length DODGE NEON 2000 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 203 of 1285

(2) Connect recovery hose to water outlet connec-

tor/thermostat housing (Fig. 29).

(3) Fill container to proper level. Refer to Cooling

System Refilling in this section.

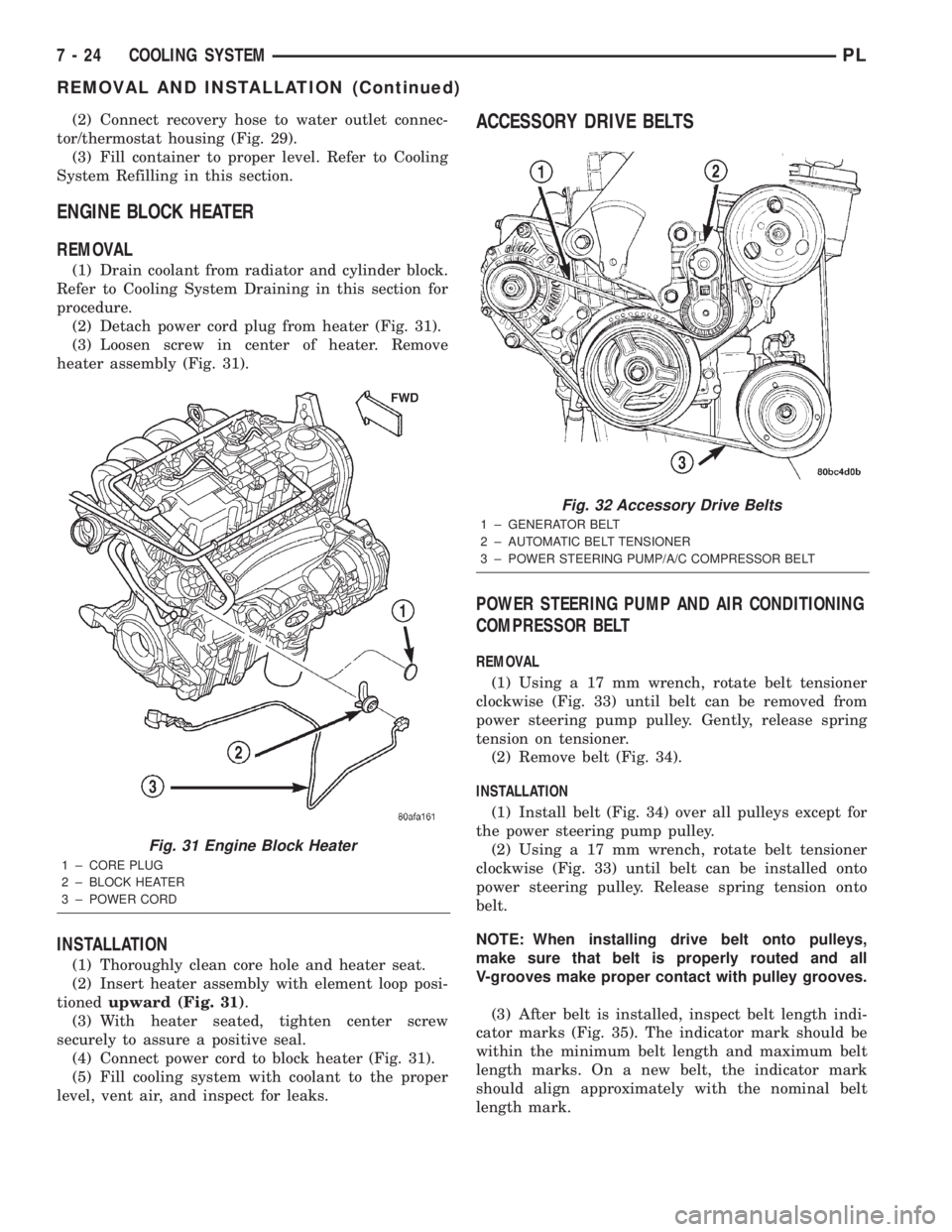

ENGINE BLOCK HEATER

REMOVAL

(1) Drain coolant from radiator and cylinder block.

Refer to Cooling System Draining in this section for

procedure.

(2) Detach power cord plug from heater (Fig. 31).

(3) Loosen screw in center of heater. Remove

heater assembly (Fig. 31).

INSTALLATION

(1) Thoroughly clean core hole and heater seat.

(2) Insert heater assembly with element loop posi-

tionedupward (Fig. 31).

(3) With heater seated, tighten center screw

securely to assure a positive seal.

(4) Connect power cord to block heater (Fig. 31).

(5) Fill cooling system with coolant to the proper

level, vent air, and inspect for leaks.

