tra DODGE NEON 2000 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 1132 of 1285

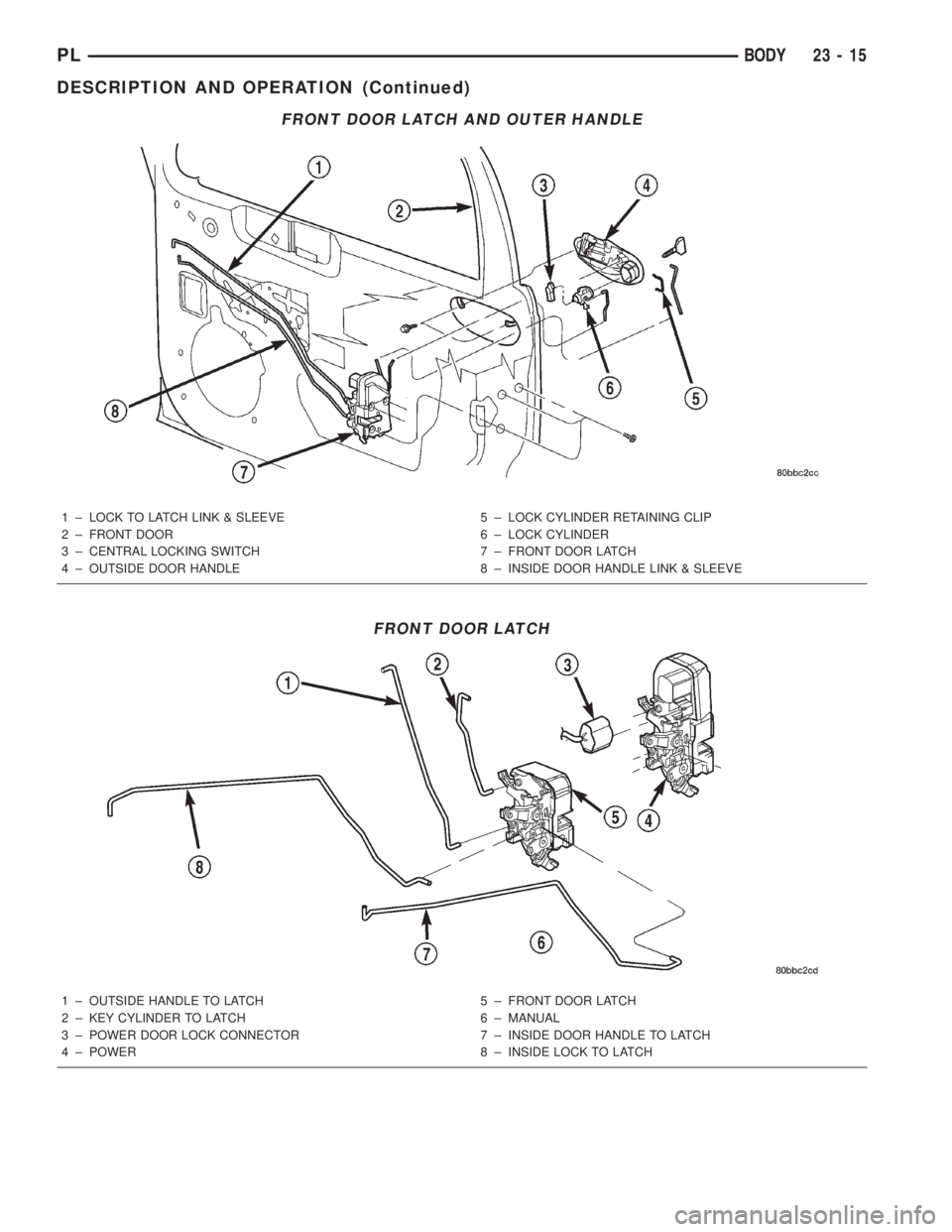

FRONT DOOR LATCH AND OUTER HANDLE

1 ± LOCK TO LATCH LINK & SLEEVE

2 ± FRONT DOOR

3 ± CENTRAL LOCKING SWITCH

4 ± OUTSIDE DOOR HANDLE5 ± LOCK CYLINDER RETAINING CLIP

6 ± LOCK CYLINDER

7 ± FRONT DOOR LATCH

8 ± INSIDE DOOR HANDLE LINK & SLEEVE

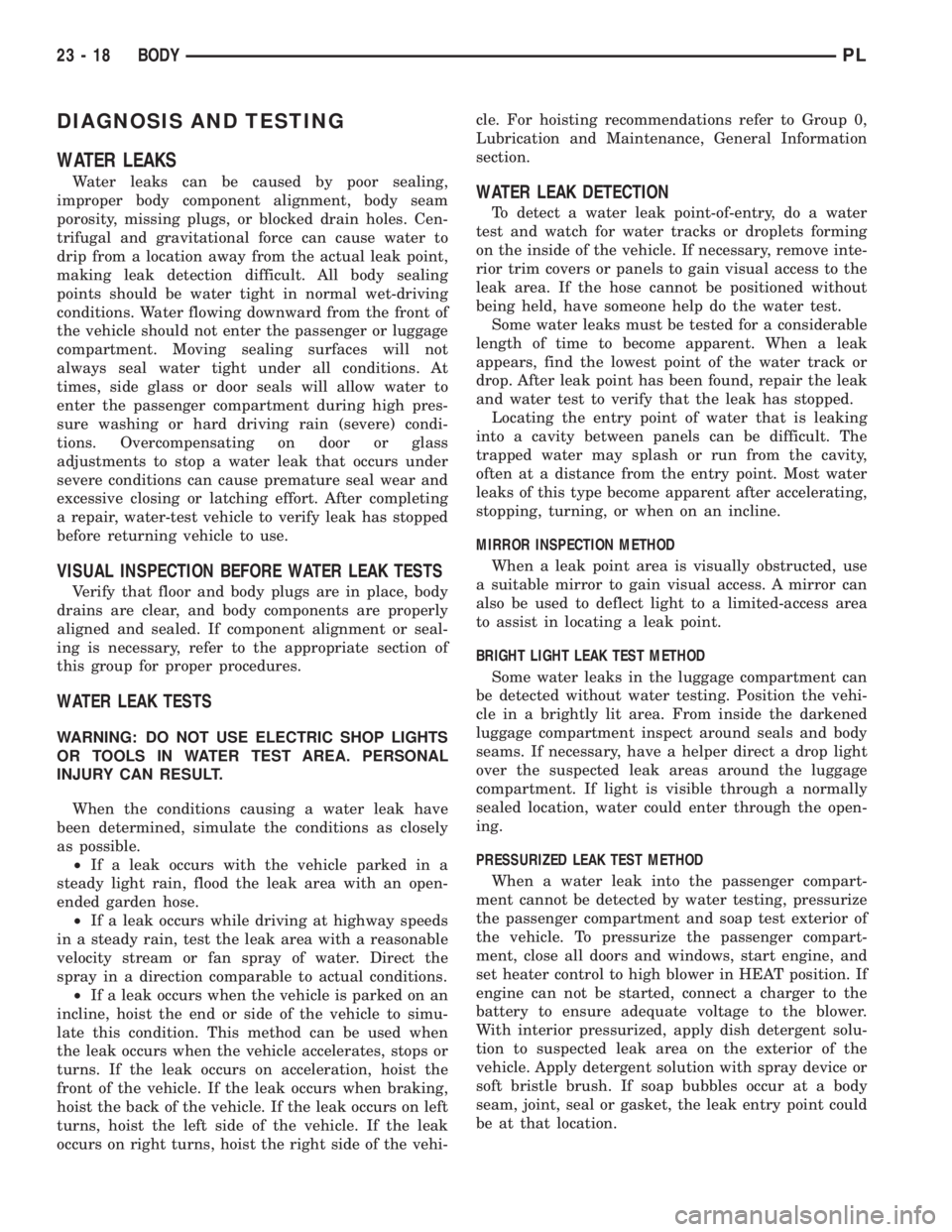

FRONT DOOR LATCH

1 ± OUTSIDE HANDLE TO LATCH

2 ± KEY CYLINDER TO LATCH

3 ± POWER DOOR LOCK CONNECTOR

4 ± POWER5 ± FRONT DOOR LATCH

6 ± MANUAL

7 ± INSIDE DOOR HANDLE TO LATCH

8 ± INSIDE LOCK TO LATCH

PLBODY 23 - 15

DESCRIPTION AND OPERATION (Continued)

Page 1135 of 1285

DIAGNOSIS AND TESTING

WATER LEAKS

Water leaks can be caused by poor sealing,

improper body component alignment, body seam

porosity, missing plugs, or blocked drain holes. Cen-

trifugal and gravitational force can cause water to

drip from a location away from the actual leak point,

making leak detection difficult. All body sealing

points should be water tight in normal wet-driving

conditions. Water flowing downward from the front of

the vehicle should not enter the passenger or luggage

compartment. Moving sealing surfaces will not

always seal water tight under all conditions. At

times, side glass or door seals will allow water to

enter the passenger compartment during high pres-

sure washing or hard driving rain (severe) condi-

tions. Overcompensating on door or glass

adjustments to stop a water leak that occurs under

severe conditions can cause premature seal wear and

excessive closing or latching effort. After completing

a repair, water-test vehicle to verify leak has stopped

before returning vehicle to use.

VISUAL INSPECTION BEFORE WATER LEAK TESTS

Verify that floor and body plugs are in place, body

drains are clear, and body components are properly

aligned and sealed. If component alignment or seal-

ing is necessary, refer to the appropriate section of

this group for proper procedures.

WATER LEAK TESTS

WARNING: DO NOT USE ELECTRIC SHOP LIGHTS

OR TOOLS IN WATER TEST AREA. PERSONAL

INJURY CAN RESULT.

When the conditions causing a water leak have

been determined, simulate the conditions as closely

as possible.

²If a leak occurs with the vehicle parked in a

steady light rain, flood the leak area with an open-

ended garden hose.

²If a leak occurs while driving at highway speeds

in a steady rain, test the leak area with a reasonable

velocity stream or fan spray of water. Direct the

spray in a direction comparable to actual conditions.

²If a leak occurs when the vehicle is parked on an

incline, hoist the end or side of the vehicle to simu-

late this condition. This method can be used when

the leak occurs when the vehicle accelerates, stops or

turns. If the leak occurs on acceleration, hoist the

front of the vehicle. If the leak occurs when braking,

hoist the back of the vehicle. If the leak occurs on left

turns, hoist the left side of the vehicle. If the leak

occurs on right turns, hoist the right side of the vehi-cle. For hoisting recommendations refer to Group 0,

Lubrication and Maintenance, General Information

section.

WATER LEAK DETECTION

To detect a water leak point-of-entry, do a water

test and watch for water tracks or droplets forming

