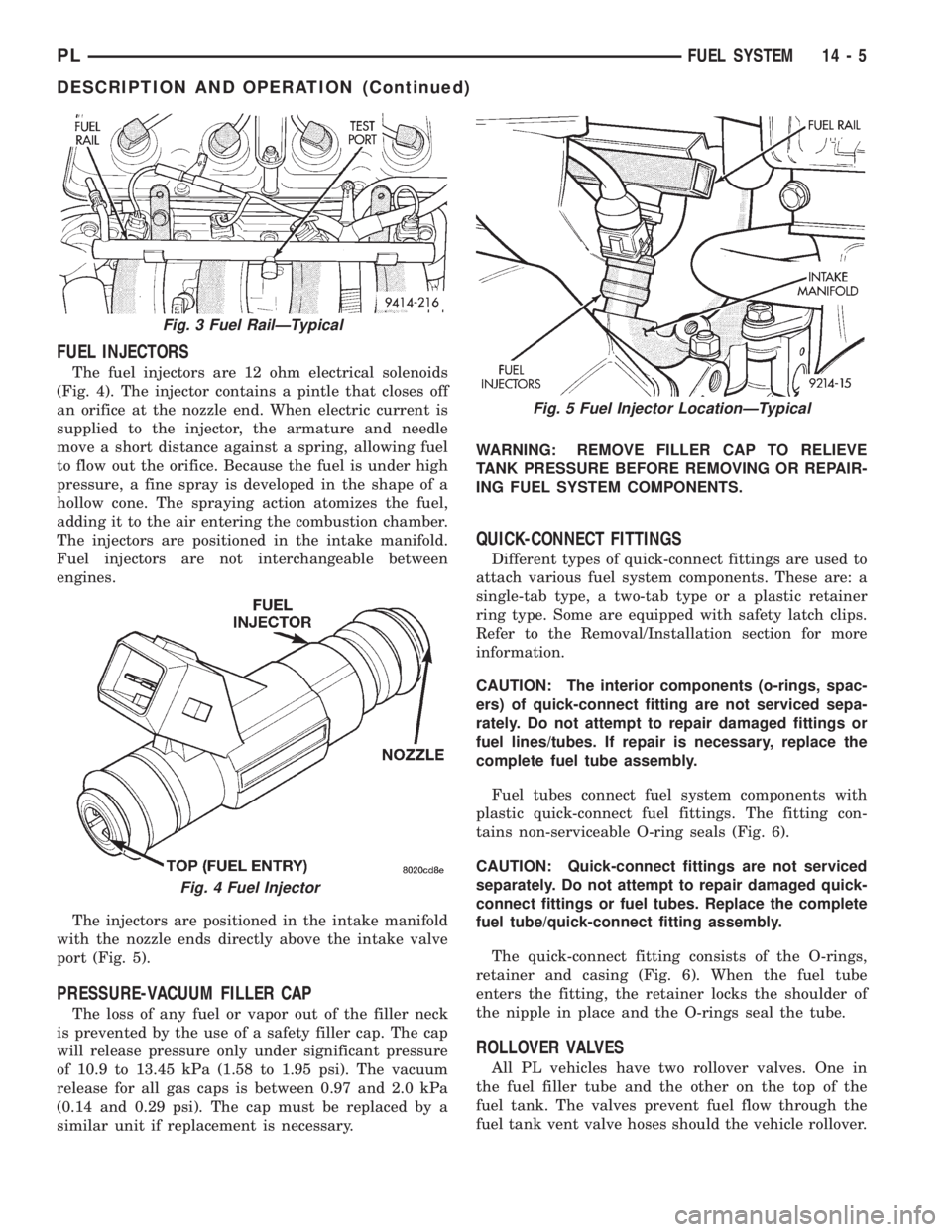

FUEL INJECTORS

The fuel injectors are 12 ohm electrical solenoids

(Fig. 4). The injector contains a pintle that closes off

an orifice at the nozzle end. When electric current is

supplied to the injector, the armature and needle

move a short distance against a spring, allowing fuel

to flow out the orifice. Because the fuel is under high

pressure, a fine spray is developed in the shape of a

hollow cone. The spraying action atomizes the fuel,

adding it to the air entering the combustion chamber.

The injectors are positioned in the intake manifold.

Fuel injectors are not interchangeable between

engines.

The injectors are positioned in the intake manifold

with the nozzle ends directly above the intake valve

port (Fig. 5).

PRESSURE-VACUUM FILLER CAP

The loss of any fuel or vapor out of the filler neck

is prevented by the use of a safety filler cap. The cap

will release pressure only under significant pressure

of 10.9 to 13.45 kPa (1.58 to 1.95 psi). The vacuum

release for all gas caps is between 0.97 and 2.0 kPa

(0.14 and 0.29 psi). The cap must be replaced by a

similar unit if replacement is necessary.WARNING: REMOVE FILLER CAP TO RELIEVE

TANK PRESSURE BEFORE REMOVING OR REPAIR-

ING FUEL SYSTEM COMPONENTS.

QUICK-CONNECT FITTINGS

Different types of quick-connect fittings are used to

attach various fuel system components. These are: a

single-tab type, a two-tab type or a plastic retainer

ring type. Some are equipped with safety latch clips.

Refer to the Removal/Installation section for more

information.

CAUTION: The interior components (o-rings, spac-

ers) of quick-connect fitting are not serviced sepa-

rately. Do not attempt to repair damaged fittings or

fuel lines/tubes. If repair is necessary, replace the

complete fuel tube assembly.

Fuel tubes connect fuel system components with

plastic quick-connect fuel fittings. The fitting con-

tains non-serviceable O-ring seals (Fig. 6).

CAUTION: Quick-connect fittings are not serviced

separately. Do not attempt to repair damaged quick-

connect fittings or fuel tubes. Replace the complete

fuel tube/quick-connect fitting assembly.

The quick-connect fitting consists of the O-rings,

retainer and casing (Fig. 6). When the fuel tube

enters the fitting, the retainer locks the shoulder of

the nipple in place and the O-rings seal the tube.

ROLLOVER VALVES

All PL vehicles have two rollover valves. One in

the fuel filler tube and the other on the top of the

fuel tank. The valves prevent fuel flow through the

fuel tank vent valve hoses should the vehicle rollover.

Fig. 3 Fuel RailÐTypical

Fig. 4 Fuel Injector

Fig. 5 Fuel Injector LocationÐTypical

PLFUEL SYSTEM 14 - 5

DESCRIPTION AND OPERATION (Continued)

Page 852 of 1200

The hose clamps have rolled edges to prevent the

clamp from cutting into the hose. Only use clamps

that are original equipment or equivalent. Other

types of clamps may cut into the hoses and cause

high pressure fuel leaks. Tighten hose clamps to 1

N´m (10 in. lbs.) torque.

QUICK-CONNECT FITTINGS

REMOVAL

When disconnecting a quick-connect fitting, the

retainer will remain on the fuel tube nipple.

WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE DISCONNECTING A QUICK-CONNECT FIT-

TINGS. REFER TO THE FUEL PRESSURE RELEASE

PROCEDURE.

(1) Disconnect negative cable from battery.

(2) Perform Fuel Pressure Release Procedure.

Refer to the Fuel Pressure Release Procedure in this

section.

(3) Squeeze retainer tabs together and pull fuel

tube/quick-connect fitting assembly off of fuel tube

nipple. The retainer will remain on fuel tube.

INSTALLATION

CAUTION: Never install a quick-connect fitting

without the retainer being either on the fuel tube or

already in the quick-connect fitting. In either case,

ensure the retainer locks securely into the quick-

connect fitting by firmly pulling on fuel tube and fit-

ting to ensure it is secured.

(1) Using a clean lint free cloth, clean the fuel tube

nipple and retainer.

(2) Prior to connecting the fitting to the fuel tube,

coat the fuel tube nipple with clean 30 weight engine

oil.

(3) Push the quick-connect fitting over the fuel

tube until theretainer seats and a click is heard.

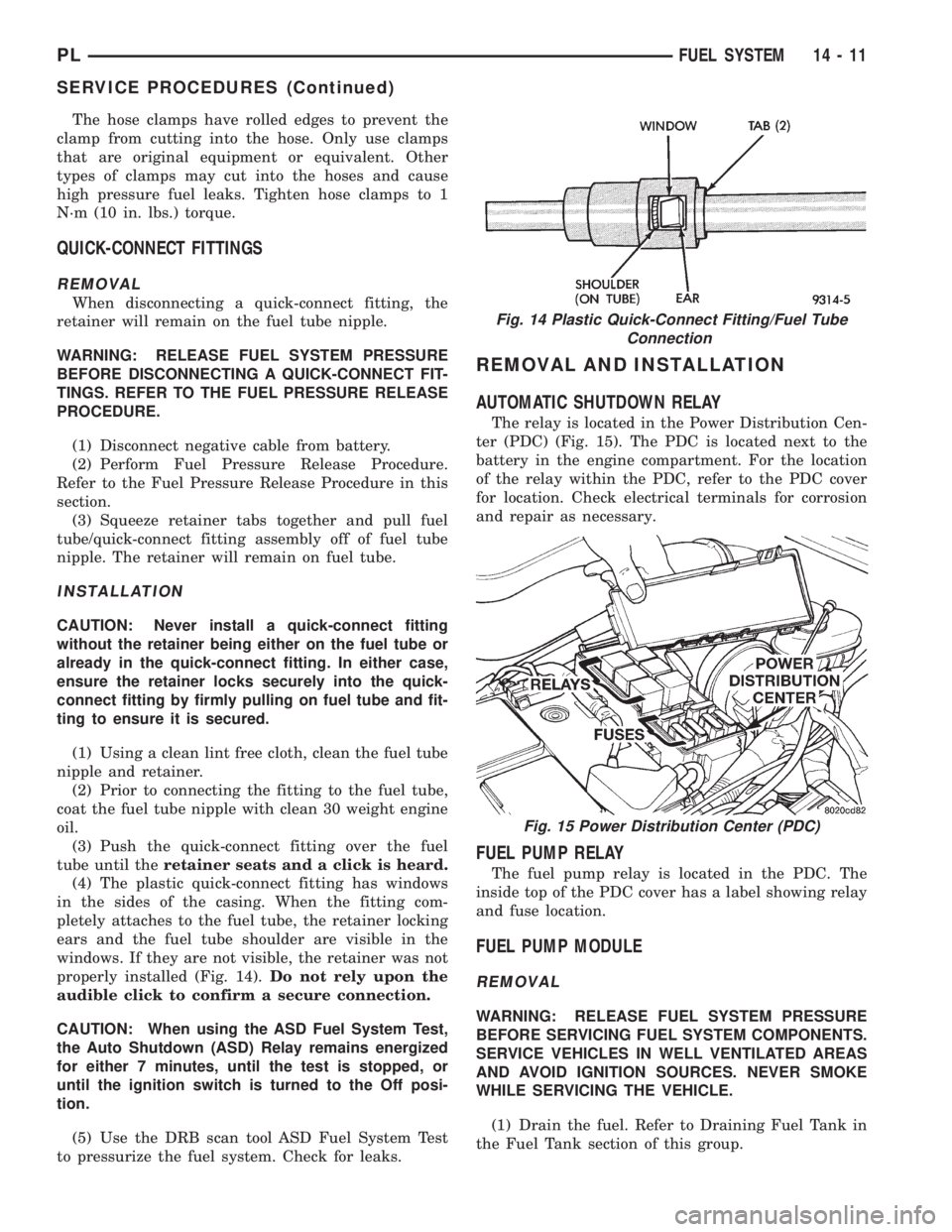

(4) The plastic quick-connect fitting has windows

in the sides of the casing. When the fitting com-

pletely attaches to the fuel tube, the retainer locking

ears and the fuel tube shoulder are visible in the

windows. If they are not visible, the retainer was not

properly installed (Fig. 14).Do not rely upon the

audible click to confirm a secure connection.

CAUTION: When using the ASD Fuel System Test,

the Auto Shutdown (ASD) Relay remains energized

for either 7 minutes, until the test is stopped, or

until the ignition switch is turned to the Off posi-

tion.

(5) Use the DRB scan tool ASD Fuel System Test

to pressurize the fuel system. Check for leaks.

