DODGE NEON 1999 Service Owner's Guide

Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 31 of 1200

CAUTION: The steering knuckle to strut assembly

attaching bolts are serrated and must not be turned

during removal. Remove nuts while holding bolts

stationary in the steering knuckles.

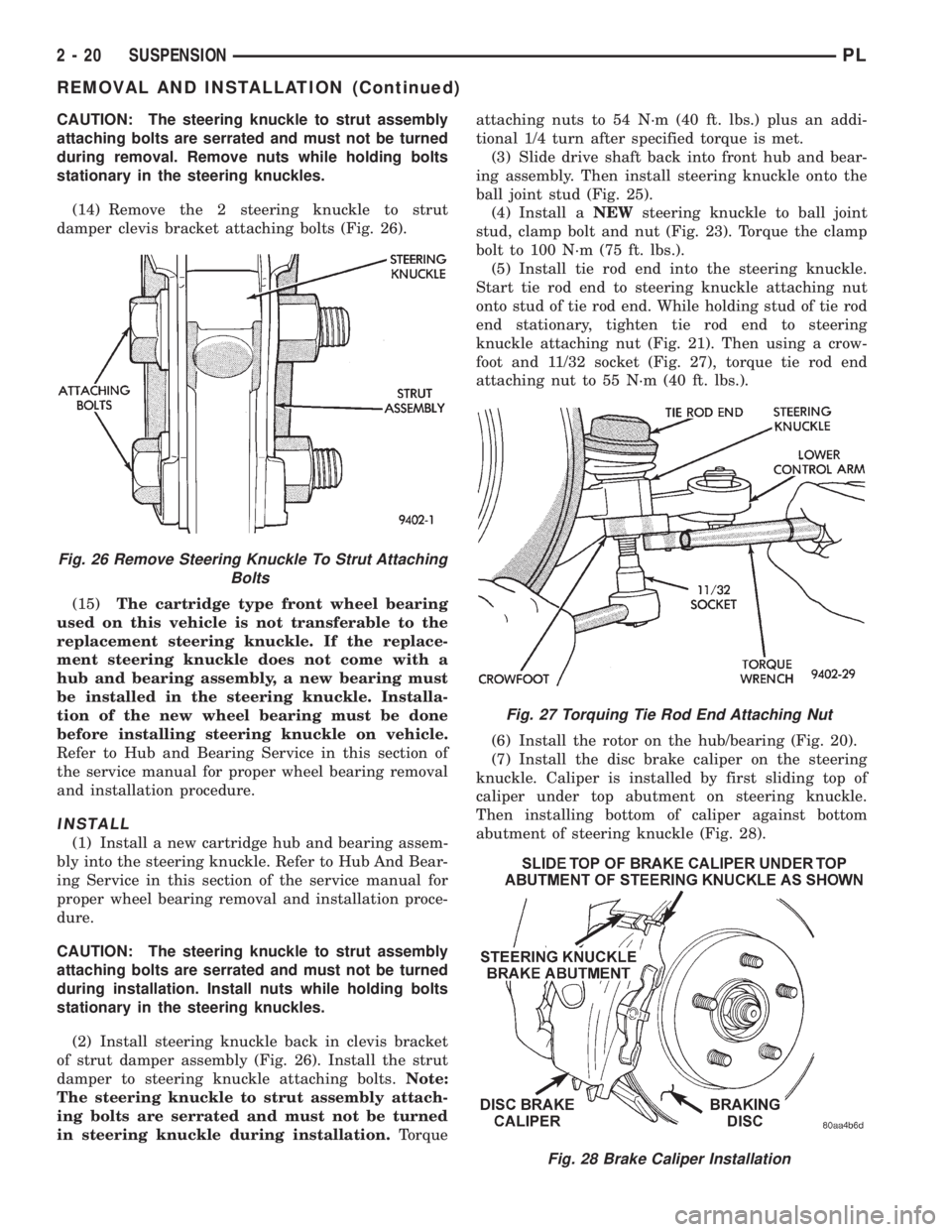

(14) Remove the 2 steering knuckle to strut

damper clevis bracket attaching bolts (Fig. 26).

(15)The cartridge type front wheel bearing

used on this vehicle is not transferable to the

replacement steering knuckle. If the replace-

ment steering knuckle does not come with a

hub and bearing assembly, a new bearing must

be installed in the steering knuckle. Installa-

tion of the new wheel bearing must be done

before installing steering knuckle on vehicle.

Refer to Hub and Bearing Service in this section of

the service manual for proper wheel bearing removal

and installation procedure.

INSTALL

(1) Install a new cartridge hub and bearing assem-

bly into the steering knuckle. Refer to Hub And Bear-

ing Service in this section of the service manual for

proper wheel bearing removal and installation proce-

dure.

CAUTION: The steering knuckle to strut assembly

attaching bolts are serrated and must not be turned

during installation. Install nuts while holding bolts

stationary in the steering knuckles.

(2) Install steering knuckle back in clevis bracket

of strut damper assembly (Fig. 26). Install the strut

damper to steering knuckle attaching bolts.Note:

The steering knuckle to strut assembly attach-

ing bolts are serrated and must not be turned

in steering knuckle during installation.Torqueattaching nuts to 54 N´m (40 ft. lbs.) plus an addi-

tional 1/4 turn after specified torque is met.

(3) Slide drive shaft back into front hub and bear-

ing assembly. Then install steering knuckle onto the

ball joint stud (Fig. 25).

(4) Install aNEWsteering knuckle to ball joint

stud, clamp bolt and nut (Fig. 23). Torque the clamp

bolt to 100 N´m (75 ft. lbs.).

(5) Install tie rod end into the steering knuckle.

Start tie rod end to steering knuckle attaching nut

onto stud of tie rod end. While holding stud of tie rod

end stationary, tighten tie rod end to steering

knuckle attaching nut (Fig. 21). Then using a crow-

foot and 11/32 socket (Fig. 27), torque tie rod end

attaching nut to 55 N´m (40 ft. lbs.).

(6) Install the rotor on the hub/bearing (Fig. 20).

(7) Install the disc brake caliper on the steering

knuckle. Caliper is installed by first sliding top of

caliper under top abutment on steering knuckle.

Then installing bottom of caliper against bottom

abutment of steering knuckle (Fig. 28).

