tra DODGE NEON 2000 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 1177 of 1285

SPECIFICATIONS

TABLE OF CONTENTS

page page

SPECIFICATIONS

BODY LUBRICATION SPECIFICATIONS........60

BODY GAP AND FLUSH MEASUREMENTS.....61

BODY OPENING DIMENSION...............62BODY SEALING LOCATIONS................64

STRUCTURAL ADHESIVE LOCATIONS........74

TORQUE SPECIFICATIONS.................76

WELD LOCATIONS.......................77

SPECIFICATIONS

BODY LUBRICATION SPECIFICATIONS

LUBRICATION REQUIREMENTS

Body mechanisms and linkages should be

inspected, cleaned, and lubricated, as required, to

maintain ease of operation and to provide protection

against rust and wear. When performing other under

hood services, the hood latch release mechanism and

safety catch should be inspected, cleaned, and lubri-

cated. During the winter season, external door lock

cylinders should be lubricated to assure proper oper-

ation when exposed to water and ice.

Prior to the application of any lubricant, the parts

concerned should be wiped clean to remove dust and

grit. If necessary, a suitable solvent can be used to

clean the item to be lubricated. After lubricating a

component, any excess oil or grease should be

removed.

LUBRICANT APPLICATION

DOOR LOCK CYLINDERS

(1) Apply a small amount of lubricant directly into

the lock cylinder.

(2) Apply a small amount of lubricant to the key.

(3) Insert key into lock cylinder and cycle the

mechanism from the locked to the unlocked position.

NOTE: Do not add more lubricant.

(4) Cycle the lock cylinder mechanism several

times to allow the lubricant to flow throughout the

cylinder.

(5) Wipe all lubricant from exterior of lock cylinder

and key.ALL OTHER BODY MECHANISMS

(1) Clean component as described above.

(2) Apply specified lubricant to all pivoting and

sliding contact areas of component.

LUBRICANT USAGE

ENGINE OIL

²Door Hinges ± Hinge Pin and Pivot Contact

Areas

²Hood Hinges ± Pivot Points

²Liftgate Hinges

²Decklid Hinges

MOPARTSPRAY WHITE CUBE OR EQUIVALENT

²Door Check Straps

²Liftgate Latches

²Liftgate Prop Pivots

²Ash Receiver

²Fuel Filler Door Remote Control Latch Mecha-

nism

²Parking Brake Mechanism

²Sliding Seat Tracks

²Decklid Latch

MOPARTMultipurpose GREASE OR EQUIVALENT

²All Other Hood Mechanisms

MOPARTLOCK CYLINDER LUBRICANT OR

EQUIVALENT

²Door Lock Cylinders

²Decklid Lock Cylinder

23 - 60 BODYPL

Page 1193 of 1285

TORQUE SPECIFICATIONS

BODY COMPONENTS

DESCRIPTION TORQUE

All seat belt anchor bolts..... 40N´m(30ft.lbs.)

All seat belt anchor nuts...... 40N´m(30ft.lbs.)

All seat belt retractor bolts.... 40N´m(30ft.lbs.)

Decklid latch striker......... 22N´m(16ft.lbs.)

Front seat track to floor pan bolts . . 55 N´m (40 ft.

lbs.)

Front seat inboard pivot bolt . . . 40 N´m (30 ft. lbs.)

Front seat recliner to seat cushion frame . . 12 N´m

(9 ft. lbs.)

Front seat track to cushion frame bolt . . 12 N´m (9

ft. lbs.)

Front seat back............. 40N´m(30ft.lbs.)DESCRIPTION TORQUE

Front seat back recliner to seat back . 12 N´m (9 ft.

lbs.)

Front door hinge to hinge pillar bolt . 28 N´m (21 ft.

lbs.)

Front door hinge to door nuts and bolt . 28 N´m (21

ft. lbs.)

Front door latch striker....... 28N´m(20ft.lbs.)

Hood latch striker.........13.5 N´m (10 ft. lbs.)

Rear door glass to regulator bolt . . 11 N´m (105 in.

lbs.)

Rear door hinge to B-pillar bolt . 28 N´m (20 ft. lbs.)

Rear door hinge to door bolt . . . 28 N´m (20 ft. lbs.)

Rear door latch striker....... 28N´m(20ft.lbs.)

Rear seat back and seat belt buckle anchor nut . 57

N´m (42 ft. lbs.)

