tra DODGE NEON 2000 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 1092 of 1285

MISFIRE

²Same Misfire Warm-Up StateÐ Indicates if

the misfire occurred when the engine was warmed up

(above 160É F).

²In Similar Misfire WindowÐ An indicator

that 'Absolute MAP When Misfire Occurred' and

'RPM When Misfire Occurred' are all in the same

range when the failure occurred. Indicated by switch-

ing from 'NO' to 'YES'.

²Absolute MAP When Misfire OccurredÐ

The stored MAP reading at the time of failure.

Informs the user at what engine load the failure

occurred.

²Absolute MAPÐ A live reading of engine load

to aid the user in accessing the Similar Conditions

Window.

²RPM When Misfire OccurredÐ The stored

RPM reading at the time of failure. Informs the user

at what engine RPM the failure occurred.

²Engine RPMÐ A live reading of engine RPM

to aid the user in accessing the Similar Conditions

Window.

²Adaptive Memory FactorÐ The PCM uti-

lizes both Short Term Compensation and Long Term

Adaptive to calculate the Adaptive Memory Factor

for total fuel correction.

²200 Rev CounterÐ Counts 0±100 720 degree

cycles.

²SCW Cat 200 Rev CounterÐ Counts when in

similar conditions.

²SCW FTP 1000 Rev CounterÐ Counts 0±4

when in similar conditions.

²Misfire Good Trip CounterÐ Counts up to

three to turn OFF the MIL.

MALFUNCTION INDICATOR LAMP (MIL)

OPERATION

As a functional test, the Malfunction Indicator

Lamp (MIL) illuminates at key-on before engine

cranking. Whenever the Powertrain Control Module

(PCM) sets a Diagnostic Trouble Code (DTC) that

affects vehicle emissions, it illuminates the MIL. If a

problem is detected, the PCM sends a message over

the PCI Bus to the instrument cluster to illuminate

the lamp. The PCM illuminates the MIL only for

DTC's that affect vehicle emissions. The MIL stays

on continuously when the PCM has entered a

Limp-In mode or identified a failed emission compo-

nent or system. The MIL remains on until the DTC

is erased. Refer to the Diagnostic Trouble Code

charts in this group for emission related codes.

Also, the MIL either flashes or illuminates contin-

uously when the PCM detects active engine misfire.

Refer to Misfire Monitoring in this section.Additionally, the PCM may reset (turn off) the MIL

when one of the following occur:

²PCM does not detect the malfunction for 3 con-

secutive trips (except misfire and fuel system moni-

tors).

²PCM does not detect a malfunction while per-

forming three successive engine misfire or fuel sys-

tem tests. The PCM performs these tests while the

engine is operating within6375 RPM of and within

10 % of the load of the operating condition at which

the malfunction was first detected.

DRB III STATE DISPLAY TEST MODE

OPERATION

The switch inputs to the Powertrain Control Mod-

ule (PCM) have two recognized states; HIGH and

LOW. For this reason, the PCM cannot recognize the

difference between a selected switch position versus

an open circuit, a short circuit, or a defective switch.

If the State Display screen shows the change from

HIGH to LOW or LOW to HIGH, assume the entire

switch circuit to the PCM functions properly. From

the state display screen, access either State Display

Inputs and Outputs or State Display Sensors.

DRB III CIRCUIT ACTUATION TEST MODE

OPERATION

The Circuit Actuation Test Mode checks for proper

operation of output circuits or devices the Powertrain

Control Module (PCM) may not internally recognize.

The PCM attempts to activate these outputs and

allow an observer to verify proper operation. Most of

the tests provide an audible or visual indication of

device operation (click of relay contacts, fuel spray,

etc.). Except for intermittent conditions, if a device

functions properly during testing, assume the device,

its associated wiring, and driver circuit work cor-

rectly.

DIAGNOSTIC TROUBLE CODES

DESCRIPTION

A Diagnostic Trouble Code (DTC) indicates the

PCM has recognized an abnormal condition in the

system.

Remember that DTC's are the results of a sys-

tem or circuit failure, but do not directly iden-

tify the failed component or components.

NOTE: For a list of DTC's, refer to the charts in this

section.

PLEMISSION CONTROL SYSTEMS 25 - 5

DESCRIPTION AND OPERATION (Continued)

Page 1097 of 1285

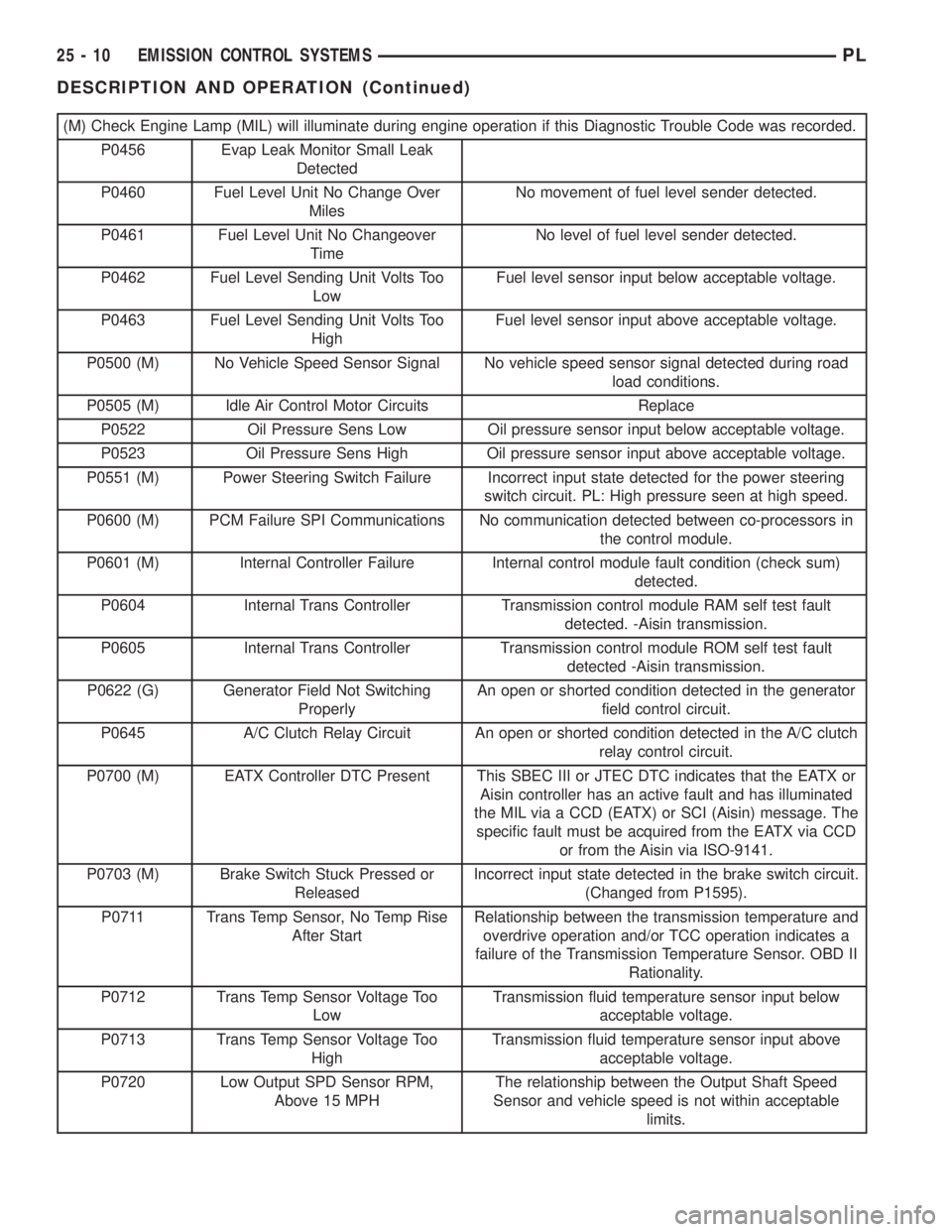

(M) Check Engine Lamp (MIL) will illuminate during engine operation if this Diagnostic Trouble Code was recorded.

