lock DODGE NEON 2000 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 893 of 1285

NOTE: The power steering gear should not be ser-

viced or adjusted. If a malfunction or oil leak occurs

with the steering gear, the complete steering gear

needs to be replaced.

REMOVAL AND INSTALLATION

SERVICE WARNINGS AND CAUTIONS

WARNING: POWER STEERING FLUID, ENGINE

PARTS AND EXHAUST SYSTEM MAY BE

EXTREMELY HOT IF ENGINE HAS BEEN RUNNING.

DO NOT START ENGINE WITH ANY LOOSE OR DIS-

CONNECTED HOSES. DO NOT ALLOW HOSES TO

TOUCH HOT EXHAUST MANIFOLD OR CATALYST.

WARNING: FLUID LEVEL SHOULD BE CHECKED

WITH THE ENGINE OFF TO PREVENT PERSONAL

INJURY FROM MOVING PARTS.

CAUTION: When the system is open, cap all open

ends of the hoses, power steering pump fittings or

power steering gear ports to prevent entry of for-

eign material into the components.

NOTE: Do not use any type of automatic transmis-

sion fluid in the power steering system.

POWER STEERING GEAR

NOTE: Before proceeding with this removal and

installation procedure, review SERVICE WARNINGS

AND CAUTIONS at the beginning of REMOVAL AND

INSTALLATION in this section.

REMOVAL

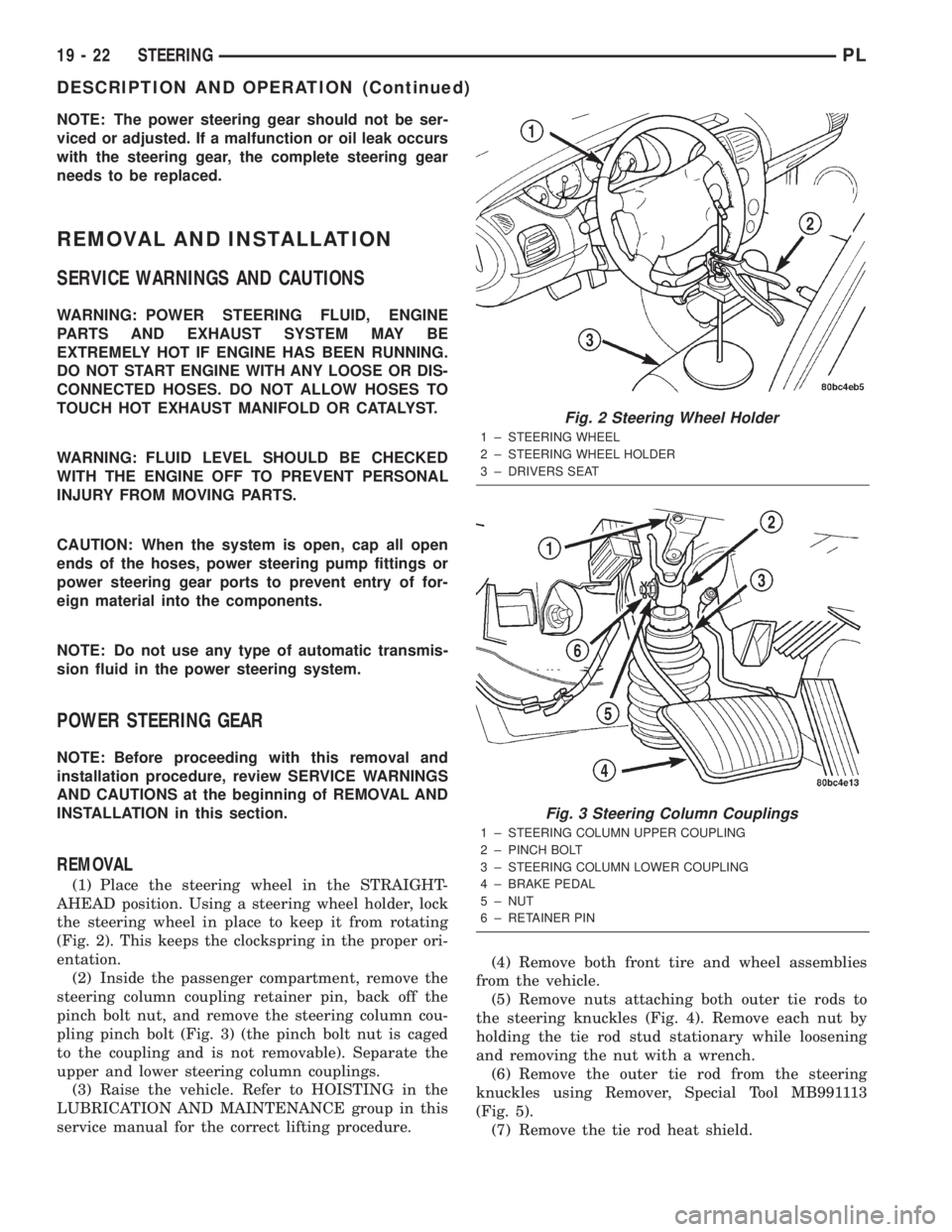

(1) Place the steering wheel in the STRAIGHT-

AHEAD position. Using a steering wheel holder, lock

the steering wheel in place to keep it from rotating

(Fig. 2). This keeps the clockspring in the proper ori-

entation.

