DODGE RAM 2001 Service Repair Manual

Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 1761 of 2889

(5) Clean the mating surfaces of shift tower and

isolator plate with suitable wax and grease remover.

(6) Apply Mopar Gasket Maker or equivalent to

sealing surface of the transmission case. Do not over

apply sealant.

(7) Install isolator plate onto the transmission case

metal side down.

(8) Install shift tower onto the isolator plate. No

sealant is necessary between the shift tower and top

of isolator plate.

(9) Verify that the shift tower, isolator plate and

the shift socket are properly aligned.

(10) Install bolts to hold the shift tower to the iso-

lator plate and the transmission case. Tighten bolts

to 10.2±11.25 N´m (7.5±8.3 ft. lbs.).

(11) Install shift boot and bezel.

(12) Connect battery negative cable.

FOUR WHEEL DRIVE

(1) Install and secure transfer case on the trans-

mission jack.

(2) Raise and align transfer case input gear with

transmission mainshaft.

(3) Move transfer case forward and seat it on

adapter.

(4) Install and tighten transfer case mounting nuts

to 41-47 N´m (30-35 ft. lbs.) if case has 3/8 studs. If

case has 5/16 studs tighten to 30-41 N´m (22-30 ft.

lbs.).

(5) Connect transfer case shift lever to range lever

on transfer case.(6) Install propeller shafts with reference marks

aligned.

(7) Fill transmission with required lubricant.

Check lubricant level in transfer case and add lubri-

cant if necessary.

(8) Install transfer case skid plate, if equipped,

and crossmember. Tighten attaching bolts/nuts to 41

N´m (30 ft. lbs.).

(9) Install exhaust system components.

(10) Remove support and lower vehicle.

(11) Shift transmission into third gear.

(12) Clean the mating surfaces of shift tower, iso-

lator plate, and transmission case with suitable wax

and grease remover.

(13) Apply Mopar Gasket Maker or equivalent to

the sealing surface of the transmission case. Do not

over apply sealant.

(14) Install isolator plate onto the transmission

case, metal side down.

(15) Install shift tower onto the isolator plate. No

sealant is necessary between the shift tower and top

of isolator plate.

(16) Verify that the shift tower, isolator plate and

the shift tower bushings are properly aligned.

(17) Install the bolts to hold the shift tower to the

isolator plate and the transmission case. Tighten the

shift tower bolts to 10.2±11.25 N´m (7.5±8.3 ft. lbs.).

(18) Install shift lever boot and bezel.

(19) Connect battery negative cable.