P0456 Evap Leak Monitor Small Leak

Detected

P0460 Fuel Level Unit No Change Over

MilesNo movement of fuel level sender detected.

P0461 Fuel Level Unit No Changeover

TimeNo level of fuel level sender detected.

P0462 Fuel Level Sending Unit Volts Too

LowFuel level sensor input below acceptable voltage.

P0463 Fuel Level Sending Unit Volts Too

HighFuel level sensor input above acceptable voltage.

P0500 (M) No Vehicle Speed Sensor Signal No vehicle speed sensor signal detected during road

load conditions.

P0505 (M) Idle Air Control Motor Circuits Replace

P0522 Oil Pressure Sens Low Oil pressure sensor input below acceptable voltage.

P0523 Oil Pressure Sens High Oil pressure sensor input above acceptable voltage.

P0551 (M) Power Steering Switch Failure Incorrect input state detected for the power steering

switch circuit. PL: High pressure seen at high speed.

P0600 (M) PCM Failure SPI Communications No communication detected between co-processors in

the control module.

P0601 (M) Internal Controller Failure Internal control module fault condition (check sum)

detected.

P0604 Internal Trans Controller Transmission control module RAM self test fault

detected. -Aisin transmission.

P0605 Internal Trans Controller Transmission control module ROM self test fault

detected -Aisin transmission.

P0622 (G) Generator Field Not Switching

ProperlyAn open or shorted condition detected in the generator

field control circuit.

P0645 A/C Clutch Relay Circuit An open or shorted condition detected in the A/C clutch

relay control circuit.

P0700 (M) EATX Controller DTC Present This SBEC III or JTEC DTC indicates that the EATX or

Aisin controller has an active fault and has illuminated

the MIL via a CCD (EATX) or SCI (Aisin) message. The

specific fault must be acquired from the EATX via CCD

or from the Aisin via ISO-9141.

P0703 (M) Brake Switch Stuck Pressed or

ReleasedIncorrect input state detected in the brake switch circuit.

(Changed from P1595).

P0711 Trans Temp Sensor, No Temp Rise

After StartRelationship between the transmission temperature and

overdrive operation and/or TCC operation indicates a

failure of the Transmission Temperature Sensor. OBD II

Rationality.

P0712 Trans Temp Sensor Voltage Too

LowTransmission fluid temperature sensor input below

acceptable voltage.

P0713 Trans Temp Sensor Voltage Too

HighTransmission fluid temperature sensor input above

acceptable voltage.

P0720 Low Output SPD Sensor RPM,

Above 15 MPHThe relationship between the Output Shaft Speed

Sensor and vehicle speed is not within acceptable

limits.

25 - 10 EMISSION CONTROL SYSTEMSPL

DESCRIPTION AND OPERATION (Continued)

Page 1098 of 1285

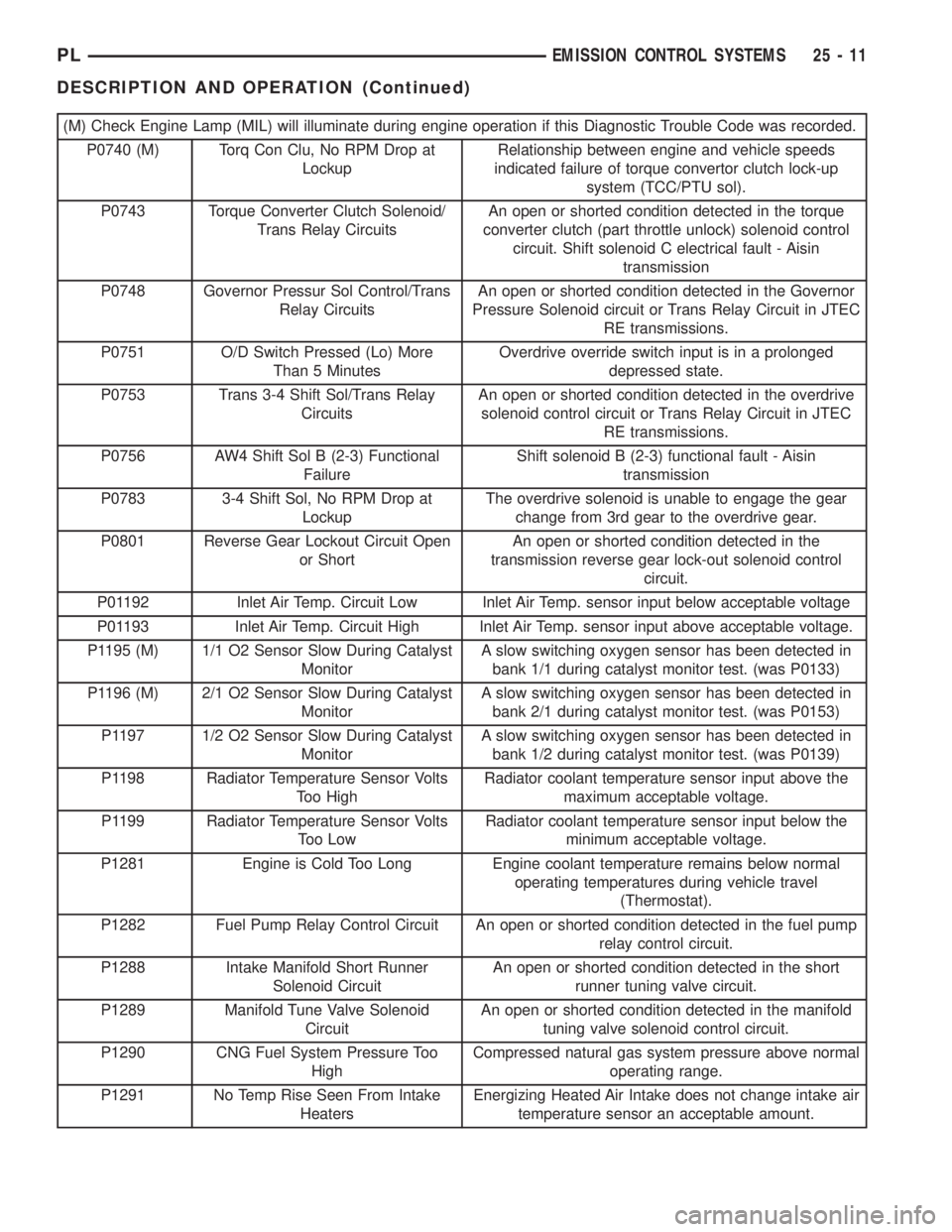

(M) Check Engine Lamp (MIL) will illuminate during engine operation if this Diagnostic Trouble Code was recorded.

P0740 (M) Torq Con Clu, No RPM Drop at

LockupRelationship between engine and vehicle speeds

indicated failure of torque convertor clutch lock-up

system (TCC/PTU sol).

P0743 Torque Converter Clutch Solenoid/

Trans Relay CircuitsAn open or shorted condition detected in the torque

converter clutch (part throttle unlock) solenoid control

circuit. Shift solenoid C electrical fault - Aisin

transmission

P0748 Governor Pressur Sol Control/Trans

Relay CircuitsAn open or shorted condition detected in the Governor

Pressure Solenoid circuit or Trans Relay Circuit in JTEC

RE transmissions.

P0751 O/D Switch Pressed (Lo) More

Than 5 MinutesOverdrive override switch input is in a prolonged

depressed state.

P0753 Trans 3-4 Shift Sol/Trans Relay

CircuitsAn open or shorted condition detected in the overdrive

solenoid control circuit or Trans Relay Circuit in JTEC

RE transmissions.

P0756 AW4 Shift Sol B (2-3) Functional

FailureShift solenoid B (2-3) functional fault - Aisin

transmission

P0783 3-4 Shift Sol, No RPM Drop at

LockupThe overdrive solenoid is unable to engage the gear

change from 3rd gear to the overdrive gear.

P0801 Reverse Gear Lockout Circuit Open

or ShortAn open or shorted condition detected in the

transmission reverse gear lock-out solenoid control

circuit.

