lock DODGE NEON 1999 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 800 of 1200

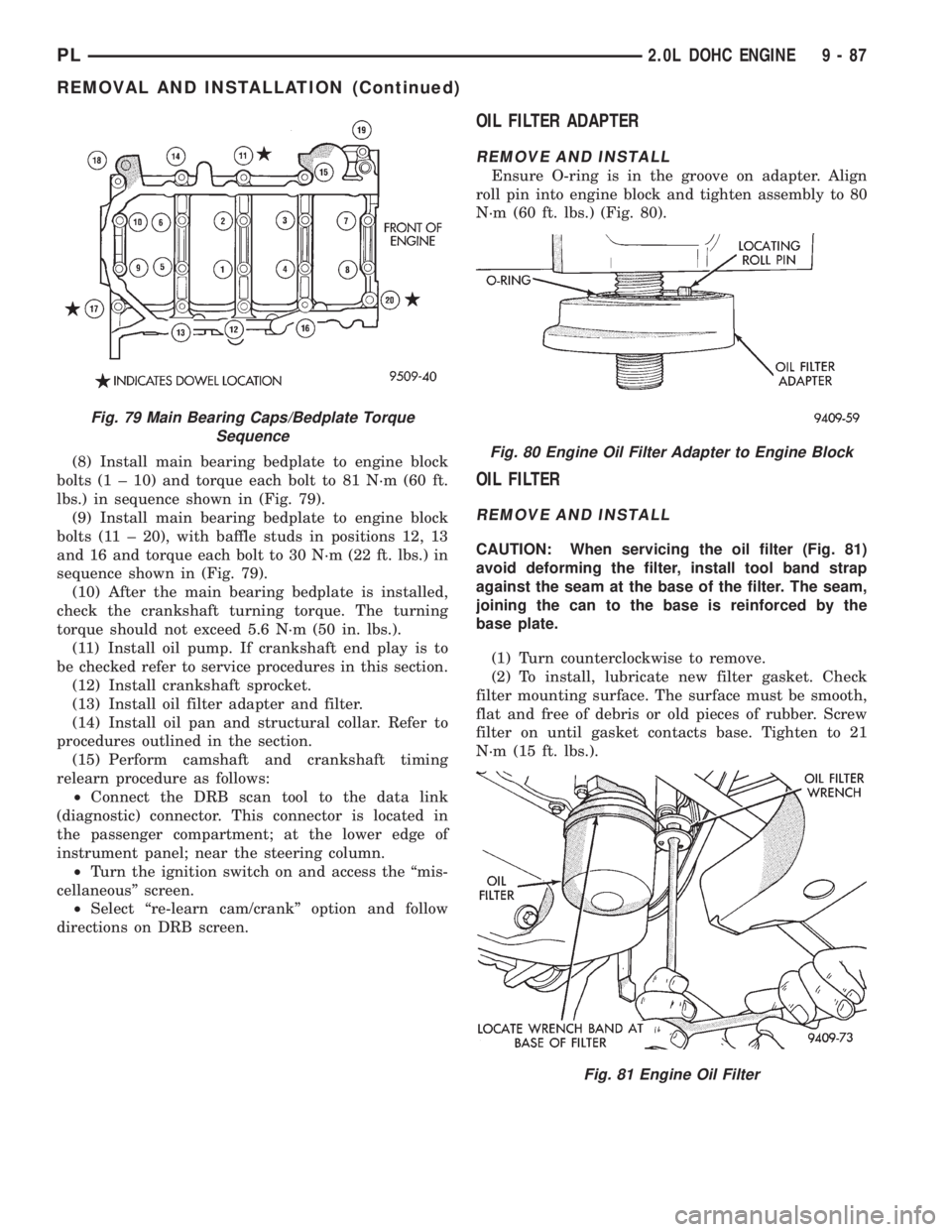

(8) Install main bearing bedplate to engine block

bolts (1 ± 10) and torque each bolt to 81 N´m (60 ft.

lbs.) in sequence shown in (Fig. 79).

(9) Install main bearing bedplate to engine block

bolts (11 ± 20), with baffle studs in positions 12, 13

and 16 and torque each bolt to 30 N´m (22 ft. lbs.) in

sequence shown in (Fig. 79).

(10) After the main bearing bedplate is installed,

check the crankshaft turning torque. The turning

torque should not exceed 5.6 N´m (50 in. lbs.).

(11) Install oil pump. If crankshaft end play is to

be checked refer to service procedures in this section.

(12) Install crankshaft sprocket.

(13) Install oil filter adapter and filter.

(14) Install oil pan and structural collar. Refer to

procedures outlined in the section.

(15) Perform camshaft and crankshaft timing

relearn procedure as follows:

²Connect the DRB scan tool to the data link

(diagnostic) connector. This connector is located in

the passenger compartment; at the lower edge of

instrument panel; near the steering column.

²Turn the ignition switch on and access the ªmis-

cellaneousº screen.

²Select ªre-learn cam/crankº option and follow

directions on DRB screen.