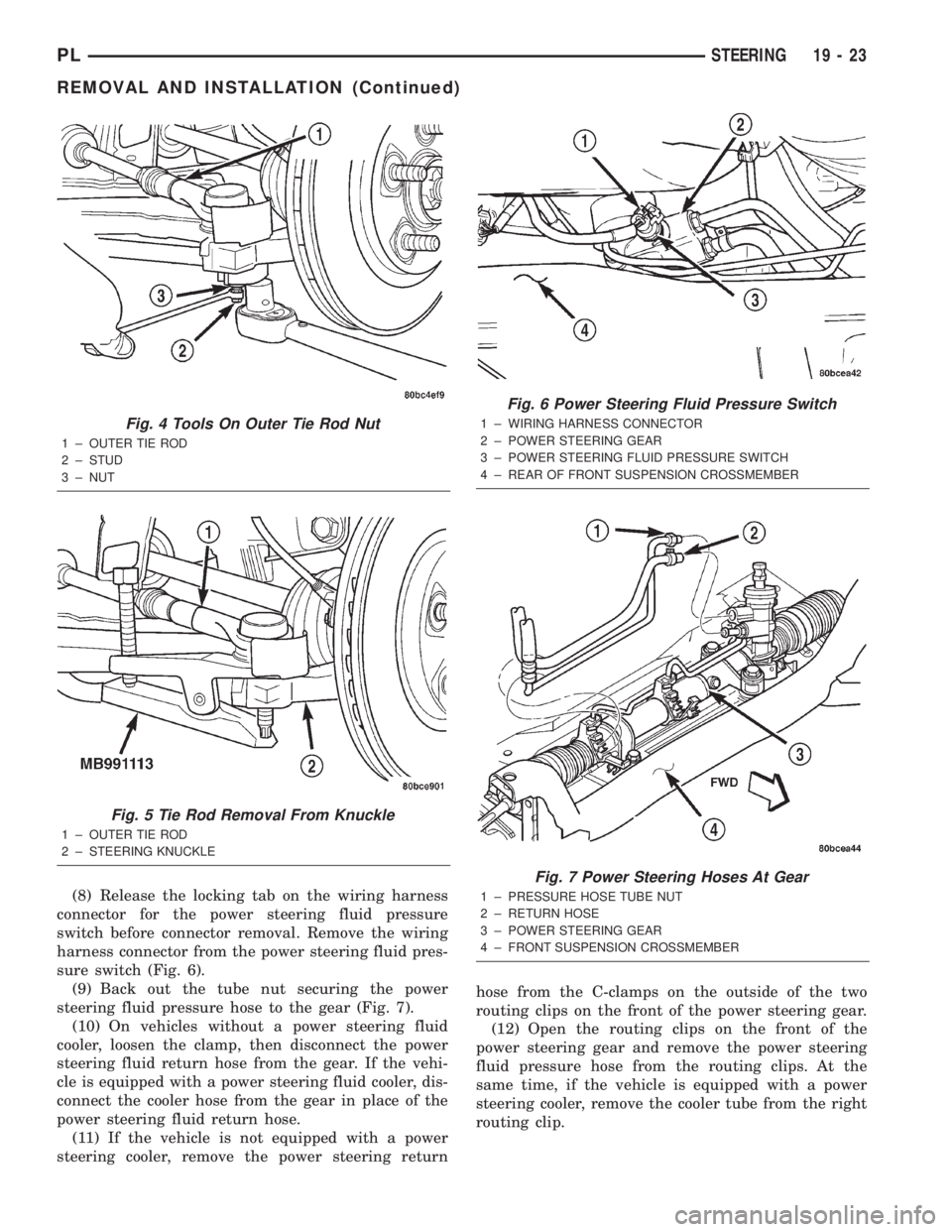

(2) Inside the passenger compartment, remove the

steering column coupling retainer pin, back off the

pinch bolt nut, and remove the steering column cou-

pling pinch bolt (Fig. 3) (the pinch bolt nut is caged

to the coupling and is not removable). Separate the

upper and lower steering column couplings.

(3) Raise the vehicle. Refer to HOISTING in the

LUBRICATION AND MAINTENANCE group in this

service manual for the correct lifting procedure.(4) Remove both front tire and wheel assemblies

from the vehicle.

(5) Remove nuts attaching both outer tie rods to

the steering knuckles (Fig. 4). Remove each nut by

holding the tie rod stud stationary while loosening

and removing the nut with a wrench.

(6) Remove the outer tie rod from the steering

knuckles using Remover, Special Tool MB991113

(Fig. 5).

(7) Remove the tie rod heat shield.

Fig. 2 Steering Wheel Holder

1 ± STEERING WHEEL

2 ± STEERING WHEEL HOLDER

3 ± DRIVERS SEAT

Fig. 3 Steering Column Couplings

1 ± STEERING COLUMN UPPER COUPLING

2 ± PINCH BOLT

3 ± STEERING COLUMN LOWER COUPLING

4 ± BRAKE PEDAL

5 ± NUT

6 ± RETAINER PIN

19 - 22 STEERINGPL

DESCRIPTION AND OPERATION (Continued)

Page 894 of 1285

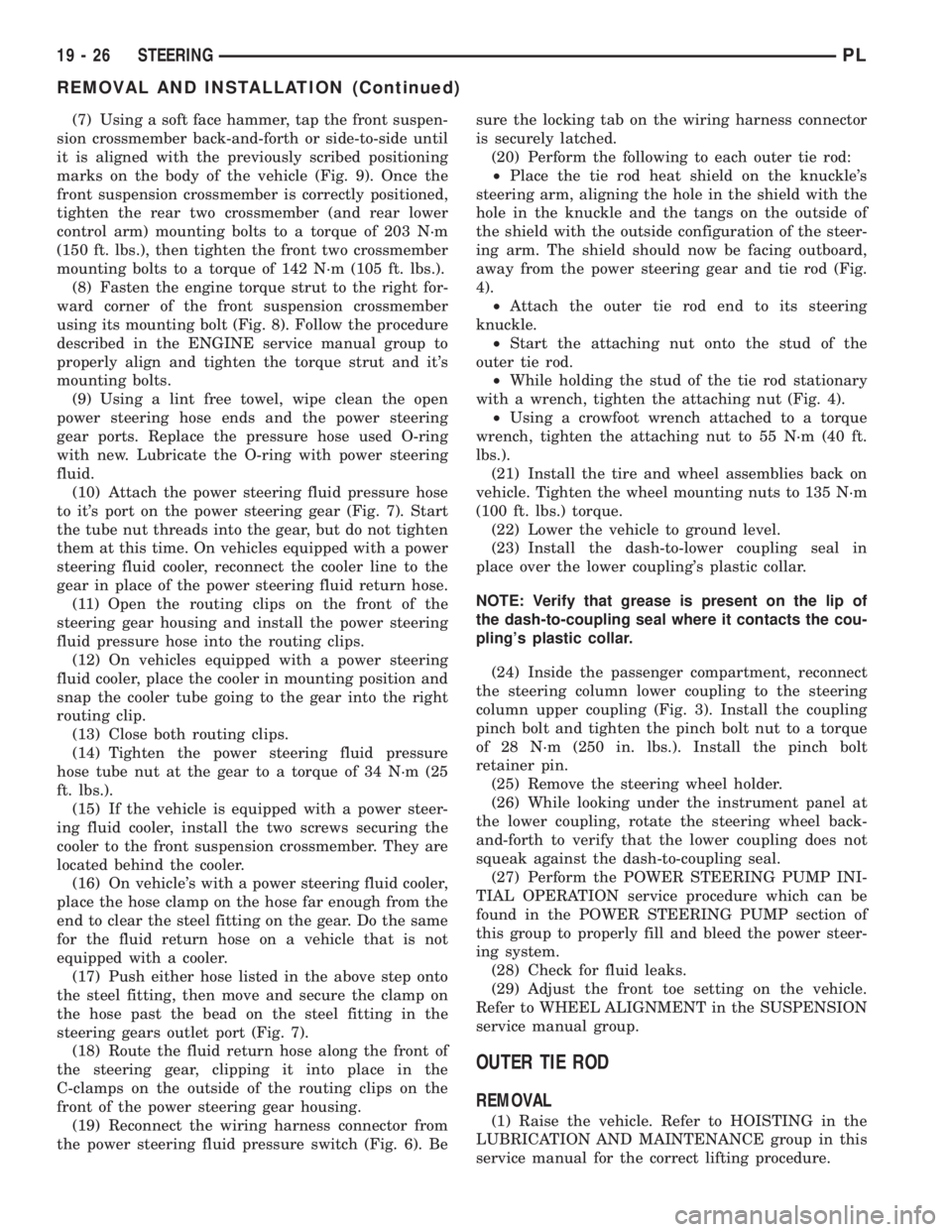

(8) Release the locking tab on the wiring harness

connector for the power steering fluid pressure

switch before connector removal. Remove the wiring

harness connector from the power steering fluid pres-

sure switch (Fig. 6).

(9) Back out the tube nut securing the power

steering fluid pressure hose to the gear (Fig. 7).

(10) On vehicles without a power steering fluid

cooler, loosen the clamp, then disconnect the power

steering fluid return hose from the gear. If the vehi-

cle is equipped with a power steering fluid cooler, dis-

connect the cooler hose from the gear in place of the

power steering fluid return hose.

(11) If the vehicle is not equipped with a power

steering cooler, remove the power steering returnhose from the C-clamps on the outside of the two

routing clips on the front of the power steering gear.

(12) Open the routing clips on the front of the

power steering gear and remove the power steering

fluid pressure hose from the routing clips. At the

same time, if the vehicle is equipped with a power

steering cooler, remove the cooler tube from the right

routing clip.

Fig. 4 Tools On Outer Tie Rod Nut

1 ± OUTER TIE ROD

2 ± STUD

3 ± NUT

Fig. 5 Tie Rod Removal From Knuckle

1 ± OUTER TIE ROD

2 ± STEERING KNUCKLE

Fig. 6 Power Steering Fluid Pressure Switch

1 ± WIRING HARNESS CONNECTOR

2 ± POWER STEERING GEAR

3 ± POWER STEERING FLUID PRESSURE SWITCH

4 ± REAR OF FRONT SUSPENSION CROSSMEMBER

Fig. 7 Power Steering Hoses At Gear

1 ± PRESSURE HOSE TUBE NUT

2 ± RETURN HOSE

3 ± POWER STEERING GEAR

4 ± FRONT SUSPENSION CROSSMEMBER

PLSTEERING 19 - 23

REMOVAL AND INSTALLATION (Continued)

Page 897 of 1285

(7) Using a soft face hammer, tap the front suspen-

sion crossmember back-and-forth or side-to-side until

it is aligned with the previously scribed positioning

marks on the body of the vehicle (Fig. 9). Once the

front suspension crossmember is correctly positioned,

tighten the rear two crossmember (and rear lower

control arm) mounting bolts to a torque of 203 N´m

(150 ft. lbs.), then tighten the front two crossmember

mounting bolts to a torque of 142 N´m (105 ft. lbs.).

