DODGE RAM 2001 Service Repair Manual

Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 1601 of 2889

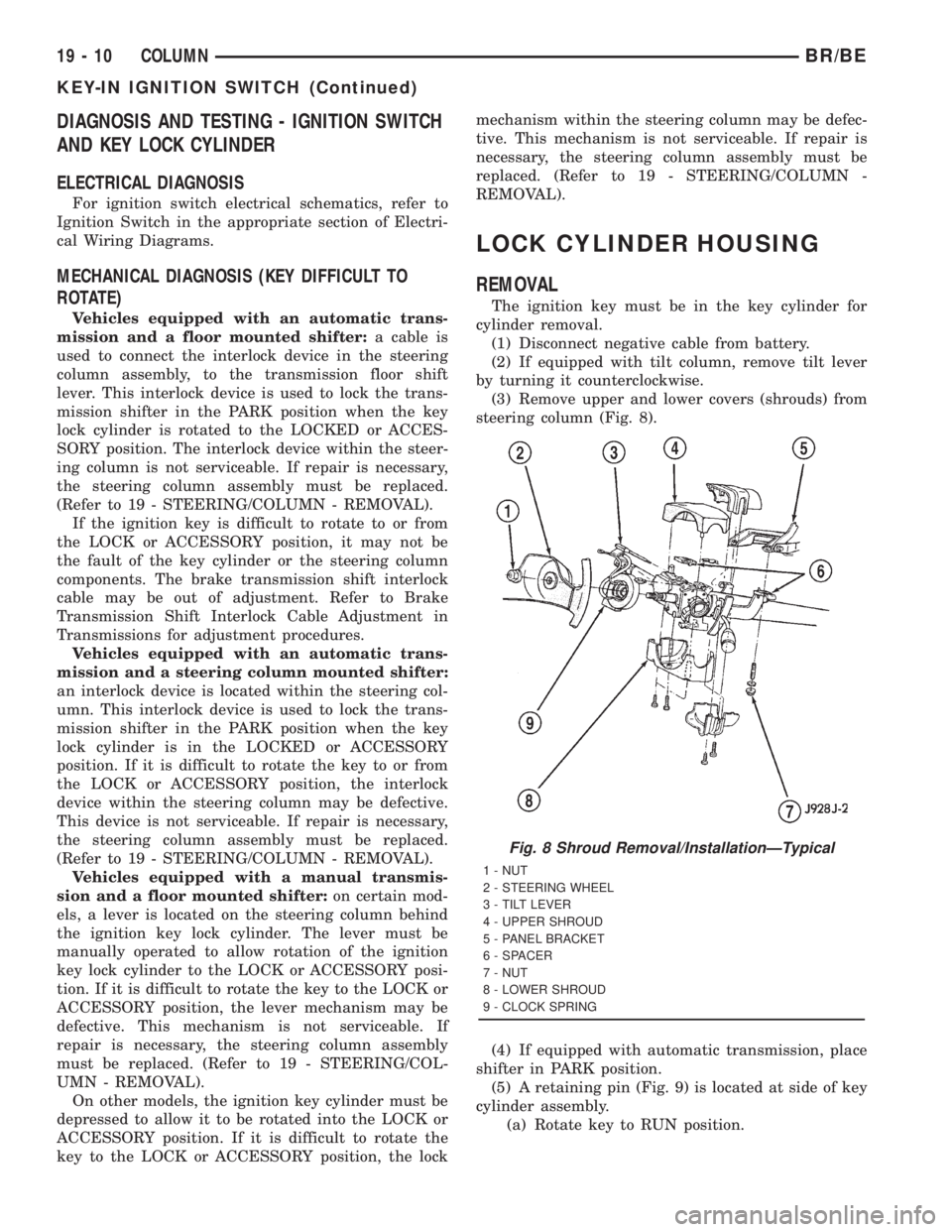

(13) Remove the electrical connections from Key-in

light, Ignition Switch, Horn, Overdrive Switch and

Clock Spring (Speed Control) (Fig. 7).

(14) Remove the wiring harness from the column

by prying out the plastic retainer buttons.

(15) Remove the toe plate fasteners.

(16) Remove the column from vehicle.

(17) Remove the Ignition and Multi-Function

Switch, then remove the Clock Spring and tape the

Clock Spring to prevent it from turning, (Refer to 8 -

ELECTRICAL/RESTRAINTS/CLOCKSPRING -

REMOVAL).INSTALLATION

(1) Install the clock spring and switches, (Refer to

8 - ELECTRICAL/RESTRAINTS/CLOCKSPRING -

INSTALLATION).

NOTE: Turn the Ignition Switch to the on position

and verify the gear shifter moves. If the shifter does

not move ensure the Ignition Switch is installed

properly.

(2) Column shift vehicles, install a new grommet.

Use multi-purpose lubricant, or equivalent, to aid

installation of the grommet.