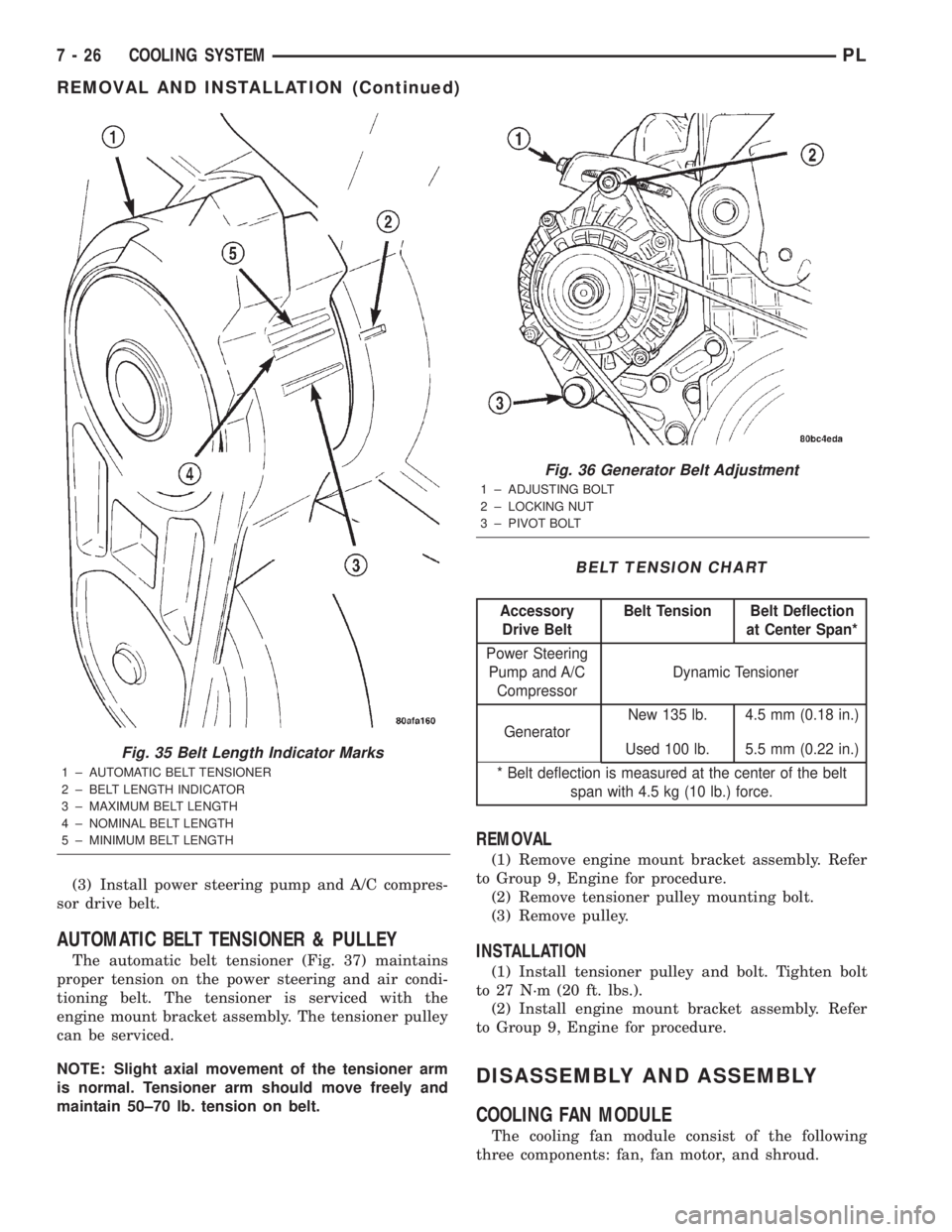

ACCESSORY DRIVE BELTS

POWER STEERING PUMP AND AIR CONDITIONING

COMPRESSOR BELT

REMOVAL

(1) Using a 17 mm wrench, rotate belt tensioner

clockwise (Fig. 33) until belt can be removed from

power steering pump pulley. Gently, release spring

tension on tensioner.

(2) Remove belt (Fig. 34).

INSTALLATION

(1) Install belt (Fig. 34) over all pulleys except for

the power steering pump pulley.

(2) Using a 17 mm wrench, rotate belt tensioner

clockwise (Fig. 33) until belt can be installed onto

power steering pulley. Release spring tension onto

belt.

NOTE: When installing drive belt onto pulleys,

make sure that belt is properly routed and all

V-grooves make proper contact with pulley grooves.

(3) After belt is installed, inspect belt length indi-

cator marks (Fig. 35). The indicator mark should be

within the minimum belt length and maximum belt

length marks. On a new belt, the indicator mark

should align approximately with the nominal belt

length mark.

Fig. 31 Engine Block Heater

1 ± CORE PLUG

2 ± BLOCK HEATER

3 ± POWER CORD

Fig. 32 Accessory Drive Belts

1 ± GENERATOR BELT

2 ± AUTOMATIC BELT TENSIONER

3 ± POWER STEERING PUMP/A/C COMPRESSOR BELT

7 - 24 COOLING SYSTEMPL

REMOVAL AND INSTALLATION (Continued)

Page 205 of 1285

(3) Install power steering pump and A/C compres-

sor drive belt.

AUTOMATIC BELT TENSIONER & PULLEY

The automatic belt tensioner (Fig. 37) maintains

proper tension on the power steering and air condi-

tioning belt. The tensioner is serviced with the

engine mount bracket assembly. The tensioner pulley

can be serviced.

NOTE: Slight axial movement of the tensioner arm

is normal. Tensioner arm should move freely and

maintain 50±70 lb. tension on belt.

REMOVAL

(1) Remove engine mount bracket assembly. Refer

to Group 9, Engine for procedure.

(2) Remove tensioner pulley mounting bolt.

(3) Remove pulley.

INSTALLATION

(1) Install tensioner pulley and bolt. Tighten bolt

to 27 N´m (20 ft. lbs.).

(2) Install engine mount bracket assembly. Refer

to Group 9, Engine for procedure.

DISASSEMBLY AND ASSEMBLY

COOLING FAN MODULE

The cooling fan module consist of the following

three components: fan, fan motor, and shroud.

Fig. 35 Belt Length Indicator Marks

1 ± AUTOMATIC BELT TENSIONER

2 ± BELT LENGTH INDICATOR

3 ± MAXIMUM BELT LENGTH

4 ± NOMINAL BELT LENGTH

5 ± MINIMUM BELT LENGTH

Fig. 36 Generator Belt Adjustment

1 ± ADJUSTING BOLT

2 ± LOCKING NUT

3 ± PIVOT BOLT

BELT TENSION CHART

Accessory

Drive BeltBelt Tension Belt Deflection

at Center Span*

Power Steering

Pump and A/C

CompressorDynamic Tensioner

GeneratorNew 135 lb. 4.5 mm (0.18 in.)

Used 100 lb. 5.5 mm (0.22 in.)

* Belt deflection is measured at the center of the belt

span with 4.5 kg (10 lb.) force.

7 - 26 COOLING SYSTEMPL

REMOVAL AND INSTALLATION (Continued)

Page 220 of 1285

(4) Remove the thermowrap from vehicle.

INSTALLATION

For installation, reverse the above procedures.

