tow DODGE RAM 2001 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 1834 of 2889

FLUID AND FILTER

DIAGNOSIS AND TESTING - EFFECTS OF

INCORRECT FLUID LEVEL

A low fluid level allows the pump to take in air

along with the fluid. Air in the fluid will cause fluid

pressures to be low and develop slower than normal.

If the transmission is overfilled, the gears churn the

fluid into foam. This aerates the fluid and causing

the same conditions occurring with a low level. In

either case, air bubbles cause fluid overheating, oxi-

dation and varnish buildup which interferes with

valve and clutch operation. Foaming also causes fluid

expansion which can result in fluid overflow from the

transmission vent or fill tube. Fluid overflow can eas-

ily be mistaken for a leak if inspection is not careful.

DIAGNOSIS AND TESTING - CAUSES OF

BURNT FLUID

Burnt, discolored fluid is a result of overheating

which has two primary causes.

(1) A result of restricted fluid flow through the

main and/or auxiliary cooler. This condition is usu-

ally the result of a faulty or improperly installed

drainback valve, a damaged main cooler, or severe

restrictions in the coolers and lines caused by debris

or kinked lines.

(2) Heavy duty operation with a vehicle not prop-

erly equipped for this type of operation. Trailer tow-

ing or similar high load operation will overheat the

transmission fluid if the vehicle is improperly

equipped. Such vehicles should have an auxiliary

transmission fluid cooler, a heavy duty cooling sys-

tem, and the engine/axle ratio combination needed to

handle heavy loads.

DIAGNOSIS AND TESTING - FLUID

CONTAMINATION

Transmission fluid contamination is generally a

result of:

²adding incorrect fluid

²failure to clean dipstick and fill tube when

checking level

²engine coolant entering the fluid

²internal failure that generates debris

²

overheat that generates sludge (fluid breakdown)

²failure to reverse flush cooler and lines after repair

²failure to replace contaminated converter after

repair

The use of non-recommended fluids can result in

transmission failure. The usual results are erratic

shifts, slippage, abnormal wear and eventual failure

due to fluid breakdown and sludge formation. Avoid

this condition by using recommended fluids only.

The dipstick cap and fill tube should be wiped clean

before checking fluid level. Dirt, grease and other for-

eign material on the cap and tube could fall into the

tube if not removed beforehand. Take the time to wipe

the cap and tube clean before withdrawing the dipstick.

Engine coolant in the transmission fluid is gener-

ally caused by a cooler malfunction. The only remedy

is to replace the radiator as the cooler in the radiator

is not a serviceable part. If coolant has circulated

through the transmission, an overhaul is necessary.

The transmission cooler and lines should be

reverse flushed whenever a malfunction generates

sludge and/or debris. The torque converter should

also be replaced at the same time.

Failure to flush the cooler and lines will result in

recontamination. Flushing applies to auxiliary coolers

as well. The torque converter should also be replaced

whenever a failure generates sludge and debris. This is

necessary because normal converter flushing procedures

will not remove all contaminants.

STANDARD PROCEDURE - FLUID LEVEL

CHECK

Low fluid level can cause a variety of conditions

because it allows the pump to take in air along with

the fluid. As in any hydraulic system, air bubbles

make the fluid spongy, therefore, pressures will be

low and build up slowly.

Improper filling can also raise the fluid level too

high. When the transmssion has too much fluid, the

geartrain churns up foam and cause the same condi-

tions which occur with a low fluid level.

In either case, air bubbles can cause overheating

and/or fluid oxidation, and varnishing. This can inter-

fere with normal valve, clutch, and accumulator opera-

tion. Foaming can also result in fluid escaping from the

transmission vent where it may be mistaken for a leak.

Along with fluid level, it is important to check the

condition of the fluid. When the fluid smells burned,

and is contaminated with metal or friction material

particles, a complete transmission recondition is

needed. Be sure to examine the fluid on the dipstick

closely. If there is any doubt about its condition,

drain out a sample for a double check.

After the fluid has been checked, seat the dipstick

fully to seal out water and dirt.

The transmission has a dipstick to check oil level.

It is located on the right side of the engine. Be sure

to wipe all dirt from dipstick handle before removing.

Fluid level is checked with the engine running at curb

idle speed, the transmission in NEUTRAL and the trans-

mission fluid at normal operating temperature.The

engine should be running at idle speed for at least

one minute, with the vehicle on level ground.

The transmission fluid level can be checked two

ways.

BR/BEAUTOMATIC TRANSMISSION - 42RE 21 - 199

Page 1848 of 2889

(10) Install all bolts that attach support to pump

housing. Then tighten bolts finger tight.

(11) Tighten support-to-pump bolts to required

torque as follows:

(a) Reverse pump assembly and install it in

transmission case. Position pump so bolts are fac-

ing out and are accessible.

(b) Secure pump assembly in case with 2 or 3

bolts, or with pilot studs.

(c) Tighten support-to-pump bolts to 20 N´m (15

ft. lbs.).

(d) Remove pump assembly from transmission

case.

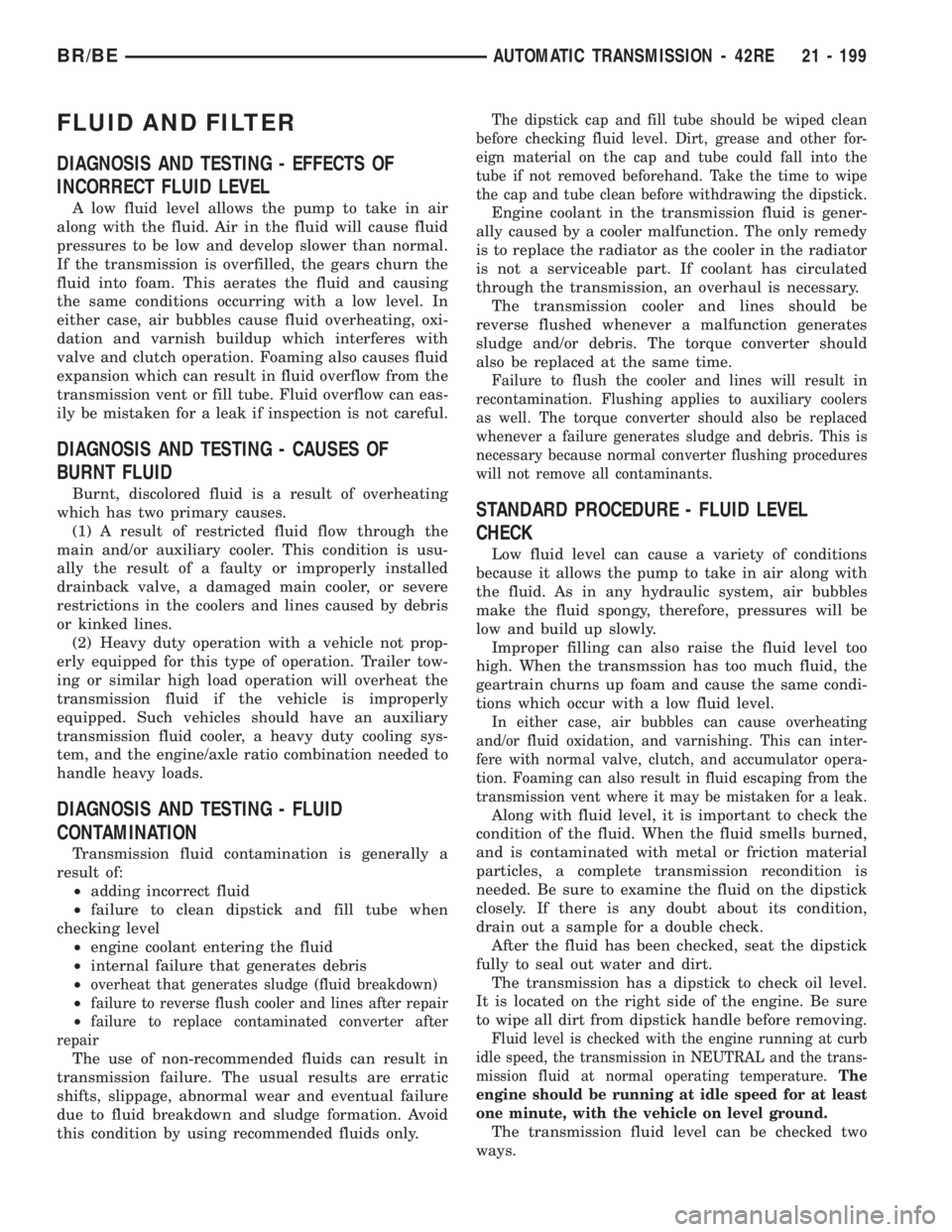

(12) Install new oil seal in pump with Special Tool

C-4193 and Tool Handle C-4171 (Fig. 110). Be sure

seal lip faces inward.