SPECIFICATIONS

SPECIFICATIONS - NV5600

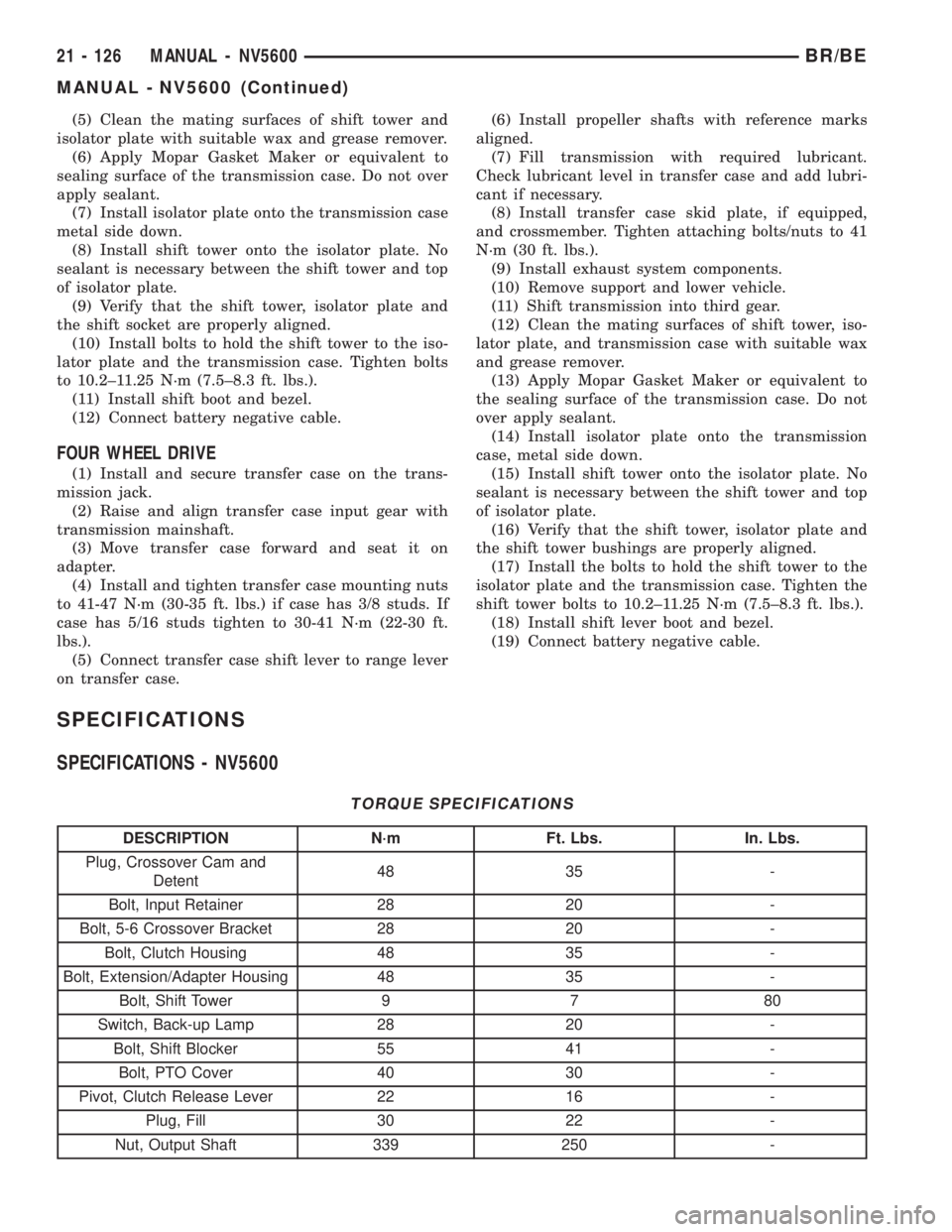

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Plug, Crossover Cam and

Detent48 35 -

Bolt, Input Retainer 28 20 -

Bolt, 5-6 Crossover Bracket 28 20 -

Bolt, Clutch Housing 48 35 -

Bolt, Extension/Adapter Housing 48 35 -

Bolt, Shift Tower 9 7 80

Switch, Back-up Lamp 28 20 -

Bolt, Shift Blocker 55 41 -

Bolt, PTO Cover 40 30 -

Pivot, Clutch Release Lever 22 16 -

Plug, Fill 30 22 -

Nut, Output Shaft 339 250 -

21 - 126 MANUAL - NV5600BR/BE

MANUAL - NV5600 (Continued)

Page 1762 of 2889

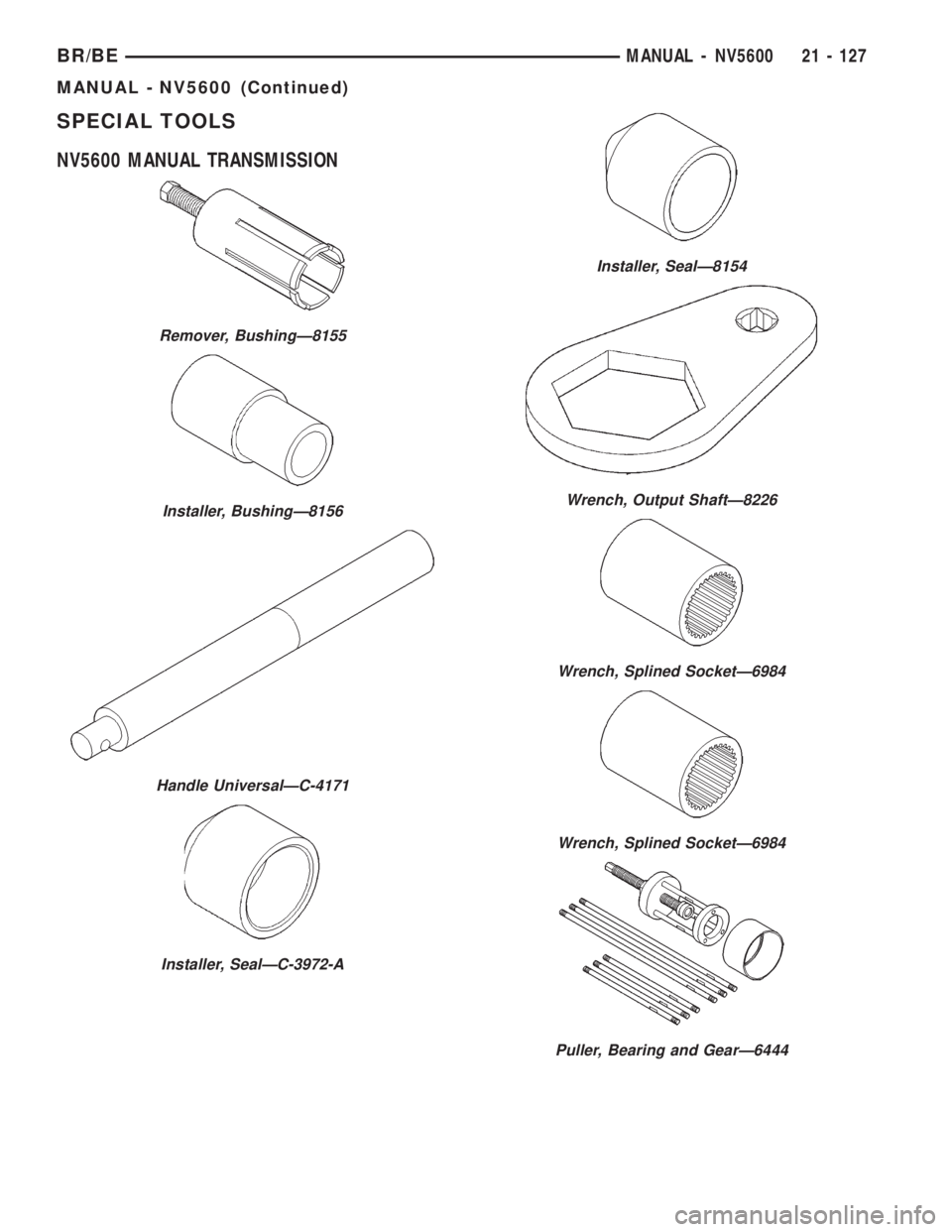

SPECIAL TOOLS

NV5600 MANUAL TRANSMISSION

Remover, BushingÐ8155

Installer, BushingÐ8156

Handle UniversalÐC-4171

Installer, SealÐC-3972-A

Installer, SealÐ8154

Wrench, Output ShaftÐ8226

Wrench, Splined SocketÐ6984

Wrench, Splined SocketÐ6984

Puller, Bearing and GearÐ6444

BR/BEMANUAL - NV5600 21 - 127

MANUAL - NV5600 (Continued)