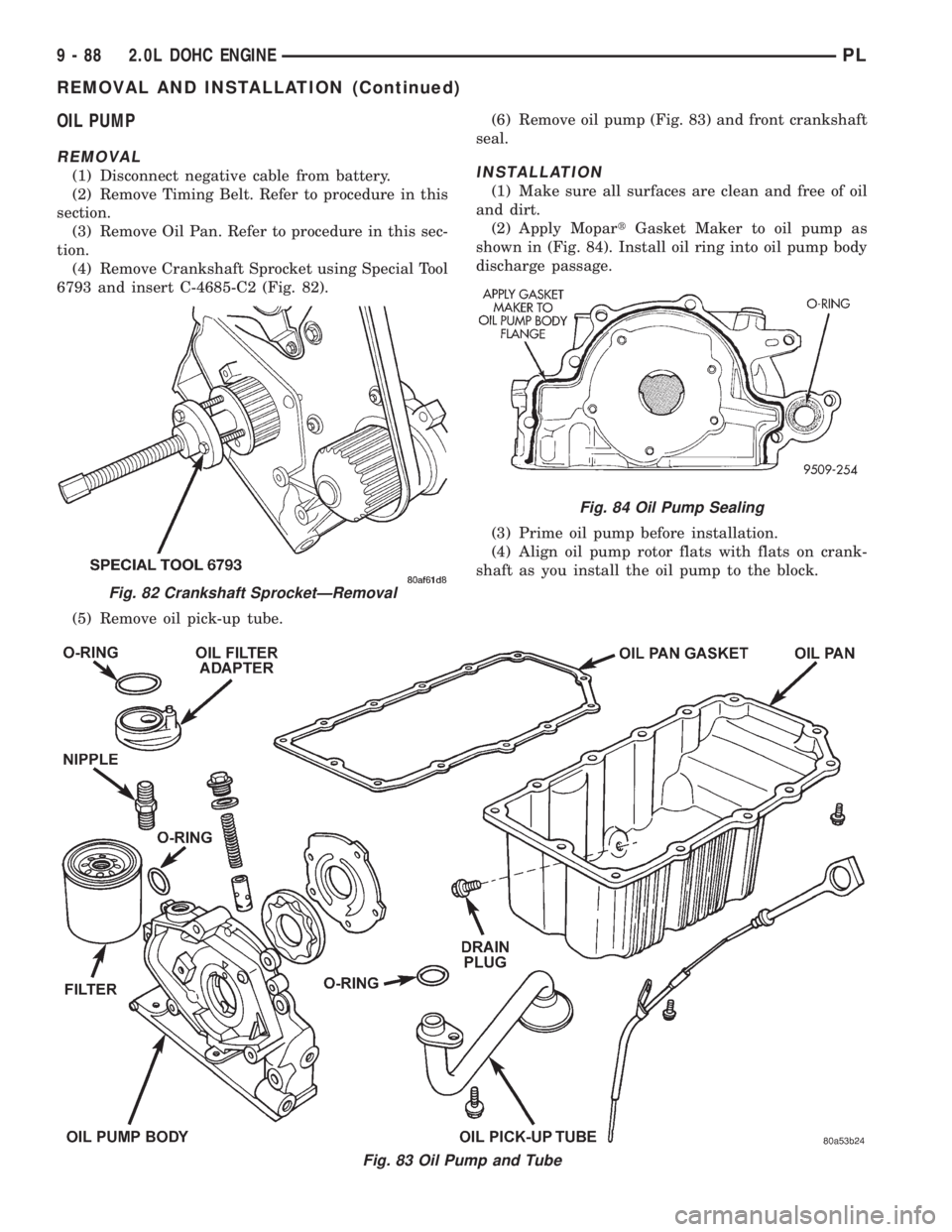

OIL FILTER ADAPTER

REMOVE AND INSTALL

Ensure O-ring is in the groove on adapter. Align

roll pin into engine block and tighten assembly to 80

N´m (60 ft. lbs.) (Fig. 80).

OIL FILTER

REMOVE AND INSTALL

CAUTION: When servicing the oil filter (Fig. 81)

avoid deforming the filter, install tool band strap

against the seam at the base of the filter. The seam,

joining the can to the base is reinforced by the

base plate.

(1) Turn counterclockwise to remove.

(2) To install, lubricate new filter gasket. Check

filter mounting surface. The surface must be smooth,

flat and free of debris or old pieces of rubber. Screw

filter on until gasket contacts base. Tighten to 21

N´m (15 ft. lbs.).

Fig. 79 Main Bearing Caps/Bedplate Torque

Sequence

Fig. 80 Engine Oil Filter Adapter to Engine Block

Fig. 81 Engine Oil Filter

PL2.0L DOHC ENGINE 9 - 87

REMOVAL AND INSTALLATION (Continued)

Page 801 of 1200

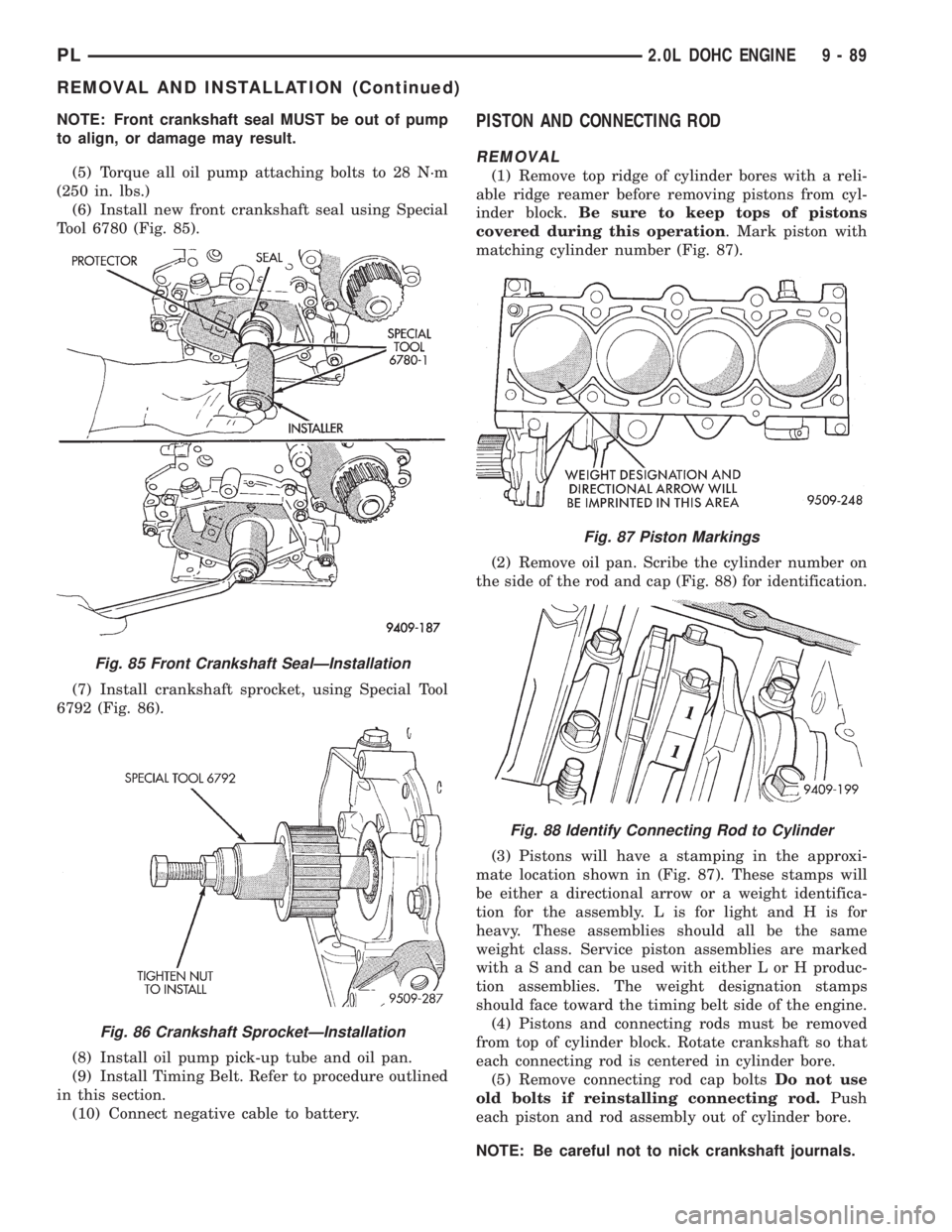

OIL PUMP

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove Timing Belt. Refer to procedure in this

section.

(3) Remove Oil Pan. Refer to procedure in this sec-

tion.

(4) Remove Crankshaft Sprocket using Special Tool

6793 and insert C-4685-C2 (Fig. 82).

(5) Remove oil pick-up tube.(6) Remove oil pump (Fig. 83) and front crankshaft

seal.INSTALLATION

(1) Make sure all surfaces are clean and free of oil

and dirt.

(2) Apply MopartGasket Maker to oil pump as

shown in (Fig. 84). Install oil ring into oil pump body

discharge passage.

(3) Prime oil pump before installation.

(4) Align oil pump rotor flats with flats on crank-

shaft as you install the oil pump to the block.

Fig. 83 Oil Pump and Tube

Fig. 82 Crankshaft SprocketÐRemoval

Fig. 84 Oil Pump Sealing

9 - 88 2.0L DOHC ENGINEPL

REMOVAL AND INSTALLATION (Continued)

Page 802 of 1200

NOTE: Front crankshaft seal MUST be out of pump

to align, or damage may result.

(5) Torque all oil pump attaching bolts to 28 N´m

(250 in. lbs.)

(6) Install new front crankshaft seal using Special

Tool 6780 (Fig. 85).

(7) Install crankshaft sprocket, using Special Tool

6792 (Fig. 86).

(8) Install oil pump pick-up tube and oil pan.

(9) Install Timing Belt. Refer to procedure outlined

in this section.

(10) Connect negative cable to battery.PISTON AND CONNECTING ROD

REMOVAL

(1) Remove top ridge of cylinder bores with a reli-

able ridge reamer before removing pistons from cyl-

inder block.Be sure to keep tops of pistons

covered during this operation. Mark piston with

matching cylinder number (Fig. 87).

(2) Remove oil pan. Scribe the cylinder number on

the side of the rod and cap (Fig. 88) for identification.

