tow DODGE RAM 2001 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 1730 of 2889

FOUR WHEEL DRIVE

(1) Disconnect transfer case shift linkage at trans-

fer case range lever.

(2) Support and secure transfer case with safety

chains to a transmission jack.

(3) Remove transfer case mounting nuts.

(4) Move transfer case rearward until input gear

clears transmission mainshaft.

(5) Lower transfer case assembly and move it from

under vehicle.

(6) Support and secure transmission with safety

chains to a transmission jack.

(7) Remove bolts/nuts attaching transmission

mount to rear crossmember.

(8) Remove rear crossmember.

(9) Remove transmission clutch housing bolts at

the engine block.

(10) Move transmission rearward until input shaft

clears clutch disc.

(11) Lower transmission and remove it from under

vehicle.

DISASSEMBLY

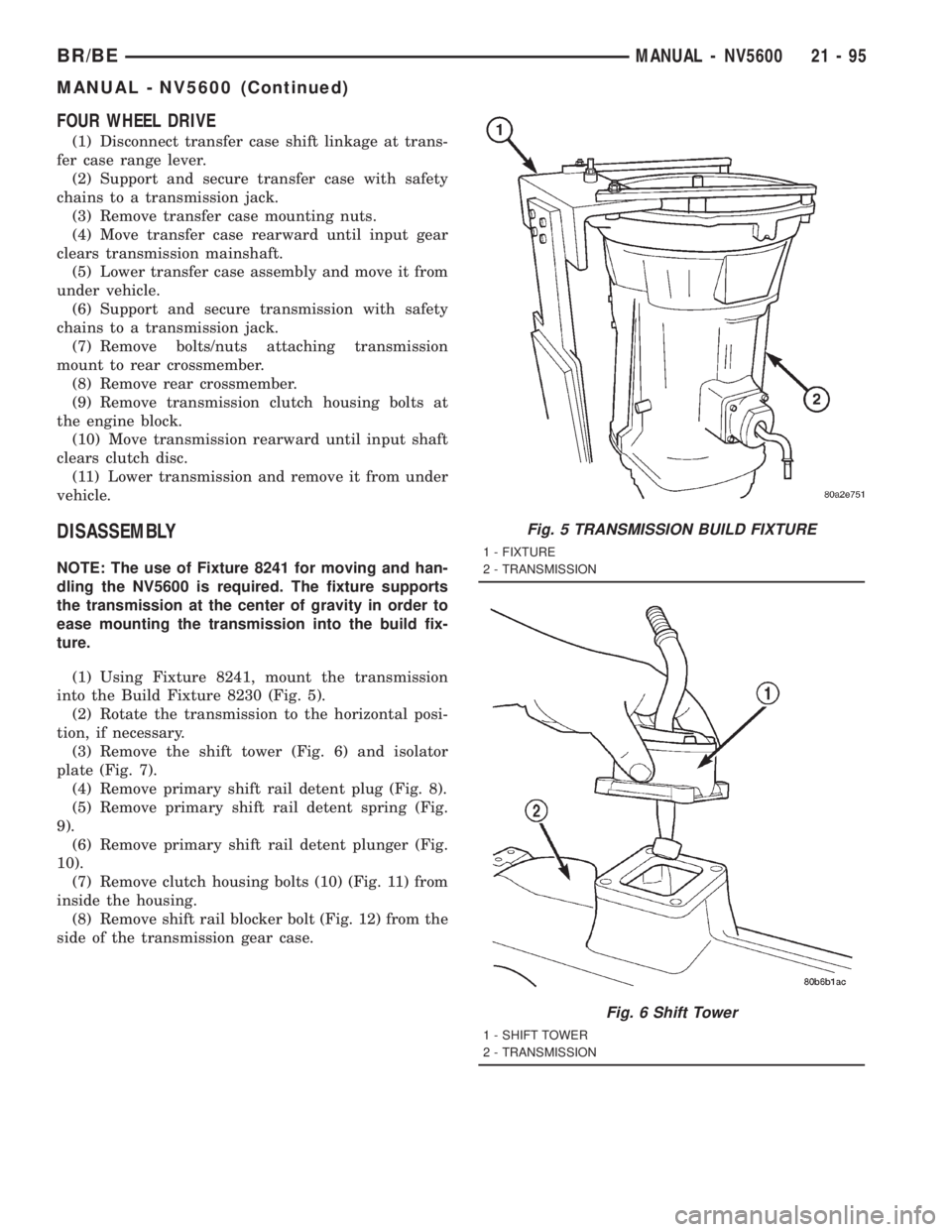

NOTE: The use of Fixture 8241 for moving and han-

dling the NV5600 is required. The fixture supports

the transmission at the center of gravity in order to

ease mounting the transmission into the build fix-

ture.

(1) Using Fixture 8241, mount the transmission

into the Build Fixture 8230 (Fig. 5).

(2) Rotate the transmission to the horizontal posi-

tion, if necessary.