Page 1763 of 2889

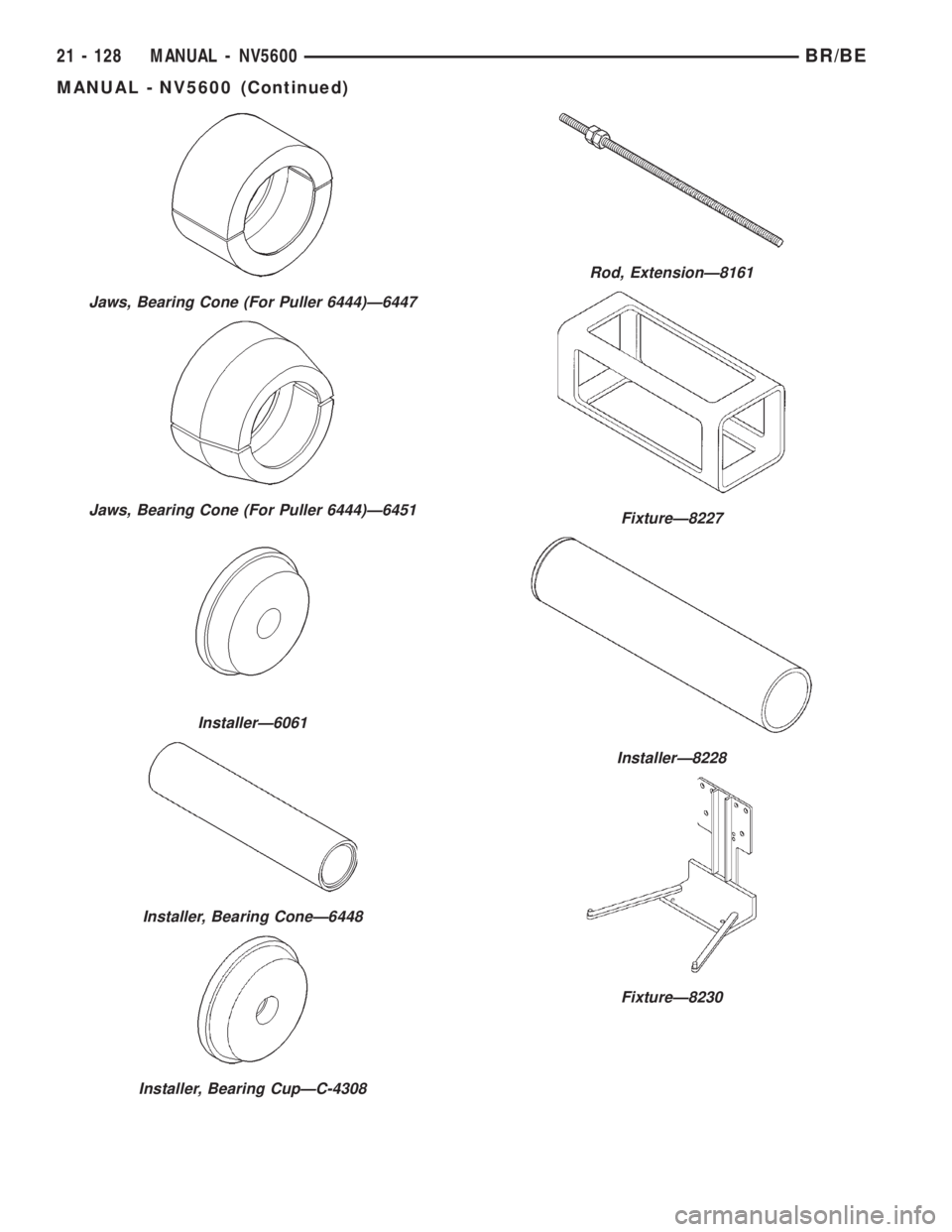

Jaws, Bearing Cone (For Puller 6444)Ð6447

Jaws, Bearing Cone (For Puller 6444)Ð6451

InstallerÐ6061

Installer, Bearing ConeÐ6448

Installer, Bearing CupÐC-4308

Rod, ExtensionÐ8161

FixtureÐ8227

InstallerÐ8228

FixtureÐ8230

21 - 128 MANUAL - NV5600BR/BE

MANUAL - NV5600 (Continued)