(3) Pistons will have a stamping in the approxi-

mate location shown in (Fig. 87). These stamps will

be either a directional arrow or a weight identifica-

tion for the assembly. L is for light and H is for

heavy. These assemblies should all be the same

weight class. Service piston assemblies are marked

with a S and can be used with either L or H produc-

tion assemblies. The weight designation stamps

should face toward the timing belt side of the engine.

(4) Pistons and connecting rods must be removed

from top of cylinder block. Rotate crankshaft so that

each connecting rod is centered in cylinder bore.

(5) Remove connecting rod cap boltsDo not use

old bolts if reinstalling connecting rod.Push

each piston and rod assembly out of cylinder bore.

NOTE: Be careful not to nick crankshaft journals.

Fig. 85 Front Crankshaft SealÐInstallation

Fig. 86 Crankshaft SprocketÐInstallation

Fig. 87 Piston Markings

Fig. 88 Identify Connecting Rod to Cylinder

PL2.0L DOHC ENGINE 9 - 89

REMOVAL AND INSTALLATION (Continued)

Page 804 of 1200

ring gaps are staggered so that neither is in line with

oil ring rail gap.

(2) Before installing the ring compressor, make

sure the oil ring expander ends are butted and the

rail gaps located as shown in (Fig. 92).

(3) Immerse the piston head and rings in clean

engine oil, slide the ring compressor, over the piston

(Fig. 93).Be sure position of rings does not

change during this operation.

(4) The weight stamp designation L or H will be in

the front half of the piston should face toward the

front of the engine for SOHC engine. The arrow

should face toward the front of the engine for DOHC

engine (Fig. 87).

(5) Rotate crankshaft so that the connecting rod

journal is on the center of the cylinder bore. Insert

rod and piston assembly into cylinder bore and guide

rod over the crankshaft journal.

(6) Tap the piston down in cylinder bore, using a

hammer handle. At the same time, guide connecting

rod into position on connecting rod journal.

(7) Install rod caps. InstallNewbolts and tighten

to 27 N´m (20 ft.lb.) Plus 1/4 turn.

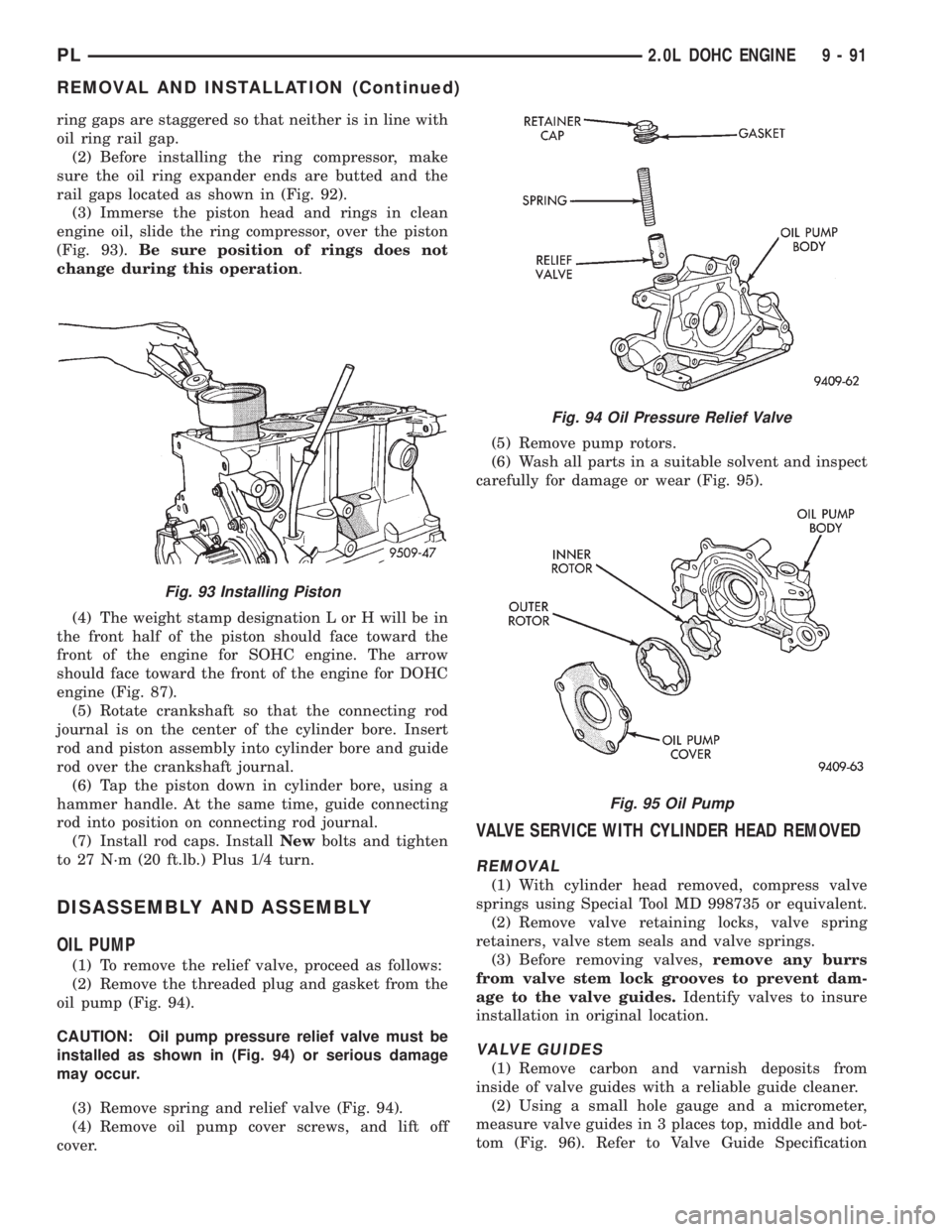

DISASSEMBLY AND ASSEMBLY

OIL PUMP

(1) To remove the relief valve, proceed as follows:

(2) Remove the threaded plug and gasket from the

oil pump (Fig. 94).

CAUTION: Oil pump pressure relief valve must be

installed as shown in (Fig. 94) or serious damage

may occur.

(3) Remove spring and relief valve (Fig. 94).

(4) Remove oil pump cover screws, and lift off

cover.(5) Remove pump rotors.

(6) Wash all parts in a suitable solvent and inspect

carefully for damage or wear (Fig. 95).

VALVE SERVICE WITH CYLINDER HEAD REMOVED

REMOVAL

(1) With cylinder head removed, compress valve

springs using Special Tool MD 998735 or equivalent.

(2) Remove valve retaining locks, valve spring

retainers, valve stem seals and valve springs.

(3) Before removing valves,remove any burrs

from valve stem lock grooves to prevent dam-

age to the valve guides.Identify valves to insure

installation in original location.

VALVE GUIDES

(1) Remove carbon and varnish deposits from

inside of valve guides with a reliable guide cleaner.