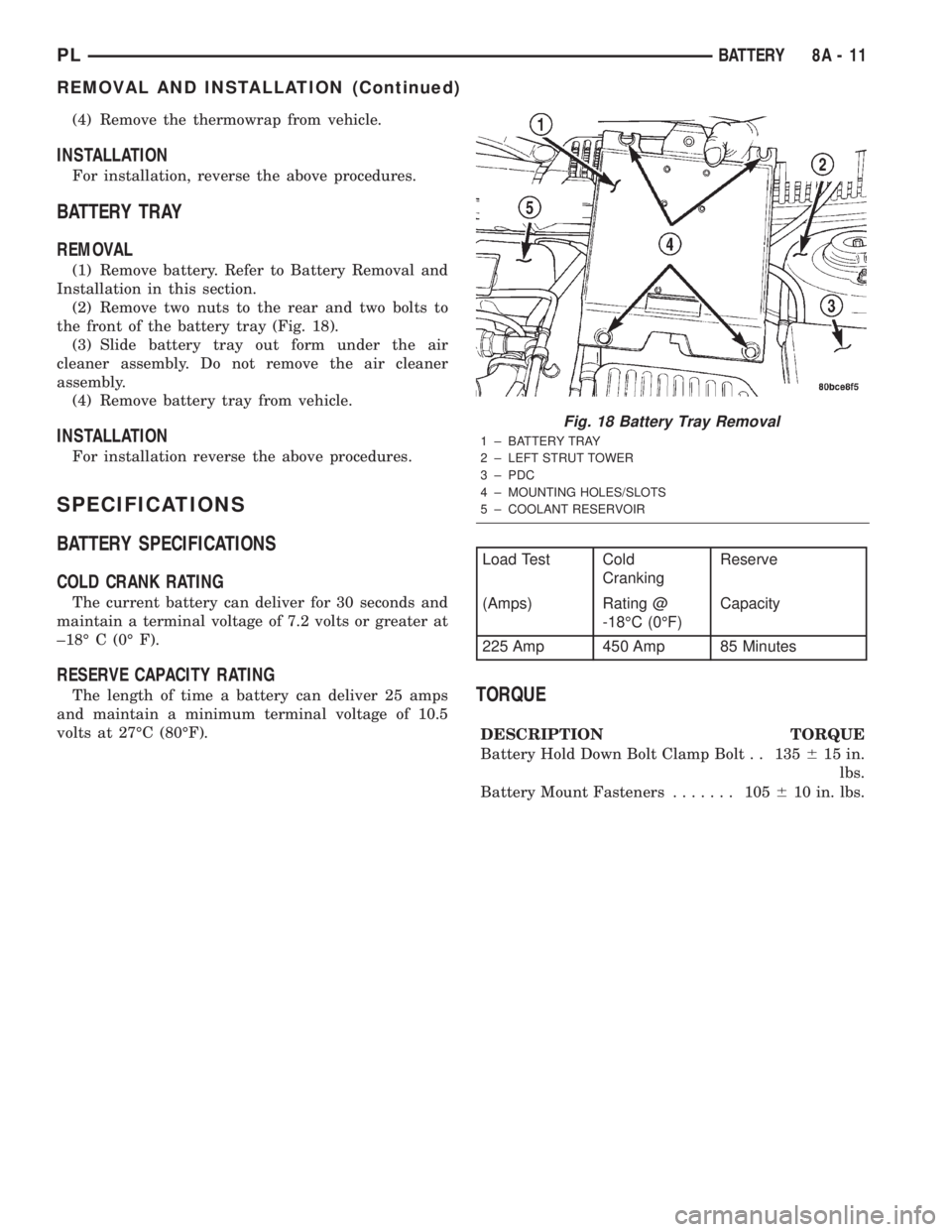

BATTERY TRAY

REMOVAL

(1) Remove battery. Refer to Battery Removal and

Installation in this section.

(2) Remove two nuts to the rear and two bolts to

the front of the battery tray (Fig. 18).

(3) Slide battery tray out form under the air

cleaner assembly. Do not remove the air cleaner

assembly.

(4) Remove battery tray from vehicle.

INSTALLATION

For installation reverse the above procedures.

SPECIFICATIONS

BATTERY SPECIFICATIONS

COLD CRANK RATING

The current battery can deliver for 30 seconds and

maintain a terminal voltage of 7.2 volts or greater at

±18É C (0É F).

RESERVE CAPACITY RATING

The length of time a battery can deliver 25 amps

and maintain a minimum terminal voltage of 10.5

volts at 27ÉC (80ÉF).TORQUE

DESCRIPTION TORQUE

Battery Hold Down Bolt Clamp Bolt . . 135615 in.

lbs.

Battery Mount Fasteners....... 105610 in. lbs.

Fig. 18 Battery Tray Removal

1 ± BATTERY TRAY

2 ± LEFT STRUT TOWER

3 ± PDC

4 ± MOUNTING HOLES/SLOTS

5 ± COOLANT RESERVOIR

Load Test Cold

CrankingReserve

(Amps) Rating @

-18ÉC (0ÉF)Capacity

225 Amp 450 Amp 85 Minutes

PLBATTERY 8A - 11

REMOVAL AND INSTALLATION (Continued)