on the inside of the vehicle. If necessary, remove inte-

rior trim covers or panels to gain visual access to the

leak area. If the hose cannot be positioned without

being held, have someone help do the water test.

Some water leaks must be tested for a considerable

length of time to become apparent. When a leak

appears, find the lowest point of the water track or

drop. After leak point has been found, repair the leak

and water test to verify that the leak has stopped.

Locating the entry point of water that is leaking

into a cavity between panels can be difficult. The

trapped water may splash or run from the cavity,

often at a distance from the entry point. Most water

leaks of this type become apparent after accelerating,

stopping, turning, or when on an incline.

MIRROR INSPECTION METHOD

When a leak point area is visually obstructed, use

a suitable mirror to gain visual access. A mirror can

also be used to deflect light to a limited-access area

to assist in locating a leak point.

BRIGHT LIGHT LEAK TEST METHOD

Some water leaks in the luggage compartment can

be detected without water testing. Position the vehi-

cle in a brightly lit area. From inside the darkened

luggage compartment inspect around seals and body

seams. If necessary, have a helper direct a drop light

over the suspected leak areas around the luggage

compartment. If light is visible through a normally

sealed location, water could enter through the open-

ing.

PRESSURIZED LEAK TEST METHOD

When a water leak into the passenger compart-

ment cannot be detected by water testing, pressurize

the passenger compartment and soap test exterior of

the vehicle. To pressurize the passenger compart-

ment, close all doors and windows, start engine, and

set heater control to high blower in HEAT position. If

engine can not be started, connect a charger to the

battery to ensure adequate voltage to the blower.

With interior pressurized, apply dish detergent solu-

tion to suspected leak area on the exterior of the

vehicle. Apply detergent solution with spray device or

soft bristle brush. If soap bubbles occur at a body

seam, joint, seal or gasket, the leak entry point could

be at that location.

23 - 18 BODYPL

Page 1136 of 1285

WIND NOISE

Wind noise is the result of most air leaks. Air leaks

can be caused by poor sealing, improper body compo-

nent alignment, body seam porosity, or missing plugs

in the engine compartment or door hinge pillar areas.

All body sealing points should be airtight in normal

driving conditions. Moving sealing surfaces will not

always seal airtight under all conditions. At times,

side glass or door seals will allow wind noise to be

noticed in the passenger compartment during high

cross winds. Over compensating on door or glass

adjustments to stop wind noise that occurs under

severe conditions can cause premature seal wear and

excessive closing or latching effort. After a repair pro-

cedure has been performed, test vehicle to verify

noise has stopped before returning vehicle to use.

Wind noise can also be caused by improperly fitted

exterior moldings or body ornamentation. Loose

moldings can flutter, creating a buzzing or chattering

noise. An open cavity or protruding edge can create a

whistling or howling noise. Inspect the exterior of the

vehicle to verify that these conditions do not exist.