(8) Fasten the engine torque strut to the right for-

ward corner of the front suspension crossmember

using its mounting bolt (Fig. 8). Follow the procedure

described in the ENGINE service manual group to

properly align and tighten the torque strut and it's

mounting bolts.

(9) Using a lint free towel, wipe clean the open

power steering hose ends and the power steering

gear ports. Replace the pressure hose used O-ring

with new. Lubricate the O-ring with power steering

fluid.

(10) Attach the power steering fluid pressure hose

to it's port on the power steering gear (Fig. 7). Start

the tube nut threads into the gear, but do not tighten

them at this time. On vehicles equipped with a power

steering fluid cooler, reconnect the cooler line to the

gear in place of the power steering fluid return hose.

(11) Open the routing clips on the front of the

steering gear housing and install the power steering

fluid pressure hose into the routing clips.

(12) On vehicles equipped with a power steering

fluid cooler, place the cooler in mounting position and

snap the cooler tube going to the gear into the right

routing clip.

(13) Close both routing clips.

(14) Tighten the power steering fluid pressure

hose tube nut at the gear to a torque of 34 N´m (25

ft. lbs.).

(15) If the vehicle is equipped with a power steer-

ing fluid cooler, install the two screws securing the

cooler to the front suspension crossmember. They are

located behind the cooler.

(16) On vehicle's with a power steering fluid cooler,

place the hose clamp on the hose far enough from the

end to clear the steel fitting on the gear. Do the same

for the fluid return hose on a vehicle that is not

equipped with a cooler.

(17) Push either hose listed in the above step onto

the steel fitting, then move and secure the clamp on

the hose past the bead on the steel fitting in the

steering gears outlet port (Fig. 7).

(18) Route the fluid return hose along the front of

the steering gear, clipping it into place in the

C-clamps on the outside of the routing clips on the

front of the power steering gear housing.

(19) Reconnect the wiring harness connector from

the power steering fluid pressure switch (Fig. 6). Besure the locking tab on the wiring harness connector

is securely latched.

(20) Perform the following to each outer tie rod:

²Place the tie rod heat shield on the knuckle's

steering arm, aligning the hole in the shield with the

hole in the knuckle and the tangs on the outside of

the shield with the outside configuration of the steer-

ing arm. The shield should now be facing outboard,

away from the power steering gear and tie rod (Fig.

4).

²Attach the outer tie rod end to its steering

knuckle.

²Start the attaching nut onto the stud of the

outer tie rod.

²While holding the stud of the tie rod stationary

with a wrench, tighten the attaching nut (Fig. 4).

²Using a crowfoot wrench attached to a torque

wrench, tighten the attaching nut to 55 N´m (40 ft.

lbs.).

(21) Install the tire and wheel assemblies back on

vehicle. Tighten the wheel mounting nuts to 135 N´m

(100 ft. lbs.) torque.

(22) Lower the vehicle to ground level.

(23) Install the dash-to-lower coupling seal in

place over the lower coupling's plastic collar.

NOTE: Verify that grease is present on the lip of

the dash-to-coupling seal where it contacts the cou-

pling's plastic collar.

(24) Inside the passenger compartment, reconnect

the steering column lower coupling to the steering

column upper coupling (Fig. 3). Install the coupling

pinch bolt and tighten the pinch bolt nut to a torque

of 28 N´m (250 in. lbs.). Install the pinch bolt

retainer pin.

(25) Remove the steering wheel holder.

(26) While looking under the instrument panel at

the lower coupling, rotate the steering wheel back-

and-forth to verify that the lower coupling does not

squeak against the dash-to-coupling seal.

(27) Perform the POWER STEERING PUMP INI-

TIAL OPERATION service procedure which can be

found in the POWER STEERING PUMP section of

this group to properly fill and bleed the power steer-

ing system.

(28) Check for fluid leaks.

(29) Adjust the front toe setting on the vehicle.

Refer to WHEEL ALIGNMENT in the SUSPENSION

service manual group.

OUTER TIE ROD

REMOVAL

(1) Raise the vehicle. Refer to HOISTING in the

LUBRICATION AND MAINTENANCE group in this

service manual for the correct lifting procedure.

19 - 26 STEERINGPL

REMOVAL AND INSTALLATION (Continued)

Page 900 of 1285

STEERING COLUMN

TABLE OF CONTENTS

page page

DESCRIPTION AND OPERATION

STEERING COLUMN......................29

STEERING COLUMN LOWER COUPLING......29

DIAGNOSIS AND TESTING

STEERING COLUMN......................30

STEERING COLUMN LOWER COUPLING......30

REMOVAL AND INSTALLATION

SERVICE WARNINGS AND CAUTIONS........31STEERING COLUMN......................31

STEERING COLUMN LOWER COUPLING......38

SPECIFICATIONS

STEERING COLUMN FASTENER TORQUE

SPECIFICATIONS.......................41

DESCRIPTION AND OPERATION

STEERING COLUMN

This vehicle is equipped with both tilt and non-tilt

steering columns. Both steering columns have been

designed to be serviced only as complete assemblies

if an internal component is found to be defective (Fig.

1). The shaft, bearings and upper coupling are all

serviced with the column.

The replaceable components on the steering col-

umn assembly are:

²the key cylinder

²the ignition switch

²the multi-function switch

²the clockspring²the trim shrouds

²the steering wheel

²the driver airbag module

These components can be serviced without removal

of the steering column from the vehicle. Refer to the

appropriate group and section of this service manual

for servicing these components separately.