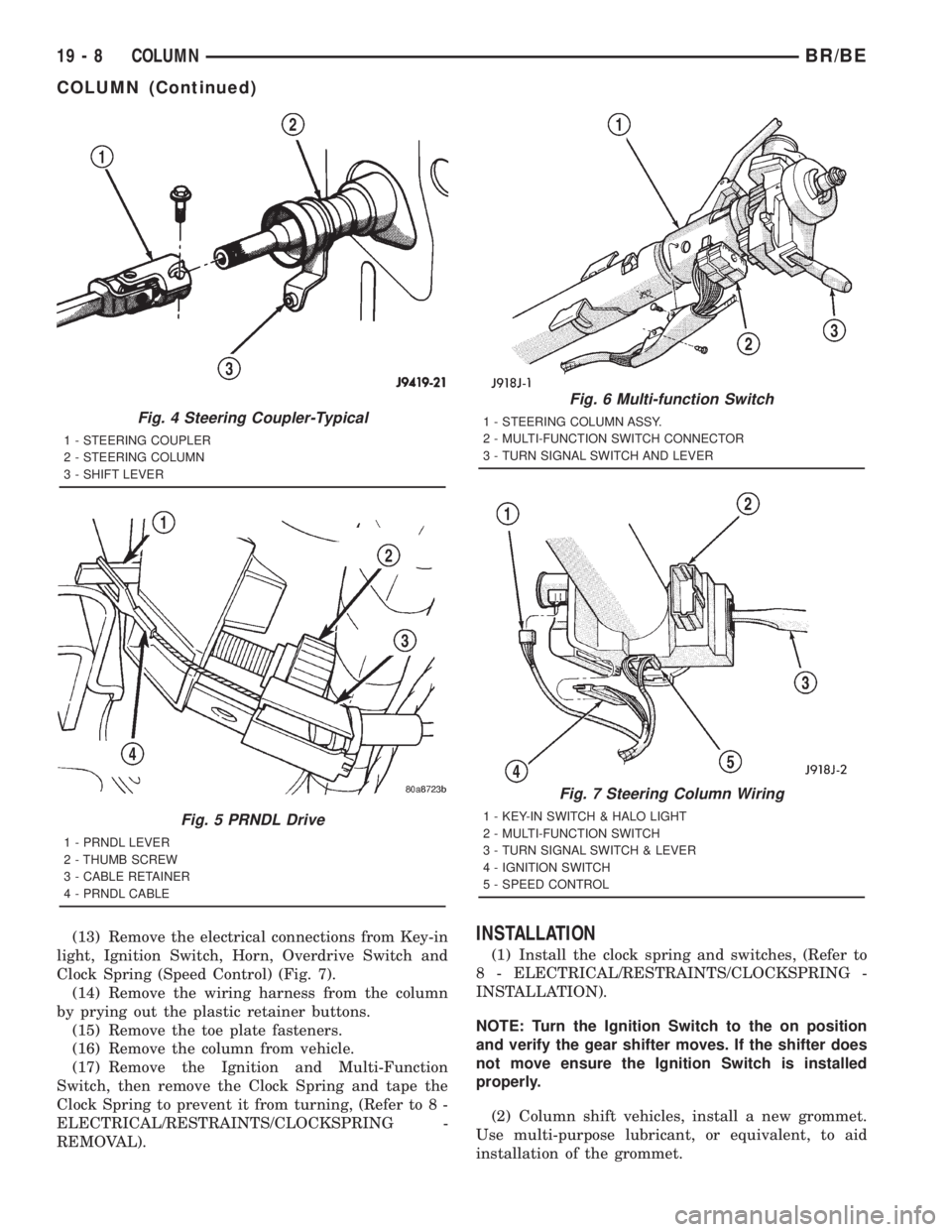

Fig. 4 Steering Coupler-Typical

1 - STEERING COUPLER

2 - STEERING COLUMN

3 - SHIFT LEVER

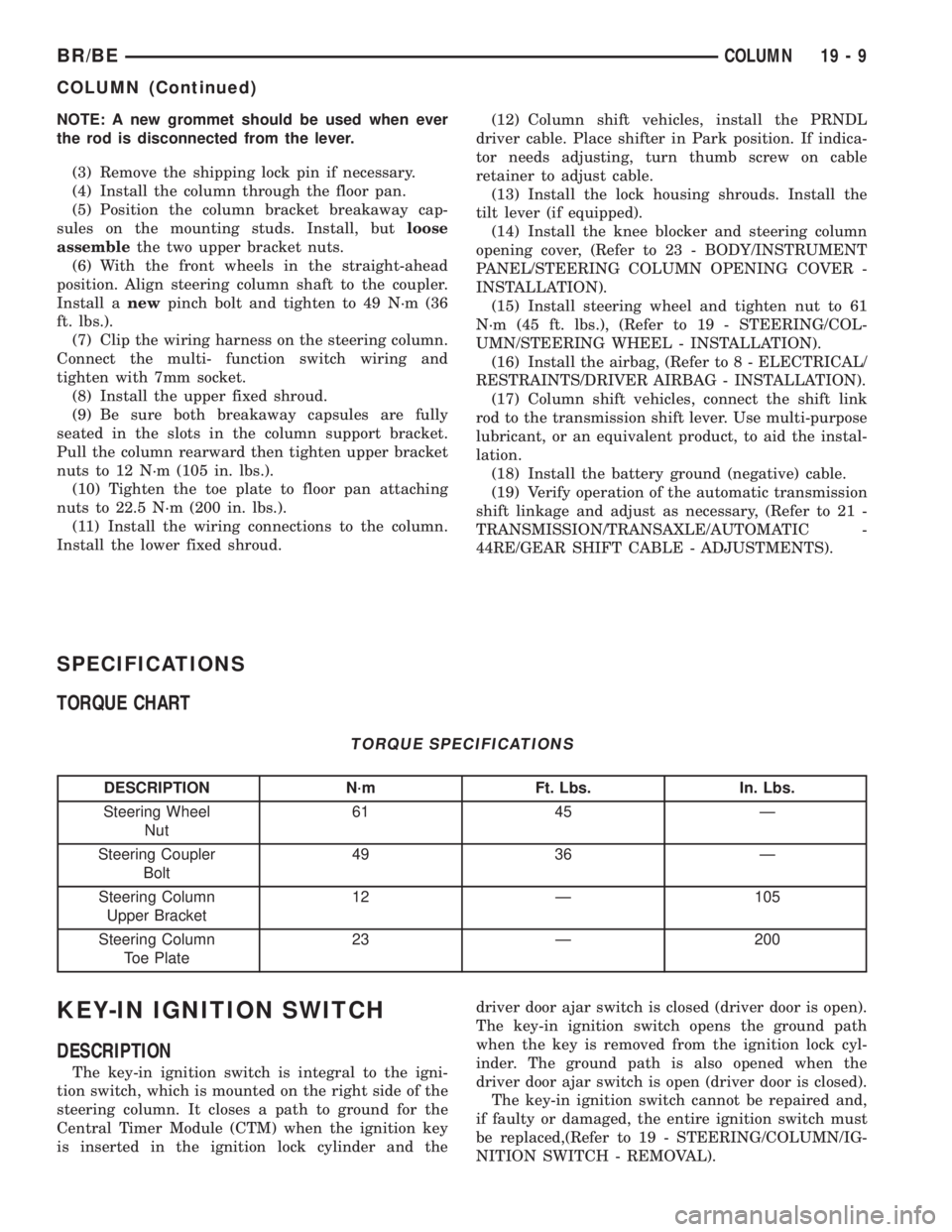

Fig. 5 PRNDL Drive

1 - PRNDL LEVER

2 - THUMB SCREW

3 - CABLE RETAINER

4 - PRNDL CABLE

Fig. 6 Multi-function Switch

1 - STEERING COLUMN ASSY.

2 - MULTI-FUNCTION SWITCH CONNECTOR

3 - TURN SIGNAL SWITCH AND LEVER

Fig. 7 Steering Column Wiring

1 - KEY-IN SWITCH & HALO LIGHT

2 - MULTI-FUNCTION SWITCH

3 - TURN SIGNAL SWITCH & LEVER

4 - IGNITION SWITCH

5 - SPEED CONTROL

19 - 8 COLUMNBR/BE

COLUMN (Continued)

Page 1602 of 2889

NOTE: A new grommet should be used when ever

the rod is disconnected from the lever.

(3) Remove the shipping lock pin if necessary.

(4) Install the column through the floor pan.

(5) Position the column bracket breakaway cap-

sules on the mounting studs. Install, butloose

assemblethe two upper bracket nuts.

(6) With the front wheels in the straight-ahead

position. Align steering column shaft to the coupler.

Install anewpinch bolt and tighten to 49 N´m (36

ft. lbs.).

(7) Clip the wiring harness on the steering column.

Connect the multi- function switch wiring and

tighten with 7mm socket.

(8) Install the upper fixed shroud.

(9) Be sure both breakaway capsules are fully

seated in the slots in the column support bracket.

Pull the column rearward then tighten upper bracket

nuts to 12 N´m (105 in. lbs.).

(10) Tighten the toe plate to floor pan attaching

nuts to 22.5 N´m (200 in. lbs.).

(11) Install the wiring connections to the column.

Install the lower fixed shroud.(12) Column shift vehicles, install the PRNDL

driver cable. Place shifter in Park position. If indica-

tor needs adjusting, turn thumb screw on cable

retainer to adjust cable.

(13) Install the lock housing shrouds. Install the

tilt lever (if equipped).

(14) Install the knee blocker and steering column

opening cover, (Refer to 23 - BODY/INSTRUMENT

PANEL/STEERING COLUMN OPENING COVER -

INSTALLATION).

(15) Install steering wheel and tighten nut to 61

N´m (45 ft. lbs.), (Refer to 19 - STEERING/COL-

UMN/STEERING WHEEL - INSTALLATION).

(16) Install the airbag, (Refer to 8 - ELECTRICAL/

RESTRAINTS/DRIVER AIRBAG - INSTALLATION).

