pressure DODGE NEON 2000 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 4 of 1285

MAINTENANCE SCHEDULES

TABLE OF CONTENTS

page page

DESCRIPTION AND OPERATION

MAINTENANCE SCHEDULES................3

SPECIFICATIONS

UNSCHEDULED INSPECTION................3SCHEDULE ± A...........................3

SCHEDULE ± B...........................4

DESCRIPTION AND OPERATION

MAINTENANCE SCHEDULES

There are two maintenance schedules that show

proper service for your vehicle.

First is Schedule ±A. It lists all the scheduled

maintenance to be performed under ªnormalº operat-

ing conditions.

Second is Schedule ±B. It is a schedule for vehi-

cles that are operated under the following conditions:

²Frequent short trip driving less than 5 miles (8

km)

²Frequent driving in dusty conditions

²Extensive idling

²More than 50% of the driving is at sustained

high speeds during hot weather, above 90É F (32É C)

SPECIFICATIONS

UNSCHEDULED INSPECTION

At Each Stop For Fuel

²Check engine oil level and add as required.

²Check windshield washer solvent and add as

required.

Once A Month

²Check tire pressure and look for unusual wear

or damage.

²Inspect the battery and clean and tighten termi-

nals as required.

²Check fluid levels of coolant reservoir, brake

master cylinder, power steering and transmission.

Add fluid as required.

²Check all lights and all other electrical items for

correct operation.

At Each Oil Change

²Inspect the exhaust system.

²Inspect brake hoses.

²Inspect the CV joints and front suspension com-

ponent boots and seals.²Rotate the tires at each oil change interval

shown on Schedule ± A (7,500 miles - 12 000 km) or

every other interval on Schedule ± B (6,000 miles -

10 000 km).

²Check the engine coolant level, hoses, and

clamps.

If mileage is less than 7,500 miles (12 000 km)

yearly, replace the engine oil filter at each oil change.

EMISSION CONTROL SYSTEM MAINTENANCE

The scheduled emission maintenance listed inbold

typeon the Maintenance Schedules, must be done at

the mileage specified to assure the continued proper

functioning of the emission control system. These,

and all other maintenance services included in this

manual, should be done to provide the best vehicle

performance and reliability. More frequent mainte-

nance may be needed for vehicles in severe operating

conditions such as dusty areas and very short trip

driving.

FLUID FILL POINTS AND LUBRICATION

LOCATIONS

The fluid fill/check locations and lubrication loca-

tions are located in each applicable group.

SCHEDULE ± A

7,500 Miles (12 000 km) or at 6 months

²Change the engine oil.

²Replace the engine oil filter.

15,000 Miles (24 000 km) or at 12 months

²Change the engine oil.

²Replace the engine oil filter.

²Adjust the drive belt tension.

22,500 Miles (36 000 km) or at 18 months

²Change the engine oil.

²Replace the engine oil filter.

²Inspect the front brake pads and rear brake lin-

ings.

PLLUBRICATION AND MAINTENANCE 0 - 3

Page 15 of 1285

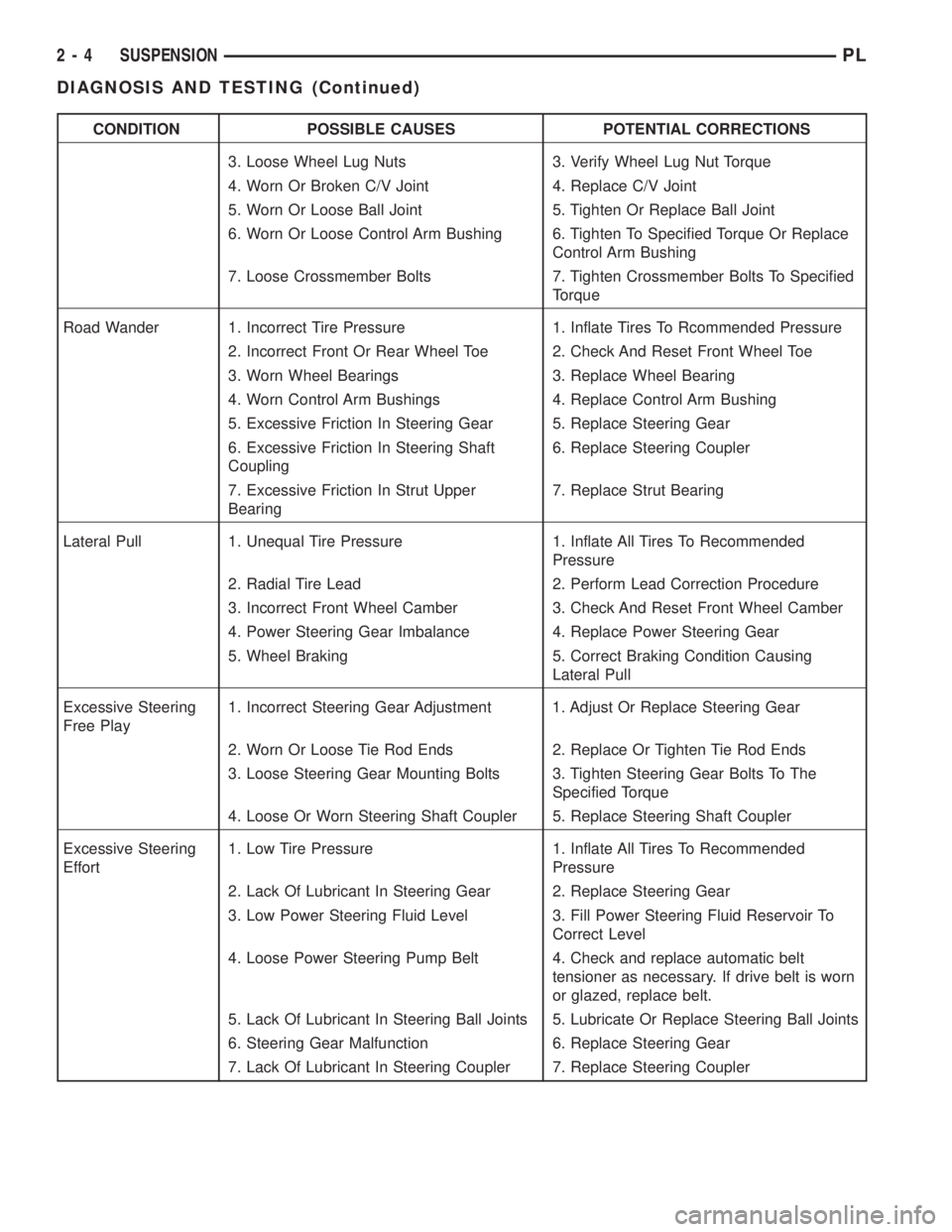

CONDITION POSSIBLE CAUSES POTENTIAL CORRECTIONS

3. Loose Wheel Lug Nuts 3. Verify Wheel Lug Nut Torque

4. Worn Or Broken C/V Joint 4. Replace C/V Joint

5. Worn Or Loose Ball Joint 5. Tighten Or Replace Ball Joint

6. Worn Or Loose Control Arm Bushing 6. Tighten To Specified Torque Or Replace

Control Arm Bushing

7. Loose Crossmember Bolts 7. Tighten Crossmember Bolts To Specified

Torque

Road Wander 1. Incorrect Tire Pressure 1. Inflate Tires To Rcommended Pressure

2. Incorrect Front Or Rear Wheel Toe 2. Check And Reset Front Wheel Toe

3. Worn Wheel Bearings 3. Replace Wheel Bearing

4. Worn Control Arm Bushings 4. Replace Control Arm Bushing

5. Excessive Friction In Steering Gear 5. Replace Steering Gear

6. Excessive Friction In Steering Shaft

Coupling6. Replace Steering Coupler

7. Excessive Friction In Strut Upper

Bearing7. Replace Strut Bearing

Lateral Pull 1. Unequal Tire Pressure 1. Inflate All Tires To Recommended

Pressure

2. Radial Tire Lead 2. Perform Lead Correction Procedure

3. Incorrect Front Wheel Camber 3. Check And Reset Front Wheel Camber

4. Power Steering Gear Imbalance 4. Replace Power Steering Gear

5. Wheel Braking 5. Correct Braking Condition Causing

Lateral Pull

Excessive Steering

Free Play1. Incorrect Steering Gear Adjustment 1. Adjust Or Replace Steering Gear