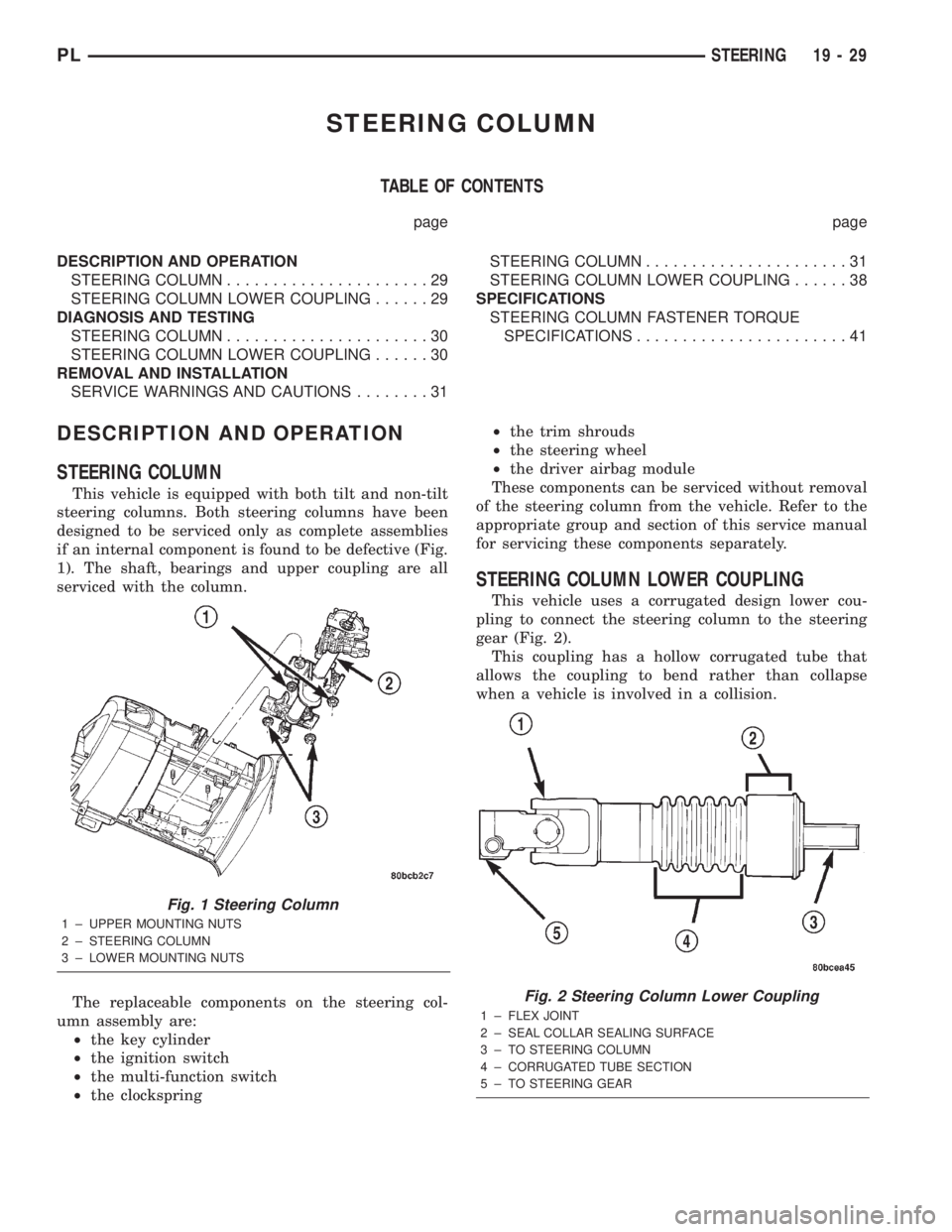

STEERING COLUMN LOWER COUPLING

This vehicle uses a corrugated design lower cou-

pling to connect the steering column to the steering

gear (Fig. 2).

This coupling has a hollow corrugated tube that

allows the coupling to bend rather than collapse

when a vehicle is involved in a collision.

Fig. 1 Steering Column

1 ± UPPER MOUNTING NUTS

2 ± STEERING COLUMN

3 ± LOWER MOUNTING NUTS

Fig. 2 Steering Column Lower Coupling

1 ± FLEX JOINT

2 ± SEAL COLLAR SEALING SURFACE

3 ± TO STEERING COLUMN

4 ± CORRUGATED TUBE SECTION

5 ± TO STEERING GEAR

PLSTEERING 19 - 29

Page 901 of 1285

DIAGNOSIS AND TESTING

STEERING COLUMN

For diagnosis of conditions relating to the steering

column, refer to the STEERING SYSTEM DIAGNO-

SIS CHARTS in DIAGNOSIS AND TESTING in the

POWER STEERING section of this service manual

group.

STEERING COLUMN LOWER COUPLING

The steering column coupling must be inspected

whenever a vehicle is involved in an impact or when-

ever any of the following conditions exist:

²whenever a vehicle is involved in a collision

which deploys the air bag, regardless of the extent of

damage done to the vehicle.

²if a vehicle is involved in an impact of the vehi-

cles front suspension or under carriage, which results

in any type of damage to the front suspension cross-

member.

²under any conditions which result in the steer-

ing column assembly or steering column shaft receiv-

ing a force great enough to move the steering column

or shaft forward or rearward in a vehicle.

STEERING COLUMN COUPLING INSPECTION

PROCEDURE

(1) Place the steering wheel in the STRAIGHT-

AHEAD position. Using a steering wheel holding

clamp, lock the steering wheel in place to keep it

from rotating. This keeps the clockspring in the

proper orientation.

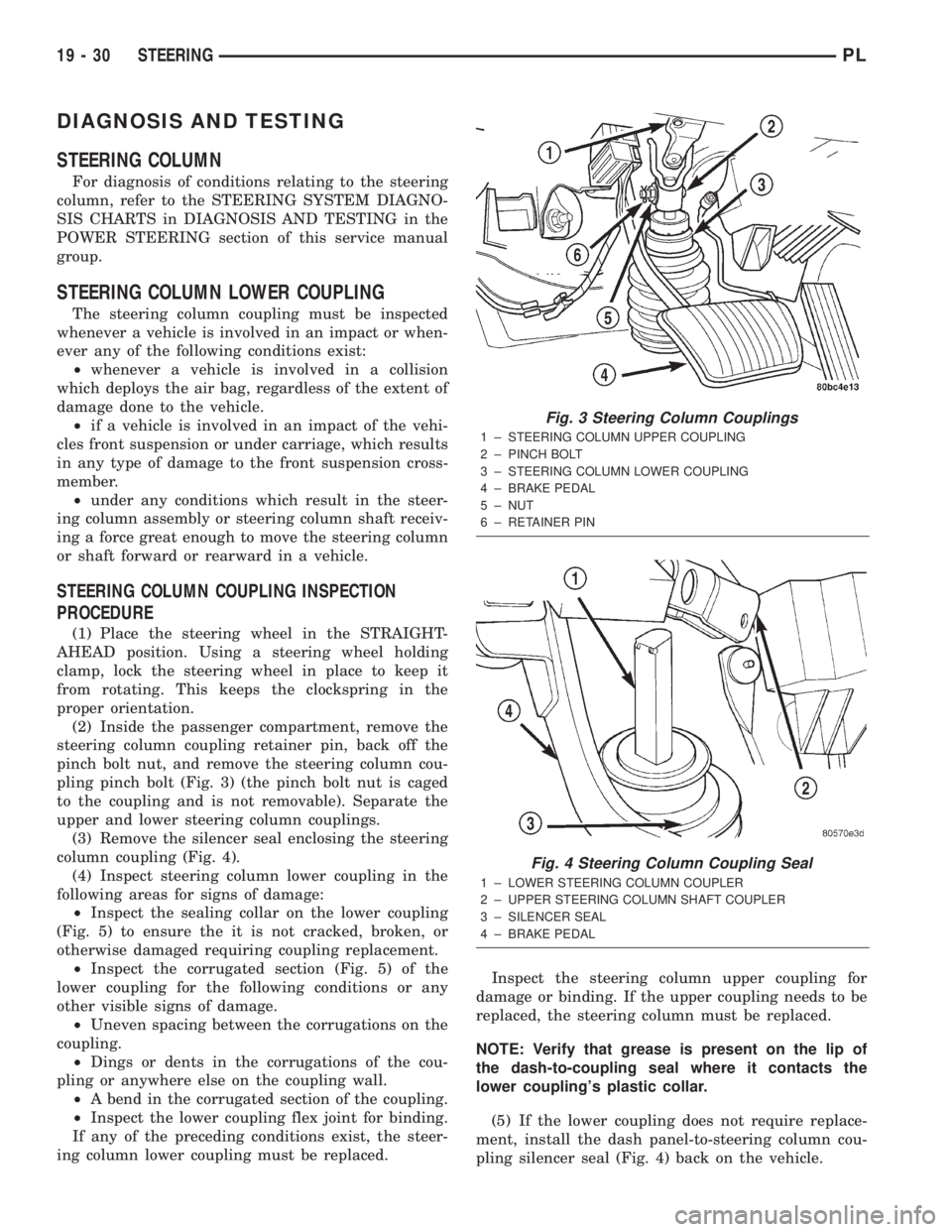

(2) Inside the passenger compartment, remove the

steering column coupling retainer pin, back off the

pinch bolt nut, and remove the steering column cou-

pling pinch bolt (Fig. 3) (the pinch bolt nut is caged

to the coupling and is not removable). Separate the

upper and lower steering column couplings.

