lock DODGE NEON 1999 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 912 of 1200

should be in the range of 345-552 kPa (50-80 psi).

The flow meter should read between 1.3 and 1.4

GPM

CAUTION: The following test procedure involves

testing power steering pump maximum pressure

output and flow control valve operation. Do not

leave valve closed for more than 5 seconds as the

pump could be damaged.

(8) Close valve fully three times and record high-

est pressure indicated each time.All three read-

ings must be above specifications and within

345 kPa (50 psi) of each other.

NOTE: Power steering pump maximum relief pres-

sure is 8240 to 8920 kPa (1195 to 1293 psi.).

²If power steering pump pressures above specifi-

cations but not within 345 kPa (50 psi) of each other,

then replace power steering pump.

²If pressures within 345 kPa (50 psi) of each

other but below specifications, then replace power

steering pump.

CAUTION: Do not force the pump to operate

against the stops for more than 5 seconds at a time

because, pump damage will result.

(9) Open test valve. Turn steering wheel to the

extreme left and right positions until against the

stops, recording the highest indicated pressure at

each position. Compare pressure gauge readings to

power steering pump specifications. If highest output

pressures are not the same against either stop, the

steering gear is leaking internally and must be

replaced.

SERVICE PROCEDURES

POWER STEERING SYSTEM FLUID LEVEL CHECK

WARNING: FLUID LEVEL SHOULD BE CHECKED

WITH ENGINE OFF TO PREVENT INJURY FROM

MOVING PARTS. DO NOT USE AUTOMATIC TRANS-

MISSION FLUID IN THE POWER STEERING SYS-

TEM. DO NOT OVERFILL THE POWER STEERING

SYSTEM.

Wipe reservoir filler cap free of dirt. Then check

fluid level. The dipstick should indicate COLD when

fluid is at normal ambient temperature, approxi-

mately 21ÉC to 27ÉC (70ÉF to 80ÉF). In all pumps add

fluid as necessary, use onlyMopar Power Steering

Fluid, or equivalent. DO NOT USE ANY TYPE

OF AUTOMATIC TRANSMISSION FLUID.

POWER STEERING PUMP INITIAL OPERATION

CAUTION: The fluid level should be checked with

engine off to prevent injury from moving compo-

nents. Use only MoparTPower Steering Fluid. Do

not use automatic transmission fluid. Do not over-

fill.

Wipe filler cap clean, then check the fluid level.

The dipstick should indicateFULL COLDwhen the

fluid is at normal temperature of approximately 21ÉC

to 27ÉC (70ÉF to 80ÉF).

(1) Fill the pump fluid reservoir to the proper level

and let the fluid settle for at least two (2) minutes.

(2) Start the engine and let run for a few seconds.

Then turn the engine off.

(3) Add fluid if necessary. Repeat the above proce-

dure until the fluid level remains constant after run-

ning the engine.

(4) Raise the front wheels off the ground.

(5) Start the engine. Slowly turn the steering

wheel right and left, lightly contacting the wheel

stops.

(6) Add power steering fluid if necessary.

(7) Lower the vehicle and turn the steering wheel

slowly from lock to lock.

(8) Stop the engine. Check the fluid level and refill

as required.

(9) If the fluid is extremely foamy, allow the vehi-

cle to stand a few minutes and repeat the above pro-

cedure.

POWER STEERING PUMP FLOW CONTROL VALVE

SEAL

The power steering pump does not require removal

from the engine for removal and replacement of the

flow control valve fitting O-Ring.

REMOVE

(1) Remove the power steering fluid pressure hose

from the power steering pump pressure fitting (Fig.

4).

(2) Remove the flow control valve fitting from the

power steering pump housing (Fig. 5).Prevent flow

control valve and spring from sliding out of

housing bore.

(3) Remove and discard O-ring seal from fitting.

INSTALL

(1) If necessary, clean and install flow control

valve and spring in pump housing bore.

(2) Install new O-ring seal on fitting.

(3) Install fitting in pump housing and tighten to

75 N´m (55 ft. lbs.)

(4) Install power steering fluid pressure hose on

flow control valve fitting.

PLSTEERING 19 - 11

DIAGNOSIS AND TESTING (Continued)

Page 914 of 1200

REMOVE

CAUTION: When removing and installing the

power steering pressure switch, the use of a 7/8

inch deep well socket is required. The deep well

socket will prevent damage to the plastic, electrical

connector area, of the power steering pressure

switch.

(1) Disconnect negative battery cable from the neg-

ative post of the battery. Be sure cable is isolated

from negative post on battery.

(2) Raise vehicle.

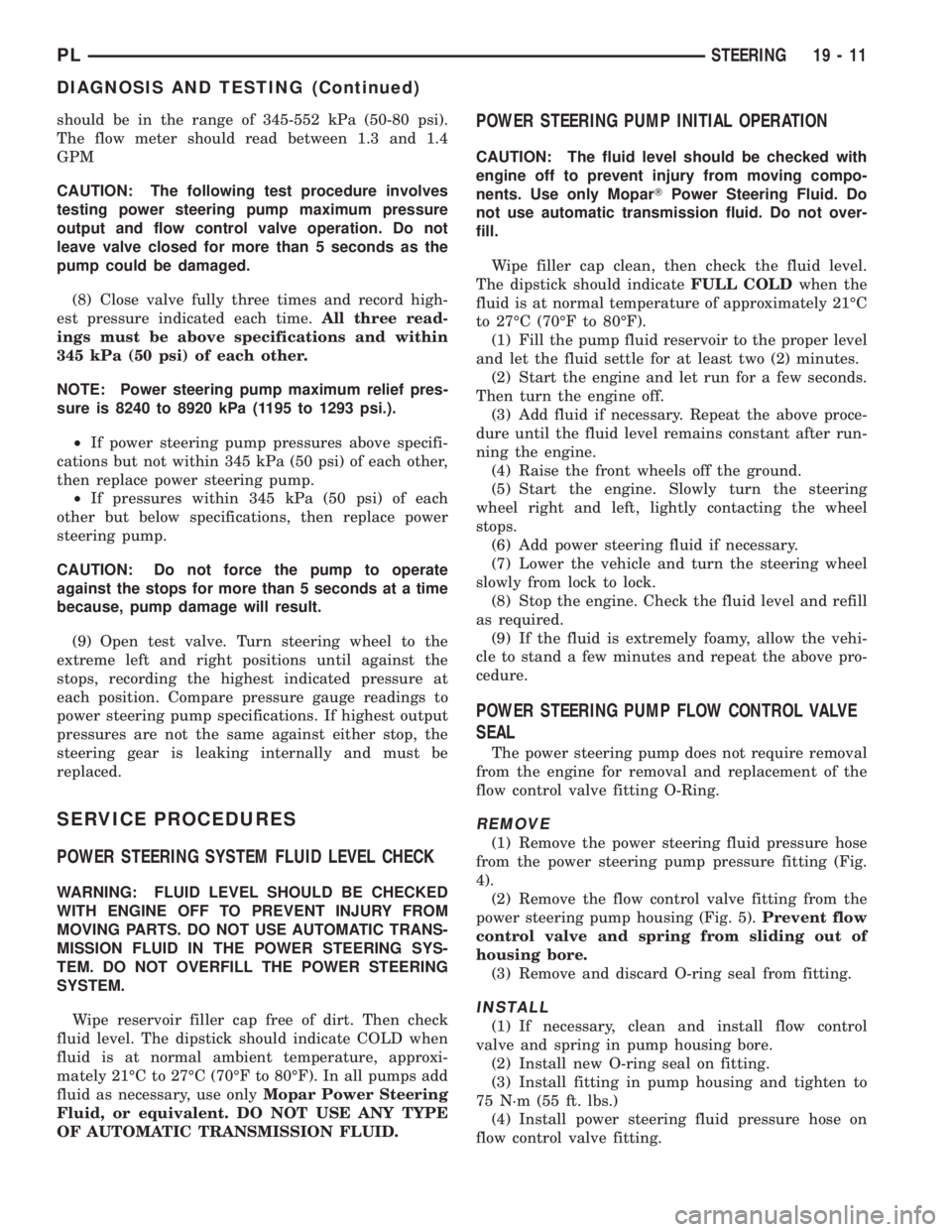

(3) Locate power steering pressure switch (Fig. 7)

on back side of power steering gear.