2. Worn Or Loose Tie Rod Ends 2. Replace Or Tighten Tie Rod Ends

3. Loose Steering Gear Mounting Bolts 3. Tighten Steering Gear Bolts To The

Specified Torque

4. Loose Or Worn Steering Shaft Coupler 5. Replace Steering Shaft Coupler

Excessive Steering

Effort1. Low Tire Pressure 1. Inflate All Tires To Recommended

Pressure

2. Lack Of Lubricant In Steering Gear 2. Replace Steering Gear

3. Low Power Steering Fluid Level 3. Fill Power Steering Fluid Reservoir To

Correct Level

4. Loose Power Steering Pump Belt 4. Check and replace automatic belt

tensioner as necessary. If drive belt is worn

or glazed, replace belt.

5. Lack Of Lubricant In Steering Ball Joints 5. Lubricate Or Replace Steering Ball Joints

6. Steering Gear Malfunction 6. Replace Steering Gear

7. Lack Of Lubricant In Steering Coupler 7. Replace Steering Coupler

2 - 4 SUSPENSIONPL

DIAGNOSIS AND TESTING (Continued)

Page 16 of 1285

SERVICE PROCEDURES

CURB HEIGHT MEASUREMENT

The wheel alignment is to be checked and all align-

ment adjustments made with the vehicle at its

required curb height specification.

Vehicle height is to be checked with the vehicle on

a flat, level surface, preferably a vehicle alignment

rack. The tires are to be inflated to the recommended

pressure. All tires are to be the same size as stan-

dard equipment. Vehicle height is checked with the

fuel tank full of fuel, and no passenger or luggage

compartment load.

Vehicle height is not adjustable. If the measure-

ment is not within specifications, inspect the vehicle

for bent or weak suspension components. Compare

the parts tag on the suspect coil spring(s) to the

parts book and the vehicle sales code, checking for a

match. Once removed from the vehicle, compare thecoil spring height to a correct new or known good coil

spring. The heights should vary if the suspect spring

is weak.

NOTE: Prior to reading the curb height measure-

ment, the front an rear of the vehicle should be

jounced. Induce jounce by grasping the center of

the rear, then front bumper (or fascia) and jouncing

the vehicle an equal number of times. Release the

bumper at the bottom of the jounce cycle.

(1) Measure from the inboard edge of the wheel

opening fender lip directly above the wheel center

(spindle), to the floor or alignment rack surface.

(2) When measuring, maximum left-to-right differ-

ential is not to exceed 10 mm (0.39 in.).

(3) Compare the measurements to specifications

listed in the following CURB HEIGHT SPECIFICA-

TIONS chart.

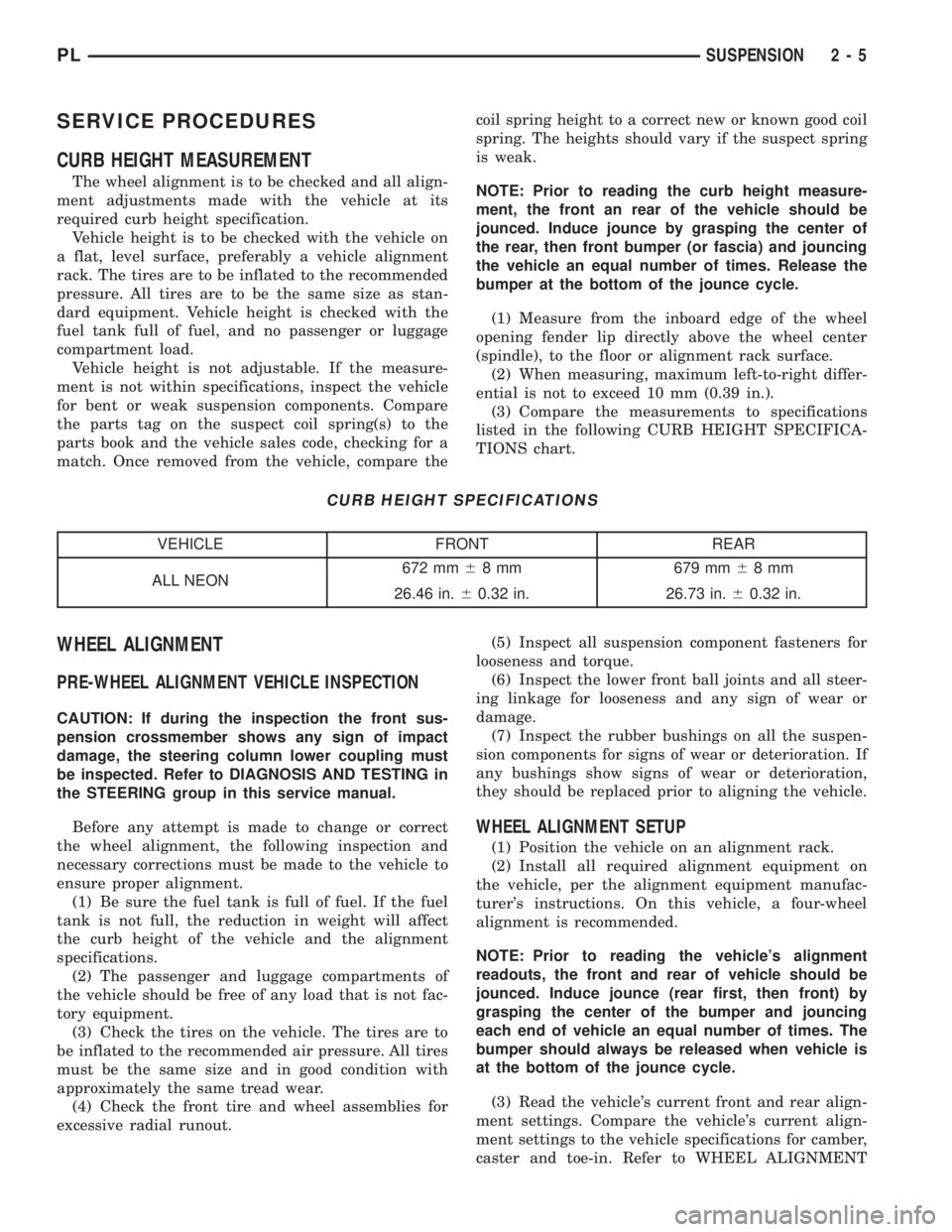

CURB HEIGHT SPECIFICATIONS

VEHICLE FRONT REAR

ALL NEON672 mm68 mm 679 mm68mm

26.46 in.60.32 in. 26.73 in.60.32 in.