P01192 Inlet Air Temp. Circuit Low Inlet Air Temp. sensor input below acceptable voltage

P01193 Inlet Air Temp. Circuit High Inlet Air Temp. sensor input above acceptable voltage.

P1195 (M) 1/1 O2 Sensor Slow During Catalyst

MonitorA slow switching oxygen sensor has been detected in

bank 1/1 during catalyst monitor test. (was P0133)

P1196 (M) 2/1 O2 Sensor Slow During Catalyst

MonitorA slow switching oxygen sensor has been detected in

bank 2/1 during catalyst monitor test. (was P0153)

P1197 1/2 O2 Sensor Slow During Catalyst

MonitorA slow switching oxygen sensor has been detected in

bank 1/2 during catalyst monitor test. (was P0139)

P1198 Radiator Temperature Sensor Volts

Too HighRadiator coolant temperature sensor input above the

maximum acceptable voltage.

P1199 Radiator Temperature Sensor Volts

Too LowRadiator coolant temperature sensor input below the

minimum acceptable voltage.

P1281 Engine is Cold Too Long Engine coolant temperature remains below normal

operating temperatures during vehicle travel

(Thermostat).

P1282 Fuel Pump Relay Control Circuit An open or shorted condition detected in the fuel pump

relay control circuit.

P1288 Intake Manifold Short Runner

Solenoid CircuitAn open or shorted condition detected in the short

runner tuning valve circuit.

P1289 Manifold Tune Valve Solenoid

CircuitAn open or shorted condition detected in the manifold

tuning valve solenoid control circuit.

P1290 CNG Fuel System Pressure Too

HighCompressed natural gas system pressure above normal

operating range.

P1291 No Temp Rise Seen From Intake

HeatersEnergizing Heated Air Intake does not change intake air

temperature sensor an acceptable amount.

PLEMISSION CONTROL SYSTEMS 25 - 11

DESCRIPTION AND OPERATION (Continued)

Page 1099 of 1285

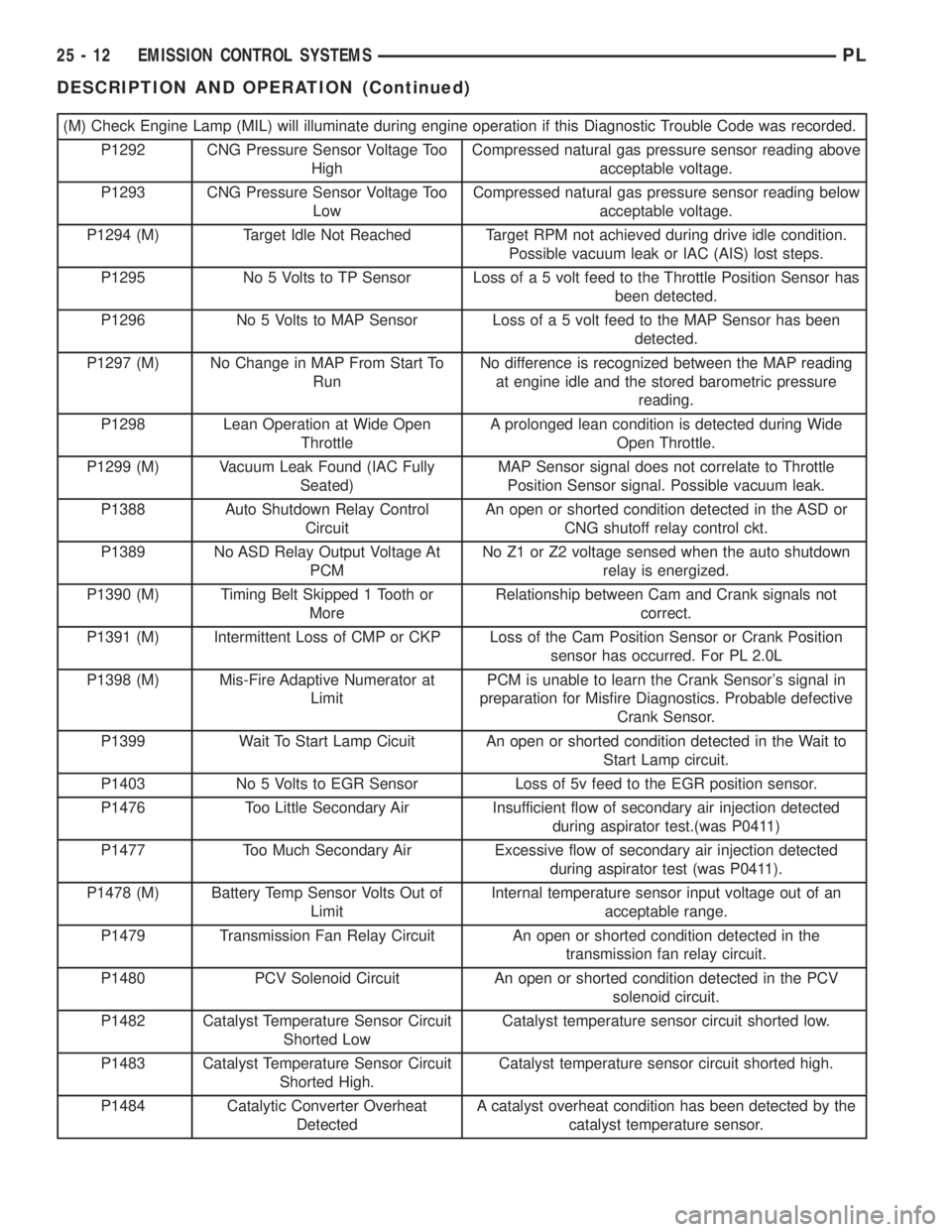

(M) Check Engine Lamp (MIL) will illuminate during engine operation if this Diagnostic Trouble Code was recorded.

P1292 CNG Pressure Sensor Voltage Too

HighCompressed natural gas pressure sensor reading above

acceptable voltage.

P1293 CNG Pressure Sensor Voltage Too

LowCompressed natural gas pressure sensor reading below

acceptable voltage.

P1294 (M) Target Idle Not Reached Target RPM not achieved during drive idle condition.

Possible vacuum leak or IAC (AIS) lost steps.

P1295 No 5 Volts to TP Sensor Loss of a 5 volt feed to the Throttle Position Sensor has

been detected.

P1296 No 5 Volts to MAP Sensor Loss of a 5 volt feed to the MAP Sensor has been

detected.

P1297 (M) No Change in MAP From Start To

RunNo difference is recognized between the MAP reading

at engine idle and the stored barometric pressure

reading.

P1298 Lean Operation at Wide Open

ThrottleA prolonged lean condition is detected during Wide

Open Throttle.

P1299 (M) Vacuum Leak Found (IAC Fully

Seated)MAP Sensor signal does not correlate to Throttle

Position Sensor signal. Possible vacuum leak.

P1388 Auto Shutdown Relay Control

CircuitAn open or shorted condition detected in the ASD or

CNG shutoff relay control ckt.

P1389 No ASD Relay Output Voltage At

PCMNo Z1 or Z2 voltage sensed when the auto shutdown

relay is energized.

P1390 (M) Timing Belt Skipped 1 Tooth or

MoreRelationship between Cam and Crank signals not

correct.

P1391 (M) Intermittent Loss of CMP or CKP Loss of the Cam Position Sensor or Crank Position

sensor has occurred. For PL 2.0L

P1398 (M) Mis-Fire Adaptive Numerator at

LimitPCM is unable to learn the Crank Sensor's signal in

preparation for Misfire Diagnostics. Probable defective

Crank Sensor.

P1399 Wait To Start Lamp Cicuit An open or shorted condition detected in the Wait to

Start Lamp circuit.

P1403 No 5 Volts to EGR Sensor Loss of 5v feed to the EGR position sensor.

P1476 Too Little Secondary Air Insufficient flow of secondary air injection detected

during aspirator test.(was P0411)

P1477 Too Much Secondary Air Excessive flow of secondary air injection detected

during aspirator test (was P0411).