(13) Install new seal ring around pump housing.

Be sure seal is properly seated in groove.

(14) Lubricate lip of pump oil seal and O-ring seal

with transmission fluid.

OUTPUT SHAFT FRONT

BEARING

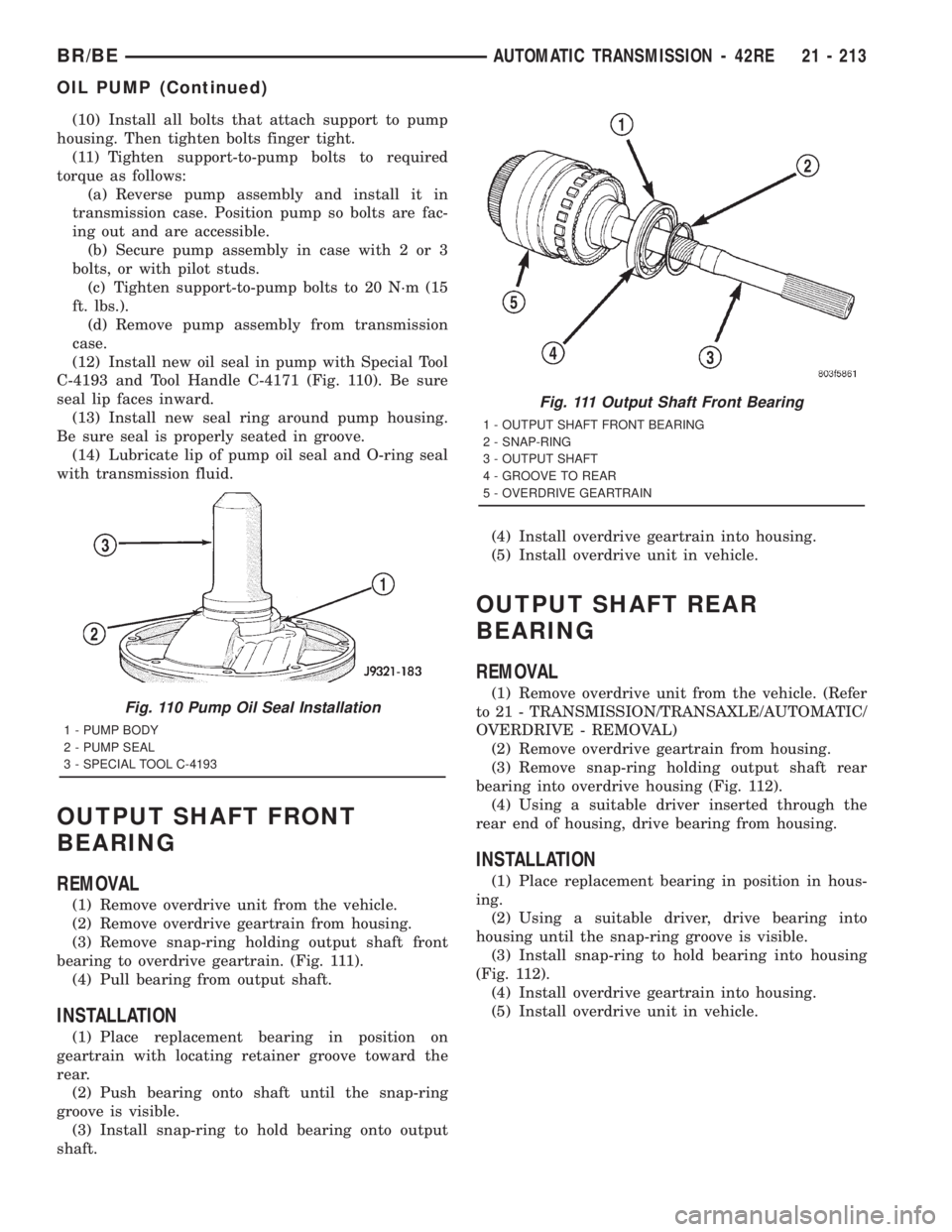

REMOVAL

(1) Remove overdrive unit from the vehicle.

(2) Remove overdrive geartrain from housing.

(3) Remove snap-ring holding output shaft front

bearing to overdrive geartrain. (Fig. 111).

(4) Pull bearing from output shaft.

INSTALLATION

(1) Place replacement bearing in position on

geartrain with locating retainer groove toward the

rear.

(2) Push bearing onto shaft until the snap-ring

groove is visible.

(3) Install snap-ring to hold bearing onto output

shaft.(4) Install overdrive geartrain into housing.

(5) Install overdrive unit in vehicle.

OUTPUT SHAFT REAR

BEARING

REMOVAL

(1) Remove overdrive unit from the vehicle. (Refer

to 21 - TRANSMISSION/TRANSAXLE/AUTOMATIC/

OVERDRIVE - REMOVAL)

(2) Remove overdrive geartrain from housing.

(3) Remove snap-ring holding output shaft rear

bearing into overdrive housing (Fig. 112).

(4) Using a suitable driver inserted through the

rear end of housing, drive bearing from housing.

INSTALLATION

(1) Place replacement bearing in position in hous-

ing.

(2) Using a suitable driver, drive bearing into

housing until the snap-ring groove is visible.

(3) Install snap-ring to hold bearing into housing

(Fig. 112).

(4) Install overdrive geartrain into housing.

(5) Install overdrive unit in vehicle.

Fig. 110 Pump Oil Seal Installation

1 - PUMP BODY

2 - PUMP SEAL

3 - SPECIAL TOOL C-4193

Fig. 111 Output Shaft Front Bearing

1 - OUTPUT SHAFT FRONT BEARING

2 - SNAP-RING

3 - OUTPUT SHAFT

4 - GROOVE TO REAR

5 - OVERDRIVE GEARTRAIN

BR/BEAUTOMATIC TRANSMISSION - 42RE 21 - 213

OIL PUMP (Continued)

Page 1859 of 2889

GEAR CASE AND PARK LOCK

(1) Remove locating ring from gear case.

(2) Remove park pawl shaft retaining bolt and

remove shaft, pawl and spring.

(3) Remove reaction plug snap-ring and remove

reaction plug.

(4) Remove output shaft seal.

CLEANING

Clean the geartrain and case components with sol-

vent. Dry all parts except the bearings with com-

pressed air. Allow bearings to air dry.

Do not use shop towels for wiping parts dry unless

the towels are made from a lint-free material. A suf-

ficient quantity of lint (from shop towels, cloths, rags,

etc.) could plug the transmission filter and fluid pas-

sages.

Discard the old case gasket and seals. Do not

attempt to salvage these parts. They are not reus-

able. Replace any of the overdrive unit snap-rings if

distorted or damaged.

Minor nicks or scratches on components can be

smoothed with crocus cloth. However, do not attempt

to reduce severe scoring on any components with

abrasive materials. Replace severely scored compo-

nents; do not try to salvage them.

INSPECTION

Check condition of the park lock components and

the overdrive case.

Check the bushings in the overdrive case. Replace

the bushings if severely scored or worn. Also replace

the case seal if loose, distorted, or damaged.

Examine the overdrive and direct clutch discs and

plates. Replace the discs if the facing is worn,

severely scored, or burned and flaking off. Replace

the clutch plates if worn, heavily scored, or cracked.