REMOVAL AND INSTALLATION

AUTOMATIC SHUTDOWN RELAY

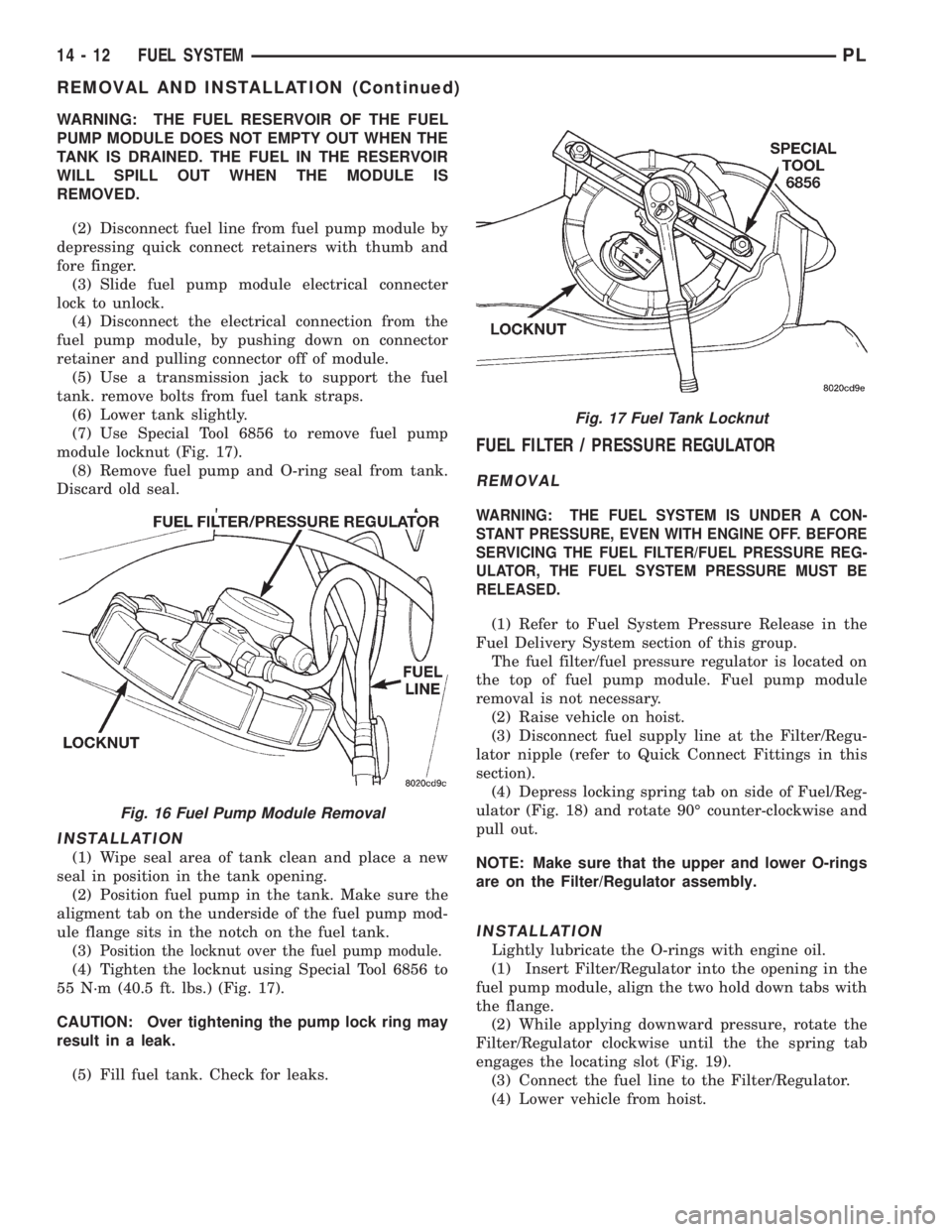

The relay is located in the Power Distribution Cen-

ter (PDC) (Fig. 15). The PDC is located next to the

battery in the engine compartment. For the location

of the relay within the PDC, refer to the PDC cover

for location. Check electrical terminals for corrosion

and repair as necessary.

FUEL PUMP RELAY

The fuel pump relay is located in the PDC. The

inside top of the PDC cover has a label showing relay

and fuse location.

FUEL PUMP MODULE

REMOVAL

WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE SERVICING FUEL SYSTEM COMPONENTS.

SERVICE VEHICLES IN WELL VENTILATED AREAS

AND AVOID IGNITION SOURCES. NEVER SMOKE

WHILE SERVICING THE VEHICLE.

(1) Drain the fuel. Refer to Draining Fuel Tank in

the Fuel Tank section of this group.

Fig. 14 Plastic Quick-Connect Fitting/Fuel Tube

Connection

Fig. 15 Power Distribution Center (PDC)

PLFUEL SYSTEM 14 - 11

SERVICE PROCEDURES (Continued)

Page 853 of 1200

WARNING: THE FUEL RESERVOIR OF THE FUEL

PUMP MODULE DOES NOT EMPTY OUT WHEN THE

TANK IS DRAINED. THE FUEL IN THE RESERVOIR

WILL SPILL OUT WHEN THE MODULE IS

REMOVED.

(2) Disconnect fuel line from fuel pump module by

depressing quick connect retainers with thumb and

fore finger.

(3) Slide fuel pump module electrical connecter

lock to unlock.

(4) Disconnect the electrical connection from the

fuel pump module, by pushing down on connector

retainer and pulling connector off of module.

(5) Use a transmission jack to support the fuel

tank. remove bolts from fuel tank straps.

(6) Lower tank slightly.

(7) Use Special Tool 6856 to remove fuel pump

module locknut (Fig. 17).

(8) Remove fuel pump and O-ring seal from tank.

Discard old seal.

INSTALLATION

(1) Wipe seal area of tank clean and place a new

seal in position in the tank opening.

(2) Position fuel pump in the tank. Make sure the

aligment tab on the underside of the fuel pump mod-

ule flange sits in the notch on the fuel tank.

(3)

Position the locknut over the fuel pump module.

(4) Tighten the locknut using Special Tool 6856 to

55 N´m (40.5 ft. lbs.) (Fig. 17).

CAUTION: Over tightening the pump lock ring may

result in a leak.

(5) Fill fuel tank. Check for leaks.

FUEL FILTER / PRESSURE REGULATOR

REMOVAL

WARNING: THE FUEL SYSTEM IS UNDER A CON-

STANT PRESSURE, EVEN WITH ENGINE OFF. BEFORE

SERVICING THE FUEL FILTER/FUEL PRESSURE REG-

ULATOR, THE FUEL SYSTEM PRESSURE MUST BE

RELEASED.

(1) Refer to Fuel System Pressure Release in the

Fuel Delivery System section of this group.

The fuel filter/fuel pressure regulator is located on

the top of fuel pump module. Fuel pump module

removal is not necessary.

(2) Raise vehicle on hoist.

(3) Disconnect fuel supply line at the Filter/Regu-

lator nipple (refer to Quick Connect Fittings in this

section).