WHEEL ALIGNMENT

PRE-WHEEL ALIGNMENT VEHICLE INSPECTION

CAUTION: If during the inspection the front sus-

pension crossmember shows any sign of impact

damage, the steering column lower coupling must

be inspected. Refer to DIAGNOSIS AND TESTING in

the STEERING group in this service manual.

Before any attempt is made to change or correct

the wheel alignment, the following inspection and

necessary corrections must be made to the vehicle to

ensure proper alignment.

(1) Be sure the fuel tank is full of fuel. If the fuel

tank is not full, the reduction in weight will affect

the curb height of the vehicle and the alignment

specifications.

(2) The passenger and luggage compartments of

the vehicle should be free of any load that is not fac-

tory equipment.

(3) Check the tires on the vehicle. The tires are to

be inflated to the recommended air pressure. All tires

must be the same size and in good condition with

approximately the same tread wear.

(4) Check the front tire and wheel assemblies for

excessive radial runout.(5) Inspect all suspension component fasteners for

looseness and torque.

(6) Inspect the lower front ball joints and all steer-

ing linkage for looseness and any sign of wear or

damage.

(7) Inspect the rubber bushings on all the suspen-

sion components for signs of wear or deterioration. If

any bushings show signs of wear or deterioration,

they should be replaced prior to aligning the vehicle.

WHEEL ALIGNMENT SETUP

(1) Position the vehicle on an alignment rack.

(2) Install all required alignment equipment on

the vehicle, per the alignment equipment manufac-

turer's instructions. On this vehicle, a four-wheel

alignment is recommended.

NOTE: Prior to reading the vehicle's alignment

readouts, the front and rear of vehicle should be

jounced. Induce jounce (rear first, then front) by

grasping the center of the bumper and jouncing

each end of vehicle an equal number of times. The

bumper should always be released when vehicle is

at the bottom of the jounce cycle.

(3) Read the vehicle's current front and rear align-

ment settings. Compare the vehicle's current align-

ment settings to the vehicle specifications for camber,

caster and toe-in. Refer to WHEEL ALIGNMENT

PLSUSPENSION 2 - 5

Page 25 of 1285

CAUTION: No attempt should be made to service

the headless grease fitting on the ball joint. It has

been purposely snapped off by the manufacturer to

avoid over-greasing.

STABILIZER BAR (FRONT)

Inspect for broken, cracked or distorted stabilizer

bar cushions and retainers. Inspect for worn or dam-

aged stabilizer bar links (Fig. 1).

SERVICE PROCEDURES

LUBRICATION

There are no serviceable lubrication points on the

front suspension. The front lower ball joints have

grease fittings which have had the head snapped off

by the manufacturer after they have been filled. This

has been done to eliminate the possibility of damag-

ing the non-vented seals. Grease will not leak from

the broken grease fittings. The ball joints are sealed

for life and require no maintenance.

CAUTION: No attempt should be made to replace

the ball joint grease fitting with a new fitting, then

filling the ball joint with grease. Damage to the

grease seal can result.

REMOVAL AND INSTALLATION

SERVICE WARNINGS AND CAUTIONS

WARNING: DO NOT REMOVE THE STRUT SHAFT

NUT WHILE STRUT ASSEMBLY IS INSTALLED IN

VEHICLE, OR BEFORE THE COIL SPRING IS COM-

PRESSED WITH A COMPRESSION TOOL. THE

SPRING IS HELD UNDER HIGH PRESSURE.

CAUTION: Only frame contact hoisting equipment

can be used on this vehicle. All vehicles have a

fully independent rear suspension. The vehicles

cannot be hoisted using equipment designed to lift

a vehicle by the rear axle. If this type of hoisting

equipment is used, damage to rear suspension

components will occur.

CAUTION: At no time when servicing a vehicle can

a sheet metal screw, bolt, or other metal fastener be

installed in the shock tower to take the place of an

original plastic clip. It may come into contact with

the strut or coil spring.CAUTION: Wheel bearing damage will result if after

loosening the hub nut, the vehicle is rolled on the

ground or the weight of the vehicle is allowed to be

supported by the tires for a length of time.

STRUT ASSEMBLY (FRONT)

NOTE: Before proceeding with this procedure,

review SERVICE WARNINGS AND CAUTIONS at the

beginning of REMOVAL AND INSTALLATION in this

section.

REMOVAL

(1) Raise the vehicle. Refer to HOISTING in the

LUBRICATION AND MAINTENANCE group for the

proper lifting procedure.

(2) Remove tire and wheel assembly from location

on front of vehicle requiring strut removal.

(3) If both strut assemblies are to be removed,

mark the strut assemblies right or left according to

which side of the vehicle they were removed from.

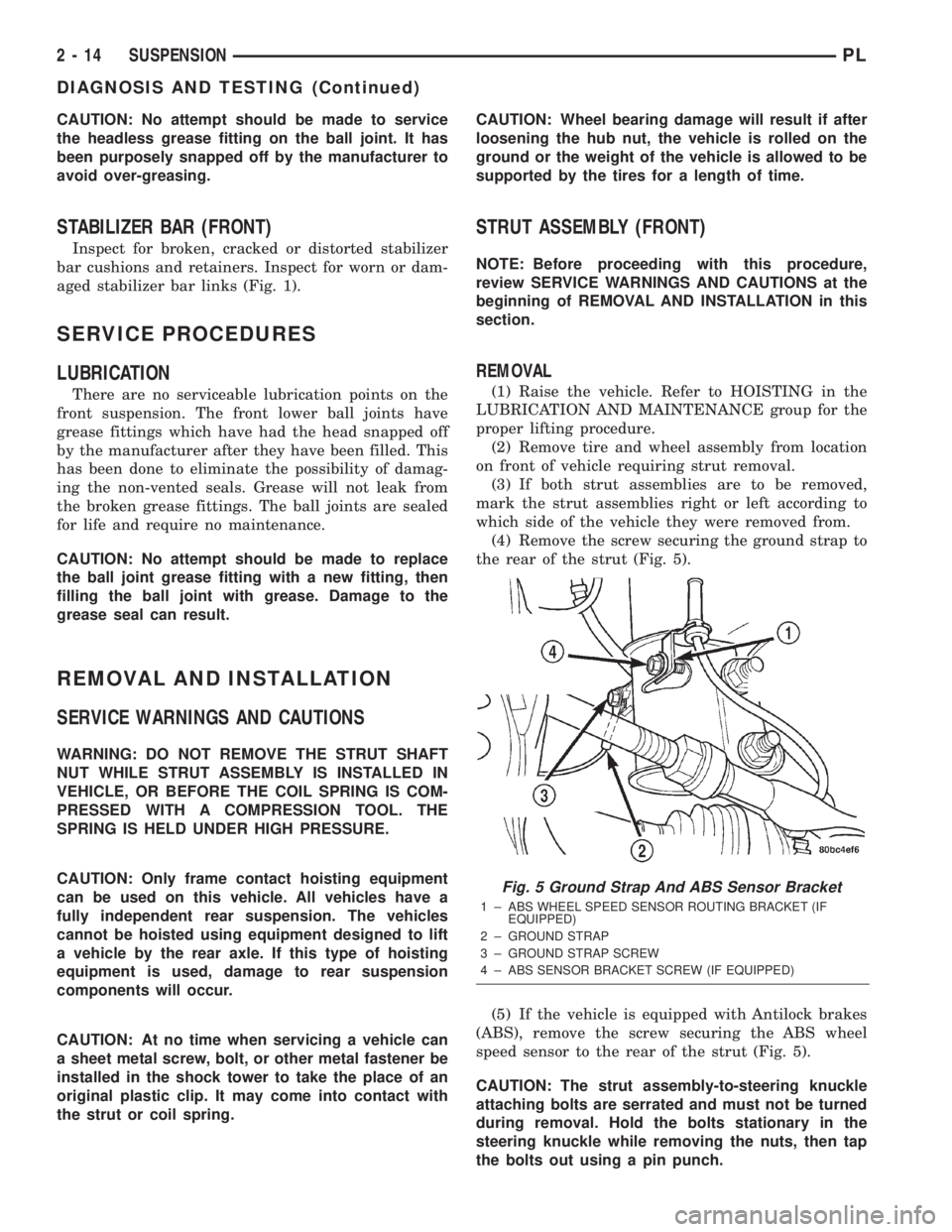

(4) Remove the screw securing the ground strap to

the rear of the strut (Fig. 5).