Check the lugs on the clutch plates for wear. The

plates should slide freely in the drum. Replace the

plates or drum if binding occurs.

Check condition of the annulus gear, direct clutch

hub, clutch drum and clutch spring. Replace the gear,

hub and drum if worn or damaged. Replace the

spring if collapsed, distorted, or cracked.

Be sure the splines and lugs on the gear, drum and

hub are in good condition. The clutch plates and

discs should slide freely in these components.

Inspect the thrust bearings and spring plate.

Replace the plate if worn or scored. Replace the bear-

ings if rough, noisy, brinnelled, or worn.

Inspect the planetary gear assembly and the sun

gear and bushings. If either the sun gear or the

bushings are damaged, replace the gear and bush-

ings as an assembly. The gear and bushings are not

serviced separately.

The planetary carrier and pinions must be in good

condition. Also be sure the pinion pins are secure and

in good condition. Replace the carrier if worn or dam-

aged.

Inspect the overrunning clutch and race. The race

surface should be smooth and free of scores. Replace

the overrunning clutch assembly or the race if either

assembly is worn or damaged in any way.

Replace the shaft pilot bushing and inner bushing

if damaged. Replace either shaft bearing if rough or

noisy. Replace the bearing snap-rings if distorted or

cracked.

Check the machined surfaces on the output shaft.

These surfaces should clean and smooth. Very minor

nicks or scratches can be smoothed with crocus cloth.

Replace the shaft if worn, scored or damaged in any

way.

Inspect the output shaft bushings. The small bush-

ing is the intermediate shaft pilot bushing. The large

bushing is the overrunning clutch hub bushing.

Replace either bushing if scored, pitted, cracked, or

worn.

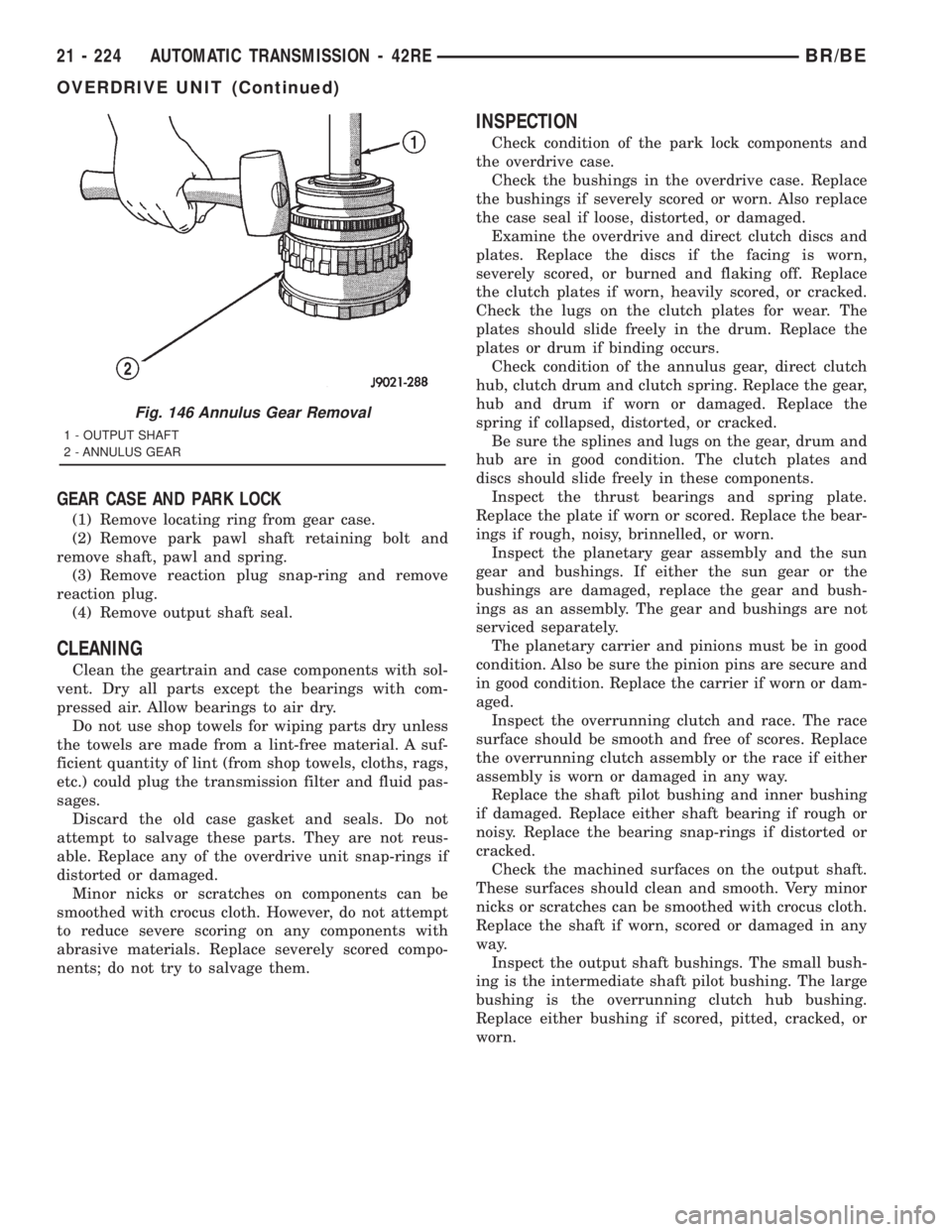

Fig. 146 Annulus Gear Removal

1 - OUTPUT SHAFT

2 - ANNULUS GEAR

21 - 224 AUTOMATIC TRANSMISSION - 42REBR/BE

OVERDRIVE UNIT (Continued)