P1478 (M) Battery Temp Sensor Volts Out of

LimitInternal temperature sensor input voltage out of an

acceptable range.

P1479 Transmission Fan Relay Circuit An open or shorted condition detected in the

transmission fan relay circuit.

P1480 PCV Solenoid Circuit An open or shorted condition detected in the PCV

solenoid circuit.

P1482 Catalyst Temperature Sensor Circuit

Shorted LowCatalyst temperature sensor circuit shorted low.

P1483 Catalyst Temperature Sensor Circuit

Shorted High.Catalyst temperature sensor circuit shorted high.

P1484 Catalytic Converter Overheat

DetectedA catalyst overheat condition has been detected by the

catalyst temperature sensor.

25 - 12 EMISSION CONTROL SYSTEMSPL

DESCRIPTION AND OPERATION (Continued)

Page 1101 of 1285

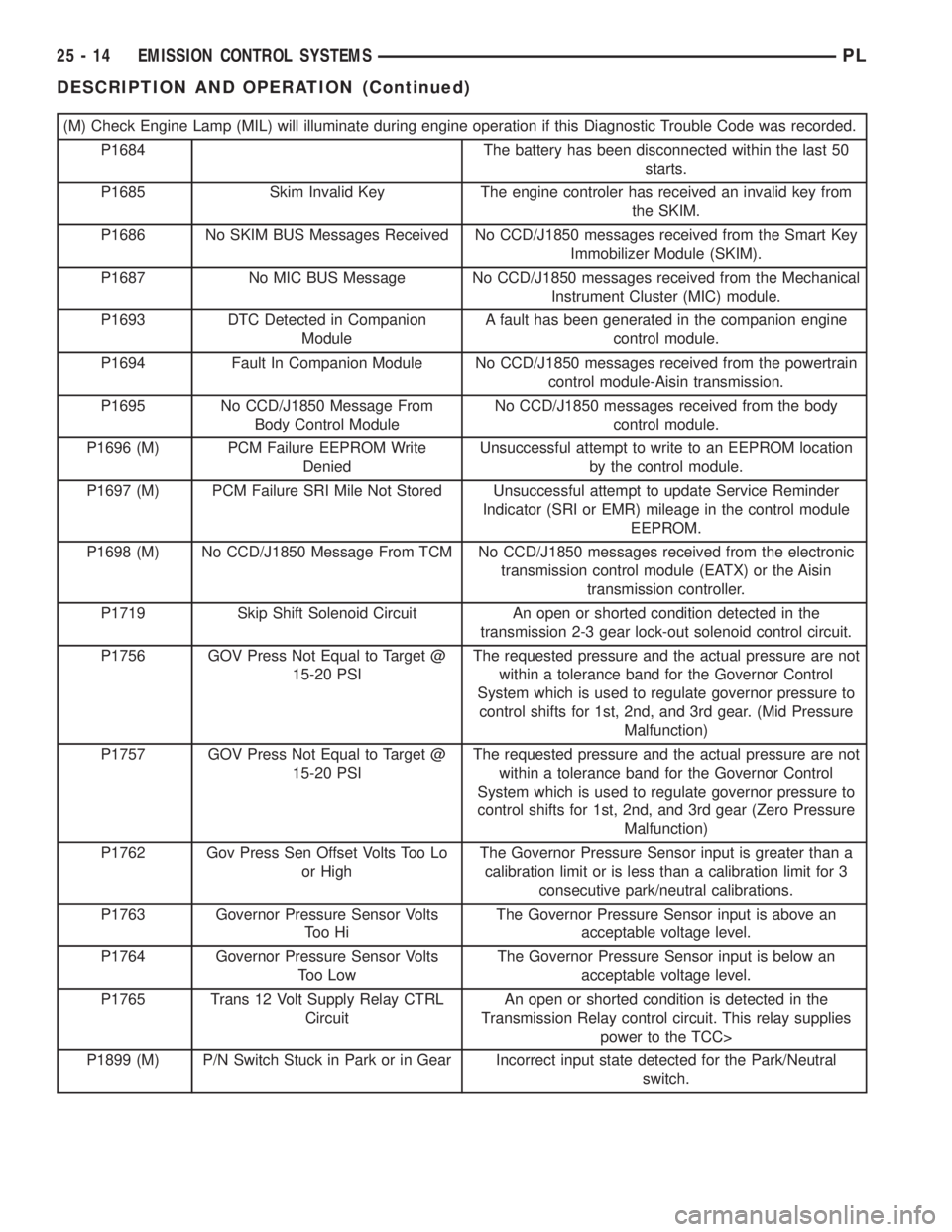

(M) Check Engine Lamp (MIL) will illuminate during engine operation if this Diagnostic Trouble Code was recorded.

P1684 The battery has been disconnected within the last 50

starts.

P1685 Skim Invalid Key The engine controler has received an invalid key from

the SKIM.

P1686 No SKIM BUS Messages Received No CCD/J1850 messages received from the Smart Key

Immobilizer Module (SKIM).

P1687 No MIC BUS Message No CCD/J1850 messages received from the Mechanical

Instrument Cluster (MIC) module.

P1693 DTC Detected in Companion

ModuleA fault has been generated in the companion engine

control module.

P1694 Fault In Companion Module No CCD/J1850 messages received from the powertrain

control module-Aisin transmission.

P1695 No CCD/J1850 Message From

Body Control ModuleNo CCD/J1850 messages received from the body

control module.

P1696 (M) PCM Failure EEPROM Write

DeniedUnsuccessful attempt to write to an EEPROM location

by the control module.

P1697 (M) PCM Failure SRI Mile Not Stored Unsuccessful attempt to update Service Reminder

Indicator (SRI or EMR) mileage in the control module

EEPROM.

P1698 (M) No CCD/J1850 Message From TCM No CCD/J1850 messages received from the electronic

transmission control module (EATX) or the Aisin

transmission controller.

P1719 Skip Shift Solenoid Circuit An open or shorted condition detected in the

transmission 2-3 gear lock-out solenoid control circuit.

P1756 GOV Press Not Equal to Target @

15-20 PSIThe requested pressure and the actual pressure are not

within a tolerance band for the Governor Control

System which is used to regulate governor pressure to

control shifts for 1st, 2nd, and 3rd gear. (Mid Pressure

Malfunction)

P1757 GOV Press Not Equal to Target @

15-20 PSIThe requested pressure and the actual pressure are not

within a tolerance band for the Governor Control

System which is used to regulate governor pressure to

control shifts for 1st, 2nd, and 3rd gear (Zero Pressure

Malfunction)

P1762 Gov Press Sen Offset Volts Too Lo

or HighThe Governor Pressure Sensor input is greater than a

calibration limit or is less than a calibration limit for 3

consecutive park/neutral calibrations.

P1763 Governor Pressure Sensor Volts

To o H iThe Governor Pressure Sensor input is above an

acceptable voltage level.

P1764 Governor Pressure Sensor Volts

Too LowThe Governor Pressure Sensor input is below an

acceptable voltage level.

P1765 Trans 12 Volt Supply Relay CTRL

CircuitAn open or shorted condition is detected in the

Transmission Relay control circuit. This relay supplies

power to the TCC>

P1899 (M) P/N Switch Stuck in Park or in Gear Incorrect input state detected for the Park/Neutral

switch.