Fig. 28 Brake Caliper Installation

Fig. 26 Remove Steering Knuckle To Strut Attaching

Bolts

Fig. 27 Torquing Tie Rod End Attaching Nut

2 - 20 SUSPENSIONPL

REMOVAL AND INSTALLATION (Continued)

Page 32 of 1200

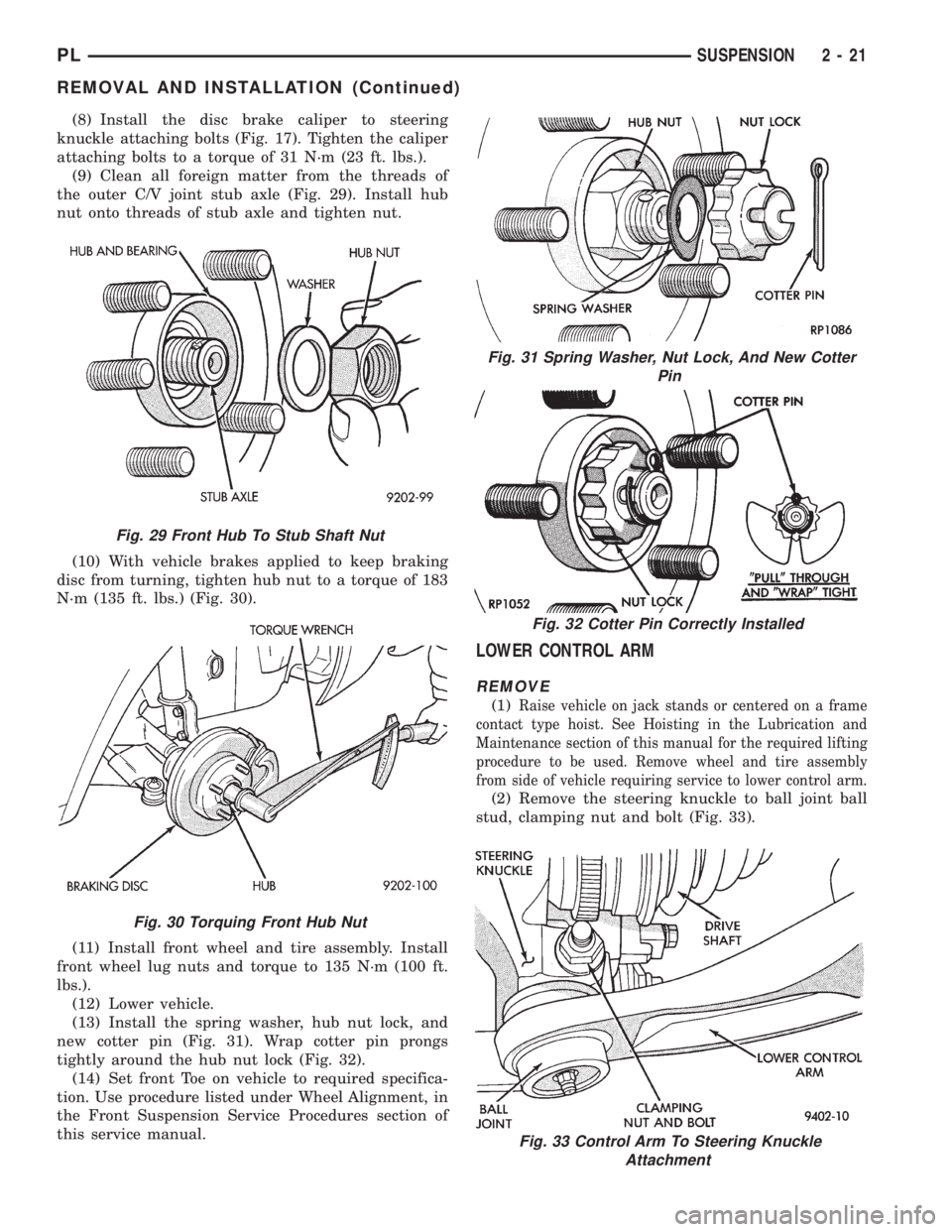

(8) Install the disc brake caliper to steering

knuckle attaching bolts (Fig. 17). Tighten the caliper

attaching bolts to a torque of 31 N´m (23 ft. lbs.).

(9) Clean all foreign matter from the threads of

the outer C/V joint stub axle (Fig. 29). Install hub

nut onto threads of stub axle and tighten nut.

(10) With vehicle brakes applied to keep braking

disc from turning, tighten hub nut to a torque of 183

N´m (135 ft. lbs.) (Fig. 30).

(11) Install front wheel and tire assembly. Install

front wheel lug nuts and torque to 135 N´m (100 ft.

lbs.).

(12) Lower vehicle.

(13) Install the spring washer, hub nut lock, and

new cotter pin (Fig. 31). Wrap cotter pin prongs

tightly around the hub nut lock (Fig. 32).

(14) Set front Toe on vehicle to required specifica-

tion. Use procedure listed under Wheel Alignment, in

the Front Suspension Service Procedures section of

this service manual.

LOWER CONTROL ARM

REMOVE

(1)Raise vehicle on jack stands or centered on a frame

contact type hoist. See Hoisting in the Lubrication and

Maintenance section of this manual for the required lifting

procedure to be used. Remove wheel and tire assembly

from side of vehicle requiring service to lower control arm.

(2) Remove the steering knuckle to ball joint ball

stud, clamping nut and bolt (Fig. 33).

Fig. 29 Front Hub To Stub Shaft Nut

Fig. 30 Torquing Front Hub Nut

Fig. 31 Spring Washer, Nut Lock, And New Cotter

Pin

Fig. 32 Cotter Pin Correctly Installed

Fig. 33 Control Arm To Steering Knuckle

Attachment

PLSUSPENSION 2 - 21

REMOVAL AND INSTALLATION (Continued)