Page 1860 of 2889

ASSEMBLY

GEARTRAIN AND DIRECT CLUTCH

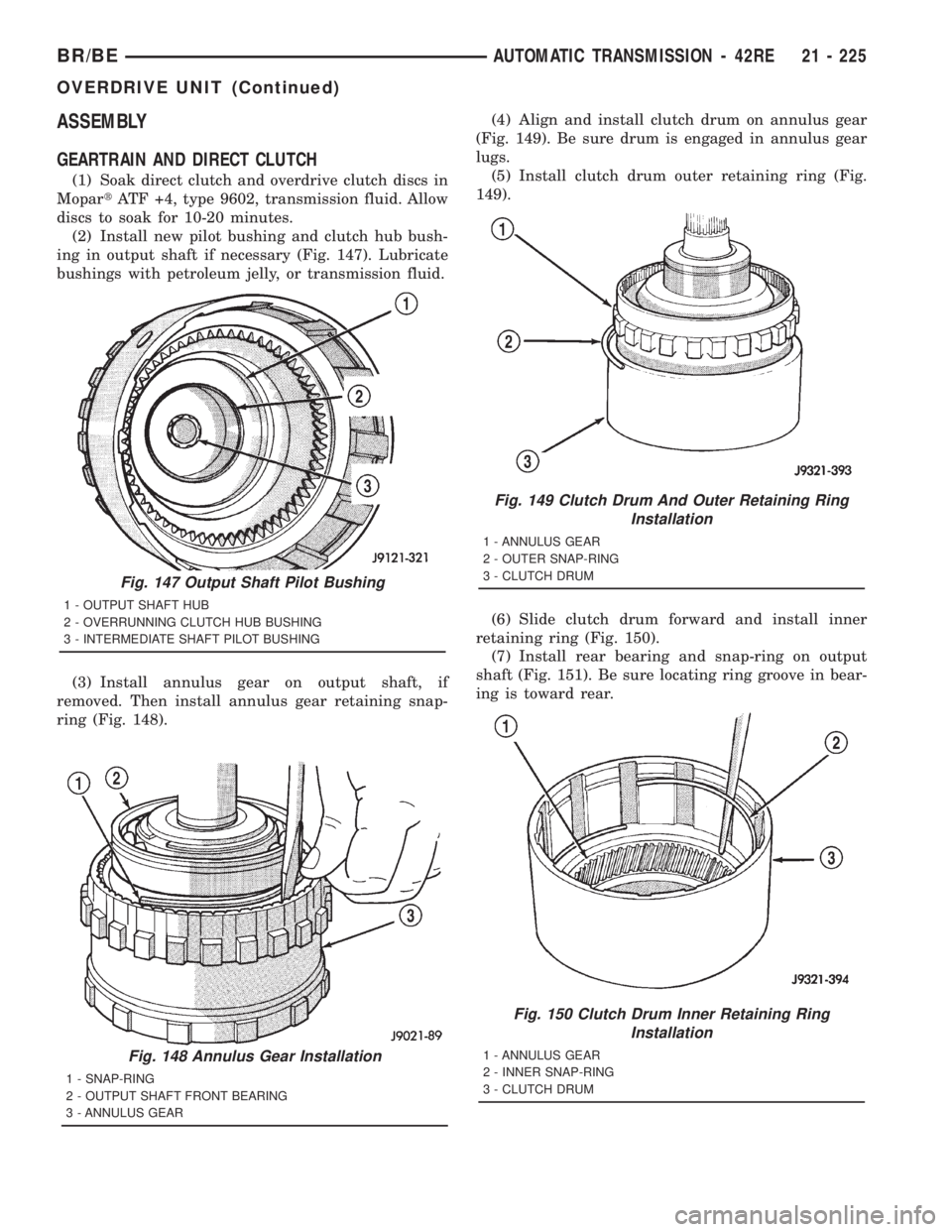

(1) Soak direct clutch and overdrive clutch discs in

MopartATF +4, type 9602, transmission fluid. Allow

discs to soak for 10-20 minutes.

(2) Install new pilot bushing and clutch hub bush-

ing in output shaft if necessary (Fig. 147). Lubricate

bushings with petroleum jelly, or transmission fluid.

(3) Install annulus gear on output shaft, if

removed. Then install annulus gear retaining snap-

ring (Fig. 148).(4) Align and install clutch drum on annulus gear

(Fig. 149). Be sure drum is engaged in annulus gear

lugs.

(5) Install clutch drum outer retaining ring (Fig.

149).

(6) Slide clutch drum forward and install inner

retaining ring (Fig. 150).

(7) Install rear bearing and snap-ring on output

shaft (Fig. 151). Be sure locating ring groove in bear-

ing is toward rear.

Fig. 148 Annulus Gear Installation

1 - SNAP-RING

2 - OUTPUT SHAFT FRONT BEARING

3 - ANNULUS GEAR

Fig. 147 Output Shaft Pilot Bushing

1 - OUTPUT SHAFT HUB

2 - OVERRUNNING CLUTCH HUB BUSHING

3 - INTERMEDIATE SHAFT PILOT BUSHING

Fig. 149 Clutch Drum And Outer Retaining Ring

Installation

1 - ANNULUS GEAR

2 - OUTER SNAP-RING

3 - CLUTCH DRUM

Fig. 150 Clutch Drum Inner Retaining Ring

Installation

1 - ANNULUS GEAR

2 - INNER SNAP-RING

3 - CLUTCH DRUM

BR/BEAUTOMATIC TRANSMISSION - 42RE 21 - 225

OVERDRIVE UNIT (Continued)

Page 1870 of 2889

OVERRUNNING CLUTCH

CAM/OVERDRIVE PISTON

RETAINER

DESCRIPTION

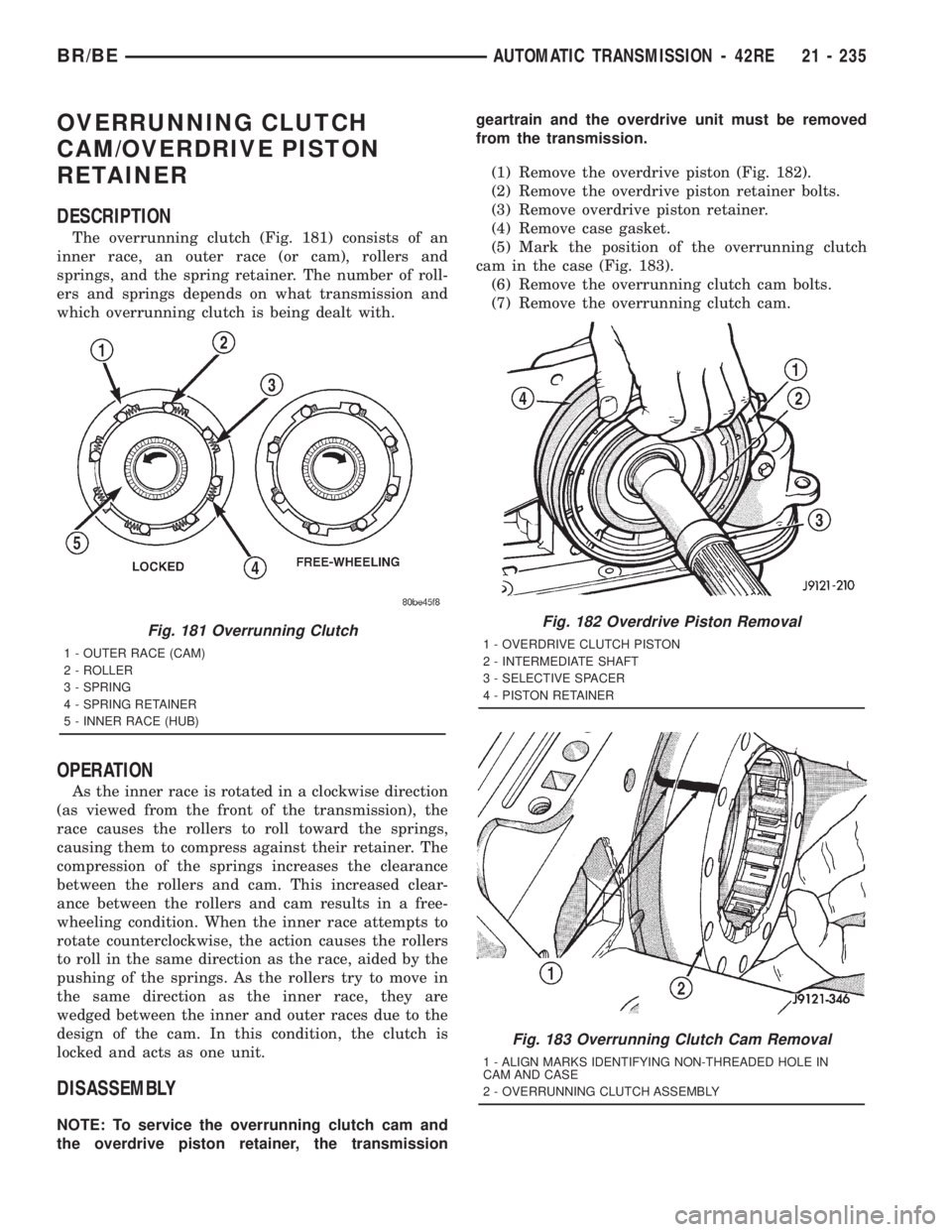

The overrunning clutch (Fig. 181) consists of an

inner race, an outer race (or cam), rollers and

springs, and the spring retainer. The number of roll-

ers and springs depends on what transmission and

which overrunning clutch is being dealt with.

OPERATION

As the inner race is rotated in a clockwise direction

(as viewed from the front of the transmission), the

race causes the rollers to roll toward the springs,

causing them to compress against their retainer. The

compression of the springs increases the clearance

between the rollers and cam. This increased clear-

ance between the rollers and cam results in a free-

wheeling condition. When the inner race attempts to

rotate counterclockwise, the action causes the rollers

to roll in the same direction as the race, aided by the

pushing of the springs. As the rollers try to move in

the same direction as the inner race, they are

wedged between the inner and outer races due to the

design of the cam. In this condition, the clutch is

locked and acts as one unit.

DISASSEMBLY

NOTE: To service the overrunning clutch cam and

the overdrive piston retainer, the transmissiongeartrain and the overdrive unit must be removed

from the transmission.