(5) If the vehicle is equipped with Antilock brakes

(ABS), remove the screw securing the ABS wheel

speed sensor to the rear of the strut (Fig. 5).

CAUTION: The strut assembly-to-steering knuckle

attaching bolts are serrated and must not be turned

during removal. Hold the bolts stationary in the

steering knuckle while removing the nuts, then tap

the bolts out using a pin punch.

Fig. 5 Ground Strap And ABS Sensor Bracket

1 ± ABS WHEEL SPEED SENSOR ROUTING BRACKET (IF

EQUIPPED)

2 ± GROUND STRAP

3 ± GROUND STRAP SCREW

4 ± ABS SENSOR BRACKET SCREW (IF EQUIPPED)

2 - 14 SUSPENSIONPL

DIAGNOSIS AND TESTING (Continued)

Page 34 of 1285

removed from, and which strut the coil spring was

removed from.

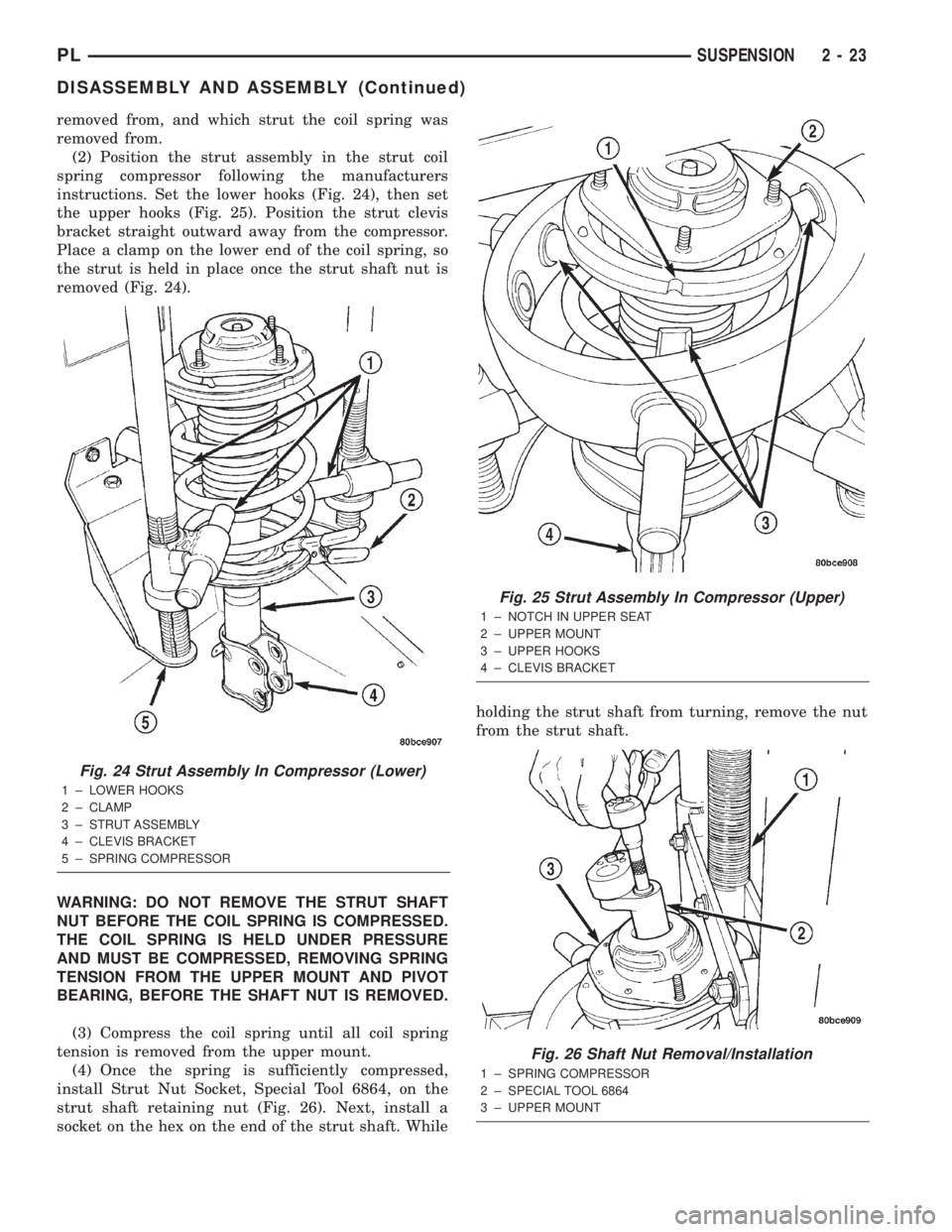

(2) Position the strut assembly in the strut coil

spring compressor following the manufacturers

instructions. Set the lower hooks (Fig. 24), then set

the upper hooks (Fig. 25). Position the strut clevis

bracket straight outward away from the compressor.

Place a clamp on the lower end of the coil spring, so

the strut is held in place once the strut shaft nut is

removed (Fig. 24).

WARNING: DO NOT REMOVE THE STRUT SHAFT

NUT BEFORE THE COIL SPRING IS COMPRESSED.

THE COIL SPRING IS HELD UNDER PRESSURE

AND MUST BE COMPRESSED, REMOVING SPRING

TENSION FROM THE UPPER MOUNT AND PIVOT

BEARING, BEFORE THE SHAFT NUT IS REMOVED.

(3) Compress the coil spring until all coil spring

tension is removed from the upper mount.

(4) Once the spring is sufficiently compressed,

install Strut Nut Socket, Special Tool 6864, on the

strut shaft retaining nut (Fig. 26). Next, install a

socket on the hex on the end of the strut shaft. Whileholding the strut shaft from turning, remove the nut

from the strut shaft.

Fig. 24 Strut Assembly In Compressor (Lower)

1 ± LOWER HOOKS

2 ± CLAMP

3 ± STRUT ASSEMBLY

4 ± CLEVIS BRACKET

5 ± SPRING COMPRESSOR

Fig. 25 Strut Assembly In Compressor (Upper)

1 ± NOTCH IN UPPER SEAT

2 ± UPPER MOUNT

3 ± UPPER HOOKS

4 ± CLEVIS BRACKET

Fig. 26 Shaft Nut Removal/Installation

1 ± SPRING COMPRESSOR

2 ± SPECIAL TOOL 6864

3 ± UPPER MOUNT

PLSUSPENSION 2 - 23

DISASSEMBLY AND ASSEMBLY (Continued)

Page 42 of 1285

ball joint bottoms against the lower control arm ball

joint bore. Do not apply excessive pressure against

ball joint and lower control arm once the ball joint

bottoms.

(5) Remove the tools and arm from the hydraulic

press.