Page 33 of 1200

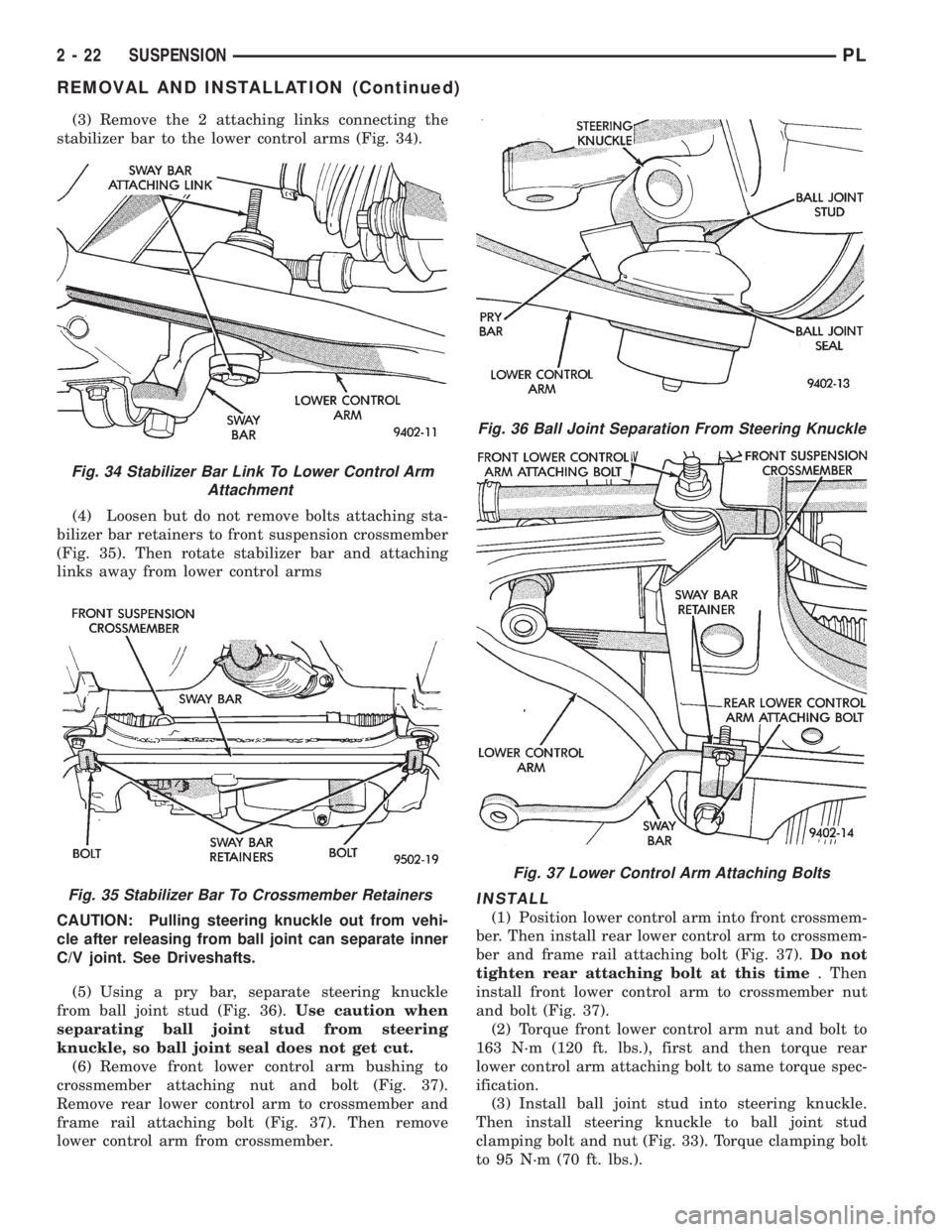

(3) Remove the 2 attaching links connecting the

stabilizer bar to the lower control arms (Fig. 34).

(4) Loosen but do not remove bolts attaching sta-

bilizer bar retainers to front suspension crossmember

(Fig. 35). Then rotate stabilizer bar and attaching

links away from lower control arms

CAUTION: Pulling steering knuckle out from vehi-

cle after releasing from ball joint can separate inner

C/V joint. See Driveshafts.

(5) Using a pry bar, separate steering knuckle

from ball joint stud (Fig. 36).Use caution when

separating ball joint stud from steering

knuckle, so ball joint seal does not get cut.

(6) Remove front lower control arm bushing to

crossmember attaching nut and bolt (Fig. 37).

Remove rear lower control arm to crossmember and

frame rail attaching bolt (Fig. 37). Then remove

lower control arm from crossmember.

INSTALL

(1) Position lower control arm into front crossmem-

ber. Then install rear lower control arm to crossmem-

ber and frame rail attaching bolt (Fig. 37).Do not

tighten rear attaching bolt at this time. Then

install front lower control arm to crossmember nut

and bolt (Fig. 37).

(2) Torque front lower control arm nut and bolt to

163 N´m (120 ft. lbs.), first and then torque rear

lower control arm attaching bolt to same torque spec-

ification.

(3) Install ball joint stud into steering knuckle.

Then install steering knuckle to ball joint stud

clamping bolt and nut (Fig. 33). Torque clamping bolt

to 95 N´m (70 ft. lbs.).

Fig. 34 Stabilizer Bar Link To Lower Control Arm

Attachment

Fig. 35 Stabilizer Bar To Crossmember Retainers

Fig. 36 Ball Joint Separation From Steering Knuckle

Fig. 37 Lower Control Arm Attaching Bolts

2 - 22 SUSPENSIONPL

REMOVAL AND INSTALLATION (Continued)

Page 34 of 1200

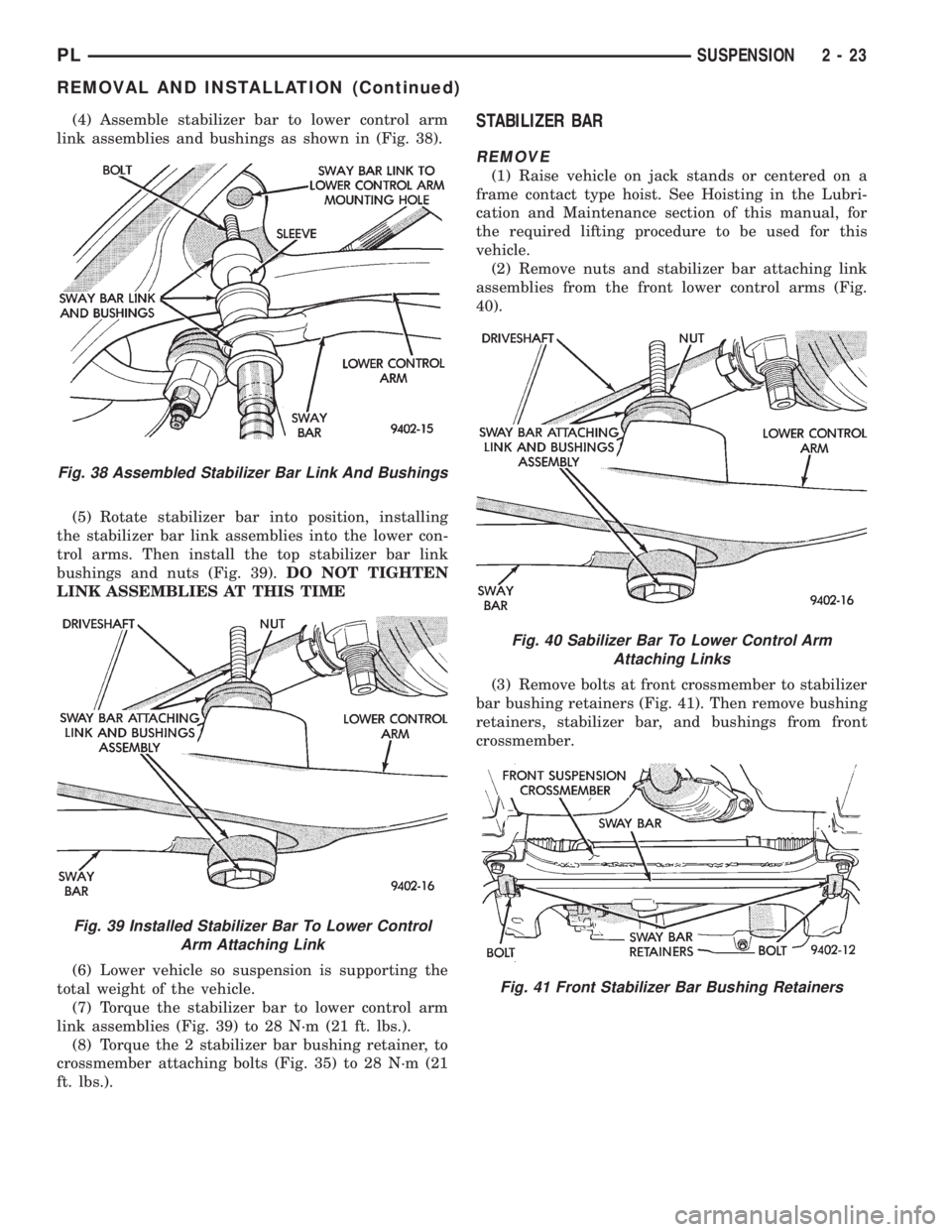

(4) Assemble stabilizer bar to lower control arm

link assemblies and bushings as shown in (Fig. 38).