25 - 14 EMISSION CONTROL SYSTEMSPL

DESCRIPTION AND OPERATION (Continued)

Page 1102 of 1285

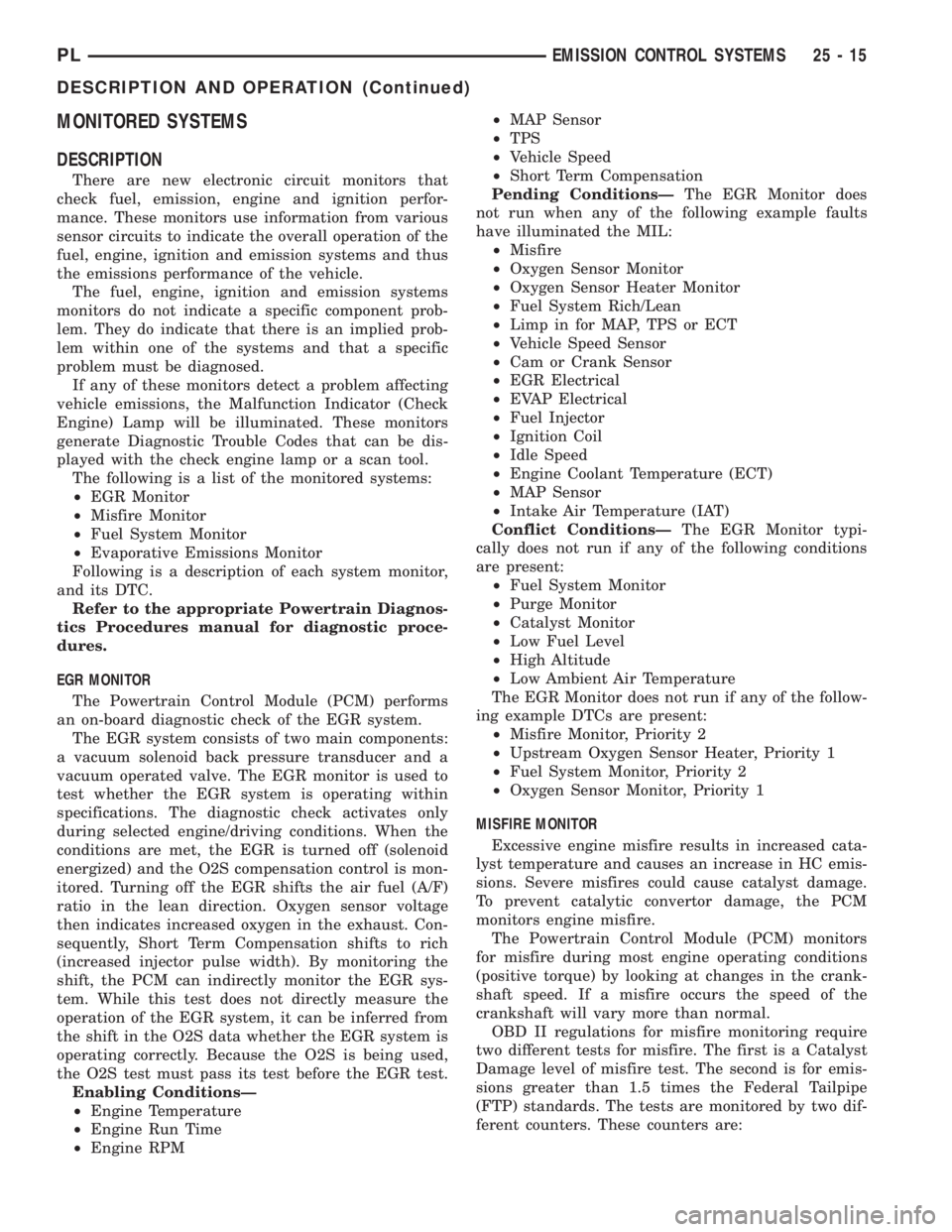

MONITORED SYSTEMS

DESCRIPTION

There are new electronic circuit monitors that

check fuel, emission, engine and ignition perfor-

mance. These monitors use information from various

sensor circuits to indicate the overall operation of the

fuel, engine, ignition and emission systems and thus

the emissions performance of the vehicle.

The fuel, engine, ignition and emission systems

monitors do not indicate a specific component prob-

lem. They do indicate that there is an implied prob-

lem within one of the systems and that a specific

problem must be diagnosed.

If any of these monitors detect a problem affecting

vehicle emissions, the Malfunction Indicator (Check

Engine) Lamp will be illuminated. These monitors

generate Diagnostic Trouble Codes that can be dis-

played with the check engine lamp or a scan tool.

The following is a list of the monitored systems:

²EGR Monitor

²Misfire Monitor

²Fuel System Monitor

²Evaporative Emissions Monitor

Following is a description of each system monitor,

and its DTC.

Refer to the appropriate Powertrain Diagnos-

tics Procedures manual for diagnostic proce-

dures.

EGR MONITOR

The Powertrain Control Module (PCM) performs

an on-board diagnostic check of the EGR system.

The EGR system consists of two main components:

a vacuum solenoid back pressure transducer and a

vacuum operated valve. The EGR monitor is used to

test whether the EGR system is operating within

specifications. The diagnostic check activates only

during selected engine/driving conditions. When the

conditions are met, the EGR is turned off (solenoid

energized) and the O2S compensation control is mon-

itored. Turning off the EGR shifts the air fuel (A/F)

ratio in the lean direction. Oxygen sensor voltage

then indicates increased oxygen in the exhaust. Con-

sequently, Short Term Compensation shifts to rich

(increased injector pulse width). By monitoring the

shift, the PCM can indirectly monitor the EGR sys-

tem. While this test does not directly measure the

operation of the EGR system, it can be inferred from

the shift in the O2S data whether the EGR system is

operating correctly. Because the O2S is being used,

the O2S test must pass its test before the EGR test.

Enabling ConditionsÐ

²Engine Temperature

²Engine Run Time

²Engine RPM²MAP Sensor

²TPS

²Vehicle Speed

²Short Term Compensation

Pending ConditionsÐThe EGR Monitor does

not run when any of the following example faults

have illuminated the MIL:

²Misfire

²Oxygen Sensor Monitor

²Oxygen Sensor Heater Monitor

²Fuel System Rich/Lean

²Limp in for MAP, TPS or ECT

²Vehicle Speed Sensor

²Cam or Crank Sensor

²EGR Electrical

²EVAP Electrical

²Fuel Injector

²Ignition Coil

²Idle Speed

²Engine Coolant Temperature (ECT)

²MAP Sensor

²Intake Air Temperature (IAT)

Conflict ConditionsÐThe EGR Monitor typi-

cally does not run if any of the following conditions

are present:

²Fuel System Monitor

²Purge Monitor

²Catalyst Monitor

²Low Fuel Level

²High Altitude

²Low Ambient Air Temperature

The EGR Monitor does not run if any of the follow-

ing example DTCs are present:

²Misfire Monitor, Priority 2

²Upstream Oxygen Sensor Heater, Priority 1

²Fuel System Monitor, Priority 2

²Oxygen Sensor Monitor, Priority 1

MISFIRE MONITOR

Excessive engine misfire results in increased cata-

lyst temperature and causes an increase in HC emis-

sions. Severe misfires could cause catalyst damage.

To prevent catalytic convertor damage, the PCM

monitors engine misfire.

The Powertrain Control Module (PCM) monitors

for misfire during most engine operating conditions

(positive torque) by looking at changes in the crank-

shaft speed. If a misfire occurs the speed of the

crankshaft will vary more than normal.

OBD II regulations for misfire monitoring require

two different tests for misfire. The first is a Catalyst

Damage level of misfire test. The second is for emis-

sions greater than 1.5 times the Federal Tailpipe

(FTP) standards. The tests are monitored by two dif-

ferent counters. These counters are:

PLEMISSION CONTROL SYSTEMS 25 - 15

DESCRIPTION AND OPERATION (Continued)