(2) Using a small hole gauge and a micrometer,

measure valve guides in 3 places top, middle and bot-

tom (Fig. 96). Refer to Valve Guide Specification

Fig. 93 Installing Piston

Fig. 94 Oil Pressure Relief Valve

Fig. 95 Oil Pump

PL2.0L DOHC ENGINE 9 - 91

REMOVAL AND INSTALLATION (Continued)

Page 807 of 1200

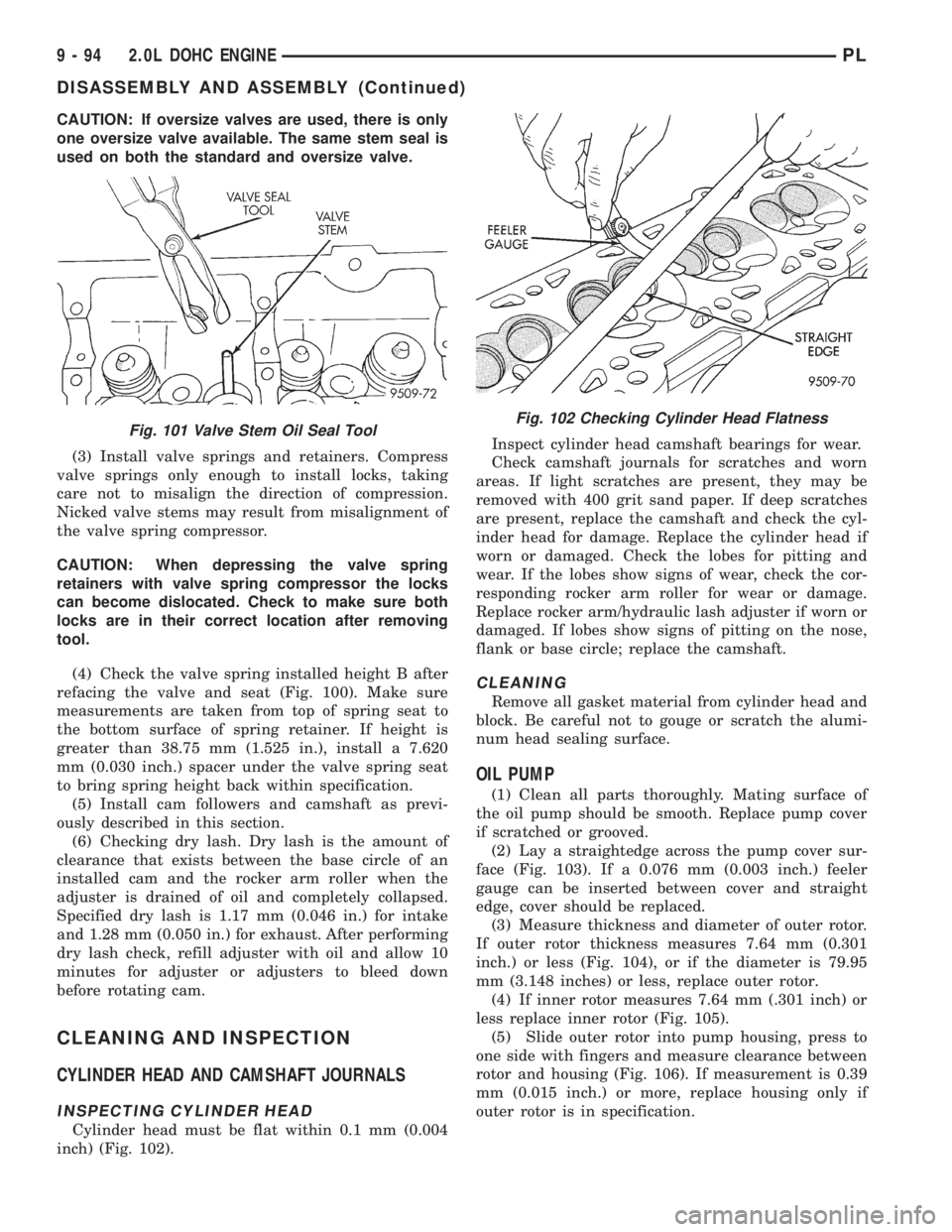

CAUTION: If oversize valves are used, there is only

one oversize valve available. The same stem seal is

used on both the standard and oversize valve.

(3) Install valve springs and retainers. Compress

valve springs only enough to install locks, taking

care not to misalign the direction of compression.

Nicked valve stems may result from misalignment of

the valve spring compressor.

CAUTION: When depressing the valve spring

retainers with valve spring compressor the locks

can become dislocated. Check to make sure both

locks are in their correct location after removing

tool.

(4) Check the valve spring installed height B after

refacing the valve and seat (Fig. 100). Make sure

measurements are taken from top of spring seat to

the bottom surface of spring retainer. If height is

greater than 38.75 mm (1.525 in.), install a 7.620

mm (0.030 inch.) spacer under the valve spring seat

to bring spring height back within specification.

(5) Install cam followers and camshaft as previ-

ously described in this section.

(6) Checking dry lash. Dry lash is the amount of

clearance that exists between the base circle of an

installed cam and the rocker arm roller when the

adjuster is drained of oil and completely collapsed.

Specified dry lash is 1.17 mm (0.046 in.) for intake

and 1.28 mm (0.050 in.) for exhaust. After performing

dry lash check, refill adjuster with oil and allow 10

minutes for adjuster or adjusters to bleed down

before rotating cam.

CLEANING AND INSPECTION

CYLINDER HEAD AND CAMSHAFT JOURNALS

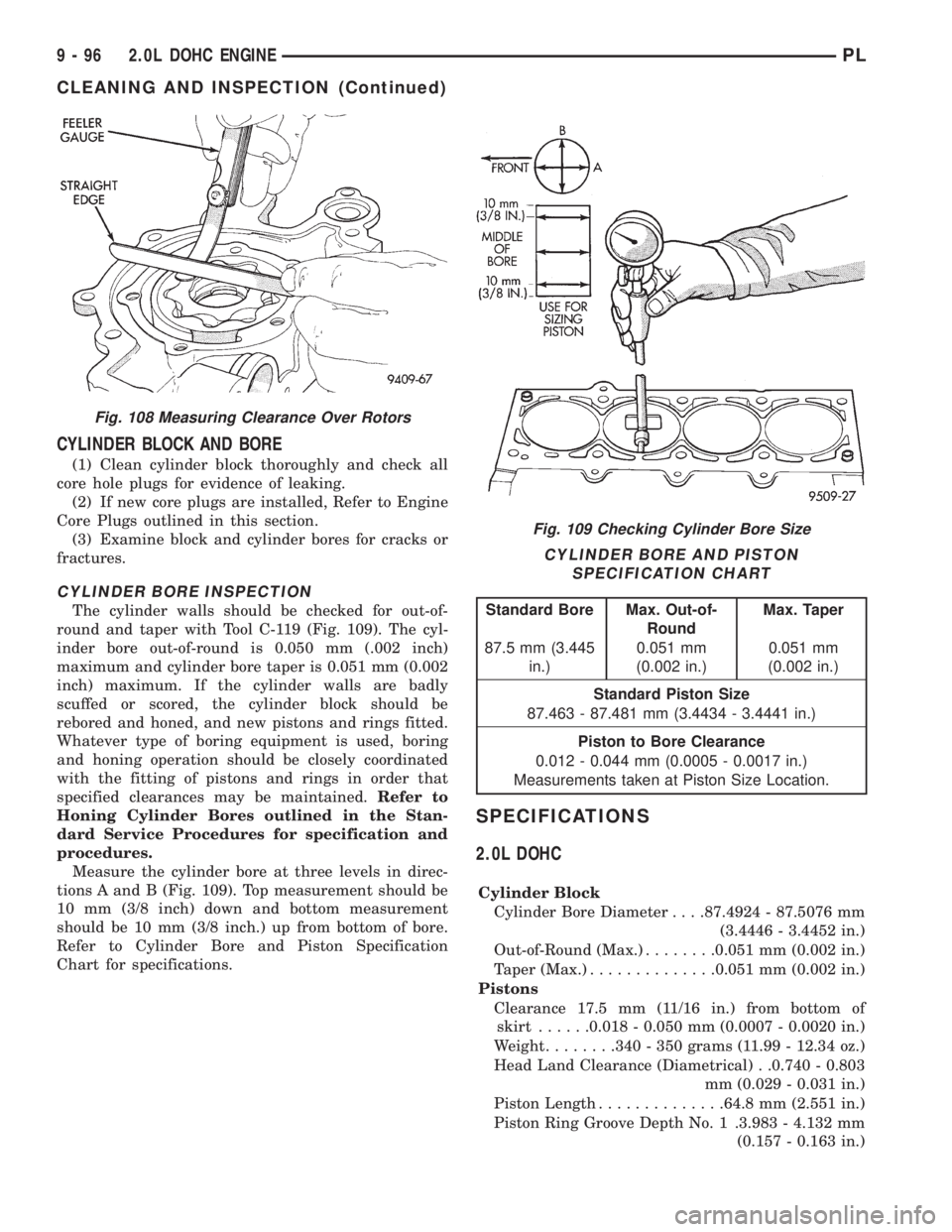

INSPECTING CYLINDER HEAD

Cylinder head must be flat within 0.1 mm (0.004

inch) (Fig. 102).Inspect cylinder head camshaft bearings for wear.