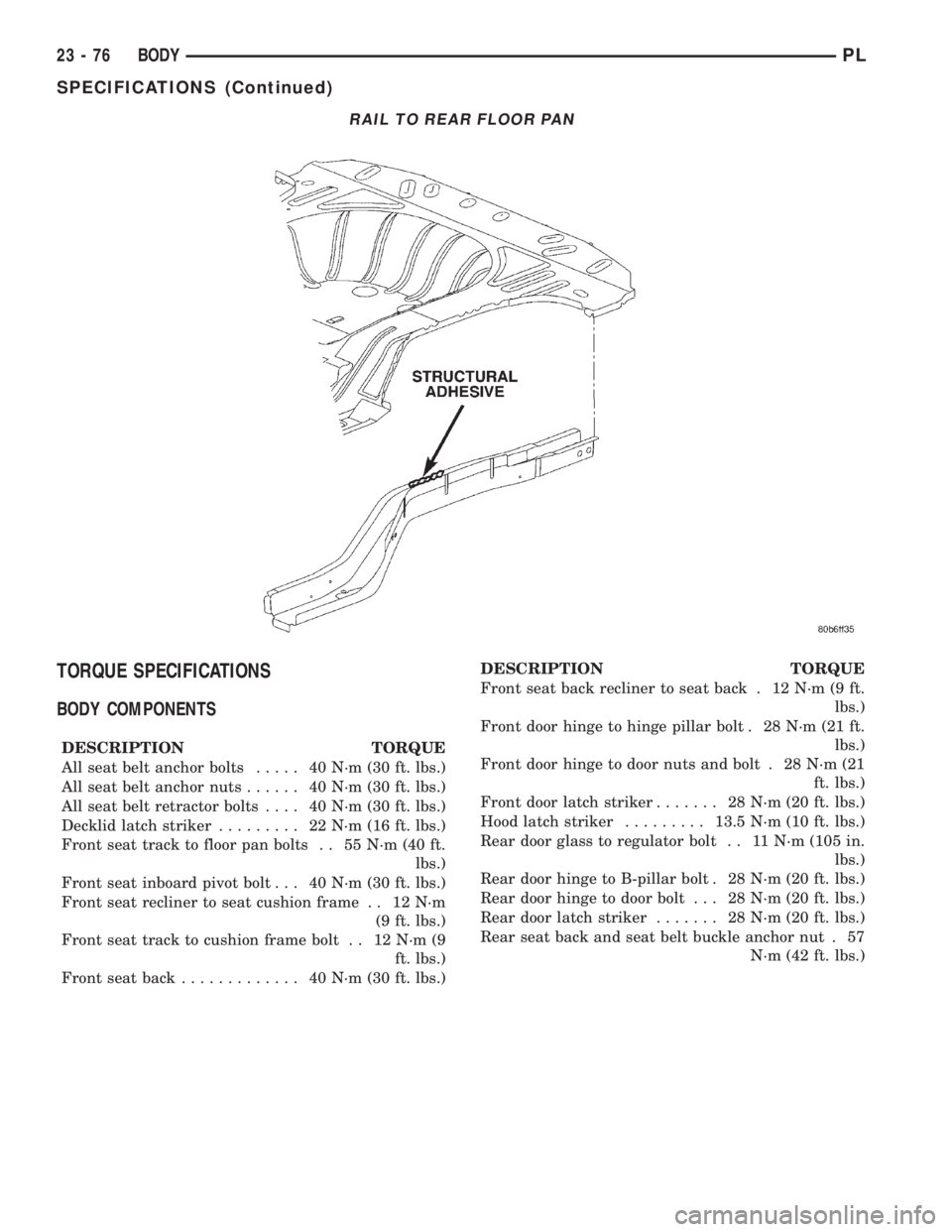

RAIL TO REAR FLOOR PAN

23 - 76 BODYPL

SPECIFICATIONS (Continued)

Page 1231 of 1285

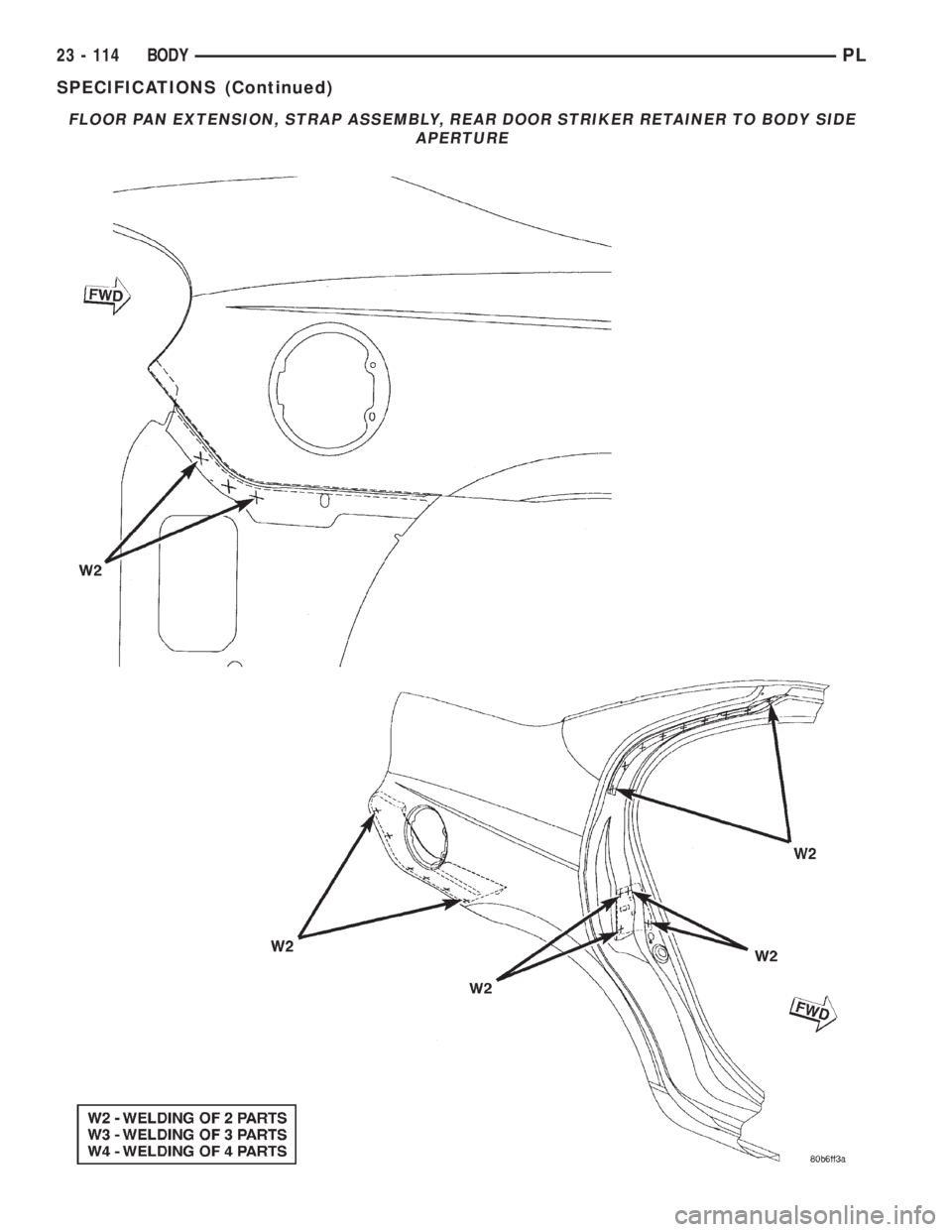

FLOOR PAN EXTENSION, STRAP ASSEMBLY, REAR DOOR STRIKER RETAINER TO BODY SIDE

APERTURE

23 - 114 BODYPL

SPECIFICATIONS (Continued)

Page 1237 of 1285

COMPRESSOR FRONT SHAFT SEAL

The compressor front shaft seal is not serviceable.

If a leak is detected at the shaft seal, the compressor

must be replaced as a unit.