Page 1105 of 1285

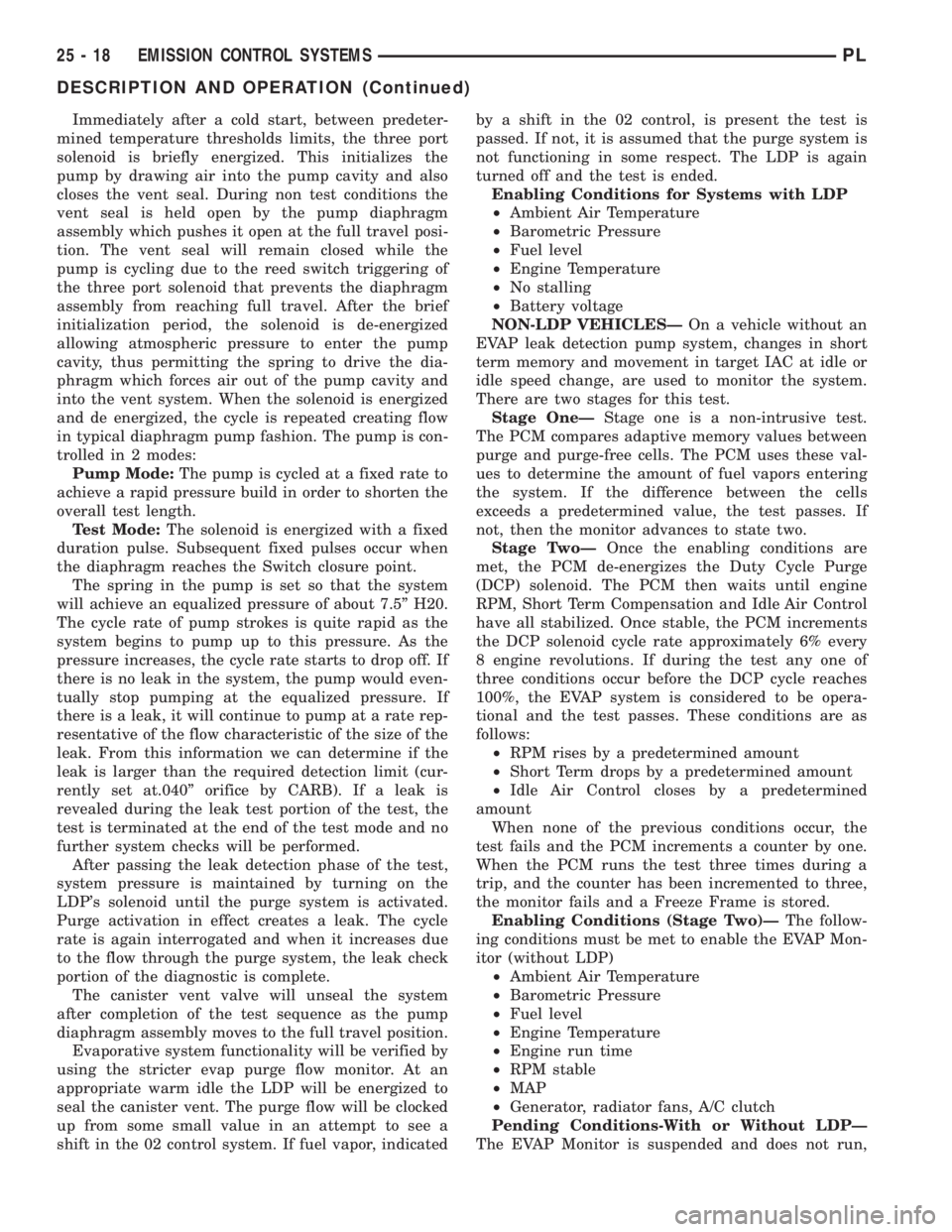

Immediately after a cold start, between predeter-

mined temperature thresholds limits, the three port

solenoid is briefly energized. This initializes the

pump by drawing air into the pump cavity and also

closes the vent seal. During non test conditions the

vent seal is held open by the pump diaphragm

assembly which pushes it open at the full travel posi-

tion. The vent seal will remain closed while the

pump is cycling due to the reed switch triggering of

the three port solenoid that prevents the diaphragm

assembly from reaching full travel. After the brief

initialization period, the solenoid is de-energized

allowing atmospheric pressure to enter the pump

cavity, thus permitting the spring to drive the dia-

phragm which forces air out of the pump cavity and

into the vent system. When the solenoid is energized

and de energized, the cycle is repeated creating flow

in typical diaphragm pump fashion. The pump is con-

trolled in 2 modes:

Pump Mode:The pump is cycled at a fixed rate to

achieve a rapid pressure build in order to shorten the

overall test length.

Test Mode:The solenoid is energized with a fixed

duration pulse. Subsequent fixed pulses occur when

the diaphragm reaches the Switch closure point.

The spring in the pump is set so that the system

will achieve an equalized pressure of about 7.5º H20.

The cycle rate of pump strokes is quite rapid as the

system begins to pump up to this pressure. As the

pressure increases, the cycle rate starts to drop off. If

there is no leak in the system, the pump would even-

tually stop pumping at the equalized pressure. If

there is a leak, it will continue to pump at a rate rep-

resentative of the flow characteristic of the size of the

leak. From this information we can determine if the

leak is larger than the required detection limit (cur-

rently set at.040º orifice by CARB). If a leak is

revealed during the leak test portion of the test, the

test is terminated at the end of the test mode and no

further system checks will be performed.

After passing the leak detection phase of the test,

system pressure is maintained by turning on the

LDP's solenoid until the purge system is activated.

Purge activation in effect creates a leak. The cycle

rate is again interrogated and when it increases due

to the flow through the purge system, the leak check

portion of the diagnostic is complete.

The canister vent valve will unseal the system

after completion of the test sequence as the pump

diaphragm assembly moves to the full travel position.

Evaporative system functionality will be verified by

using the stricter evap purge flow monitor. At an

appropriate warm idle the LDP will be energized to

seal the canister vent. The purge flow will be clocked

up from some small value in an attempt to see a

shift in the 02 control system. If fuel vapor, indicatedby a shift in the 02 control, is present the test is

passed. If not, it is assumed that the purge system is

not functioning in some respect. The LDP is again

turned off and the test is ended.

Enabling Conditions for Systems with LDP

²Ambient Air Temperature

²Barometric Pressure

²Fuel level

²Engine Temperature

²No stalling

²Battery voltage

NON-LDP VEHICLESÐOn a vehicle without an

EVAP leak detection pump system, changes in short

term memory and movement in target IAC at idle or

idle speed change, are used to monitor the system.

There are two stages for this test.

Stage OneÐStage one is a non-intrusive test.

The PCM compares adaptive memory values between

purge and purge-free cells. The PCM uses these val-

ues to determine the amount of fuel vapors entering

the system. If the difference between the cells

exceeds a predetermined value, the test passes. If

not, then the monitor advances to state two.

Stage TwoÐOnce the enabling conditions are

met, the PCM de-energizes the Duty Cycle Purge

(DCP) solenoid. The PCM then waits until engine

RPM, Short Term Compensation and Idle Air Control

have all stabilized. Once stable, the PCM increments

the DCP solenoid cycle rate approximately 6% every

8 engine revolutions. If during the test any one of

three conditions occur before the DCP cycle reaches

100%, the EVAP system is considered to be opera-

tional and the test passes. These conditions are as

follows:

²RPM rises by a predetermined amount

²Short Term drops by a predetermined amount

²Idle Air Control closes by a predetermined

amount

When none of the previous conditions occur, the

test fails and the PCM increments a counter by one.

When the PCM runs the test three times during a

trip, and the counter has been incremented to three,

the monitor fails and a Freeze Frame is stored.