(4) Remove vehicle wiring harness connector (Fig.

7), from power steering pressure switch.

(5) Remove power steering pressure switch, from

power steering gear.

INSTALL

CAUTION: When installing the power steering

pressure switch in the steering gear, do not exceed

the torque specification shown in step 1 below.

Over-torquing will result in stripping the threads out

of the power steering pressure switch port on the

steering gear.

(1) By hand, install the power steering pressure

switch into the power steering gear until fully seated.

Then tighten the power steering pressure switch to a

maximum torque of 8 N´m (70 in. lbs.).

(2) Install vehicle wiring harness connector (Fig. 7)

onto power steering pressure switch. Be sure latch on

wiring harness connector is fully engaged with lock-

ing tab on power steering pressure switch.CAUTION: Do not use automatic transmission fluid

in power steering system. Only use MoparT, Power

Steering Fluid, or equivalent.

(3) Fill power steering reservoir to correct fluid

level.

(4) Connect negative cable back on negative post of

battery.

(5) Start engine and turn steering wheel several

times from stop to stop to bleed air from fluid in sys-

tem. Stop engine, check fluid level, and inspect sys-

tem for leaks. See Checking Fluid Level.

POWER STEERING FLUID PRESSURE HOSE

CAUTION: Cap all open ends of hoses, power

steering pump fittings and steering gear ports to

prevent entry of foreign material into the compo-

nents.

WARNING: POWER STEERING OIL, ENGINE

PARTS AND EXHAUST SYSTEM MAY BE

EXTREMELY HOT IF ENGINE HAS BEEN RUNNING.

DO NOT START ENGINE WITH ANY LOOSE OR DIS-

CONNECTED HOSES. DO NOT ALLOW HOSES TO

TOUCH HOT EXHAUST MANIFOLD OR CATALYST.

For part reference and part location on the vehicle

being serviced, refer to the following figure numbers.

These figures show the hose bracket locations, hose

routings and fitting locations. Use these figure num-

bers when referring to the removal or installation

procedures for the power steering hoses listed below.

REMOVE

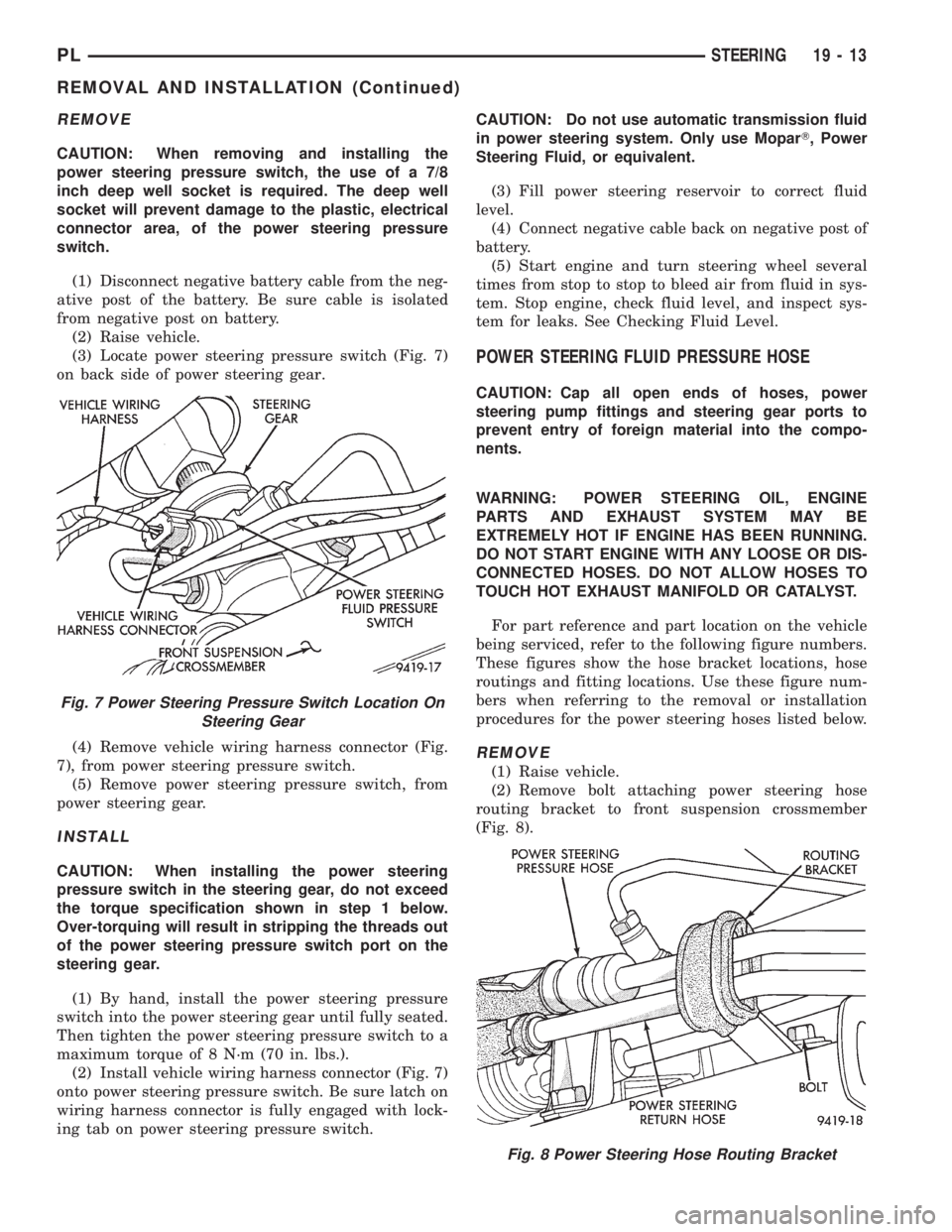

(1) Raise vehicle.

(2) Remove bolt attaching power steering hose

routing bracket to front suspension crossmember

(Fig. 8).

Fig. 7 Power Steering Pressure Switch Location On

Steering Gear

Fig. 8 Power Steering Hose Routing Bracket

PLSTEERING 19 - 13

REMOVAL AND INSTALLATION (Continued)

Page 916 of 1200

(8) Correctly route power steering pressure hose

avoiding tight bends or kinking of the hose. Install

power steering pressure hose to generator shield

routing clip attaching screw (Fig. 11)but do not

tighten at this time.

(9) Raise vehicle.

CAUTION: Hoses must remain away from exhaust

system, vehicle components and unfriendly sur-

faces causing possible damage to power steering

hoses.

(10) Route power steering pressure hose to pres-

sure port on power steering gear. Install power steer-

ing pressure hose, on steering gear and loosely

install tube nut into steering gear (Fig. 9).Tighten

and torque tube nut after routing bracket is

installed, correctly positioning hoses in vehicle.(11) Install the power steering pressure and return

hose routing clip on hoses (Fig. 8). Install bolt attach-

ing routing clip to front suspension crossmember.

Torque routing clip to front suspension crossmember

attaching bolt to 23 N´m (17 ft. lbs.)

(12) Torque power steering pressure hose to steer-

ing gear tube nut to 34 N´m (25 ft. lbs.).

(13) Install power steering pressure hose in rout-

ing clip on generator shield (Fig. 10).

(14) Lower Vehicle.

(15) Position locating pin on power steering pres-

sure hose banjo fitting so it is against power steering

pump mounting bracket (Fig. 12). While holding

locating pin against power steering pump bracket,

torque pump end Banjo bolt to 34 N´m (25 ft. lbs.).

(16) Securely tighten bolt attaching power steering

pressure hose bracket to generator shield.

(17) Start the engine and let run for a few seconds.

Then turn the engine off.

(18) Add fluid if necessary. Repeat the above pro-

cedure until the fluid level remains constant after

running the engine.

(19) Raise front wheels of vehicle off the ground.

(20) Start the engine. Slowly turn the steering

wheel right and left, lightly contacting the wheel

stops. Then turn the engine off.

(21) Add power steering fluid if necessary.

(22) Lower the vehicle and turn the steering wheel

slowly from lock to lock.

(23) Stop the engine. Check the fluid level and

refill as required.

(24) If the fluid is extremely foamy, allow the vehi-

cle to stand a few minutes and repeat the above pro-

cedure.

