ABS DODGE NEON 1999 Service Manual PDF

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 275 of 1200

(8) If all tests performed test good, replace the dial

and gauge assembly.

(9) If the tachometer continues to be inoperative,

replace the print circuit board.

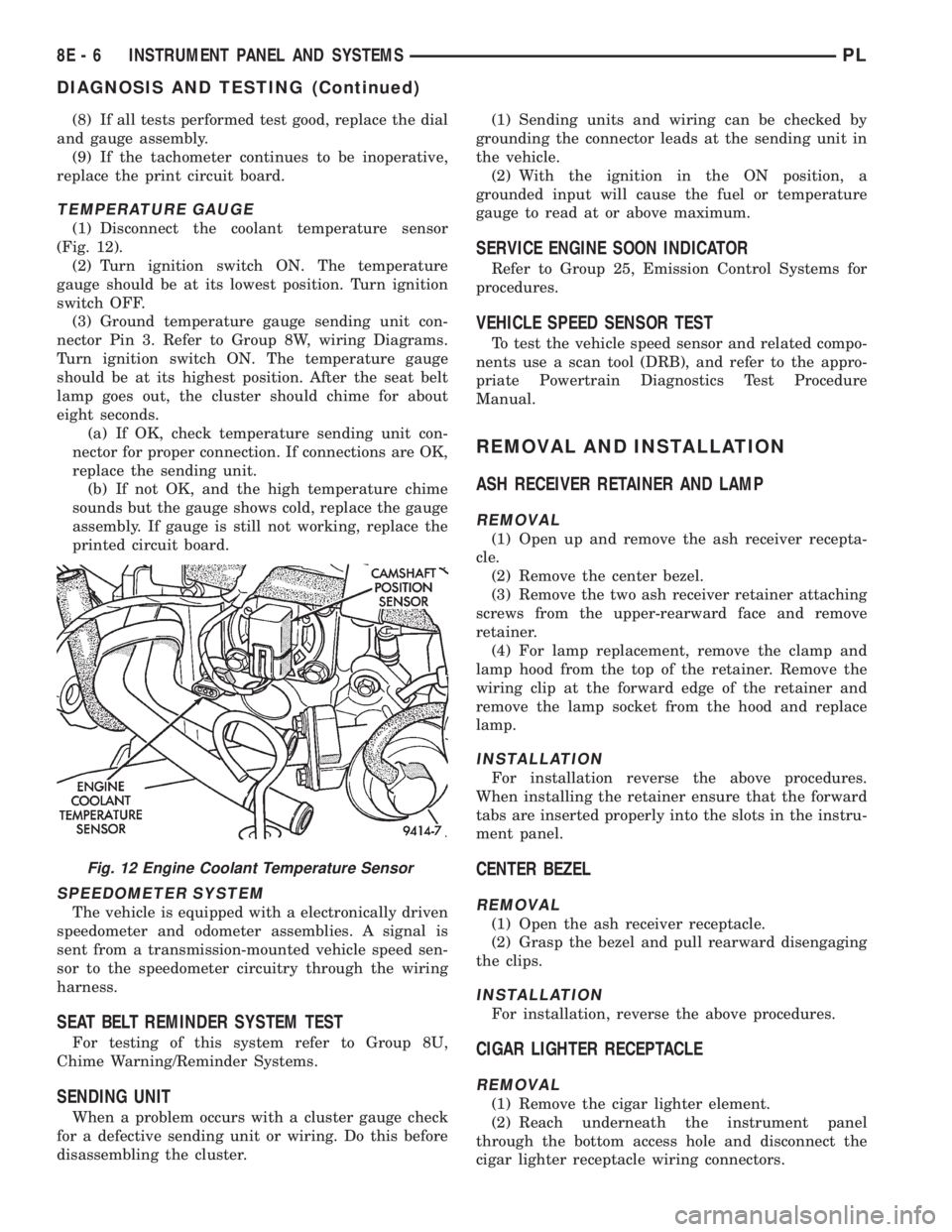

TEMPERATURE GAUGE

(1) Disconnect the coolant temperature sensor

(Fig. 12).

(2) Turn ignition switch ON. The temperature

gauge should be at its lowest position. Turn ignition

switch OFF.

(3) Ground temperature gauge sending unit con-

nector Pin 3. Refer to Group 8W, wiring Diagrams.

Turn ignition switch ON. The temperature gauge

should be at its highest position. After the seat belt

lamp goes out, the cluster should chime for about

eight seconds.

(a) If OK, check temperature sending unit con-

nector for proper connection. If connections are OK,

replace the sending unit.

(b) If not OK, and the high temperature chime

sounds but the gauge shows cold, replace the gauge

assembly. If gauge is still not working, replace the

printed circuit board.

SPEEDOMETER SYSTEM

The vehicle is equipped with a electronically driven

speedometer and odometer assemblies. A signal is

sent from a transmission-mounted vehicle speed sen-

sor to the speedometer circuitry through the wiring

harness.

SEAT BELT REMINDER SYSTEM TEST

For testing of this system refer to Group 8U,

Chime Warning/Reminder Systems.

SENDING UNIT

When a problem occurs with a cluster gauge check

for a defective sending unit or wiring. Do this before

disassembling the cluster.(1) Sending units and wiring can be checked by

grounding the connector leads at the sending unit in

the vehicle.

(2) With the ignition in the ON position, a

grounded input will cause the fuel or temperature

gauge to read at or above maximum.

SERVICE ENGINE SOON INDICATOR

Refer to Group 25, Emission Control Systems for

procedures.

VEHICLE SPEED SENSOR TEST

To test the vehicle speed sensor and related compo-

nents use a scan tool (DRB), and refer to the appro-

priate Powertrain Diagnostics Test Procedure

Manual.

REMOVAL AND INSTALLATION

ASH RECEIVER RETAINER AND LAMP

REMOVAL

(1) Open up and remove the ash receiver recepta-

cle.

(2) Remove the center bezel.

(3) Remove the two ash receiver retainer attaching

screws from the upper-rearward face and remove

retainer.

(4) For lamp replacement, remove the clamp and

lamp hood from the top of the retainer. Remove the

wiring clip at the forward edge of the retainer and

remove the lamp socket from the hood and replace

lamp.

INSTALLATION

For installation reverse the above procedures.

When installing the retainer ensure that the forward

tabs are inserted properly into the slots in the instru-

ment panel.

CENTER BEZEL

REMOVAL

(1) Open the ash receiver receptacle.

(2) Grasp the bezel and pull rearward disengaging

the clips.

INSTALLATION

For installation, reverse the above procedures.

CIGAR LIGHTER RECEPTACLE

REMOVAL

(1) Remove the cigar lighter element.

(2) Reach underneath the instrument panel

through the bottom access hole and disconnect the

cigar lighter receptacle wiring connectors.