Enabling Conditions (Stage Two)ÐThe follow-

ing conditions must be met to enable the EVAP Mon-

itor (without LDP)

²Ambient Air Temperature

²Barometric Pressure

²Fuel level

²Engine Temperature

²Engine run time

²RPM stable

²MAP

²Generator, radiator fans, A/C clutch

Pending Conditions-With or Without LDPÐ

The EVAP Monitor is suspended and does not run,

25 - 18 EMISSION CONTROL SYSTEMSPL

DESCRIPTION AND OPERATION (Continued)

Page 1106 of 1285

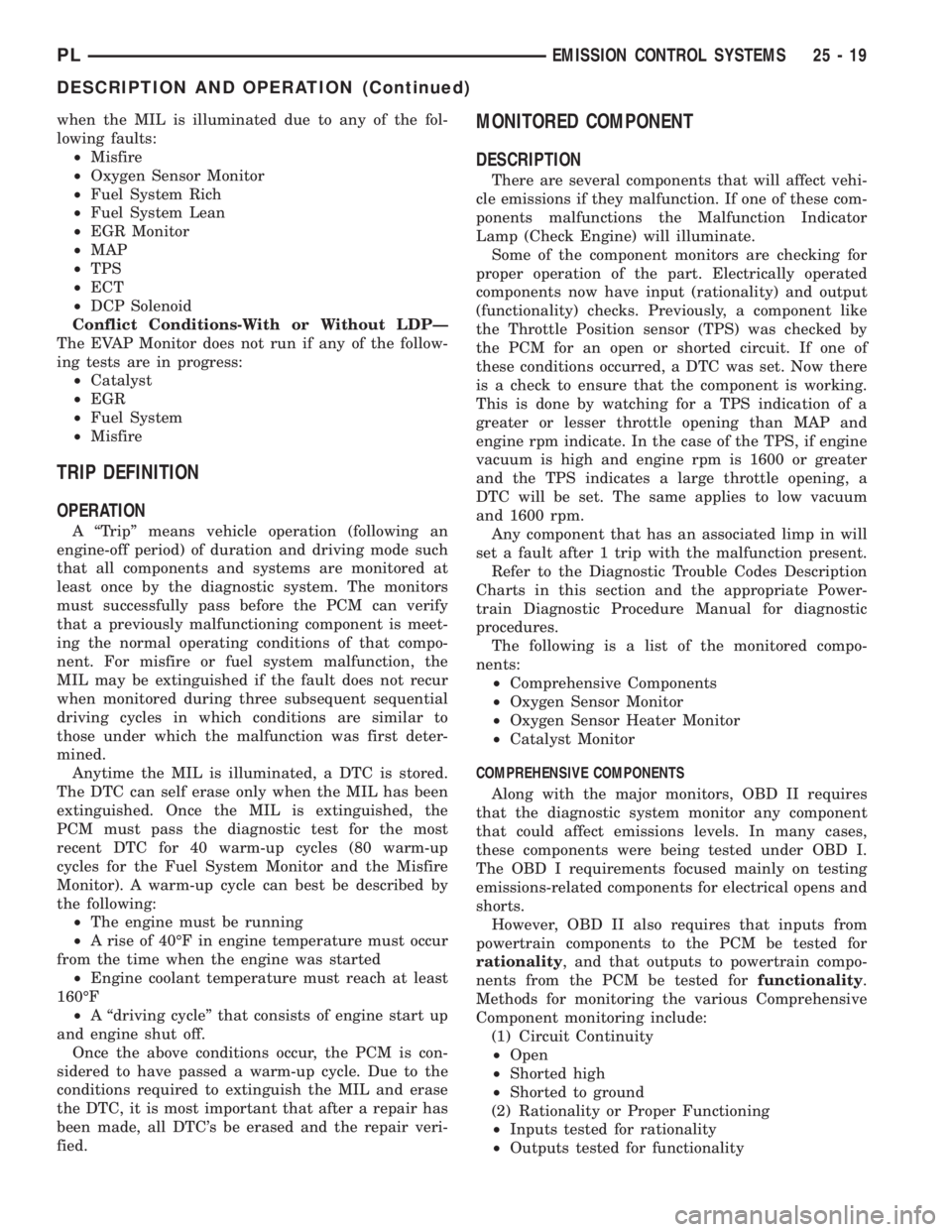

when the MIL is illuminated due to any of the fol-

lowing faults:

²Misfire

²Oxygen Sensor Monitor

²Fuel System Rich

²Fuel System Lean

²EGR Monitor

²MAP

²TPS

²ECT

²DCP Solenoid

Conflict Conditions-With or Without LDPÐ

The EVAP Monitor does not run if any of the follow-

ing tests are in progress:

²Catalyst

²EGR

²Fuel System

²Misfire

TRIP DEFINITION

OPERATION

A ªTripº means vehicle operation (following an

engine-off period) of duration and driving mode such

that all components and systems are monitored at

least once by the diagnostic system. The monitors

must successfully pass before the PCM can verify

that a previously malfunctioning component is meet-

ing the normal operating conditions of that compo-

nent. For misfire or fuel system malfunction, the

MIL may be extinguished if the fault does not recur

when monitored during three subsequent sequential

driving cycles in which conditions are similar to

those under which the malfunction was first deter-

mined.

Anytime the MIL is illuminated, a DTC is stored.

The DTC can self erase only when the MIL has been

extinguished. Once the MIL is extinguished, the

PCM must pass the diagnostic test for the most

recent DTC for 40 warm-up cycles (80 warm-up

cycles for the Fuel System Monitor and the Misfire

Monitor). A warm-up cycle can best be described by

the following:

²The engine must be running

²A rise of 40ÉF in engine temperature must occur

from the time when the engine was started

²Engine coolant temperature must reach at least

160ÉF

²A ªdriving cycleº that consists of engine start up

and engine shut off.

Once the above conditions occur, the PCM is con-

sidered to have passed a warm-up cycle. Due to the

conditions required to extinguish the MIL and erase

the DTC, it is most important that after a repair has

been made, all DTC's be erased and the repair veri-

fied.

MONITORED COMPONENT

DESCRIPTION

There are several components that will affect vehi-

cle emissions if they malfunction. If one of these com-

ponents malfunctions the Malfunction Indicator

Lamp (Check Engine) will illuminate.

Some of the component monitors are checking for

proper operation of the part. Electrically operated

components now have input (rationality) and output

(functionality) checks. Previously, a component like

the Throttle Position sensor (TPS) was checked by

the PCM for an open or shorted circuit. If one of

these conditions occurred, a DTC was set. Now there

is a check to ensure that the component is working.

This is done by watching for a TPS indication of a

greater or lesser throttle opening than MAP and

engine rpm indicate. In the case of the TPS, if engine

vacuum is high and engine rpm is 1600 or greater

and the TPS indicates a large throttle opening, a

DTC will be set. The same applies to low vacuum

and 1600 rpm.

Any component that has an associated limp in will

set a fault after 1 trip with the malfunction present.

Refer to the Diagnostic Trouble Codes Description

Charts in this section and the appropriate Power-

train Diagnostic Procedure Manual for diagnostic

procedures.

The following is a list of the monitored compo-

nents:

²Comprehensive Components

²Oxygen Sensor Monitor

²Oxygen Sensor Heater Monitor

²Catalyst Monitor

COMPREHENSIVE COMPONENTS

Along with the major monitors, OBD II requires

that the diagnostic system monitor any component

that could affect emissions levels. In many cases,

these components were being tested under OBD I.

The OBD I requirements focused mainly on testing

emissions-related components for electrical opens and

shorts.

However, OBD II also requires that inputs from

powertrain components to the PCM be tested for

rationality, and that outputs to powertrain compo-

nents from the PCM be tested forfunctionality.

Methods for monitoring the various Comprehensive

Component monitoring include:

(1) Circuit Continuity

²Open

²Shorted high

²Shorted to ground

(2) Rationality or Proper Functioning

²Inputs tested for rationality

²Outputs tested for functionality

PLEMISSION CONTROL SYSTEMS 25 - 19

DESCRIPTION AND OPERATION (Continued)

Page 1107 of 1285

NOTE: Comprehensive component monitors are

continuous. Therefore, enabling conditions do not

apply.

Input RationalityÐWhile input signals to the

PCM are constantly being monitored for electrical

opens and shorts, they are also tested for rationality.

This means that the input signal is compared against

other inputs and information to see if it makes sense

under the current conditions.

PCM sensor inputs that are checked for rationality

include:

²Manifold Absolute Pressure (MAP) Sensor

²Oxygen Sensor (O2S)

²Engine Coolant Temperature (ECT) Sensor

²Camshaft Position (CMP) Sensor

²Vehicle Speed Sensor

²Crankshaft Position (CKP) Sensor

²Intake Air Temperature (IAT) Sensor

²Throttle Position (TPS) Sensor

²Ambient/Battery Temperature Sensors

²Power Steering Switch

²Oxygen Sensor Heater

²Engine Controller

²Brake Switch

²Leak Detection Pump Switch

²P/N Switch

²Trans Controls

Output FunctionalityÐPCM outputs are tested

for functionality in addition to testing for opens and

shorts. When the PCM provides a voltage to an out-

put component, it can verify that the command was

carried out by monitoring specific input signals for

expected changes. For example, when the PCM com-

mands the Idle Air Control (IAC) Motor to a specific

position under certain operating conditions, it expects

to see a specific (target) idle speed (RPM). If it does

not, it stores a DTC.