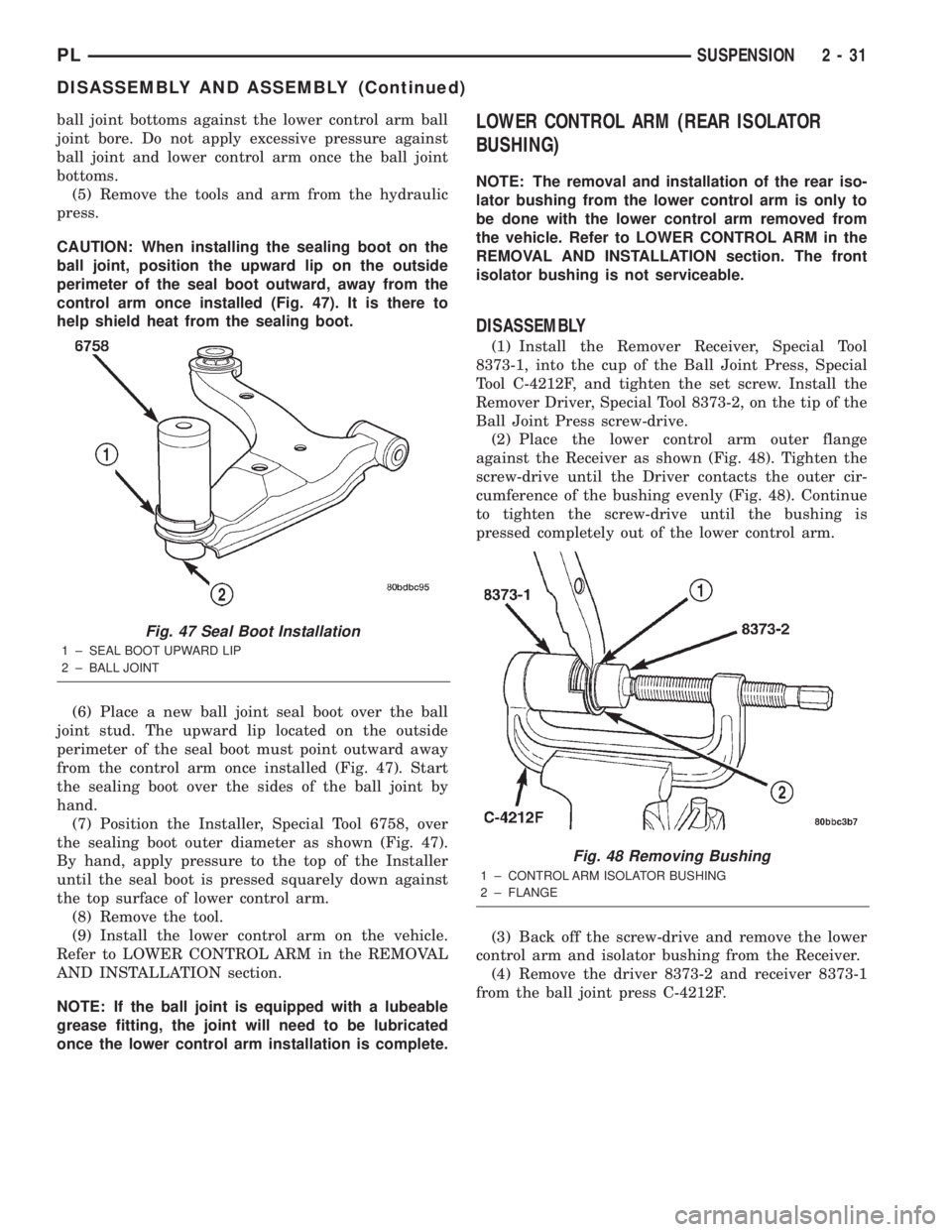

CAUTION: When installing the sealing boot on the

ball joint, position the upward lip on the outside

perimeter of the seal boot outward, away from the

control arm once installed (Fig. 47). It is there to

help shield heat from the sealing boot.

(6) Place a new ball joint seal boot over the ball

joint stud. The upward lip located on the outside

perimeter of the seal boot must point outward away

from the control arm once installed (Fig. 47). Start

the sealing boot over the sides of the ball joint by

hand.

(7) Position the Installer, Special Tool 6758, over

the sealing boot outer diameter as shown (Fig. 47).

By hand, apply pressure to the top of the Installer

until the seal boot is pressed squarely down against

the top surface of lower control arm.

(8) Remove the tool.

(9) Install the lower control arm on the vehicle.

Refer to LOWER CONTROL ARM in the REMOVAL

AND INSTALLATION section.

NOTE: If the ball joint is equipped with a lubeable

grease fitting, the joint will need to be lubricated

once the lower control arm installation is complete.LOWER CONTROL ARM (REAR ISOLATOR

BUSHING)

NOTE: The removal and installation of the rear iso-

lator bushing from the lower control arm is only to

be done with the lower control arm removed from

the vehicle. Refer to LOWER CONTROL ARM in the

REMOVAL AND INSTALLATION section. The front

isolator bushing is not serviceable.

DISASSEMBLY

(1) Install the Remover Receiver, Special Tool

8373-1, into the cup of the Ball Joint Press, Special

Tool C-4212F, and tighten the set screw. Install the

Remover Driver, Special Tool 8373-2, on the tip of the

Ball Joint Press screw-drive.

(2) Place the lower control arm outer flange

against the Receiver as shown (Fig. 48). Tighten the

screw-drive until the Driver contacts the outer cir-

cumference of the bushing evenly (Fig. 48). Continue

to tighten the screw-drive until the bushing is

pressed completely out of the lower control arm.

(3) Back off the screw-drive and remove the lower

control arm and isolator bushing from the Receiver.

(4) Remove the driver 8373-2 and receiver 8373-1

from the ball joint press C-4212F.

Fig. 47 Seal Boot Installation

1 ± SEAL BOOT UPWARD LIP

2 ± BALL JOINT

Fig. 48 Removing Bushing

1 ± CONTROL ARM ISOLATOR BUSHING

2 ± FLANGE

PLSUSPENSION 2 - 31

DISASSEMBLY AND ASSEMBLY (Continued)

Page 51 of 1285

REMOVAL AND INSTALLATION

SERVICE WARNINGS AND CAUTIONS

WARNING: DO NOT REMOVE THE STRUT SHAFT

NUT WHILE STRUT ASSEMBLY IS INSTALLED IN

VEHICLE, OR BEFORE THE COIL SPRING IS COM-

PRESSED WITH A COMPRESSION TOOL. THE

SPRING IS HELD UNDER HIGH PRESSURE.

CAUTION: Only frame contact or wheel lift hoisting

equipment can be used on vehicles having a fully

independent rear suspension. Vehicles with inde-

pendent rear suspension can not be hoisted using

equipment designed to lift a vehicle by the rear

axle. If this type of hoisting equipment is used dam-

age to rear suspension components will occur.

NOTE: If a rear suspension component becomes

bent, damaged or fails, no attempt should be made

to straighten or repair it. Always replace it with a

new component.

STRUT ASSEMBLY (REAR)

NOTE: Before proceeding with this procedure,

review SERVICE WARNINGS AND CAUTIONS at the

beginning of REMOVAL AND INSTALLATION in this

section.