CONDENSATION DRAIN TUBE

Condensation that accumulates in the evaporator

housing is drained from a tube through the dash and

on to the ground. This tube must be kept open to

prevent condensate water from collecting in the bot-

tom of the housing.

The tapered end of the drain tube is designed to

keep contaminants from entering the heater A/C unit

housing. If the tube is pinched or blocked, condensate

cannot drain, causing water to back up and spill into

the passenger compartment. It is normal to see con-

densate drainage below the vehicle. If the tube is

damaged, it should be replaced.

ENGINE COOLING SYSTEM REQUIREMENTS

To maintain ample temperature levels from the

heating-A/C system, the cooling system must be in

proper working order. Refer to Group 0, Lubrication

and Maintenance or Group 7, Cooling System of this

manual.

The use of a bug screen is not recommended. Any

obstructions forward of the condenser can reduce the

effectiveness of the air conditioning system.

EVAPORATOR PROBE

The evaporator probe can be replaced without hav-

ing to remove the unit housing from the vehicle.

The evaporator probe is located in the unit housing

and placed in the evaporator fins. The probe prevents

evaporator freeze-up. This is done by cycling the com-

pressor clutch OFF when evaporator temperature

drops below freeze point. It cycles ON when the

evaporator temperature rises above freeze point. The

evaporator probe uses a thermistor probe in a capil-

lary tube. The tube is inserted between the evapora-

tor fins in the heater-A/C unit housing.

HANDLING TUBING AND FITTINGS

Kinks in the refrigerant tubing or sharp bends in

the refrigerant hose lines will greatly reduce the

capacity of the entire system. High pressures are pro-

duced in the system when it is operating. Extreme

care must be exercised to make sure that all connec-

tions are pressure tight. Dirt and moisture can enter

the system when it is opened for repair or replace-

ment of lines or components. The refrigerant oil will

absorb moisture readily out of the air. This moisture

will convert into acids within a closed system.CAUTION: The system must be completely empty

before opening any fitting or connection in the

refrigeration system. Open fittings with caution

even after the system has been emptied. If any

pressure is noticed as a fitting is loosened,

retighten fitting and evacuate the system again.

A good rule for the flexible hose lines is to keep

the radius of all bends at least 10 times the diame-

ter of the hose. Sharper bends will reduce the flow

of refrigerant. The flexible hose lines should be

routed so they are at least 3 inches (80 mm) from

the exhaust manifold. Inspect all flexible hose lines

to make sure they are in good condition and prop-

erly routed.

The use of correct wrenches when making con-

nections is very important. Improper wrenches or

improper use of wrenches can damage the fittings.

The internal parts of the A/C system will remain

stable as long as moisture-free refrigerant and

refrigerant oil is used. Abnormal amounts of dirt,

moisture or air can upset the chemical stability.

This may cause operational troubles or even seri-

ous damage if present in more than very small

quantities.

When opening a refrigeration system, have every-

thing you will need to repair the system ready. This

will minimize the amount of time the system must

be opened. Cap or plug all lines and fittings as

soon as they are opened. This will help prevent the

entrance of dirt and moisture. All new lines and

components should be capped or sealed until they

are ready to be used.

All tools, including the refrigerant dispensing

manifold, the manifold gauge set, and test hoses

should be kept clean and dry.

HIGH PRESSURE CUT OUT SWITCH

The high pressure cut out switch is located on the

rear of the compressor (Fig. 7). It turns off the com-

pressor if the system pressure exceeds 3240 kPa (470

psi).

LOW PRESSURE CUT OFF SWITCH

The Low Pressure Cut Off Switch (Fig. 8) monitors

the refrigerant gas pressure on the suction side of

the system. The low pressure cut off switch is located

on the expansion valve. The low pressure cut off

switch turns off voltage to the compressor clutch coil

when refrigerant gas pressure drops to levels that

could damage the compressor. The low pressure cut

out switch is a sealed factory calibrated unit. It must

be replaced if defective.

24 - 6 HEATING AND AIR CONDITIONINGPL

DESCRIPTION AND OPERATION (Continued)

Page 1242 of 1285

BLOWER MOTOR VIBRATION AND/OR NOISE

DIAGNOSIS

The resistor block supplies the blower motor with

varied voltage (low and middle speeds) or battery

voltage (high speed).

CAUTION: Stay clear of the blower motor and resis-

tor block (Hot). Do not operate the blower motor

with the resistor block removed from the heater-A/C

housing.

Refer to the Blower Motor Vibration/Noise chart

for diagnosis.

COMPRESSOR NOISE DIAGNOSIS

Excessive noise while the A/C is being used, can be

caused by loose mounts, loose clutch, or high operat-

ing pressure. Verify compressor drive belt condition,

proper refrigerant charge and head pressure before

compressor repair is performed.

If the A/C drive belt slips at initial start-up, it does

not necessarily mean the compressor has failed.

With the close tolerances of a compressor it is pos-

sible to experience a temporary lockup. The longer

the A/C system is inactive, the more likely the condi-

tion to occur.

This condition is the result of normal refrigerant

movement within the A/C system caused by temper-

ature changes. The refrigerant movement may wash

the oil out of the compressor.

EVAPORATOR PROBE TEST

The work area and vehicle must be between 16É C

(60É F) and 32É C (90É F) when testing the switch.

(1) Disconnect the three wire connector from the

evaporator probe lead located behind the glove box

(Fig. 12).

(2) Start engine and set A/C to low blower motor

speed, panel, full cool, and RECIRC.

(3) Using a voltmeter, check for battery voltage

between Pin 1 and 2. If no voltage is detected, there

is no power to the switch. Check wiring and fuses.

Refer to Group 8W, Wiring Diagrams for circuit diag-

nosis.

(4) Using a voltmeter, check for battery voltage

between Pin 1 and Pin 3. If no voltage is detected,

there is no voltage from the Powertrain Control Mod-

ule. Refer to Group 8W, Wiring Diagrams. If voltage

is OK, connect a jumper wire between Pin 1 and Pin

3. The compressor clutch should engage. If the clutch

engages, remove the jumper wire immediately and go

to Step 5. If the compressor clutch does not engage,

check the operation of the clutch and repair as nec-

essary.(5) If compressor clutch engages, connect the evap-

orator probe 3-way connector. The compressor clutch

should engage or cycle depending on evaporator tem-

perature. If OK, go to Step 6. If not OK, replace the

clutch cycling switch.