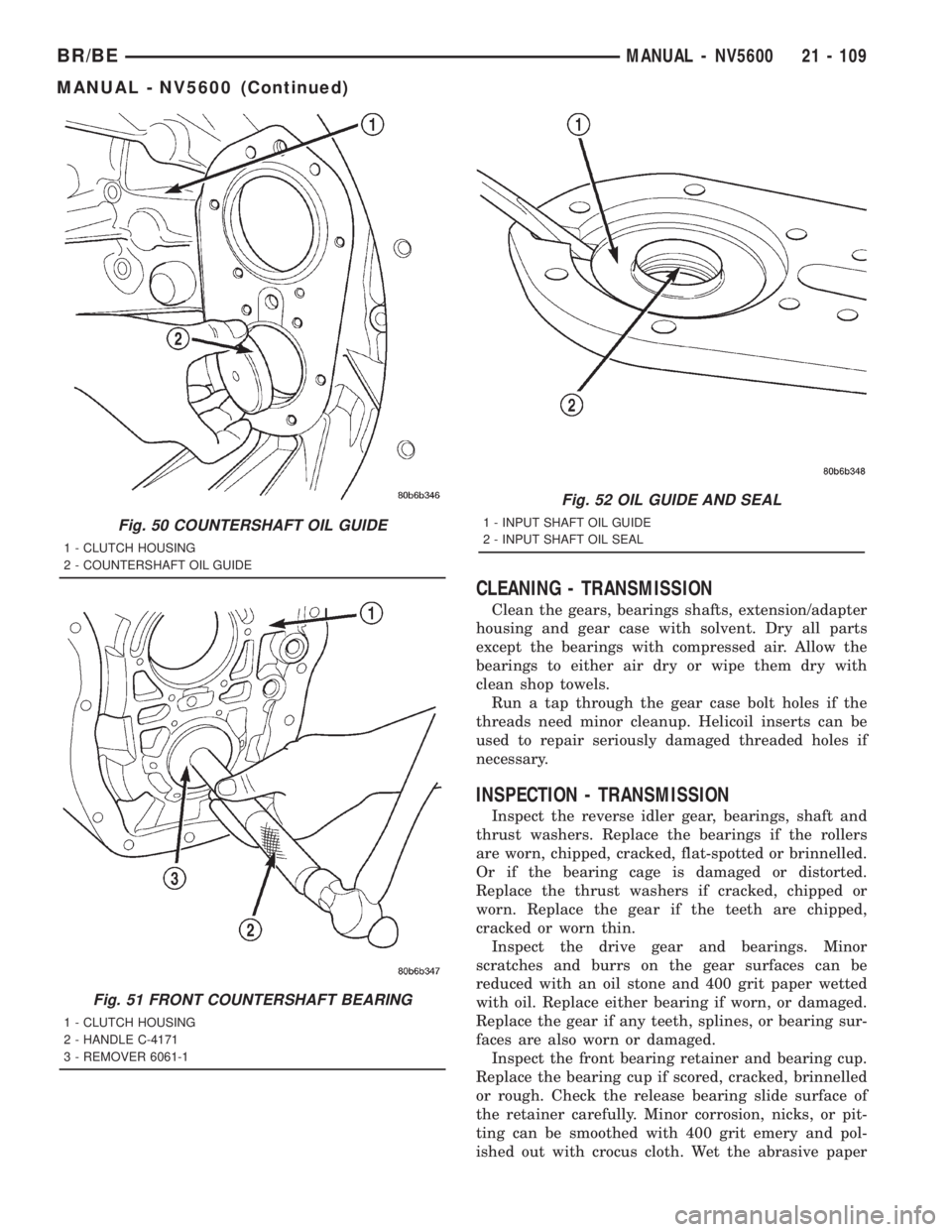

(3) Remove the shift tower (Fig. 6) and isolator

plate (Fig. 7).

(4) Remove primary shift rail detent plug (Fig. 8).

(5) Remove primary shift rail detent spring (Fig.

9).

(6) Remove primary shift rail detent plunger (Fig.

10).

(7) Remove clutch housing bolts (10) (Fig. 11) from

inside the housing.

(8) Remove shift rail blocker bolt (Fig. 12) from the

side of the transmission gear case.

Fig. 5 TRANSMISSION BUILD FIXTURE

1 - FIXTURE

2 - TRANSMISSION

Fig. 6 Shift Tower

1 - SHIFT TOWER

2 - TRANSMISSION

BR/BEMANUAL - NV5600 21 - 95

MANUAL - NV5600 (Continued)

Page 1744 of 2889

CLEANING - TRANSMISSION

Clean the gears, bearings shafts, extension/adapter

housing and gear case with solvent. Dry all parts

except the bearings with compressed air. Allow the

bearings to either air dry or wipe them dry with

clean shop towels.

Run a tap through the gear case bolt holes if the

threads need minor cleanup. Helicoil inserts can be

used to repair seriously damaged threaded holes if

necessary.

INSPECTION - TRANSMISSION

Inspect the reverse idler gear, bearings, shaft and

thrust washers. Replace the bearings if the rollers

are worn, chipped, cracked, flat-spotted or brinnelled.

Or if the bearing cage is damaged or distorted.

Replace the thrust washers if cracked, chipped or

worn. Replace the gear if the teeth are chipped,

cracked or worn thin.

Inspect the drive gear and bearings. Minor

scratches and burrs on the gear surfaces can be

reduced with an oil stone and 400 grit paper wetted

with oil. Replace either bearing if worn, or damaged.

Replace the gear if any teeth, splines, or bearing sur-

faces are also worn or damaged.

Inspect the front bearing retainer and bearing cup.

Replace the bearing cup if scored, cracked, brinnelled

or rough. Check the release bearing slide surface of

the retainer carefully. Minor corrosion, nicks, or pit-

ting can be smoothed with 400 grit emery and pol-

ished out with crocus cloth. Wet the abrasive paper

Fig. 50 COUNTERSHAFT OIL GUIDE

1 - CLUTCH HOUSING

2 - COUNTERSHAFT OIL GUIDE

Fig. 51 FRONT COUNTERSHAFT BEARING

1 - CLUTCH HOUSING

2 - HANDLE C-4171

3 - REMOVER 6061-1

Fig. 52 OIL GUIDE AND SEAL

1 - INPUT SHAFT OIL GUIDE

2 - INPUT SHAFT OIL SEAL

BR/BEMANUAL - NV5600 21 - 109

MANUAL - NV5600 (Continued)

Page 1759 of 2889

EXTENSION/ADAPTER HOUSING

(1) Install extension housing bushing with

Installer 8156 and Handle C-4171, if necessary. The

oil feed hole must be at the 12 o'clock position when

installed.

(2) On 4X2 vehicles, install extension housing seal

with Installer 8154 and Handle C-4171, with the

weep hole at the bottom.

NOTE: Drain hole located in the dust boot portion

of the seal must face downward ( toward the

ground) when installed.

(3) On 4X4 vehicles, install adapter housing seal

with Installer C-3860-A and Handle C-4171.

(4) Install the crossover cam bushing into the

extension/adapter housing with Installer 8239 and

Handle C-4171.

(5) Clean the rear of the transmission case of all

sealer.

(6) Install reverse countershaft gear bearing race

onto the reverse countershaft gear bearing.

(7) Measure the distance from the back of the

bearing race to Gauge Bar 6311 (Fig. 94).(8) Measure thickness of the gauge bar and record

the total of the two measurements.

(9) Clean all the sealer from the extension/adapter

housing.

(10) Place Gauge Bar 6311 across the housing face.

Measure the distance from the top of the bar to the

bottom of the reverse countershaft bearing race bore

(Fig. 95).

(11) Subtract thickness of the gauge bar from the

measurement and record the result.

(12) The difference between the two measurements

is the end-play for the reverse countershaft gear

assembly.

(13) Install shims to achieve 0.15-0.25 mm (0.006-

0.010 in.) end-play for the reverse countershaft gear

assembly into the reverse countershaft bearing race

bore.

(14) Use Installer to install the reverse counter-

shaft bearing race into the extension/adapter hous-

ing.