Page 1764 of 2889

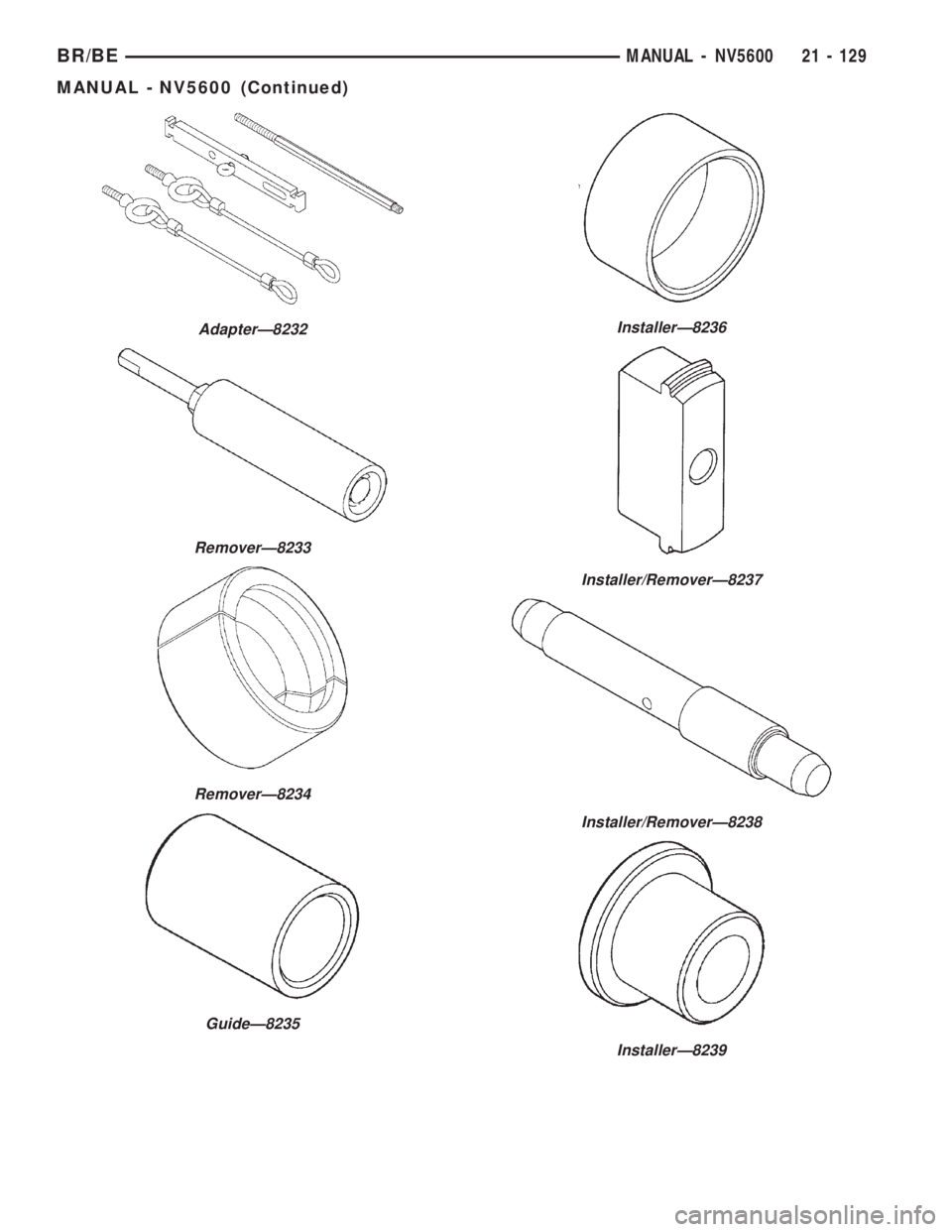

AdapterÐ8232

RemoverÐ8233

RemoverÐ8234

GuideÐ8235

InstallerÐ8236

Installer/RemoverÐ8237

Installer/RemoverÐ8238

InstallerÐ8239

BR/BEMANUAL - NV5600 21 - 129

MANUAL - NV5600 (Continued)