(17) Column shift vehicles, connect the shift link

rod to the transmission shift lever. Use multi-purpose

lubricant, or an equivalent product, to aid the instal-

lation.

(18) Install the battery ground (negative) cable.

(19) Verify operation of the automatic transmission

shift linkage and adjust as necessary, (Refer to 21 -

TRANSMISSION/TRANSAXLE/AUTOMATIC -

44RE/GEAR SHIFT CABLE - ADJUSTMENTS).

SPECIFICATIONS

TORQUE CHART

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Steering Wheel

Nut61 45 Ð

Steering Coupler

Bolt49 36 Ð

Steering Column

Upper Bracket12 Ð 105

Steering Column

Toe Plate23 Ð 200

KEY-IN IGNITION SWITCH

DESCRIPTION

The key-in ignition switch is integral to the igni-

tion switch, which is mounted on the right side of the

steering column. It closes a path to ground for the

Central Timer Module (CTM) when the ignition key

is inserted in the ignition lock cylinder and thedriver door ajar switch is closed (driver door is open).

The key-in ignition switch opens the ground path

when the key is removed from the ignition lock cyl-

inder. The ground path is also opened when the

driver door ajar switch is open (driver door is closed).

The key-in ignition switch cannot be repaired and,

if faulty or damaged, the entire ignition switch must

be replaced,(Refer to 19 - STEERING/COLUMN/IG-

NITION SWITCH - REMOVAL).

BR/BECOLUMN 19 - 9

COLUMN (Continued)

Page 1603 of 2889

DIAGNOSIS AND TESTING - IGNITION SWITCH

AND KEY LOCK CYLINDER

ELECTRICAL DIAGNOSIS

For ignition switch electrical schematics, refer to

Ignition Switch in the appropriate section of Electri-

cal Wiring Diagrams.

MECHANICAL DIAGNOSIS (KEY DIFFICULT TO

ROTATE)

Vehicles equipped with an automatic trans-

mission and a floor mounted shifter:a cable is

used to connect the interlock device in the steering

column assembly, to the transmission floor shift

lever. This interlock device is used to lock the trans-

mission shifter in the PARK position when the key

lock cylinder is rotated to the LOCKED or ACCES-

SORY position. The interlock device within the steer-

ing column is not serviceable. If repair is necessary,

the steering column assembly must be replaced.

(Refer to 19 - STEERING/COLUMN - REMOVAL).

If the ignition key is difficult to rotate to or from

the LOCK or ACCESSORY position, it may not be

the fault of the key cylinder or the steering column

components. The brake transmission shift interlock

cable may be out of adjustment. Refer to Brake

Transmission Shift Interlock Cable Adjustment in

Transmissions for adjustment procedures.

Vehicles equipped with an automatic trans-

mission and a steering column mounted shifter:

an interlock device is located within the steering col-

umn. This interlock device is used to lock the trans-

mission shifter in the PARK position when the key

lock cylinder is in the LOCKED or ACCESSORY

position. If it is difficult to rotate the key to or from

the LOCK or ACCESSORY position, the interlock

device within the steering column may be defective.

This device is not serviceable. If repair is necessary,

the steering column assembly must be replaced.

(Refer to 19 - STEERING/COLUMN - REMOVAL).

Vehicles equipped with a manual transmis-

sion and a floor mounted shifter:on certain mod-

els, a lever is located on the steering column behind

the ignition key lock cylinder. The lever must be

manually operated to allow rotation of the ignition

key lock cylinder to the LOCK or ACCESSORY posi-

tion. If it is difficult to rotate the key to the LOCK or

ACCESSORY position, the lever mechanism may be

defective. This mechanism is not serviceable. If

repair is necessary, the steering column assembly

must be replaced. (Refer to 19 - STEERING/COL-

UMN - REMOVAL).

On other models, the ignition key cylinder must be

depressed to allow it to be rotated into the LOCK or

ACCESSORY position. If it is difficult to rotate the

key to the LOCK or ACCESSORY position, the lockmechanism within the steering column may be defec-

tive. This mechanism is not serviceable. If repair is

necessary, the steering column assembly must be

replaced. (Refer to 19 - STEERING/COLUMN -

REMOVAL).

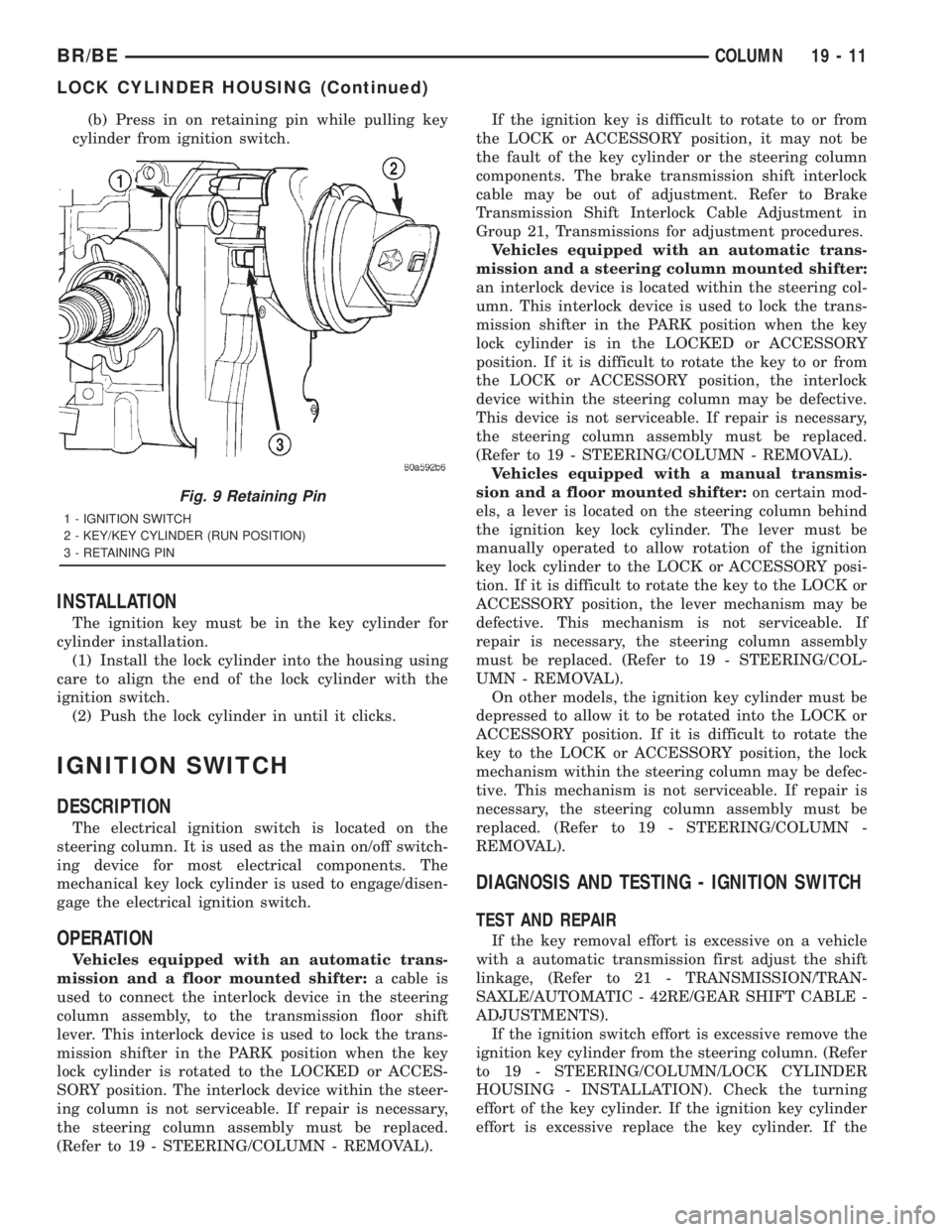

LOCK CYLINDER HOUSING

REMOVAL

The ignition key must be in the key cylinder for

cylinder removal.