(15) Install back-up lamp switch and a new gasket

into the extension/adapter housing. Tighten switch to

28 N´m (20 ft.lbs.).

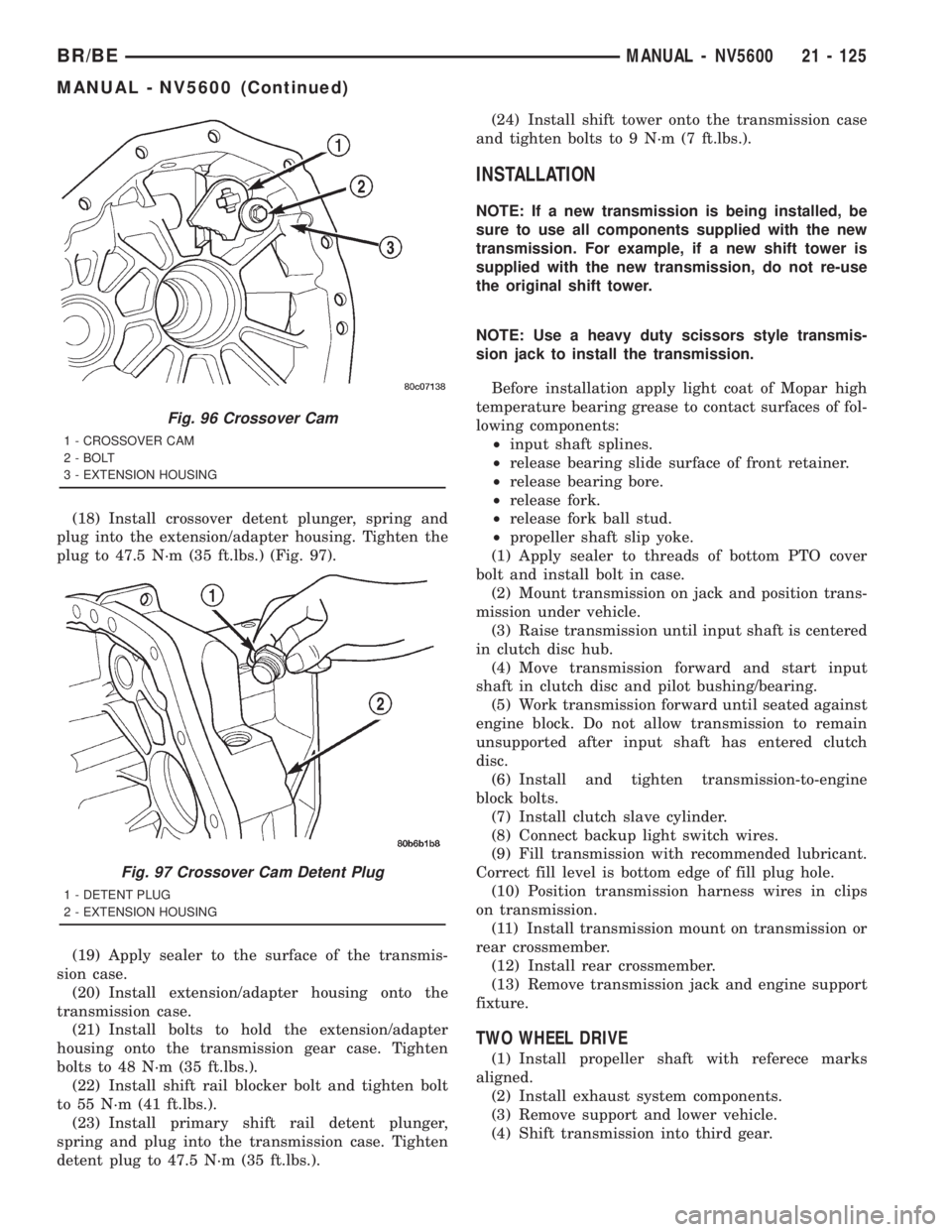

(16) Install crossover cam into the extension/

adapter housing.

(17) Install bolt to hold the crossover cam to the

extension/adapter housing (Fig. 96).

Fig. 94 Measure Height of Reverse Countershaft

1 - MEASURE DISTANCE FROM RACE TO GAUGE BAR 6311

Fig. 95 Reverse Countershaft Gear Bearing Race

Bore

1 - GAUGE BAR 6311 TO BEARING RACE BORE

MEASUREMENT

21 - 124 MANUAL - NV5600BR/BE

MANUAL - NV5600 (Continued)

Page 1760 of 2889

(18) Install crossover detent plunger, spring and

plug into the extension/adapter housing. Tighten the

plug to 47.5 N´m (35 ft.lbs.) (Fig. 97).

(19) Apply sealer to the surface of the transmis-

sion case.

(20) Install extension/adapter housing onto the

transmission case.

(21) Install bolts to hold the extension/adapter

housing onto the transmission gear case. Tighten

bolts to 48 N´m (35 ft.lbs.).

(22) Install shift rail blocker bolt and tighten bolt

to 55 N´m (41 ft.lbs.).

(23) Install primary shift rail detent plunger,

spring and plug into the transmission case. Tighten

detent plug to 47.5 N´m (35 ft.lbs.).(24) Install shift tower onto the transmission case

and tighten bolts to 9 N´m (7 ft.lbs.).

INSTALLATION

NOTE: If a new transmission is being installed, be

sure to use all components supplied with the new

transmission. For example, if a new shift tower is

supplied with the new transmission, do not re-use

the original shift tower.

NOTE: Use a heavy duty scissors style transmis-

sion jack to install the transmission.

Before installation apply light coat of Mopar high

temperature bearing grease to contact surfaces of fol-

lowing components:

²input shaft splines.

²release bearing slide surface of front retainer.

²release bearing bore.

²release fork.

²release fork ball stud.

²propeller shaft slip yoke.

(1) Apply sealer to threads of bottom PTO cover

bolt and install bolt in case.

(2) Mount transmission on jack and position trans-

mission under vehicle.

(3) Raise transmission until input shaft is centered

in clutch disc hub.

(4) Move transmission forward and start input

shaft in clutch disc and pilot bushing/bearing.

(5) Work transmission forward until seated against

engine block. Do not allow transmission to remain

unsupported after input shaft has entered clutch

disc.

(6) Install and tighten transmission-to-engine

block bolts.

(7) Install clutch slave cylinder.

(8) Connect backup light switch wires.

(9) Fill transmission with recommended lubricant.

Correct fill level is bottom edge of fill plug hole.

(10) Position transmission harness wires in clips

on transmission.

(11) Install transmission mount on transmission or

rear crossmember.

(12) Install rear crossmember.

(13) Remove transmission jack and engine support

fixture.

TWO WHEEL DRIVE

(1) Install propeller shaft with referece marks

aligned.

(2) Install exhaust system components.

(3) Remove support and lower vehicle.

(4) Shift transmission into third gear.

Fig. 96 Crossover Cam

1 - CROSSOVER CAM

2 - BOLT

3 - EXTENSION HOUSING

Fig. 97 Crossover Cam Detent Plug

1 - DETENT PLUG

2 - EXTENSION HOUSING

BR/BEMANUAL - NV5600 21 - 125

MANUAL - NV5600 (Continued)

Page 1761 of 2889

(5) Clean the mating surfaces of shift tower and

isolator plate with suitable wax and grease remover.

(6) Apply Mopar Gasket Maker or equivalent to

sealing surface of the transmission case. Do not over

apply sealant.

(7) Install isolator plate onto the transmission case

metal side down.

(8) Install shift tower onto the isolator plate. No

sealant is necessary between the shift tower and top

of isolator plate.

(9) Verify that the shift tower, isolator plate and

the shift socket are properly aligned.

(10) Install bolts to hold the shift tower to the iso-

lator plate and the transmission case. Tighten bolts

to 10.2±11.25 N´m (7.5±8.3 ft. lbs.).

(11) Install shift boot and bezel.

(12) Connect battery negative cable.

FOUR WHEEL DRIVE

(1) Install and secure transfer case on the trans-

mission jack.