VISUAL INSPECTION BEFORE TESTS

Verify that floor and body plugs are in place and

body components are aligned and sealed. If compo-

nent alignment or sealing is necessary, refer to the

appropriate section of this group for proper proce-

dures.

ROAD TESTING WIND NOISE

(1) Drive the vehicle to verify the general location

of the wind noise.

(2) Apply 50 mm (2 in.) masking tape in 150 mm

(6 in.) lengths along weatherstrips, weld seams or

moldings. After each length is applied, drive the vehi-

cle. If noise goes away after a piece of tape is applied,

remove tape, locate, and repair defect.

POSSIBLE CAUSE OF WIND NOISE

²Moldings standing away from body surface can

catch wind and whistle.

²Gaps in sealed areas behind overhanging body

flanges can cause wind-rushing sounds.

²Misaligned movable components.

²Missing or improperly installed plugs in pillars.

²Weld burn through holes.

SERVICE PROCEDURES

HEAT STAKING

(1) Remove trim panel.

(2) Bend or move the trim panel components at

the heat staked joints. Observe the heat staked loca-

tions and/or component seams for looseness.(3) Heat stake the components.

(a) If the heat staked or component seam loca-

tion is loose, hold the two components tightly

together and using a soldering gun with a flat tip,

melt the material securing the components

together. Do not over heat the affected area, dam-

age to the exterior of the trim panel may occur.

(b) If the heat staked material is broken or miss-

ing, use a hot glue gun to apply new material to

the area to be repaired. The panels that are being

heat staked must be held together while the apply-

ing the glue. Once the new material is in place, it

may be necessary to use a soldering gun to melt

the newly applied material. Do not over heat the

affected area, damage to the exterior of the trim

panel may occur.

(4) Allow the repaired area to cool and verify the

repair.

(5) Install trim panel.

PLASTIC BODY PANEL REPAIR

DESCRIPTION OPERATION

Resin Transfer Molded (RTM) body panels are rein-

forced with a continuous fiberglass mesh. Epoxy

resin is injected into a gel-coated and fiberglass-lined

mold to form a body panel. Sheet molded compound

(SMC) body panels are constructed with fiberglass

strands usually 1 inch or shorter, epoxy resin formed

into sheet stock and pressed in mold flowing material

to form a sheet molded compound (SMC) body panel.

RTM and SMC body panels can be repaired with

epoxy adhesive after market products. Refer to

instructions provided by the manufacturer of prod-

ucts being used to repair RTM or SMC. Daimler-

Chrysler Corporation recommends that a trained

automotive body technician perform body panel

repair procedures (Fig. 1).

Fig. 1 Panel Repair

PLBODY 23 - 19

DIAGNOSIS AND TESTING (Continued)

Page 1137 of 1285

SAFETY PRECAUTION AND WARNINGS

WARNING: EYE PROTECTION SHOULD BE USED

WHEN SERVICING RTM AND SMC COMPONENTS.

PERSONAL INJURE CAN RESULT.

USE AN OSHA APPROVED BREATHING DEVICE

WHEN MIXING EPOXY, GRINDING RTM AND SMC,

AND SPRAYING PAINT OR SOLVENTS IN A CON-

FINED AREA. PERSONAL INJURY CAN RESULT.

AVOID PROLONGED SKIN CONTACT WITH

EPOXY RESIN, PETROLEUM, OR ALCOHOL BASED

SOLVENTS. PERSONAL INJURY CAN RESULT.

DO NOT VENTURE UNDER A HOISTED VEHICLE

THAT IS NOT PROPERLY SUPPORTED ON SAFETY

STANDS. PERSONAL INJURY CAN RESULT.

²When holes must be drilled or cut in body pan-

els, verify locations of internal body components and

electrical wiring. Damage to vehicle can result.

²Do not use abrasive chemicals or compounds on

undamaged painted surfaces around repair areas.

Damage to finish can result.

PANEL SECTIONING

If it is required to section a large panel for an SMC

or RTM repair, it will be necessary to reinforce the

panel with epoxy structural adhesive (rigid repair

adhesive) (Fig. 2). To bond two plastic panels

together, a reinforcement must overlap both panels.

The panels must be ªV'dº at a 20 degree angle. The

area to be reinforced should be washed, then sanded.

Be sure to wipe off any excess soap and water when

finished. Lightly sand or abrade the plastic with an

abrasive pad or sandpaper. Blow off any dust with

compressed air or wipe with a clean dry rag.When bonding SMC or RTM panels, use a two-part

epoxy adhesive. Properly mix parts A and B, and

apply it to the panels being repaired. Be sure that

enough adhesive has been applied to allow squeeze

out and to fill the full bond line. Once the pieces

have been brought together, do not move them until

the adhesive is cured. The assembly can be held

together with clamps, rivets, etc. A faster cure can be

obtained by heating with a heat lamp or heat gun.

After the parts have been bonded and have had

time to cure, rough sand the seam and apply the

final adhesive filler to the area being repaired.

Smooth the filler with a spatula, wooden tongue

depressor, or squeegee. For fine texturing, a small

amount of water can be applied to the filler surface

while smoothing. The cured filler can be sanded as

necessary and, as a final step, cleanup can be done

withy soapy water. Wipe the surface clean with a dry

cloth allowing time for the panel to dry before mov-

ing on with the repair.