Page 1765 of 2889

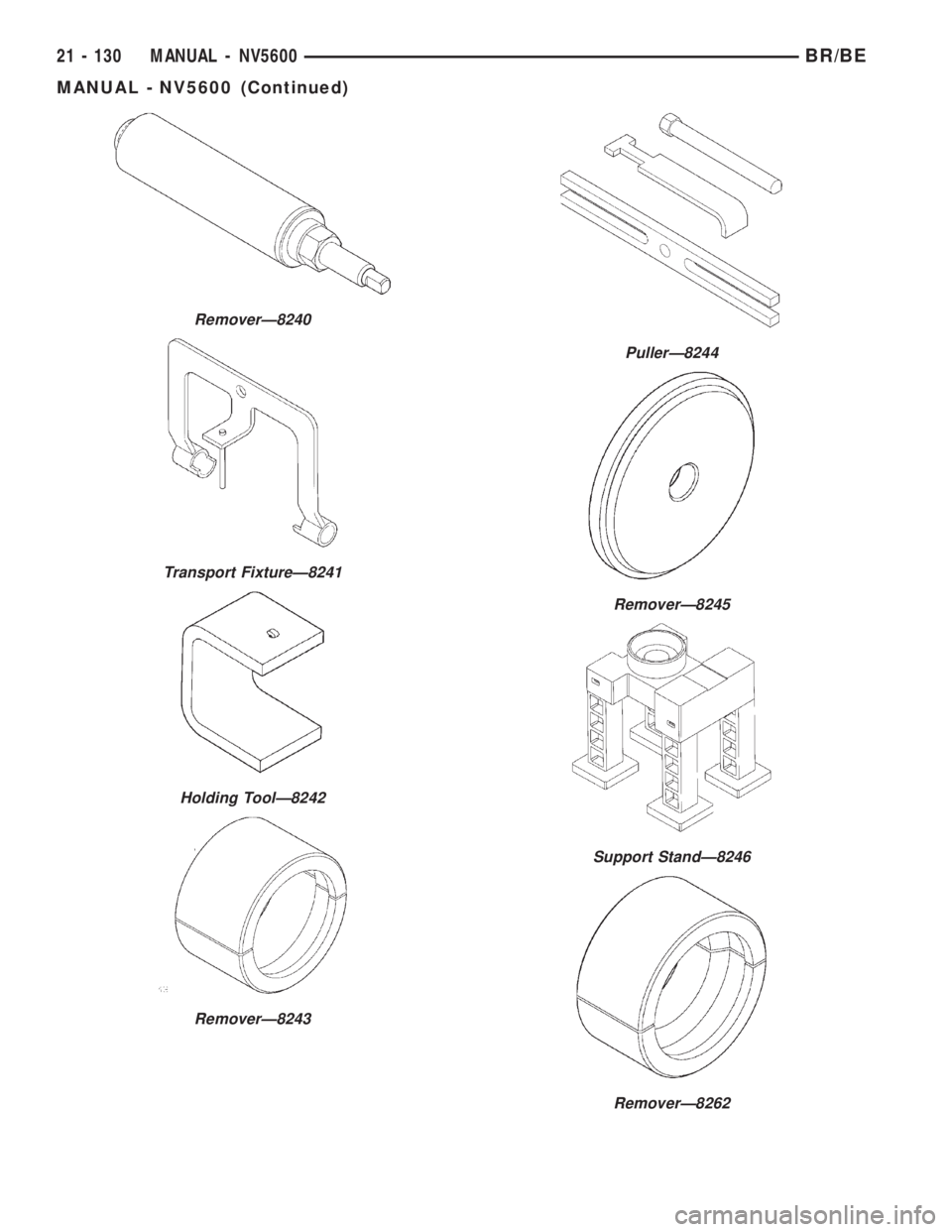

RemoverÐ8240

Transport FixtureÐ8241

Holding ToolÐ8242

RemoverÐ8243

PullerÐ8244

RemoverÐ8245

Support StandÐ8246

RemoverÐ8262

21 - 130 MANUAL - NV5600BR/BE

MANUAL - NV5600 (Continued)

Page 1766 of 2889

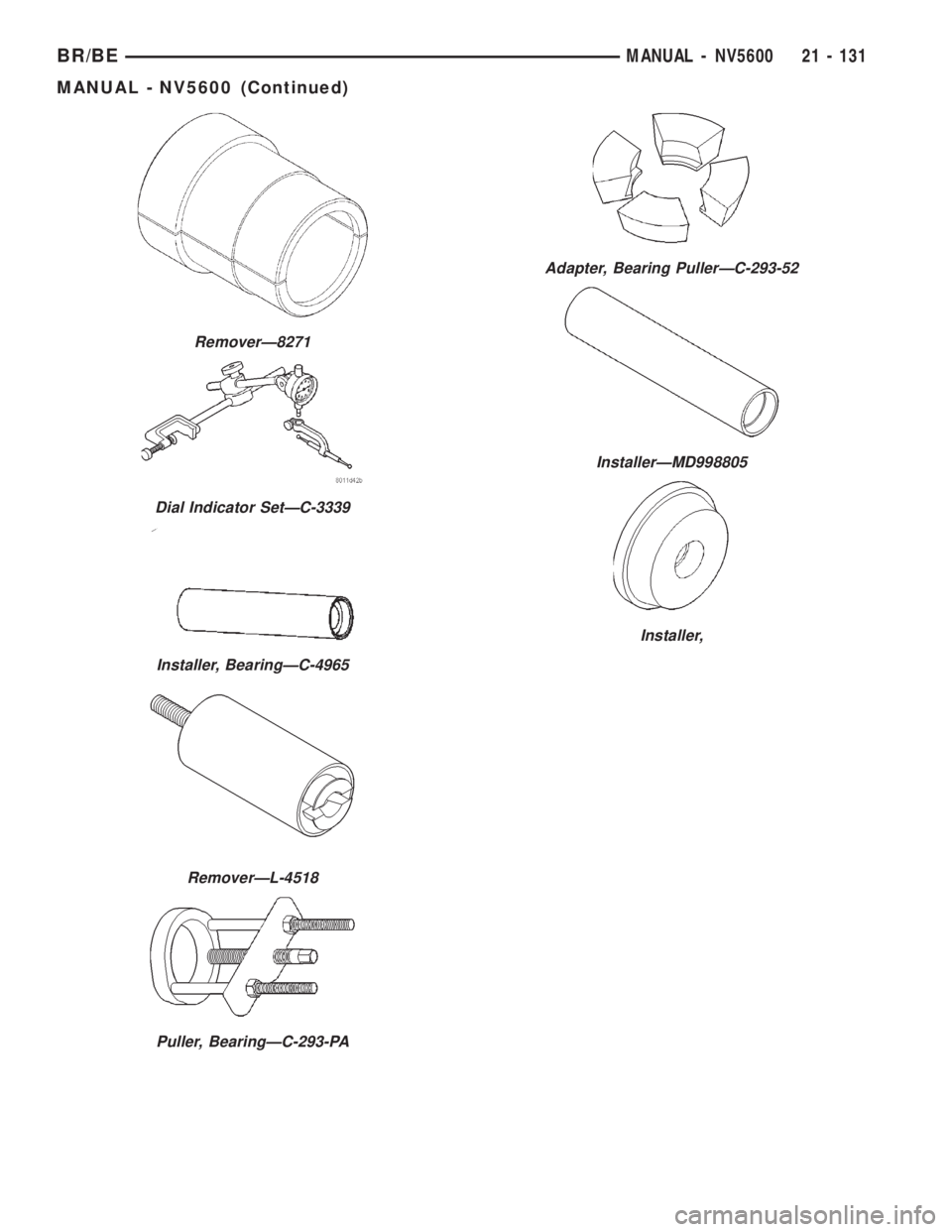

RemoverÐ8271

Dial Indicator SetÐC-3339

Installer, BearingÐC-4965

RemoverÐL-4518

Puller, BearingÐC-293-PA

Adapter, Bearing PullerÐC-293-52

InstallerÐMD998805

Installer,

BR/BEMANUAL - NV5600 21 - 131

MANUAL - NV5600 (Continued)

Page 1767 of 2889

ADAPTER HOUSING SEAL

REMOVAL

(1) Remove the propeller shaft.

(2) Remove the transfer case.

(3) Remove adapter housing seal with a pry tool or

a slide hammer mounted screw.

INSTALLATION

(1) Install extension housing seal with Installer

8154 and Handle C-4171.

(2) Install propeller shaft with reference marks

aligned.

EXTENSION HOUSING SEAL

REMOVAL

(1) Raise and support vehicle.

(2) Mark propeller shaft and pinion yoke for

installation reference and remove the propeller shaft.