(5) Rotate stabilizer bar into position, installing

the stabilizer bar link assemblies into the lower con-

trol arms. Then install the top stabilizer bar link

bushings and nuts (Fig. 39).DO NOT TIGHTEN

LINK ASSEMBLIES AT THIS TIME

(6) Lower vehicle so suspension is supporting the

total weight of the vehicle.

(7) Torque the stabilizer bar to lower control arm

link assemblies (Fig. 39) to 28 N´m (21 ft. lbs.).

(8) Torque the 2 stabilizer bar bushing retainer, to

crossmember attaching bolts (Fig. 35) to 28 N´m (21

ft. lbs.).STABILIZER BAR

REMOVE

(1) Raise vehicle on jack stands or centered on a

frame contact type hoist. See Hoisting in the Lubri-

cation and Maintenance section of this manual, for

the required lifting procedure to be used for this

vehicle.

(2) Remove nuts and stabilizer bar attaching link

assemblies from the front lower control arms (Fig.

40).

(3) Remove bolts at front crossmember to stabilizer

bar bushing retainers (Fig. 41). Then remove bushing

retainers, stabilizer bar, and bushings from front

crossmember.

Fig. 38 Assembled Stabilizer Bar Link And Bushings

Fig. 39 Installed Stabilizer Bar To Lower Control

Arm Attaching Link

Fig. 40 Sabilizer Bar To Lower Control Arm

Attaching Links

Fig. 41 Front Stabilizer Bar Bushing Retainers

PLSUSPENSION 2 - 23

REMOVAL AND INSTALLATION (Continued)

Page 35 of 1200

INSTALL

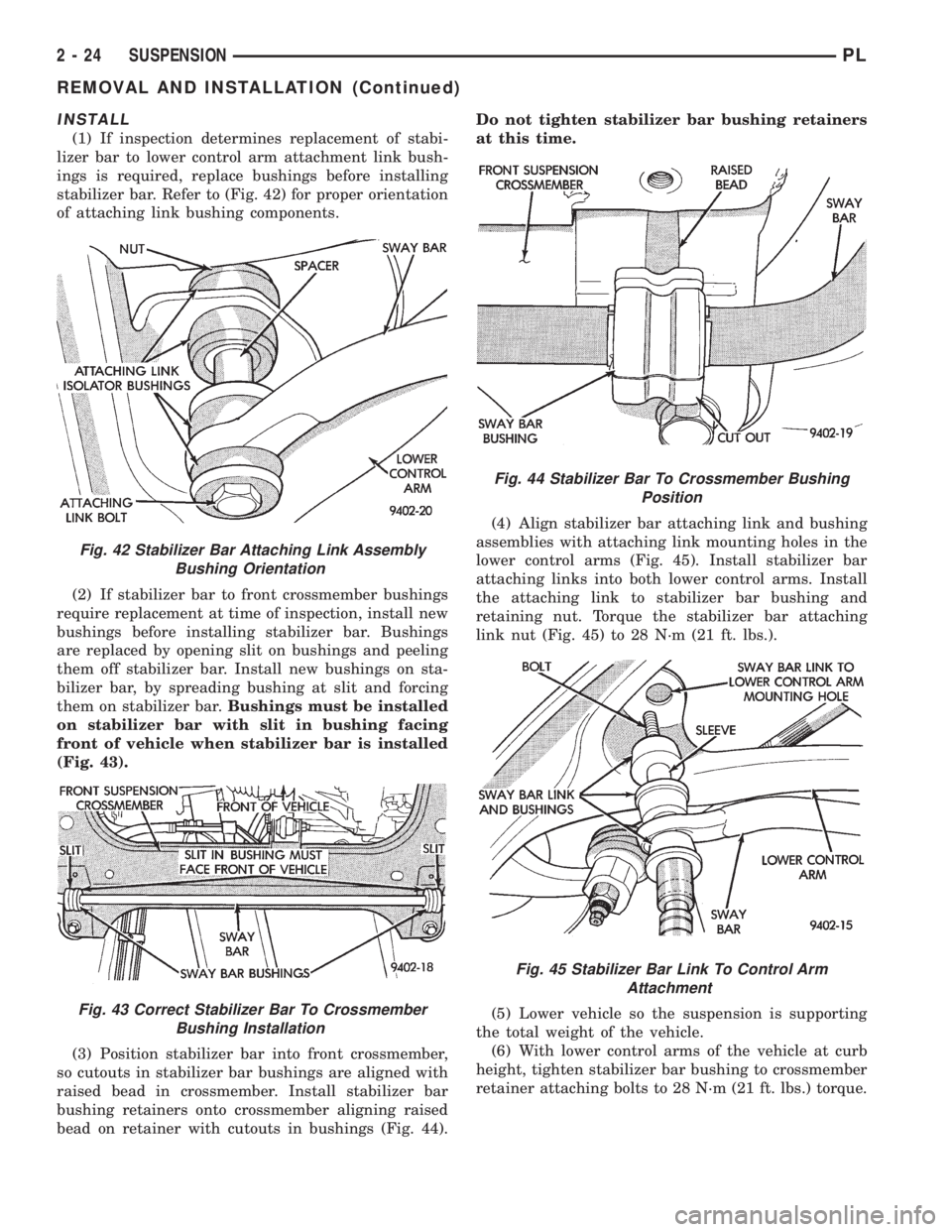

(1) If inspection determines replacement of stabi-

lizer bar to lower control arm attachment link bush-

ings is required, replace bushings before installing

stabilizer bar. Refer to (Fig. 42) for proper orientation

of attaching link bushing components.

(2) If stabilizer bar to front crossmember bushings

require replacement at time of inspection, install new

bushings before installing stabilizer bar. Bushings

are replaced by opening slit on bushings and peeling

them off stabilizer bar. Install new bushings on sta-

bilizer bar, by spreading bushing at slit and forcing

them on stabilizer bar.Bushings must be installed

on stabilizer bar with slit in bushing facing

front of vehicle when stabilizer bar is installed

(Fig. 43).