(1) Disconnect negative cable from battery.

(2) If equipped with tilt column, remove tilt lever

by turning it counterclockwise.

(3) Remove upper and lower covers (shrouds) from

steering column (Fig. 8).

(4) If equipped with automatic transmission, place

shifter in PARK position.

(5) A retaining pin (Fig. 9) is located at side of key

cylinder assembly.

(a) Rotate key to RUN position.

Fig. 8 Shroud Removal/InstallationÐTypical

1 - NUT

2 - STEERING WHEEL

3 - TILT LEVER

4 - UPPER SHROUD

5 - PANEL BRACKET

6 - SPACER

7 - NUT

8 - LOWER SHROUD

9 - CLOCK SPRING

19 - 10 COLUMNBR/BE

KEY-IN IGNITION SWITCH (Continued)

Page 1604 of 2889

(b) Press in on retaining pin while pulling key

cylinder from ignition switch.

INSTALLATION

The ignition key must be in the key cylinder for

cylinder installation.

(1) Install the lock cylinder into the housing using

care to align the end of the lock cylinder with the

ignition switch.

(2) Push the lock cylinder in until it clicks.

IGNITION SWITCH

DESCRIPTION

The electrical ignition switch is located on the

steering column. It is used as the main on/off switch-

ing device for most electrical components. The

mechanical key lock cylinder is used to engage/disen-

gage the electrical ignition switch.

OPERATION

Vehicles equipped with an automatic trans-

mission and a floor mounted shifter:a cable is

used to connect the interlock device in the steering

column assembly, to the transmission floor shift

lever. This interlock device is used to lock the trans-

mission shifter in the PARK position when the key

lock cylinder is rotated to the LOCKED or ACCES-

SORY position. The interlock device within the steer-

ing column is not serviceable. If repair is necessary,

the steering column assembly must be replaced.

(Refer to 19 - STEERING/COLUMN - REMOVAL).If the ignition key is difficult to rotate to or from

the LOCK or ACCESSORY position, it may not be

the fault of the key cylinder or the steering column

components. The brake transmission shift interlock

cable may be out of adjustment. Refer to Brake

Transmission Shift Interlock Cable Adjustment in

Group 21, Transmissions for adjustment procedures.

Vehicles equipped with an automatic trans-

mission and a steering column mounted shifter:

an interlock device is located within the steering col-

umn. This interlock device is used to lock the trans-

mission shifter in the PARK position when the key

lock cylinder is in the LOCKED or ACCESSORY

position. If it is difficult to rotate the key to or from

the LOCK or ACCESSORY position, the interlock

device within the steering column may be defective.

This device is not serviceable. If repair is necessary,

the steering column assembly must be replaced.

(Refer to 19 - STEERING/COLUMN - REMOVAL).

Vehicles equipped with a manual transmis-

sion and a floor mounted shifter:on certain mod-

els, a lever is located on the steering column behind

the ignition key lock cylinder. The lever must be

manually operated to allow rotation of the ignition

key lock cylinder to the LOCK or ACCESSORY posi-

tion. If it is difficult to rotate the key to the LOCK or

ACCESSORY position, the lever mechanism may be

defective. This mechanism is not serviceable. If

repair is necessary, the steering column assembly

must be replaced. (Refer to 19 - STEERING/COL-

UMN - REMOVAL).

On other models, the ignition key cylinder must be

depressed to allow it to be rotated into the LOCK or

ACCESSORY position. If it is difficult to rotate the

key to the LOCK or ACCESSORY position, the lock

mechanism within the steering column may be defec-

tive. This mechanism is not serviceable. If repair is

necessary, the steering column assembly must be

replaced. (Refer to 19 - STEERING/COLUMN -

REMOVAL).

DIAGNOSIS AND TESTING - IGNITION SWITCH

TEST AND REPAIR

If the key removal effort is excessive on a vehicle

with a automatic transmission first adjust the shift

linkage, (Refer to 21 - TRANSMISSION/TRAN-

SAXLE/AUTOMATIC - 42RE/GEAR SHIFT CABLE -

ADJUSTMENTS).

If the ignition switch effort is excessive remove the

ignition key cylinder from the steering column. (Refer

to 19 - STEERING/COLUMN/LOCK CYLINDER

HOUSING - INSTALLATION). Check the turning

effort of the key cylinder. If the ignition key cylinder

effort is excessive replace the key cylinder. If the

Fig. 9 Retaining Pin

1 - IGNITION SWITCH

2 - KEY/KEY CYLINDER (RUN POSITION)

3 - RETAINING PIN

BR/BECOLUMN 19 - 11

LOCK CYLINDER HOUSING (Continued)

Page 1605 of 2889

ignition key cylinder operates properly look for the

following conditions.