(3) Remove the extension housing seal with a suit-

able pry tool or a slide hammer mounted screw.

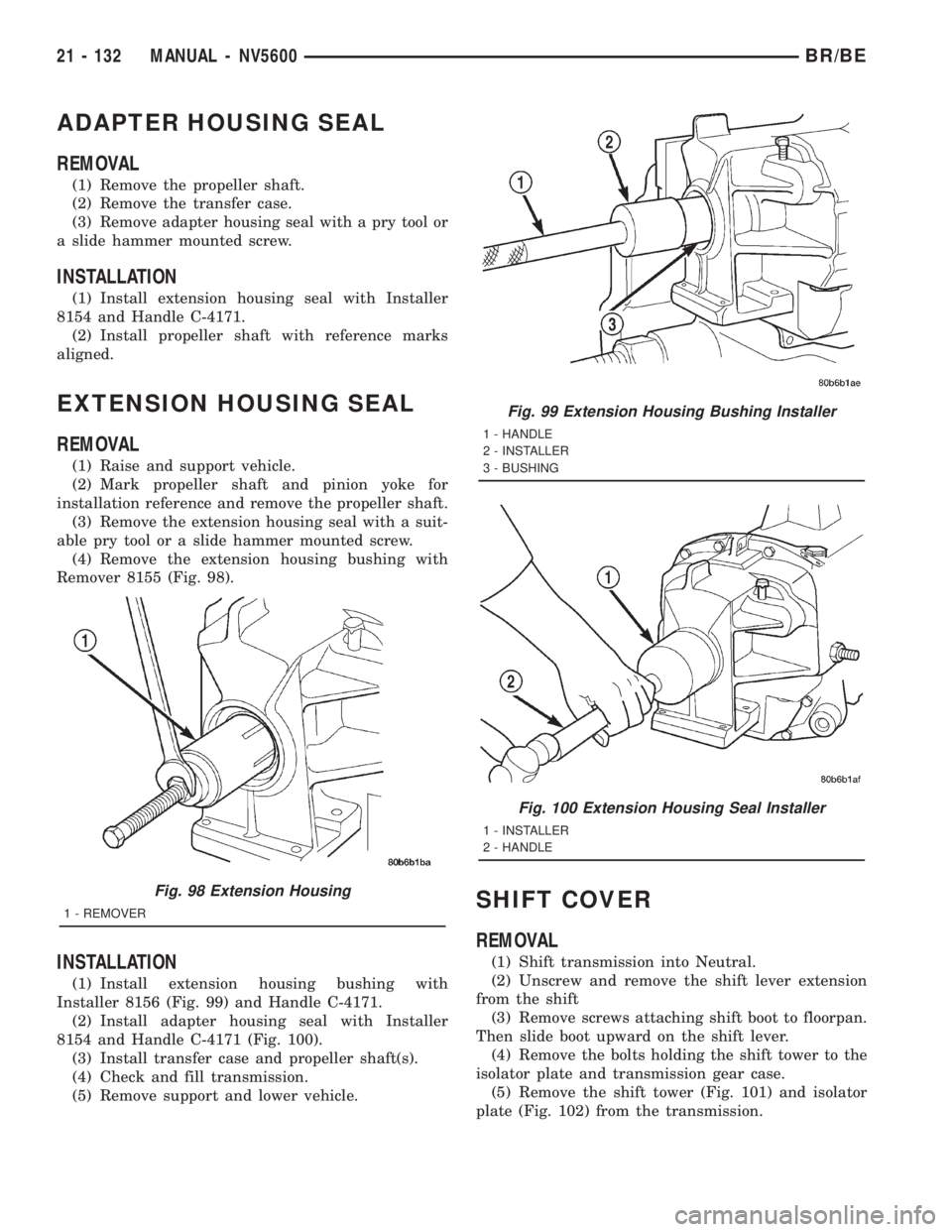

(4) Remove the extension housing bushing with

Remover 8155 (Fig. 98).

INSTALLATION

(1) Install extension housing bushing with

Installer 8156 (Fig. 99) and Handle C-4171.

(2) Install adapter housing seal with Installer

8154 and Handle C-4171 (Fig. 100).

(3) Install transfer case and propeller shaft(s).

(4) Check and fill transmission.

(5) Remove support and lower vehicle.