REMOVAL

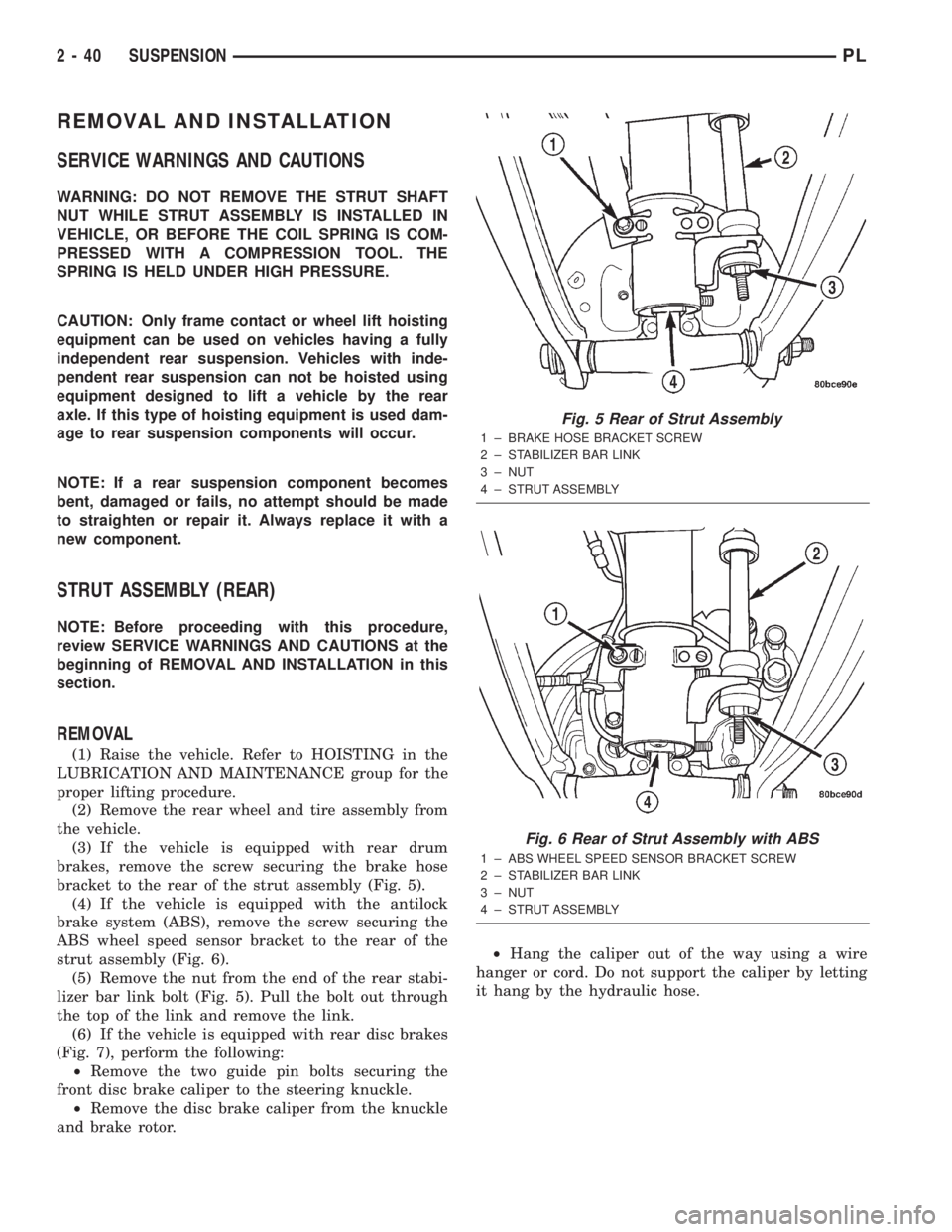

(1) Raise the vehicle. Refer to HOISTING in the

LUBRICATION AND MAINTENANCE group for the

proper lifting procedure.

(2) Remove the rear wheel and tire assembly from

the vehicle.

(3) If the vehicle is equipped with rear drum

brakes, remove the screw securing the brake hose

bracket to the rear of the strut assembly (Fig. 5).

(4) If the vehicle is equipped with the antilock

brake system (ABS), remove the screw securing the

ABS wheel speed sensor bracket to the rear of the

strut assembly (Fig. 6).

(5) Remove the nut from the end of the rear stabi-

lizer bar link bolt (Fig. 5). Pull the bolt out through

the top of the link and remove the link.

(6) If the vehicle is equipped with rear disc brakes

(Fig. 7), perform the following:

²Remove the two guide pin bolts securing the

front disc brake caliper to the steering knuckle.

²Remove the disc brake caliper from the knuckle

and brake rotor.²Hang the caliper out of the way using a wire

hanger or cord. Do not support the caliper by letting

it hang by the hydraulic hose.