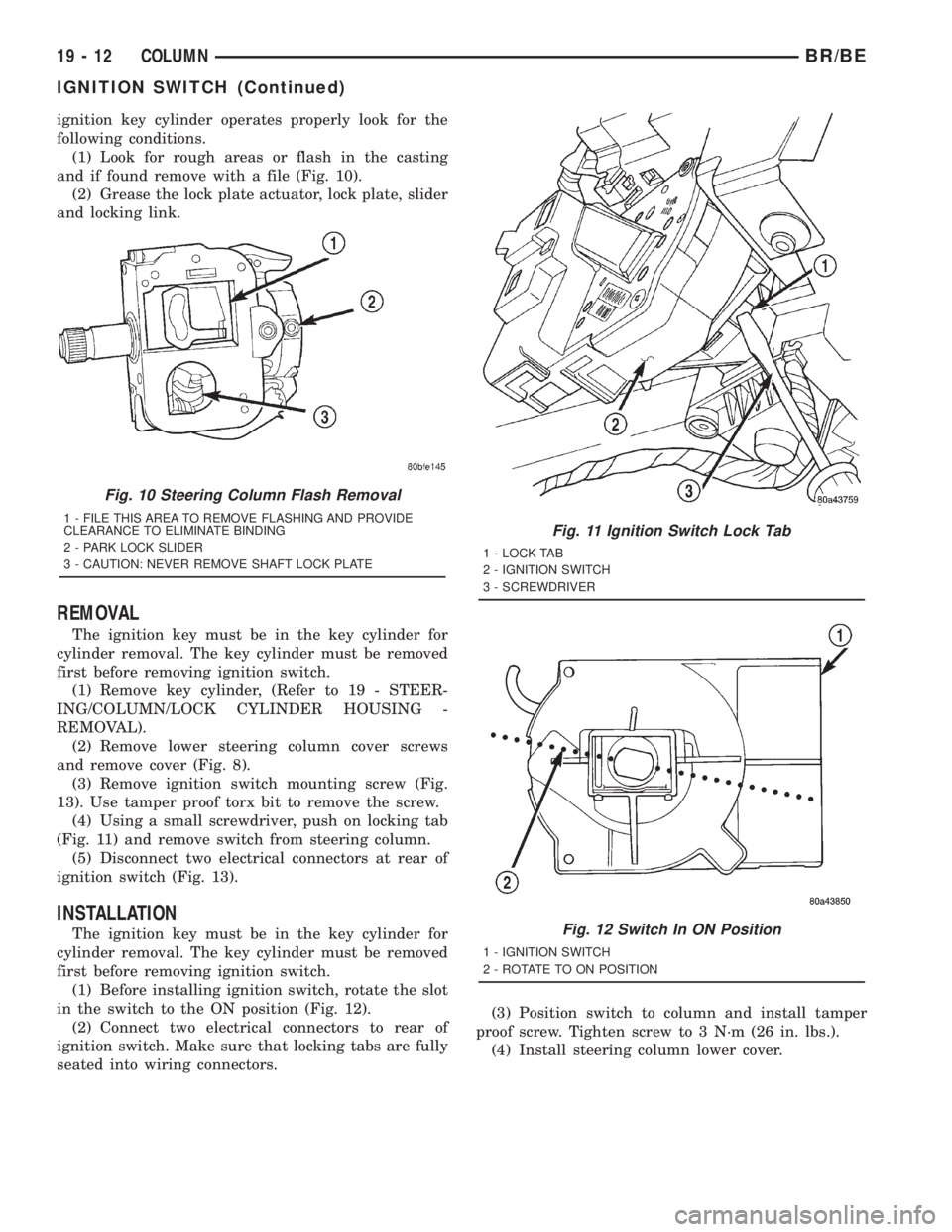

(1) Look for rough areas or flash in the casting

and if found remove with a file (Fig. 10).

(2) Grease the lock plate actuator, lock plate, slider

and locking link.

REMOVAL

The ignition key must be in the key cylinder for

cylinder removal. The key cylinder must be removed

first before removing ignition switch.

(1) Remove key cylinder, (Refer to 19 - STEER-

ING/COLUMN/LOCK CYLINDER HOUSING -

REMOVAL).

(2) Remove lower steering column cover screws

and remove cover (Fig. 8).

(3) Remove ignition switch mounting screw (Fig.

13). Use tamper proof torx bit to remove the screw.

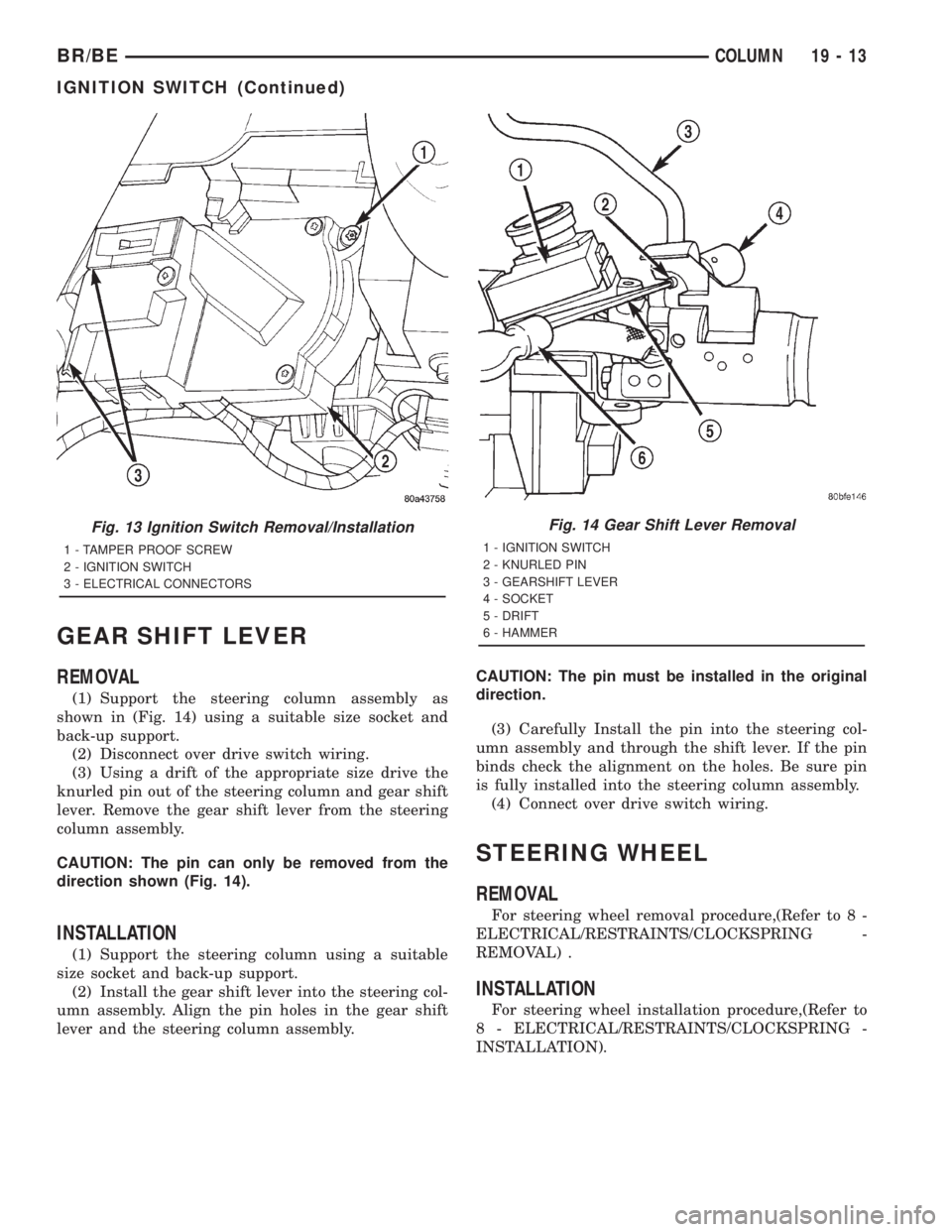

(4) Using a small screwdriver, push on locking tab

(Fig. 11) and remove switch from steering column.

(5) Disconnect two electrical connectors at rear of

ignition switch (Fig. 13).

INSTALLATION

The ignition key must be in the key cylinder for

cylinder removal. The key cylinder must be removed

first before removing ignition switch.

