DODGE RAM 2001 Service Repair Manual

Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 2701 of 2889

INSTALLATION

(1) Position trim panel in vehicle and route seat

belt webbing through opening in quarter trim panel.

(2) Open quarter vent window.

(3) Position trim panel on quarter panel and

engage clips on upper portion of panel.

(4) Engage clips attaching lower portion of quarter

trim panel to quarter panel.

(5) Install lower seat belt anchor bolt.

(6) Install door sill cover as necessary.

(7) Install rear seat. (Refer to 23 - BODY/SEATS/

REAR SEAT - INSTALLATION)

C-PILLAR TRIM

REMOVAL

(1) Remove rear floor stowage tray. (Refer to 23 -

BODY/INTERIOR/REAR FLOOR STOWAGE TRAY -

REMOVAL)

(2) Remove door sill cover as necessary to clear

C-pillar trim.

(3) Remove bolt attaching seat belt anchor to floor.

(4) Unsnap turning loop, push cover up and

remove bolt attaching turning loop to C-pillar.(5) Remove seat belt exit plug.

(6) Disengage clips attaching C-pillar trim to

upper C-pillar.

(7) Separate C-pillar trim from C-pillar.

(8) Route seat belt webbing through opening in

C-pillar trim.

INSTALLATION

(1) Route seat belt webbing through opening in

C-pillar trim.

(2) Position C-pillar trim at C-pillar.

(3) Starting at the top, engage clips attaching

C-pillar trim to upper C-pillar.

(4) Install seat belt exit plug.

(5) Install bolt attaching turning loop to C-pillar

and position turning loop cover. Snap turning loop

cover into place.

(6) Install bolt attaching seat belt anchor to floor.

(7) Install door sill cover.

(8) Install rear floor stowage tray. (Refer to 23 -

BODY/INTERIOR/REAR FLOOR STOWAGE TRAY -

INSTALLATION)

23 - 128 INTERIORBR/BE

QUARTER TRIM PANEL (Continued)