(25) After hose is installed, check for leaks at all

hose connections.POWER STEERING FLUID RETURN HOSE

CAUTION: Cap all open ends of hoses, power

steering pump fittings and steering gear ports to

prevent entry of foreign material into the compo-

nents.

WARNING: POWER STEERING OIL, ENGINE

PARTS AND EXHAUST SYSTEM MAY BE

EXTREMELY HOT IF ENGINE HAS BEEN RUNNING.

DO NOT START ENGINE WITH ANY LOOSE OR DIS-

CONNECTED HOSES. DO NOT ALLOW HOSES TO

TOUCH HOT EXHAUST MANIFOLD OR CATALYST.

REMOVE

(1) Raise vehicle.

(2) Remove hose clamp, attaching return hose to

steel tube at power steering gear (Fig. 15). Let power

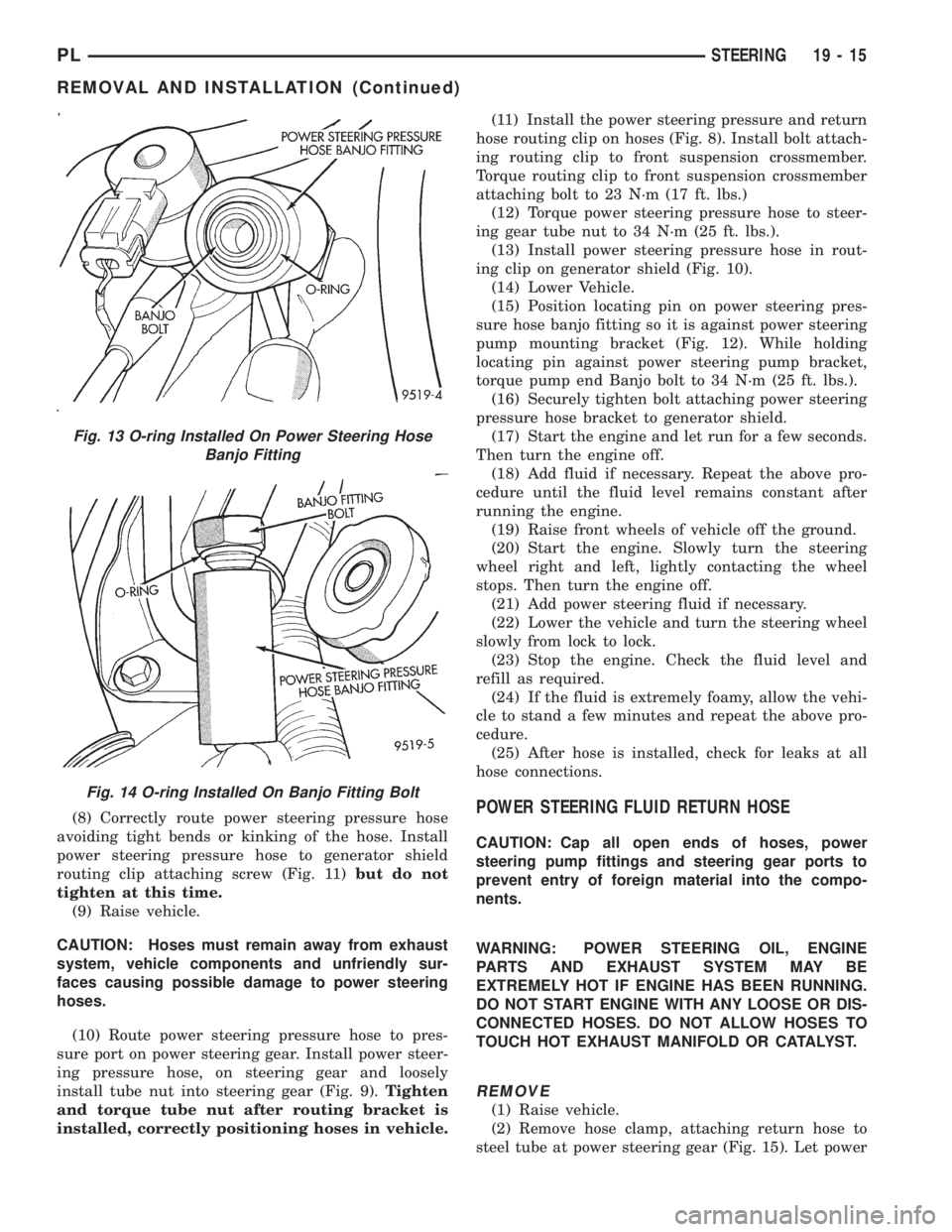

Fig. 13 O-ring Installed On Power Steering Hose

Banjo Fitting

Fig. 14 O-ring Installed On Banjo Fitting Bolt

PLSTEERING 19 - 15

REMOVAL AND INSTALLATION (Continued)

Page 918 of 1200

installed on return hose past upset bead on

power steering fluid reservoir.

(3) Raise vehicle.

(4) Clip power steering return hose and pressure

hose together (Fig. 17).

(5) Install power steering return hose on steel tube

at power steering gear (Fig. 15). Install hose clamp

on power steering return hose at power steering gear

(Fig. 15).Be sure hose clamp is installed on

return hose past upset bead on steel tube at

power gear.

(6) Install power steering return hose on routing

clip at generator shield (Fig. 16).

(7) Lower vehicle.

(8) Start the engine and let run for a few seconds.

Then turn the engine off.

(9) Add fluid if necessary. Repeat the above proce-

dure until the fluid level remains constant after run-

ning the engine.

(10) Raise front wheels of vehicle off the ground.

(11) Start the engine. Slowly turn the steering

wheel right and left, lightly contacting the wheel

stops. Then turn the engine off.

(12) Add power steering fluid if necessary.

(13) Lower the vehicle and turn the steering wheel

slowly from lock to lock.

(14) Stop the engine. Check the fluid level and

refill as required.

(15) If the fluid is extremely foamy, allow the vehi-

cle to stand a few minutes and repeat the above pro-

cedure.

(16) After hose is installed, check for leaks at all

hose connections.

POWER STEERING FLUID SUPPLY HOSE

RESERVOIR TO POWER STEERING PUMP

WARNING: POWER STEERING OIL, ENGINE

PARTS AND EXHAUST SYSTEM MAY BE

EXTREMELY HOT IF ENGINE HAS BEEN RUNNING.

DO NOT START ENGINE WITH ANY LOOSE OR DIS-

CONNECTED HOSES. DO NOT ALLOW HOSES TO

TOUCH HOT EXHAUST MANIFOLD OR CATALYST.

REMOVE

CAUTION: Care must be used when removing the

power steering fluid supply hose from power steer-

ing fluid reservoir. If excessive force is used when

trying to remove hose from nipple on power steer-

ing fluid reservoir, nipple can break off of the res-

ervoir.