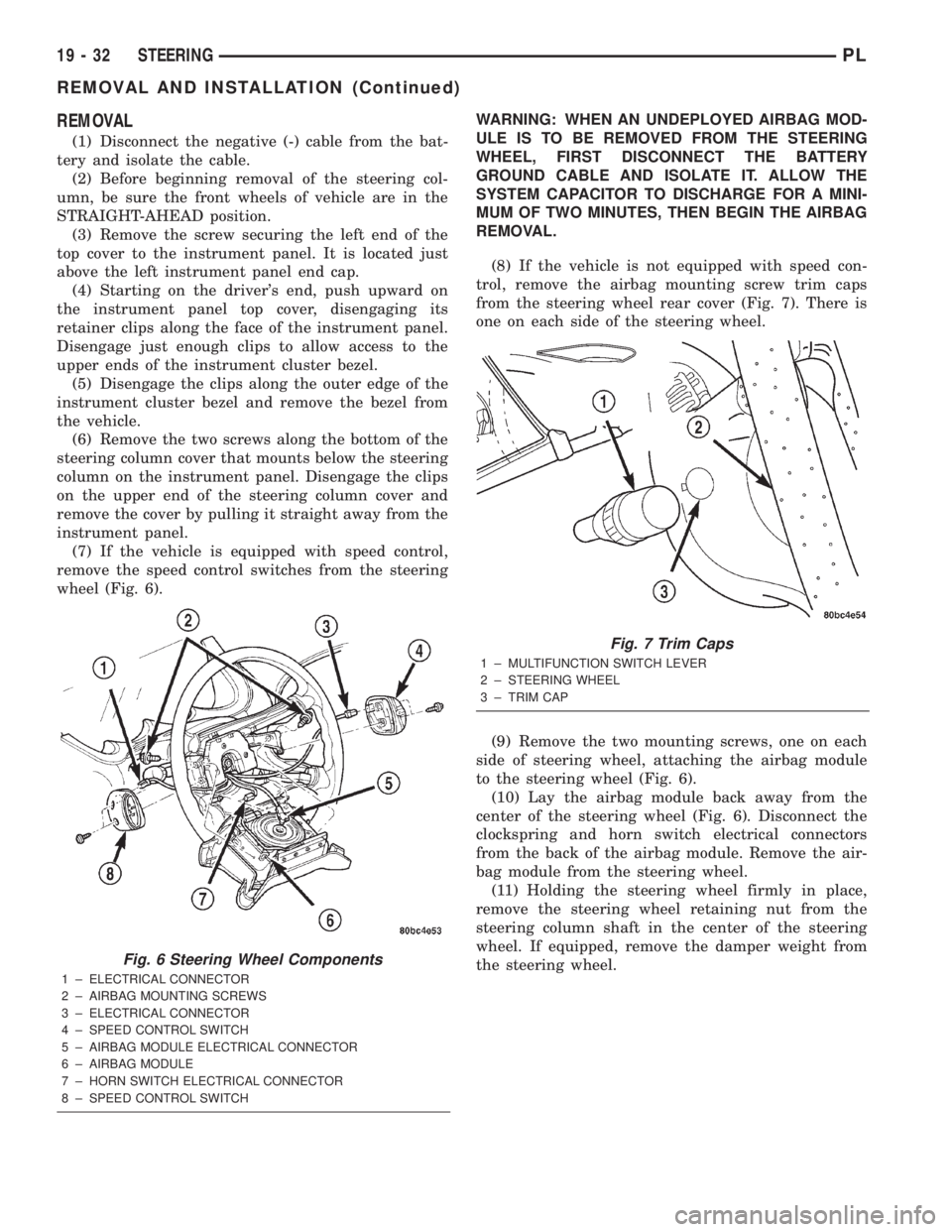

(3) Remove the silencer seal enclosing the steering

column coupling (Fig. 4).

(4) Inspect steering column lower coupling in the

following areas for signs of damage:

²Inspect the sealing collar on the lower coupling

(Fig. 5) to ensure the it is not cracked, broken, or

otherwise damaged requiring coupling replacement.

²Inspect the corrugated section (Fig. 5) of the

lower coupling for the following conditions or any

other visible signs of damage.

²Uneven spacing between the corrugations on the

coupling.

²Dings or dents in the corrugations of the cou-

pling or anywhere else on the coupling wall.

²A bend in the corrugated section of the coupling.

²Inspect the lower coupling flex joint for binding.

If any of the preceding conditions exist, the steer-

ing column lower coupling must be replaced.Inspect the steering column upper coupling for

damage or binding. If the upper coupling needs to be

replaced, the steering column must be replaced.

NOTE: Verify that grease is present on the lip of

the dash-to-coupling seal where it contacts the

lower coupling's plastic collar.

(5) If the lower coupling does not require replace-

ment, install the dash panel-to-steering column cou-

pling silencer seal (Fig. 4) back on the vehicle.

Fig. 3 Steering Column Couplings

1 ± STEERING COLUMN UPPER COUPLING

2 ± PINCH BOLT

3 ± STEERING COLUMN LOWER COUPLING

4 ± BRAKE PEDAL

5 ± NUT

6 ± RETAINER PIN

Fig. 4 Steering Column Coupling Seal

1 ± LOWER STEERING COLUMN COUPLER

2 ± UPPER STEERING COLUMN SHAFT COUPLER

3 ± SILENCER SEAL

4 ± BRAKE PEDAL

19 - 30 STEERINGPL

Page 903 of 1285

REMOVAL

(1) Disconnect the negative (-) cable from the bat-

tery and isolate the cable.

(2) Before beginning removal of the steering col-

umn, be sure the front wheels of vehicle are in the

STRAIGHT-AHEAD position.

(3) Remove the screw securing the left end of the

top cover to the instrument panel. It is located just

above the left instrument panel end cap.

(4) Starting on the driver's end, push upward on

the instrument panel top cover, disengaging its

retainer clips along the face of the instrument panel.

Disengage just enough clips to allow access to the

upper ends of the instrument cluster bezel.

(5) Disengage the clips along the outer edge of the

instrument cluster bezel and remove the bezel from

the vehicle.

(6) Remove the two screws along the bottom of the

steering column cover that mounts below the steering

column on the instrument panel. Disengage the clips

on the upper end of the steering column cover and

remove the cover by pulling it straight away from the

instrument panel.