Page 2702 of 2889

PAINT

TABLE OF CONTENTS

page page

PAINT

SPECIFICATIONS........................129

BASE COAT/CLEAR COAT FINISH

DESCRIPTION..........................129

OPERATION............................129

PAINT CODE

DESCRIPTION..........................129PAINT TOUCH-UP

DESCRIPTION..........................129

WET SANDING/BUFFING & POLISHING

DESCRIPTION..........................130

PAINT

SPECIFICATIONS

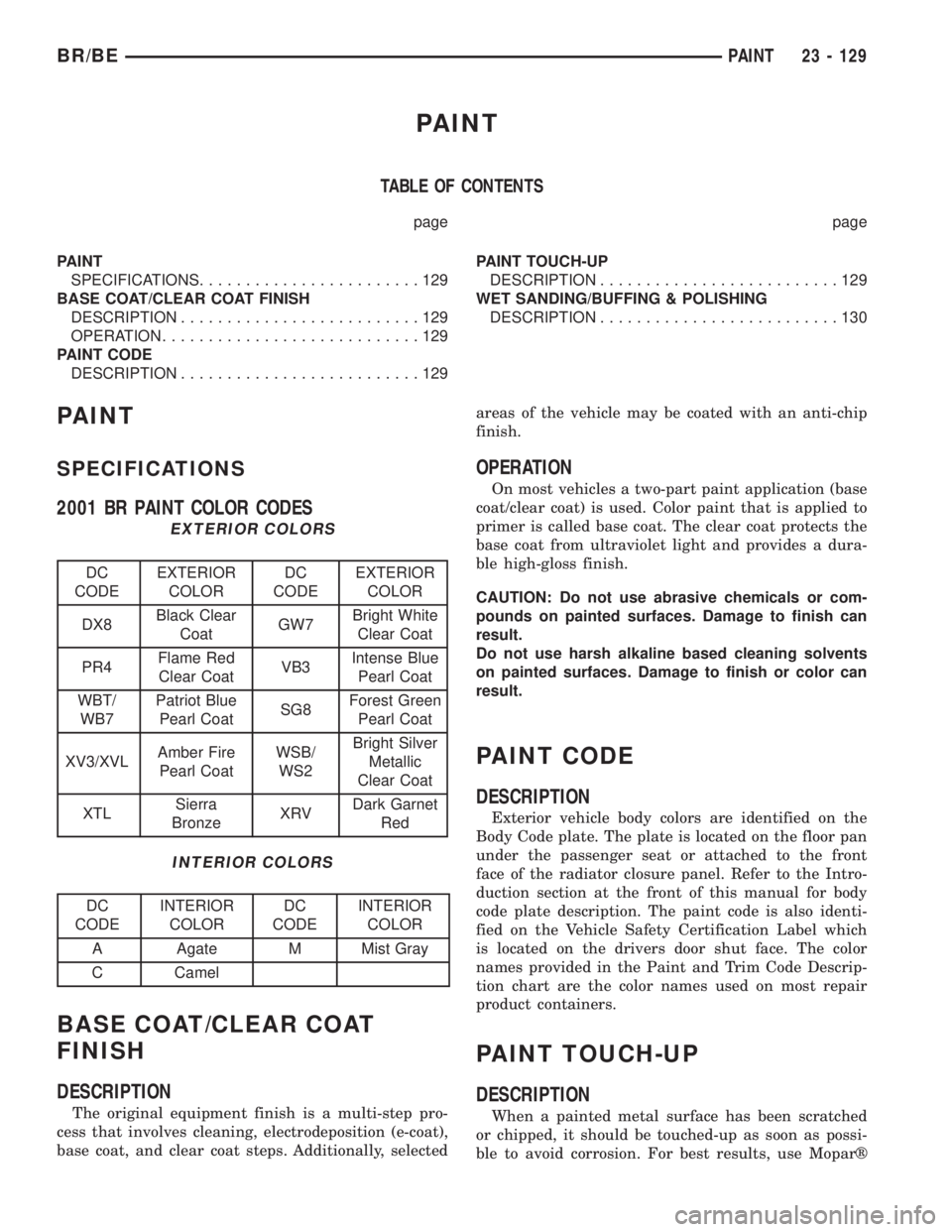

2001 BR PAINT COLOR CODES

EXTERIOR COLORS

DC

CODEEXTERIOR

COLORDC

CODEEXTERIOR

COLOR

DX8Black Clear

CoatGW7Bright White

Clear Coat

PR4Flame Red

Clear CoatVB3Intense Blue

Pearl Coat

WBT/

WB7Patriot Blue

Pearl CoatSG8Forest Green

Pearl Coat

XV3/XVLAmber Fire

Pearl CoatWSB/

WS2Bright Silver

Metallic

Clear Coat

XTLSierra

BronzeXRVDark Garnet

Red

INTERIOR COLORS

DC

CODEINTERIOR

COLORDC

CODEINTERIOR

COLOR

A Agate M Mist Gray

C Camel

BASE COAT/CLEAR COAT

FINISH

DESCRIPTION

The original equipment finish is a multi-step pro-

cess that involves cleaning, electrodeposition (e-coat),

base coat, and clear coat steps. Additionally, selectedareas of the vehicle may be coated with an anti-chip

finish.

OPERATION

On most vehicles a two-part paint application (base

coat/clear coat) is used. Color paint that is applied to

primer is called base coat. The clear coat protects the

base coat from ultraviolet light and provides a dura-

ble high-gloss finish.

CAUTION: Do not use abrasive chemicals or com-

pounds on painted surfaces. Damage to finish can

result.

Do not use harsh alkaline based cleaning solvents

on painted surfaces. Damage to finish or color can

result.

PAINT CODE

DESCRIPTION

Exterior vehicle body colors are identified on the

Body Code plate. The plate is located on the floor pan

under the passenger seat or attached to the front

face of the radiator closure panel. Refer to the Intro-

duction section at the front of this manual for body

code plate description. The paint code is also identi-

fied on the Vehicle Safety Certification Label which

is located on the drivers door shut face. The color

names provided in the Paint and Trim Code Descrip-

tion chart are the color names used on most repair

product containers.

PAINT TOUCH-UP

DESCRIPTION

When a painted metal surface has been scratched

or chipped, it should be touched-up as soon as possi-

ble to avoid corrosion. For best results, use Moparž

BR/BEPAINT 23 - 129

Page 2703 of 2889

Scratch Filler/Primer, Touch-Up Paints and Clear Top

Coat. Refer to Introduction group of this manual for

Body Code Plate information.

WARNING: USE A OSHA APPROVED BREATHING

FILTER WHEN SPRAYING PAINT OR SOLVENTS IN

A CONFINED AREA. PERSONAL INJURY CAN

RESULT.

OPERATION

(1) Scrape loose paint and corrosion from inside

scratch or chip.

(2) Clean affected area with Moparž Tar/Road Oil

Remover, and allow to dry.

(3) Fill the inside of the scratch or chip with a coat

of filler/primer. Do not overlap primer onto good sur-

face finish. The applicator brush should be wet

enough to puddle-fill the defect without running. Do

not stroke brush applicator on body surface. Allow

the filler/primer to dry hard.

(4) Cover the filler/primer with color touch-up

paint. Do not overlap touch-up color onto the original

color coat around the scratch or chip. Butt the new

color to the original color, if possible. Do not stroke

applicator brush on body surface. Allow touch-up

paint to dry hard.

(5) On vehicles without clear coat, the touch-up

color can be lightly finesse sanded (1500 grit) and

polished with rubbing compound.(6) On vehicles with clear coat, apply clear top coat

to touch-up paint with the same technique as

described in Step 4. Allow clear top coat to dry hard.

If desired, Step 5 can be performed on clear top coat.

WARNING: AVOID PROLONGED SKIN CONTACT

WITH PETROLEUM OR ALCOHOL ± BASED CLEAN-

ING SOLVENTS. PERSONAL INJURY CAN RESULT.

AVOID PROLONGED SKIN CONTACT WITH PETRO-

LEUM OR ALCOHOL ± BASED CLEANING SOL-

VENTS. PERSONAL INJURY CAN RESULT.

WET SANDING/BUFFING &

POLISHING

DESCRIPTION

Minor acid etching, orange peel, or smudging in

clear coat or single-stage finishes can be reduced

with light finesse sanding, hand buffing, and polish-

ing.If the finish has been finesse sanded in the

past, it cannot be repeated. Finesse sanding

operation should be performed by a trained

automotive paint technician.