Check camshaft journals for scratches and worn

areas. If light scratches are present, they may be

removed with 400 grit sand paper. If deep scratches

are present, replace the camshaft and check the cyl-

inder head for damage. Replace the cylinder head if

worn or damaged. Check the lobes for pitting and

wear. If the lobes show signs of wear, check the cor-

responding rocker arm roller for wear or damage.

Replace rocker arm/hydraulic lash adjuster if worn or

damaged. If lobes show signs of pitting on the nose,

flank or base circle; replace the camshaft.

CLEANING

Remove all gasket material from cylinder head and

block. Be careful not to gouge or scratch the alumi-

num head sealing surface.

OIL PUMP

(1) Clean all parts thoroughly. Mating surface of

the oil pump should be smooth. Replace pump cover

if scratched or grooved.

(2) Lay a straightedge across the pump cover sur-

face (Fig. 103). If a 0.076 mm (0.003 inch.) feeler

gauge can be inserted between cover and straight

edge, cover should be replaced.

(3) Measure thickness and diameter of outer rotor.

If outer rotor thickness measures 7.64 mm (0.301

inch.) or less (Fig. 104), or if the diameter is 79.95

mm (3.148 inches) or less, replace outer rotor.

(4) If inner rotor measures 7.64 mm (.301 inch) or

less replace inner rotor (Fig. 105).

(5) Slide outer rotor into pump housing, press to

one side with fingers and measure clearance between

rotor and housing (Fig. 106). If measurement is 0.39

mm (0.015 inch.) or more, replace housing only if

outer rotor is in specification.

Fig. 101 Valve Stem Oil Seal ToolFig. 102 Checking Cylinder Head Flatness

9 - 94 2.0L DOHC ENGINEPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 809 of 1200

CYLINDER BLOCK AND BORE

(1) Clean cylinder block thoroughly and check all

core hole plugs for evidence of leaking.

(2) If new core plugs are installed, Refer to Engine

Core Plugs outlined in this section.

(3) Examine block and cylinder bores for cracks or

fractures.

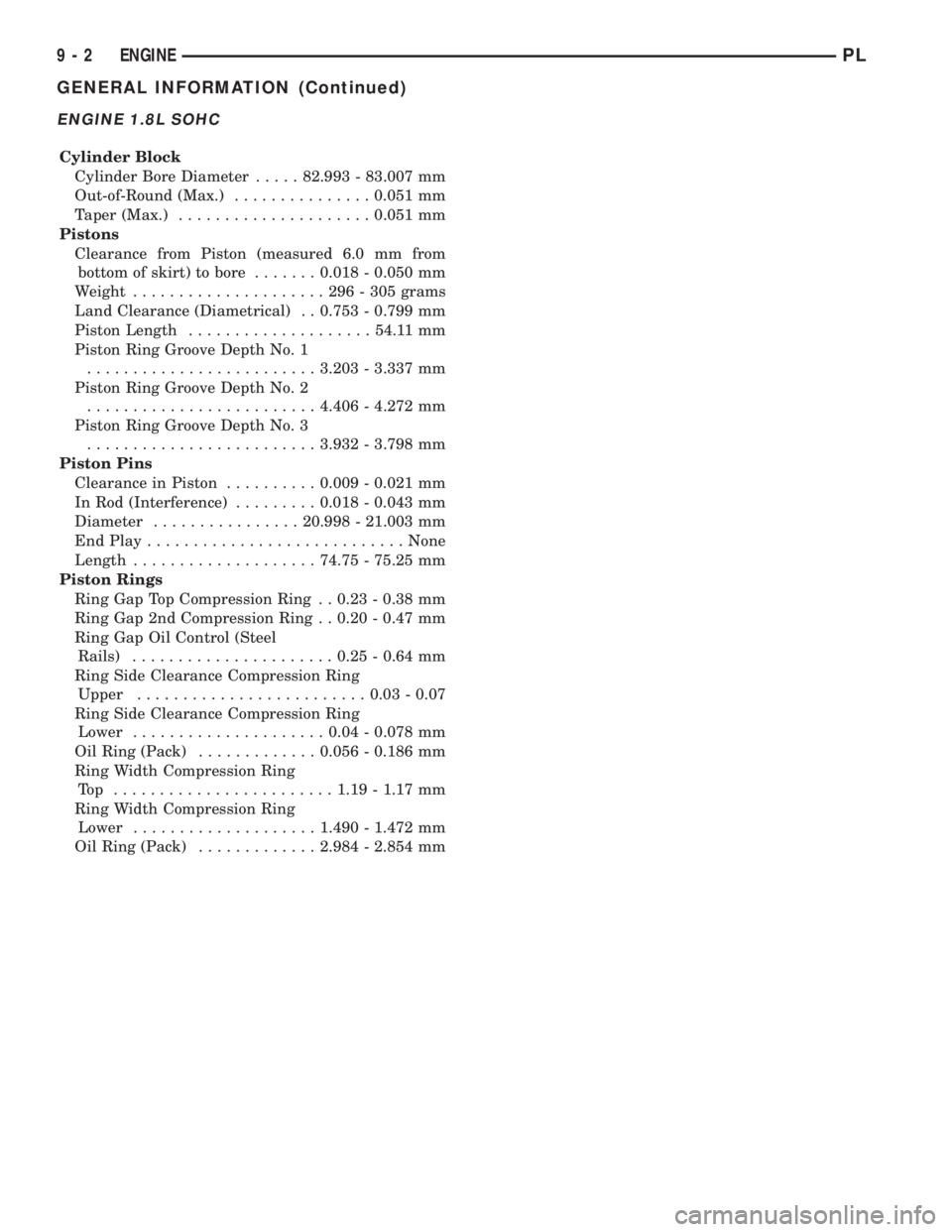

CYLINDER BORE INSPECTION

The cylinder walls should be checked for out-of-

round and taper with Tool C-119 (Fig. 109). The cyl-

inder bore out-of-round is 0.050 mm (.002 inch)

maximum and cylinder bore taper is 0.051 mm (0.002

inch) maximum. If the cylinder walls are badly

scuffed or scored, the cylinder block should be

rebored and honed, and new pistons and rings fitted.

Whatever type of boring equipment is used, boring

and honing operation should be closely coordinated

with the fitting of pistons and rings in order that

specified clearances may be maintained.Refer to

Honing Cylinder Bores outlined in the Stan-

dard Service Procedures for specification and

procedures.

Measure the cylinder bore at three levels in direc-

tions A and B (Fig. 109). Top measurement should be

10 mm (3/8 inch) down and bottom measurement

should be 10 mm (3/8 inch.) up from bottom of bore.

Refer to Cylinder Bore and Piston Specification

Chart for specifications.