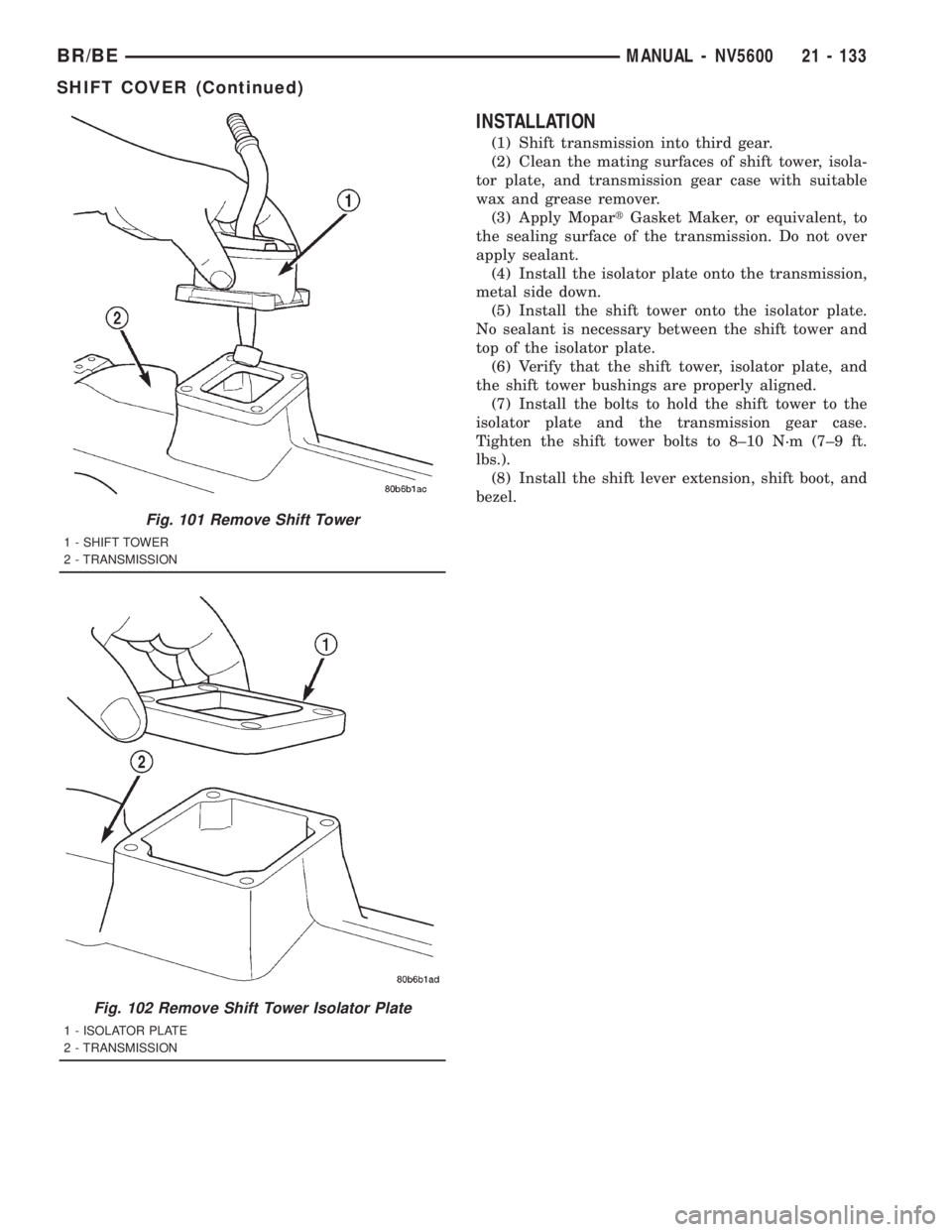

SHIFT COVER

REMOVAL

(1) Shift transmission into Neutral.

(2) Unscrew and remove the shift lever extension

from the shift

(3) Remove screws attaching shift boot to floorpan.

Then slide boot upward on the shift lever.

(4) Remove the bolts holding the shift tower to the

isolator plate and transmission gear case.

(5) Remove the shift tower (Fig. 101) and isolator

plate (Fig. 102) from the transmission.

Fig. 99 Extension Housing Bushing Installer

1 - HANDLE

2 - INSTALLER

3 - BUSHING

Fig. 100 Extension Housing Seal Installer

1 - INSTALLER

2 - HANDLE

Fig. 98 Extension Housing

1 - REMOVER

21 - 132 MANUAL - NV5600BR/BE

Page 1768 of 2889

INSTALLATION

(1) Shift transmission into third gear.

(2) Clean the mating surfaces of shift tower, isola-

tor plate, and transmission gear case with suitable

wax and grease remover.

(3) Apply MopartGasket Maker, or equivalent, to

the sealing surface of the transmission. Do not over

apply sealant.

(4) Install the isolator plate onto the transmission,

metal side down.

(5) Install the shift tower onto the isolator plate.

No sealant is necessary between the shift tower and

top of the isolator plate.

(6) Verify that the shift tower, isolator plate, and

the shift tower bushings are properly aligned.

(7) Install the bolts to hold the shift tower to the

isolator plate and the transmission gear case.

Tighten the shift tower bolts to 8±10 N´m (7±9 ft.

lbs.).

(8) Install the shift lever extension, shift boot, and

bezel.

Fig. 101 Remove Shift Tower

1 - SHIFT TOWER

2 - TRANSMISSION

Fig. 102 Remove Shift Tower Isolator Plate

1 - ISOLATOR PLATE

2 - TRANSMISSION

BR/BEMANUAL - NV5600 21 - 133

SHIFT COVER (Continued)