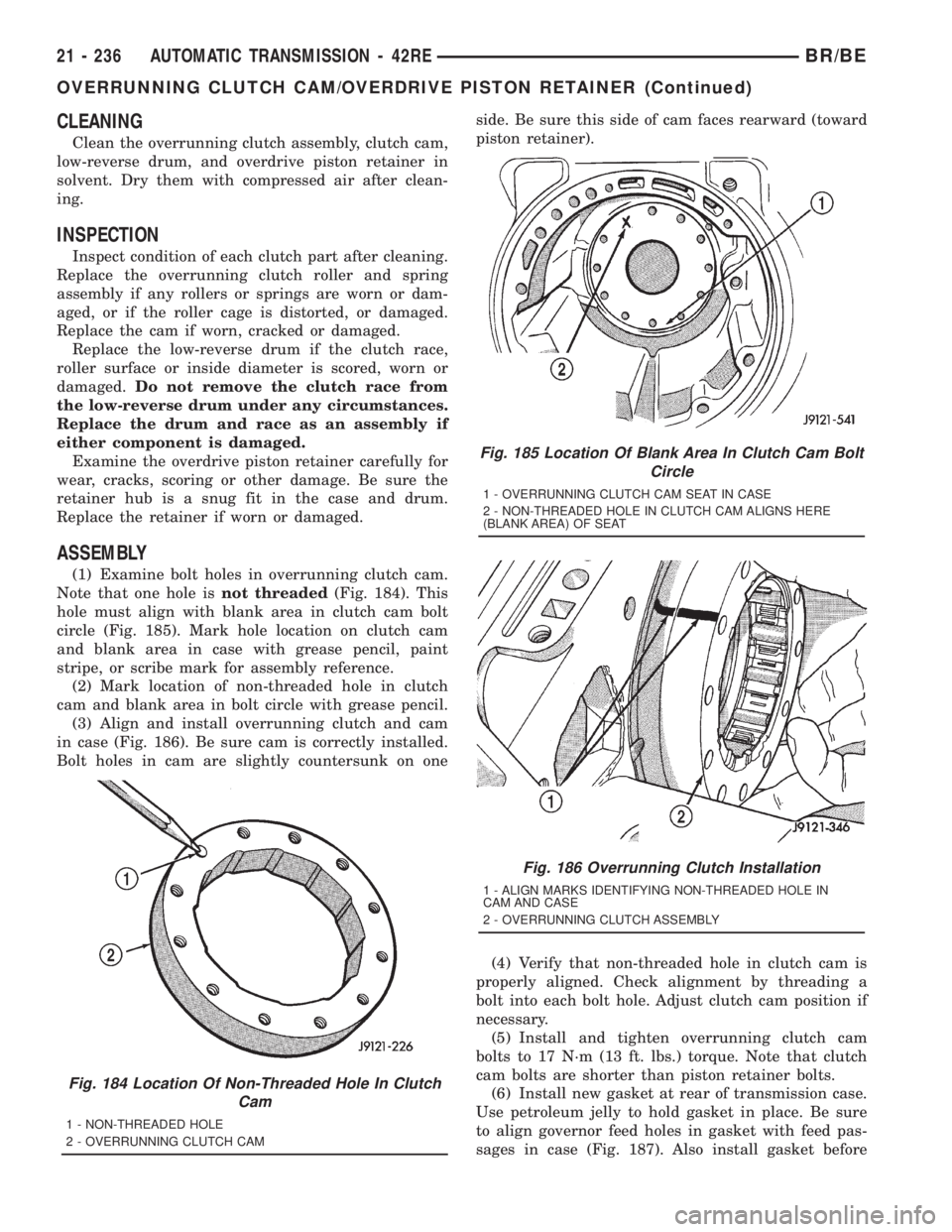

(1) Remove the overdrive piston (Fig. 182).

(2) Remove the overdrive piston retainer bolts.

(3) Remove overdrive piston retainer.

(4) Remove case gasket.

(5) Mark the position of the overrunning clutch

cam in the case (Fig. 183).

(6) Remove the overrunning clutch cam bolts.

(7) Remove the overrunning clutch cam.

Fig. 181 Overrunning Clutch

1 - OUTER RACE (CAM)

2 - ROLLER

3 - SPRING

4 - SPRING RETAINER

5 - INNER RACE (HUB)

Fig. 182 Overdrive Piston Removal

1 - OVERDRIVE CLUTCH PISTON

2 - INTERMEDIATE SHAFT

3 - SELECTIVE SPACER

4 - PISTON RETAINER

Fig. 183 Overrunning Clutch Cam Removal

1 - ALIGN MARKS IDENTIFYING NON-THREADED HOLE IN

CAM AND CASE

2 - OVERRUNNING CLUTCH ASSEMBLY

BR/BEAUTOMATIC TRANSMISSION - 42RE 21 - 235

Page 1871 of 2889

CLEANING

Clean the overrunning clutch assembly, clutch cam,

low-reverse drum, and overdrive piston retainer in

solvent. Dry them with compressed air after clean-

ing.

INSPECTION

Inspect condition of each clutch part after cleaning.

Replace the overrunning clutch roller and spring

assembly if any rollers or springs are worn or dam-

aged, or if the roller cage is distorted, or damaged.

Replace the cam if worn, cracked or damaged.

Replace the low-reverse drum if the clutch race,

roller surface or inside diameter is scored, worn or

damaged.Do not remove the clutch race from

the low-reverse drum under any circumstances.

Replace the drum and race as an assembly if

either component is damaged.

Examine the overdrive piston retainer carefully for

wear, cracks, scoring or other damage. Be sure the

retainer hub is a snug fit in the case and drum.

Replace the retainer if worn or damaged.

ASSEMBLY

(1) Examine bolt holes in overrunning clutch cam.

Note that one hole isnot threaded(Fig. 184). This

hole must align with blank area in clutch cam bolt

circle (Fig. 185). Mark hole location on clutch cam

and blank area in case with grease pencil, paint

stripe, or scribe mark for assembly reference.

(2) Mark location of non-threaded hole in clutch

cam and blank area in bolt circle with grease pencil.

(3) Align and install overrunning clutch and cam

in case (Fig. 186). Be sure cam is correctly installed.

Bolt holes in cam are slightly countersunk on oneside. Be sure this side of cam faces rearward (toward

piston retainer).

(4) Verify that non-threaded hole in clutch cam is

properly aligned. Check alignment by threading a

bolt into each bolt hole. Adjust clutch cam position if

necessary.

(5) Install and tighten overrunning clutch cam

bolts to 17 N´m (13 ft. lbs.) torque. Note that clutch

cam bolts are shorter than piston retainer bolts.

(6) Install new gasket at rear of transmission case.

Use petroleum jelly to hold gasket in place. Be sure

to align governor feed holes in gasket with feed pas-

sages in case (Fig. 187). Also install gasket before

Fig. 184 Location Of Non-Threaded Hole In Clutch

Cam

1 - NON-THREADED HOLE

2 - OVERRUNNING CLUTCH CAM

Fig. 185 Location Of Blank Area In Clutch Cam Bolt

Circle

1 - OVERRUNNING CLUTCH CAM SEAT IN CASE

2 - NON-THREADED HOLE IN CLUTCH CAM ALIGNS HERE

(BLANK AREA) OF SEAT

Fig. 186 Overrunning Clutch Installation

1 - ALIGN MARKS IDENTIFYING NON-THREADED HOLE IN

CAM AND CASE

2 - OVERRUNNING CLUTCH ASSEMBLY

21 - 236 AUTOMATIC TRANSMISSION - 42REBR/BE

OVERRUNNING CLUTCH CAM/OVERDRIVE PISTON RETAINER (Continued)

Page 1882 of 2889

and disengages the clutch. The release spring also

helps to cushion the application of the clutch assem-

bly. When the clutch is in the process of being

released by the release spring, fluid flows through a

vent and one-way ball-check-valve located in the pis-

ton. The check-valve is needed to eliminate the pos-

sibility of plate drag caused by centrifugal force

acting on the residual fluid trapped in the clutch pis-

ton retainer.