SPECIFICATIONS

2.0L DOHC

Cylinder Block

Cylinder Bore Diameter. . . .87.4924 - 87.5076 mm

(3.4446 - 3.4452 in.)

Out-of-Round (Max.)........0.051 mm (0.002 in.)

Taper (Max.)..............0.051 mm (0.002 in.)

Pistons

Clearance 17.5 mm (11/16 in.) from bottom of

skirt......0.018 - 0.050 mm (0.0007 - 0.0020 in.)

Weight........340 - 350 grams (11.99 - 12.34 oz.)

Head Land Clearance (Diametrical) . .0.740 - 0.803

mm (0.029 - 0.031 in.)

Piston Length..............64.8 mm (2.551 in.)

Piston Ring Groove Depth No. 1 .3.983 - 4.132 mm

(0.157 - 0.163 in.)

Fig. 108 Measuring Clearance Over Rotors

Fig. 109 Checking Cylinder Bore Size

CYLINDER BORE AND PISTON

SPECIFICATION CHART

Standard Bore Max. Out-of-

RoundMax. Taper

87.5 mm (3.445

in.)0.051 mm

(0.002 in.)0.051 mm

(0.002 in.)

Standard Piston Size

87.463 - 87.481 mm (3.4434 - 3.4441 in.)

Piston to Bore Clearance

0.012 - 0.044 mm (0.0005 - 0.0017 in.)

Measurements taken at Piston Size Location.

9 - 96 2.0L DOHC ENGINEPL

CLEANING AND INSPECTION (Continued)

Page 815 of 1200

ENGINE 1.8L SOHC

Cylinder Block

Cylinder Bore Diameter.....82.993 - 83.007 mm

Out-of-Round (Max.)...............0.051 mm

Taper (Max.).....................0.051 mm

Pistons

Clearance from Piston (measured 6.0 mm from

bottom of skirt) to bore.......0.018 - 0.050 mm

Weight.....................296-305grams

Land Clearance (Diametrical) . . 0.753 - 0.799 mm

Piston Length....................54.11 mm

Piston Ring Groove Depth No. 1

.........................3.203 - 3.337 mm

Piston Ring Groove Depth No. 2

.........................4.406 - 4.272 mm

Piston Ring Groove Depth No. 3

.........................3.932 - 3.798 mm

Piston Pins

Clearance in Piston..........0.009 - 0.021 mm

In Rod (Interference).........0.018 - 0.043 mm

Diameter................20.998 - 21.003 mm

End Play............................None

Length....................74.75 - 75.25 mm

Piston Rings

Ring Gap Top Compression Ring . . 0.23 - 0.38 mm

Ring Gap 2nd Compression Ring . . 0.20 - 0.47 mm

Ring Gap Oil Control (Steel

Rails)......................0.25 - 0.64 mm

Ring Side Clearance Compression Ring

Upper.........................0.03 - 0.07

Ring Side Clearance Compression Ring

Lower.....................0.04 - 0.078 mm

Oil Ring (Pack).............0.056 - 0.186 mm

Ring Width Compression Ring

Top ........................1.19 - 1.17 mm

Ring Width Compression Ring

Lower....................1.490 - 1.472 mm

Oil Ring (Pack).............2.984 - 2.854 mm

9 - 2 ENGINEPL

GENERAL INFORMATION (Continued)

Page 821 of 1200

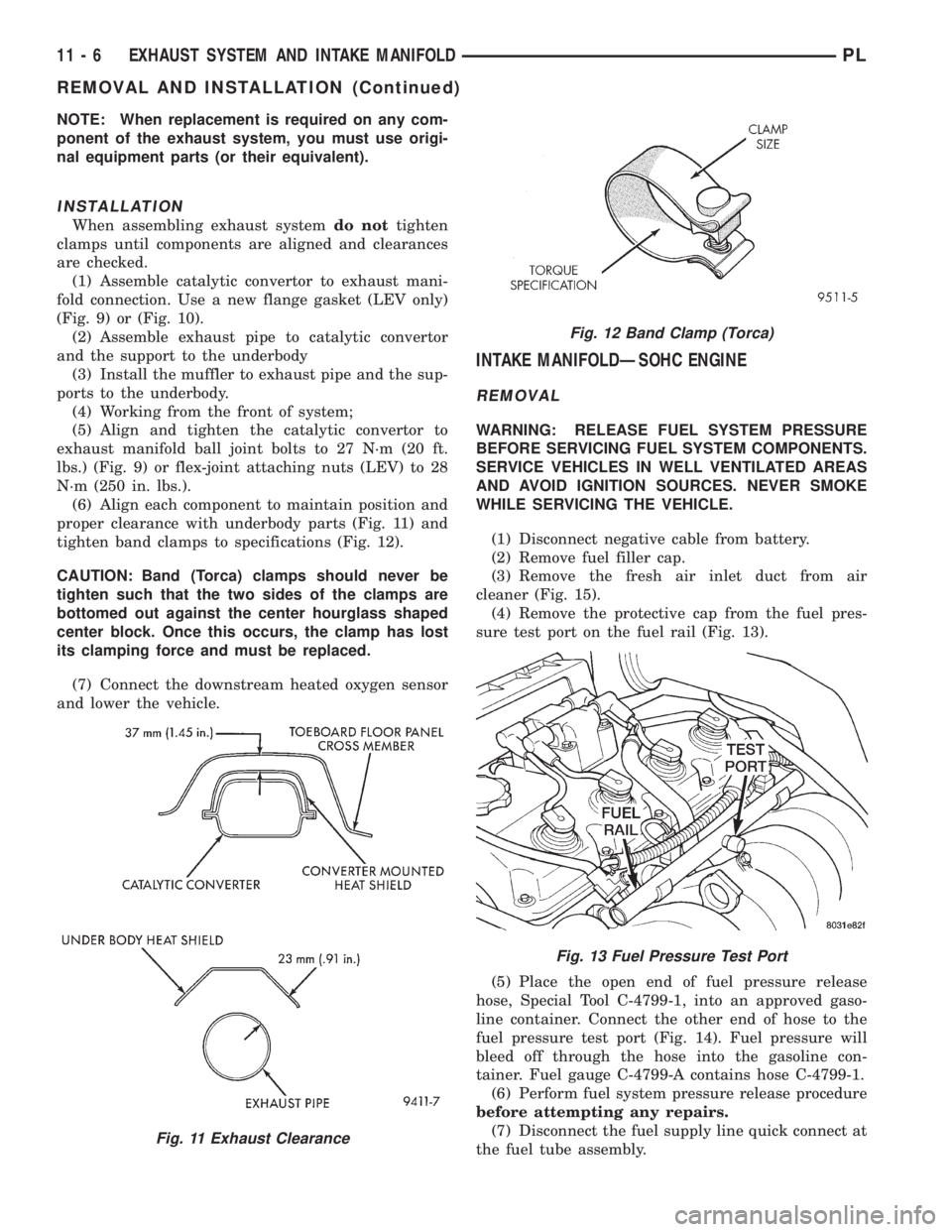

NOTE: When replacement is required on any com-

ponent of the exhaust system, you must use origi-

nal equipment parts (or their equivalent).

INSTALLATION

When assembling exhaust systemdo nottighten

clamps until components are aligned and clearances

are checked.

(1) Assemble catalytic convertor to exhaust mani-

fold connection. Use a new flange gasket (LEV only)

(Fig. 9) or (Fig. 10).

(2) Assemble exhaust pipe to catalytic convertor

and the support to the underbody

(3) Install the muffler to exhaust pipe and the sup-

ports to the underbody.