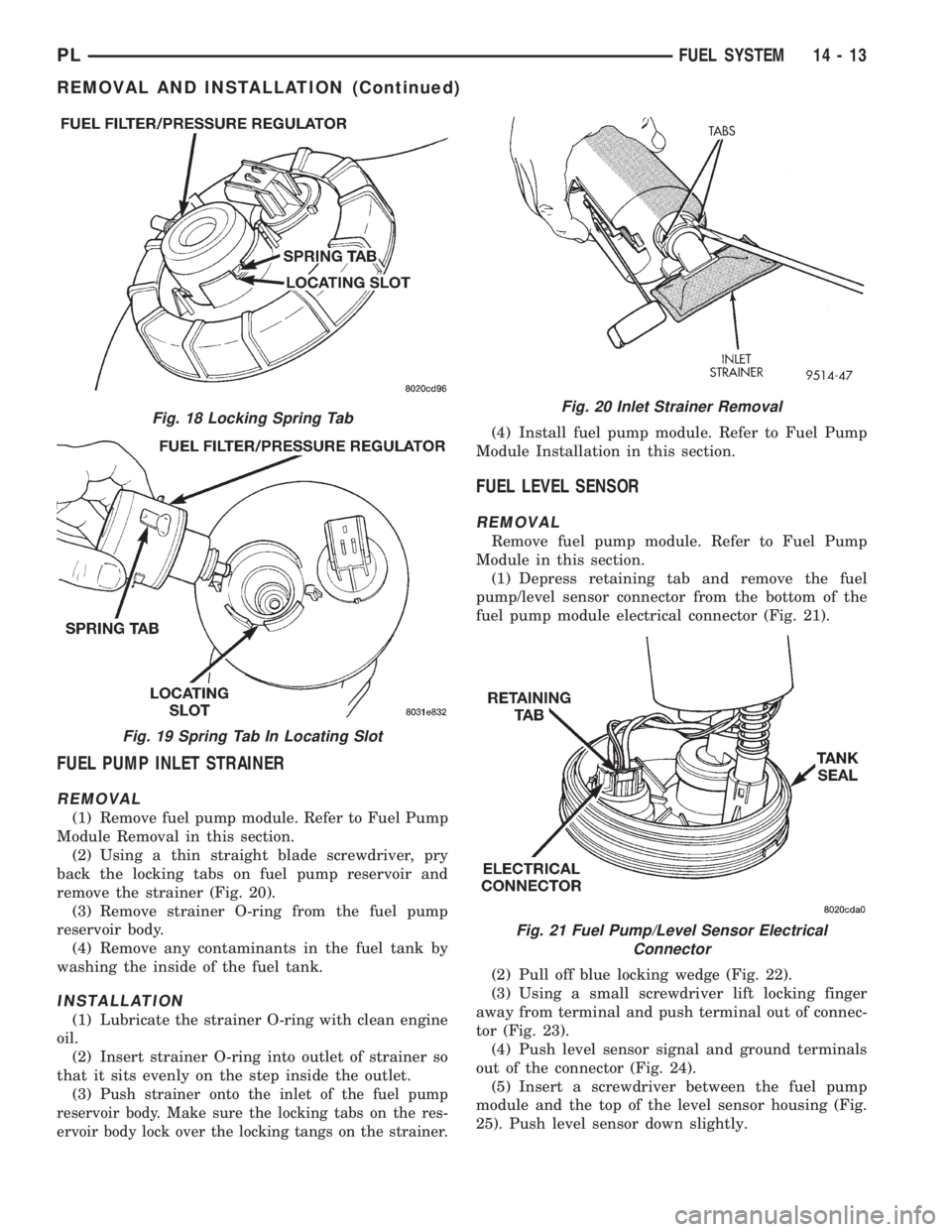

(4) Depress locking spring tab on side of Fuel/Reg-

ulator (Fig. 18) and rotate 90É counter-clockwise and

pull out.

NOTE: Make sure that the upper and lower O-rings

are on the Filter/Regulator assembly.

INSTALLATION

Lightly lubricate the O-rings with engine oil.

(1) Insert Filter/Regulator into the opening in the

fuel pump module, align the two hold down tabs with

the flange.

(2) While applying downward pressure, rotate the

Filter/Regulator clockwise until the the spring tab

engages the locating slot (Fig. 19).

(3) Connect the fuel line to the Filter/Regulator.

(4) Lower vehicle from hoist.

Fig. 16 Fuel Pump Module Removal

Fig. 17 Fuel Tank Locknut

14 - 12 FUEL SYSTEMPL

REMOVAL AND INSTALLATION (Continued)

Page 854 of 1200

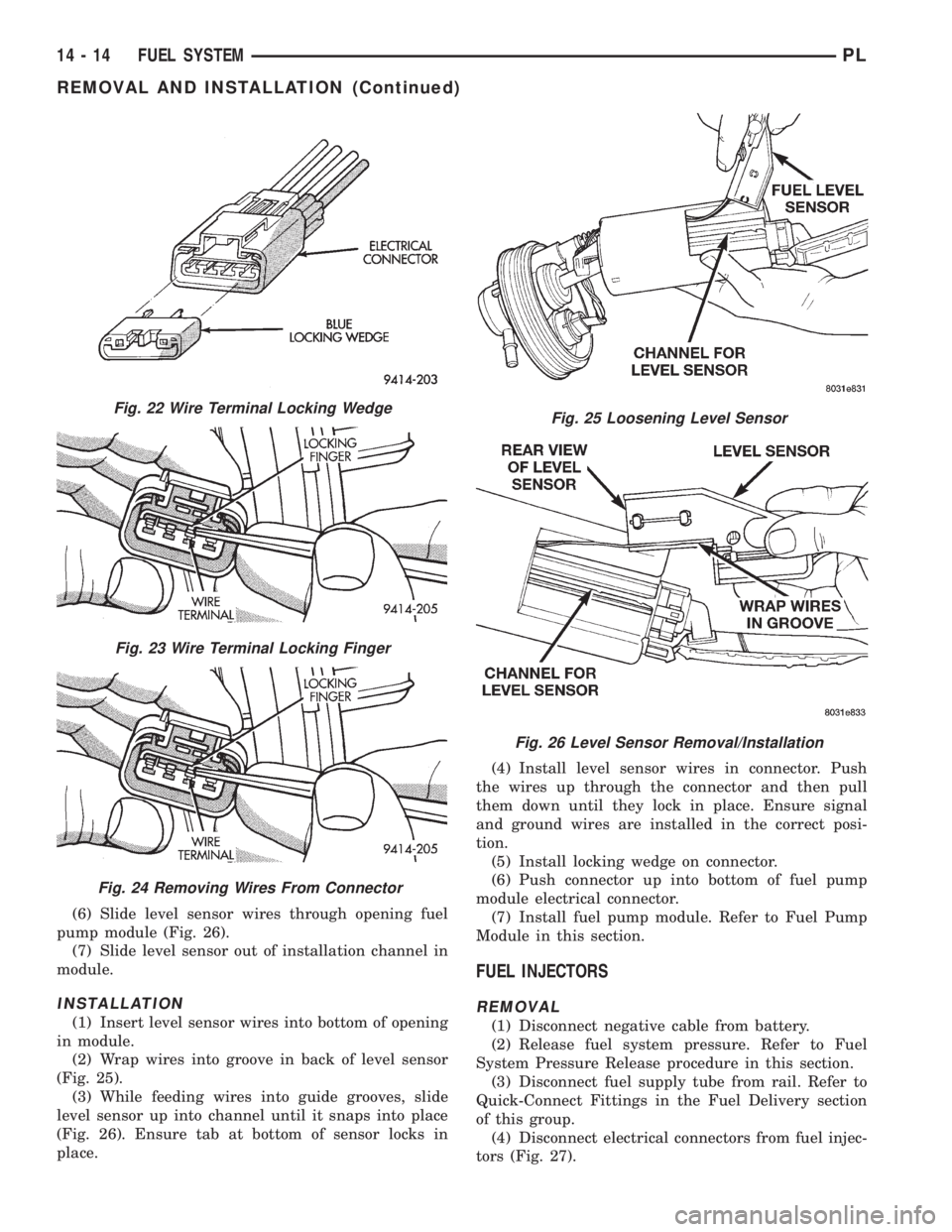

FUEL PUMP INLET STRAINER

REMOVAL

(1) Remove fuel pump module. Refer to Fuel Pump

Module Removal in this section.