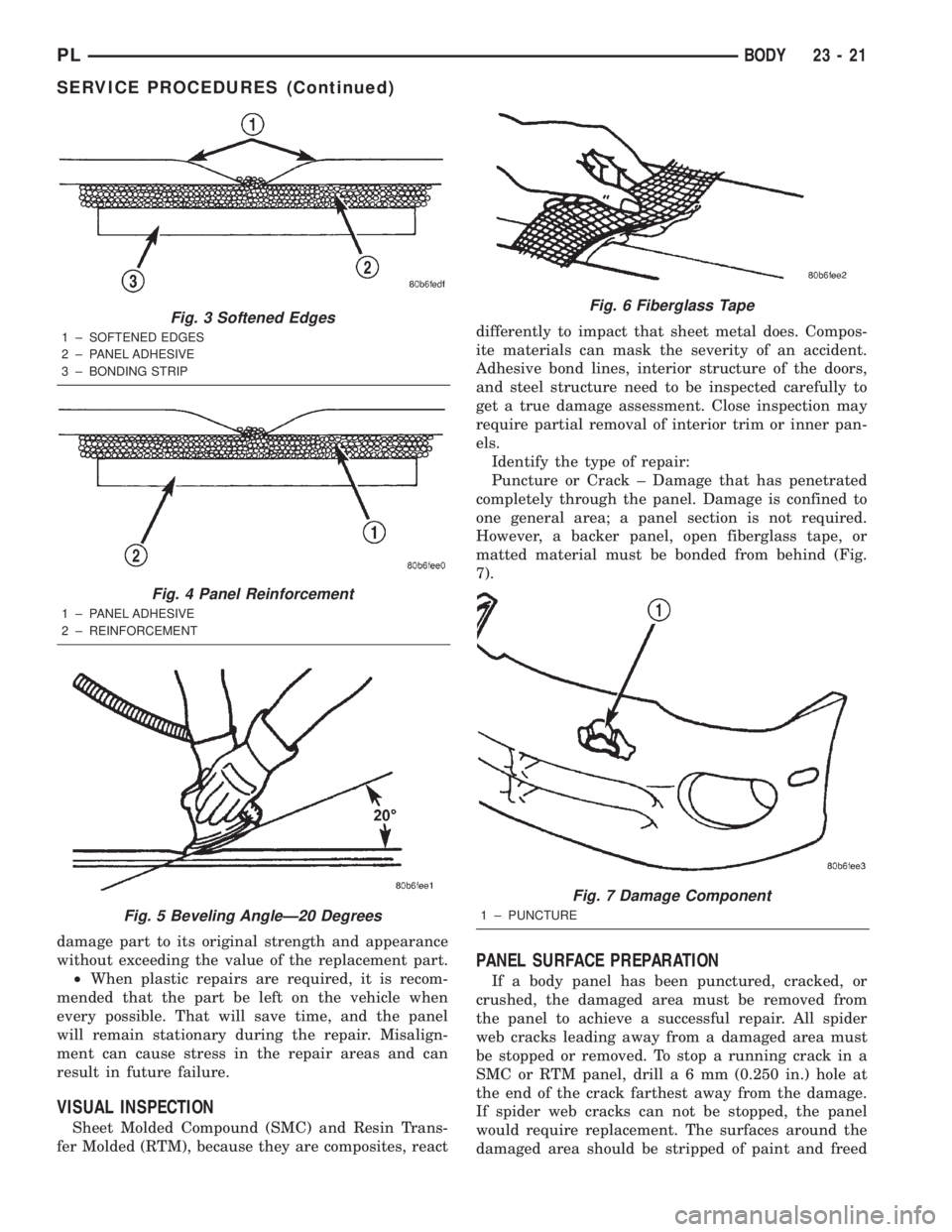

PANEL REINFORCEMENT

Structural repair procedures for rigid panels such

as Sheet Molded compound (SMC) or Resin Transfer

Molded (RTM) with large cracks and holes will

require a reinforcement backing. Reinforcements can

be made with several applications of glass cloth sat-

urated with epoxy structural adhesive, semirigid or

flexible repair materials should be used for semirigid

or flexible part repairs (Fig. 3) and (Fig. 4). Open

meshed fiberglass dry wall tape can be used to form

a reinforcement. The dry wall tape allows the resin

to penetrate through and make a good bond between

the panel and the epoxy adhesive. Structurally, the

more dry wall tape used, the stronger the repair.

Another kind of repair that can be done to repair

large cracks and holes is to use a scrap piece of sim-

ilar plastic and bond with structural adhesive. The

reinforcement should cover the entire break and

should have a generous amount of overlap on either

side of the cracked or broken area.

When repairing plastic, the damaged area is first

ªV'dº out, or beveled. Large bonding areas are desir-

able when repairing plastic because small repairs are

less likely to hold permanently. Beveling the area

around a crack at a 20 degree angle will increase the

bonding surface for a repair (Fig. 5). It is recom-

mended that sharp edges be avoided because the

joint may show through after the panel is refinished.

²Panel repair for both flexible and rigid panels

are basically the same. The primary difference

between flexible panel repair and rigid panel repair

is in the adhesive materials used (Fig. 6).

²The technician should first decide what needs to

be done when working on any type of body panel.

One should determine if it is possible to return the

Fig. 2 Panel Sectioning

1 ± EXISTING PANEL

2 ± NEW PANEL

3 ± PANEL ADHESIVE

4 ± BONDING STRIP

23 - 20 BODYPL

SERVICE PROCEDURES (Continued)

Page 1138 of 1285

damage part to its original strength and appearance

without exceeding the value of the replacement part.

²When plastic repairs are required, it is recom-

mended that the part be left on the vehicle when

every possible. That will save time, and the panel

will remain stationary during the repair. Misalign-

ment can cause stress in the repair areas and can

result in future failure.

VISUAL INSPECTION

Sheet Molded Compound (SMC) and Resin Trans-

fer Molded (RTM), because they are composites, reactdifferently to impact that sheet metal does. Compos-

ite materials can mask the severity of an accident.

Adhesive bond lines, interior structure of the doors,

and steel structure need to be inspected carefully to

get a true damage assessment. Close inspection may

require partial removal of interior trim or inner pan-

els.

Identify the type of repair:

Puncture or Crack ± Damage that has penetrated

completely through the panel. Damage is confined to

one general area; a panel section is not required.

However, a backer panel, open fiberglass tape, or

matted material must be bonded from behind (Fig.

7).

PANEL SURFACE PREPARATION

If a body panel has been punctured, cracked, or

crushed, the damaged area must be removed from

the panel to achieve a successful repair. All spider

web cracks leading away from a damaged area must

be stopped or removed. To stop a running crack in a

SMC or RTM panel, drilla6mm(0.250 in.) hole at

the end of the crack farthest away from the damage.

If spider web cracks can not be stopped, the panel

would require replacement. The surfaces around the

damaged area should be stripped of paint and freed

Fig. 3 Softened Edges

1 ± SOFTENED EDGES

2 ± PANEL ADHESIVE

3 ± BONDING STRIP

Fig. 4 Panel Reinforcement

1 ± PANEL ADHESIVE

2 ± REINFORCEMENT

Fig. 5 Beveling AngleÐ20 Degrees

Fig. 6 Fiberglass Tape

Fig. 7 Damage Component

1 ± PUNCTURE

PLBODY 23 - 21

SERVICE PROCEDURES (Continued)