Page 276 of 1285

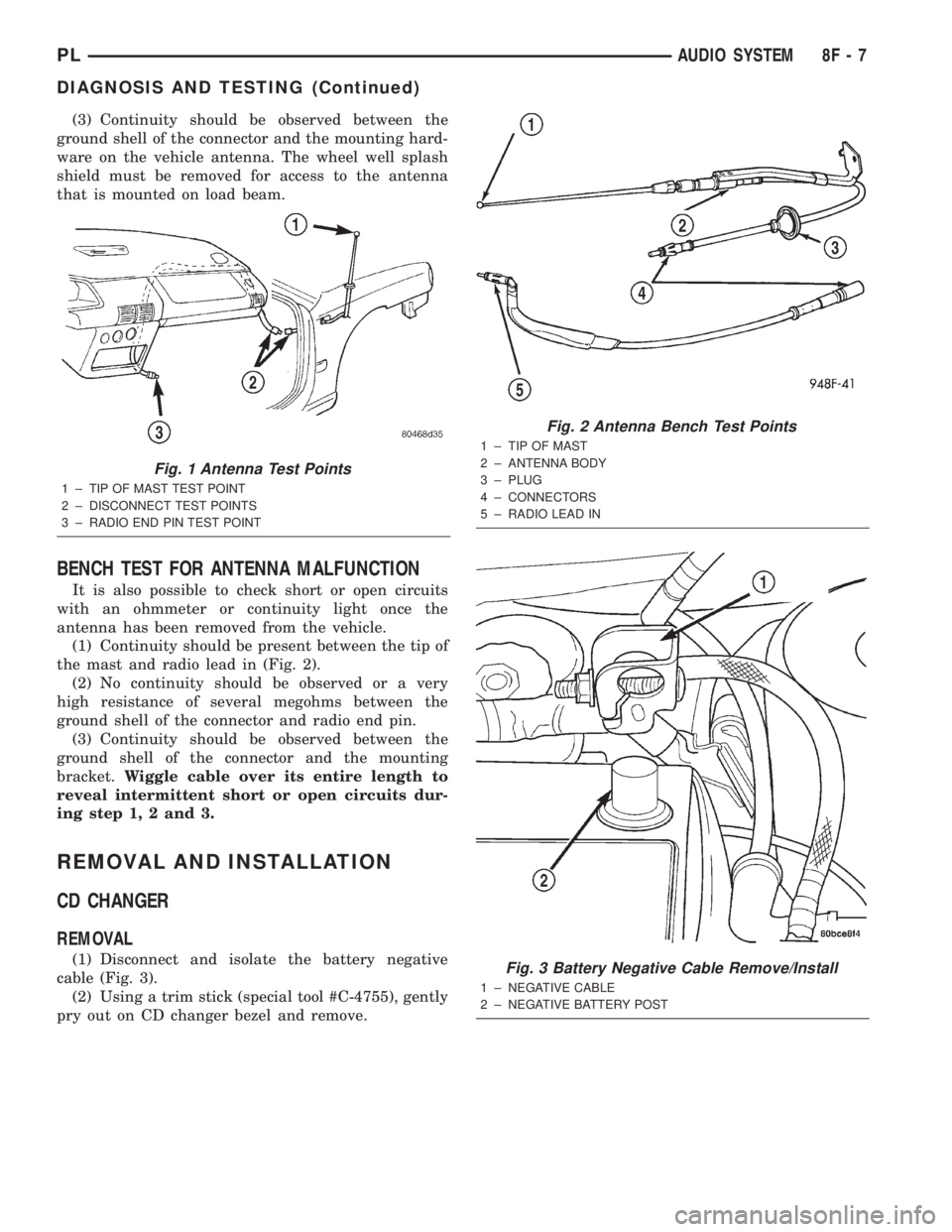

(3) Continuity should be observed between the

ground shell of the connector and the mounting hard-

ware on the vehicle antenna. The wheel well splash

shield must be removed for access to the antenna

that is mounted on load beam.

BENCH TEST FOR ANTENNA MALFUNCTION

It is also possible to check short or open circuits

with an ohmmeter or continuity light once the

antenna has been removed from the vehicle.

(1) Continuity should be present between the tip of

the mast and radio lead in (Fig. 2).

(2) No continuity should be observed or a very

high resistance of several megohms between the

ground shell of the connector and radio end pin.

(3) Continuity should be observed between the

ground shell of the connector and the mounting

bracket.Wiggle cable over its entire length to

reveal intermittent short or open circuits dur-

ing step 1, 2 and 3.

REMOVAL AND INSTALLATION

CD CHANGER

REMOVAL

(1) Disconnect and isolate the battery negative

cable (Fig. 3).

(2) Using a trim stick (special tool #C-4755), gently

pry out on CD changer bezel and remove.

Fig. 1 Antenna Test Points

1 ± TIP OF MAST TEST POINT

2 ± DISCONNECT TEST POINTS

3 ± RADIO END PIN TEST POINT

Fig. 2 Antenna Bench Test Points

1 ± TIP OF MAST

2 ± ANTENNA BODY

3 ± PLUG

4 ± CONNECTORS

5 ± RADIO LEAD IN

Fig. 3 Battery Negative Cable Remove/Install

1 ± NEGATIVE CABLE

2 ± NEGATIVE BATTERY POST

PLAUDIO SYSTEM 8F - 7

DIAGNOSIS AND TESTING (Continued)

Page 298 of 1285

WINDSHIELD WIPER and WASHER SYSTEMS

TABLE OF CONTENTS

page page

WINDSHIELD WIPER SYSTEM................ 1WINDSHIELD WASHER SYSTEM.............. 8

WINDSHIELD WIPER SYSTEM

TABLE OF CONTENTS

page page

GENERAL INFORMATION

INTRODUCTION..........................1

DESCRIPTION AND OPERATION

WIPER BLADES...........................1

DIAGNOSIS AND TESTING

WINDSHIELD WIPER CONDITIONS............2

WINDSHIELD WIPER MOTOR................3

WINDSHIELD WIPER/WASHER SWITCH........5

REMOVAL AND INSTALLATION

WINDSHIELD WIPER ARM(S)................5WINDSHIELD WIPER BLADE(S)..............5

WINDSHIELD WIPER BLADE ELEMENT........5

WINDSHIELD WIPER LINKAGE...............5

WINDSHIELD WIPER MODULE...............6

WINDSHIELD WIPER MOTOR................6

WINDSHIELD WIPER/WASHER SWITCH........6

CLEANING AND INSPECTION

WINDSHIELD WIPER BLADE(S)..............6

ADJUSTMENTS

WINDSHIELD WIPER ARM(S)................6

GENERAL INFORMATION

INTRODUCTION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO GROUP 8M, PASSIVE

RESTRAINT SYSTEMS FOR STEERING WHEEL

REMOVAL AND INSTALLATION.

The windshield wipers will only operate with the

ignition switch in the ACCESSORY or IGNITION

RUN position. The wiper circuit is protected against

over loads by a fuse in the fuse block and a circuit

breaker within the wiper motor. This protects the cir-

cuitry of the wiper system and the vehicle. The wiper

motor has permanent magnet fields.

The intermittent wiper system, in addition to low

and high speed, has a delay mode and a pulse wipe

mode. The delay mode has a range of 1 to 15 seconds.

Pulse wipe is accomplished by momentarily moving

the stalk lever into the WASH position while the

wiper switch is in either OFF or DELAY position.

The wiper blades then sweep once or twice and

return to the previous wiper switch mode, OFF or

DELAY.The intermittent wiper function is integral to the

wiper switch. All electronics and relay are inside the

switch assembly.

The wiper system completes the wipe cycle when

the switch is turned OFF. The blades park in the

lowest portion of the wipe pattern.

The wiper switch also includes the MIST feature

which provides a single wipe when actuated.

DESCRIPTION AND OPERATION

WIPER BLADES

Wiper blades, exposed to the weather for a long

period of time, tend to lose their wiping effectiveness.

Periodic cleaning of the wiper blade is suggested to

remove the accumulation of salt and road film. The

wiper blades, arms, and windshield should be

cleaned with a sponge or cloth and a mild detergent

or nonabrasive cleaner. If the blades continue to

streak or smear, they should be replaced. The right

and left wipers are different blade lengths. The

driver side length is 550 mm and the passenger side

length is 475 mm. The blades should not be inter-

changed.

PLWINDSHIELD WIPER and WASHER SYSTEMS 8K - 1

Page 406 of 1285

kit 6680. Pull on the wire to remove the terminal

from the connector (Fig. 16) (Fig. 17).

(5) Reset the terminal locking tang, if it has one.

(6) Insert the removed wire in the same cavity on

the repair connector.