(2) Using a thin straight blade screwdriver, pry

back the locking tabs on fuel pump reservoir and

remove the strainer (Fig. 20).

(3) Remove strainer O-ring from the fuel pump

reservoir body.

(4) Remove any contaminants in the fuel tank by

washing the inside of the fuel tank.

INSTALLATION

(1) Lubricate the strainer O-ring with clean engine

oil.

(2) Insert strainer O-ring into outlet of strainer so

that it sits evenly on the step inside the outlet.

(3) P

ush strainer onto the inlet of the fuel pump

reservoir body. Make sure the locking tabs on the res-

ervoir body lock over the locking tangs on the strainer.

(4) Install fuel pump module. Refer to Fuel Pump

Module Installation in this section.

FUEL LEVEL SENSOR

REMOVAL

Remove fuel pump module. Refer to Fuel Pump

Module in this section.

(1) Depress retaining tab and remove the fuel

pump/level sensor connector from the bottom of the

fuel pump module electrical connector (Fig. 21).

(2) Pull off blue locking wedge (Fig. 22).

(3) Using a small screwdriver lift locking finger

away from terminal and push terminal out of connec-

tor (Fig. 23).

(4) Push level sensor signal and ground terminals

out of the connector (Fig. 24).

(5) Insert a screwdriver between the fuel pump

module and the top of the level sensor housing (Fig.

25). Push level sensor down slightly.

Fig. 18 Locking Spring Tab

Fig. 19 Spring Tab In Locating Slot

Fig. 20 Inlet Strainer Removal

Fig. 21 Fuel Pump/Level Sensor Electrical

Connector

PLFUEL SYSTEM 14 - 13

REMOVAL AND INSTALLATION (Continued)

Page 855 of 1200

(6) Slide level sensor wires through opening fuel

pump module (Fig. 26).

(7) Slide level sensor out of installation channel in

module.

INSTALLATION

(1) Insert level sensor wires into bottom of opening

in module.

(2) Wrap wires into groove in back of level sensor

(Fig. 25).

(3) While feeding wires into guide grooves, slide

level sensor up into channel until it snaps into place

(Fig. 26). Ensure tab at bottom of sensor locks in

place.(4) Install level sensor wires in connector. Push

the wires up through the connector and then pull

them down until they lock in place. Ensure signal

and ground wires are installed in the correct posi-

tion.

(5) Install locking wedge on connector.

(6) Push connector up into bottom of fuel pump

module electrical connector.

(7) Install fuel pump module. Refer to Fuel Pump

Module in this section.

FUEL INJECTORS

REMOVAL

(1) Disconnect negative cable from battery.

(2) Release fuel system pressure. Refer to Fuel

System Pressure Release procedure in this section.

(3) Disconnect fuel supply tube from rail. Refer to

Quick-Connect Fittings in the Fuel Delivery section

of this group.

(4) Disconnect electrical connectors from fuel injec-

tors (Fig. 27).

Fig. 22 Wire Terminal Locking Wedge

Fig. 23 Wire Terminal Locking Finger

Fig. 24 Removing Wires From Connector

Fig. 25 Loosening Level Sensor

Fig. 26 Level Sensor Removal/Installation

14 - 14 FUEL SYSTEMPL

REMOVAL AND INSTALLATION (Continued)

Page 860 of 1200

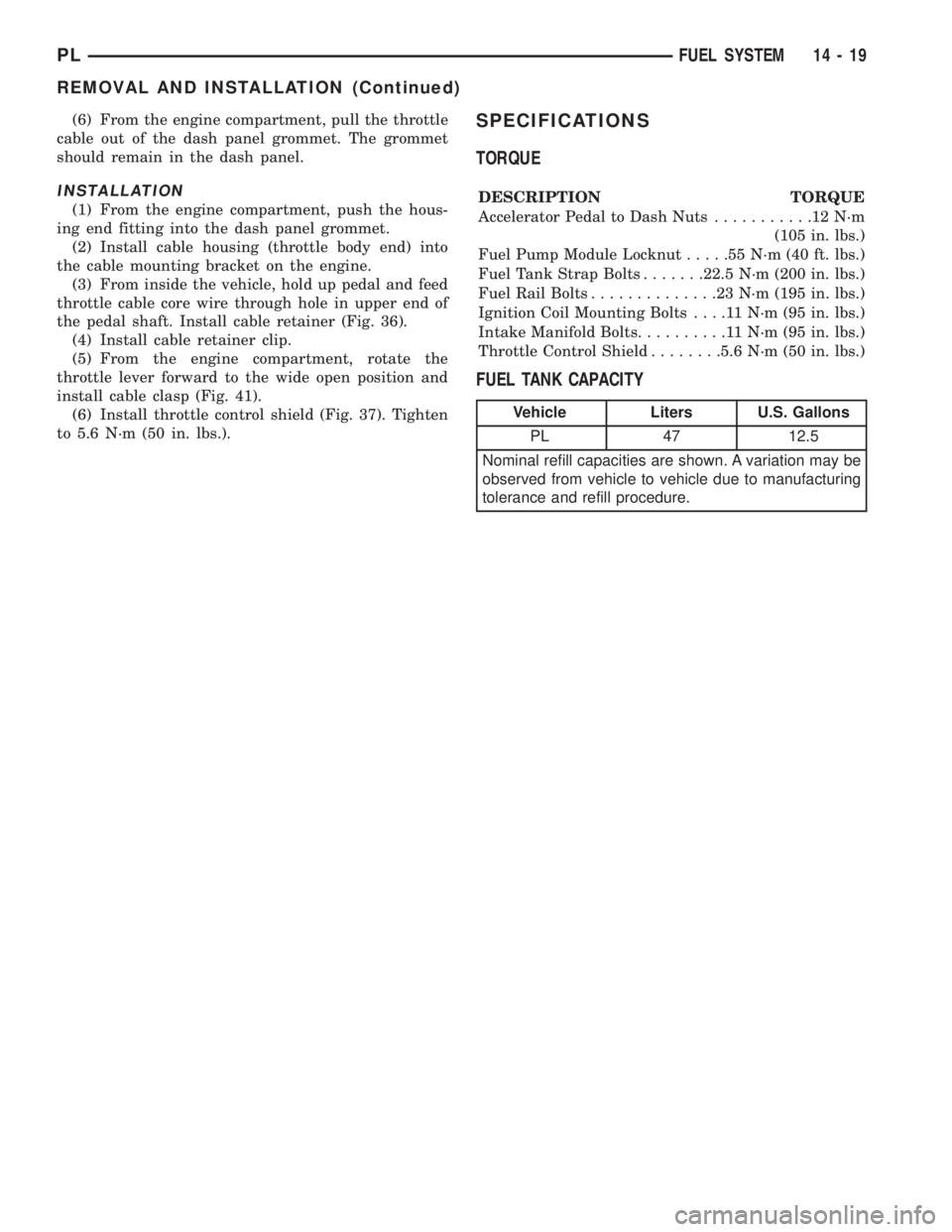

(6) From the engine compartment, pull the throttle

cable out of the dash panel grommet. The grommet

should remain in the dash panel.