Fig. 12 Engine Coolant Temperature Sensor

8E - 6 INSTRUMENT PANEL AND SYSTEMSPL

DIAGNOSIS AND TESTING (Continued)

Page 282 of 1200

the panel rearward to disengage the three locator

pins and remove.

(6) Reach in and disconnect the wiring connector(s)

for the rear window defogger and/or fog lamp

switch(s) as required.

INSTALLATION

For installation, reverse the above procedures.

SHIFTER KNOB

AUTOMATIC TRANSMISSION SHIFTER

REMOVAL

(1) Loosen the set screw at the left side under the

button area.

(2) Pull up until the knob slides off the shifter

shaft.

INSTALLATION

For installation, reverse the above procedures.

MANUAL TRANSMISSION SHIFTER

REMOVAL

(1) Pull the top part of the boot down until the two

tabs at the bottom of the knob are exposed.

(2) Release the locking tabs from the pins on the

shifter shaft.

(3) Pull up until the knob slides off the shifter

shaft.INSTALLATION

For installation, reverse the above procedures.

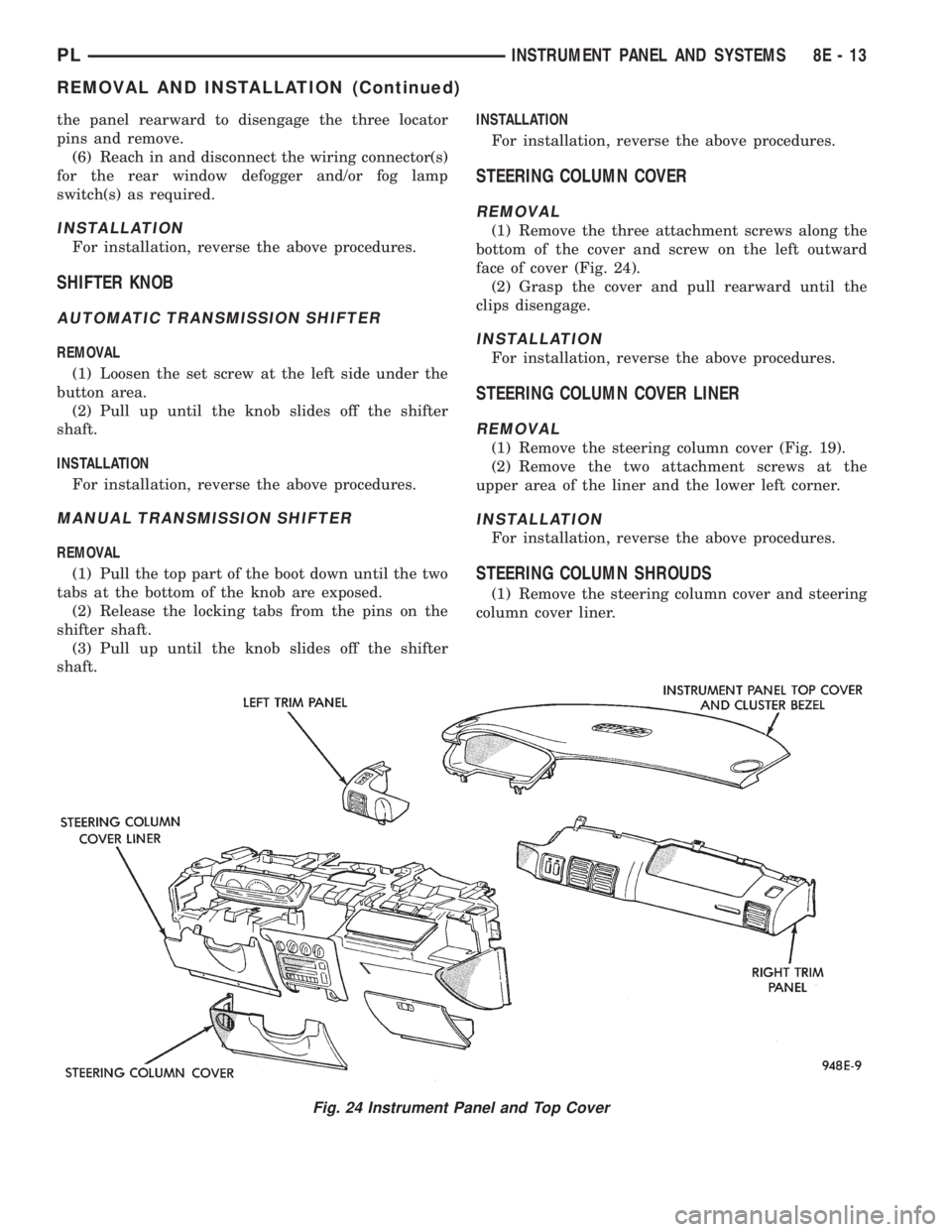

STEERING COLUMN COVER

REMOVAL

(1) Remove the three attachment screws along the

bottom of the cover and screw on the left outward

face of cover (Fig. 24).

(2) Grasp the cover and pull rearward until the

clips disengage.

INSTALLATION

For installation, reverse the above procedures.

STEERING COLUMN COVER LINER

REMOVAL

(1) Remove the steering column cover (Fig. 19).

(2) Remove the two attachment screws at the

upper area of the liner and the lower left corner.

INSTALLATION

For installation, reverse the above procedures.

STEERING COLUMN SHROUDS

(1) Remove the steering column cover and steering

column cover liner.

Fig. 24 Instrument Panel and Top Cover

PLINSTRUMENT PANEL AND SYSTEMS 8E - 13

REMOVAL AND INSTALLATION (Continued)

Page 306 of 1200

the plunger reaches the end of its travel. A ratchet-

ing sound will be heard during this procedure.

Connect the wiring harness to the switch. Mount

the switch into the bracket by holding the switch

with the plunger facing forward in car. There is an

index key on the switch that mates with the bracket

slot at the top of the square hole. Align key and push

switch into square hole in bracket while depressing

the brake pedal. Once the switch is seated in the

hole, rotate clockwise approximately 30 degrees to

lock into place. The switch will automatically adjust

when the pedal is released. Pull back on the pedal to

assure correct adjustment.