(2) Raise and align transfer case input gear with

transmission mainshaft.

(3) Move transfer case forward and seat it on

adapter.

(4) Install and tighten transfer case mounting nuts

to 41-47 N´m (30-35 ft. lbs.) if case has 3/8 studs. If

case has 5/16 studs tighten to 30-41 N´m (22-30 ft.

lbs.).

(5) Connect transfer case shift lever to range lever

on transfer case.(6) Install propeller shafts with reference marks

aligned.

(7) Fill transmission with required lubricant.

Check lubricant level in transfer case and add lubri-

cant if necessary.

(8) Install transfer case skid plate, if equipped,

and crossmember. Tighten attaching bolts/nuts to 41

N´m (30 ft. lbs.).

(9) Install exhaust system components.

(10) Remove support and lower vehicle.

(11) Shift transmission into third gear.

(12) Clean the mating surfaces of shift tower, iso-

lator plate, and transmission case with suitable wax

and grease remover.

(13) Apply Mopar Gasket Maker or equivalent to

the sealing surface of the transmission case. Do not

over apply sealant.

(14) Install isolator plate onto the transmission

case, metal side down.

(15) Install shift tower onto the isolator plate. No

sealant is necessary between the shift tower and top

of isolator plate.

(16) Verify that the shift tower, isolator plate and

the shift tower bushings are properly aligned.

(17) Install the bolts to hold the shift tower to the

isolator plate and the transmission case. Tighten the

shift tower bolts to 10.2±11.25 N´m (7.5±8.3 ft. lbs.).

(18) Install shift lever boot and bezel.

(19) Connect battery negative cable.

SPECIFICATIONS

SPECIFICATIONS - NV5600

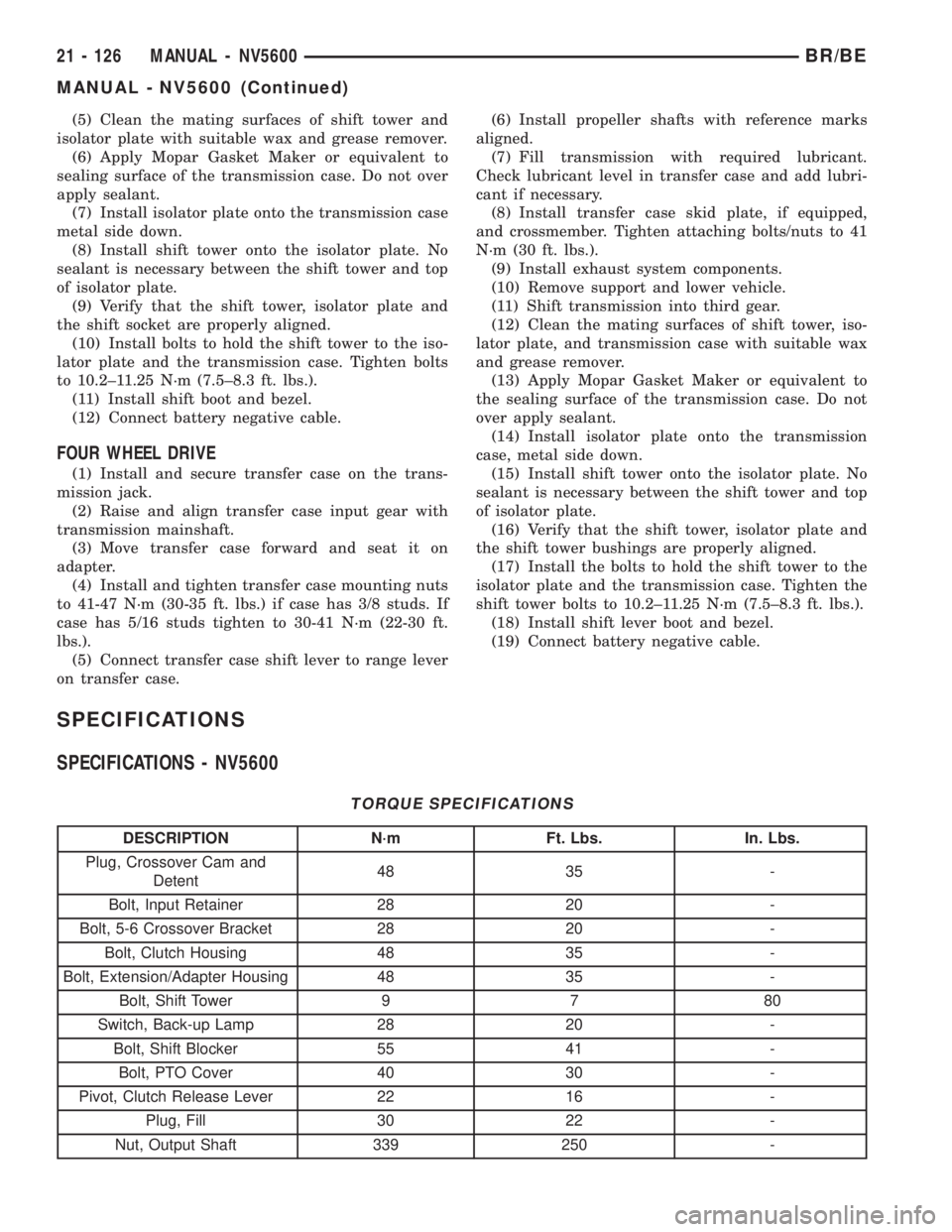

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Plug, Crossover Cam and

Detent48 35 -

Bolt, Input Retainer 28 20 -

Bolt, 5-6 Crossover Bracket 28 20 -

Bolt, Clutch Housing 48 35 -

Bolt, Extension/Adapter Housing 48 35 -

Bolt, Shift Tower 9 7 80

Switch, Back-up Lamp 28 20 -

Bolt, Shift Blocker 55 41 -

Bolt, PTO Cover 40 30 -

Pivot, Clutch Release Lever 22 16 -

Plug, Fill 30 22 -

Nut, Output Shaft 339 250 -

21 - 126 MANUAL - NV5600BR/BE

MANUAL - NV5600 (Continued)

Page 1767 of 2889

ADAPTER HOUSING SEAL

REMOVAL

(1) Remove the propeller shaft.

(2) Remove the transfer case.

(3) Remove adapter housing seal with a pry tool or

a slide hammer mounted screw.

INSTALLATION

(1) Install extension housing seal with Installer

8154 and Handle C-4171.

(2) Install propeller shaft with reference marks

aligned.

EXTENSION HOUSING SEAL

REMOVAL

(1) Raise and support vehicle.

(2) Mark propeller shaft and pinion yoke for

installation reference and remove the propeller shaft.

(3) Remove the extension housing seal with a suit-

able pry tool or a slide hammer mounted screw.