Page 1145 of 1285

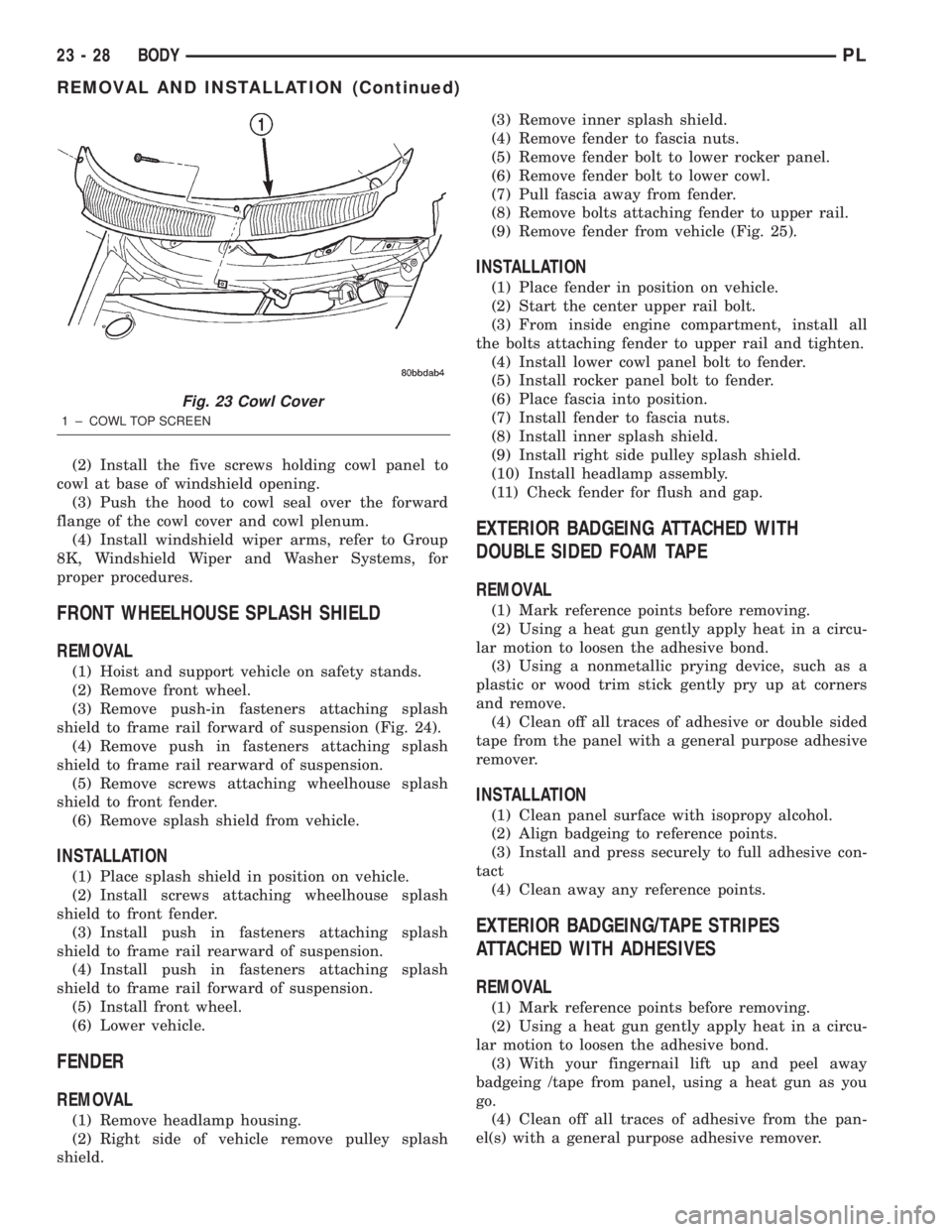

(2) Install the five screws holding cowl panel to

cowl at base of windshield opening.

(3) Push the hood to cowl seal over the forward

flange of the cowl cover and cowl plenum.

(4) Install windshield wiper arms, refer to Group

8K, Windshield Wiper and Washer Systems, for

proper procedures.

FRONT WHEELHOUSE SPLASH SHIELD

REMOVAL

(1) Hoist and support vehicle on safety stands.

(2) Remove front wheel.

(3) Remove push-in fasteners attaching splash

shield to frame rail forward of suspension (Fig. 24).

(4) Remove push in fasteners attaching splash

shield to frame rail rearward of suspension.

(5) Remove screws attaching wheelhouse splash

shield to front fender.

(6) Remove splash shield from vehicle.

INSTALLATION

(1) Place splash shield in position on vehicle.

(2) Install screws attaching wheelhouse splash

shield to front fender.

(3) Install push in fasteners attaching splash

shield to frame rail rearward of suspension.

(4) Install push in fasteners attaching splash

shield to frame rail forward of suspension.

(5) Install front wheel.

(6) Lower vehicle.

FENDER

REMOVAL

(1) Remove headlamp housing.

(2) Right side of vehicle remove pulley splash

shield.(3) Remove inner splash shield.

(4) Remove fender to fascia nuts.

(5) Remove fender bolt to lower rocker panel.

(6) Remove fender bolt to lower cowl.

(7) Pull fascia away from fender.

(8) Remove bolts attaching fender to upper rail.

(9) Remove fender from vehicle (Fig. 25).

INSTALLATION

(1) Place fender in position on vehicle.

(2) Start the center upper rail bolt.

(3) From inside engine compartment, install all

the bolts attaching fender to upper rail and tighten.

(4) Install lower cowl panel bolt to fender.

(5) Install rocker panel bolt to fender.

(6) Place fascia into position.

(7) Install fender to fascia nuts.

(8) Install inner splash shield.

(9) Install right side pulley splash shield.

(10) Install headlamp assembly.

(11) Check fender for flush and gap.

EXTERIOR BADGEING ATTACHED WITH

DOUBLE SIDED FOAM TAPE

REMOVAL

(1) Mark reference points before removing.

(2) Using a heat gun gently apply heat in a circu-

lar motion to loosen the adhesive bond.

(3) Using a nonmetallic prying device, such as a

plastic or wood trim stick gently pry up at corners

and remove.

(4) Clean off all traces of adhesive or double sided

tape from the panel with a general purpose adhesive

remover.

INSTALLATION

(1) Clean panel surface with isopropy alcohol.

(2) Align badgeing to reference points.

(3) Install and press securely to full adhesive con-

tact

(4) Clean away any reference points.

EXTERIOR BADGEING/TAPE STRIPES

ATTACHED WITH ADHESIVES

REMOVAL

(1) Mark reference points before removing.

(2) Using a heat gun gently apply heat in a circu-

lar motion to loosen the adhesive bond.

(3) With your fingernail lift up and peel away

badgeing /tape from panel, using a heat gun as you

go.

(4) Clean off all traces of adhesive from the pan-

el(s) with a general purpose adhesive remover.

Fig. 23 Cowl Cover

1 ± COWL TOP SCREEN

23 - 28 BODYPL

REMOVAL AND INSTALLATION (Continued)

Page 1150 of 1285

FRONT DOOR OUTSIDE HANDLE

REMOVAL

(1) Remove door trim panel and water dam.

(2) Close door glass.

(3) Disconnect lock and latch rods from door latch.

(4) Remove nut attaching door handle retainer to

outer door panel (Fig. 32).

(5) Remove retainer from back of door handle.

(6) Remove door handle from vehicle.

INSTALLATION

(1) Position door handle into door and install

retainer at back of handle.

(2) Install nut attaching door handle retainer to

outer door panel.

(3) Connect lock and latch rods to door latch.

(4) Install door trim panel and water dam.

DOOR LOCK CYLINDER

REMOVAL

(1) Remove door trim panel and water dam.

(2) Close door glass.

(3) Disconnect door lock rod from latch.

(4) Remove clip attaching lock cylinder to door

handle.

(5) Pull lock cylinder from door handle (Fig. 33).