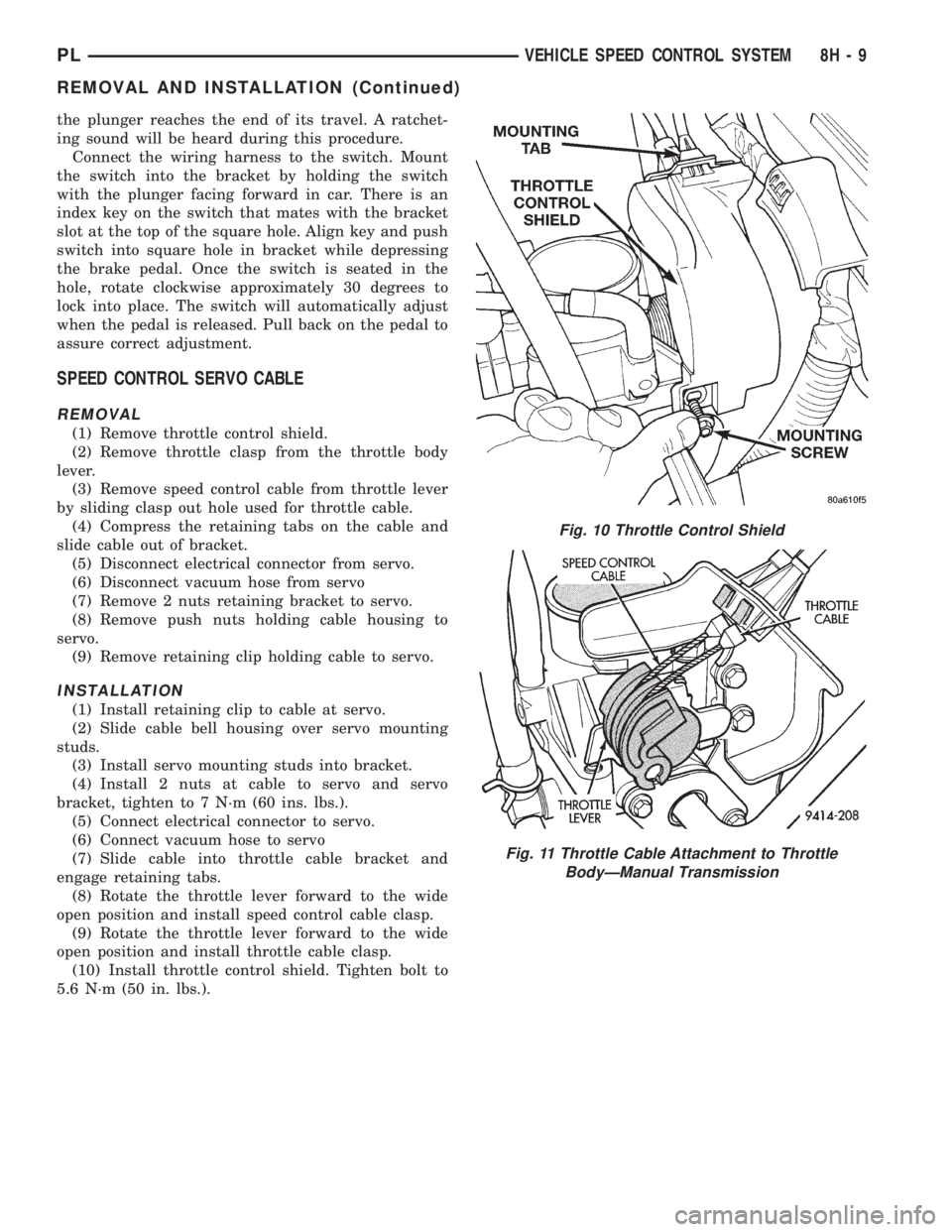

SPEED CONTROL SERVO CABLE

REMOVAL

(1) Remove throttle control shield.

(2) Remove throttle clasp from the throttle body

lever.

(3) Remove speed control cable from throttle lever

by sliding clasp out hole used for throttle cable.

(4) Compress the retaining tabs on the cable and

slide cable out of bracket.

(5) Disconnect electrical connector from servo.

(6) Disconnect vacuum hose from servo

(7) Remove 2 nuts retaining bracket to servo.

(8) Remove push nuts holding cable housing to

servo.

(9) Remove retaining clip holding cable to servo.

INSTALLATION

(1) Install retaining clip to cable at servo.

(2) Slide cable bell housing over servo mounting

studs.

(3) Install servo mounting studs into bracket.

(4) Install 2 nuts at cable to servo and servo

bracket, tighten to 7 N´m (60 ins. lbs.).

(5) Connect electrical connector to servo.

(6) Connect vacuum hose to servo

(7) Slide cable into throttle cable bracket and

engage retaining tabs.

(8) Rotate the throttle lever forward to the wide

open position and install speed control cable clasp.

(9) Rotate the throttle lever forward to the wide

open position and install throttle cable clasp.

(10) Install throttle control shield. Tighten bolt to

5.6 N´m (50 in. lbs.).

Fig. 10 Throttle Control Shield

Fig. 11 Throttle Cable Attachment to Throttle

BodyÐManual Transmission

PLVEHICLE SPEED CONTROL SYSTEM 8H - 9

REMOVAL AND INSTALLATION (Continued)