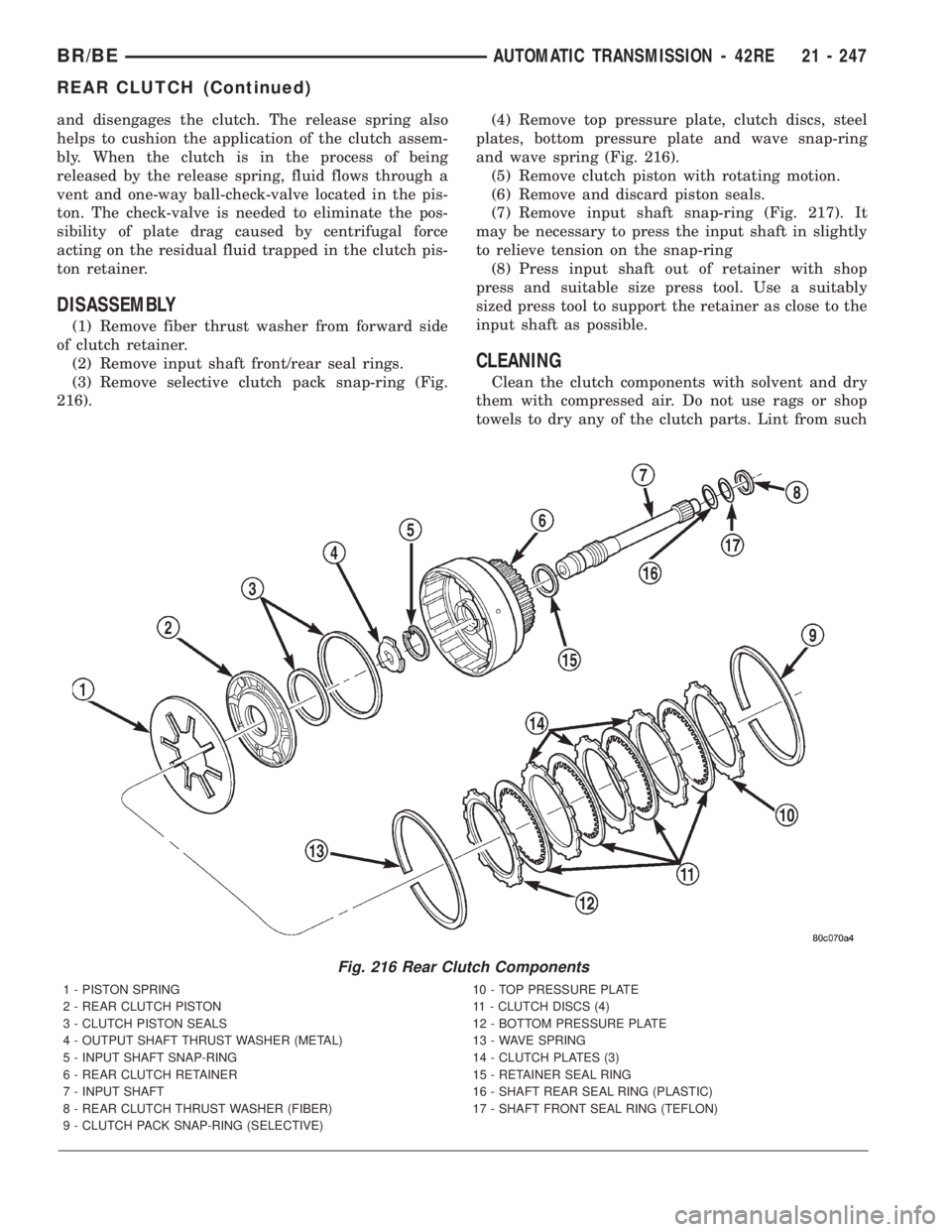

DISASSEMBLY

(1) Remove fiber thrust washer from forward side

of clutch retainer.

(2) Remove input shaft front/rear seal rings.

(3) Remove selective clutch pack snap-ring (Fig.

216).(4) Remove top pressure plate, clutch discs, steel

plates, bottom pressure plate and wave snap-ring

and wave spring (Fig. 216).

(5) Remove clutch piston with rotating motion.

(6) Remove and discard piston seals.

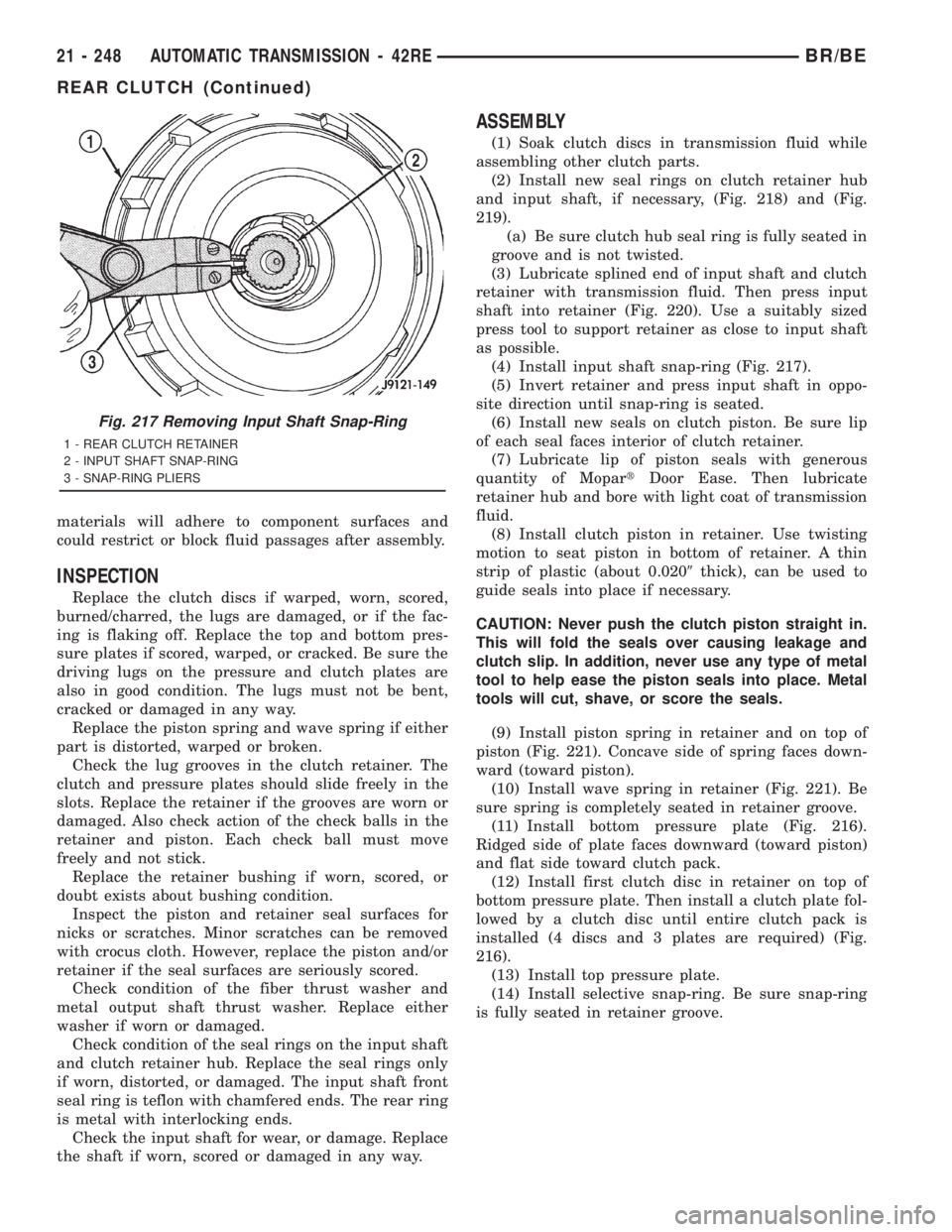

(7) Remove input shaft snap-ring (Fig. 217). It

may be necessary to press the input shaft in slightly

to relieve tension on the snap-ring

(8) Press input shaft out of retainer with shop

press and suitable size press tool. Use a suitably

sized press tool to support the retainer as close to the

input shaft as possible.