(4) Remove the extension housing bushing with

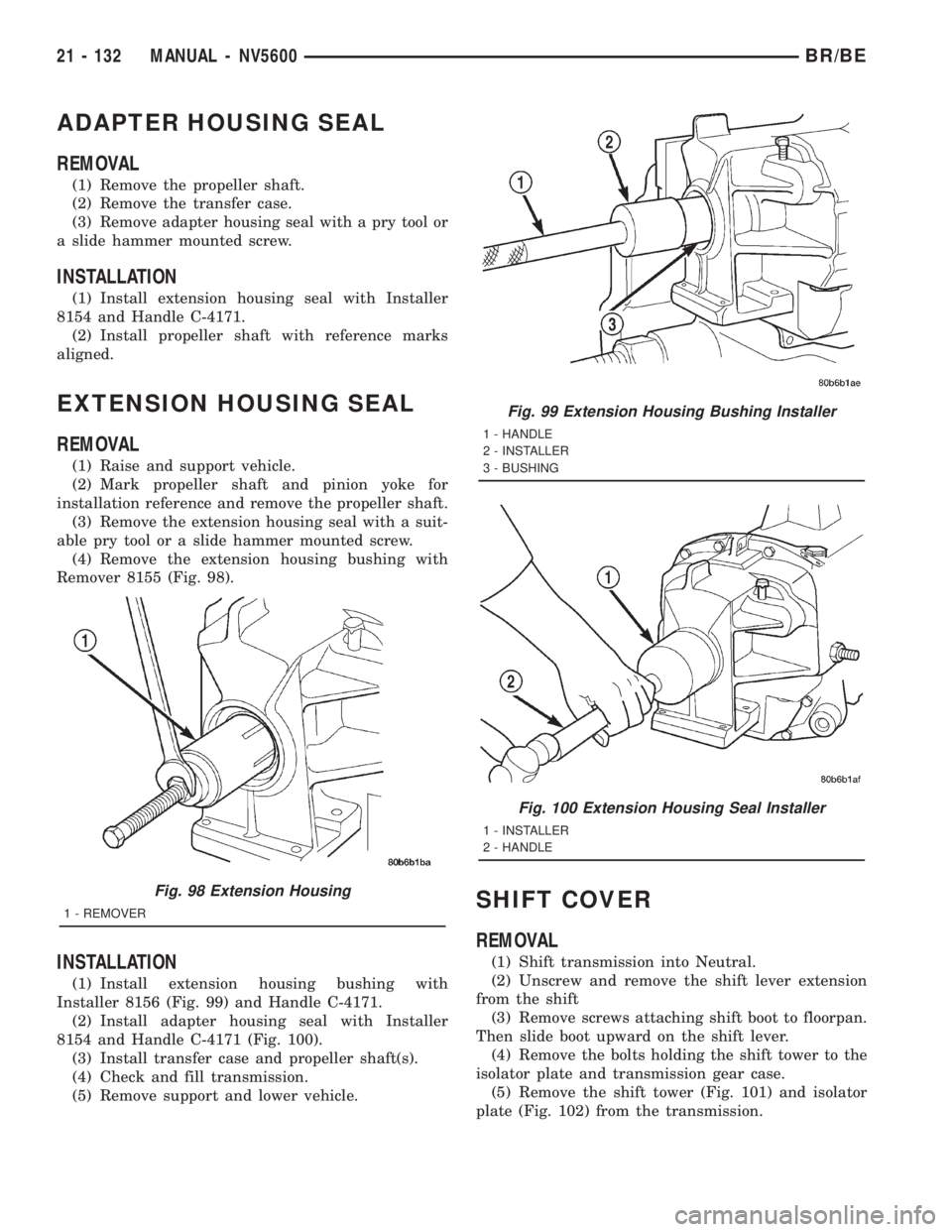

Remover 8155 (Fig. 98).

INSTALLATION

(1) Install extension housing bushing with

Installer 8156 (Fig. 99) and Handle C-4171.

(2) Install adapter housing seal with Installer

8154 and Handle C-4171 (Fig. 100).

(3) Install transfer case and propeller shaft(s).

(4) Check and fill transmission.

(5) Remove support and lower vehicle.

SHIFT COVER

REMOVAL

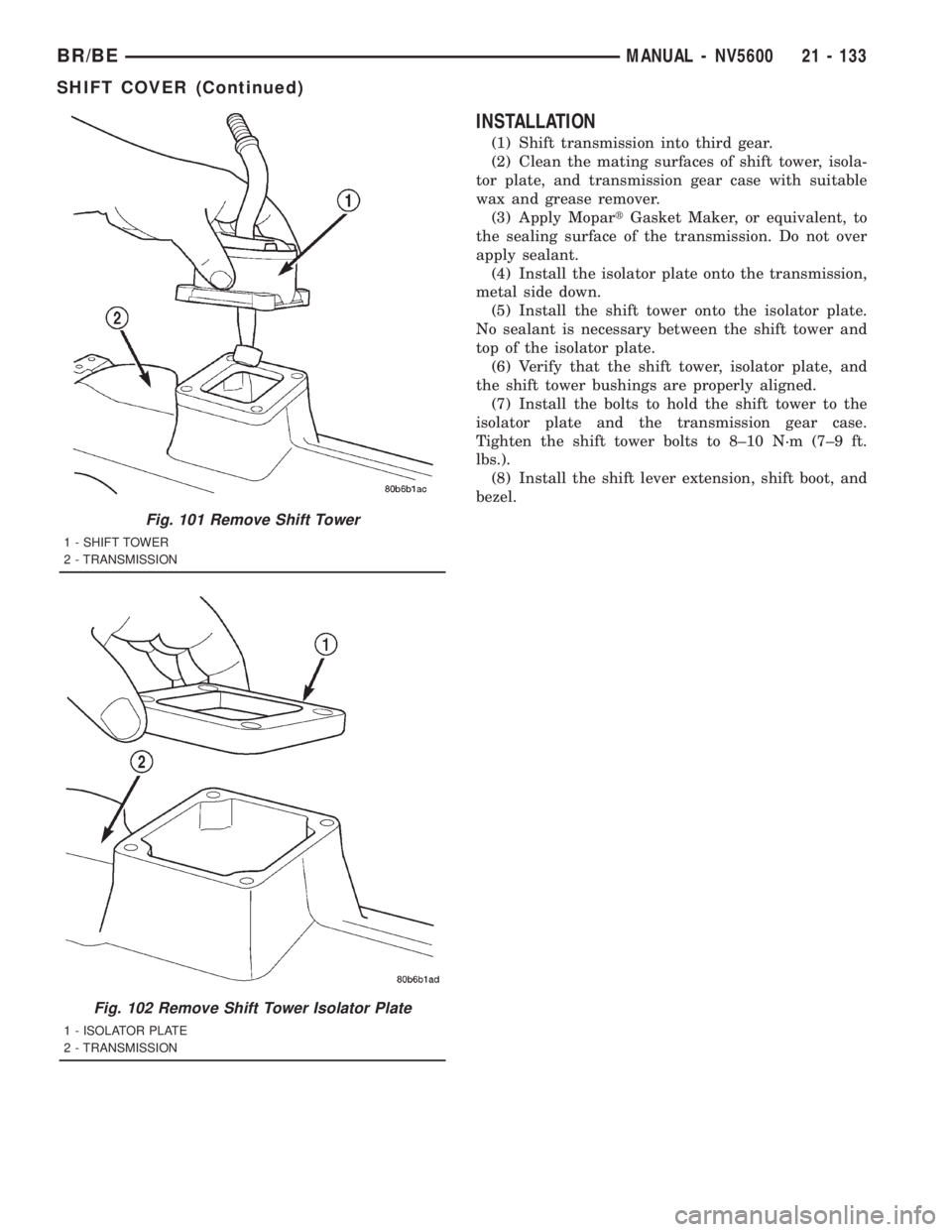

(1) Shift transmission into Neutral.