Page 1769 of 2889

AUTOMATIC TRANSMISSION - 42RE

TABLE OF CONTENTS

page page

AUTOMATIC TRANSMISSION - 42RE

DESCRIPTION..........................135

OPERATION............................137

DIAGNOSIS AND TESTING................143

AUTOMATIC TRANSMISSION.............143

PRELIMINARY........................143

ROAD TESTING.......................143

HYDRAULIC PRESSURE TEST...........144

AIR CHECKING TRANSMISSION CLUTCH

AND BAND OPERATION.................147

CONVERTER HOUSING FLUID LEAK......148

DIAGNOSIS CHARTS...................149

STANDARD PROCEDURE.................159

ALUMINUM THREAD REPAIR.............159

REMOVAL.............................159

DISASSEMBLY..........................160

CLEANING.............................165

INSPECTION...........................165

ASSEMBLY............................166

INSTALLATION..........................173

SCHEMATICS AND DIAGRAMS.............174

SPECIFICATIONS........................186

SPECIAL TOOLS........................188

ACCUMULATOR

DESCRIPTION..........................191

OPERATION............................191

INSPECTION...........................192

BANDS

DESCRIPTION..........................192

OPERATION............................192

ADJUSTMENTS.........................193

ELECTRONIC GOVERNOR

DESCRIPTION..........................194

OPERATION............................194

REMOVAL.............................196

INSTALLATION..........................197

EXTENSION HOUSING BUSHING

REMOVAL.............................198

INSTALLATION..........................198

EXTENSION HOUSING SEAL

REMOVAL.............................198

INSTALLATION..........................198

FLUID AND FILTER

DIAGNOSIS AND TESTING................199

EFFECTS OF INCORRECT FLUID LEVEL . . . 199

CAUSES OF BURNT FLUID..............199

FLUID CONTAMINATION................199

STANDARD PROCEDURE.................199

FLUID LEVEL CHECK...................199FLUID AND FILTER REPLACEMENT.......201

TRANSMISSION FILL...................201

FRONT CLUTCH

DESCRIPTION..........................202

OPERATION............................202

DISASSEMBLY..........................202

INSPECTION...........................205

ASSEMBLY............................206

FRONT SERVO

DESCRIPTION..........................206

OPERATION............................207

DISASSEMBLY..........................207

CLEANING.............................207

INSPECTION...........................207

ASSEMBLY............................208

OIL PUMP

DESCRIPTION..........................208

OPERATION............................208

STANDARD PROCEDURE.................209

OIL PUMP VOLUME CHECK..............209

DISASSEMBLY..........................209

CLEANING.............................211

INSPECTION...........................211

ASSEMBLY............................212

OUTPUT SHAFT FRONT BEARING

REMOVAL.............................213

INSTALLATION..........................213

OUTPUT SHAFT REAR BEARING

REMOVAL.............................213

INSTALLATION..........................213

OVERDRIVE CLUTCH

DESCRIPTION..........................214

OPERATION............................214

OVERDRIVE OFF SWITCH

DESCRIPTION..........................215

OPERATION............................215

DIAGNOSIS AND TESTING................215

OVERDRIVE ELECTRICAL CONTROLS.....215

REMOVAL.............................215

INSTALLATION..........................215

OVERDRIVE UNIT

REMOVAL.............................216

DISASSEMBLY..........................217

CLEANING.............................224

INSPECTION...........................224

ASSEMBLY............................225

INSTALLATION..........................234

21 - 134 AUTOMATIC TRANSMISSION - 42REBR/BE

Page 1770 of 2889

OVERRUNNING CLUTCH CAM/OVERDRIVE

PISTON RETAINER

DESCRIPTION..........................235

OPERATION............................235

DISASSEMBLY..........................235

CLEANING.............................236

INSPECTION...........................236

ASSEMBLY............................236

PARK/NEUTRAL POSITION SWITCH

DIAGNOSIS AND TESTING................237

PARK/NEUTRAL POSITION SWITCH.......237

REMOVAL.............................238

INSTALLATION..........................238

PISTONS

DESCRIPTION..........................238

OPERATION............................238

PLANETARY GEARTRAIN/OUTPUT SHAFT

DESCRIPTION..........................240

OPERATION............................240

DISASSEMBLY..........................240

INSPECTION...........................241

ASSEMBLY............................241

REAR CLUTCH

DESCRIPTION..........................246

OPERATION............................246

DISASSEMBLY..........................247

CLEANING.............................247

INSPECTION...........................248

ASSEMBLY............................248

REAR SERVO

DESCRIPTION..........................250

OPERATION............................250

DISASSEMBLY..........................251

CLEANING.............................251

ASSEMBLY............................251

SHIFT MECHANISM

DESCRIPTION..........................251OPERATION............................251

ADJUSTMENTS.........................252

SOLENOID

DESCRIPTION..........................252

OPERATION............................253

SPEED SENSOR

DESCRIPTION..........................253

OPERATION............................253

THROTTLE VALVE CABLE

DESCRIPTION..........................253

ADJUSTMENTS.........................254

TORQUE CONVERTER

DESCRIPTION..........................256

OPERATION............................260

REMOVAL.............................261

INSTALLATION..........................261

TORQUE CONVERTER DRAINBACK VALVE

DESCRIPTION..........................262

OPERATION............................262

STANDARD PROCEDURE.................262

TORQUE CONVERTER DRAINBACK VALVE . 262

TRANSMISSION TEMPERATURE SENSOR

DESCRIPTION..........................262

OPERATION............................262

VALVE BODY

DESCRIPTION..........................263

OPERATION............................267

REMOVAL.............................281

DISASSEMBLY..........................282

CLEANING.............................293

INSPECTION...........................293

ASSEMBLY............................294

INSTALLATION..........................303

ADJUSTMENTS.........................304

AUTOMATIC TRANSMISSION -

42RE

DESCRIPTION

The 42RE is a four speed fully automatic transmis-

sion (Fig. 1) with an electronic governor. The 42RE is

equipped with a lock-up clutch in the torque con-

verter. First through third gear ranges are provided

by the clutches, bands, overrunning clutch, and plan-

etary gear sets in the transmission. Fourth gear

range is provided by the overdrive unit that contains

an overdrive clutch, direct clutch, planetary gear set,

and overrunning clutch.

The transmission contains a front, rear, and direct

clutch which function as the input driving compo-

nents. It also contains the kickdown (front) and thelow/reverse (rear) bands which, along with the over-

running clutch and overdrive clutch, serve as the

holding components. The driving and holding compo-

nents combine to select the necessary planetary gear

components, in the front, rear, or overdrive planetary

gear set, transfer the engine power from the input

shaft through to the output shaft.

The valve body is mounted to the lower side of the

transmission and contains the valves to control pres-

sure regulation, fluid flow control, and clutch/band

application. The oil pump is mounted at the front of

the transmission and is driven by the torque con-

verter hub. The pump supplies the oil pressure nec-

essary for clutch/band actuation and transmission

lubrication.

BR/BEAUTOMATIC TRANSMISSION - 42RE 21 - 135