Page 322 of 1200

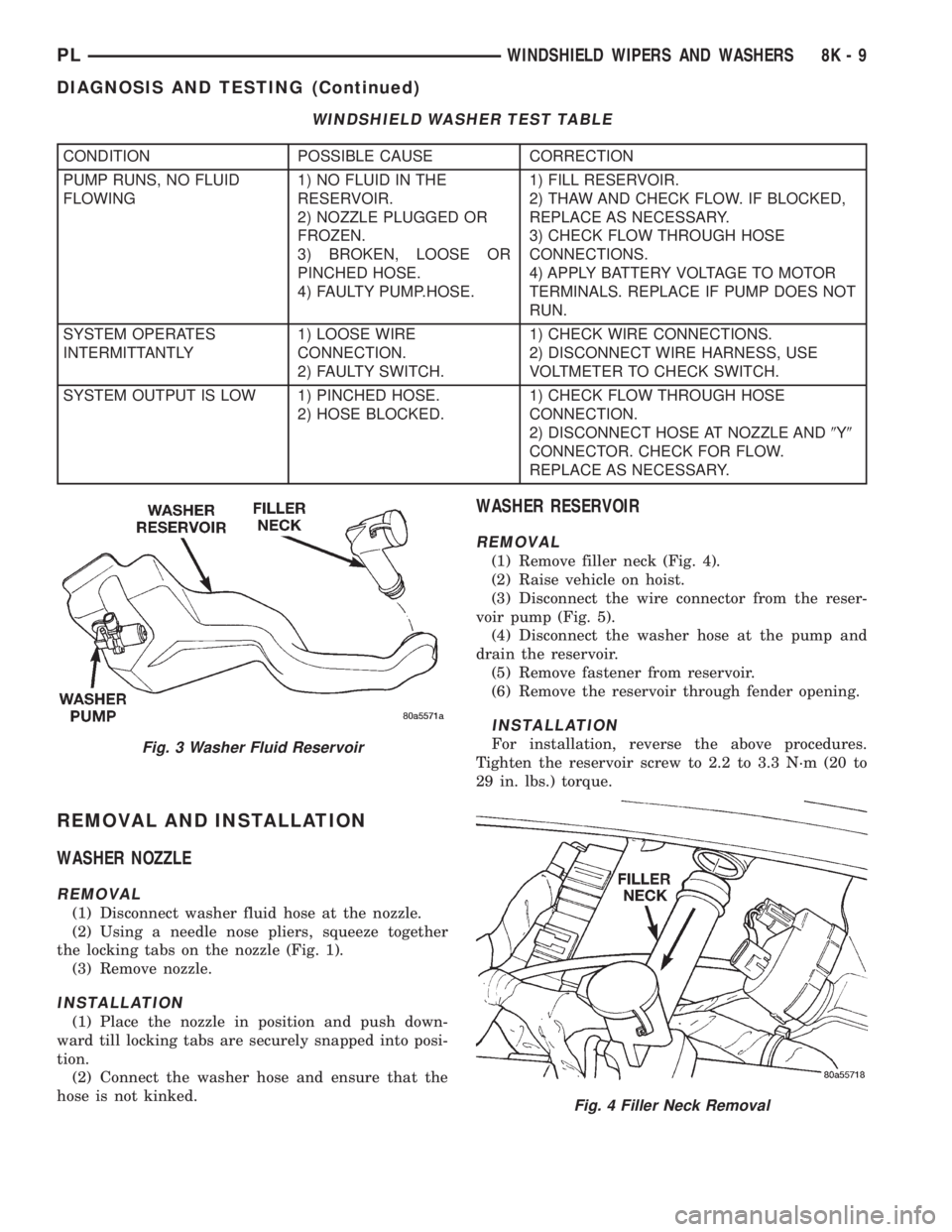

REMOVAL AND INSTALLATION

WASHER NOZZLE

REMOVAL

(1) Disconnect washer fluid hose at the nozzle.

(2) Using a needle nose pliers, squeeze together

the locking tabs on the nozzle (Fig. 1).

(3) Remove nozzle.

INSTALLATION

(1) Place the nozzle in position and push down-

ward till locking tabs are securely snapped into posi-

tion.

(2) Connect the washer hose and ensure that the

hose is not kinked.

WASHER RESERVOIR

REMOVAL

(1) Remove filler neck (Fig. 4).

(2) Raise vehicle on hoist.

(3) Disconnect the wire connector from the reser-

voir pump (Fig. 5).

(4) Disconnect the washer hose at the pump and

drain the reservoir.

(5) Remove fastener from reservoir.

(6) Remove the reservoir through fender opening.

INSTALLATION

For installation, reverse the above procedures.

Tighten the reservoir screw to 2.2 to 3.3 N´m (20 to

29 in. lbs.) torque.

WINDSHIELD WASHER TEST TABLE

CONDITION POSSIBLE CAUSE CORRECTION

PUMP RUNS, NO FLUID

FLOWING1) NO FLUID IN THE

RESERVOIR.

2) NOZZLE PLUGGED OR

FROZEN.

3) BROKEN, LOOSE OR

PINCHED HOSE.

4) FAULTY PUMP.HOSE.1) FILL RESERVOIR.

2) THAW AND CHECK FLOW. IF BLOCKED,

REPLACE AS NECESSARY.

3) CHECK FLOW THROUGH HOSE

CONNECTIONS.

4) APPLY BATTERY VOLTAGE TO MOTOR

TERMINALS. REPLACE IF PUMP DOES NOT

RUN.

SYSTEM OPERATES

INTERMITTANTLY1) LOOSE WIRE

CONNECTION.

2) FAULTY SWITCH.1) CHECK WIRE CONNECTIONS.

2) DISCONNECT WIRE HARNESS, USE

VOLTMETER TO CHECK SWITCH.

SYSTEM OUTPUT IS LOW 1) PINCHED HOSE.

2) HOSE BLOCKED.1) CHECK FLOW THROUGH HOSE

CONNECTION.

2) DISCONNECT HOSE AT NOZZLE AND9Y9

CONNECTOR. CHECK FOR FLOW.

REPLACE AS NECESSARY.

Fig. 3 Washer Fluid Reservoir

Fig. 4 Filler Neck Removal

PLWINDSHIELD WIPERS AND WASHERS 8K - 9

DIAGNOSIS AND TESTING (Continued)