(2) Unscrew and remove the shift lever extension

from the shift

(3) Remove screws attaching shift boot to floorpan.

Then slide boot upward on the shift lever.

(4) Remove the bolts holding the shift tower to the

isolator plate and transmission gear case.

(5) Remove the shift tower (Fig. 101) and isolator

plate (Fig. 102) from the transmission.

Fig. 99 Extension Housing Bushing Installer

1 - HANDLE

2 - INSTALLER

3 - BUSHING

Fig. 100 Extension Housing Seal Installer

1 - INSTALLER

2 - HANDLE

Fig. 98 Extension Housing

1 - REMOVER

21 - 132 MANUAL - NV5600BR/BE

Page 1768 of 2889

INSTALLATION

(1) Shift transmission into third gear.

(2) Clean the mating surfaces of shift tower, isola-

tor plate, and transmission gear case with suitable

wax and grease remover.

(3) Apply MopartGasket Maker, or equivalent, to

the sealing surface of the transmission. Do not over

apply sealant.

(4) Install the isolator plate onto the transmission,

metal side down.

(5) Install the shift tower onto the isolator plate.

No sealant is necessary between the shift tower and

top of the isolator plate.

(6) Verify that the shift tower, isolator plate, and

the shift tower bushings are properly aligned.

(7) Install the bolts to hold the shift tower to the

isolator plate and the transmission gear case.

Tighten the shift tower bolts to 8±10 N´m (7±9 ft.

lbs.).

(8) Install the shift lever extension, shift boot, and

bezel.

Fig. 101 Remove Shift Tower

1 - SHIFT TOWER

2 - TRANSMISSION

Fig. 102 Remove Shift Tower Isolator Plate

1 - ISOLATOR PLATE

2 - TRANSMISSION

BR/BEMANUAL - NV5600 21 - 133

SHIFT COVER (Continued)

Page 1800 of 2889

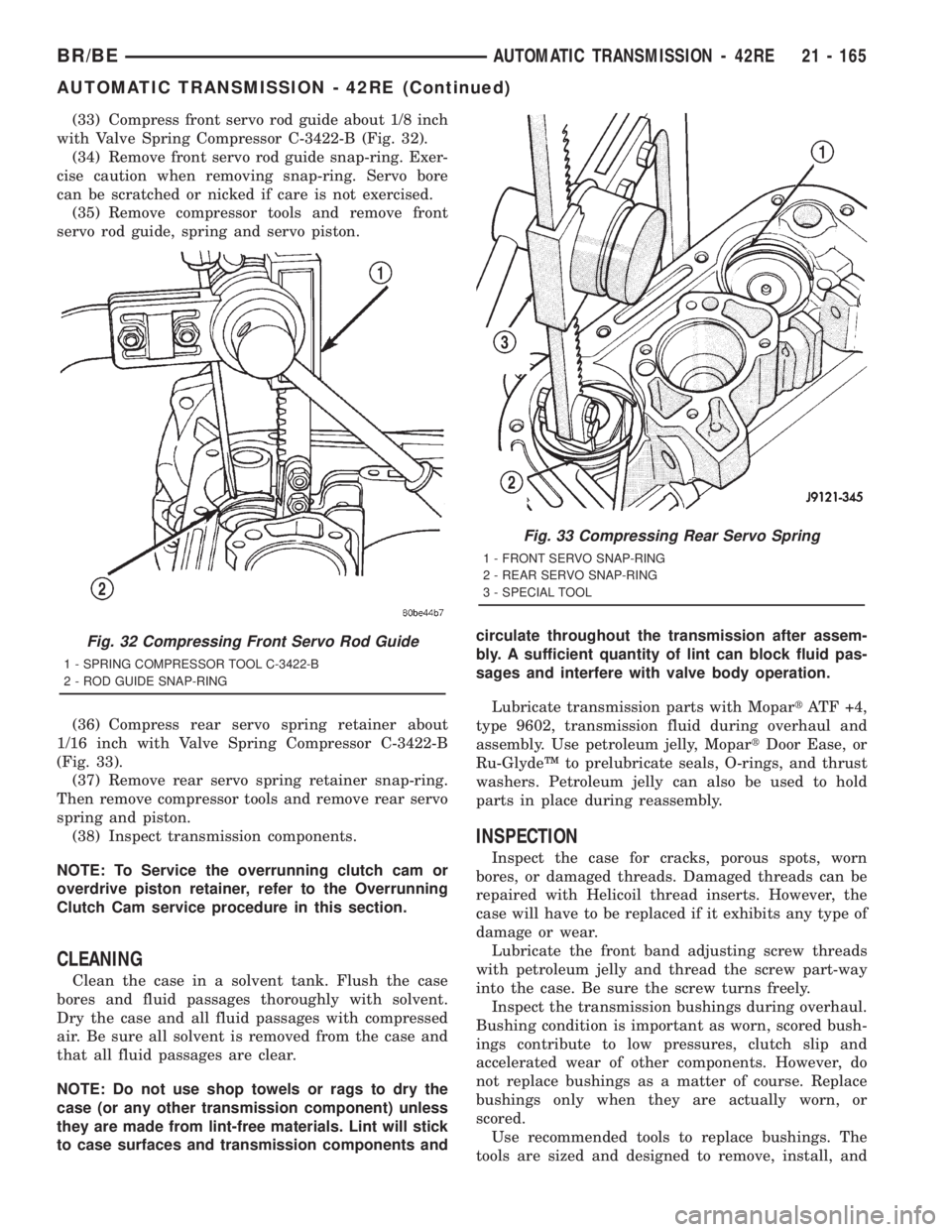

(33) Compress front servo rod guide about 1/8 inch

with Valve Spring Compressor C-3422-B (Fig. 32).

(34) Remove front servo rod guide snap-ring. Exer-

cise caution when removing snap-ring. Servo bore

can be scratched or nicked if care is not exercised.

(35) Remove compressor tools and remove front

servo rod guide, spring and servo piston.

(36) Compress rear servo spring retainer about

1/16 inch with Valve Spring Compressor C-3422-B

(Fig. 33).

(37) Remove rear servo spring retainer snap-ring.

Then remove compressor tools and remove rear servo

spring and piston.

(38) Inspect transmission components.

NOTE: To Service the overrunning clutch cam or

overdrive piston retainer, refer to the Overrunning

Clutch Cam service procedure in this section.

CLEANING

Clean the case in a solvent tank. Flush the case

bores and fluid passages thoroughly with solvent.