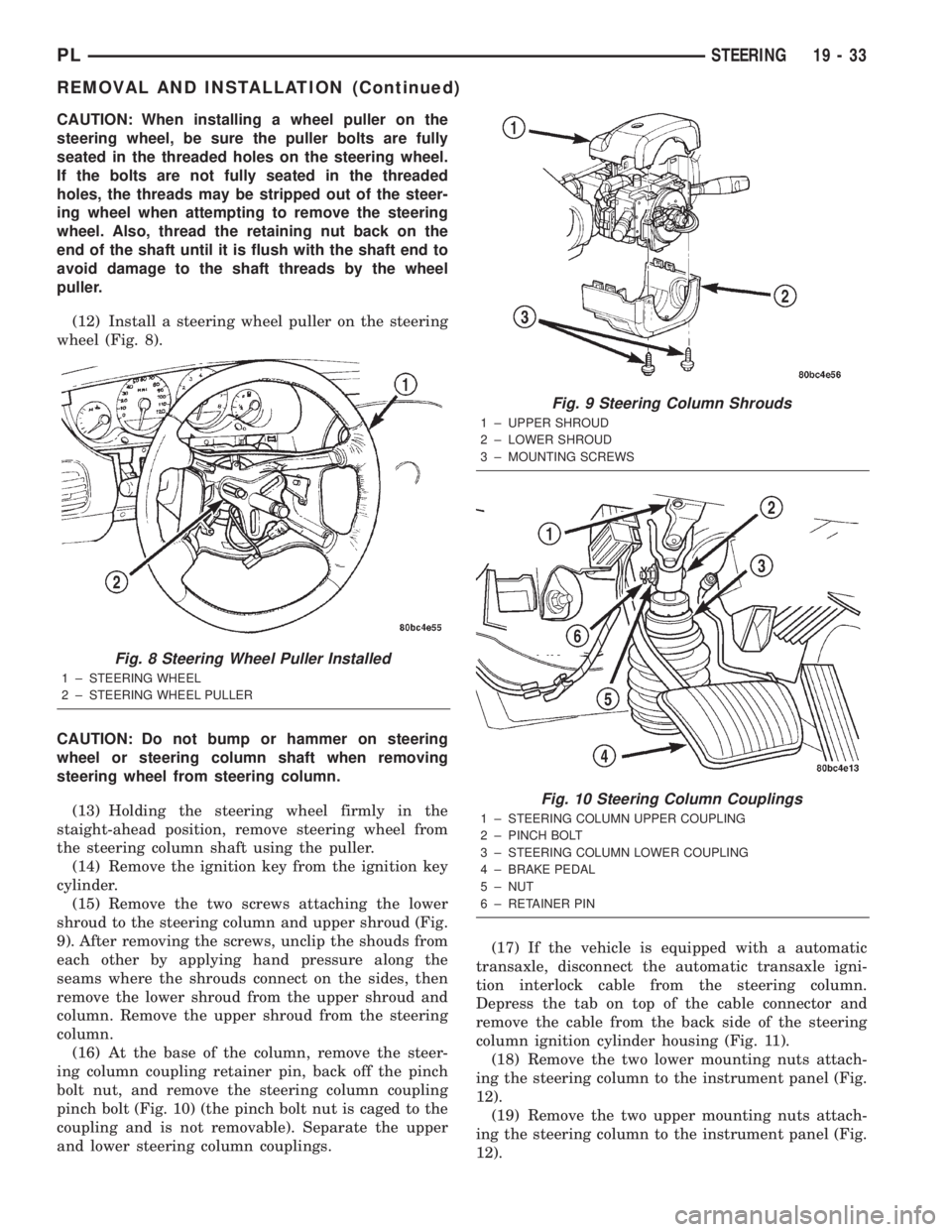

(7) If the vehicle is equipped with speed control,

remove the speed control switches from the steering

wheel (Fig. 6).WARNING: WHEN AN UNDEPLOYED AIRBAG MOD-

ULE IS TO BE REMOVED FROM THE STEERING

WHEEL, FIRST DISCONNECT THE BATTERY

GROUND CABLE AND ISOLATE IT. ALLOW THE

SYSTEM CAPACITOR TO DISCHARGE FOR A MINI-

MUM OF TWO MINUTES, THEN BEGIN THE AIRBAG

REMOVAL.

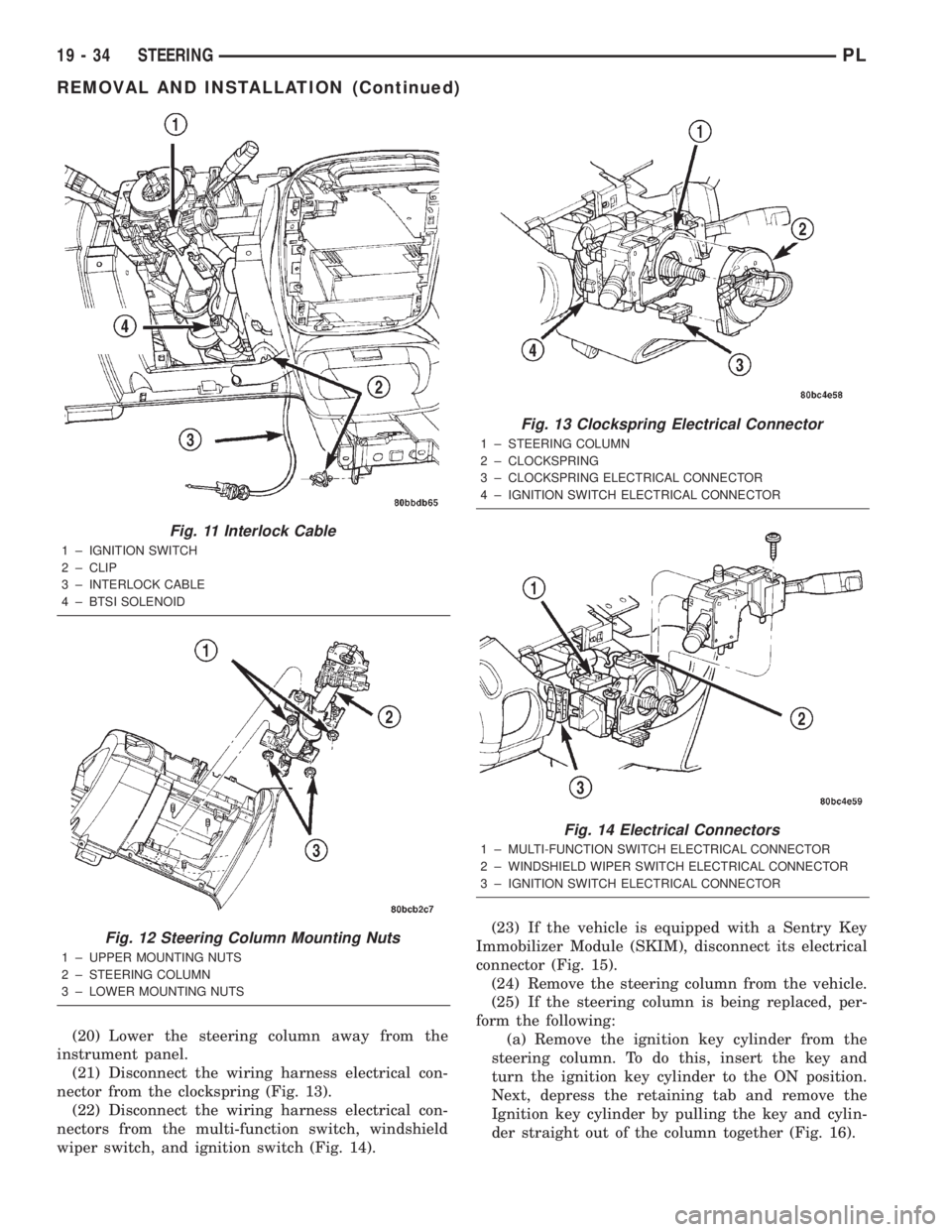

(8) If the vehicle is not equipped with speed con-

trol, remove the airbag mounting screw trim caps

from the steering wheel rear cover (Fig. 7). There is

one on each side of the steering wheel.

(9) Remove the two mounting screws, one on each

side of steering wheel, attaching the airbag module

to the steering wheel (Fig. 6).

(10) Lay the airbag module back away from the

center of the steering wheel (Fig. 6). Disconnect the

clockspring and horn switch electrical connectors

from the back of the airbag module. Remove the air-

bag module from the steering wheel.

(11) Holding the steering wheel firmly in place,

remove the steering wheel retaining nut from the

steering column shaft in the center of the steering

wheel. If equipped, remove the damper weight from

the steering wheel.

Fig. 6 Steering Wheel Components

1 ± ELECTRICAL CONNECTOR

2 ± AIRBAG MOUNTING SCREWS

3 ± ELECTRICAL CONNECTOR

4 ± SPEED CONTROL SWITCH

5 ± AIRBAG MODULE ELECTRICAL CONNECTOR

6 ± AIRBAG MODULE

7 ± HORN SWITCH ELECTRICAL CONNECTOR

8 ± SPEED CONTROL SWITCH

Fig. 7 Trim Caps

1 ± MULTIFUNCTION SWITCH LEVER

2 ± STEERING WHEEL

3 ± TRIM CAP

19 - 32 STEERINGPL

REMOVAL AND INSTALLATION (Continued)

Page 904 of 1285

CAUTION: When installing a wheel puller on the

steering wheel, be sure the puller bolts are fully

seated in the threaded holes on the steering wheel.

If the bolts are not fully seated in the threaded

holes, the threads may be stripped out of the steer-

ing wheel when attempting to remove the steering

wheel. Also, thread the retaining nut back on the

end of the shaft until it is flush with the shaft end to

avoid damage to the shaft threads by the wheel

puller.

(12) Install a steering wheel puller on the steering

wheel (Fig. 8).

CAUTION: Do not bump or hammer on steering

wheel or steering column shaft when removing

steering wheel from steering column.

(13) Holding the steering wheel firmly in the

staight-ahead position, remove steering wheel from

the steering column shaft using the puller.