Page 346 of 1200

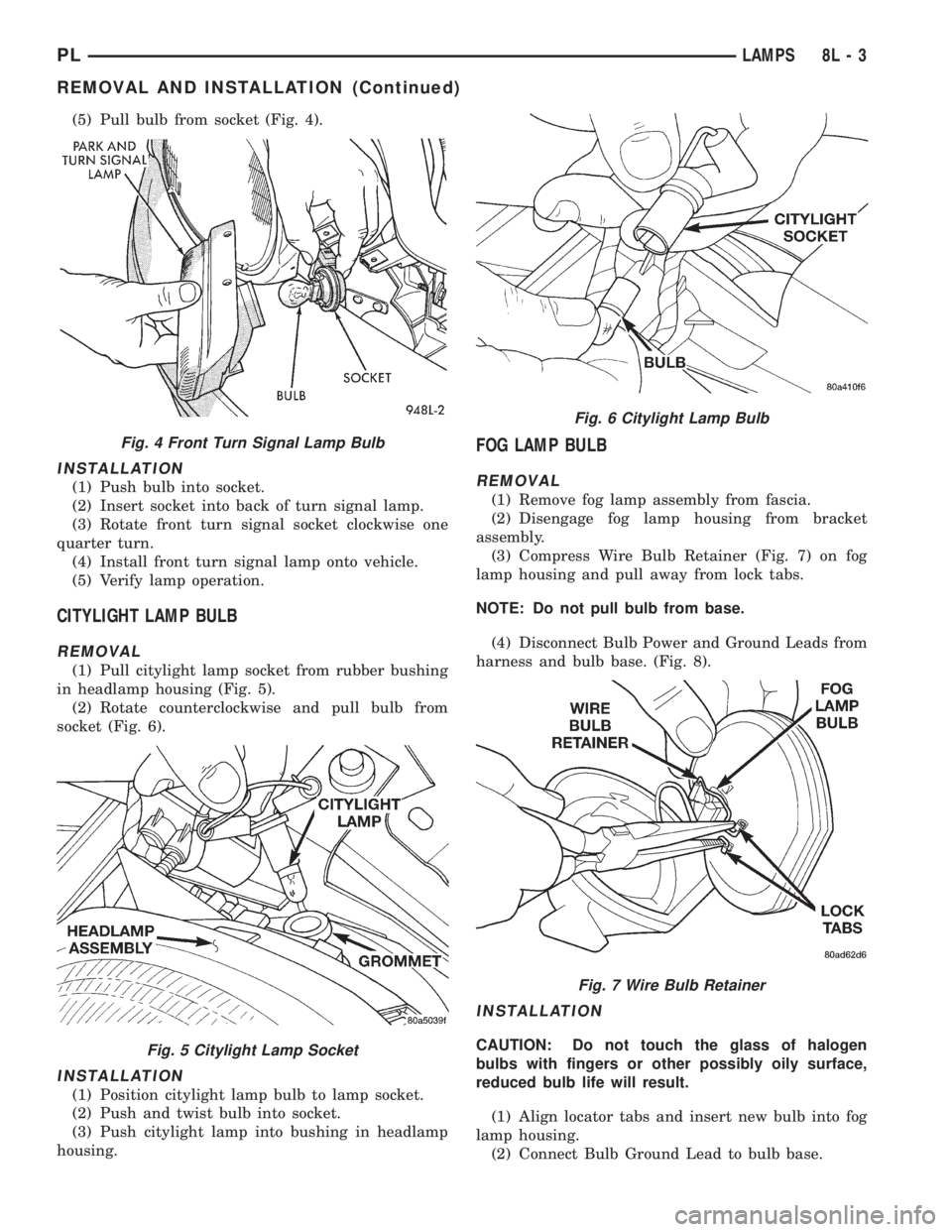

(5) Pull bulb from socket (Fig. 4).

INSTALLATION

(1) Push bulb into socket.

(2) Insert socket into back of turn signal lamp.

(3) Rotate front turn signal socket clockwise one

quarter turn.

(4) Install front turn signal lamp onto vehicle.

(5) Verify lamp operation.

CITYLIGHT LAMP BULB

REMOVAL

(1) Pull citylight lamp socket from rubber bushing

in headlamp housing (Fig. 5).

(2) Rotate counterclockwise and pull bulb from

socket (Fig. 6).

INSTALLATION

(1) Position citylight lamp bulb to lamp socket.

(2) Push and twist bulb into socket.

(3) Push citylight lamp into bushing in headlamp

housing.

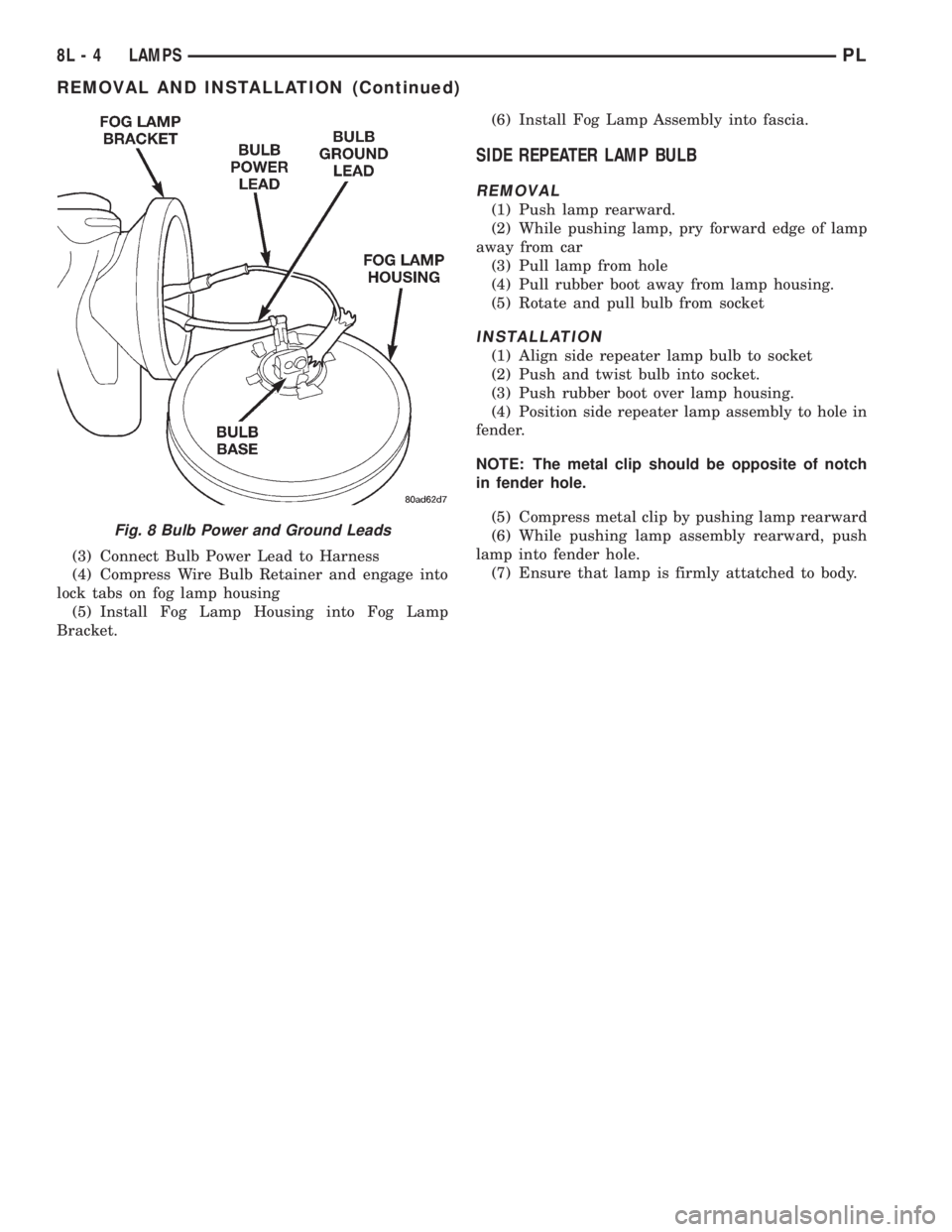

FOG LAMP BULB

REMOVAL

(1) Remove fog lamp assembly from fascia.

(2) Disengage fog lamp housing from bracket

assembly.

(3) Compress Wire Bulb Retainer (Fig. 7) on fog

lamp housing and pull away from lock tabs.

NOTE: Do not pull bulb from base.

(4) Disconnect Bulb Power and Ground Leads from

harness and bulb base. (Fig. 8).

INSTALLATION

CAUTION: Do not touch the glass of halogen

bulbs with fingers or other possibly oily surface,

reduced bulb life will result.

(1) Align locator tabs and insert new bulb into fog

lamp housing.

(2) Connect Bulb Ground Lead to bulb base.

Fig. 4 Front Turn Signal Lamp Bulb

Fig. 5 Citylight Lamp Socket

Fig. 6 Citylight Lamp Bulb

Fig. 7 Wire Bulb Retainer

PLLAMPS 8L - 3

REMOVAL AND INSTALLATION (Continued)

Page 347 of 1200

(3) Connect Bulb Power Lead to Harness

(4) Compress Wire Bulb Retainer and engage into

lock tabs on fog lamp housing

(5) Install Fog Lamp Housing into Fog Lamp

Bracket.(6) Install Fog Lamp Assembly into fascia.

SIDE REPEATER LAMP BULB

REMOVAL

(1) Push lamp rearward.