CAUTION: Do not remove clear coat finish, if

equipped. Base coat paint must retain clear coat for

durability.

23 - 130 PAINTBR/BE

PAINT TOUCH-UP (Continued)

Page 2704 of 2889

SEATS

TABLE OF CONTENTS

page page

SEATS

DESCRIPTION..........................131

OPERATION............................131

CENTER CONSOLE LID

REMOVAL.............................131

INSTALLATION..........................132

CENTER SEAT ARMREST/CONSOLE

REMOVAL.............................132

INSTALLATION..........................132

CENTER SEAT ARMREST/LATCH COVER

REMOVAL.............................132

INSTALLATION..........................132

LUMBAR SUPPORT

REMOVAL.............................133

INSTALLATION..........................133

SEAT - BENCH SEAT

REMOVAL.............................133

INSTALLATION..........................133

SEAT - SPLIT BENCH

REMOVAL.............................134

INSTALLATION..........................134

SEAT BACK - BENCH SEAT

REMOVAL.............................135

INSTALLATION..........................135

SEAT BACK - SPLIT BENCH

REMOVAL.............................135

INSTALLATION..........................136

SEAT BACK COVER

REMOVAL.............................137

INSTALLATION..........................137

SEAT BACK COVER - SPLIT BENCH

REMOVAL.............................137

INSTALLATION..........................138SEAT BACK RECLINER

REMOVAL.............................138

INSTALLATION..........................138

SEAT CUSHION

REMOVAL.............................138

INSTALLATION..........................138

SEAT CUSHION COVER

REMOVAL.............................139

INSTALLATION..........................139

SEAT CUSHION COVER - SPLIT BENCH

REMOVAL.............................139

INSTALLATION..........................140

SEAT RISER

REMOVAL.............................141

INSTALLATION..........................141

SEAT TRACK

REMOVAL.............................141

INSTALLATION..........................141

SEAT TRACK - SPLIT BENCH

REMOVAL.............................142

INSTALLATION..........................142

EASY ENTRY SEAT TRACK

REMOVAL.............................142

INSTALLATION..........................142

SEAT TRACK ADJUSTER

REMOVAL.............................143

INSTALLATION..........................143

STANCHION COVER

REMOVAL.............................143

INSTALLATION..........................143

REAR SEAT

REMOVAL.............................144

INSTALLATION..........................144

SEATS

DESCRIPTION

Seat modules are made up of a seat frame, seat

cushion, seat back cushion, a covering material, and

the electrical components used for power operation, if

equipped. Some seat systems also contain seat belt

components and supplemental restraint systems.

OPERATION

Seat assemblies transport the occupants in comfort

and safety. Seat assemblies also help position occupants

correctly in the event of airbag deployment. Seat cush-

ions, coverings, and electrical components are service-

able. Refer to the appropriate group in this manual.

CENTER CONSOLE LID

REMOVAL

(1) Open console lid.

(2) Using a small flat blade screwdriver, disengage

locking tabs located under the console lid trim bezel.

(3) Separate bezel from lid.

(4) Move driver and passenger seat to full forward

position.

(5) Using a small drift and hammer, tap out con-

sole lid hinge pin.

(6) Separate lid from console.

BR/BESEATS 23 - 131

Page 2705 of 2889

INSTALLATION

(1) Align console lid with console. Verify lid tension

spring is in position.

(2) Install hinge pin.

(3) Position trim bezel on lid and snap into place.

CENTER SEAT ARMREST/

CONSOLE

REMOVAL

(1) Remove bolts on driver and passenger seat

inboard seat tracks.

(2) Separate center section.

INSTALLATION

(1) Position and align center section on driver and

passenger seat inboard seat tracks.

(2) Install bolts. Tighten to 19.5 N´m (14 ft. lbs.)

torque.