(6) The engine running and the A/C set to:

²Blower motor on low speed

²Panel position

²Full cool

²RECIRC.

Close all doors and windows. Place a thermometer in

the center discharge vent.

(7) If the clutch does not begin to cycle off between

2É C to 7É C (35É F to 45É F), verify that the evapo-

rator probe is fully installed and not loose in evapo-

rator. If it is not properly installed, install probe and

retest outlet temperature. If the evaporator probe is

properly installed, replace the clutch cycling switch.

EXPANSION VALVE

NOTE: Expansion valve tests should be performed

after compressor tests.

Liquid CO2 is required to test the expansion

valve. It is available from most welding supply facil-

ities. CO2 is also available from companies which

service and sell fire extinguishers.

Review Safety Precautions and Warnings in the

General Information section of this Group. The work

area and vehicle must be 21É to 27ÉC (70É to 85ÉF)

when testing expansion valve. To test the expansion

valve:

(1) Connect a charging station or manifold gauge

set to the refrigerant system service ports.

(2) Disconnect wire connector at low pressure cut-

off switch (Fig. 13). Using a jumper wire, jump ter-

minals inside wire connector boot.

(3) Close all doors, windows and vents to the pas-

senger compartment.

(4) Set Heater-A/C control to A/C, full heat, floor,

RECIRC. and high blower.

(5) Start the engine and hold the idle speed (1000

rpm). After the engine has reached running temper-

ature, allow the passenger compartment to heat up.

This will create the need for maximum refrigerant

flow into the evaporator.

(6) If the refrigerant charge is sufficient, discharge

(high pressure) gauge should read 965 to 2620 kPa

(140 to 380 psi). Suction (low pressure) gauge should

read 103 to 2417 kPa (15 to 35 psi). If system cannot

achieve proper pressure readings, replace the expan-

sion valve. If pressure is correct, proceed with test.

PLHEATING AND AIR CONDITIONING 24 - 11

DIAGNOSIS AND TESTING (Continued)

Page 1245 of 1285

POSSIBLE LOCATIONS OR CAUSE OF

OBSTRUCTED COOLANT FLOW

(1) Pinched or kinked heater hoses.

(2) Improper heater hose routing.

(3) Plugged heater hoses or supply and return

ports at cooling system connections, refer to Group 7,

Cooling System.

(4) Plugged heater core.

(5) Air locked heater core.

(6) If coolant flow is verified and outlet tempera-

ture is insufficient, a mechanical problem may exist.

POSSIBLE LOCATION OR CAUSE OF INSUFFICIENT

HEAT

(1) Obstructed cowl air intake.

(2) Obstructed heater system outlets.

(3) Blend-air door not functioning properly.

TEMPERATURE CONTROL

If temperature cannot be adjusted with the TEMP

lever on the control panel, the following could require

service:

(1) Blend-air door binding.

(2) Faulty blend-air door cable.

(3) Improper engine coolant temperature.

(4) Faulty Instrument Panel Control.

LOW PRESSURE CUT OFF SWITCH

The work area must not be below 21ÉC (70ÉF) to

test the compressor clutch circuit.

(1) With gear selector in park or neutral and park

brake set, start engine and allow to idle.

(2) Raise hood and disconnect low pressure cut off

switch connector boot.

(3) Using a suitable jumper wire, jump across the

terminals inside wire connector boot.

(4) If the compressor clutch does not engage, the

cycling clutch switch, wiring, relay, or fuse can be

defective. Refer to Group 8W, Wiring Diagrams.

(5) If clutch engages, connect manifold gauge set.

Read low pressure gauge. At pressure above 97 kPa

(14 psi) and above, low pressure out off switch will

complete the clutch circuit. If the low pressure gauge

reads below 140 kPa (20 psi), the system is low on

refrigerant charge or empty due to a leak. Refer to

Service Procedures, System Leak Checking in this

section.

(6) Install connector boot on switch and repeat

Step 3. If the clutch does not engage, replace the low

pressure cut off switch.

SYSTEM CHARGE LEVEL TEST

The procedure below should be used to check

and/or fill the refrigerant charge in the air condition-

ing system.

WARNING: AVOID BREATHING A/C REFRIGERANT

AND LUBRICANT VAPOR OR MIST. EXPOSURE MAY

IRRITATE EYES, NOSE AND THROAT. USE ONLY

APPROVED SERVICE EQUIPMENT MEETING SAE

REQUIREMENTS TO DISCHARGE R-134a SYSTEM.

IF ACCIDENTAL SYSTEM DISCHARGE OCCURS,

VENTILATE WORK AREA BEFORE RESUMING SER-

VICE.

R-134a SERVICE EQUIPMENT OR VEHICLE A/C

SYSTEM SHOULD NOT BE PRESSURE TESTED OR

LEAK TESTED WITH COMPRESSED AIR. MIXTURE

OF AIR and R-134a CAN BE COMBUSTIBLE AT ELE-

VATED PRESSURES. THESE MIXTURES ARE

POTENTIALLY DANGEROUS AND MAY RESULT IN

FIRE OR EXPLOSION CAUSING INJURY OR PROP-

ERTY DAMAGE.

NOTE: The maximum amount of R-134a refrigerant

that the air conditioning system holds is 765 grams

(27 oz. or 1.69 lbs.)

It is recommended to use the gauges or reclaim/re-

cycle equipment.

(1) Use a manifold gauge and check the liquid line

pressure.

(2) Attach a clamp-on thermocouple (P. S. E.

66-324-0014 or 80PK-1A) or equivalent to the liquid

line near the filter/drier.

(3) The vehicle must be in the following modes:

²Automatic transaxle in park or manual tran-

saxle in neutral.

²Engine at idle

²A/C controls set to outside air

²Panel mode

²A/C ON full cool

²Blower motor ON high speed

²Vehicle windows closed

(4) Operate system for a couple of minutes to allow

the system to stabilize.

(5) Observe filter/drier pressure and Liquid line

temperature. Using the Charge Determination Chart

(Fig. 14) determine where the system is currently

operating. If the system is not in the proper range,

reclaim all the refrigerant and recharge per A/C

label.