INSTALLATION

(1) Push lock cylinder into door handle.

(2) Install clip attaching lock cylinder to door han-

dle.

(3) Connect door lock rod from latch.

(4) Install door trim panel and water dam.

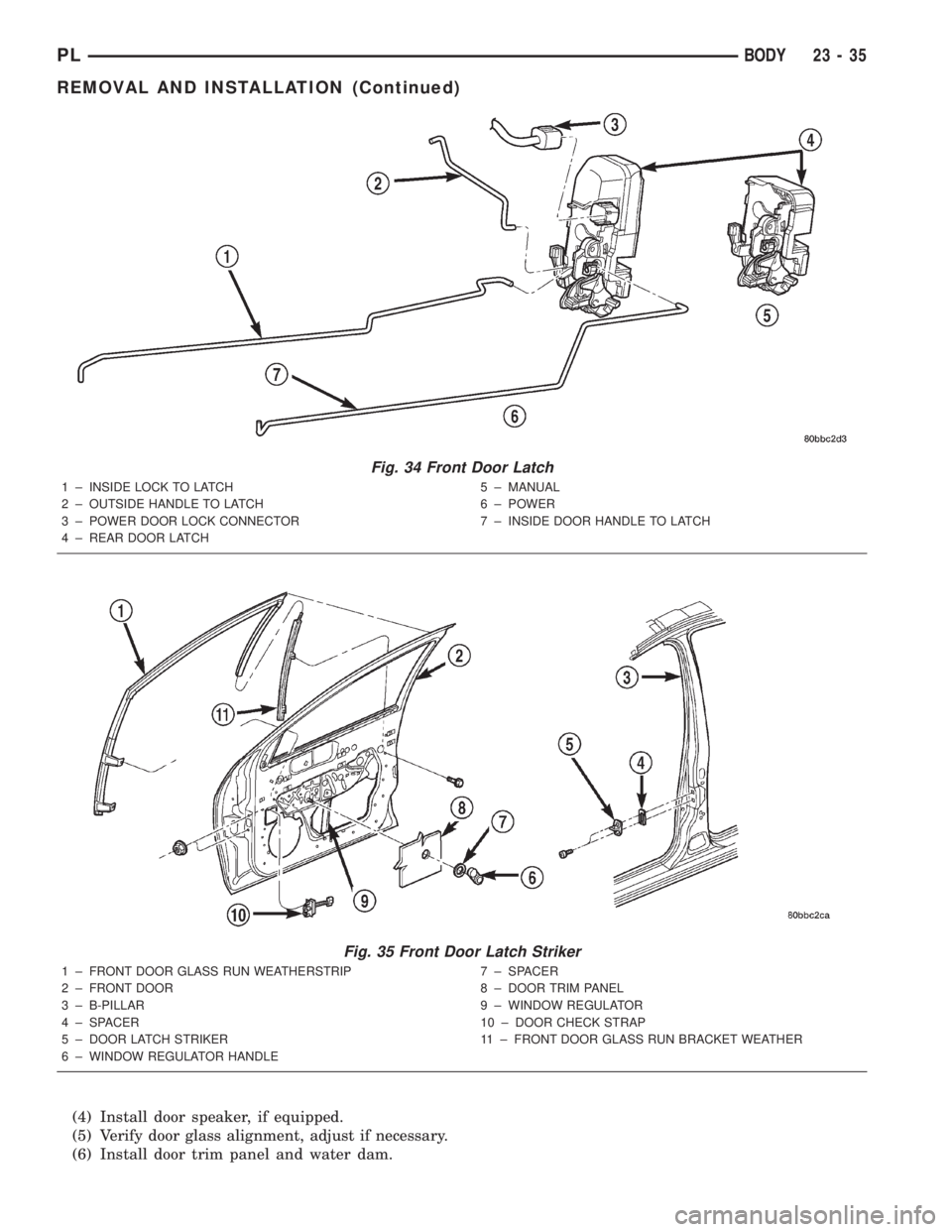

FRONT DOOR LATCH

REMOVAL

(1) Remove door trim panel and water shield.

(2) Close door glass.

(3) Disconnect lock and latch rods from door latch

(Fig. 34).

(4) Disengage wire connector from power door lock

motor, if equipped.

(5) Remove screws holding latch to door end

frame.

(6) Remove door latch from vehicle.

INSTALLATION

CAUTION: Do not close door before adjusting the

door latch. Door may fail to open.

(1) Position door latch inside door and install

screws holding latch to door end frame.

(2) Engage wire connector into power door lock

motor, if so equipped.