CENTER SEAT ARMREST/

LATCH COVER

REMOVAL

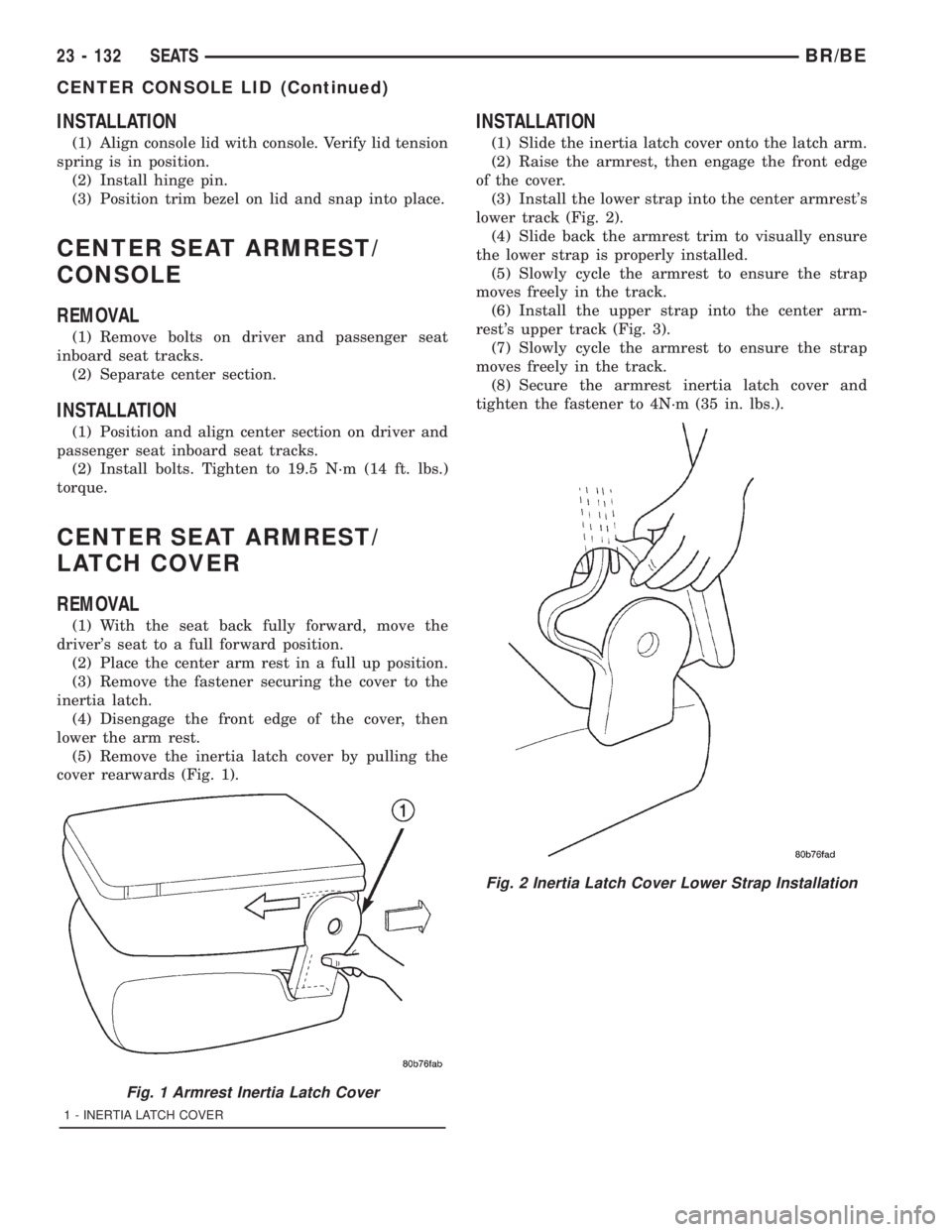

(1) With the seat back fully forward, move the

driver's seat to a full forward position.

(2) Place the center arm rest in a full up position.

(3) Remove the fastener securing the cover to the

inertia latch.

(4) Disengage the front edge of the cover, then

lower the arm rest.

(5) Remove the inertia latch cover by pulling the

cover rearwards (Fig. 1).