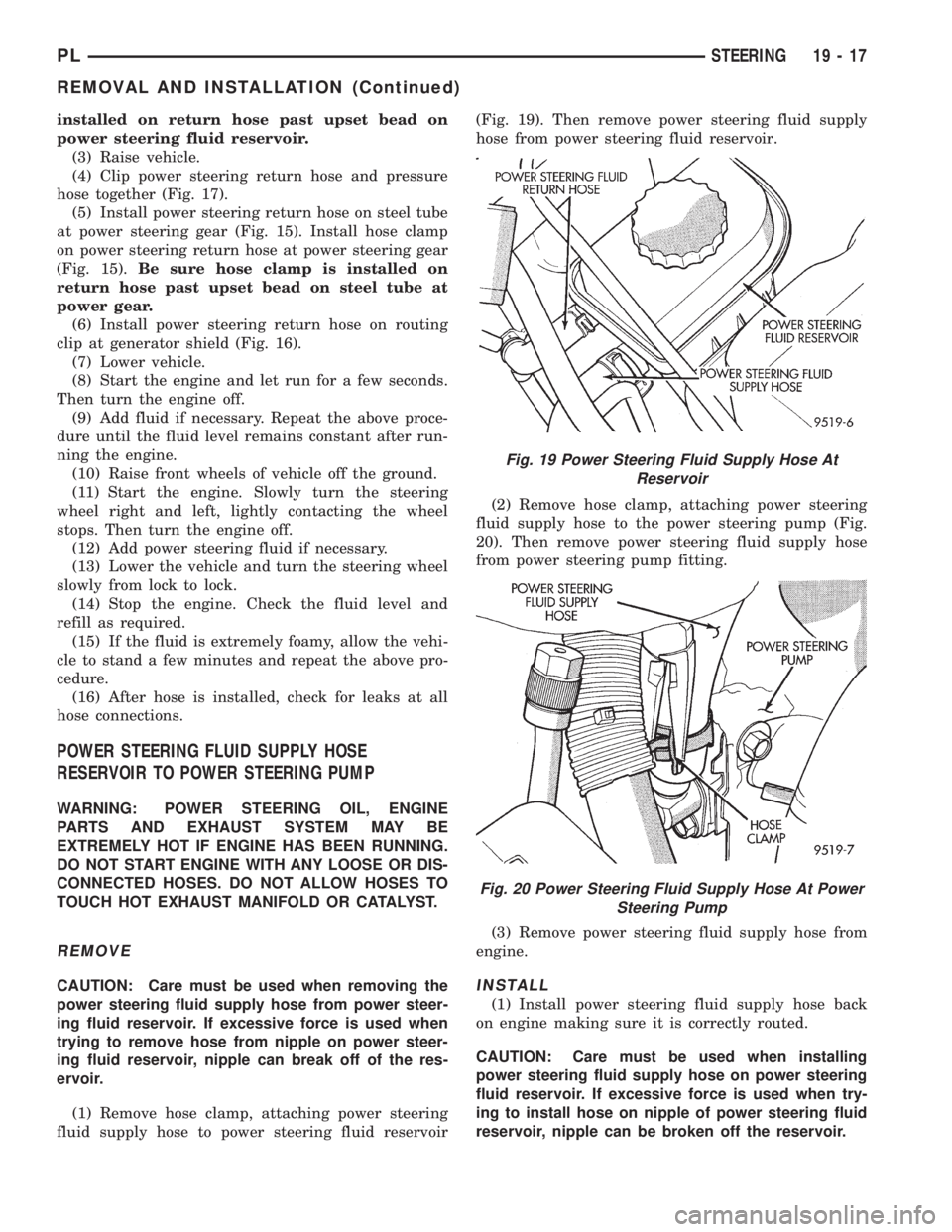

(1) Remove hose clamp, attaching power steering

fluid supply hose to power steering fluid reservoir(Fig. 19). Then remove power steering fluid supply

hose from power steering fluid reservoir.

(2) Remove hose clamp, attaching power steering

fluid supply hose to the power steering pump (Fig.

20). Then remove power steering fluid supply hose

from power steering pump fitting.

(3) Remove power steering fluid supply hose from

engine.INSTALL

(1) Install power steering fluid supply hose back

on engine making sure it is correctly routed.

CAUTION: Care must be used when installing

power steering fluid supply hose on power steering

fluid reservoir. If excessive force is used when try-

ing to install hose on nipple of power steering fluid

reservoir, nipple can be broken off the reservoir.

Fig. 19 Power Steering Fluid Supply Hose At

Reservoir

Fig. 20 Power Steering Fluid Supply Hose At Power

Steering Pump

PLSTEERING 19 - 17

REMOVAL AND INSTALLATION (Continued)

Page 919 of 1200

(2) Install power steering fluid supply hose on

power steering fluid reservoir fitting. Install hose

clamp on power steering fluid supply hose at power

steering fluid reservoir (Fig. 19).Be sure hose

clamp is installed on return hose past upset

bead on power steering fluid reservoir.

(3) Install power steering fluid supply hose on

power steering pump fitting. Install hose clamp on

power steering fluid supply hose at power steering

pump fitting (Fig. 20).Be sure hose clamp is

installed on power steering fluid supply hose

past upset bead on power steering pump fit-

ting.

(4) Start the engine and let run for a few seconds.

Then turn the engine off.

(5) Add fluid if necessary. Repeat the above proce-

dure until the fluid level remains constant after run-

ning the engine.

(6) Raise front wheels of vehicle off the ground.

(7) Start the engine. Slowly turn the steering

wheel right and left, lightly contacting the wheel

stops. Then turn the engine off.

(8) Add power steering fluid if necessary.

(9) Lower the vehicle and turn the steering wheel

slowly from lock to lock.

(10) Stop the engine. Check the fluid level and

refill as required.

(11) If the fluid is extremely foamy, allow the vehi-

cle to stand a few minutes and repeat the above pro-

cedure.

(12) After hose is installed, check for leaks at all

hose connections.

POWER STEERING PUMP (ALL ENGINES)

WARNING: POWER STEERING OIL, ENGINE COM-

PONENTS AND EXHAUST SYSTEM MAY BE

EXTREMELY HOT IF ENGINE HAS BEEN RUNNING.

DO NOT START ENGINE WITH ANY LOOSE OR DIS-

CONNECTED HOSES, OR ALLOW HOSES TO

TOUCH HOT EXHAUST MANIFOLD OR CATALYST.

The power steering pump removal procedure and

pump and bracket fastener locations are the same for

both engine applications used for this vehicle. The

front power steering pump bracket must be removed

as an assembly with the power steering pump and

removed from the pump after removing the pulley

from the power steering pump.

REMOVE

(1) Remove battery cable from (-) negative post on

battery.

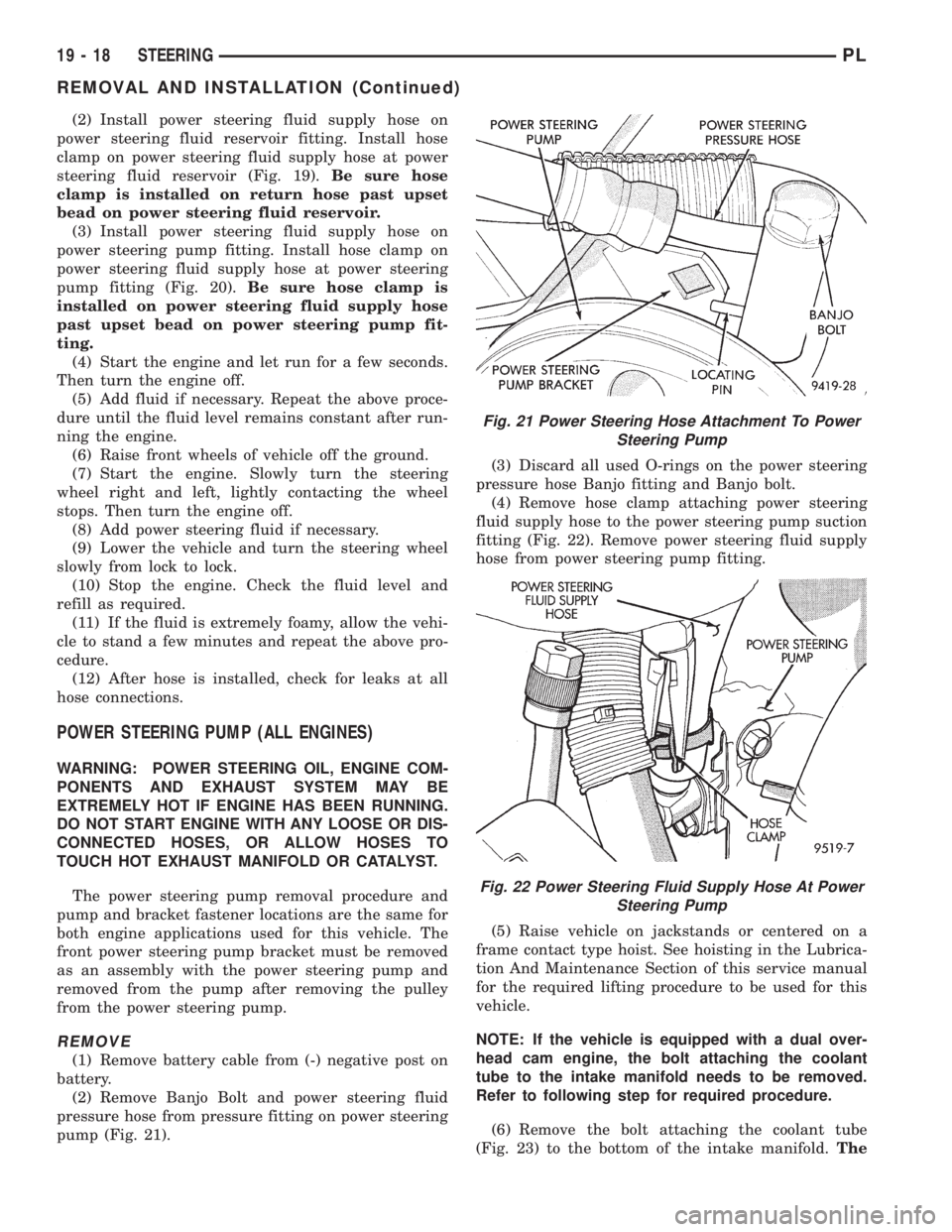

(2) Remove Banjo Bolt and power steering fluid

pressure hose from pressure fitting on power steering

pump (Fig. 21).(3) Discard all used O-rings on the power steering

pressure hose Banjo fitting and Banjo bolt.