24 - 14 HEATING AND AIR CONDITIONINGPL

DIAGNOSIS AND TESTING (Continued)

Page 1249 of 1285

CAUTION: Do not overcharge refrigerant system,

as excessive compressor head pressure can cause

noise and system failure.

After the system has been tested for leaks and

evacuated, a refrigerant (R-134a) charge can be

injected into the system.

NOTE: When connecting the service equipment

coupling to the line fitting, verify that the valve of

the coupling is fully closed. This will reduce the

amount of effort required to make the connection.

(1) If using a separate vacuum pump close all

valves before disconnecting pump. Connect manifold

gauge set to the A/C service ports (Fig. 16).

NOTE: The air conditioning system in this vehicle

holds (27 oz. or 1.69 lbs.) of R-134a refrigerant.

(2) Measure refrigerant (refer to capacities). Refer

to the instructions provided with the equipment

being used.

(3) Verify engine is shut off. Open the suction and

discharge valves. Open the charge valve to allow the

refrigerant to flow into the system. When the trans-

fer of refrigerant has stopped, close the suction and

discharge valve.

(4) If all of the charge did not transfer from the

dispensing device, put vehicle controls into the fol-

lowing mode:

²Automatic transaxle in park or manual tran-

saxle in neutral

²Engine idling at 700 rpm

²A/C control set in 100 percent outside air

²Panel mode

²Blower motor ON high speed

²Vehicle windows closed

If the A/C compressor does not engage, test the

compressor clutch control circuit and correct any fail-

ure. Refer to Group 8W, Wiring Diagrams.

(5) Open the suction valve to allow the remaining

refrigerant to transfer to the system.

WARNING: TAKE CARE NOT TO OPEN THE DIS-

CHARGE (HIGH-PRESSURE) VALVE AT THIS TIME.

(6) Close all valves and test the A/C system perfor-

mance.

(7) Disconnect the charging station or manifold

gauge set. Install the service port caps.

EVACUATING REFRIGERANT SYSTEM

NOTE: Special effort must be used to prevent mois-

ture from entering the A/C system oil. Moisture in

the oil is very difficult to remove and will cause a

reliability problem with the compressor.If a compressor designed to use R-134a refrigerant

is left open to the atmosphere for an extended period

of time. It is recommended that the refrigerant oil be

drained and replaced with new oil or a new compres-

sor be used. This will eliminate the possibility of con-

taminating the refrigerant system.

If the refrigerant system has been open to the

atmosphere, it must be evacuated before the system

can be filled. Moisture and air mixed with the refrig-

erant will raise the compressor head pressure above

acceptable operating levels. This will reduce the per-

formance of the air conditioner and damage the com-

pressor. Moisture will boil at near room temperature

when exposed to vacuum. To evacuate the refrigerant

system:

NOTE: When connecting the service equipment

coupling to the line fitting, verify that the valve of

the coupling is fully closed. This will reduce the

amount of effort required to make the connection.

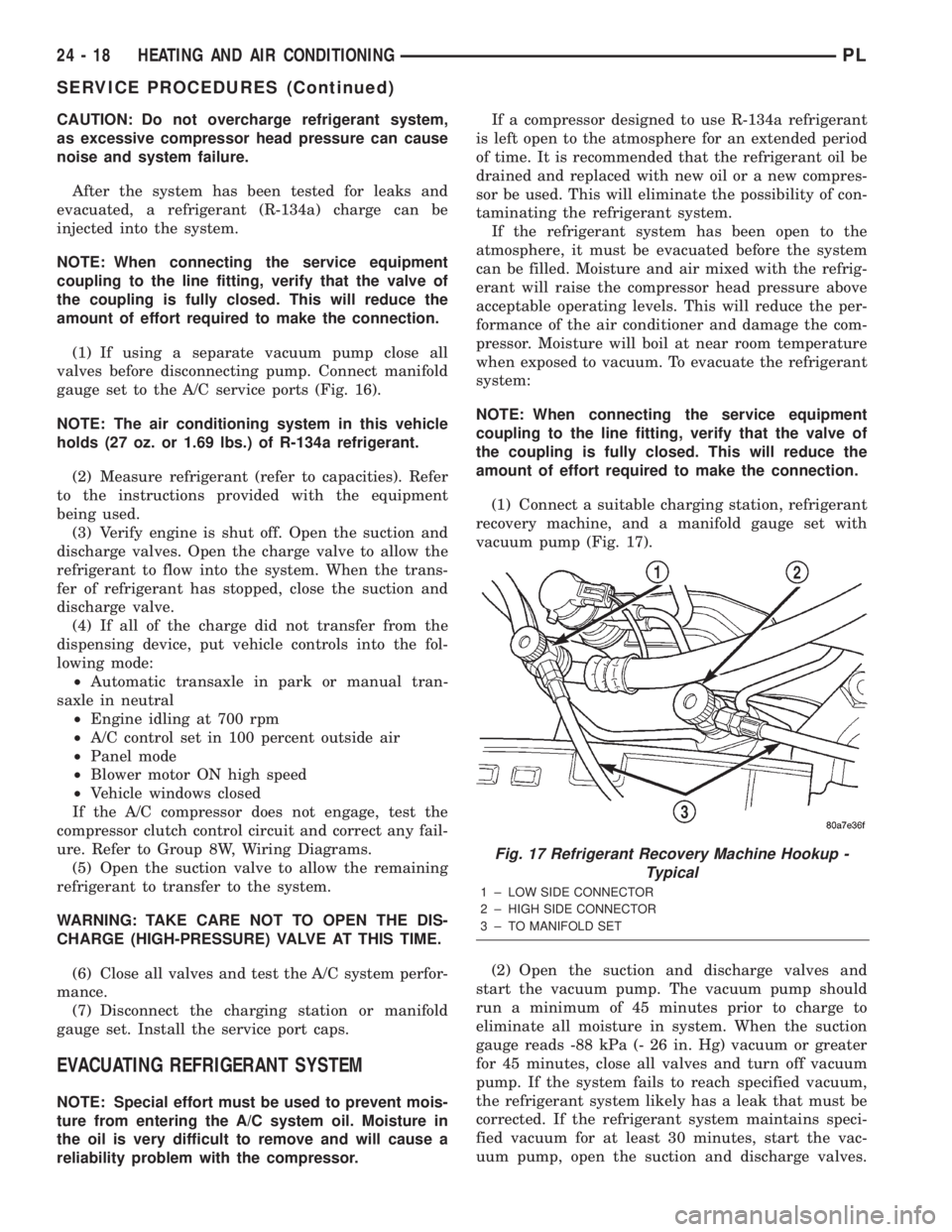

(1) Connect a suitable charging station, refrigerant

recovery machine, and a manifold gauge set with

vacuum pump (Fig. 17).