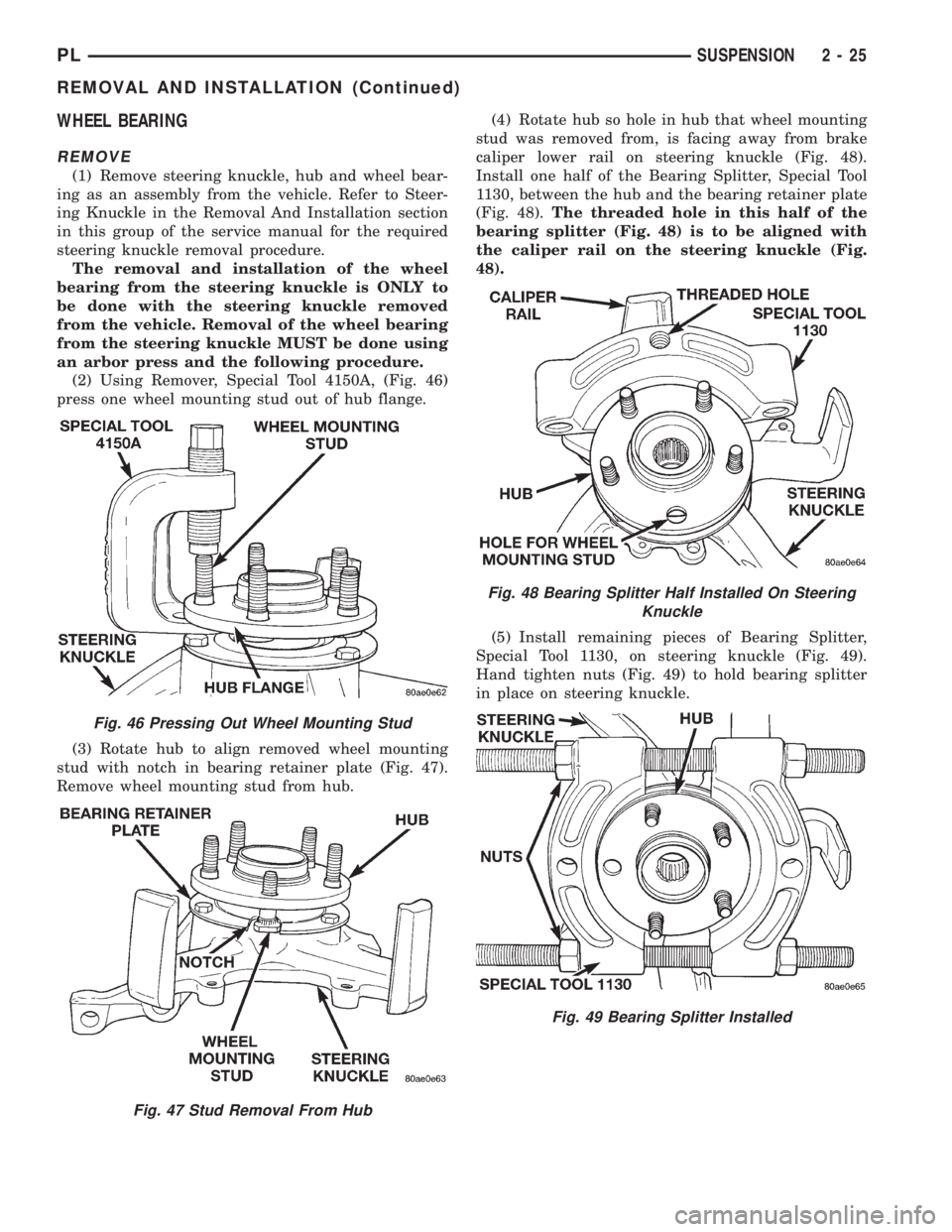

(3) Position stabilizer bar into front crossmember,

so cutouts in stabilizer bar bushings are aligned with

raised bead in crossmember. Install stabilizer bar

bushing retainers onto crossmember aligning raised

bead on retainer with cutouts in bushings (Fig. 44).Do not tighten stabilizer bar bushing retainers

at this time.

(4) Align stabilizer bar attaching link and bushing

assemblies with attaching link mounting holes in the

lower control arms (Fig. 45). Install stabilizer bar

attaching links into both lower control arms. Install

the attaching link to stabilizer bar bushing and

retaining nut. Torque the stabilizer bar attaching

link nut (Fig. 45) to 28 N´m (21 ft. lbs.).

(5) Lower vehicle so the suspension is supporting

the total weight of the vehicle.

(6) With lower control arms of the vehicle at curb

height, tighten stabilizer bar bushing to crossmember

retainer attaching bolts to 28 N´m (21 ft. lbs.) torque.

Fig. 42 Stabilizer Bar Attaching Link Assembly

Bushing Orientation

Fig. 43 Correct Stabilizer Bar To Crossmember

Bushing Installation

Fig. 44 Stabilizer Bar To Crossmember Bushing

Position

Fig. 45 Stabilizer Bar Link To Control Arm

Attachment

2 - 24 SUSPENSIONPL

REMOVAL AND INSTALLATION (Continued)

Page 36 of 1200

WHEEL BEARING

REMOVE

(1) Remove steering knuckle, hub and wheel bear-

ing as an assembly from the vehicle. Refer to Steer-

ing Knuckle in the Removal And Installation section

in this group of the service manual for the required

steering knuckle removal procedure.

The removal and installation of the wheel

bearing from the steering knuckle is ONLY to

be done with the steering knuckle removed

from the vehicle. Removal of the wheel bearing

from the steering knuckle MUST be done using

an arbor press and the following procedure.