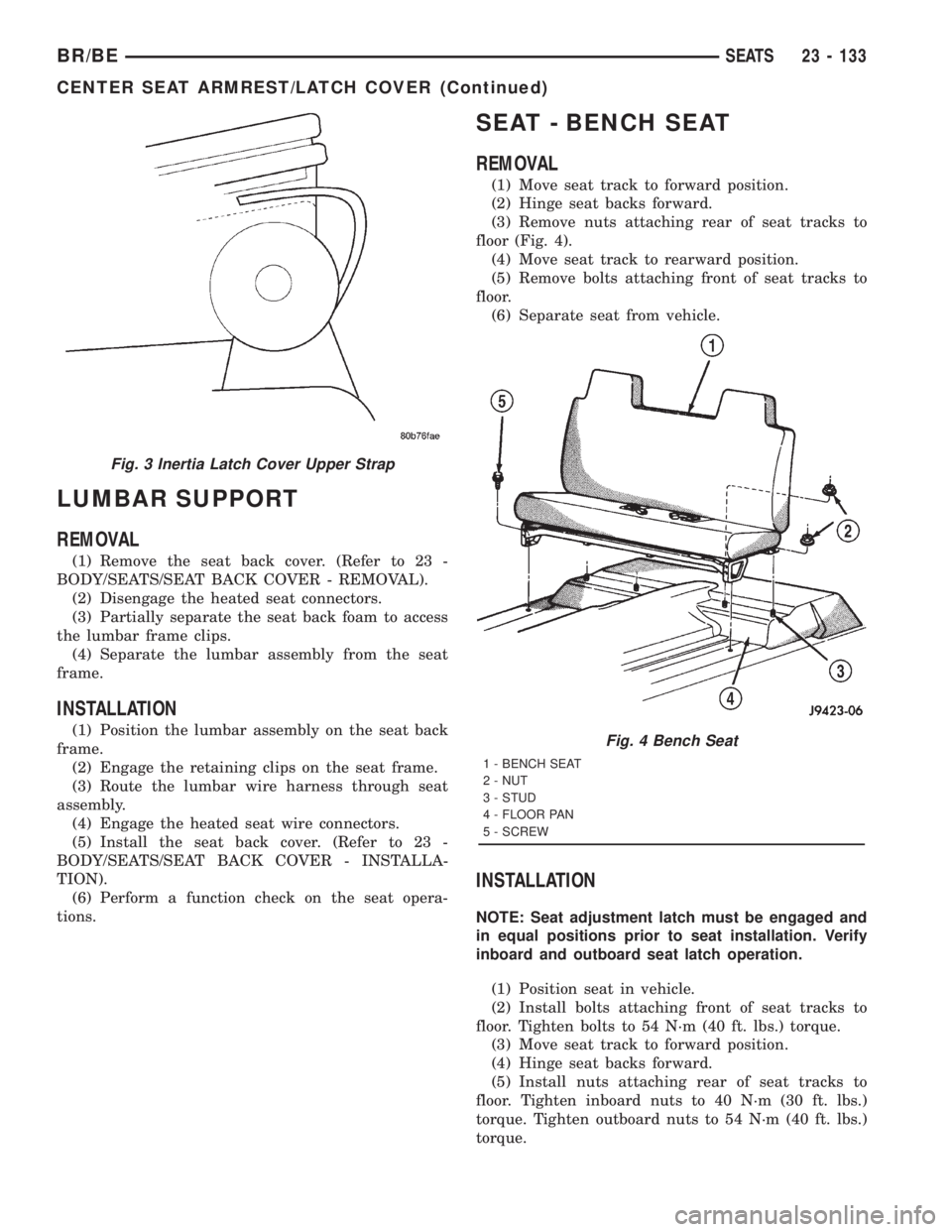

INSTALLATION

(1) Slide the inertia latch cover onto the latch arm.

(2) Raise the armrest, then engage the front edge

of the cover.

(3) Install the lower strap into the center armrest's

lower track (Fig. 2).

(4) Slide back the armrest trim to visually ensure

the lower strap is properly installed.

(5) Slowly cycle the armrest to ensure the strap

moves freely in the track.

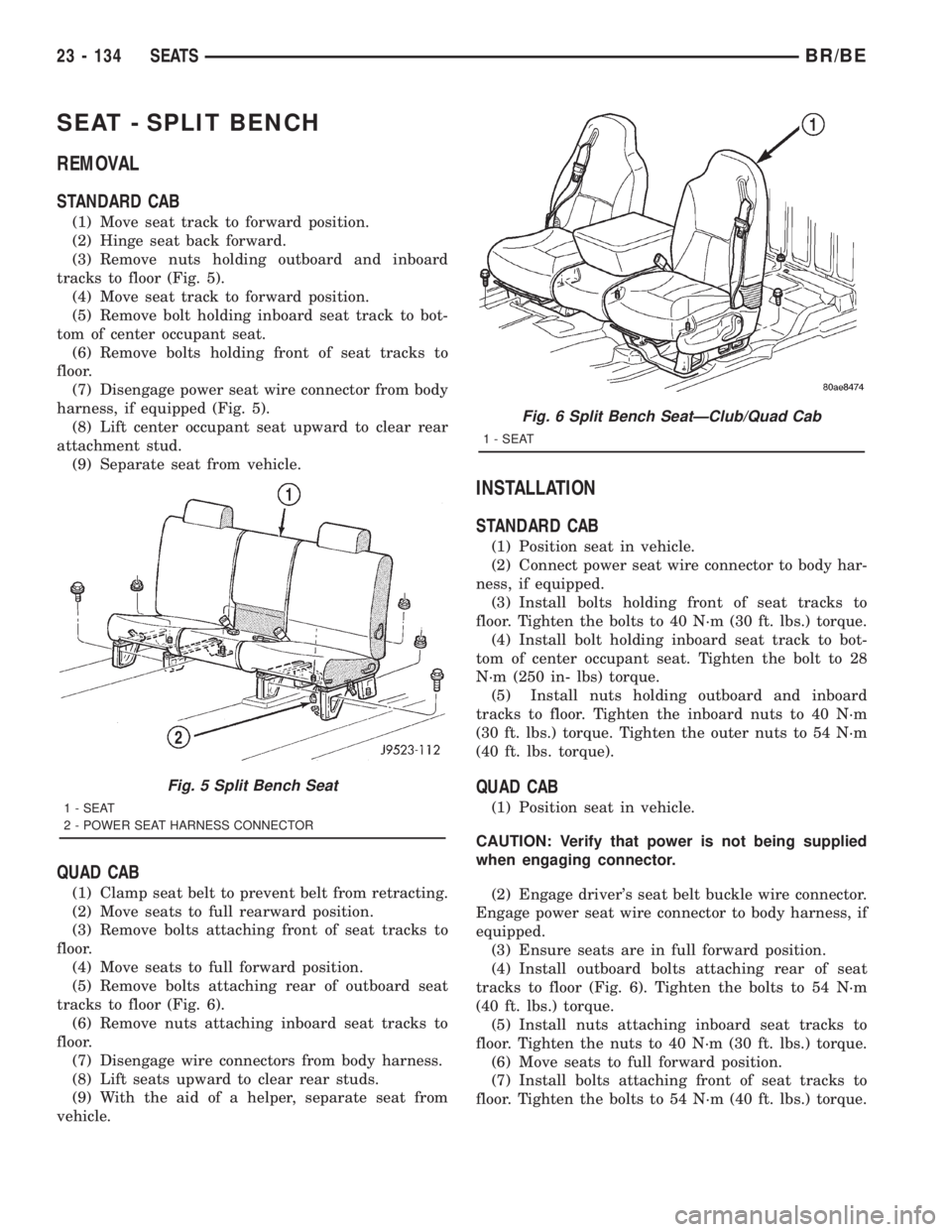

(6) Install the upper strap into the center arm-

rest's upper track (Fig. 3).