(2) Open the suction and discharge valves and

start the vacuum pump. The vacuum pump should

run a minimum of 45 minutes prior to charge to

eliminate all moisture in system. When the suction

gauge reads -88 kPa (- 26 in. Hg) vacuum or greater

for 45 minutes, close all valves and turn off vacuum

pump. If the system fails to reach specified vacuum,

the refrigerant system likely has a leak that must be

corrected. If the refrigerant system maintains speci-

fied vacuum for at least 30 minutes, start the vac-

uum pump, open the suction and discharge valves.

Fig. 17 Refrigerant Recovery Machine Hookup -

Typical

1 ± LOW SIDE CONNECTOR

2 ± HIGH SIDE CONNECTOR

3 ± TO MANIFOLD SET

24 - 18 HEATING AND AIR CONDITIONINGPL

SERVICE PROCEDURES (Continued)

Page 1251 of 1285

(1) Discharge refrigerant system using recovery/re-

cycling equipment if charge is present.

(2) Disconnect refrigerant lines from A/C compres-

sor. Cap the open lines to prevent moisture from

entering system.

(3) Remove compressor from vehicle.

(4) From suction port on top of compressor, drain

lubricant from compressor.

(5) Add system capacity minus the capacity of

components that have not been replaced. Refer to the

Lubricant Capacity Chart. Add lubricant through the

suction port on compressor. This is not to exceed 180

ml (6.10 oz.) in total.

(6) Install compressor and connect refrigerant

lines. Then evacuate and charge refrigerant system.

SYSTEM LEAK CHECKING

WARNING: R-134a SERVICE EQUIPMENT OR VEHI-

CLE A/C SYSTEM SHOULD NOT BE PRESSURE

TESTED OR LEAK TESTED WITH COMPRESSED

AIR. MIXTURE OF AIR and R-134a CAN BE COM-

BUSTIBLE AT ELEVATED PRESSURES. THESE MIX-

TURES ARE POTENTIALLY DANGEROUS AND MAY

RESULT IN FIRE OR EXPLOSION CAUSING INJURY

OR PROPERTY DAMAGE.

AVOID BREATHING A/C REFRIGERANT AND

LUBRICANT VAPOR OR MIST. EXPOSURE MAY

IRRITATE EYES, NOSE AND THROAT. USE ONLY

APPROVED SERVICE EQUIPMENT MEETING SAE

REQUIREMENTS TO DISCHARGE R-134a SYSTEM.

IF ACCIDENTAL SYSTEM DISCHARGE OCCURS,

VENTILATE WORK AREA BEFORE RESUMING SER-

VICE.

If the A/C system is not cooling properly, determine

if the refrigerant system is fully charged with

R-134a. This is accomplished by performing a system

Charge Level-Check or Fill. If while performing this

test A/C liquid line pressure is less than 345 kPa (50

psi) proceed to Empty Refrigerant System Leak Test.

If liquid line pressure is greater than 345 kPa (50

psi) proceed to low refrigerant level leak test. If the

refrigerant system is empty or low in refrigerant

charge, a leak at any line fitting or component seal is

likely. A review of the fittings, lines and components

for oily residue is an indication of the leak location.

To detect a leak in the refrigerant system, perform

one of the following procedures as indicated by the

symptoms.

EMPTY REFRIGERANT SYSTEM LEAK TEST

(1) Evacuate the refrigerant system to the lowest

degree of vacuum possible (approx. 28 in Hg.). Deter-

mine if the system holds a vacuum for 15 minutes. If

vacuum is held, a leak is probably not present. If sys-tem will not maintain vacuum level, proceed with

this procedure.

(2) Prepare a.284 Kg. (10 oz.) refrigerant charge to

be injected into the system.

(3) Connect and dispense.284 Kg. (10 oz.) of refrig-

erant into the evacuated refrigerant system.

(4) Proceed to Step 2 of Low Refrigerant Level

Leak Test.

LOW REFRIGERANT LEVEL LEAK TEST

(1) Determine if there is any (R-134a) refrigerant

in the system.

(2) Position the vehicle in a wind free work area.

This will aid in detecting small leaks.

(3) Bring the refrigerant system up to operating

temperature and pressure. This is done by allowing

the engine to run for five minutes with the system

set to the following:

²Transaxle in Park

²Engine Idling at 700 rpm

²A/C Controls Set in 100 percent outside air

²Blower switch in the high A/C position

²A/C in the ON position

²Open all windows

CAUTION: A leak detector designed for R-12 refrig-

erant (only) will not detect leaks in a R-134a refrig-

erant system.

(4) Shut off the vehicle and wait 2 to 7 minutes.

Then use an Electronic Leak Detector that is

designed to detect R-134a type refrigerant and search

for leaks. Fittings, lines, or components that appear

to be oily usually indicates a refrigerant leak. To

inspect the evaporator core for leaks, insert the leak

detector probe into the drain tube opening or a heat

duct. A R-134a dye is available to aid in leak detec-

tion, use only Chrysler approved refrigerant dye.

If a thorough leak check has been completed with-

out indication of a leak, proceed to System Charge

Level.

REMOVAL AND INSTALLATION

A/C FILTER/DRIER

The filter/drier is mounted in a rubber grommet on

the right side of the engine compartment. The refrig-

erant must be recovered from the A/C system before

replacing the filter/drier assembly.

WARNING: THE REFRIGERATION SYSTEM MUST

BE COMPLETELY RECOVERED BEFORE PRO-

CEEDING WITH THIS OPERATION.