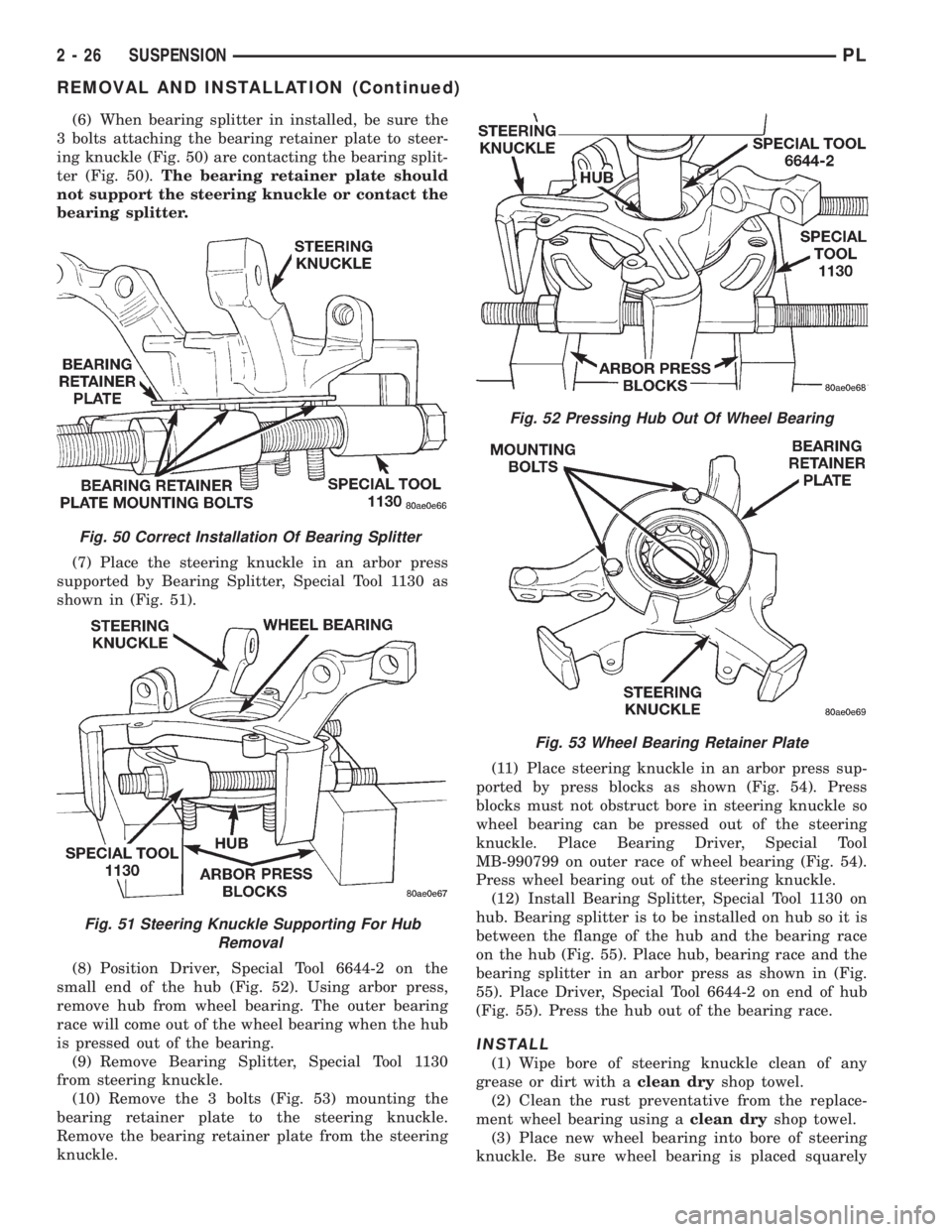

(2) Using Remover, Special Tool 4150A, (Fig. 46)

press one wheel mounting stud out of hub flange.

(3) Rotate hub to align removed wheel mounting

stud with notch in bearing retainer plate (Fig. 47).

Remove wheel mounting stud from hub.(4) Rotate hub so hole in hub that wheel mounting

stud was removed from, is facing away from brake

caliper lower rail on steering knuckle (Fig. 48).

Install one half of the Bearing Splitter, Special Tool

1130, between the hub and the bearing retainer plate

(Fig. 48).The threaded hole in this half of the

bearing splitter (Fig. 48) is to be aligned with

the caliper rail on the steering knuckle (Fig.

48).

(5) Install remaining pieces of Bearing Splitter,

Special Tool 1130, on steering knuckle (Fig. 49).

Hand tighten nuts (Fig. 49) to hold bearing splitter

in place on steering knuckle.

Fig. 46 Pressing Out Wheel Mounting Stud

Fig. 47 Stud Removal From Hub

Fig. 48 Bearing Splitter Half Installed On Steering

Knuckle

Fig. 49 Bearing Splitter Installed

PLSUSPENSION 2 - 25

REMOVAL AND INSTALLATION (Continued)

Page 37 of 1200

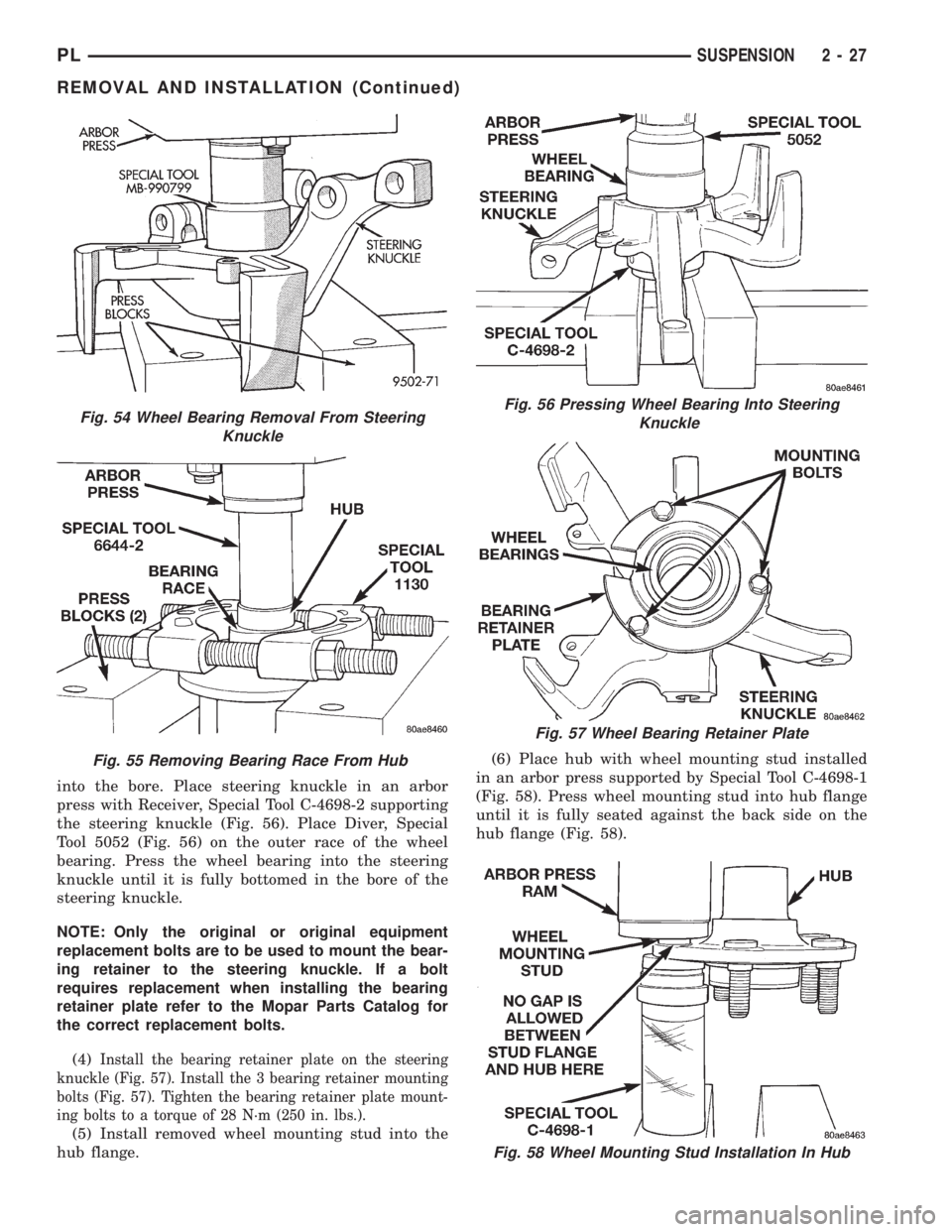

(6) When bearing splitter in installed, be sure the

3 bolts attaching the bearing retainer plate to steer-

ing knuckle (Fig. 50) are contacting the bearing split-

ter (Fig. 50).The bearing retainer plate should

not support the steering knuckle or contact the

bearing splitter.

(7) Place the steering knuckle in an arbor press

supported by Bearing Splitter, Special Tool 1130 as

shown in (Fig. 51).

(8) Position Driver, Special Tool 6644-2 on the

small end of the hub (Fig. 52). Using arbor press,

remove hub from wheel bearing. The outer bearing

race will come out of the wheel bearing when the hub

is pressed out of the bearing.

(9) Remove Bearing Splitter, Special Tool 1130

from steering knuckle.

(10) Remove the 3 bolts (Fig. 53) mounting the

bearing retainer plate to the steering knuckle.