(4) Remove hose clamp attaching power steering

fluid supply hose to the power steering pump suction

fitting (Fig. 22). Remove power steering fluid supply

hose from power steering pump fitting.

(5) Raise vehicle on jackstands or centered on a

frame contact type hoist. See hoisting in the Lubrica-

tion And Maintenance Section of this service manual

for the required lifting procedure to be used for this

vehicle.

NOTE: If the vehicle is equipped with a dual over-

head cam engine, the bolt attaching the coolant

tube to the intake manifold needs to be removed.

Refer to following step for required procedure.

(6) Remove the bolt attaching the coolant tube

(Fig. 23) to the bottom of the intake manifold.The

Fig. 21 Power Steering Hose Attachment To Power

Steering Pump

Fig. 22 Power Steering Fluid Supply Hose At Power

Steering Pump

19 - 18 STEERINGPL

REMOVAL AND INSTALLATION (Continued)

Page 921 of 1200

drive belt tension. See Accessory Drive Belts in

Group 7 Cooling System of this service manual for

the correct drive belt tension specification. When cor-

rect drive belt tension is obtained torque the 2 bolts

at the power steering pump cast mounting bracket

(Fig. 24) to 54 N´m (40 ft. lbs.). Then torque the front

power steering pump mounting bracket bolt (Fig. 25)

to 54 N´m (40 ft. lbs.).

(6) Install power steering supply hose on power

steering pump suction fitting (Fig. 22). Install hose

clamp on hose, being sure hose clamp is installed on

hose past upset bead on power steering pump tube.

(7) Using a lint free towel, wipe clean all open

power steering hose ends, and power steering pump

fittings.

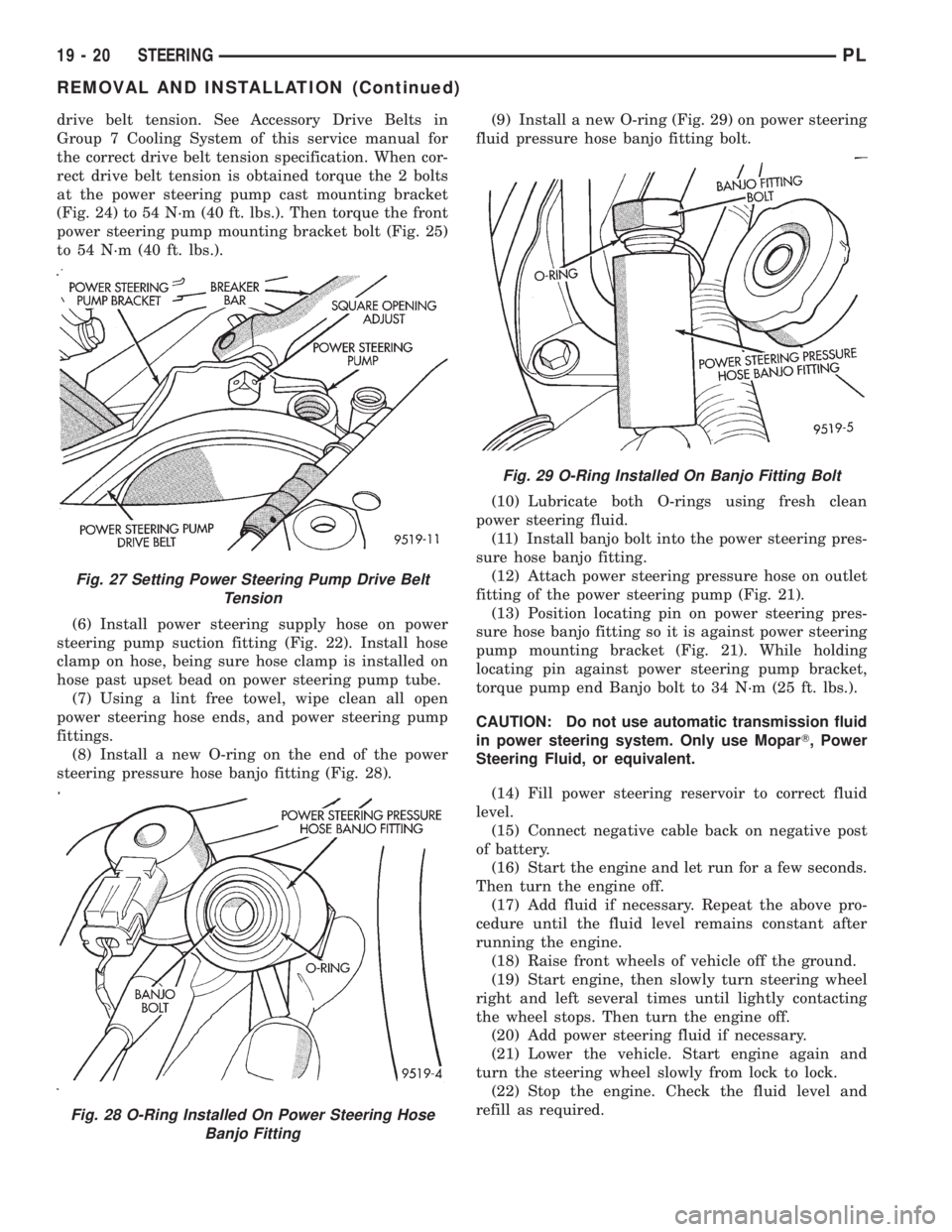

(8) Install a new O-ring on the end of the power

steering pressure hose banjo fitting (Fig. 28).(9) Install a new O-ring (Fig. 29) on power steering

fluid pressure hose banjo fitting bolt.

(10) Lubricate both O-rings using fresh clean

power steering fluid.

(11) Install banjo bolt into the power steering pres-

sure hose banjo fitting.

(12) Attach power steering pressure hose on outlet

fitting of the power steering pump (Fig. 21).

(13) Position locating pin on power steering pres-

sure hose banjo fitting so it is against power steering

pump mounting bracket (Fig. 21). While holding

locating pin against power steering pump bracket,

torque pump end Banjo bolt to 34 N´m (25 ft. lbs.).

CAUTION: Do not use automatic transmission fluid

in power steering system. Only use MoparT, Power

Steering Fluid, or equivalent.

(14) Fill power steering reservoir to correct fluid

level.

(15) Connect negative cable back on negative post

of battery.

(16) Start the engine and let run for a few seconds.

Then turn the engine off.

(17) Add fluid if necessary. Repeat the above pro-

cedure until the fluid level remains constant after

running the engine.

(18) Raise front wheels of vehicle off the ground.

(19) Start engine, then slowly turn steering wheel

right and left several times until lightly contacting

the wheel stops. Then turn the engine off.

(20) Add power steering fluid if necessary.

(21) Lower the vehicle. Start engine again and

turn the steering wheel slowly from lock to lock.

(22) Stop the engine. Check the fluid level and

refill as required.