(4) Working from the front of system;

(5) Align and tighten the catalytic convertor to

exhaust manifold ball joint bolts to 27 N´m (20 ft.

lbs.) (Fig. 9) or flex-joint attaching nuts (LEV) to 28

N´m (250 in. lbs.).

(6) Align each component to maintain position and

proper clearance with underbody parts (Fig. 11) and

tighten band clamps to specifications (Fig. 12).

CAUTION: Band (Torca) clamps should never be

tighten such that the two sides of the clamps are

bottomed out against the center hourglass shaped

center block. Once this occurs, the clamp has lost

its clamping force and must be replaced.

(7) Connect the downstream heated oxygen sensor

and lower the vehicle.

INTAKE MANIFOLDÐSOHC ENGINE

REMOVAL

WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE SERVICING FUEL SYSTEM COMPONENTS.

SERVICE VEHICLES IN WELL VENTILATED AREAS

AND AVOID IGNITION SOURCES. NEVER SMOKE

WHILE SERVICING THE VEHICLE.

(1) Disconnect negative cable from battery.

(2) Remove fuel filler cap.

(3) Remove the fresh air inlet duct from air

cleaner (Fig. 15).

(4) Remove the protective cap from the fuel pres-

sure test port on the fuel rail (Fig. 13).

(5) Place the open end of fuel pressure release

hose, Special Tool C-4799-1, into an approved gaso-

line container. Connect the other end of hose to the

fuel pressure test port (Fig. 14). Fuel pressure will

bleed off through the hose into the gasoline con-

tainer. Fuel gauge C-4799-A contains hose C-4799-1.

(6) Perform fuel system pressure release procedure

before attempting any repairs.

(7) Disconnect the fuel supply line quick connect at

the fuel tube assembly.

Fig. 11 Exhaust Clearance

Fig. 12 Band Clamp (Torca)

Fig. 13 Fuel Pressure Test Port

11 - 6 EXHAUST SYSTEM AND INTAKE MANIFOLDPL

REMOVAL AND INSTALLATION (Continued)

Page 823 of 1200

INSTALLATION

Before installing manifold. Clean all mating sur-

faces. Replace all seals, with new seals. All intakemanifold fasteners and washers are to be discarded

andNEWfasteners and washers are to be used.

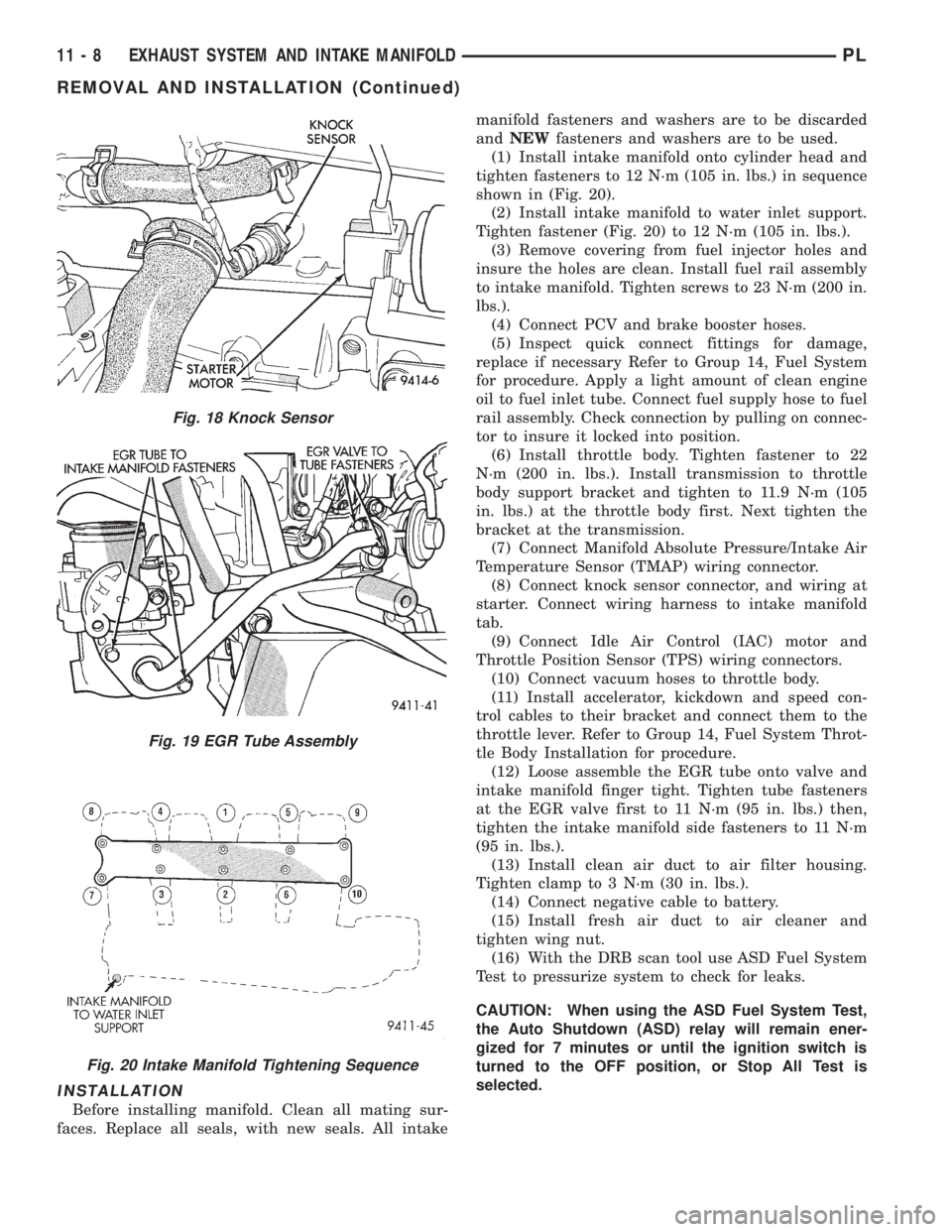

(1) Install intake manifold onto cylinder head and

tighten fasteners to 12 N´m (105 in. lbs.) in sequence

shown in (Fig. 20).

(2) Install intake manifold to water inlet support.

Tighten fastener (Fig. 20) to 12 N´m (105 in. lbs.).

(3) Remove covering from fuel injector holes and

insure the holes are clean. Install fuel rail assembly

to intake manifold. Tighten screws to 23 N´m (200 in.

lbs.).

(4) Connect PCV and brake booster hoses.

(5) Inspect quick connect fittings for damage,

replace if necessary Refer to Group 14, Fuel System

for procedure. Apply a light amount of clean engine

oil to fuel inlet tube. Connect fuel supply hose to fuel

rail assembly. Check connection by pulling on connec-

tor to insure it locked into position.

(6) Install throttle body. Tighten fastener to 22

N´m (200 in. lbs.). Install transmission to throttle

body support bracket and tighten to 11.9 N´m (105

in. lbs.) at the throttle body first. Next tighten the

bracket at the transmission.

(7) Connect Manifold Absolute Pressure/Intake Air

Temperature Sensor (TMAP) wiring connector.

(8) Connect knock sensor connector, and wiring at

starter. Connect wiring harness to intake manifold

tab.

(9) Connect Idle Air Control (IAC) motor and

Throttle Position Sensor (TPS) wiring connectors.

(10) Connect vacuum hoses to throttle body.

(11) Install accelerator, kickdown and speed con-

trol cables to their bracket and connect them to the

throttle lever. Refer to Group 14, Fuel System Throt-

tle Body Installation for procedure.

(12) Loose assemble the EGR tube onto valve and

intake manifold finger tight. Tighten tube fasteners

at the EGR valve first to 11 N´m (95 in. lbs.) then,

tighten the intake manifold side fasteners to 11 N´m

(95 in. lbs.).