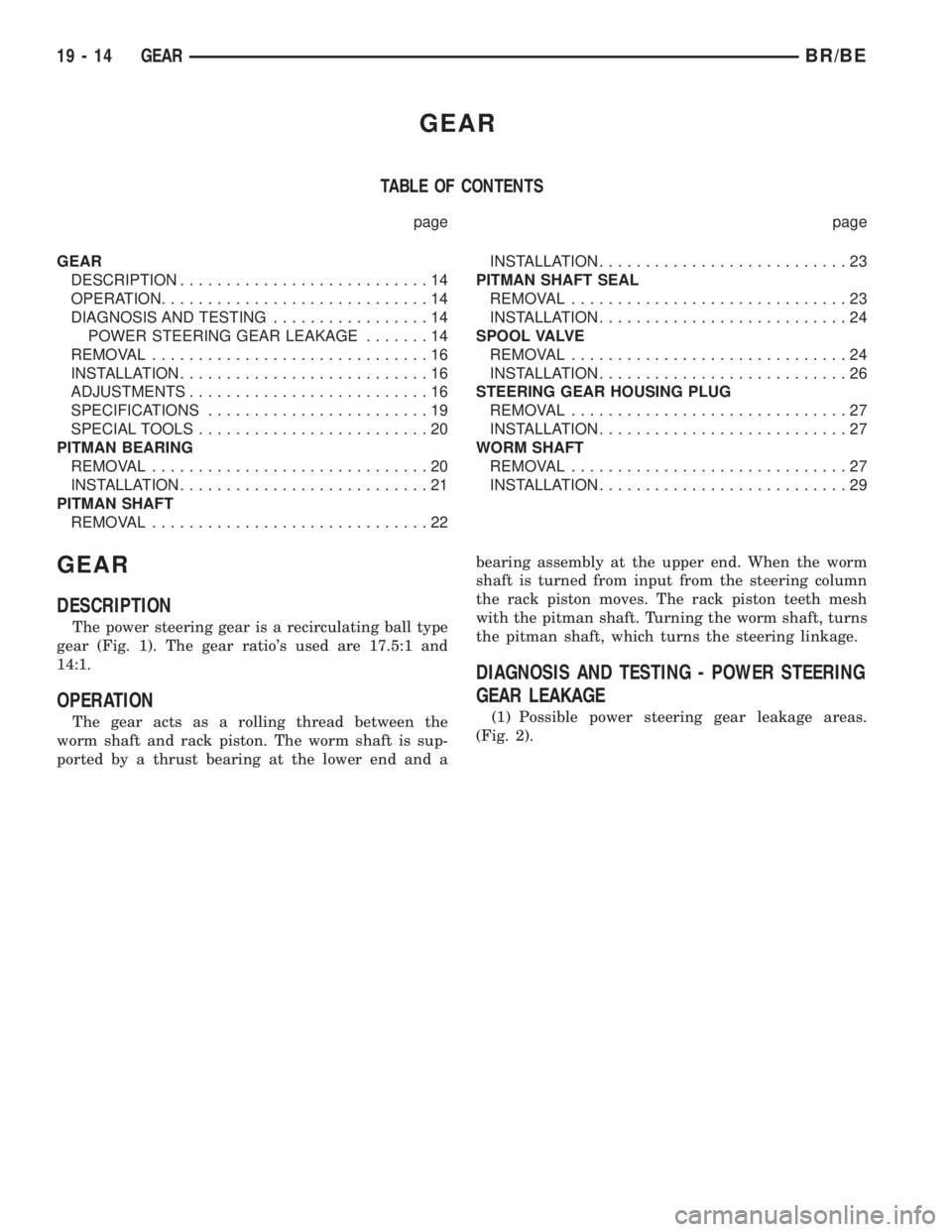

(1) Before installing ignition switch, rotate the slot

in the switch to the ON position (Fig. 12).

(2) Connect two electrical connectors to rear of

ignition switch. Make sure that locking tabs are fully

seated into wiring connectors.(3) Position switch to column and install tamper

proof screw. Tighten screw to 3 N´m (26 in. lbs.).

(4) Install steering column lower cover.

Fig. 10 Steering Column Flash Removal

1 - FILE THIS AREA TO REMOVE FLASHING AND PROVIDE

CLEARANCE TO ELIMINATE BINDING

2 - PARK LOCK SLIDER

3 - CAUTION: NEVER REMOVE SHAFT LOCK PLATEFig. 11 Ignition Switch Lock Tab

1 - LOCK TAB

2 - IGNITION SWITCH

3 - SCREWDRIVER

Fig. 12 Switch In ON Position

1 - IGNITION SWITCH

2 - ROTATE TO ON POSITION

19 - 12 COLUMNBR/BE

IGNITION SWITCH (Continued)

Page 1606 of 2889

GEAR SHIFT LEVER

REMOVAL

(1) Support the steering column assembly as

shown in (Fig. 14) using a suitable size socket and

back-up support.

(2) Disconnect over drive switch wiring.

(3) Using a drift of the appropriate size drive the

knurled pin out of the steering column and gear shift

lever. Remove the gear shift lever from the steering

column assembly.

CAUTION: The pin can only be removed from the

direction shown (Fig. 14).

INSTALLATION

(1) Support the steering column using a suitable

size socket and back-up support.

(2) Install the gear shift lever into the steering col-

umn assembly. Align the pin holes in the gear shift

lever and the steering column assembly.CAUTION: The pin must be installed in the original

direction.

(3) Carefully Install the pin into the steering col-

umn assembly and through the shift lever. If the pin

binds check the alignment on the holes. Be sure pin

is fully installed into the steering column assembly.

(4) Connect over drive switch wiring.

STEERING WHEEL

REMOVAL

For steering wheel removal procedure,(Refer to 8 -

ELECTRICAL/RESTRAINTS/CLOCKSPRING -

REMOVAL) .

INSTALLATION

For steering wheel installation procedure,(Refer to

8 - ELECTRICAL/RESTRAINTS/CLOCKSPRING -

INSTALLATION).

Fig. 13 Ignition Switch Removal/Installation

1 - TAMPER PROOF SCREW

2 - IGNITION SWITCH

3 - ELECTRICAL CONNECTORS

Fig. 14 Gear Shift Lever Removal

1 - IGNITION SWITCH

2 - KNURLED PIN

3 - GEARSHIFT LEVER

4 - SOCKET

5 - DRIFT

6 - HAMMER

BR/BECOLUMN 19 - 13

IGNITION SWITCH (Continued)