Fig. 27 Setting Power Steering Pump Drive Belt

Tension

Fig. 28 O-Ring Installed On Power Steering Hose

Banjo Fitting

Fig. 29 O-Ring Installed On Banjo Fitting Bolt

19 - 20 STEERINGPL

REMOVAL AND INSTALLATION (Continued)

Page 923 of 1200

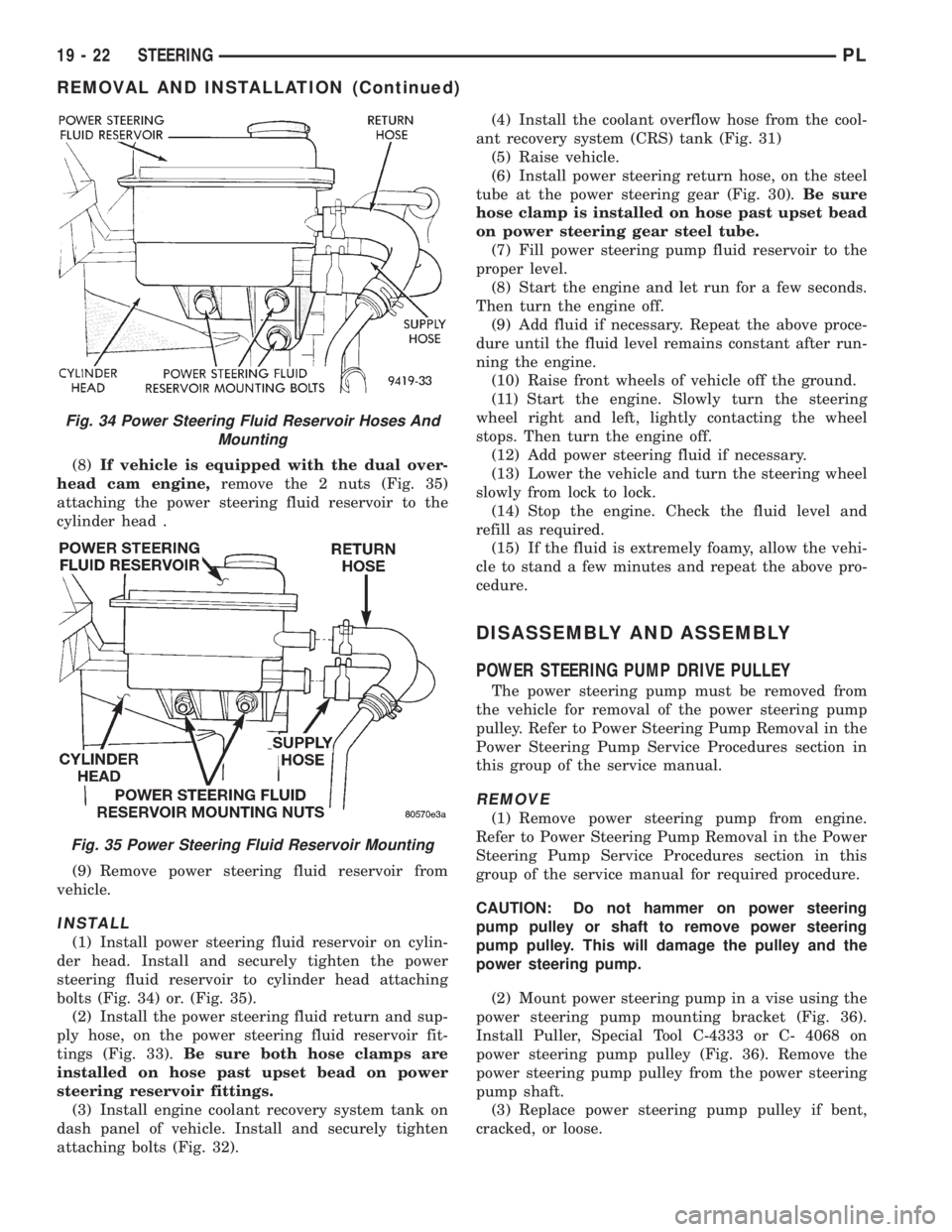

(8)If vehicle is equipped with the dual over-

head cam engine,remove the 2 nuts (Fig. 35)

attaching the power steering fluid reservoir to the

cylinder head .

(9) Remove power steering fluid reservoir from

vehicle.

INSTALL

(1) Install power steering fluid reservoir on cylin-

der head. Install and securely tighten the power

steering fluid reservoir to cylinder head attaching

bolts (Fig. 34) or. (Fig. 35).

(2) Install the power steering fluid return and sup-

ply hose, on the power steering fluid reservoir fit-

tings (Fig. 33).Be sure both hose clamps are

installed on hose past upset bead on power

steering reservoir fittings.

(3) Install engine coolant recovery system tank on

dash panel of vehicle. Install and securely tighten

attaching bolts (Fig. 32).(4) Install the coolant overflow hose from the cool-

ant recovery system (CRS) tank (Fig. 31)

(5) Raise vehicle.

(6) Install power steering return hose, on the steel

tube at the power steering gear (Fig. 30).Be sure

hose clamp is installed on hose past upset bead

on power steering gear steel tube.

(7) Fill power steering pump fluid reservoir to the

proper level.

(8) Start the engine and let run for a few seconds.

Then turn the engine off.

(9) Add fluid if necessary. Repeat the above proce-

dure until the fluid level remains constant after run-

ning the engine.

(10) Raise front wheels of vehicle off the ground.

(11) Start the engine. Slowly turn the steering

wheel right and left, lightly contacting the wheel

stops. Then turn the engine off.

(12) Add power steering fluid if necessary.

(13) Lower the vehicle and turn the steering wheel

slowly from lock to lock.

(14) Stop the engine. Check the fluid level and

refill as required.

(15) If the fluid is extremely foamy, allow the vehi-

cle to stand a few minutes and repeat the above pro-

cedure.

DISASSEMBLY AND ASSEMBLY

POWER STEERING PUMP DRIVE PULLEY

The power steering pump must be removed from

the vehicle for removal of the power steering pump

pulley. Refer to Power Steering Pump Removal in the

Power Steering Pump Service Procedures section in

this group of the service manual.

REMOVE

(1) Remove power steering pump from engine.

Refer to Power Steering Pump Removal in the Power

Steering Pump Service Procedures section in this

group of the service manual for required procedure.

CAUTION: Do not hammer on power steering

pump pulley or shaft to remove power steering

pump pulley. This will damage the pulley and the

power steering pump.

(2) Mount power steering pump in a vise using the

power steering pump mounting bracket (Fig. 36).

Install Puller, Special Tool C-4333 or C- 4068 on

power steering pump pulley (Fig. 36). Remove the

power steering pump pulley from the power steering

pump shaft.

(3) Replace power steering pump pulley if bent,

cracked, or loose.

Fig. 34 Power Steering Fluid Reservoir Hoses And

Mounting

Fig. 35 Power Steering Fluid Reservoir Mounting

19 - 22 STEERINGPL

REMOVAL AND INSTALLATION (Continued)

Page 932 of 1200

Torque the 4 steering gear mounting bolts to 68 N´m

(50 ft. lbs.).

(2) Using the transmission jack, raise front sus-

pension crossmember and steering gear against body

and frame rails of vehicle. Start the 2 rear bolts into

tapping plates, attaching front suspension crossmem-

ber to body of vehicle (Fig. 13). Then install the 2

front bolts, attaching front suspension crossmember

to frame rails of vehicle (Fig. 13). Tighten the 4

mounting bolts, until front suspension crossmember

is against body of vehicle at the 4 mounting points.

Then torque the 4 mounting bolts to 2 N´m (20 in.

lbs.) to hold front suspension crossmember in posi-

tion.