(13) Install clean air duct to air filter housing.

Tighten clamp to 3 N´m (30 in. lbs.).

(14) Connect negative cable to battery.

(15) Install fresh air duct to air cleaner and

tighten wing nut.

(16) With the DRB scan tool use ASD Fuel System

Test to pressurize system to check for leaks.

CAUTION: When using the ASD Fuel System Test,

the Auto Shutdown (ASD) relay will remain ener-

gized for 7 minutes or until the ignition switch is

turned to the OFF position, or Stop All Test is

selected.

Fig. 18 Knock Sensor

Fig. 19 EGR Tube Assembly

Fig. 20 Intake Manifold Tightening Sequence

11 - 8 EXHAUST SYSTEM AND INTAKE MANIFOLDPL

REMOVAL AND INSTALLATION (Continued)

Page 826 of 1200

INSTALLATION

Before installing manifolds. Clean all mating sur-

faces. Replace all gaskets, with new.

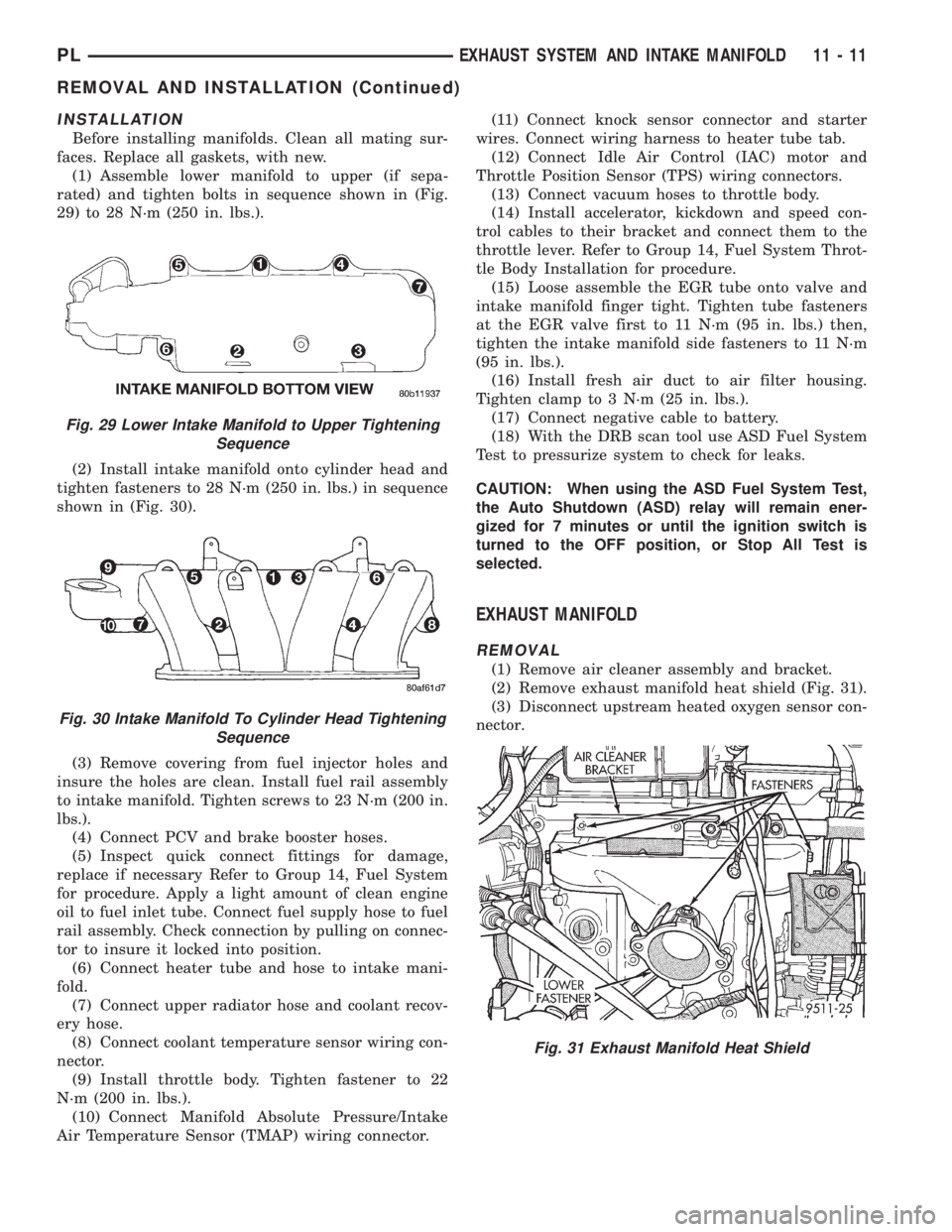

(1) Assemble lower manifold to upper (if sepa-

rated) and tighten bolts in sequence shown in (Fig.

29) to 28 N´m (250 in. lbs.).

(2) Install intake manifold onto cylinder head and

tighten fasteners to 28 N´m (250 in. lbs.) in sequence

shown in (Fig. 30).

(3) Remove covering from fuel injector holes and

insure the holes are clean. Install fuel rail assembly

to intake manifold. Tighten screws to 23 N´m (200 in.

lbs.).

(4) Connect PCV and brake booster hoses.

(5) Inspect quick connect fittings for damage,

replace if necessary Refer to Group 14, Fuel System

for procedure. Apply a light amount of clean engine

oil to fuel inlet tube. Connect fuel supply hose to fuel

rail assembly. Check connection by pulling on connec-

tor to insure it locked into position.

(6) Connect heater tube and hose to intake mani-

fold.

(7) Connect upper radiator hose and coolant recov-

ery hose.

(8) Connect coolant temperature sensor wiring con-

nector.

(9) Install throttle body. Tighten fastener to 22

N´m (200 in. lbs.).

(10) Connect Manifold Absolute Pressure/Intake

Air Temperature Sensor (TMAP) wiring connector.(11) Connect knock sensor connector and starter

wires. Connect wiring harness to heater tube tab.

(12) Connect Idle Air Control (IAC) motor and

Throttle Position Sensor (TPS) wiring connectors.

(13) Connect vacuum hoses to throttle body.

(14) Install accelerator, kickdown and speed con-

trol cables to their bracket and connect them to the

throttle lever. Refer to Group 14, Fuel System Throt-

tle Body Installation for procedure.

(15) Loose assemble the EGR tube onto valve and

intake manifold finger tight. Tighten tube fasteners

at the EGR valve first to 11 N´m (95 in. lbs.) then,

tighten the intake manifold side fasteners to 11 N´m

(95 in. lbs.).

(16) Install fresh air duct to air filter housing.

Tighten clamp to 3 N´m (25 in. lbs.).

(17) Connect negative cable to battery.

(18) With the DRB scan tool use ASD Fuel System

Test to pressurize system to check for leaks.

CAUTION: When using the ASD Fuel System Test,

the Auto Shutdown (ASD) relay will remain ener-

gized for 7 minutes or until the ignition switch is

turned to the OFF position, or Stop All Test is

selected.

EXHAUST MANIFOLD

REMOVAL

(1) Remove air cleaner assembly and bracket.

(2) Remove exhaust manifold heat shield (Fig. 31).

(3) Disconnect upstream heated oxygen sensor con-

nector.

Fig. 29 Lower Intake Manifold to Upper Tightening

Sequence

Fig. 30 Intake Manifold To Cylinder Head Tightening

Sequence

Fig. 31 Exhaust Manifold Heat Shield

PLEXHAUST SYSTEM AND INTAKE MANIFOLD 11 - 11

REMOVAL AND INSTALLATION (Continued)