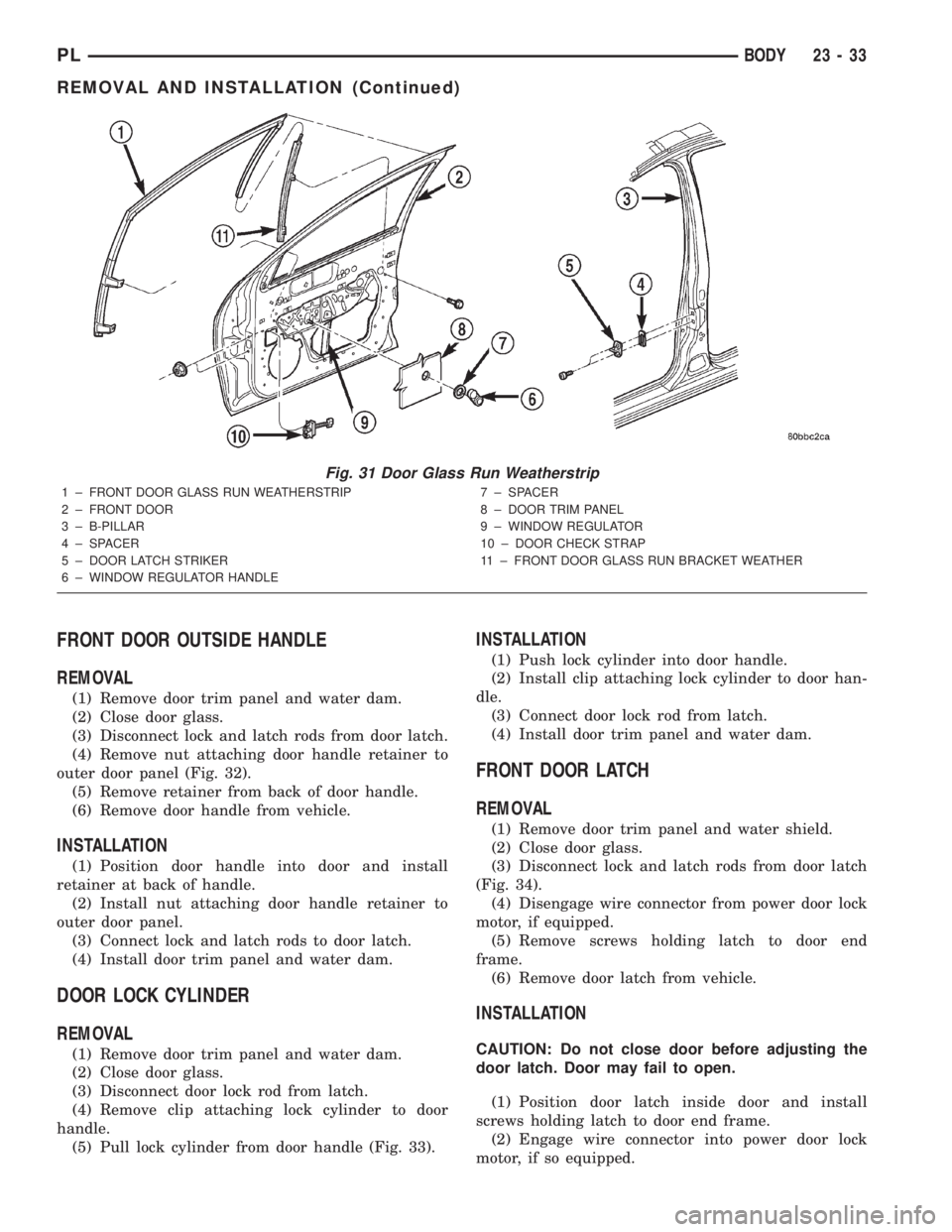

Fig. 31 Door Glass Run Weatherstrip

1 ± FRONT DOOR GLASS RUN WEATHERSTRIP

2 ± FRONT DOOR

3 ± B-PILLAR

4 ± SPACER

5 ± DOOR LATCH STRIKER

6 ± WINDOW REGULATOR HANDLE7 ± SPACER

8 ± DOOR TRIM PANEL

9 ± WINDOW REGULATOR

10 ± DOOR CHECK STRAP

11 ± FRONT DOOR GLASS RUN BRACKET WEATHER

PLBODY 23 - 33

REMOVAL AND INSTALLATION (Continued)

Page 1152 of 1285

(4) Install door speaker, if equipped.

(5) Verify door glass alignment, adjust if necessary.

(6) Install door trim panel and water dam.

Fig. 34 Front Door Latch

1 ± INSIDE LOCK TO LATCH

2 ± OUTSIDE HANDLE TO LATCH

3 ± POWER DOOR LOCK CONNECTOR

4 ± REAR DOOR LATCH5 ± MANUAL

6 ± POWER

7 ± INSIDE DOOR HANDLE TO LATCH

Fig. 35 Front Door Latch Striker

1 ± FRONT DOOR GLASS RUN WEATHERSTRIP

2 ± FRONT DOOR

3 ± B-PILLAR

4 ± SPACER

5 ± DOOR LATCH STRIKER

6 ± WINDOW REGULATOR HANDLE7 ± SPACER

8 ± DOOR TRIM PANEL

9 ± WINDOW REGULATOR

10 ± DOOR CHECK STRAP

11 ± FRONT DOOR GLASS RUN BRACKET WEATHER

PLBODY 23 - 35

REMOVAL AND INSTALLATION (Continued)

Page 1153 of 1285

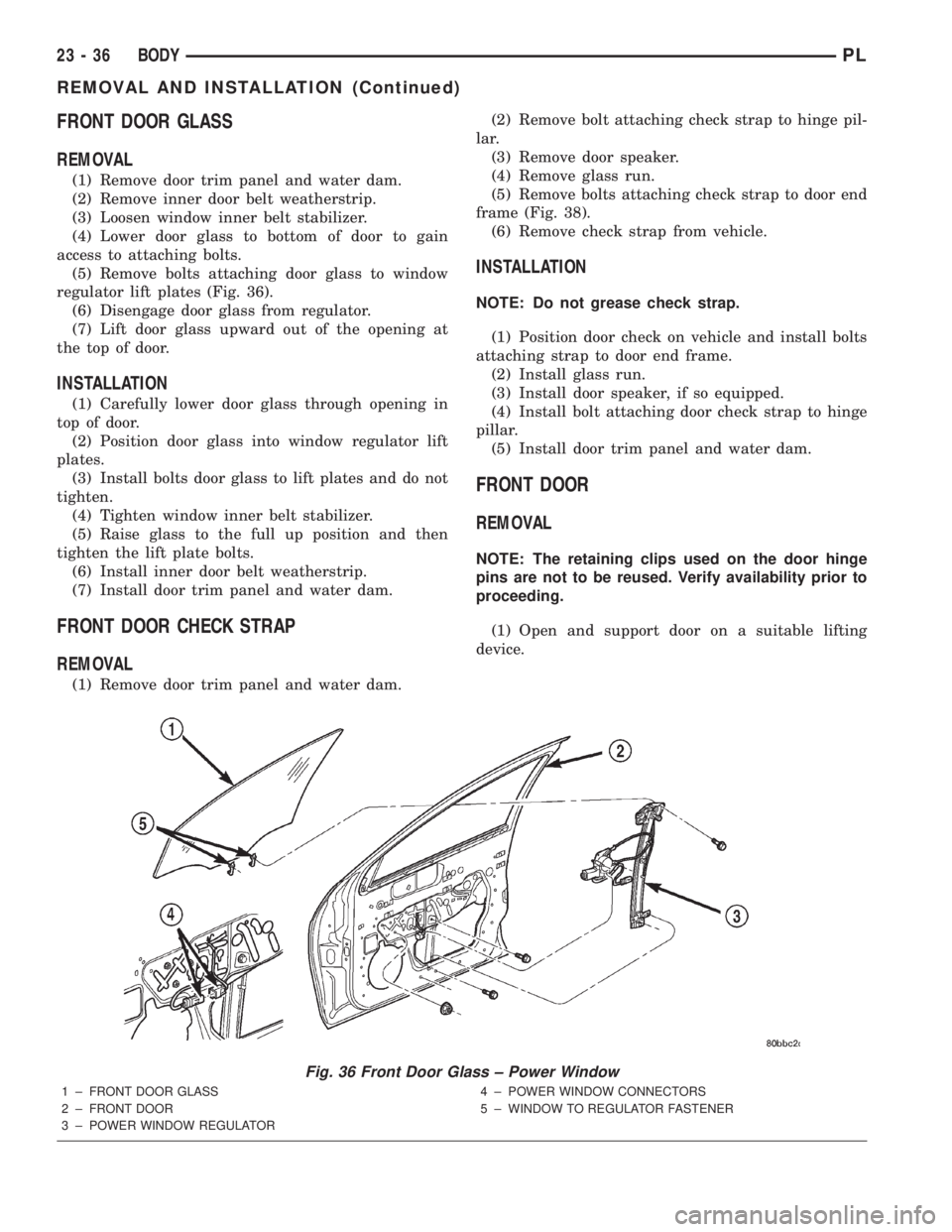

FRONT DOOR GLASS

REMOVAL

(1) Remove door trim panel and water dam.