INSTALLATION

(1) From the engine compartment, push the hous-

ing end fitting into the dash panel grommet.

(2) Install cable housing (throttle body end) into

the cable mounting bracket on the engine.

(3) From inside the vehicle, hold up pedal and feed

throttle cable core wire through hole in upper end of

the pedal shaft. Install cable retainer (Fig. 36).

(4) Install cable retainer clip.

(5) From the engine compartment, rotate the

throttle lever forward to the wide open position and

install cable clasp (Fig. 41).

(6) Install throttle control shield (Fig. 37). Tighten

to 5.6 N´m (50 in. lbs.).

SPECIFICATIONS

TORQUE

DESCRIPTION TORQUE

Accelerator Pedal to Dash Nuts...........12N´m

(105 in. lbs.)

Fuel Pump Module Locknut.....55N´m(40ft.lbs.)

Fuel Tank Strap Bolts.......22.5 N´m (200 in. lbs.)

Fuel Rail Bolts..............23N´m(195 in. lbs.)

Ignition Coil Mounting Bolts....11N´m(95in.lbs.)

Intake Manifold Bolts..........11N´m(95in.lbs.)

Throttle Control Shield........5.6 N´m (50 in. lbs.)

FUEL TANK CAPACITY

Vehicle Liters U.S. Gallons

PL 47 12.5

Nominal refill capacities are shown. A variation may be

observed from vehicle to vehicle due to manufacturing

tolerance and refill procedure.

PLFUEL SYSTEM 14 - 19

REMOVAL AND INSTALLATION (Continued)

Page 867 of 1200

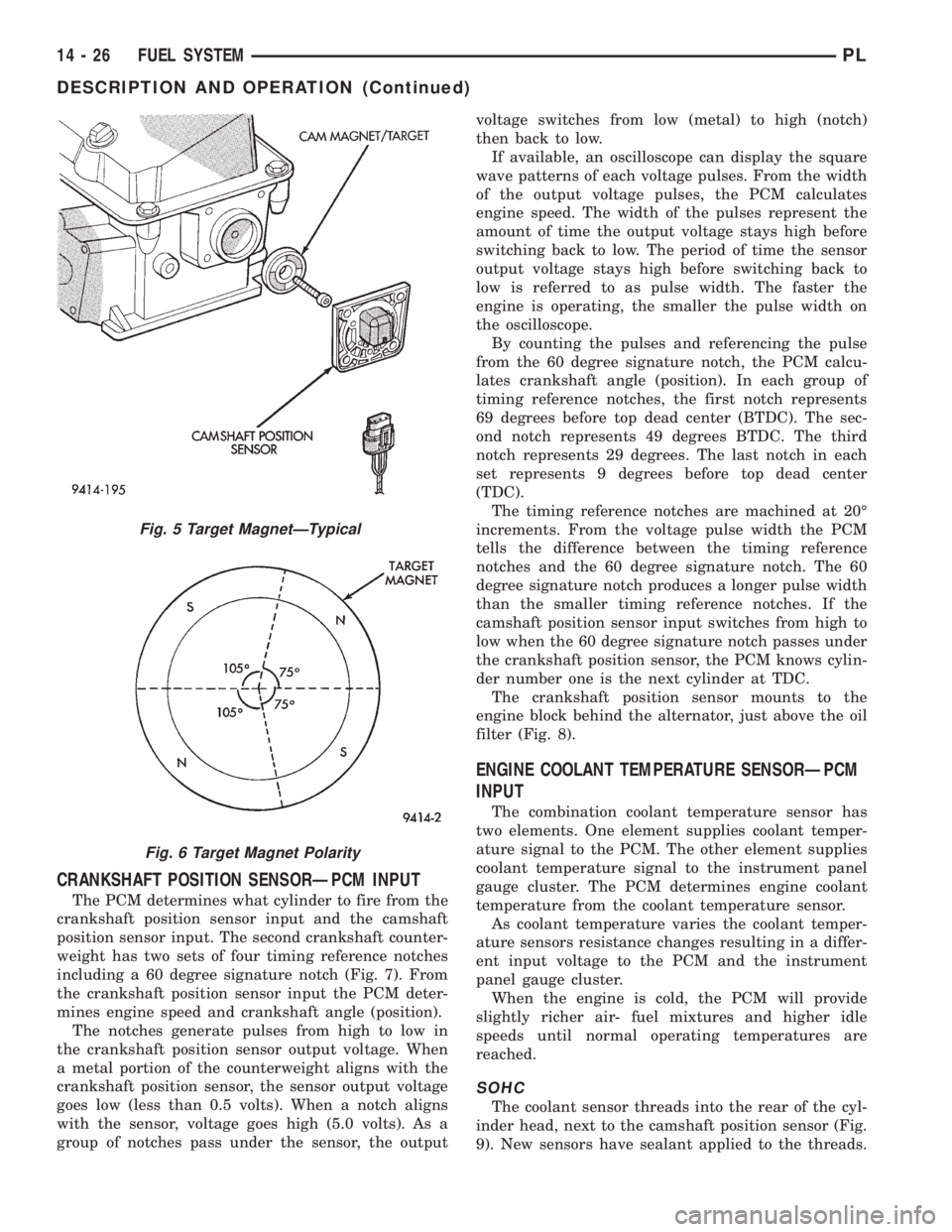

CRANKSHAFT POSITION SENSORÐPCM INPUT

The PCM determines what cylinder to fire from the

crankshaft position sensor input and the camshaft

position sensor input. The second crankshaft counter-

weight has two sets of four timing reference notches

including a 60 degree signature notch (Fig. 7). From

the crankshaft position sensor input the PCM deter-

mines engine speed and crankshaft angle (position).

The notches generate pulses from high to low in

the crankshaft position sensor output voltage. When

a metal portion of the counterweight aligns with the

crankshaft position sensor, the sensor output voltage

goes low (less than 0.5 volts). When a notch aligns

with the sensor, voltage goes high (5.0 volts). As a

group of notches pass under the sensor, the outputvoltage switches from low (metal) to high (notch)

then back to low.

If available, an oscilloscope can display the square

wave patterns of each voltage pulses. From the width

of the output voltage pulses, the PCM calculates

engine speed. The width of the pulses represent the

amount of time the output voltage stays high before

switching back to low. The period of time the sensor

output voltage stays high before switching back to

low is referred to as pulse width. The faster the

engine is operating, the smaller the pulse width on

the oscilloscope.

By counting the pulses and referencing the pulse

from the 60 degree signature notch, the PCM calcu-

lates crankshaft angle (position). In each group of

timing reference notches, the first notch represents

69 degrees before top dead center (BTDC). The sec-

ond notch represents 49 degrees BTDC. The third

notch represents 29 degrees. The last notch in each

set represents 9 degrees before top dead center

(TDC).