24 - 20 HEATING AND AIR CONDITIONINGPL

SERVICE PROCEDURES (Continued)

Page 1256 of 1285

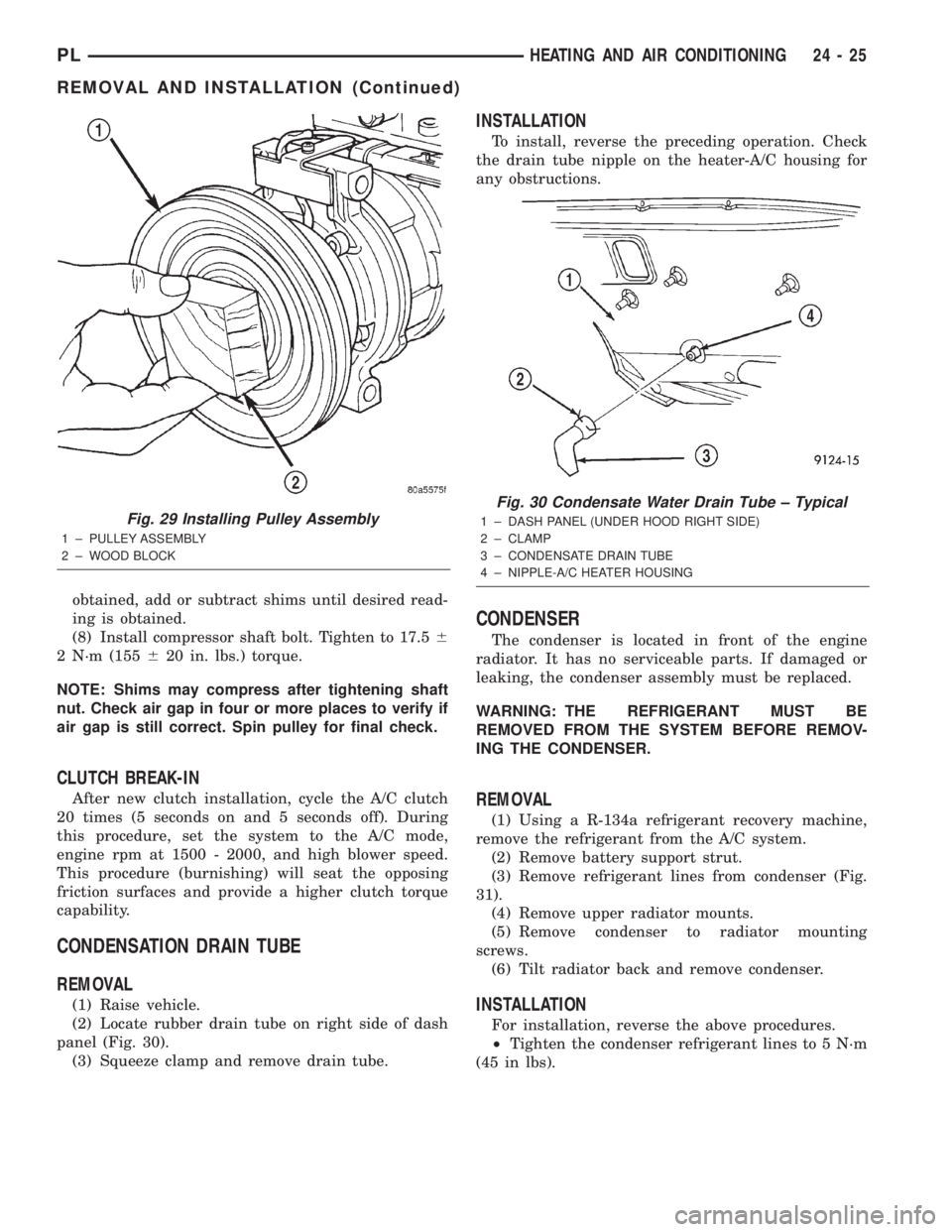

obtained, add or subtract shims until desired read-

ing is obtained.

(8) Install compressor shaft bolt. Tighten to 17.56

2 N´m (155620 in. lbs.) torque.

NOTE: Shims may compress after tightening shaft

nut. Check air gap in four or more places to verify if

air gap is still correct. Spin pulley for final check.

CLUTCH BREAK-IN

After new clutch installation, cycle the A/C clutch

20 times (5 seconds on and 5 seconds off). During

this procedure, set the system to the A/C mode,

engine rpm at 1500 - 2000, and high blower speed.

This procedure (burnishing) will seat the opposing

friction surfaces and provide a higher clutch torque

capability.