Remove the bearing retainer plate from the steering

knuckle.(11) Place steering knuckle in an arbor press sup-

ported by press blocks as shown (Fig. 54). Press

blocks must not obstruct bore in steering knuckle so

wheel bearing can be pressed out of the steering

knuckle. Place Bearing Driver, Special Tool

MB-990799 on outer race of wheel bearing (Fig. 54).

Press wheel bearing out of the steering knuckle.

(12) Install Bearing Splitter, Special Tool 1130 on

hub. Bearing splitter is to be installed on hub so it is

between the flange of the hub and the bearing race

on the hub (Fig. 55). Place hub, bearing race and the

bearing splitter in an arbor press as shown in (Fig.

55). Place Driver, Special Tool 6644-2 on end of hub

(Fig. 55). Press the hub out of the bearing race.

INSTALL

(1) Wipe bore of steering knuckle clean of any

grease or dirt with aclean dryshop towel.

(2) Clean the rust preventative from the replace-

ment wheel bearing using aclean dryshop towel.

(3) Place new wheel bearing into bore of steering

knuckle. Be sure wheel bearing is placed squarely

Fig. 50 Correct Installation Of Bearing Splitter

Fig. 51 Steering Knuckle Supporting For Hub

Removal

Fig. 52 Pressing Hub Out Of Wheel Bearing

Fig. 53 Wheel Bearing Retainer Plate

2 - 26 SUSPENSIONPL

REMOVAL AND INSTALLATION (Continued)

Page 38 of 1200

into the bore. Place steering knuckle in an arbor

press with Receiver, Special Tool C-4698-2 supporting

the steering knuckle (Fig. 56). Place Diver, Special

Tool 5052 (Fig. 56) on the outer race of the wheel

bearing. Press the wheel bearing into the steering

knuckle until it is fully bottomed in the bore of the

steering knuckle.

NOTE: Only the original or original equipment

replacement bolts are to be used to mount the bear-

ing retainer to the steering knuckle. If a bolt

requires replacement when installing the bearing

retainer plate refer to the Mopar Parts Catalog for

the correct replacement bolts.

(4)

Install the bearing retainer plate on the steering

knuckle (Fig. 57). Install the 3 bearing retainer mounting

bolts (Fig. 57). Tighten the bearing retainer plate mount-

ing bolts to a torque of 28 N´m (250 in. lbs.).

(5) Install removed wheel mounting stud into the

hub flange.(6) Place hub with wheel mounting stud installed

in an arbor press supported by Special Tool C-4698-1

(Fig. 58). Press wheel mounting stud into hub flange

until it is fully seated against the back side on the

hub flange (Fig. 58).

Fig. 58 Wheel Mounting Stud Installation In Hub

Fig. 54 Wheel Bearing Removal From Steering

Knuckle

Fig. 55 Removing Bearing Race From Hub

Fig. 56 Pressing Wheel Bearing Into Steering

Knuckle

Fig. 57 Wheel Bearing Retainer Plate

PLSUSPENSION 2 - 27

REMOVAL AND INSTALLATION (Continued)

Page 39 of 1200

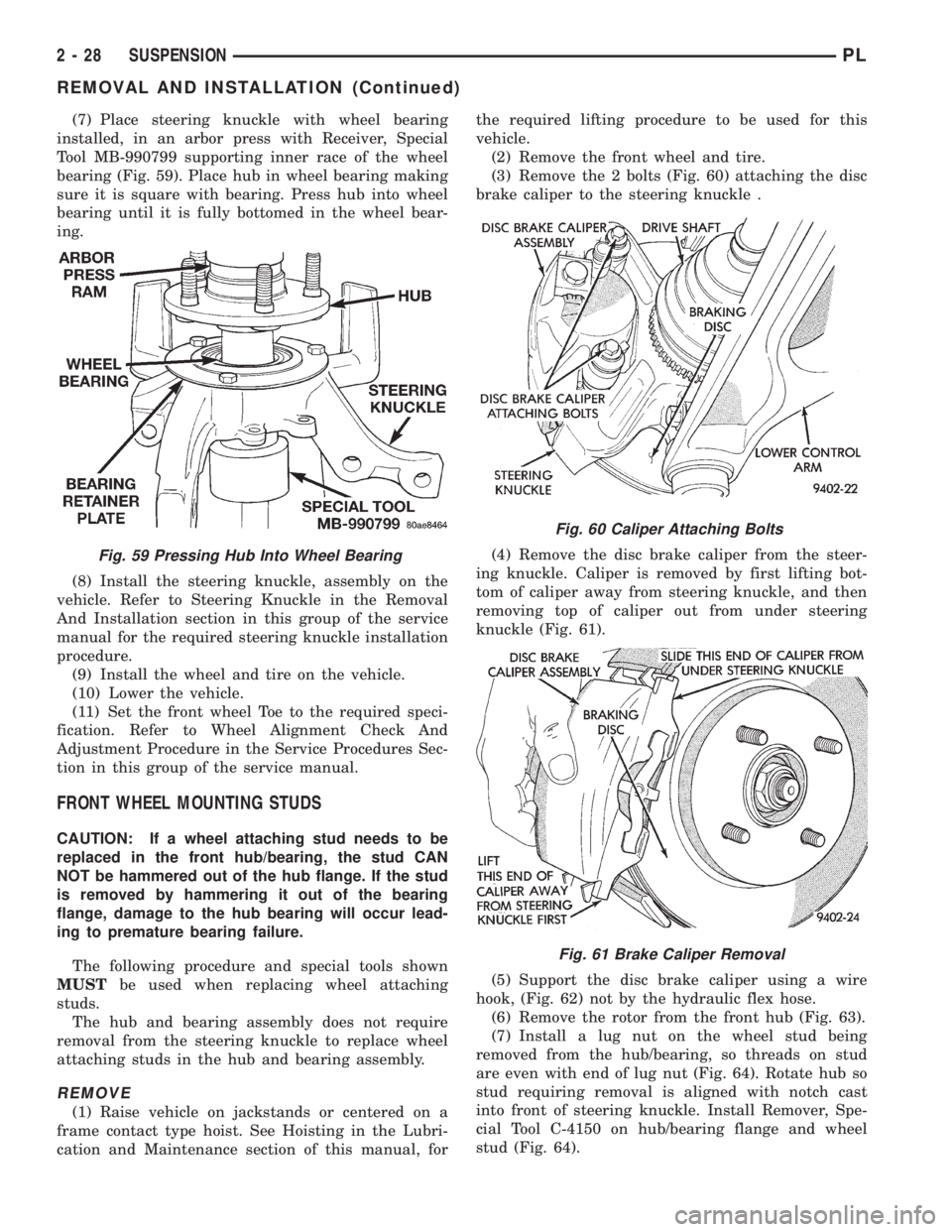

(7) Place steering knuckle with wheel bearing

installed, in an arbor press with Receiver, Special

Tool MB-990799 supporting inner race of the wheel

bearing (Fig. 59). Place hub in wheel bearing making

sure it is square with bearing. Press hub into wheel

bearing until it is fully bottomed in the wheel bear-

ing.

(8) Install the steering knuckle, assembly on the

vehicle. Refer to Steering Knuckle in the Removal

And Installation section in this group of the service

manual for the required steering knuckle installation

procedure.