(2) While pushing lamp, pry forward edge of lamp

away from car

(3) Pull lamp from hole

(4) Pull rubber boot away from lamp housing.

(5) Rotate and pull bulb from socket

INSTALLATION

(1) Align side repeater lamp bulb to socket

(2) Push and twist bulb into socket.

(3) Push rubber boot over lamp housing.

(4) Position side repeater lamp assembly to hole in

fender.

NOTE: The metal clip should be opposite of notch

in fender hole.

(5) Compress metal clip by pushing lamp rearward

(6) While pushing lamp assembly rearward, push

lamp into fender hole.

(7) Ensure that lamp is firmly attatched to body.

Fig. 8 Bulb Power and Ground Leads

8L - 4 LAMPSPL

REMOVAL AND INSTALLATION (Continued)

Page 351 of 1200

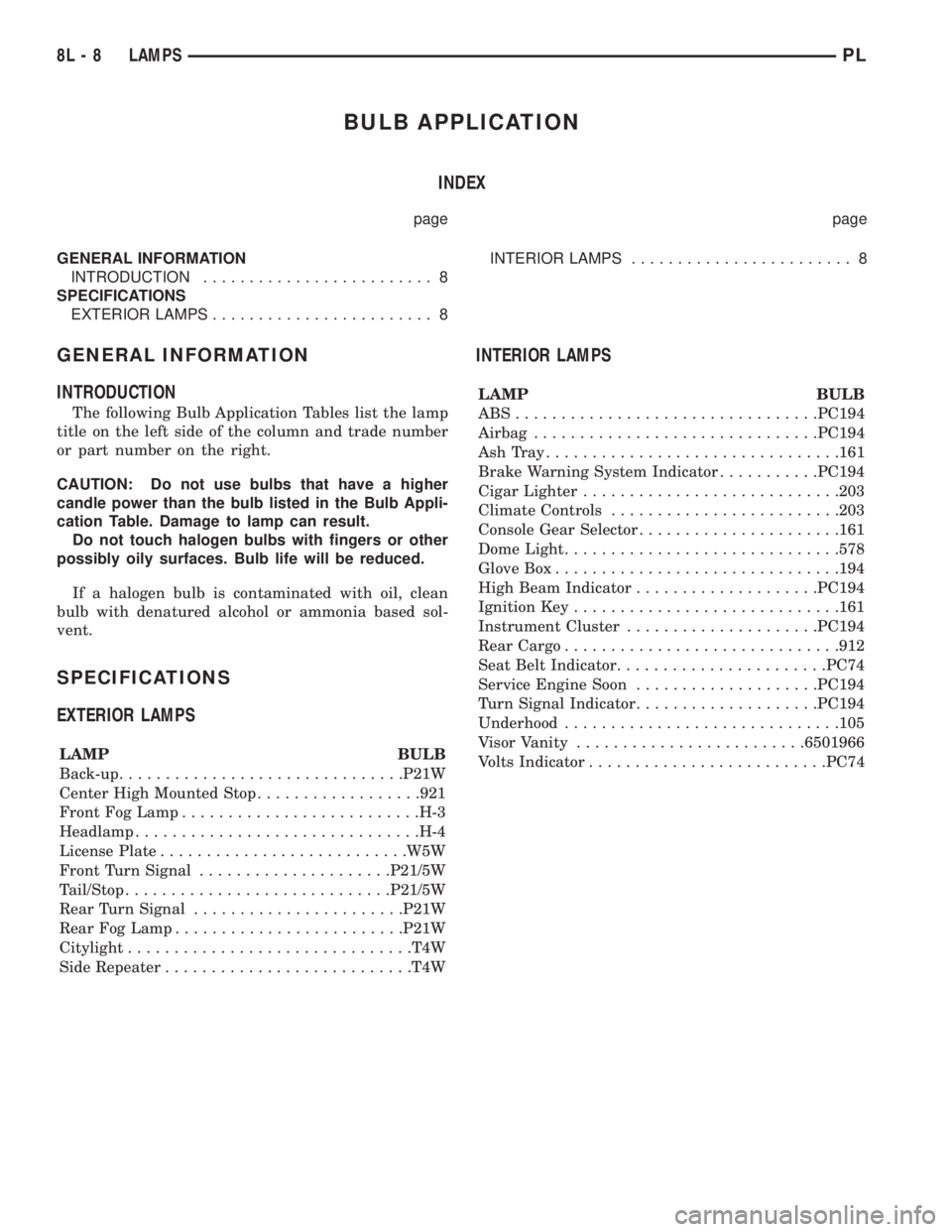

BULB APPLICATION

INDEX

page page

GENERAL INFORMATION

INTRODUCTION......................... 8

SPECIFICATIONS

EXTERIOR LAMPS........................ 8INTERIOR LAMPS........................ 8

GENERAL INFORMATION

INTRODUCTION

The following Bulb Application Tables list the lamp

title on the left side of the column and trade number

or part number on the right.

CAUTION: Do not use bulbs that have a higher

candle power than the bulb listed in the Bulb Appli-

cation Table. Damage to lamp can result.

Do not touch halogen bulbs with fingers or other

possibly oily surfaces. Bulb life will be reduced.

If a halogen bulb is contaminated with oil, clean

bulb with denatured alcohol or ammonia based sol-

vent.