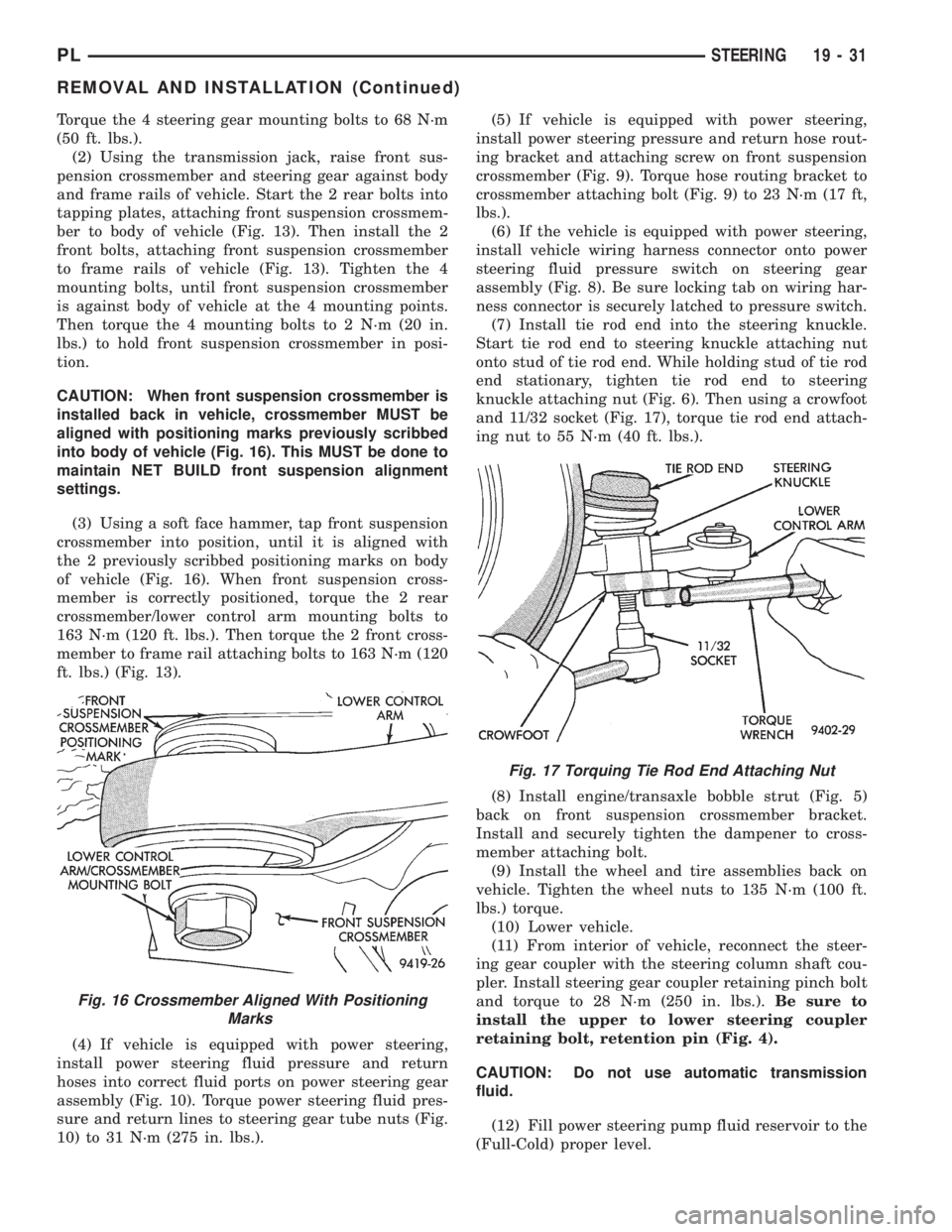

CAUTION: When front suspension crossmember is

installed back in vehicle, crossmember MUST be

aligned with positioning marks previously scribbed

into body of vehicle (Fig. 16). This MUST be done to

maintain NET BUILD front suspension alignment

settings.

(3) Using a soft face hammer, tap front suspension

crossmember into position, until it is aligned with

the 2 previously scribbed positioning marks on body

of vehicle (Fig. 16). When front suspension cross-

member is correctly positioned, torque the 2 rear

crossmember/lower control arm mounting bolts to

163 N´m (120 ft. lbs.). Then torque the 2 front cross-

member to frame rail attaching bolts to 163 N´m (120

ft. lbs.) (Fig. 13).

(4) If vehicle is equipped with power steering,

install power steering fluid pressure and return

hoses into correct fluid ports on power steering gear

assembly (Fig. 10). Torque power steering fluid pres-

sure and return lines to steering gear tube nuts (Fig.

10) to 31 N´m (275 in. lbs.).(5) If vehicle is equipped with power steering,

install power steering pressure and return hose rout-

ing bracket and attaching screw on front suspension

crossmember (Fig. 9). Torque hose routing bracket to

crossmember attaching bolt (Fig. 9) to 23 N´m (17 ft,

lbs.).

(6) If the vehicle is equipped with power steering,

install vehicle wiring harness connector onto power

steering fluid pressure switch on steering gear

assembly (Fig. 8). Be sure locking tab on wiring har-

ness connector is securely latched to pressure switch.

(7) Install tie rod end into the steering knuckle.

Start tie rod end to steering knuckle attaching nut

onto stud of tie rod end. While holding stud of tie rod

end stationary, tighten tie rod end to steering

knuckle attaching nut (Fig. 6). Then using a crowfoot

and 11/32 socket (Fig. 17), torque tie rod end attach-

ing nut to 55 N´m (40 ft. lbs.).

(8) Install engine/transaxle bobble strut (Fig. 5)

back on front suspension crossmember bracket.

Install and securely tighten the dampener to cross-

member attaching bolt.

(9) Install the wheel and tire assemblies back on

vehicle. Tighten the wheel nuts to 135 N´m (100 ft.

lbs.) torque.

(10) Lower vehicle.

(11) From interior of vehicle, reconnect the steer-

ing gear coupler with the steering column shaft cou-

pler. Install steering gear coupler retaining pinch bolt

and torque to 28 N´m (250 in. lbs.).Be sure to

install the upper to lower steering coupler

retaining bolt, retention pin (Fig. 4).

CAUTION: Do not use automatic transmission

fluid.

(12) Fill power steering pump fluid reservoir to the

(Full-Cold) proper level.

Fig. 16 Crossmember Aligned With Positioning

Marks

Fig. 17 Torquing Tie Rod End Attaching Nut

PLSTEERING 19 - 31

REMOVAL AND INSTALLATION (Continued)