(9) Install the wheel and tire on the vehicle.

(10) Lower the vehicle.

(11) Set the front wheel Toe to the required speci-

fication. Refer to Wheel Alignment Check And

Adjustment Procedure in the Service Procedures Sec-

tion in this group of the service manual.

FRONT WHEEL MOUNTING STUDS

CAUTION: If a wheel attaching stud needs to be

replaced in the front hub/bearing, the stud CAN

NOT be hammered out of the hub flange. If the stud

is removed by hammering it out of the bearing

flange, damage to the hub bearing will occur lead-

ing to premature bearing failure.

The following procedure and special tools shown

MUSTbe used when replacing wheel attaching

studs.

The hub and bearing assembly does not require

removal from the steering knuckle to replace wheel

attaching studs in the hub and bearing assembly.

REMOVE

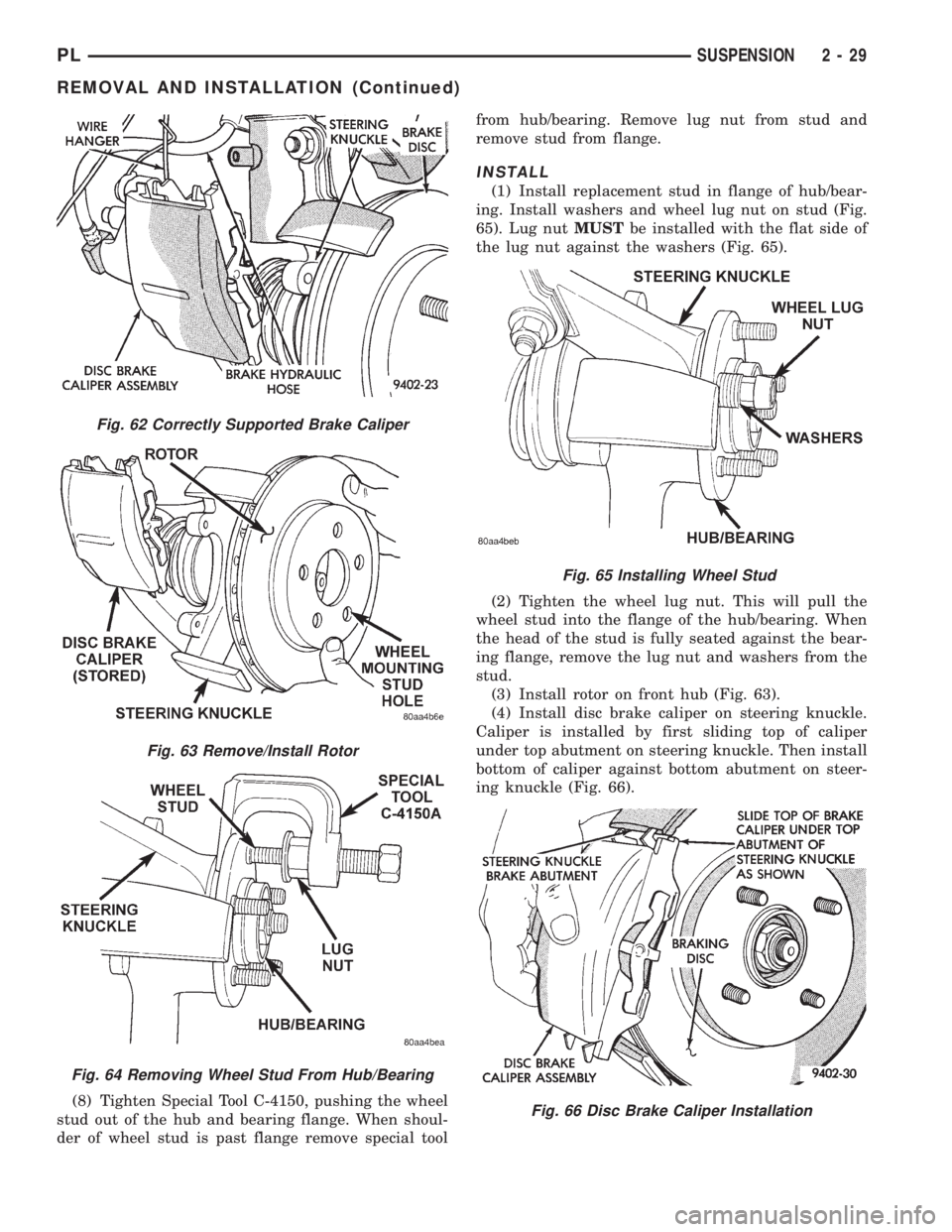

(1) Raise vehicle on jackstands or centered on a

frame contact type hoist. See Hoisting in the Lubri-

cation and Maintenance section of this manual, forthe required lifting procedure to be used for this

vehicle.

(2) Remove the front wheel and tire.

(3) Remove the 2 bolts (Fig. 60) attaching the disc

brake caliper to the steering knuckle .

(4) Remove the disc brake caliper from the steer-

ing knuckle. Caliper is removed by first lifting bot-

tom of caliper away from steering knuckle, and then

removing top of caliper out from under steering

knuckle (Fig. 61).

(5) Support the disc brake caliper using a wire

hook, (Fig. 62) not by the hydraulic flex hose.

(6) Remove the rotor from the front hub (Fig. 63).

(7) Install a lug nut on the wheel stud being

removed from the hub/bearing, so threads on stud

are even with end of lug nut (Fig. 64). Rotate hub so

stud requiring removal is aligned with notch cast

into front of steering knuckle. Install Remover, Spe-

cial Tool C-4150 on hub/bearing flange and wheel

stud (Fig. 64).

Fig. 59 Pressing Hub Into Wheel Bearing

Fig. 60 Caliper Attaching Bolts

Fig. 61 Brake Caliper Removal

2 - 28 SUSPENSIONPL

REMOVAL AND INSTALLATION (Continued)

Page 40 of 1200

(8) Tighten Special Tool C-4150, pushing the wheel

stud out of the hub and bearing flange. When shoul-

der of wheel stud is past flange remove special toolfrom hub/bearing. Remove lug nut from stud and

remove stud from flange.

INSTALL

(1) Install replacement stud in flange of hub/bear-

ing. Install washers and wheel lug nut on stud (Fig.

65). Lug nutMUSTbe installed with the flat side of

the lug nut against the washers (Fig. 65).

(2) Tighten the wheel lug nut. This will pull the

wheel stud into the flange of the hub/bearing. When

the head of the stud is fully seated against the bear-

ing flange, remove the lug nut and washers from the

stud.

(3) Install rotor on front hub (Fig. 63).

(4) Install disc brake caliper on steering knuckle.

Caliper is installed by first sliding top of caliper

under top abutment on steering knuckle. Then install

bottom of caliper against bottom abutment on steer-

ing knuckle (Fig. 66).

Fig. 62 Correctly Supported Brake Caliper

Fig. 63 Remove/Install Rotor

Fig. 64 Removing Wheel Stud From Hub/Bearing

Fig. 65 Installing Wheel Stud

Fig. 66 Disc Brake Caliper Installation

PLSUSPENSION 2 - 29

REMOVAL AND INSTALLATION (Continued)