Page 1607 of 2889

GEAR

TABLE OF CONTENTS

page page

GEAR

DESCRIPTION...........................14

OPERATION.............................14

DIAGNOSIS AND TESTING.................14

POWER STEERING GEAR LEAKAGE.......14

REMOVAL..............................16

INSTALLATION...........................16

ADJUSTMENTS..........................16

SPECIFICATIONS........................19

SPECIAL TOOLS.........................20

PITMAN BEARING

REMOVAL..............................20

INSTALLATION...........................21

PITMAN SHAFT

REMOVAL..............................22INSTALLATION...........................23

PITMAN SHAFT SEAL

REMOVAL..............................23

INSTALLATION...........................24

SPOOL VALVE

REMOVAL..............................24

INSTALLATION...........................26

STEERING GEAR HOUSING PLUG

REMOVAL..............................27

INSTALLATION...........................27

WORM SHAFT

REMOVAL..............................27

INSTALLATION...........................29

GEAR

DESCRIPTION

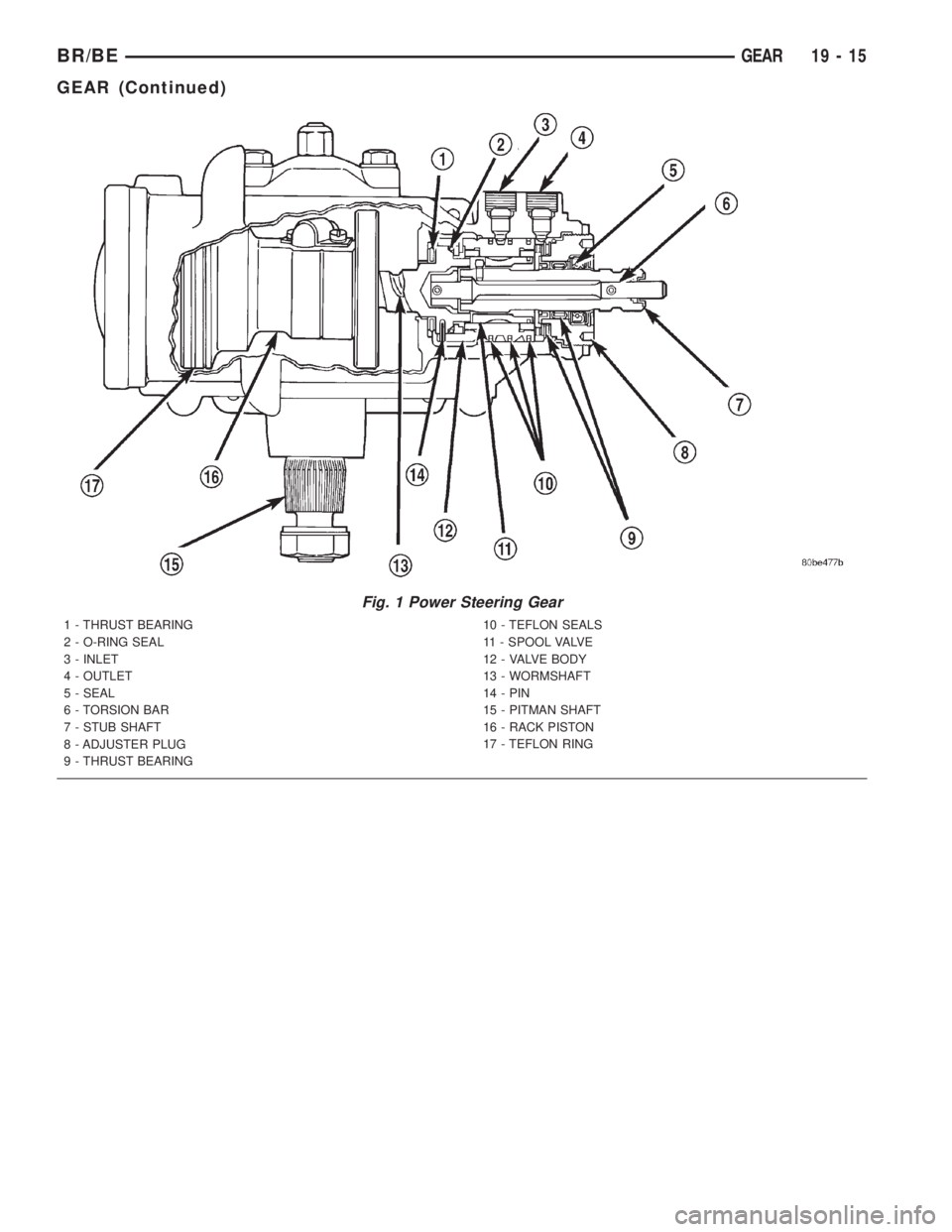

The power steering gear is a recirculating ball type

gear (Fig. 1). The gear ratio's used are 17.5:1 and

14:1.

OPERATION

The gear acts as a rolling thread between the

worm shaft and rack piston. The worm shaft is sup-

ported by a thrust bearing at the lower end and abearing assembly at the upper end. When the worm

shaft is turned from input from the steering column

the rack piston moves. The rack piston teeth mesh

with the pitman shaft. Turning the worm shaft, turns

the pitman shaft, which turns the steering linkage.

DIAGNOSIS AND TESTING - POWER STEERING

GEAR LEAKAGE

(1) Possible power steering gear leakage areas.

(Fig. 2).

19 - 14 GEARBR/BE

Page 1608 of 2889

Fig. 1 Power Steering Gear

1 - THRUST BEARING

2 - O-RING SEAL

3 - INLET

4 - OUTLET

5 - SEAL

6 - TORSION BAR

7 - STUB SHAFT

8 - ADJUSTER PLUG

9 - THRUST BEARING10 - TEFLON SEALS

11 - SPOOL VALVE

12 - VALVE BODY

13 - WORMSHAFT

14 - PIN

15 - PITMAN SHAFT

16 - RACK PISTON

17 - TEFLON RING

BR/BEGEAR 19 - 15

GEAR (Continued)

Page 1609 of 2889

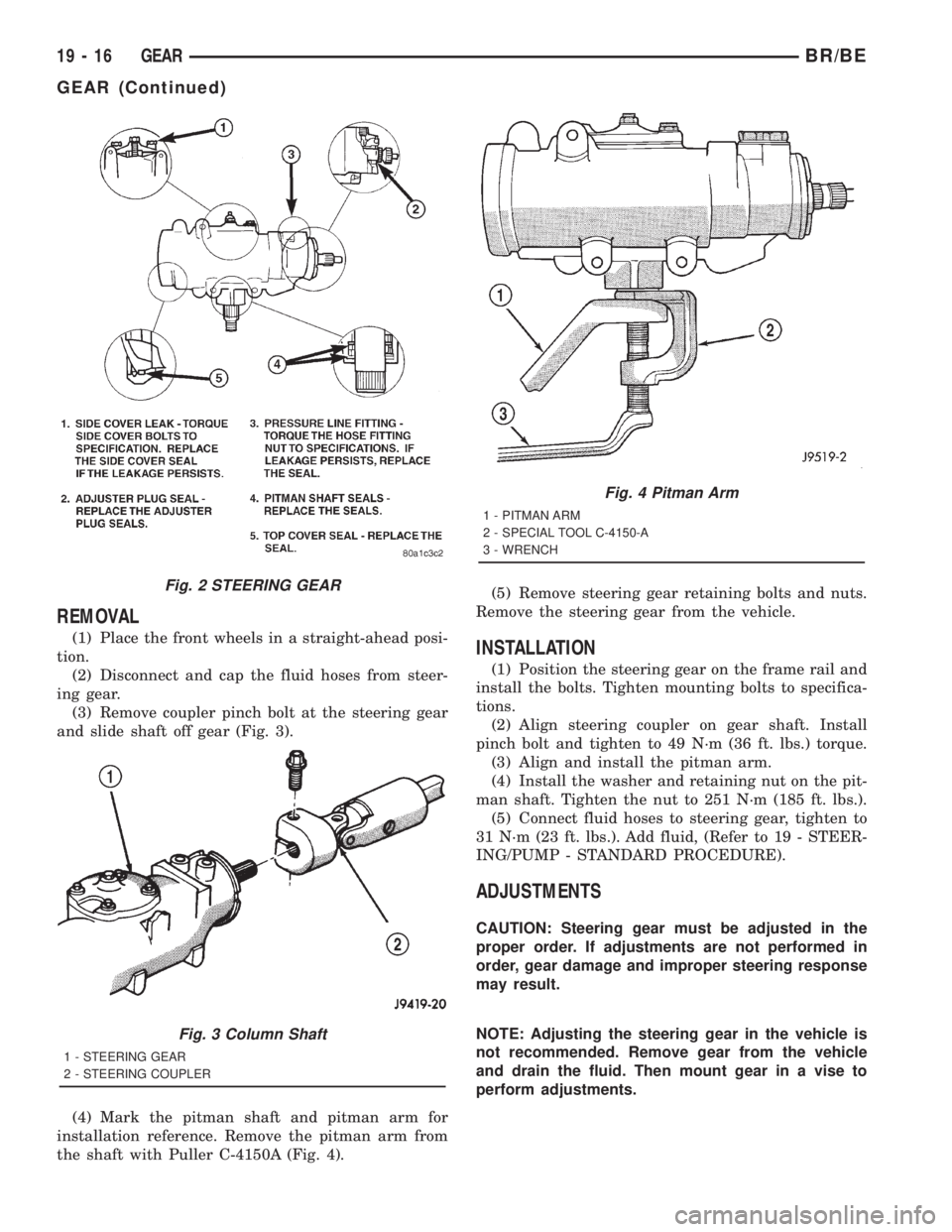

REMOVAL

(1) Place the front wheels in a straight-ahead posi-

tion.