SPECIFICATIONS

EXTERIOR LAMPS

LAMP BULB

Back-up...............................P21W

Center High Mounted Stop..................921

Front Fog Lamp..........................H-3

Headlamp...............................H-4

License Plate...........................W5W

Front Turn Signal.....................P21/5W

Tail/Stop.............................P21/5W

Rear Turn Signal.......................P21W

Rear Fog Lamp.........................P21W

Citylight...............................T4W

Side Repeater...........................T4W

INTERIOR LAMPS

LAMP BULB

ABS.................................PC194

Airbag...............................PC194

AshTray................................161

Brake Warning System Indicator...........PC194

Cigar Lighter............................203

Climate Controls.........................203

Console Gear Selector......................161

Dome Light..............................578

Glove Box...............................194

High Beam Indicator....................PC194

Ignition Key.............................161

Instrument Cluster.....................PC194

Rear Cargo..............................912

Seat Belt Indicator.......................PC74

Service Engine Soon....................PC194

Turn Signal Indicator....................PC194

Underhood..............................105

Visor Vanity.........................6501966

Volts Indicator..........................PC74

8L - 8 LAMPSPL

Page 359 of 1200

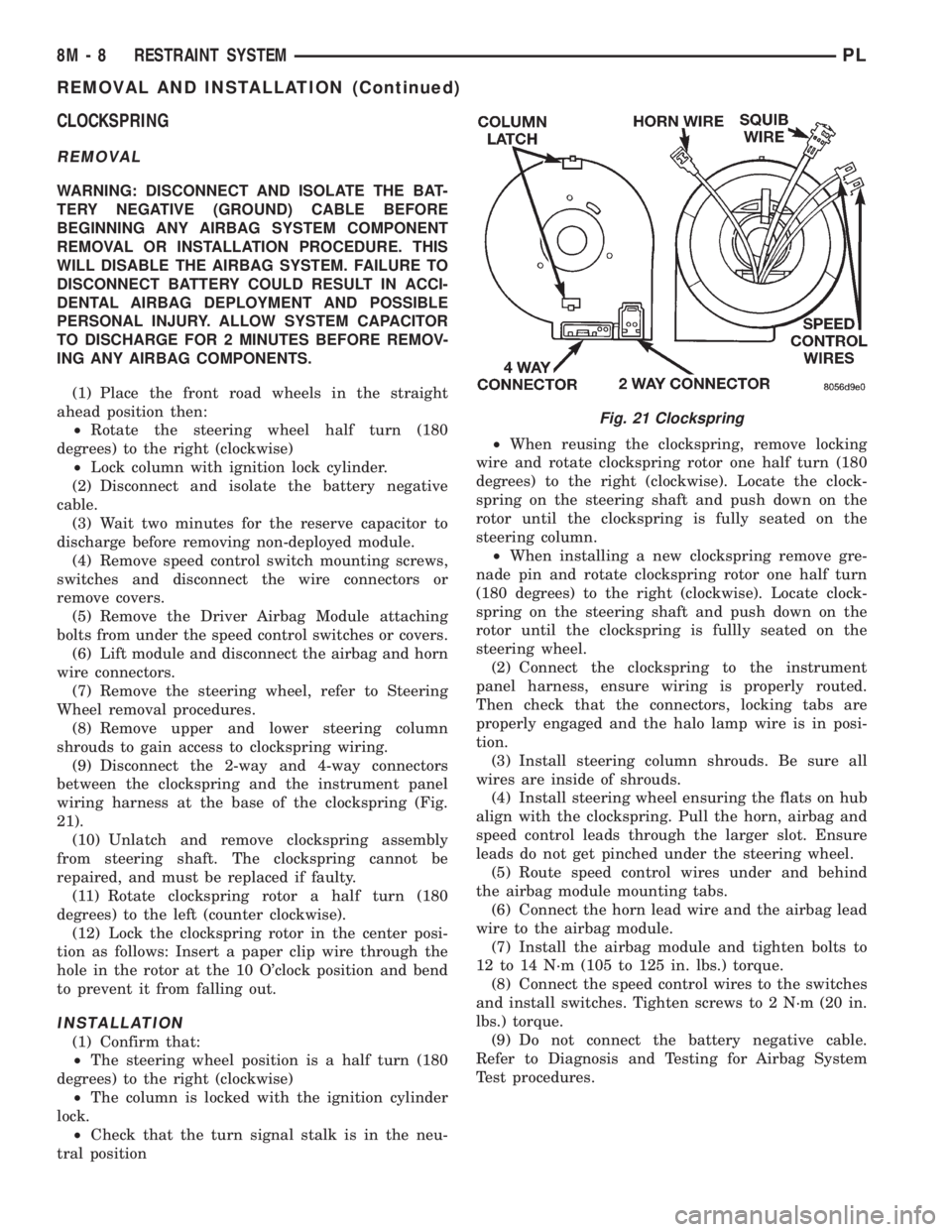

CLOCKSPRING

REMOVAL

WARNING: DISCONNECT AND ISOLATE THE BAT-

TERY NEGATIVE (GROUND) CABLE BEFORE

BEGINNING ANY AIRBAG SYSTEM COMPONENT

REMOVAL OR INSTALLATION PROCEDURE. THIS

WILL DISABLE THE AIRBAG SYSTEM. FAILURE TO

DISCONNECT BATTERY COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY. ALLOW SYSTEM CAPACITOR

TO DISCHARGE FOR 2 MINUTES BEFORE REMOV-

ING ANY AIRBAG COMPONENTS.

(1) Place the front road wheels in the straight

ahead position then:

²Rotate the steering wheel half turn (180

degrees) to the right (clockwise)

²Lock column with ignition lock cylinder.

(2) Disconnect and isolate the battery negative

cable.

(3) Wait two minutes for the reserve capacitor to

discharge before removing non-deployed module.

(4) Remove speed control switch mounting screws,

switches and disconnect the wire connectors or

remove covers.

(5) Remove the Driver Airbag Module attaching

bolts from under the speed control switches or covers.

(6) Lift module and disconnect the airbag and horn

wire connectors.

(7) Remove the steering wheel, refer to Steering

Wheel removal procedures.

(8) Remove upper and lower steering column

shrouds to gain access to clockspring wiring.

(9) Disconnect the 2-way and 4-way connectors

between the clockspring and the instrument panel

wiring harness at the base of the clockspring (Fig.

21).

(10) Unlatch and remove clockspring assembly

from steering shaft. The clockspring cannot be

repaired, and must be replaced if faulty.

(11) Rotate clockspring rotor a half turn (180

degrees) to the left (counter clockwise).

(12) Lock the clockspring rotor in the center posi-

tion as follows: Insert a paper clip wire through the

hole in the rotor at the 10 O'clock position and bend

to prevent it from falling out.

INSTALLATION

(1) Confirm that:

²The steering wheel position is a half turn (180

degrees) to the right (clockwise)

²The column is locked with the ignition cylinder

lock.

²Check that the turn signal stalk is in the neu-

tral position²When reusing the clockspring, remove locking

wire and rotate clockspring rotor one half turn (180

degrees) to the right (clockwise). Locate the clock-

spring on the steering shaft and push down on the

rotor until the clockspring is fully seated on the

steering column.

²When installing a new clockspring remove gre-

nade pin and rotate clockspring rotor one half turn

(180 degrees) to the right (clockwise). Locate clock-

spring on the steering shaft and push down on the

rotor until the clockspring is fullly seated on the

steering wheel.

(2) Connect the clockspring to the instrument

panel harness, ensure wiring is properly routed.

Then check that the connectors, locking tabs are

properly engaged and the halo lamp wire is in posi-

tion.

(3) Install steering column shrouds. Be sure all

wires are inside of shrouds.

(4) Install steering wheel ensuring the flats on hub

align with the clockspring. Pull the horn, airbag and

speed control leads through the larger slot. Ensure

leads do not get pinched under the steering wheel.

(5) Route speed control wires under and behind

the airbag module mounting tabs.

(6) Connect the horn lead wire and the airbag lead

wire to the airbag module.

(7) Install the airbag module and tighten bolts to

12 to 14 N´m (105 to 125 in. lbs.) torque.

(8) Connect the speed control wires to the switches

and install switches. Tighten screws to 2 N´m (20 in.

lbs.) torque.

(9) Do not connect the battery negative cable.