(7) Slowly cycle the armrest to ensure the strap

moves freely in the track.

(8) Secure the armrest inertia latch cover and

tighten the fastener to 4N´m (35 in. lbs.).

Fig. 1 Armrest Inertia Latch Cover

1 - INERTIA LATCH COVER

Fig. 2 Inertia Latch Cover Lower Strap Installation

23 - 132 SEATSBR/BE

CENTER CONSOLE LID (Continued)

Page 2706 of 2889

LUMBAR SUPPORT

REMOVAL

(1) Remove the seat back cover. (Refer to 23 -

BODY/SEATS/SEAT BACK COVER - REMOVAL).

(2) Disengage the heated seat connectors.

(3) Partially separate the seat back foam to access

the lumbar frame clips.

(4) Separate the lumbar assembly from the seat

frame.

INSTALLATION

(1) Position the lumbar assembly on the seat back

frame.

(2) Engage the retaining clips on the seat frame.

(3) Route the lumbar wire harness through seat

assembly.

(4) Engage the heated seat wire connectors.

(5) Install the seat back cover. (Refer to 23 -

BODY/SEATS/SEAT BACK COVER - INSTALLA-

TION).

(6) Perform a function check on the seat opera-

tions.

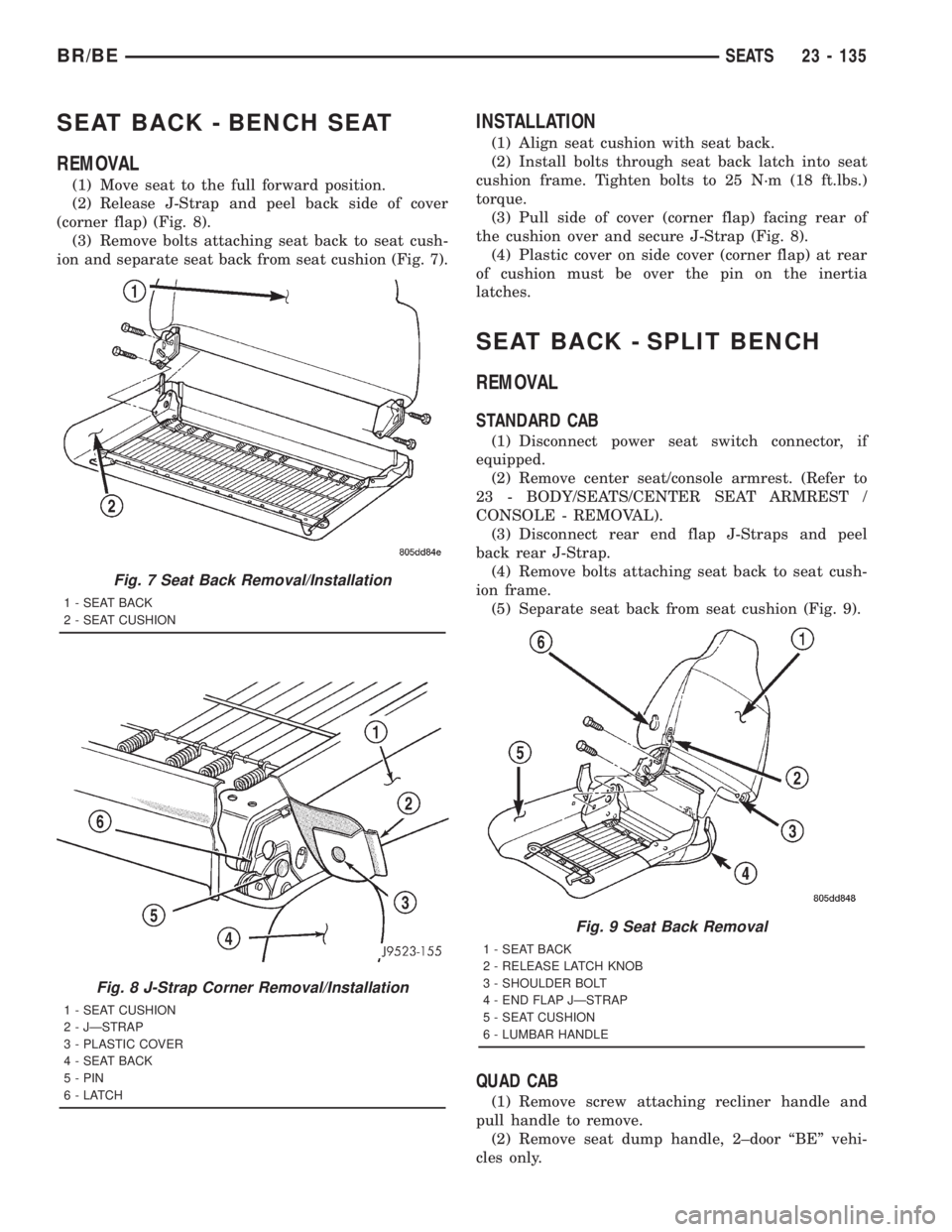

SEAT - BENCH SEAT

REMOVAL

(1) Move seat track to forward position.