The timing reference notches are machined at 20É

increments. From the voltage pulse width the PCM

tells the difference between the timing reference

notches and the 60 degree signature notch. The 60

degree signature notch produces a longer pulse width

than the smaller timing reference notches. If the

camshaft position sensor input switches from high to

low when the 60 degree signature notch passes under

the crankshaft position sensor, the PCM knows cylin-

der number one is the next cylinder at TDC.

The crankshaft position sensor mounts to the

engine block behind the alternator, just above the oil

filter (Fig. 8).

ENGINE COOLANT TEMPERATURE SENSORÐPCM

INPUT

The combination coolant temperature sensor has

two elements. One element supplies coolant temper-

ature signal to the PCM. The other element supplies

coolant temperature signal to the instrument panel

gauge cluster. The PCM determines engine coolant

temperature from the coolant temperature sensor.

As coolant temperature varies the coolant temper-

ature sensors resistance changes resulting in a differ-

ent input voltage to the PCM and the instrument

panel gauge cluster.

When the engine is cold, the PCM will provide

slightly richer air- fuel mixtures and higher idle

speeds until normal operating temperatures are

reached.

SOHC

The coolant sensor threads into the rear of the cyl-

inder head, next to the camshaft position sensor (Fig.

9). New sensors have sealant applied to the threads.

Fig. 5 Target MagnetÐTypical

Fig. 6 Target Magnet Polarity

14 - 26 FUEL SYSTEMPL

DESCRIPTION AND OPERATION (Continued)

Page 870 of 1200

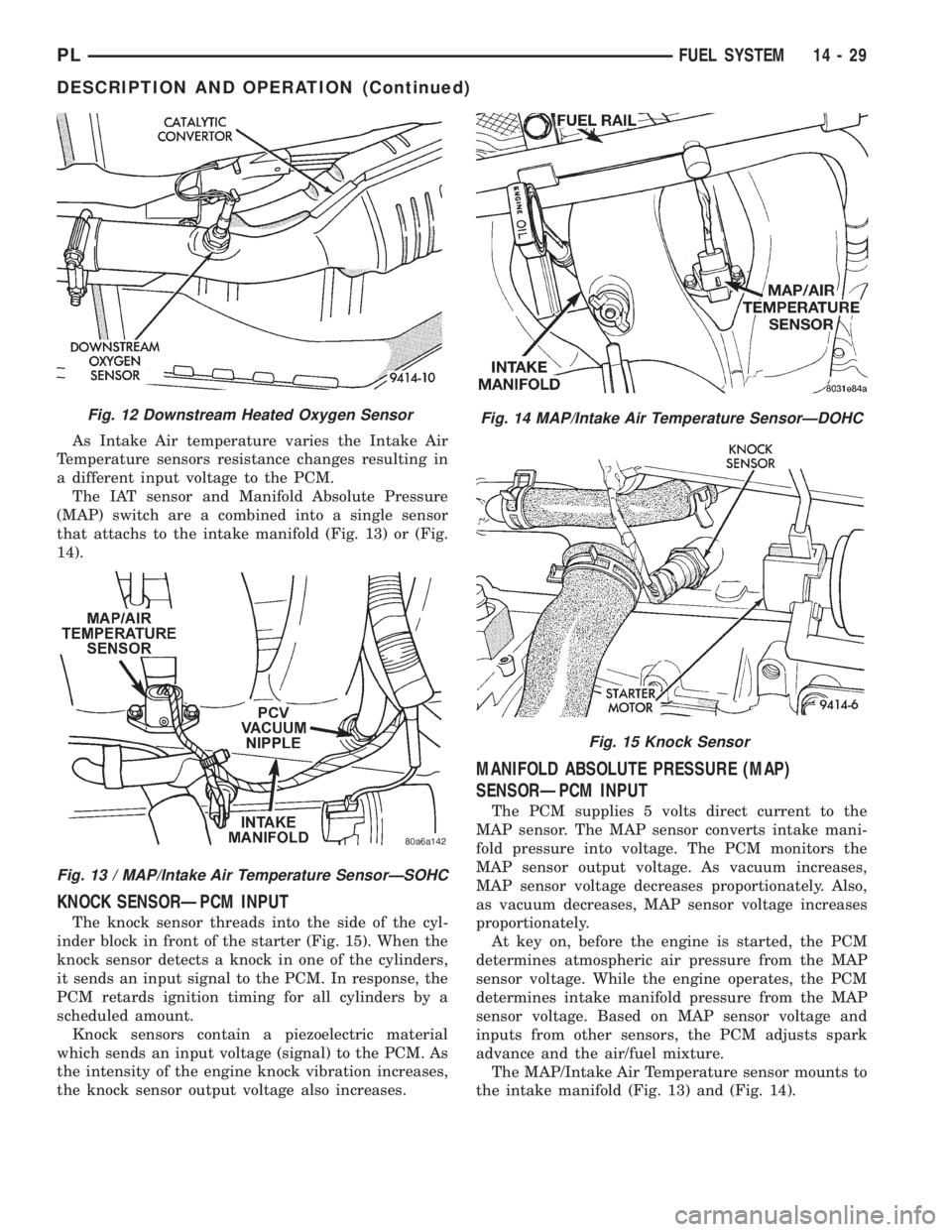

As Intake Air temperature varies the Intake Air

Temperature sensors resistance changes resulting in

a different input voltage to the PCM.

The IAT sensor and Manifold Absolute Pressure

(MAP) switch are a combined into a single sensor

that attachs to the intake manifold (Fig. 13) or (Fig.

14).

KNOCK SENSORÐPCM INPUT

The knock sensor threads into the side of the cyl-

inder block in front of the starter (Fig. 15). When the

knock sensor detects a knock in one of the cylinders,

it sends an input signal to the PCM. In response, the

PCM retards ignition timing for all cylinders by a

scheduled amount.

Knock sensors contain a piezoelectric material

which sends an input voltage (signal) to the PCM. As

the intensity of the engine knock vibration increases,

the knock sensor output voltage also increases.

MANIFOLD ABSOLUTE PRESSURE (MAP)

SENSORÐPCM INPUT

The PCM supplies 5 volts direct current to the

MAP sensor. The MAP sensor converts intake mani-

fold pressure into voltage. The PCM monitors the

MAP sensor output voltage. As vacuum increases,

MAP sensor voltage decreases proportionately. Also,

as vacuum decreases, MAP sensor voltage increases

proportionately.

At key on, before the engine is started, the PCM

determines atmospheric air pressure from the MAP

sensor voltage. While the engine operates, the PCM

determines intake manifold pressure from the MAP

sensor voltage. Based on MAP sensor voltage and

inputs from other sensors, the PCM adjusts spark

advance and the air/fuel mixture.

The MAP/Intake Air Temperature sensor mounts to

the intake manifold (Fig. 13) and (Fig. 14).