(2) Disconnect and cap the fluid hoses from steer-

ing gear.

(3) Remove coupler pinch bolt at the steering gear

and slide shaft off gear (Fig. 3).

(4) Mark the pitman shaft and pitman arm for

installation reference. Remove the pitman arm from

the shaft with Puller C-4150A (Fig. 4).(5) Remove steering gear retaining bolts and nuts.

Remove the steering gear from the vehicle.INSTALLATION

(1) Position the steering gear on the frame rail and

install the bolts. Tighten mounting bolts to specifica-

tions.

(2) Align steering coupler on gear shaft. Install

pinch bolt and tighten to 49 N´m (36 ft. lbs.) torque.

(3) Align and install the pitman arm.

(4) Install the washer and retaining nut on the pit-

man shaft. Tighten the nut to 251 N´m (185 ft. lbs.).

(5) Connect fluid hoses to steering gear, tighten to

31 N´m (23 ft. lbs.). Add fluid, (Refer to 19 - STEER-

ING/PUMP - STANDARD PROCEDURE).

ADJUSTMENTS

CAUTION: Steering gear must be adjusted in the

proper order. If adjustments are not performed in

order, gear damage and improper steering response

may result.

NOTE: Adjusting the steering gear in the vehicle is

not recommended. Remove gear from the vehicle

and drain the fluid. Then mount gear in a vise to

perform adjustments.

Fig. 2 STEERING GEAR

Fig. 3 Column Shaft

1 - STEERING GEAR

2 - STEERING COUPLER

Fig. 4 Pitman Arm

1 - PITMAN ARM

2 - SPECIAL TOOL C-4150-A

3 - WRENCH

19 - 16 GEARBR/BE

GEAR (Continued)

Page 1610 of 2889

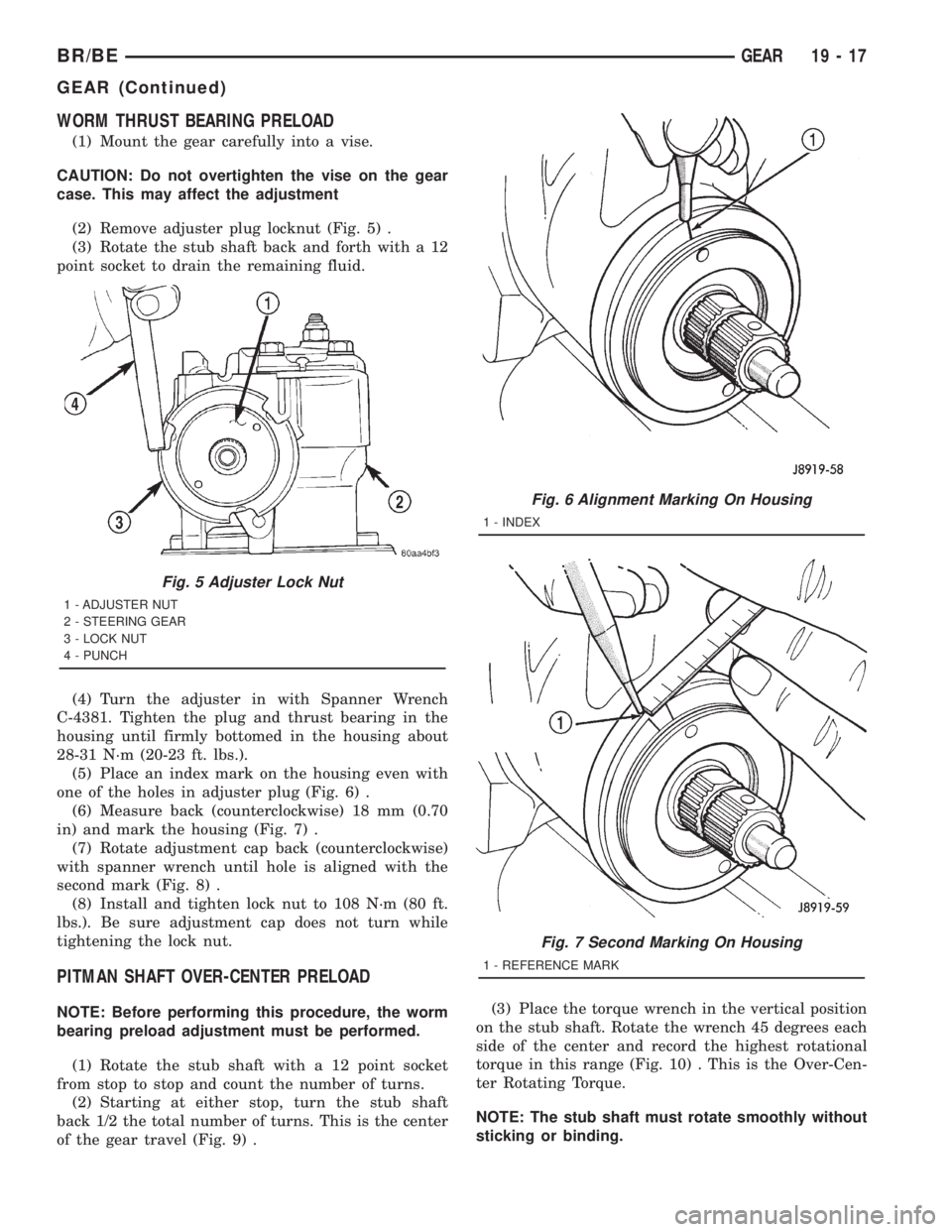

WORM THRUST BEARING PRELOAD

(1) Mount the gear carefully into a vise.

CAUTION: Do not overtighten the vise on the gear

case. This may affect the adjustment

(2) Remove adjuster plug locknut (Fig. 5) .

(3) Rotate the stub shaft back and forth with a 12

point socket to drain the remaining fluid.

(4) Turn the adjuster in with Spanner Wrench

C-4381. Tighten the plug and thrust bearing in the

housing until firmly bottomed in the housing about

28-31 N´m (20-23 ft. lbs.).

(5) Place an index mark on the housing even with

one of the holes in adjuster plug (Fig. 6) .

(6) Measure back (counterclockwise) 18 mm (0.70

in) and mark the housing (Fig. 7) .

(7) Rotate adjustment cap back (counterclockwise)

with spanner wrench until hole is aligned with the

second mark (Fig. 8) .

(8) Install and tighten lock nut to 108 N´m (80 ft.

lbs.). Be sure adjustment cap does not turn while

tightening the lock nut.

PITMAN SHAFT OVER-CENTER PRELOAD

NOTE: Before performing this procedure, the worm

bearing preload adjustment must be performed.

(1) Rotate the stub shaft with a 12 point socket

from stop to stop and count the number of turns.

(2) Starting at either stop, turn the stub shaft

back 1/2 the total number of turns. This is the center

of the gear travel (Fig. 9) .(3) Place the torque wrench in the vertical position

on the stub shaft. Rotate the wrench 45 degrees each

side of the center and record the highest rotational

torque in this range (Fig. 10) . This is the Over-Cen-

ter Rotating Torque.

NOTE: The stub shaft must rotate smoothly without

sticking or binding.

Fig. 5 Adjuster Lock Nut

1 - ADJUSTER NUT

2 - STEERING GEAR

3 - LOCK NUT

4 - PUNCH

Fig. 6 Alignment Marking On Housing

1 - INDEX

Fig. 7 Second Marking On Housing

1 - REFERENCE MARK

BR/BEGEAR 19 - 17

GEAR (Continued)