(2) Hinge seat backs forward.

(3) Remove nuts attaching rear of seat tracks to

floor (Fig. 4).

(4) Move seat track to rearward position.

(5) Remove bolts attaching front of seat tracks to

floor.

(6) Separate seat from vehicle.

INSTALLATION

NOTE: Seat adjustment latch must be engaged and

in equal positions prior to seat installation. Verify

inboard and outboard seat latch operation.

(1) Position seat in vehicle.

(2) Install bolts attaching front of seat tracks to

floor. Tighten bolts to 54 N´m (40 ft. lbs.) torque.

(3) Move seat track to forward position.

(4) Hinge seat backs forward.

(5) Install nuts attaching rear of seat tracks to

floor. Tighten inboard nuts to 40 N´m (30 ft. lbs.)

torque. Tighten outboard nuts to 54 N´m (40 ft. lbs.)

torque.

Fig. 3 Inertia Latch Cover Upper Strap

Fig. 4 Bench Seat

1 - BENCH SEAT

2 - NUT

3 - STUD

4 - FLOOR PAN

5 - SCREW

BR/BESEATS 23 - 133

CENTER SEAT ARMREST/LATCH COVER (Continued)

Page 2707 of 2889

SEAT - SPLIT BENCH

REMOVAL

STANDARD CAB

(1) Move seat track to forward position.

(2) Hinge seat back forward.

(3) Remove nuts holding outboard and inboard

tracks to floor (Fig. 5).

(4) Move seat track to forward position.

(5) Remove bolt holding inboard seat track to bot-

tom of center occupant seat.

(6) Remove bolts holding front of seat tracks to

floor.

(7) Disengage power seat wire connector from body

harness, if equipped (Fig. 5).

(8) Lift center occupant seat upward to clear rear

attachment stud.

(9) Separate seat from vehicle.

QUAD CAB

(1) Clamp seat belt to prevent belt from retracting.

(2) Move seats to full rearward position.

(3) Remove bolts attaching front of seat tracks to

floor.

(4) Move seats to full forward position.

(5) Remove bolts attaching rear of outboard seat

tracks to floor (Fig. 6).

(6) Remove nuts attaching inboard seat tracks to

floor.

(7) Disengage wire connectors from body harness.

(8) Lift seats upward to clear rear studs.

(9) With the aid of a helper, separate seat from

vehicle.

INSTALLATION

STANDARD CAB

(1) Position seat in vehicle.

(2) Connect power seat wire connector to body har-

ness, if equipped.

(3) Install bolts holding front of seat tracks to

floor. Tighten the bolts to 40 N´m (30 ft. lbs.) torque.

(4) Install bolt holding inboard seat track to bot-

tom of center occupant seat. Tighten the bolt to 28

N´m (250 in- lbs) torque.

(5) Install nuts holding outboard and inboard

tracks to floor. Tighten the inboard nuts to 40 N´m

(30 ft. lbs.) torque. Tighten the outer nuts to 54 N´m

(40 ft. lbs. torque).

QUAD CAB

(1) Position seat in vehicle.

CAUTION: Verify that power is not being supplied

when engaging connector.

(2) Engage driver's seat belt buckle wire connector.

Engage power seat wire connector to body harness, if

equipped.

(3) Ensure seats are in full forward position.

(4) Install outboard bolts attaching rear of seat

tracks to floor (Fig. 6). Tighten the bolts to 54 N´m

(40 ft. lbs.) torque.

(5) Install nuts attaching inboard seat tracks to

floor. Tighten the nuts to 40 N´m (30 ft. lbs.) torque.

(6) Move seats to full forward position.

(7) Install bolts attaching front of seat tracks to

floor. Tighten the bolts to 54 N´m (40 ft. lbs.) torque.

Fig. 5 Split Bench Seat

1 - SEAT

2 - POWER SEAT HARNESS CONNECTOR

Fig. 6 Split Bench SeatÐClub/Quad Cab

1 - SEAT

23 - 134 SEATSBR/BE

Page 2708 of 2889

SEAT BACK - BENCH SEAT

REMOVAL

(1) Move seat to the full forward position.

(2) Release J-Strap and peel back side of cover

(corner flap) (Fig. 8).

(3) Remove bolts attaching seat back to seat cush-

ion and separate seat back from seat cushion (Fig. 7).

INSTALLATION

(1) Align seat cushion with seat back.

(2) Install bolts through seat back latch into seat

cushion frame. Tighten bolts to 25 N´m (18 ft.lbs.)

torque.

(3) Pull side of cover (corner flap) facing rear of

the cushion over and secure J-Strap (Fig. 8).

(4) Plastic cover on side cover (corner flap) at rear

of cushion must be over the pin on the inertia

latches.

SEAT BACK - SPLIT BENCH

REMOVAL

STANDARD CAB

(1) Disconnect power seat switch connector, if

equipped.