Page 936 of 1200

STEERING COLUMN

INDEX

page page

DESCRIPTION AND OPERATION

STEERING COLUMN ASSEMBLY............ 35

STEERING GEAR TO STEERING

COLUMN COUPLING................... 36

DIAGNOSIS AND TESTING

STEERING COLUMN TO STEERING

GEAR COUPLING...................... 36

STEERING COLUMN..................... 36REMOVAL AND INSTALLATION

STEERING COLUMN SERVICE

PROCEDURE WARNINGS............... 37

STEERING COLUMN..................... 38

SPECIFICATIONS

STEERING COLUMN FASTEER

TORQUE SPECIFICATIONS.............. 42

DESCRIPTION AND OPERATION

STEERING COLUMN ASSEMBLY

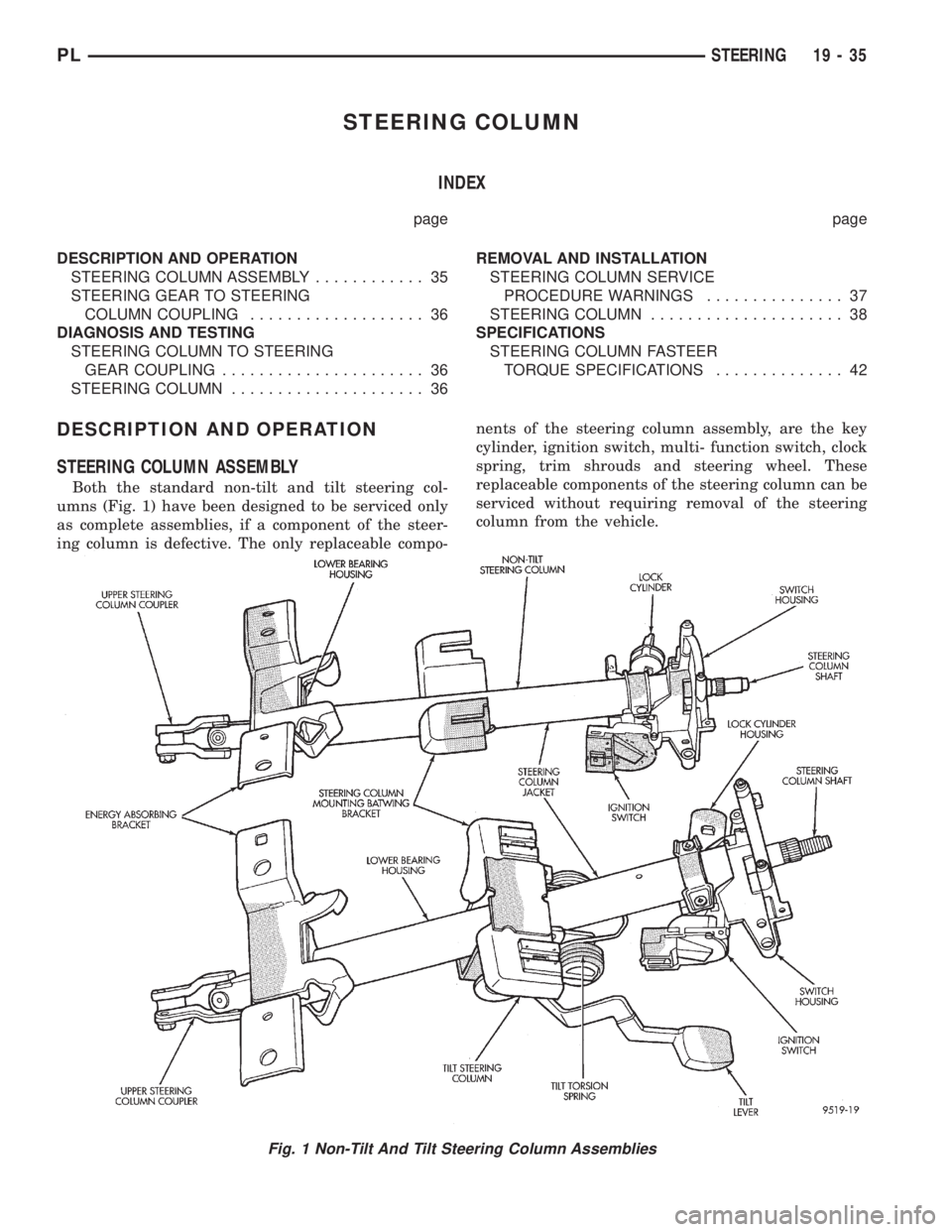

Both the standard non-tilt and tilt steering col-

umns (Fig. 1) have been designed to be serviced only

as complete assemblies, if a component of the steer-

ing column is defective. The only replaceable compo-nents of the steering column assembly, are the key

cylinder, ignition switch, multi- function switch, clock

spring, trim shrouds and steering wheel. These

replaceable components of the steering column can be

serviced without requiring removal of the steering

column from the vehicle.

Fig. 1 Non-Tilt And Tilt Steering Column Assemblies

PLSTEERING 19 - 35

Page 940 of 1200

WARNING: WHEN HANDLING AN UNDEPLOYED

AIR BAG MODULE DURING SERVICING OF THE

STEERING COLUMN THE FOLLOWING PRECAU-

TIONS SHOULD BE OBSERVED. AT NO TIME

SHOULD ANY SOURCE OF ELECTRICITY BE PER-

MITTED NEAR THE INFLATOR ON THE BACK OF

THE AIR BAG MODULE. WHEN CARRYING A LIVE

MODULE, THE TRIM COVER SHOULD BE POINTED

AWAY FROM THE BODY TO MINIMIZE INJURY IF

MODULE ACCIDENTLY DEPLOYS. IF AIR BAG MOD-

ULE IS PLACED ON A BENCH OR OTHER SUR-

FACE, PLASTIC COVER SHOULD BE FACE UP TO

MINIMIZE MOVEMENT IN CASE OF ACCIDENTAL

DEPLOYMENT.

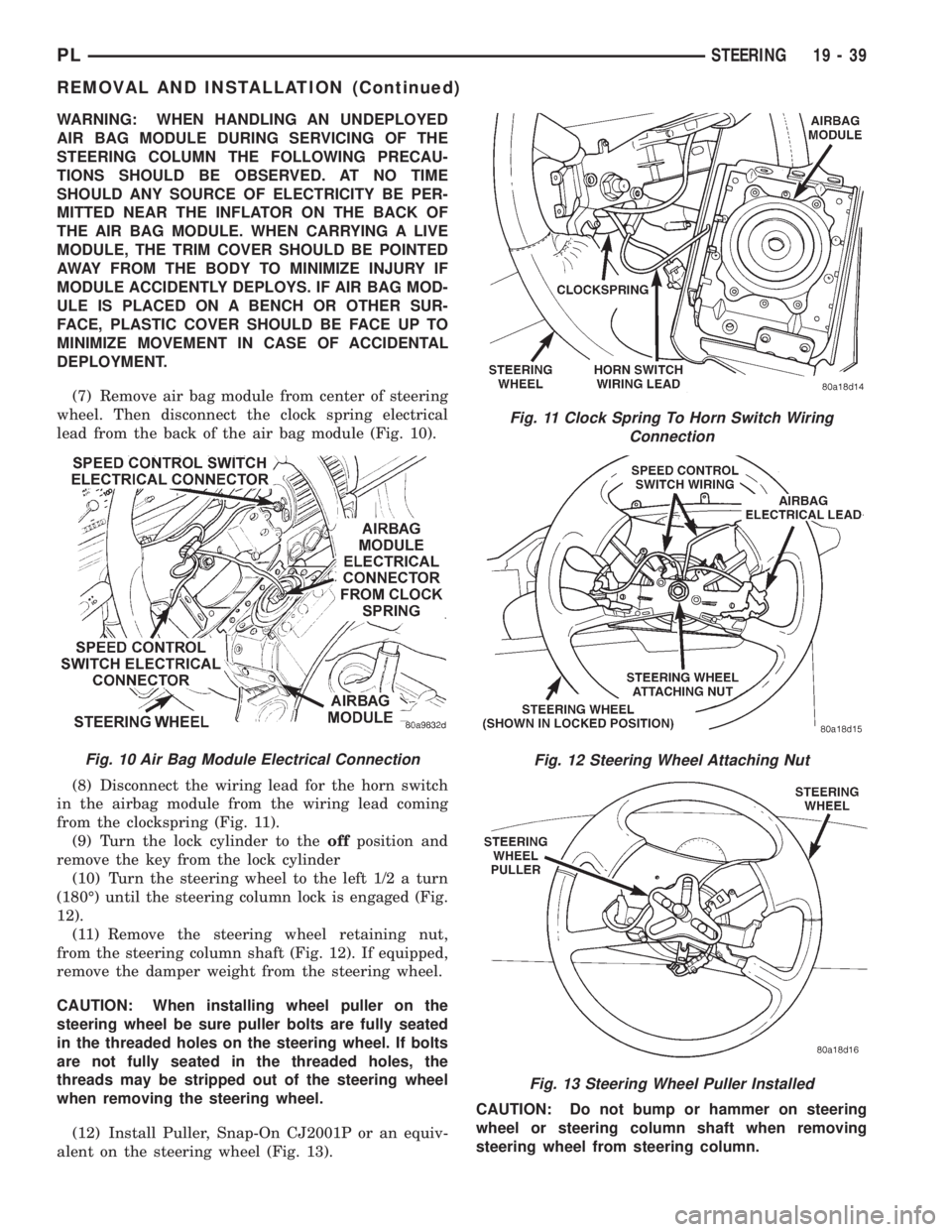

(7) Remove air bag module from center of steering

wheel. Then disconnect the clock spring electrical

lead from the back of the air bag module (Fig. 10).

(8) Disconnect the wiring lead for the horn switch

in the airbag module from the wiring lead coming

from the clockspring (Fig. 11).

(9) Turn the lock cylinder to theoffposition and

remove the key from the lock cylinder

(10) Turn the steering wheel to the left 1/2 a turn

(180É) until the steering column lock is engaged (Fig.

12).

(11) Remove the steering wheel retaining nut,

from the steering column shaft (Fig. 12). If equipped,

remove the damper weight from the steering wheel.

CAUTION: When installing wheel puller on the

steering wheel be sure puller bolts are fully seated

in the threaded holes on the steering wheel. If bolts

are not fully seated in the threaded holes, the

threads may be stripped out of the steering wheel

when removing the steering wheel.

(12) Install Puller, Snap-On CJ2001P or an equiv-

alent on the steering wheel (Fig. 13).CAUTION: Do not bump or hammer on steering

wheel or steering column shaft when removing

steering wheel from steering column.

Fig. 11 Clock Spring To Horn Switch Wiring

Connection

Fig. 12 Steering Wheel Attaching Nut

Fig. 13 Steering Wheel Puller Installed

Fig. 10 Air Bag Module Electrical Connection

PLSTEERING 19 - 39

REMOVAL AND INSTALLATION (Continued)