CLEANING

Clean the clutch components with solvent and dry

them with compressed air. Do not use rags or shop

towels to dry any of the clutch parts. Lint from such

Fig. 216 Rear Clutch Components

1 - PISTON SPRING 10 - TOP PRESSURE PLATE

2 - REAR CLUTCH PISTON 11 - CLUTCH DISCS (4)

3 - CLUTCH PISTON SEALS 12 - BOTTOM PRESSURE PLATE

4 - OUTPUT SHAFT THRUST WASHER (METAL) 13 - WAVE SPRING

5 - INPUT SHAFT SNAP-RING 14 - CLUTCH PLATES (3)

6 - REAR CLUTCH RETAINER 15 - RETAINER SEAL RING

7 - INPUT SHAFT 16 - SHAFT REAR SEAL RING (PLASTIC)

8 - REAR CLUTCH THRUST WASHER (FIBER) 17 - SHAFT FRONT SEAL RING (TEFLON)

9 - CLUTCH PACK SNAP-RING (SELECTIVE)

BR/BEAUTOMATIC TRANSMISSION - 42RE 21 - 247

REAR CLUTCH (Continued)

Page 1883 of 2889

materials will adhere to component surfaces and

could restrict or block fluid passages after assembly.

INSPECTION

Replace the clutch discs if warped, worn, scored,

burned/charred, the lugs are damaged, or if the fac-

ing is flaking off. Replace the top and bottom pres-

sure plates if scored, warped, or cracked. Be sure the

driving lugs on the pressure and clutch plates are

also in good condition. The lugs must not be bent,

cracked or damaged in any way.

Replace the piston spring and wave spring if either

part is distorted, warped or broken.

Check the lug grooves in the clutch retainer. The

clutch and pressure plates should slide freely in the

slots. Replace the retainer if the grooves are worn or

damaged. Also check action of the check balls in the

retainer and piston. Each check ball must move

freely and not stick.

Replace the retainer bushing if worn, scored, or

doubt exists about bushing condition.

Inspect the piston and retainer seal surfaces for

nicks or scratches. Minor scratches can be removed

with crocus cloth. However, replace the piston and/or

retainer if the seal surfaces are seriously scored.

Check condition of the fiber thrust washer and

metal output shaft thrust washer. Replace either

washer if worn or damaged.

Check condition of the seal rings on the input shaft

and clutch retainer hub. Replace the seal rings only

if worn, distorted, or damaged. The input shaft front

seal ring is teflon with chamfered ends. The rear ring

is metal with interlocking ends.

Check the input shaft for wear, or damage. Replace

the shaft if worn, scored or damaged in any way.

ASSEMBLY

(1) Soak clutch discs in transmission fluid while

assembling other clutch parts.

(2) Install new seal rings on clutch retainer hub

and input shaft, if necessary, (Fig. 218) and (Fig.

219).

(a) Be sure clutch hub seal ring is fully seated in

groove and is not twisted.

(3) Lubricate splined end of input shaft and clutch

retainer with transmission fluid. Then press input

shaft into retainer (Fig. 220). Use a suitably sized

press tool to support retainer as close to input shaft

as possible.

(4) Install input shaft snap-ring (Fig. 217).

(5) Invert retainer and press input shaft in oppo-

site direction until snap-ring is seated.

(6) Install new seals on clutch piston. Be sure lip

of each seal faces interior of clutch retainer.

(7) Lubricate lip of piston seals with generous

quantity of MopartDoor Ease. Then lubricate

retainer hub and bore with light coat of transmission

fluid.

(8) Install clutch piston in retainer. Use twisting

motion to seat piston in bottom of retainer. A thin

strip of plastic (about 0.0209thick), can be used to

guide seals into place if necessary.

CAUTION: Never push the clutch piston straight in.

This will fold the seals over causing leakage and

clutch slip. In addition, never use any type of metal

tool to help ease the piston seals into place. Metal

tools will cut, shave, or score the seals.

(9) Install piston spring in retainer and on top of

piston (Fig. 221). Concave side of spring faces down-

ward (toward piston).

(10) Install wave spring in retainer (Fig. 221). Be

sure spring is completely seated in retainer groove.

(11) Install bottom pressure plate (Fig. 216).

Ridged side of plate faces downward (toward piston)

and flat side toward clutch pack.

(12) Install first clutch disc in retainer on top of

bottom pressure plate. Then install a clutch plate fol-

lowed by a clutch disc until entire clutch pack is

installed (4 discs and 3 plates are required) (Fig.

216).

(13) Install top pressure plate.

(14) Install selective snap-ring. Be sure snap-ring

is fully seated in retainer groove.

Fig. 217 Removing Input Shaft Snap-Ring

1 - REAR CLUTCH RETAINER

2 - INPUT SHAFT SNAP-RING

3 - SNAP-RING PLIERS

21 - 248 AUTOMATIC TRANSMISSION - 42REBR/BE

REAR CLUTCH (Continued)

Page 1895 of 2889

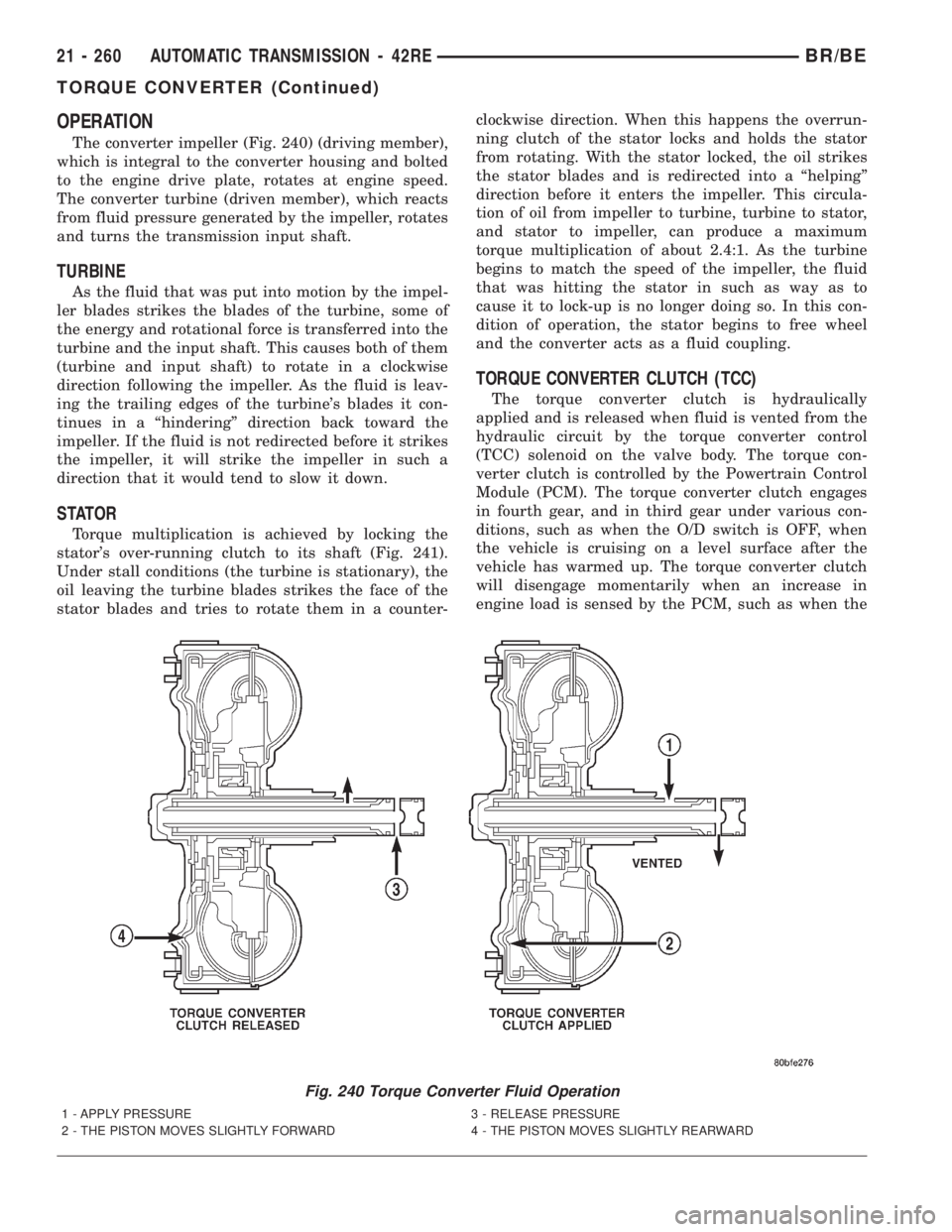

OPERATION

The converter impeller (Fig. 240) (driving member),

which is integral to the converter housing and bolted

to the engine drive plate, rotates at engine speed.