Fig. 5 Rear of Strut Assembly

1 ± BRAKE HOSE BRACKET SCREW

2 ± STABILIZER BAR LINK

3 ± NUT

4 ± STRUT ASSEMBLY

Fig. 6 Rear of Strut Assembly with ABS

1 ± ABS WHEEL SPEED SENSOR BRACKET SCREW

2 ± STABILIZER BAR LINK

3 ± NUT

4 ± STRUT ASSEMBLY

2 - 40 SUSPENSIONPL

Page 59 of 1285

DISASSEMBLY

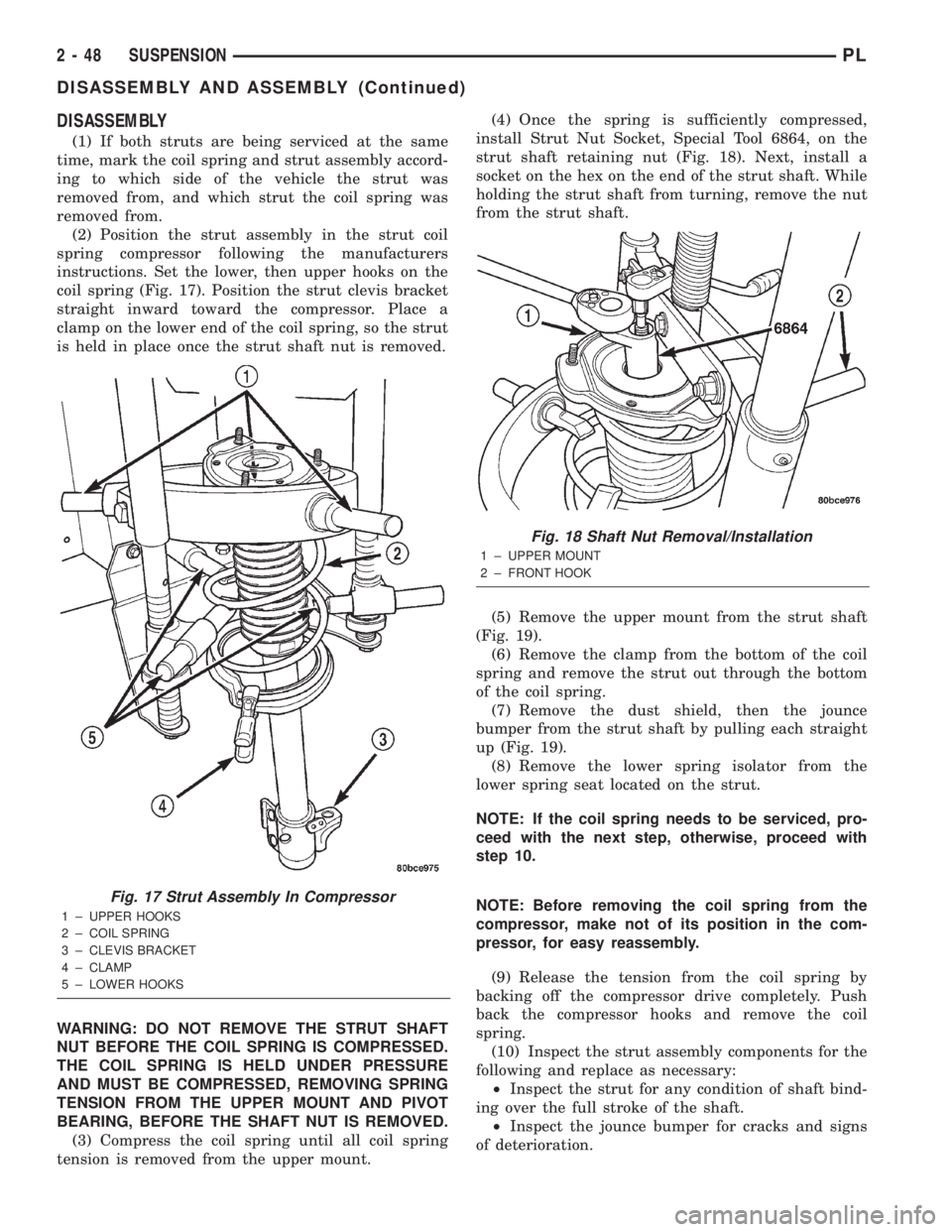

(1) If both struts are being serviced at the same

time, mark the coil spring and strut assembly accord-

ing to which side of the vehicle the strut was

removed from, and which strut the coil spring was

removed from.

(2) Position the strut assembly in the strut coil

spring compressor following the manufacturers

instructions. Set the lower, then upper hooks on the

coil spring (Fig. 17). Position the strut clevis bracket

straight inward toward the compressor. Place a

clamp on the lower end of the coil spring, so the strut

is held in place once the strut shaft nut is removed.

WARNING: DO NOT REMOVE THE STRUT SHAFT

NUT BEFORE THE COIL SPRING IS COMPRESSED.

THE COIL SPRING IS HELD UNDER PRESSURE

AND MUST BE COMPRESSED, REMOVING SPRING

TENSION FROM THE UPPER MOUNT AND PIVOT

BEARING, BEFORE THE SHAFT NUT IS REMOVED.

(3) Compress the coil spring until all coil spring

tension is removed from the upper mount.(4) Once the spring is sufficiently compressed,

install Strut Nut Socket, Special Tool 6864, on the

strut shaft retaining nut (Fig. 18). Next, install a

socket on the hex on the end of the strut shaft. While

holding the strut shaft from turning, remove the nut

from the strut shaft.

(5) Remove the upper mount from the strut shaft

(Fig. 19).

(6) Remove the clamp from the bottom of the coil

spring and remove the strut out through the bottom

of the coil spring.

(7) Remove the dust shield, then the jounce

bumper from the strut shaft by pulling each straight

up (Fig. 19).

(8) Remove the lower spring isolator from the

lower spring seat located on the strut.

NOTE: If the coil spring needs to be serviced, pro-

ceed with the next step, otherwise, proceed with

step 10.

NOTE: Before removing the coil spring from the

compressor, make not of its position in the com-

pressor, for easy reassembly.

(9) Release the tension from the coil spring by

backing off the compressor drive completely. Push

back the compressor hooks and remove the coil

spring.

(10) Inspect the strut assembly components for the

following and replace as necessary:

²Inspect the strut for any condition of shaft bind-

ing over the full stroke of the shaft.

²Inspect the jounce bumper for cracks and signs

of deterioration.

Fig. 17 Strut Assembly In Compressor

1 ± UPPER HOOKS

2 ± COIL SPRING

3 ± CLEVIS BRACKET

4 ± CLAMP

5 ± LOWER HOOKS

Fig. 18 Shaft Nut Removal/Installation

1 ± UPPER MOUNT

2 ± FRONT HOOK

2 - 48 SUSPENSIONPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 65 of 1285

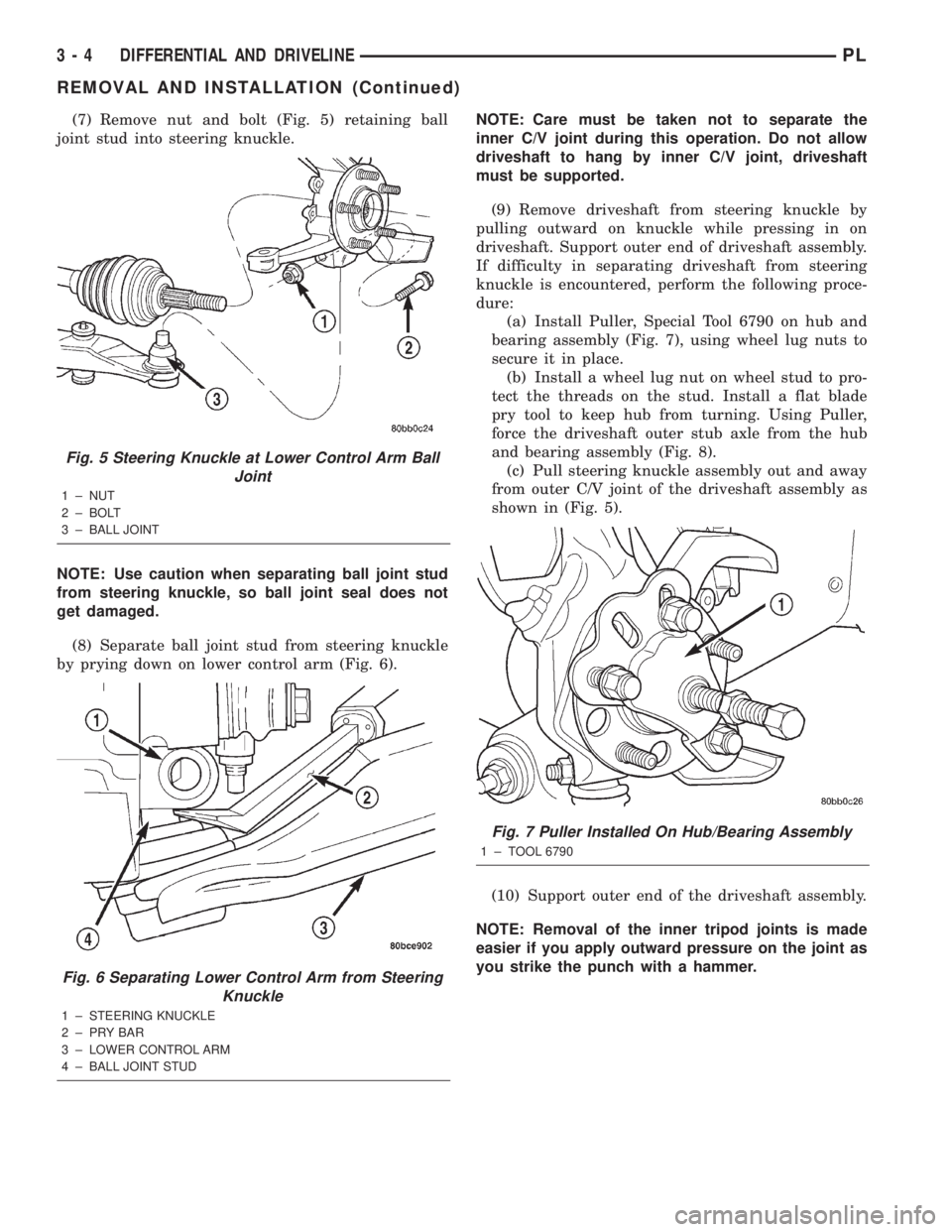

(7) Remove nut and bolt (Fig. 5) retaining ball

joint stud into steering knuckle.