(7) Repeat steps four through six for each wire in

the connector, being sure that all wires are inserted

into the proper cavities. For additional connector pin-

out identification, refer to the wiring diagrams.

(8) Insert the connector locking wedge into the

repaired connector, if required.

(9) Connect connector to its mating half/compo-

nent.

(10) Connect battery and test all affected systems.CONNECTOR AND TERMINAL REPLACEMENT

(1) Disconnect battery.

(2) Disconnect the connector (that is to be

repaired) from its mating half/component.

(3) Cut off the existing wire connector directly

behind the insulator. Remove six inches of tape from

the harness.

(4) Stagger cut all wires on the harness side at 1/2

inch intervals (Fig. 18).

(5) Remove 1 inch of insulation from each wire on

the harness side.

(6) Stagger cut the matching wires on the repair

connector assembly in the opposite order as was done

on the harness side of the repair. Allow extra length

for soldered connections. Check that the overall

length is the same as the original (Fig. 18).

(7) Remove 1 inch of insulation from each wire.

(8) Place a piece of heat shrink tubing over one

side of the wire. Be sure the tubing will be long

enough to cover and seal the entire repair area.

(9) Spread the strands of the wire apart on each

part of the exposed wires.

(10) Push the two ends of wire together until the

strands of wire are close to the insulation.

(11) Twist the wires together.

(12) Solder the connection together using rosin

core type solder only.Do not use acid core solder.

(13) Center the heat shrink tubing over the joint

and heat using a heat gun. Heat the joint until the

tubing is tightly sealed and sealant comes out of both

ends of the tubing.

(14) Repeat steps 8 through 13 for each wire.

(15) Re-tape the wire harness starting 1-1/2 inches

behind the connector and 2 inches past the repair.

(16) Re-connect the repaired connector.

Fig. 16 Terminal Removal

1 ± CONNECTOR

2 ± FROM SPECIAL TOOL KIT 6680

Fig. 17 Terminal Removal Using Special Tool

1 ± FROM SPECIAL TOOL KIT 6680

2 ± CONNECTOR

PL8W - 01 GENERAL INFORMATION 8W - 01 - 13

SERVICE PROCEDURES (Continued)

Page 407 of 1285

(17) Connect the battery, and test all affected sys-

tems.

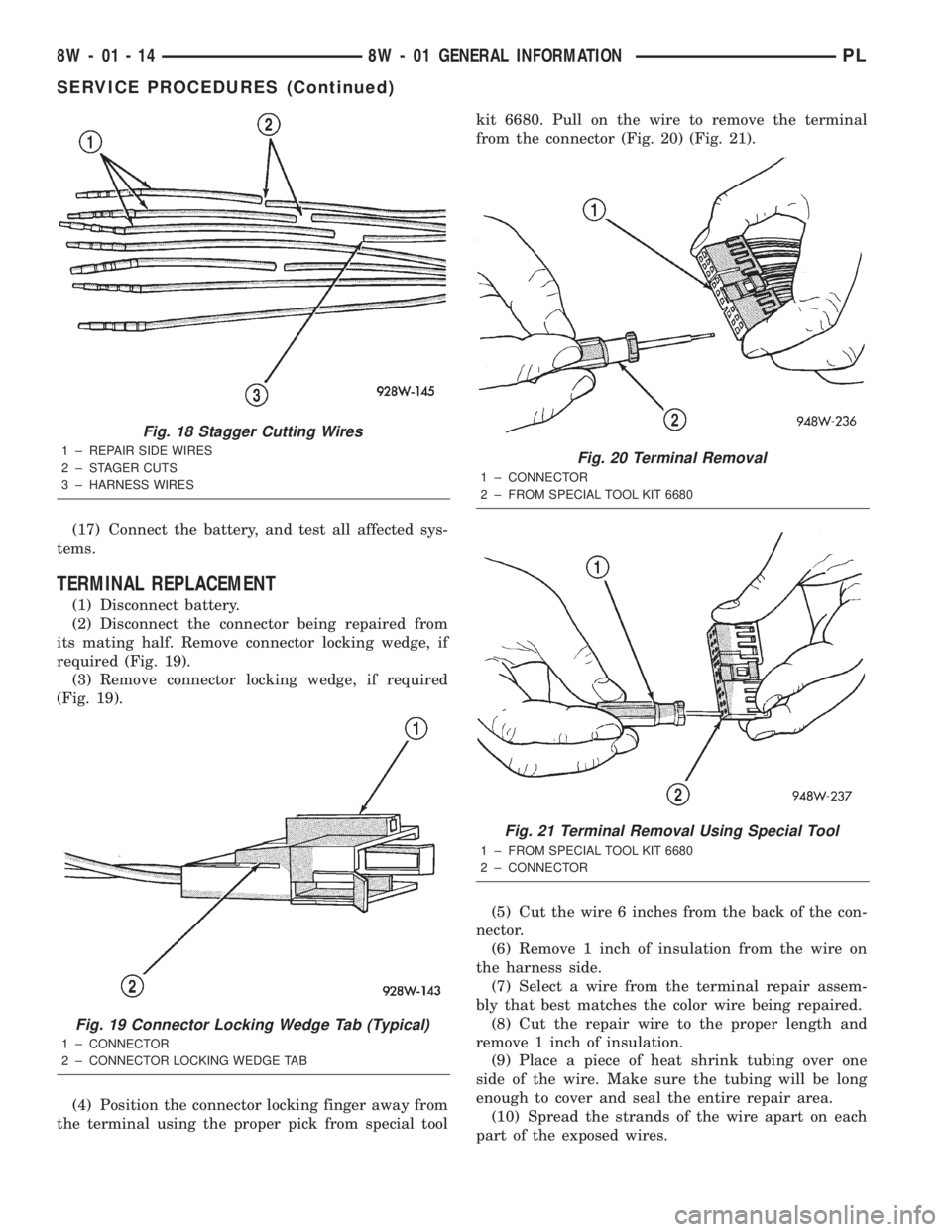

TERMINAL REPLACEMENT

(1) Disconnect battery.

(2) Disconnect the connector being repaired from

its mating half. Remove connector locking wedge, if

required (Fig. 19).

(3) Remove connector locking wedge, if required

(Fig. 19).

(4) Position the connector locking finger away from

the terminal using the proper pick from special toolkit 6680. Pull on the wire to remove the terminal

from the connector (Fig. 20) (Fig. 21).

(5) Cut the wire 6 inches from the back of the con-

nector.