Dry the case and all fluid passages with compressed

air. Be sure all solvent is removed from the case and

that all fluid passages are clear.

NOTE: Do not use shop towels or rags to dry the

case (or any other transmission component) unless

they are made from lint-free materials. Lint will stick

to case surfaces and transmission components andcirculate throughout the transmission after assem-

bly. A sufficient quantity of lint can block fluid pas-

sages and interfere with valve body operation.

Lubricate transmission parts with MopartATF +4,

type 9602, transmission fluid during overhaul and

assembly. Use petroleum jelly, MopartDoor Ease, or

Ru-GlydeŸ to prelubricate seals, O-rings, and thrust

washers. Petroleum jelly can also be used to hold

parts in place during reassembly.

INSPECTION

Inspect the case for cracks, porous spots, worn

bores, or damaged threads. Damaged threads can be

repaired with Helicoil thread inserts. However, the

case will have to be replaced if it exhibits any type of

damage or wear.

Lubricate the front band adjusting screw threads

with petroleum jelly and thread the screw part-way

into the case. Be sure the screw turns freely.

Inspect the transmission bushings during overhaul.

Bushing condition is important as worn, scored bush-

ings contribute to low pressures, clutch slip and

accelerated wear of other components. However, do

not replace bushings as a matter of course. Replace

bushings only when they are actually worn, or

scored.

Use recommended tools to replace bushings. The

tools are sized and designed to remove, install, and

Fig. 32 Compressing Front Servo Rod Guide

1 - SPRING COMPRESSOR TOOL C-3422-B

2 - ROD GUIDE SNAP-RING

Fig. 33 Compressing Rear Servo Spring

1 - FRONT SERVO SNAP-RING

2 - REAR SERVO SNAP-RING

3 - SPECIAL TOOL

BR/BEAUTOMATIC TRANSMISSION - 42RE 21 - 165

AUTOMATIC TRANSMISSION - 42RE (Continued)

Page 1801 of 2889

seat bushings correctly. The bushing replacement

tools are included in Bushing Tool Set C-3887-B.

Pre-sized service bushings are available for

replacement purposes. Only the sun gear bushings

are not serviced.

The use of crocus cloth is permissible where neces-

sary, providing it is used carefully. When used on

shafts, or valves, use extreme care to avoid rounding

off sharp edges. Sharp edges are vital as they pre-

vent foreign matter from getting between the valve

and valve bore.

Do not reuse oil seals, gaskets, seal rings, or

O-rings during overhaul. Replace these parts as a

matter of course. Also do not reuse snap rings or

E-clips that are bent or distorted. Replace these parts

as well.

ASSEMBLY

Do not allow dirt, grease, or foreign material to

enter the case or transmission components during

assembly. Keep the transmission case and compo-

nents clean. Also make sure the tools and workbench

area used for assembly operations are equally clean.

Shop towels used for wiping off tools and hands

must be made fromlint freematerial. Lint will stick

to transmission parts and could interfere with valve

operation, or even restrict fluid passages.

Lubricate the transmission components with

Moparttransmission fluid during reassembly. Use

MopartDoor Ease, or Ru-GlydeŸ on seals and

O-rings to ease installation.

Petroleum jelly can also be used to hold thrust

washers, thrust plates and gaskets in position during

assembly. However,do notuse chassis grease, bear-

ing grease, white grease, or similar lubricants on any

transmission part. These types of lubricants can

eventually block or restrict fluid passages and inter-

fere with valve operation. Use petroleum jelly only.

Do not force parts into place. The transmission

components and subassemblies are easily installed by

hand when properly aligned.

If a part seems extremely difficult to install, it is

either misaligned or incorrectly assembled. Also ver-

ify that thrust washers, thrust plates and seal rings

are correctly positioned before assembly. These parts

can interfere with proper assembly if mis-positioned.

The planetary geartrain, front/rear clutch assem-

blies and oil pump are all much easier to install

when the transmission case is upright.

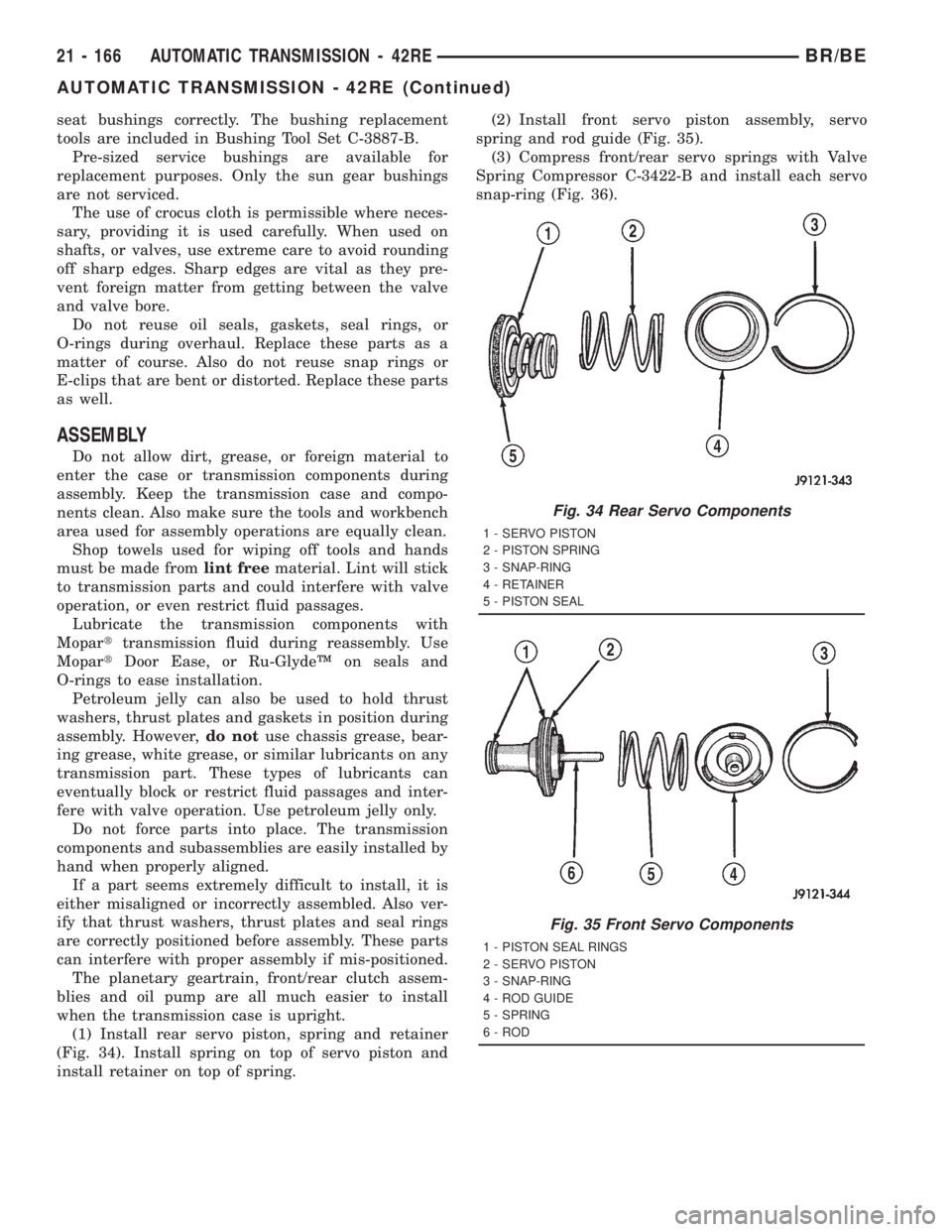

(1) Install rear servo piston, spring and retainer

(Fig. 34). Install spring on top of servo piston and

install retainer on top of spring.(2) Install front servo piston assembly, servo

spring and rod guide (Fig. 35).