NOTE: Use caution when separating ball joint stud

from steering knuckle, so ball joint seal does not

get damaged.

(8) Separate ball joint stud from steering knuckle

by prying down on lower control arm (Fig. 6).NOTE: Care must be taken not to separate the

inner C/V joint during this operation. Do not allow

driveshaft to hang by inner C/V joint, driveshaft

must be supported.

(9) Remove driveshaft from steering knuckle by

pulling outward on knuckle while pressing in on

driveshaft. Support outer end of driveshaft assembly.

If difficulty in separating driveshaft from steering

knuckle is encountered, perform the following proce-

dure:

(a) Install Puller, Special Tool 6790 on hub and

bearing assembly (Fig. 7), using wheel lug nuts to

secure it in place.

(b) Install a wheel lug nut on wheel stud to pro-

tect the threads on the stud. Install a flat blade

pry tool to keep hub from turning. Using Puller,

force the driveshaft outer stub axle from the hub

and bearing assembly (Fig. 8).

(c) Pull steering knuckle assembly out and away

from outer C/V joint of the driveshaft assembly as

shown in (Fig. 5).

(10) Support outer end of the driveshaft assembly.

NOTE: Removal of the inner tripod joints is made

easier if you apply outward pressure on the joint as

you strike the punch with a hammer.

Fig. 5 Steering Knuckle at Lower Control Arm Ball

Joint

1 ± NUT

2 ± BOLT

3 ± BALL JOINT

Fig. 6 Separating Lower Control Arm from Steering

Knuckle

1 ± STEERING KNUCKLE

2±PRYBAR

3 ± LOWER CONTROL ARM

4 ± BALL JOINT STUD

Fig. 7 Puller Installed On Hub/Bearing Assembly

1 ± TOOL 6790

3 - 4 DIFFERENTIAL AND DRIVELINEPL

REMOVAL AND INSTALLATION (Continued)

Page 72 of 1285

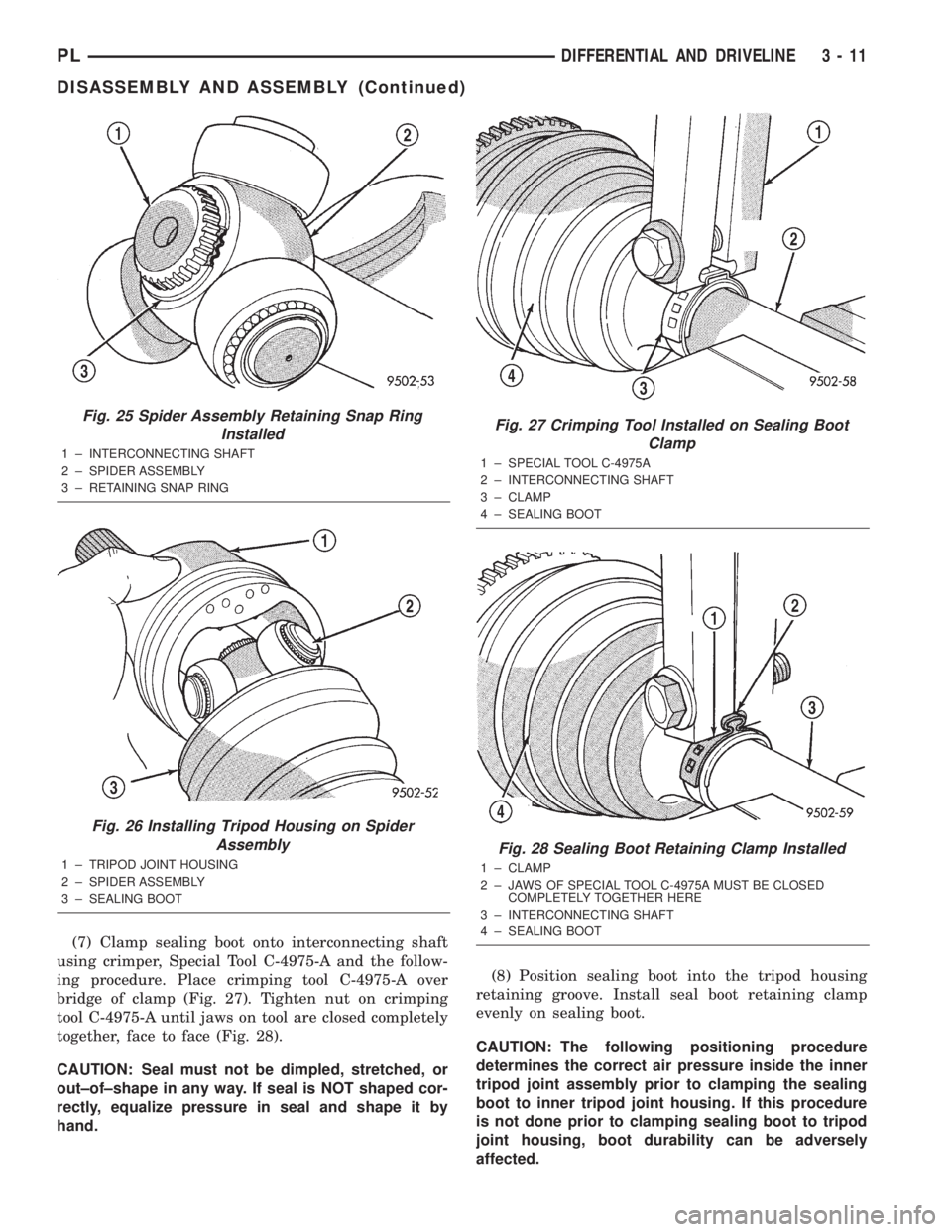

(7) Clamp sealing boot onto interconnecting shaft

using crimper, Special Tool C-4975-A and the follow-

ing procedure. Place crimping tool C-4975-A over

bridge of clamp (Fig. 27). Tighten nut on crimping

tool C-4975-A until jaws on tool are closed completely

together, face to face (Fig. 28).

CAUTION: Seal must not be dimpled, stretched, or

out±of±shape in any way. If seal is NOT shaped cor-

rectly, equalize pressure in seal and shape it by

hand.(8) Position sealing boot into the tripod housing

retaining groove. Install seal boot retaining clamp

evenly on sealing boot.

CAUTION: The following positioning procedure

determines the correct air pressure inside the inner

tripod joint assembly prior to clamping the sealing

boot to inner tripod joint housing. If this procedure

is not done prior to clamping sealing boot to tripod

joint housing, boot durability can be adversely

affected.

Fig. 25 Spider Assembly Retaining Snap Ring

Installed

1 ± INTERCONNECTING SHAFT

2 ± SPIDER ASSEMBLY

3 ± RETAINING SNAP RING

Fig. 26 Installing Tripod Housing on Spider

Assembly

1 ± TRIPOD JOINT HOUSING

2 ± SPIDER ASSEMBLY

3 ± SEALING BOOT

Fig. 27 Crimping Tool Installed on Sealing Boot

Clamp

1 ± SPECIAL TOOL C-4975A

2 ± INTERCONNECTING SHAFT

3 ± CLAMP

4 ± SEALING BOOT

Fig. 28 Sealing Boot Retaining Clamp Installed

1 ± CLAMP

2 ± JAWS OF SPECIAL TOOL C-4975A MUST BE CLOSED

COMPLETELY TOGETHER HERE

3 ± INTERCONNECTING SHAFT

4 ± SEALING BOOT

PLDIFFERENTIAL AND DRIVELINE 3 - 11

DISASSEMBLY AND ASSEMBLY (Continued)