The converter turbine (driven member), which reacts

from fluid pressure generated by the impeller, rotates

and turns the transmission input shaft.

TURBINE

As the fluid that was put into motion by the impel-

ler blades strikes the blades of the turbine, some of

the energy and rotational force is transferred into the

turbine and the input shaft. This causes both of them

(turbine and input shaft) to rotate in a clockwise

direction following the impeller. As the fluid is leav-

ing the trailing edges of the turbine's blades it con-

tinues in a ªhinderingº direction back toward the

impeller. If the fluid is not redirected before it strikes

the impeller, it will strike the impeller in such a

direction that it would tend to slow it down.

STATOR

Torque multiplication is achieved by locking the

stator's over-running clutch to its shaft (Fig. 241).

Under stall conditions (the turbine is stationary), the

oil leaving the turbine blades strikes the face of the

stator blades and tries to rotate them in a counter-clockwise direction. When this happens the overrun-

ning clutch of the stator locks and holds the stator

from rotating. With the stator locked, the oil strikes

the stator blades and is redirected into a ªhelpingº

direction before it enters the impeller. This circula-

tion of oil from impeller to turbine, turbine to stator,

and stator to impeller, can produce a maximum

torque multiplication of about 2.4:1. As the turbine

begins to match the speed of the impeller, the fluid

that was hitting the stator in such as way as to

cause it to lock-up is no longer doing so. In this con-

dition of operation, the stator begins to free wheel

and the converter acts as a fluid coupling.

TORQUE CONVERTER CLUTCH (TCC)

The torque converter clutch is hydraulically

applied and is released when fluid is vented from the

hydraulic circuit by the torque converter control

(TCC) solenoid on the valve body. The torque con-

verter clutch is controlled by the Powertrain Control

Module (PCM). The torque converter clutch engages

in fourth gear, and in third gear under various con-

ditions, such as when the O/D switch is OFF, when

the vehicle is cruising on a level surface after the

vehicle has warmed up. The torque converter clutch

will disengage momentarily when an increase in

engine load is sensed by the PCM, such as when the

Fig. 240 Torque Converter Fluid Operation

1 - APPLY PRESSURE 3 - RELEASE PRESSURE

2 - THE PISTON MOVES SLIGHTLY FORWARD 4 - THE PISTON MOVES SLIGHTLY REARWARD

21 - 260 AUTOMATIC TRANSMISSION - 42REBR/BE

TORQUE CONVERTER (Continued)

Page 1907 of 2889

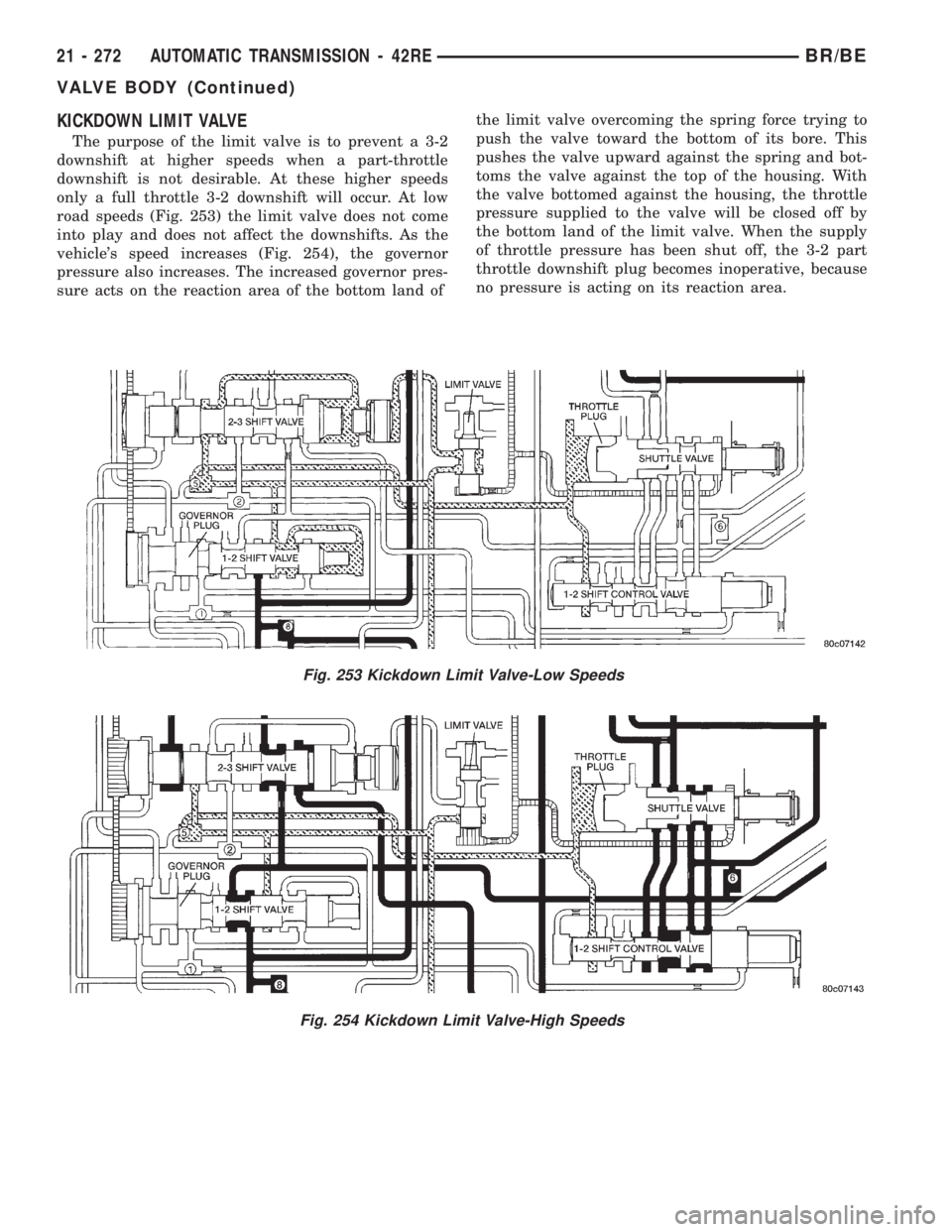

KICKDOWN LIMIT VALVE

The purpose of the limit valve is to prevent a 3-2

downshift at higher speeds when a part-throttle

downshift is not desirable. At these higher speeds

only a full throttle 3-2 downshift will occur. At low

road speeds (Fig. 253) the limit valve does not come

into play and does not affect the downshifts. As the

vehicle's speed increases (Fig. 254), the governor

pressure also increases. The increased governor pres-

sure acts on the reaction area of the bottom land ofthe limit valve overcoming the spring force trying to

push the valve toward the bottom of its bore. This

pushes the valve upward against the spring and bot-

toms the valve against the top of the housing. With

the valve bottomed against the housing, the throttle

pressure supplied to the valve will be closed off by

the bottom land of the limit valve. When the supply

of throttle pressure has been shut off, the 3-2 part

throttle downshift plug becomes inoperative, because

no pressure is acting on its reaction area.

Fig. 253 Kickdown Limit Valve-Low Speeds

Fig. 254 Kickdown Limit Valve-High Speeds

21 - 272 AUTOMATIC TRANSMISSION - 42REBR/BE

VALVE BODY (Continued)