(6) Remove 1 inch of insulation from the wire on

the harness side.

(7) Select a wire from the terminal repair assem-

bly that best matches the color wire being repaired.

(8) Cut the repair wire to the proper length and

remove 1 inch of insulation.

(9) Place a piece of heat shrink tubing over one

side of the wire. Make sure the tubing will be long

enough to cover and seal the entire repair area.

(10) Spread the strands of the wire apart on each

part of the exposed wires.

Fig. 18 Stagger Cutting Wires

1 ± REPAIR SIDE WIRES

2 ± STAGER CUTS

3 ± HARNESS WIRES

Fig. 19 Connector Locking Wedge Tab (Typical)

1 ± CONNECTOR

2 ± CONNECTOR LOCKING WEDGE TAB

Fig. 20 Terminal Removal

1 ± CONNECTOR

2 ± FROM SPECIAL TOOL KIT 6680

Fig. 21 Terminal Removal Using Special Tool

1 ± FROM SPECIAL TOOL KIT 6680

2 ± CONNECTOR

8W - 01 - 14 8W - 01 GENERAL INFORMATIONPL

SERVICE PROCEDURES (Continued)

Page 740 of 1285

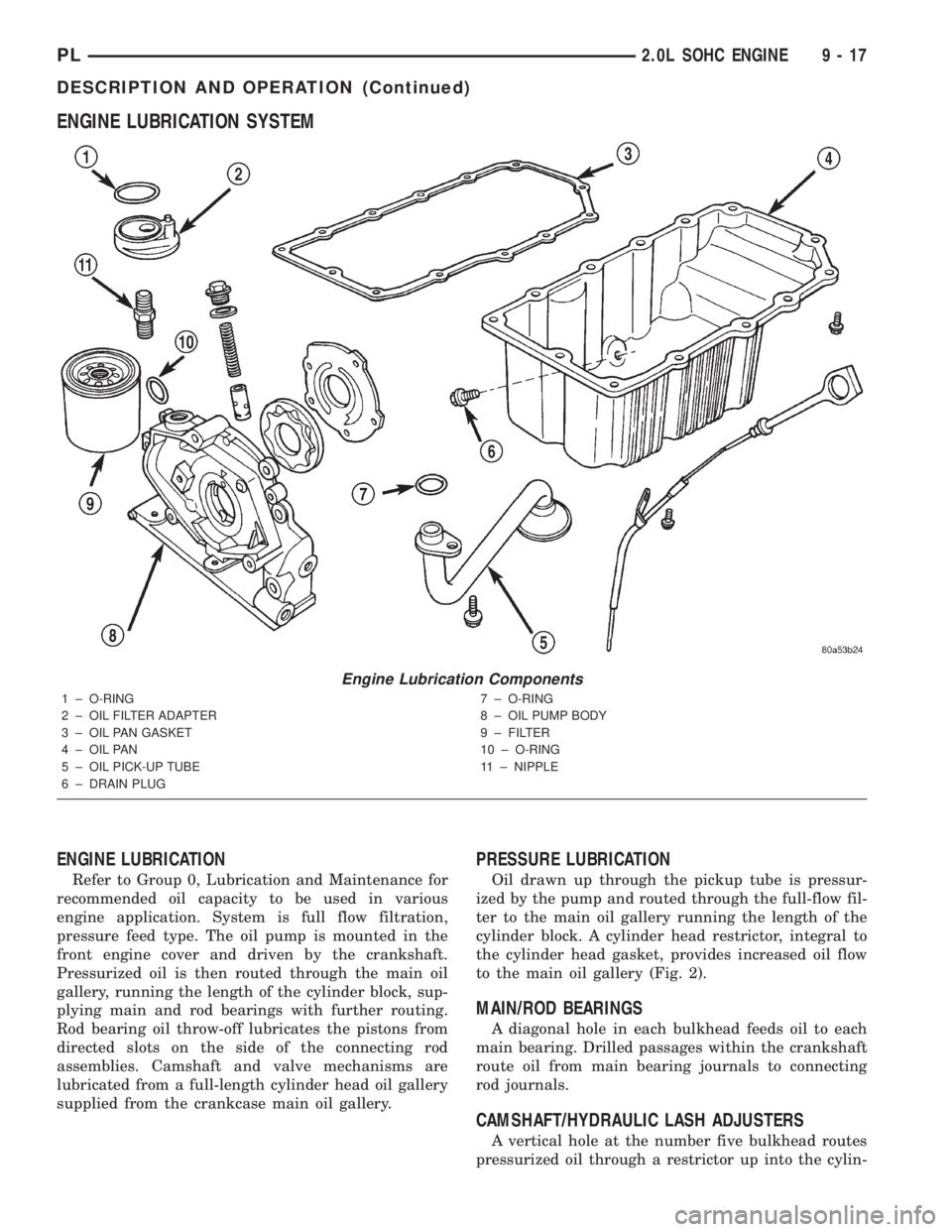

ENGINE LUBRICATION SYSTEM

ENGINE LUBRICATION

Refer to Group 0, Lubrication and Maintenance for

recommended oil capacity to be used in various

engine application. System is full flow filtration,

pressure feed type. The oil pump is mounted in the

front engine cover and driven by the crankshaft.

Pressurized oil is then routed through the main oil

gallery, running the length of the cylinder block, sup-

plying main and rod bearings with further routing.

Rod bearing oil throw-off lubricates the pistons from

directed slots on the side of the connecting rod

assemblies. Camshaft and valve mechanisms are

lubricated from a full-length cylinder head oil gallery

supplied from the crankcase main oil gallery.

PRESSURE LUBRICATION

Oil drawn up through the pickup tube is pressur-

ized by the pump and routed through the full-flow fil-

ter to the main oil gallery running the length of the

cylinder block. A cylinder head restrictor, integral to

the cylinder head gasket, provides increased oil flow

to the main oil gallery (Fig. 2).

MAIN/ROD BEARINGS

A diagonal hole in each bulkhead feeds oil to each

main bearing. Drilled passages within the crankshaft

route oil from main bearing journals to connecting

rod journals.