Refer to Diagnosis and Testing for Airbag System

Test procedures.

Fig. 21 Clockspring

8M - 8 RESTRAINT SYSTEMPL

REMOVAL AND INSTALLATION (Continued)

Page 381 of 1200

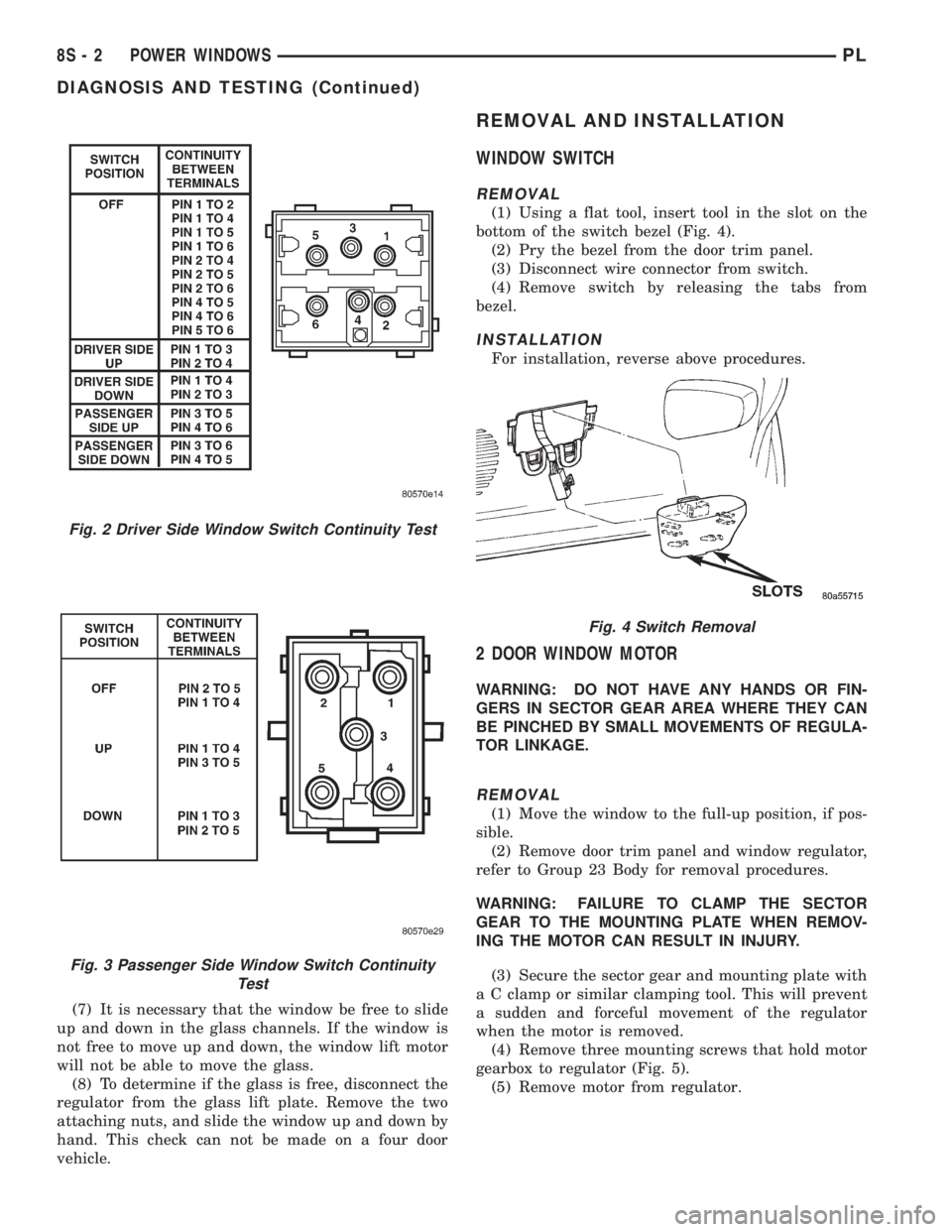

(7) It is necessary that the window be free to slide

up and down in the glass channels. If the window is

not free to move up and down, the window lift motor

will not be able to move the glass.

(8) To determine if the glass is free, disconnect the

regulator from the glass lift plate. Remove the two

attaching nuts, and slide the window up and down by

hand. This check can not be made on a four door

vehicle.

REMOVAL AND INSTALLATION

WINDOW SWITCH

REMOVAL

(1) Using a flat tool, insert tool in the slot on the

bottom of the switch bezel (Fig. 4).

(2) Pry the bezel from the door trim panel.

(3) Disconnect wire connector from switch.

(4) Remove switch by releasing the tabs from

bezel.

INSTALLATION

For installation, reverse above procedures.

2 DOOR WINDOW MOTOR

WARNING: DO NOT HAVE ANY HANDS OR FIN-

GERS IN SECTOR GEAR AREA WHERE THEY CAN

BE PINCHED BY SMALL MOVEMENTS OF REGULA-

TOR LINKAGE.

REMOVAL

(1) Move the window to the full-up position, if pos-

sible.

(2) Remove door trim panel and window regulator,

refer to Group 23 Body for removal procedures.

WARNING: FAILURE TO CLAMP THE SECTOR

GEAR TO THE MOUNTING PLATE WHEN REMOV-

ING THE MOTOR CAN RESULT IN INJURY.

(3) Secure the sector gear and mounting plate with

a C clamp or similar clamping tool. This will prevent

a sudden and forceful movement of the regulator

when the motor is removed.

(4) Remove three mounting screws that hold motor

gearbox to regulator (Fig. 5).

(5) Remove motor from regulator.

Fig. 2 Driver Side Window Switch Continuity Test

Fig. 3 Passenger Side Window Switch Continuity

Test

Fig. 4 Switch Removal

8S - 2 POWER WINDOWSPL

DIAGNOSIS AND TESTING (Continued)

Page 404 of 1200

(2) Disconnect the connector from its mating half/

component.

(3) Insert the terminal releasing special tool 6742

into the terminal end of the connector (Fig. 10).(4) Using special tool 6742 release the locking fin-

gers on the terminal (Fig. 11).

(5) Pull on the wire to remove it from the connec-

tor.

(6) Repair or replace the connector or terminal, as

necessary.TERMINAL/CONNECTOR REPAIRÐTHOMAS AND

BETTS CONNECTORS

(1) Disconnect battery.

(2) Disconnect the connector from its mating half/

component.

(3) Push in the two lock tabs on the side of the

connector (Fig. 12).

Fig. 9 Wire Repair

Fig. 10 Molex Connector Repair

Fig. 11 Using Special Tool 6742

Fig. 12 Thomas and Betts Connector Lock Release

Tabs

PL8W - 01 GENERAL INFORMATION 8W - 01 - 11

SERVICE PROCEDURES (Continued)