(14) Remove the ignition key from the ignition key

cylinder.

(15) Remove the two screws attaching the lower

shroud to the steering column and upper shroud (Fig.

9). After removing the screws, unclip the shouds from

each other by applying hand pressure along the

seams where the shrouds connect on the sides, then

remove the lower shroud from the upper shroud and

column. Remove the upper shroud from the steering

column.

(16) At the base of the column, remove the steer-

ing column coupling retainer pin, back off the pinch

bolt nut, and remove the steering column coupling

pinch bolt (Fig. 10) (the pinch bolt nut is caged to the

coupling and is not removable). Separate the upper

and lower steering column couplings.(17) If the vehicle is equipped with a automatic

transaxle, disconnect the automatic transaxle igni-

tion interlock cable from the steering column.

Depress the tab on top of the cable connector and

remove the cable from the back side of the steering

column ignition cylinder housing (Fig. 11).

(18) Remove the two lower mounting nuts attach-

ing the steering column to the instrument panel (Fig.

12).

(19) Remove the two upper mounting nuts attach-

ing the steering column to the instrument panel (Fig.

12).

Fig. 8 Steering Wheel Puller Installed

1 ± STEERING WHEEL

2 ± STEERING WHEEL PULLER

Fig. 9 Steering Column Shrouds

1 ± UPPER SHROUD

2 ± LOWER SHROUD

3 ± MOUNTING SCREWS

Fig. 10 Steering Column Couplings

1 ± STEERING COLUMN UPPER COUPLING

2 ± PINCH BOLT

3 ± STEERING COLUMN LOWER COUPLING

4 ± BRAKE PEDAL

5 ± NUT

6 ± RETAINER PIN

PLSTEERING 19 - 33

REMOVAL AND INSTALLATION (Continued)

Page 905 of 1285

(20) Lower the steering column away from the

instrument panel.

(21) Disconnect the wiring harness electrical con-

nector from the clockspring (Fig. 13).

(22) Disconnect the wiring harness electrical con-

nectors from the multi-function switch, windshield

wiper switch, and ignition switch (Fig. 14).(23) If the vehicle is equipped with a Sentry Key

Immobilizer Module (SKIM), disconnect its electrical

connector (Fig. 15).

(24) Remove the steering column from the vehicle.

(25) If the steering column is being replaced, per-

form the following:

(a) Remove the ignition key cylinder from the

steering column. To do this, insert the key and

turn the ignition key cylinder to the ON position.

Next, depress the retaining tab and remove the

Ignition key cylinder by pulling the key and cylin-

der straight out of the column together (Fig. 16).

Fig. 11 Interlock Cable

1 ± IGNITION SWITCH

2 ± CLIP

3 ± INTERLOCK CABLE

4 ± BTSI SOLENOID

Fig. 12 Steering Column Mounting Nuts

1 ± UPPER MOUNTING NUTS

2 ± STEERING COLUMN

3 ± LOWER MOUNTING NUTS

Fig. 13 Clockspring Electrical Connector

1 ± STEERING COLUMN

2 ± CLOCKSPRING

3 ± CLOCKSPRING ELECTRICAL CONNECTOR

4 ± IGNITION SWITCH ELECTRICAL CONNECTOR

Fig. 14 Electrical Connectors

1 ± MULTI-FUNCTION SWITCH ELECTRICAL CONNECTOR

2 ± WINDSHIELD WIPER SWITCH ELECTRICAL CONNECTOR

3 ± IGNITION SWITCH ELECTRICAL CONNECTOR

19 - 34 STEERINGPL

REMOVAL AND INSTALLATION (Continued)

Page 906 of 1285

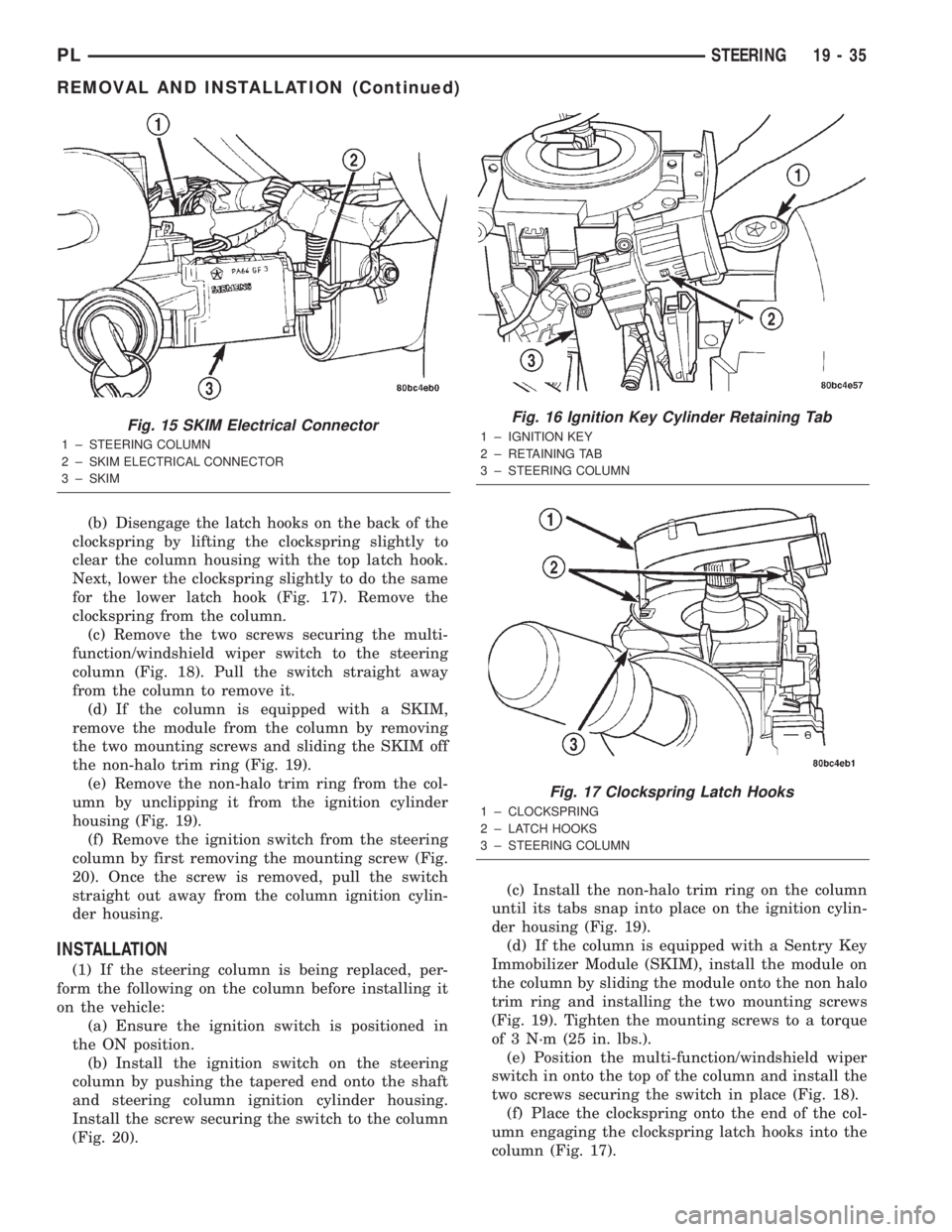

(b) Disengage the latch hooks on the back of the

clockspring by lifting the clockspring slightly to

clear the column housing with the top latch hook.

Next, lower the clockspring slightly to do the same

for the lower latch hook (Fig. 17). Remove the

clockspring from the column.