CAMSHAFT/HYDRAULIC LASH ADJUSTERS

A vertical hole at the number five bulkhead routes

pressurized oil through a restrictor up into the cylin-

Engine Lubrication Components

1 ± O-RING

2 ± OIL FILTER ADAPTER

3 ± OIL PAN GASKET

4 ± OIL PAN

5 ± OIL PICK-UP TUBE

6 ± DRAIN PLUG7 ± O-RING

8 ± OIL PUMP BODY

9 ± FILTER

10 ± O-RING

11 ± NIPPLE

PL2.0L SOHC ENGINE 9 - 17

DESCRIPTION AND OPERATION (Continued)

Page 783 of 1285

(10) Install connecting rod lower bearing half and

cap. InstallNewbolts and tighten to 27 N´m (20 ft.

lbs.) plus 1/4 turn.

(11) Install cylinder head and oil pan. Refer to pro-

cedures in this section.

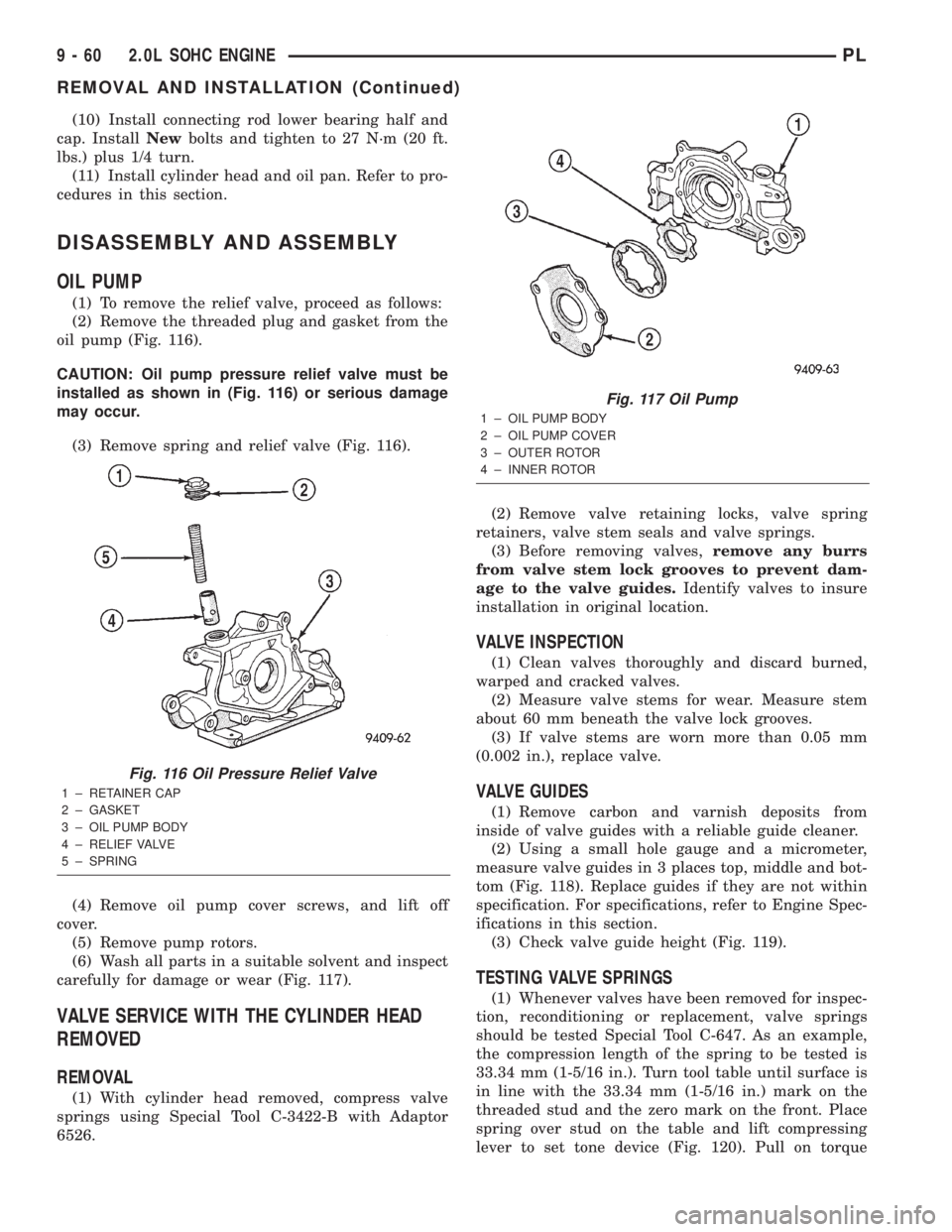

DISASSEMBLY AND ASSEMBLY

OIL PUMP

(1) To remove the relief valve, proceed as follows:

(2) Remove the threaded plug and gasket from the

oil pump (Fig. 116).

CAUTION: Oil pump pressure relief valve must be

installed as shown in (Fig. 116) or serious damage

may occur.

(3) Remove spring and relief valve (Fig. 116).

(4) Remove oil pump cover screws, and lift off

cover.

(5) Remove pump rotors.

(6) Wash all parts in a suitable solvent and inspect

carefully for damage or wear (Fig. 117).

VALVE SERVICE WITH THE CYLINDER HEAD

REMOVED

REMOVAL

(1) With cylinder head removed, compress valve

springs using Special Tool C-3422-B with Adaptor

6526.(2) Remove valve retaining locks, valve spring

retainers, valve stem seals and valve springs.

(3) Before removing valves,remove any burrs

from valve stem lock grooves to prevent dam-

age to the valve guides.Identify valves to insure

installation in original location.

VALVE INSPECTION

(1) Clean valves thoroughly and discard burned,

warped and cracked valves.

(2) Measure valve stems for wear. Measure stem

about 60 mm beneath the valve lock grooves.

(3) If valve stems are worn more than 0.05 mm

(0.002 in.), replace valve.

VALVE GUIDES

(1) Remove carbon and varnish deposits from

inside of valve guides with a reliable guide cleaner.