(2) Remove inner door belt weatherstrip.

(3) Loosen window inner belt stabilizer.

(4) Lower door glass to bottom of door to gain

access to attaching bolts.

(5) Remove bolts attaching door glass to window

regulator lift plates (Fig. 36).

(6) Disengage door glass from regulator.

(7) Lift door glass upward out of the opening at

the top of door.

INSTALLATION

(1) Carefully lower door glass through opening in

top of door.

(2) Position door glass into window regulator lift

plates.

(3) Install bolts door glass to lift plates and do not

tighten.

(4) Tighten window inner belt stabilizer.

(5) Raise glass to the full up position and then

tighten the lift plate bolts.

(6) Install inner door belt weatherstrip.

(7) Install door trim panel and water dam.

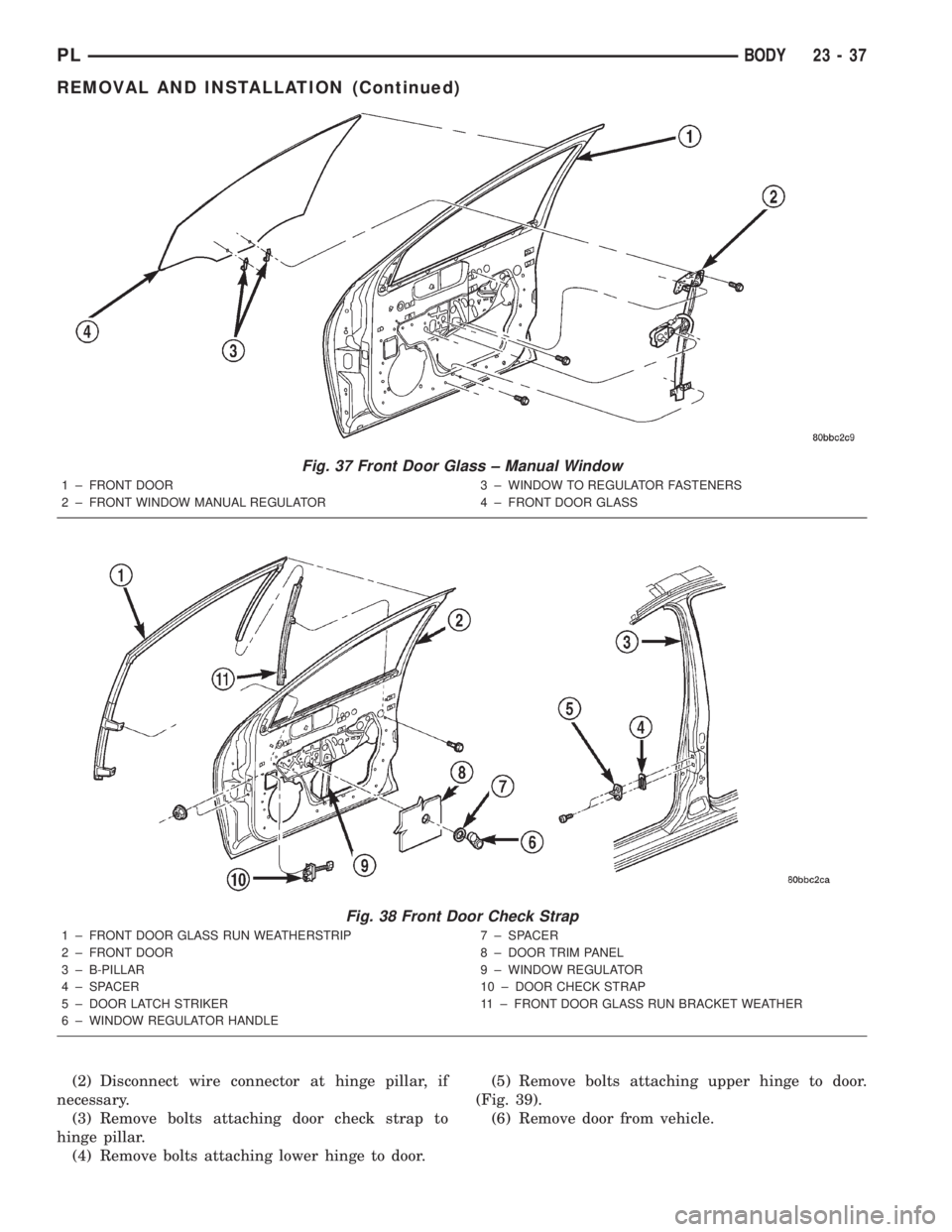

FRONT DOOR CHECK STRAP

REMOVAL

(1) Remove door trim panel and water dam.(2) Remove bolt attaching check strap to hinge pil-

lar.

(3) Remove door speaker.

(4) Remove glass run.

(5) Remove bolts attaching check strap to door end

frame (Fig. 38).

(6) Remove check strap from vehicle.

INSTALLATION

NOTE: Do not grease check strap.

(1) Position door check on vehicle and install bolts

attaching strap to door end frame.

(2) Install glass run.

(3) Install door speaker, if so equipped.

(4) Install bolt attaching door check strap to hinge

pillar.

(5) Install door trim panel and water dam.

FRONT DOOR

REMOVAL

NOTE: The retaining clips used on the door hinge

pins are not to be reused. Verify availability prior to

proceeding.

(1) Open and support door on a suitable lifting

device.

Fig. 36 Front Door Glass ± Power Window

1 ± FRONT DOOR GLASS

2 ± FRONT DOOR

3 ± POWER WINDOW REGULATOR4 ± POWER WINDOW CONNECTORS

5 ± WINDOW TO REGULATOR FASTENER

23 - 36 BODYPL

REMOVAL AND INSTALLATION (Continued)

Page 1154 of 1285

(2) Disconnect wire connector at hinge pillar, if

necessary.

(3) Remove bolts attaching door check strap to

hinge pillar.

(4) Remove bolts attaching lower hinge to door.(5) Remove bolts attaching upper hinge to door.

(Fig. 39).

(6) Remove door from vehicle.

Fig. 37 Front Door Glass ± Manual Window

1 ± FRONT DOOR

2 ± FRONT WINDOW MANUAL REGULATOR3 ± WINDOW TO REGULATOR FASTENERS

4 ± FRONT DOOR GLASS

Fig. 38 Front Door Check Strap

1 ± FRONT DOOR GLASS RUN WEATHERSTRIP

2 ± FRONT DOOR

3 ± B-PILLAR

4 ± SPACER

5 ± DOOR LATCH STRIKER

6 ± WINDOW REGULATOR HANDLE7 ± SPACER

8 ± DOOR TRIM PANEL

9 ± WINDOW REGULATOR

10 ± DOOR CHECK STRAP

11 ± FRONT DOOR GLASS RUN BRACKET WEATHER

PLBODY 23 - 37

REMOVAL AND INSTALLATION (Continued)