(3) Compress front/rear servo springs with Valve

Spring Compressor C-3422-B and install each servo

snap-ring (Fig. 36).

Fig. 34 Rear Servo Components

1 - SERVO PISTON

2 - PISTON SPRING

3 - SNAP-RING

4 - RETAINER

5 - PISTON SEAL

Fig. 35 Front Servo Components

1 - PISTON SEAL RINGS

2 - SERVO PISTON

3 - SNAP-RING

4 - ROD GUIDE

5 - SPRING

6 - ROD

21 - 166 AUTOMATIC TRANSMISSION - 42REBR/BE

AUTOMATIC TRANSMISSION - 42RE (Continued)

Page 1804 of 2889

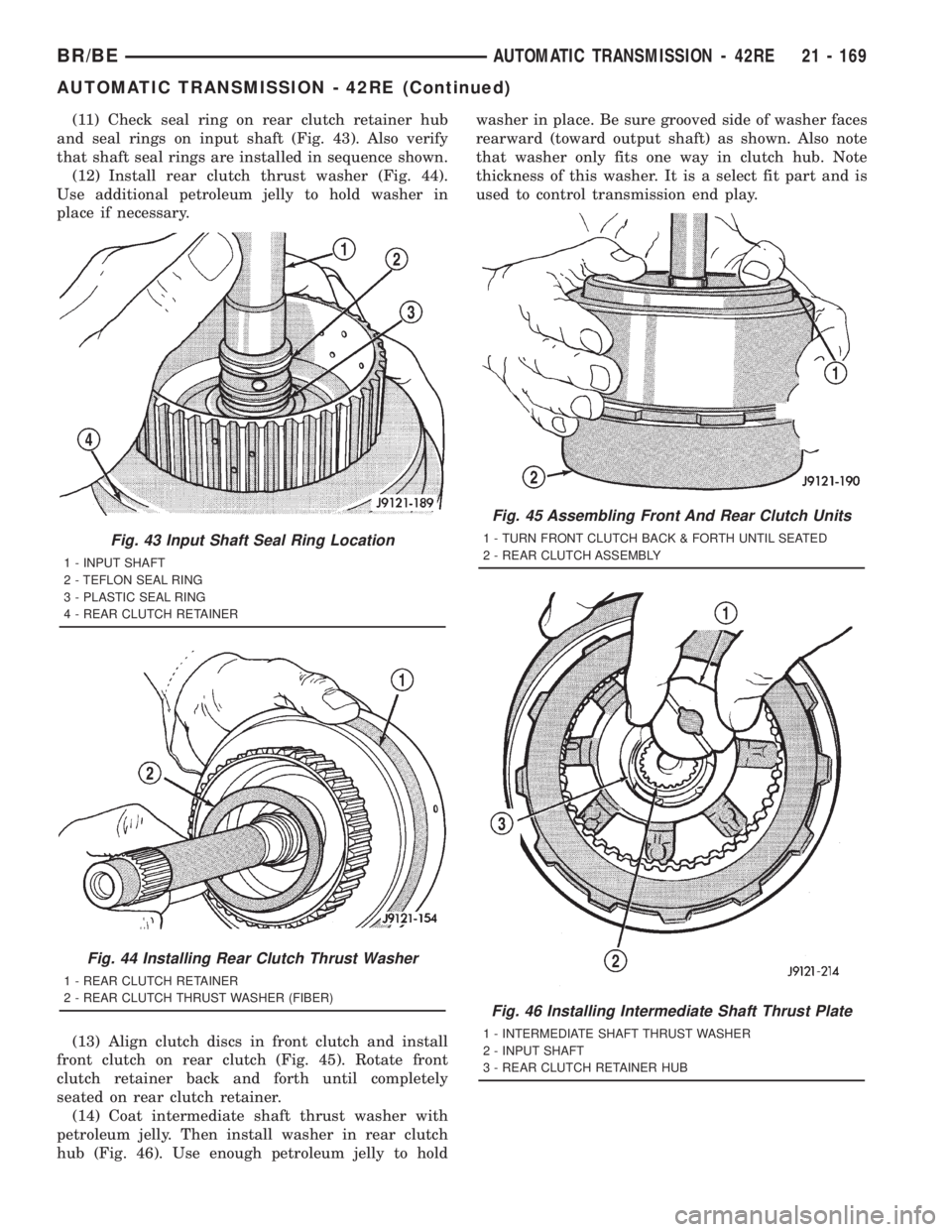

(11) Check seal ring on rear clutch retainer hub

and seal rings on input shaft (Fig. 43). Also verify

that shaft seal rings are installed in sequence shown.

(12) Install rear clutch thrust washer (Fig. 44).

Use additional petroleum jelly to hold washer in

place if necessary.

(13) Align clutch discs in front clutch and install

front clutch on rear clutch (Fig. 45). Rotate front

clutch retainer back and forth until completely

seated on rear clutch retainer.

(14) Coat intermediate shaft thrust washer with

petroleum jelly. Then install washer in rear clutch

hub (Fig. 46). Use enough petroleum jelly to holdwasher in place. Be sure grooved side of washer faces

rearward (toward output shaft) as shown. Also note

that washer only fits one way in clutch hub. Note

thickness of this washer. It is a select fit part and is

used to control transmission end play.

Fig. 43 Input Shaft Seal Ring Location

1 - INPUT SHAFT

2 - TEFLON SEAL RING

3 - PLASTIC SEAL RING

4 - REAR CLUTCH RETAINER

Fig. 44 Installing Rear Clutch Thrust Washer

1 - REAR CLUTCH RETAINER

2 - REAR CLUTCH THRUST WASHER (FIBER)

Fig. 45 Assembling Front And Rear Clutch Units

1 - TURN FRONT CLUTCH BACK & FORTH UNTIL SEATED

2 - REAR CLUTCH ASSEMBLY

Fig. 46 Installing Intermediate Shaft Thrust Plate

1 - INTERMEDIATE SHAFT THRUST WASHER

2 - INPUT SHAFT

3 - REAR CLUTCH RETAINER HUB

BR/BEAUTOMATIC TRANSMISSION - 42RE 21 - 169

AUTOMATIC TRANSMISSION - 42RE (Continued)