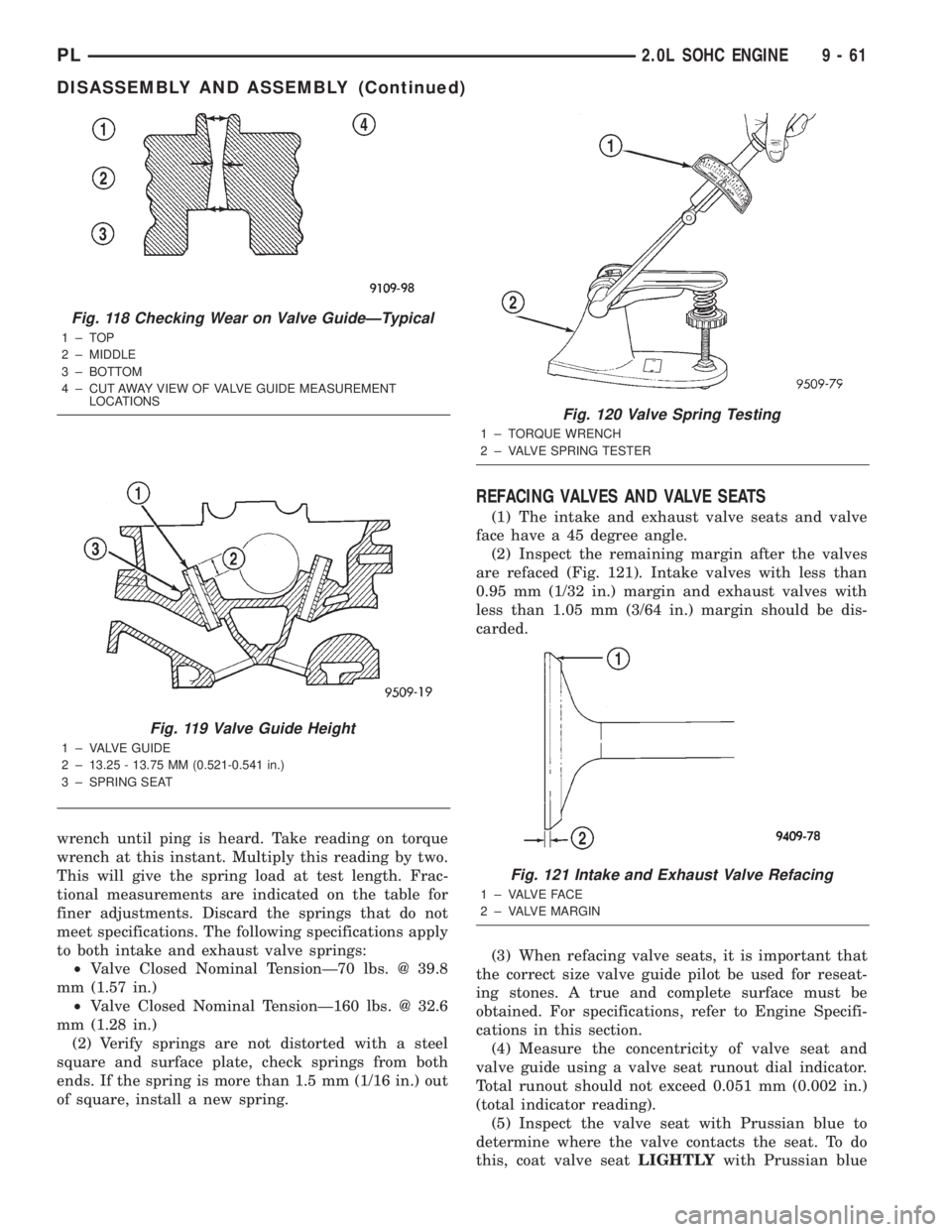

(2) Using a small hole gauge and a micrometer,

measure valve guides in 3 places top, middle and bot-

tom (Fig. 118). Replace guides if they are not within

specification. For specifications, refer to Engine Spec-

ifications in this section.

(3) Check valve guide height (Fig. 119).

TESTING VALVE SPRINGS

(1) Whenever valves have been removed for inspec-

tion, reconditioning or replacement, valve springs

should be tested Special Tool C-647. As an example,

the compression length of the spring to be tested is

33.34 mm (1-5/16 in.). Turn tool table until surface is

in line with the 33.34 mm (1-5/16 in.) mark on the

threaded stud and the zero mark on the front. Place

spring over stud on the table and lift compressing

lever to set tone device (Fig. 120). Pull on torque

Fig. 116 Oil Pressure Relief Valve

1 ± RETAINER CAP

2 ± GASKET

3 ± OIL PUMP BODY

4 ± RELIEF VALVE

5 ± SPRING

Fig. 117 Oil Pump

1 ± OIL PUMP BODY

2 ± OIL PUMP COVER

3 ± OUTER ROTOR

4 ± INNER ROTOR

9 - 60 2.0L SOHC ENGINEPL

REMOVAL AND INSTALLATION (Continued)

Page 784 of 1285

wrench until ping is heard. Take reading on torque

wrench at this instant. Multiply this reading by two.

This will give the spring load at test length. Frac-

tional measurements are indicated on the table for

finer adjustments. Discard the springs that do not

meet specifications. The following specifications apply

to both intake and exhaust valve springs:

²Valve Closed Nominal TensionÐ70 lbs. @ 39.8

mm (1.57 in.)

²Valve Closed Nominal TensionÐ160 lbs. @ 32.6

mm (1.28 in.)

(2) Verify springs are not distorted with a steel

square and surface plate, check springs from both

ends. If the spring is more than 1.5 mm (1/16 in.) out

of square, install a new spring.

REFACING VALVES AND VALVE SEATS

(1) The intake and exhaust valve seats and valve

face have a 45 degree angle.

(2) Inspect the remaining margin after the valves

are refaced (Fig. 121). Intake valves with less than

0.95 mm (1/32 in.) margin and exhaust valves with

less than 1.05 mm (3/64 in.) margin should be dis-

carded.

(3) When refacing valve seats, it is important that

the correct size valve guide pilot be used for reseat-

ing stones. A true and complete surface must be

obtained. For specifications, refer to Engine Specifi-

cations in this section.

(4) Measure the concentricity of valve seat and

valve guide using a valve seat runout dial indicator.

Total runout should not exceed 0.051 mm (0.002 in.)

(total indicator reading).

(5) Inspect the valve seat with Prussian blue to

determine where the valve contacts the seat. To do

this, coat valve seatLIGHTLYwith Prussian blue

Fig. 118 Checking Wear on Valve GuideÐTypical

1±TOP

2 ± MIDDLE

3 ± BOTTOM

4 ± CUT AWAY VIEW OF VALVE GUIDE MEASUREMENT

LOCATIONS

Fig. 119 Valve Guide Height

1 ± VALVE GUIDE

2 ± 13.25 - 13.75 MM (0.521-0.541 in.)

3 ± SPRING SEAT

Fig. 120 Valve Spring Testing

1 ± TORQUE WRENCH

2 ± VALVE SPRING TESTER

Fig. 121 Intake and Exhaust Valve Refacing

1 ± VALVE FACE

2 ± VALVE MARGIN

PL2.0L SOHC ENGINE 9 - 61

DISASSEMBLY AND ASSEMBLY (Continued)