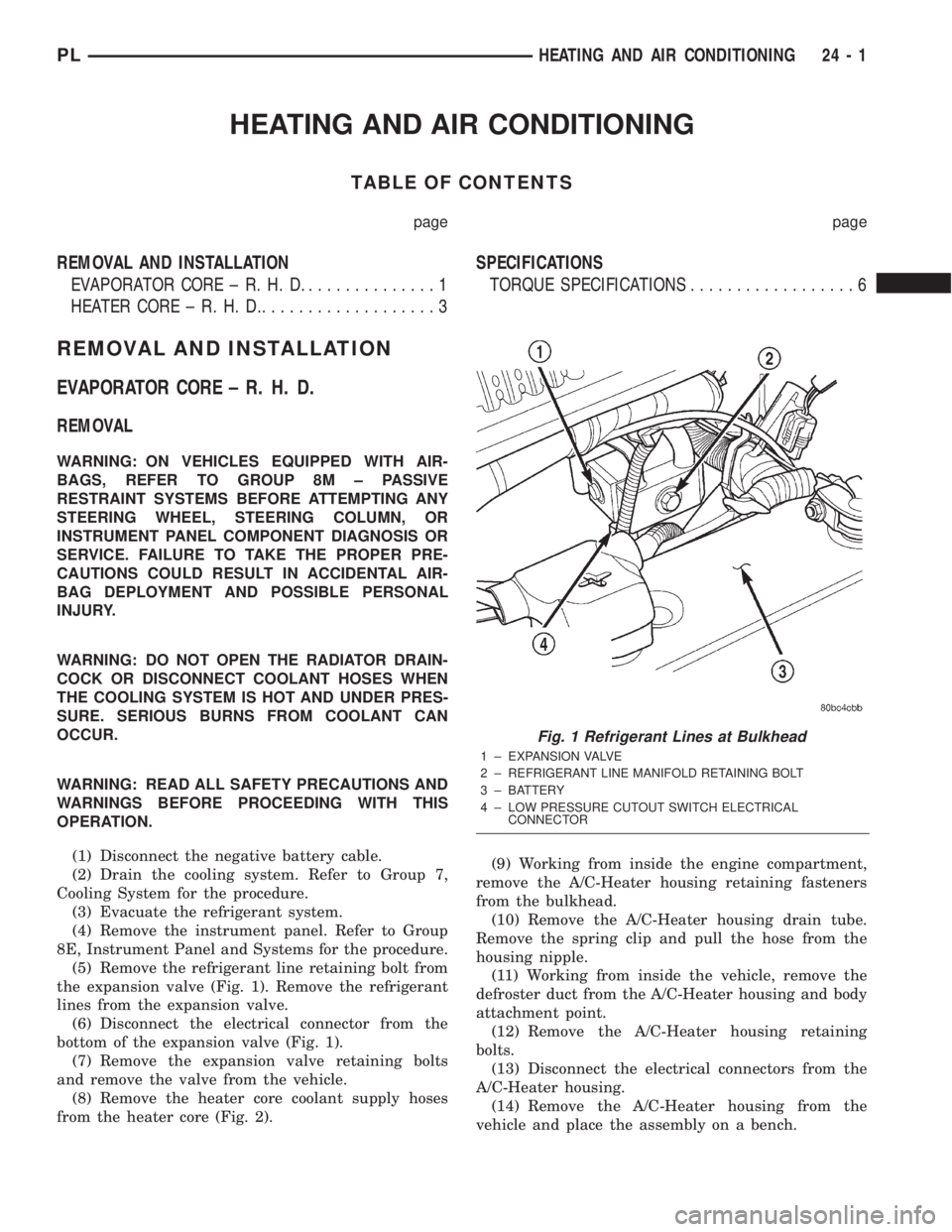

CONDENSATION DRAIN TUBE

REMOVAL

(1) Raise vehicle.

(2) Locate rubber drain tube on right side of dash

panel (Fig. 30).

(3) Squeeze clamp and remove drain tube.

INSTALLATION

To install, reverse the preceding operation. Check

the drain tube nipple on the heater-A/C housing for

any obstructions.

CONDENSER

The condenser is located in front of the engine

radiator. It has no serviceable parts. If damaged or

leaking, the condenser assembly must be replaced.

WARNING: THE REFRIGERANT MUST BE

REMOVED FROM THE SYSTEM BEFORE REMOV-

ING THE CONDENSER.

REMOVAL

(1) Using a R-134a refrigerant recovery machine,

remove the refrigerant from the A/C system.

(2) Remove battery support strut.

(3) Remove refrigerant lines from condenser (Fig.

31).

(4) Remove upper radiator mounts.

(5) Remove condenser to radiator mounting

screws.

(6) Tilt radiator back and remove condenser.

INSTALLATION

For installation, reverse the above procedures.

²Tighten the condenser refrigerant lines to 5 N´m

(45 in lbs).

Fig. 29 Installing Pulley Assembly

1 ± PULLEY ASSEMBLY

2 ± WOOD BLOCK

Fig. 30 Condensate Water Drain Tube ± Typical

1 ± DASH PANEL (UNDER HOOD RIGHT SIDE)

2 ± CLAMP

3 ± CONDENSATE DRAIN TUBE

4 ± NIPPLE-A/C HEATER HOUSING

PLHEATING AND AIR CONDITIONING 24 - 25

REMOVAL AND INSTALLATION (Continued)

Page 1268 of 1285

HEATING AND AIR CONDITIONING

TABLE OF CONTENTS

page page

REMOVAL AND INSTALLATION

EVAPORATOR CORE ± R. H. D...............1

HEATER CORE ± R. H. D....................3SPECIFICATIONS

TORQUE SPECIFICATIONS..................6

REMOVAL AND INSTALLATION

EVAPORATOR CORE ± R. H. D.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO GROUP 8M ± PASSIVE

RESTRAINT SYSTEMS BEFORE ATTEMPTING ANY

STEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

WARNING: DO NOT OPEN THE RADIATOR DRAIN-

COCK OR DISCONNECT COOLANT HOSES WHEN

THE COOLING SYSTEM IS HOT AND UNDER PRES-

SURE. SERIOUS BURNS FROM COOLANT CAN

OCCUR.

WARNING: READ ALL SAFETY PRECAUTIONS AND

WARNINGS BEFORE PROCEEDING WITH THIS

OPERATION.

(1) Disconnect the negative battery cable.

(2) Drain the cooling system. Refer to Group 7,

Cooling System for the procedure.

(3) Evacuate the refrigerant system.

(4) Remove the instrument panel. Refer to Group

8E, Instrument Panel and Systems for the procedure.

(5) Remove the refrigerant line retaining bolt from

the expansion valve (Fig. 1). Remove the refrigerant

lines from the expansion valve.

(6) Disconnect the electrical connector from the

bottom of the expansion valve (Fig. 1).

(7) Remove the expansion valve retaining bolts

and remove the valve from the vehicle.

(8) Remove the heater core coolant supply hoses

from the heater core (Fig. 2).(9) Working from inside the engine compartment,

remove the A/C-Heater housing retaining fasteners

from the bulkhead.

(10) Remove the A/C-Heater housing drain tube.

Remove the spring clip and pull the hose from the

housing nipple.

(11) Working from inside the vehicle, remove the

defroster duct from the A/C-Heater housing and body

attachment point.

(12) Remove the A/C-Heater housing retaining

bolts.

(13) Disconnect the electrical connectors from the

A/C-Heater housing.

(14) Remove the A/C-Heater housing from the

vehicle and place the assembly on a bench.

Fig. 1 Refrigerant Lines at Bulkhead

1 ± EXPANSION VALVE

2 ± REFRIGERANT LINE MANIFOLD RETAINING BOLT

3 ± BATTERY

4 ± LOW PRESSURE CUTOUT SWITCH ELECTRICAL

CONNECTOR

PLHEATING AND AIR CONDITIONING 24 - 1