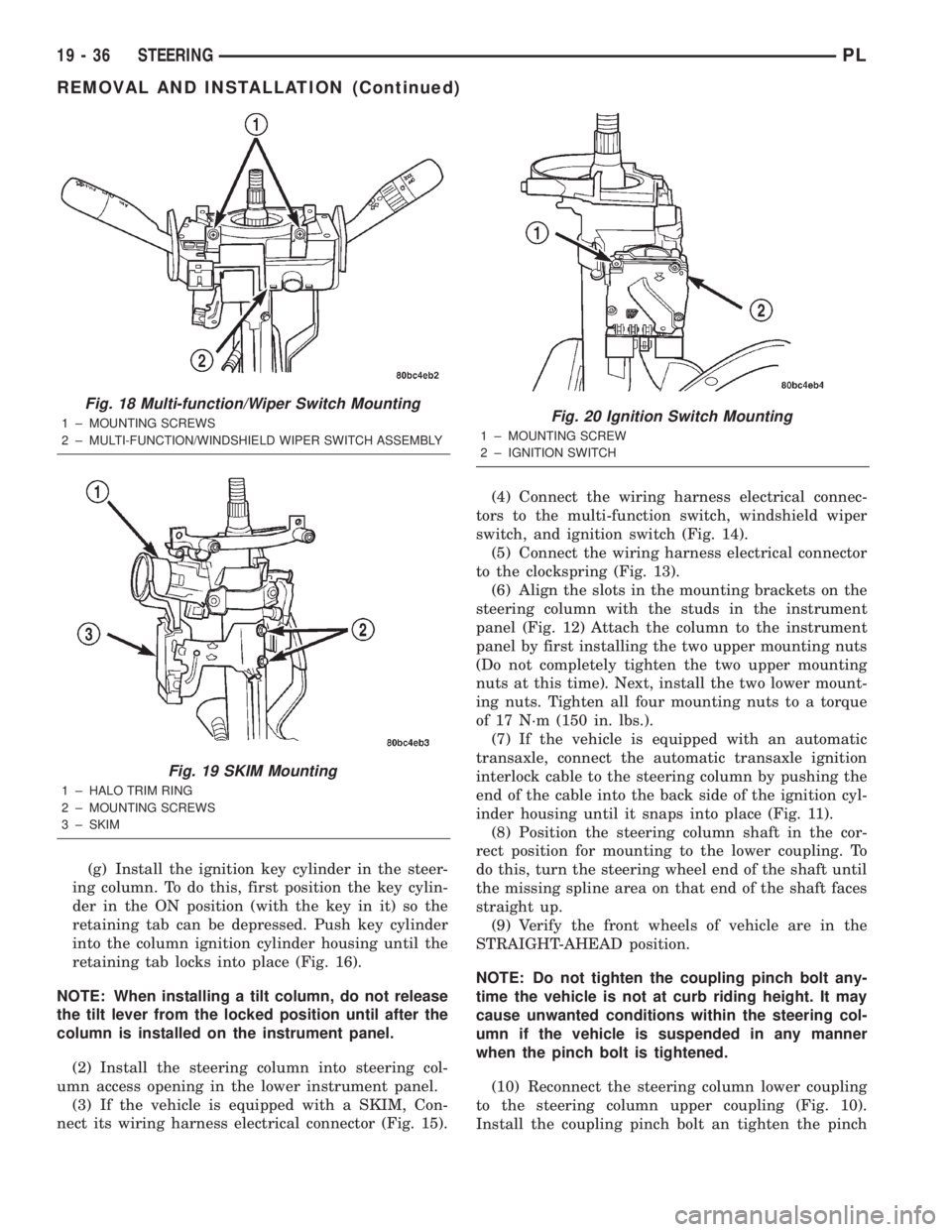

(c) Remove the two screws securing the multi-

function/windshield wiper switch to the steering

column (Fig. 18). Pull the switch straight away

from the column to remove it.

(d) If the column is equipped with a SKIM,

remove the module from the column by removing

the two mounting screws and sliding the SKIM off

the non-halo trim ring (Fig. 19).

(e) Remove the non-halo trim ring from the col-

umn by unclipping it from the ignition cylinder

housing (Fig. 19).

(f) Remove the ignition switch from the steering

column by first removing the mounting screw (Fig.

20). Once the screw is removed, pull the switch

straight out away from the column ignition cylin-

der housing.

INSTALLATION

(1) If the steering column is being replaced, per-

form the following on the column before installing it

on the vehicle:

(a) Ensure the ignition switch is positioned in

the ON position.

(b) Install the ignition switch on the steering

column by pushing the tapered end onto the shaft

and steering column ignition cylinder housing.

Install the screw securing the switch to the column

(Fig. 20).(c) Install the non-halo trim ring on the column

until its tabs snap into place on the ignition cylin-

der housing (Fig. 19).

(d) If the column is equipped with a Sentry Key

Immobilizer Module (SKIM), install the module on

the column by sliding the module onto the non halo

trim ring and installing the two mounting screws

(Fig. 19). Tighten the mounting screws to a torque

of 3 N´m (25 in. lbs.).

(e) Position the multi-function/windshield wiper

switch in onto the top of the column and install the

two screws securing the switch in place (Fig. 18).

(f) Place the clockspring onto the end of the col-

umn engaging the clockspring latch hooks into the

column (Fig. 17).

Fig. 15 SKIM Electrical Connector

1 ± STEERING COLUMN

2 ± SKIM ELECTRICAL CONNECTOR

3 ± SKIM

Fig. 16 Ignition Key Cylinder Retaining Tab

1 ± IGNITION KEY

2 ± RETAINING TAB

3 ± STEERING COLUMN

Fig. 17 Clockspring Latch Hooks

1 ± CLOCKSPRING

2 ± LATCH HOOKS

3 ± STEERING COLUMN

PLSTEERING 19 - 35

REMOVAL AND INSTALLATION (Continued)

Page 907 of 1285

(g) Install the ignition key cylinder in the steer-

ing column. To do this, first position the key cylin-

der in the ON position (with the key in it) so the

retaining tab can be depressed. Push key cylinder

into the column ignition cylinder housing until the

retaining tab locks into place (Fig. 16).

NOTE: When installing a tilt column, do not release

the tilt lever from the locked position until after the

column is installed on the instrument panel.

(2) Install the steering column into steering col-

umn access opening in the lower instrument panel.

(3) If the vehicle is equipped with a SKIM, Con-

nect its wiring harness electrical connector (Fig. 15).(4) Connect the wiring harness electrical connec-

tors to the multi-function switch, windshield wiper

switch, and ignition switch (Fig. 14).

(5) Connect the wiring harness electrical connector

to the clockspring (Fig. 13).

(6) Align the slots in the mounting brackets on the

steering column with the studs in the instrument

panel (Fig. 12) Attach the column to the instrument

panel by first installing the two upper mounting nuts

(Do not completely tighten the two upper mounting

nuts at this time). Next, install the two lower mount-

ing nuts. Tighten all four mounting nuts to a torque

of 17 N´m (150 in. lbs.).

(7) If the vehicle is equipped with an automatic

transaxle, connect the automatic transaxle ignition

interlock cable to the steering column by pushing the

end of the cable into the back side of the ignition cyl-

inder housing until it snaps into place (Fig. 11).

(8) Position the steering column shaft in the cor-

rect position for mounting to the lower coupling. To

do this, turn the steering wheel end of the shaft until

the missing spline area on that end of the shaft faces

straight up.

(9) Verify the front wheels of vehicle are in the

STRAIGHT-AHEAD position.

NOTE: Do not tighten the coupling pinch bolt any-

time the vehicle is not at curb riding height. It may

cause unwanted conditions within the steering col-

umn if the vehicle is suspended in any manner

when the pinch bolt is tightened.

(10) Reconnect the steering column lower coupling

to the steering column upper coupling (Fig. 10).

Install the coupling pinch bolt an tighten the pinch

Fig. 18 Multi-function/Wiper Switch Mounting

1 ± MOUNTING SCREWS

2 ± MULTI-FUNCTION/WINDSHIELD WIPER SWITCH ASSEMBLY

Fig. 19 SKIM Mounting

1 ± HALO TRIM RING

2 ± MOUNTING SCREWS

3 ± SKIM

Fig. 20 Ignition Switch Mounting

1 ± MOUNTING SCREW

2 ± IGNITION SWITCH

19 - 36 STEERINGPL

REMOVAL AND INSTALLATION (Continued)