PCM outputs monitored for functionality include:

²Fuel Injectors

²Ignition Coils

²Torque Converter Clutch Solenoid

²Idle Air Control

²Purge Solenoid

²EGR Solenoid

²LDP Solenoid

²Radiator Fan Control

²Trans Controls

OXYGEN SENSOR (O2S) MONITOR

DESCRIPTIONÐEffective control of exhaust

emissions is achieved by an oxygen feedback system.

The most important element of the feedback system

is the O2S. The O2S is located in the exhaust path.

Once it reaches operating temperature 300É to 350ÉC

(572É to 662ÉF), the sensor generates a voltage that

is inversely proportional to the amount of oxygen inthe exhaust. When there is a large amount of oxygen

in the exhaust caused by a lean condition, the sensor

produces a low voltage, below 450 mV. When the oxy-

gen content is lower, caused by a rich condition, the

sensor produces a higher voltage, above 450mV.

The information obtained by the sensor is used to

calculate the fuel injector pulse width. This main-

tains a 14.7 to 1 air fuel (A/F) ratio. At this mixture

ratio, the catalyst works best to remove hydrocarbons

(HC), carbon monoxide (CO) and nitrous oxide (NOx)

from the exhaust.

The O2S is also the main sensing element for the

EGR, Catalyst and Fuel Monitors.

The O2S may fail in any or all of the following

manners:

²Slow response rate (Big Slope)

²Reduced output voltage (Half Cycle)

²Heater Performance

Slow Response Rate (Big Slope)ÐResponse

rate is the time required for the sensor to switch

from lean to rich signal output once it is exposed to a

richer than optimum A/F mixture or vice versa. As

the PCM adjusts the air/fuel ratio, the sensor must

be able to rapidly detect the change. As the sensor

ages, it could take longer to detect the changes in the

oxygen content of the exhaust gas. The rate of

change that an oxygen sensor experiences is called

'Big Slope'. The PCM checks the oxygen sensor volt-

age in increments of a few milliseconds.

Reduced Output Voltage (Half Cycle)ÐThe

output voltage of the O2S ranges from 0 to 1 volt. A

good sensor can easily generate any output voltage in

this range as it is exposed to different concentrations

of oxygen. To detect a shift in the A/F mixture (lean

or rich), the output voltage has to change beyond a

threshold value. A malfunctioning sensor could have

difficulty changing beyond the threshold value. Each

time the voltage signal surpasses the threshold, a

counter is incremented by one. This is called the Half

Cycle Counter.

Heater PerformanceÐThe heater is tested by a

separate monitor. Refer to the Oxygen Sensor Heater

Monitor.

OPERATIONÐAs the Oxygen Sensor signal

switches, the PCM monitors the half cycle and big

slope signals from the oxygen sensor. If during the

test neither counter reaches a predetermined value, a

malfunction is entered and a Freeze Frame is stored.

Only one counter reaching its predetermined value is

needed for the monitor to pass.

The Oxygen Sensor Monitor is a two trip monitor

that is tested only once per trip. When the Oxygen

Sensor fails the test in two consecutive trips, the

MIL is illuminated and a DTC is set. The MIL is

extinguished when the Oxygen Sensor monitor

passes in three consecutive trips. The DTC is erased

25 - 20 EMISSION CONTROL SYSTEMSPL

DESCRIPTION AND OPERATION (Continued)

Page 1108 of 1285

from memory after 40 consecutive warm-up cycles

without test failure.

Enabling ConditionsÐThe following conditions

must typically be met for the PCM to run the oxygen

sensor monitor:

²Battery voltage

²Engine temperature

²Engine run time

²Engine run time at a predetermined speed

²Engine run time at a predetermined speed and

throttle opening

²Transmission in gear (automatic only)

²Fuel system in Closed Loop

²Long Term Adaptive (within parameters)

²Power Steering Switch in low PSI (no load)

²Engine at idle

²Fuel level above 15%

²Ambient air temperature

²Barometric pressure

²Engine RPM within acceptable range of desired

idle

²Closed throttle speed

Pending ConditionsÐThe Task Manager typi-

cally does not run the Oxygen Sensor Monitor if over-

lapping monitors are running or the MIL is

illuminated for any of the following:

²Misfire Monitor

²Front Oxygen Sensor and Heater Monitor

²MAP Sensor

²Vehicle Speed Sensor

²Engine Coolant Temperature Sensor

²Throttle Position Sensor

²Engine Controller Self Test Faults

²Cam or Crank Sensor

²Injector and Coil

²Idle Air Control Motor

²EVAP Electrical

²EGR Solenoid Electrical

²Intake Air Temperature

²5 Volt Feed

ConflictÐThe Task Manager does not run the

Oxygen Sensor Monitor if any of the following condi-

tions are present:

²A/C ON (A/C clutch cycling temporarily sus-

pends monitor)

²Purge flow in progress

SuspendÐThe Task Manager suspends maturing

a fault for the Oxygen Sensor Monitor if an of the fol-

lowing are present:

²Oxygen Sensor Heater Monitor, Priority 1

²Misfire Monitor, Priority 2

OXYGEN SENSOR HEATER MONITOR

DESCRIPTIONÐIf there is an oxygen sensor

(O2S) DTC as well as a O2S heater DTC, the O2S

fault MUST be repaired first. After the O2S fault isrepaired, verify that the heater circuit is operating

correctly.

The voltage readings taken from the O2S are very

temperature sensitive. The readings are not accurate

below 300ÉC. Heating of the O2S is done to allow the

engine controller to shift to closed loop control as

soon as possible. The heating element used to heat

the O2S must be tested to ensure that it is heating

the sensor properly.

The heater element itself is not tested. The sensor

output is used to test the heater by isolating the

effect of the heater element on the O2S output volt-

age from the other effects. The resistance is normally

between 100 ohms and 4.5 megaohms. When oxygen

sensor temperature increases, the resistance in the

internal circuit decreases. The PCM sends a 5 volts

biased signal through the oxygen sensors to ground

this monitoring circuit. As the temperature increases,

resistance decreases and the PCM detects a lower

voltage at the reference signal. Inversely, as the tem-

perature decreases, the resistance increases and the

PCM detects a higher voltage at the reference signal.

an The O2S circuit is monitored for a drop in voltage.

OPERATIONÐThe Oxygen Sensor Heater Moni-

tor begins after the ignition has been turned OFF

and the O2 sensors have cooled. The PCM sends a 5

volt bias to the oxygen sensor every 1.6 seconds. The

PCM keeps it biased for 35 ms each time. As the sen-

sor cools down, the resistance increases and the PCM

reads the increase in voltage. Once voltage has

increased to a predetermined amount, higher than

when the test started, the oxygen sensor is cool

enough to test heater operation.

When the oxygen sensor is cool enough, the PCM

energizes the ASD relay. Voltage to the O2 sensor

begins to increase the temperature. As the sensor

temperature increases, the internal resistance

decreases. The PCM continues biasing the 5 volt sig-

nal to the sensor. Each time the signal is biased, the

PCM reads a voltage decrease. When the PCM

detects a voltage decrease of a predetermined value

for several biased pulses, the test passes.

The heater elements are tested each time the

engine is turned OFF if all the enabling conditions

are met. If the monitor fails, the PCM stores a

maturing fault and a Freeze Frame is entered. If two

consecutive tests fail, a DTC is stored. Because the

ignition is OFF, the MIL is illuminated at the begin-

ning of the next key cycle.

Enabling ConditionsÐThe following conditions

must be met for the PCM to run the oxygen sensor

heater test:

²Engine run time of at least 5.1 minutes

²Key OFF power down

²Battery voltage of at least 10 volts

²Sufficient Oxygen Sensor cool down

PLEMISSION CONTROL SYSTEMS 25 - 21

DESCRIPTION AND OPERATION (Continued)