Fig. 12 Downstream Heated Oxygen Sensor

Fig. 13 / MAP/Intake Air Temperature SensorÐSOHC

Fig. 14 MAP/Intake Air Temperature SensorÐDOHC

Fig. 15 Knock Sensor

PLFUEL SYSTEM 14 - 29

DESCRIPTION AND OPERATION (Continued)

Page 893 of 1200

(9) Rotate throttle lever forward to the wide open

position and slide kickdown cable connector onto nail

head.

(10) Install throttle cable cover. Tighten bolt to 5.6

N´m (50 ins. lbs.).

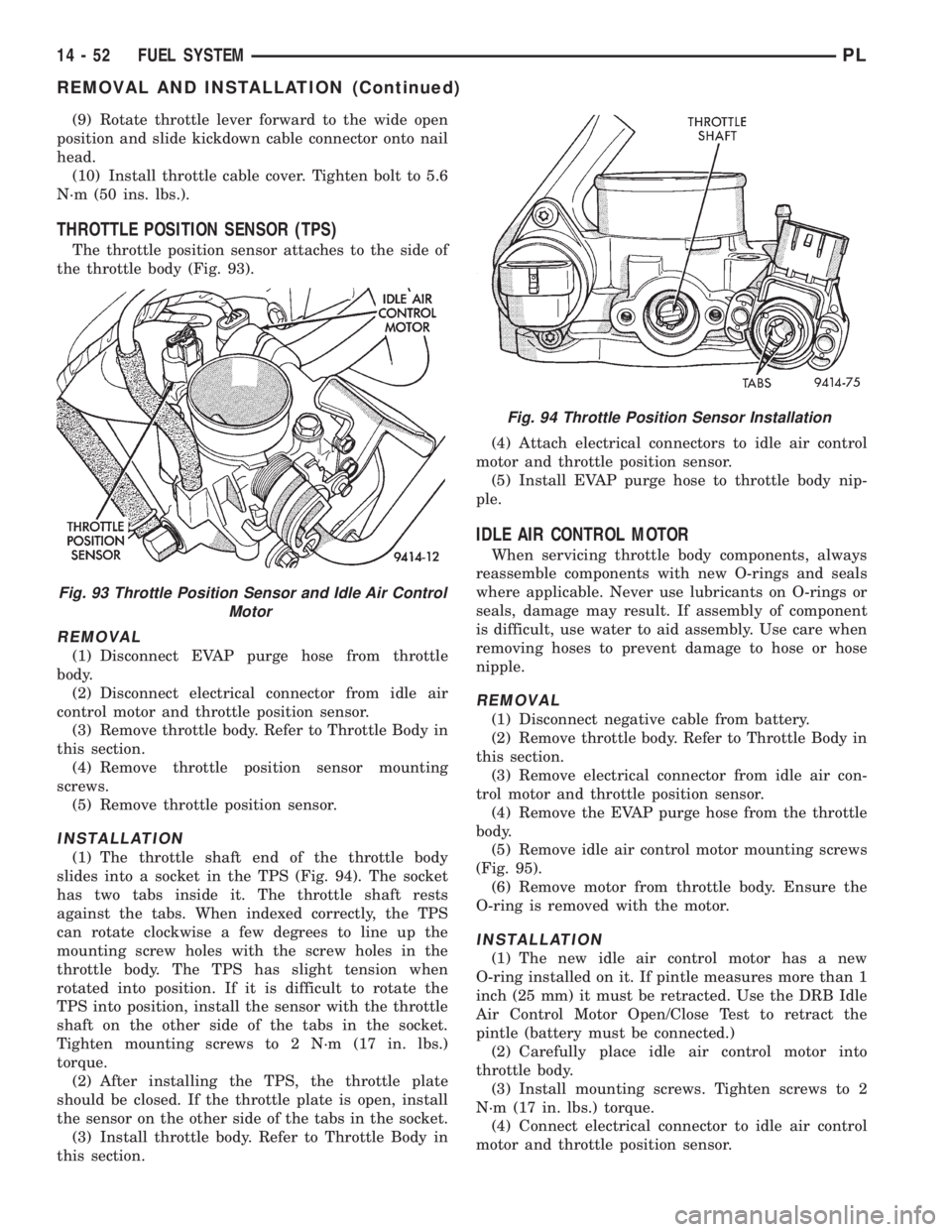

THROTTLE POSITION SENSOR (TPS)

The throttle position sensor attaches to the side of

the throttle body (Fig. 93).

REMOVAL

(1) Disconnect EVAP purge hose from throttle

body.

(2) Disconnect electrical connector from idle air

control motor and throttle position sensor.

(3) Remove throttle body. Refer to Throttle Body in

this section.

(4) Remove throttle position sensor mounting

screws.

(5) Remove throttle position sensor.

INSTALLATION

(1) The throttle shaft end of the throttle body

slides into a socket in the TPS (Fig. 94). The socket

has two tabs inside it. The throttle shaft rests

against the tabs. When indexed correctly, the TPS

can rotate clockwise a few degrees to line up the

mounting screw holes with the screw holes in the

throttle body. The TPS has slight tension when

rotated into position. If it is difficult to rotate the

TPS into position, install the sensor with the throttle

shaft on the other side of the tabs in the socket.

Tighten mounting screws to 2 N´m (17 in. lbs.)

torque.

(2) After installing the TPS, the throttle plate

should be closed. If the throttle plate is open, install

the sensor on the other side of the tabs in the socket.

(3) Install throttle body. Refer to Throttle Body in

this section.(4) Attach electrical connectors to idle air control

motor and throttle position sensor.

(5) Install EVAP purge hose to throttle body nip-

ple.

IDLE AIR CONTROL MOTOR

When servicing throttle body components, always

reassemble components with new O-rings and seals

where applicable. Never use lubricants on O-rings or

seals, damage may result. If assembly of component

is difficult, use water to aid assembly. Use care when

removing hoses to prevent damage to hose or hose

nipple.

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove throttle body. Refer to Throttle Body in

this section.

(3) Remove electrical connector from idle air con-

trol motor and throttle position sensor.

(4) Remove the EVAP purge hose from the throttle

body.

(5) Remove idle air control motor mounting screws

(Fig. 95).

(6) Remove motor from throttle body. Ensure the

O-ring is removed with the motor.

INSTALLATION

(1) The new idle air control motor has a new

O-ring installed on it. If pintle measures more than 1

inch (25 mm) it must be retracted. Use the DRB Idle

Air Control Motor Open/Close Test to retract the

pintle (battery must be connected.)

(2) Carefully place idle air control motor into

throttle body.

(3) Install mounting screws. Tighten screws to 2

N´m (17 in. lbs.) torque.

(4) Connect electrical connector to idle air control

motor and throttle position sensor.

Fig. 93 Throttle Position Sensor and Idle Air Control

Motor

Fig. 94 Throttle Position Sensor Installation

14 - 52 FUEL SYSTEMPL

REMOVAL AND INSTALLATION (Continued)