(2) Remove center seat/console armrest. (Refer to

23 - BODY/SEATS/CENTER SEAT ARMREST /

CONSOLE - REMOVAL).

(3) Disconnect rear end flap J-Straps and peel

back rear J-Strap.

(4) Remove bolts attaching seat back to seat cush-

ion frame.

(5) Separate seat back from seat cushion (Fig. 9).

QUAD CAB

(1) Remove screw attaching recliner handle and

pull handle to remove.

(2) Remove seat dump handle, 2±door ªBEº vehi-

cles only.

Fig. 7 Seat Back Removal/Installation

1 - SEAT BACK

2 - SEAT CUSHION

Fig. 8 J-Strap Corner Removal/Installation

1 - SEAT CUSHION

2 - JÐSTRAP

3 - PLASTIC COVER

4 - SEAT BACK

5 - PIN

6-LATCH

Fig. 9 Seat Back Removal

1 - SEAT BACK

2 - RELEASE LATCH KNOB

3 - SHOULDER BOLT

4 - END FLAP JÐSTRAP

5 - SEAT CUSHION

6 - LUMBAR HANDLE

BR/BESEATS 23 - 135

Page 2709 of 2889

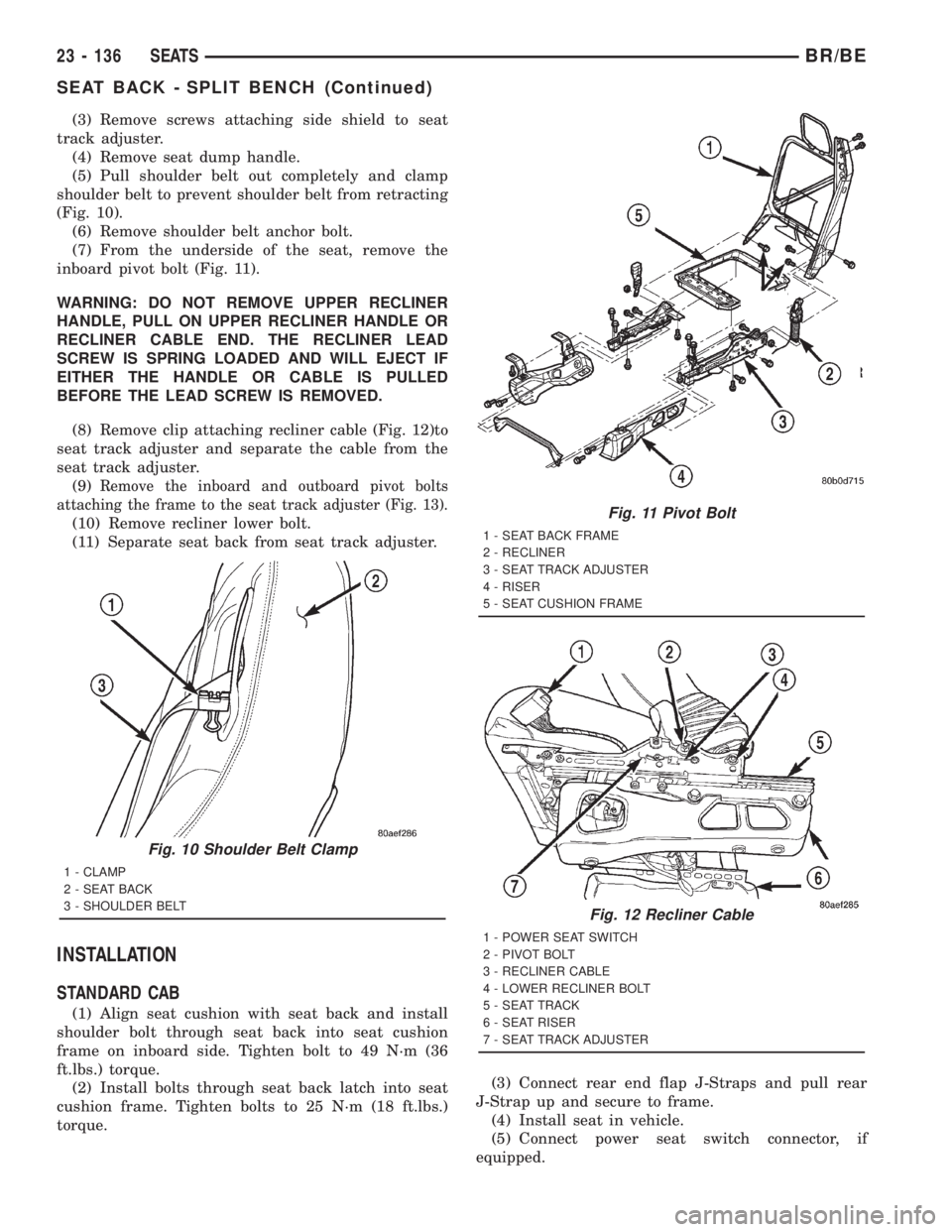

(3) Remove screws attaching side shield to seat

track adjuster.

(4) Remove seat dump handle.

(5) Pull shoulder belt out completely and clamp

shoulder belt to prevent shoulder belt from retracting

(Fig. 10).

(6) Remove shoulder belt anchor bolt.

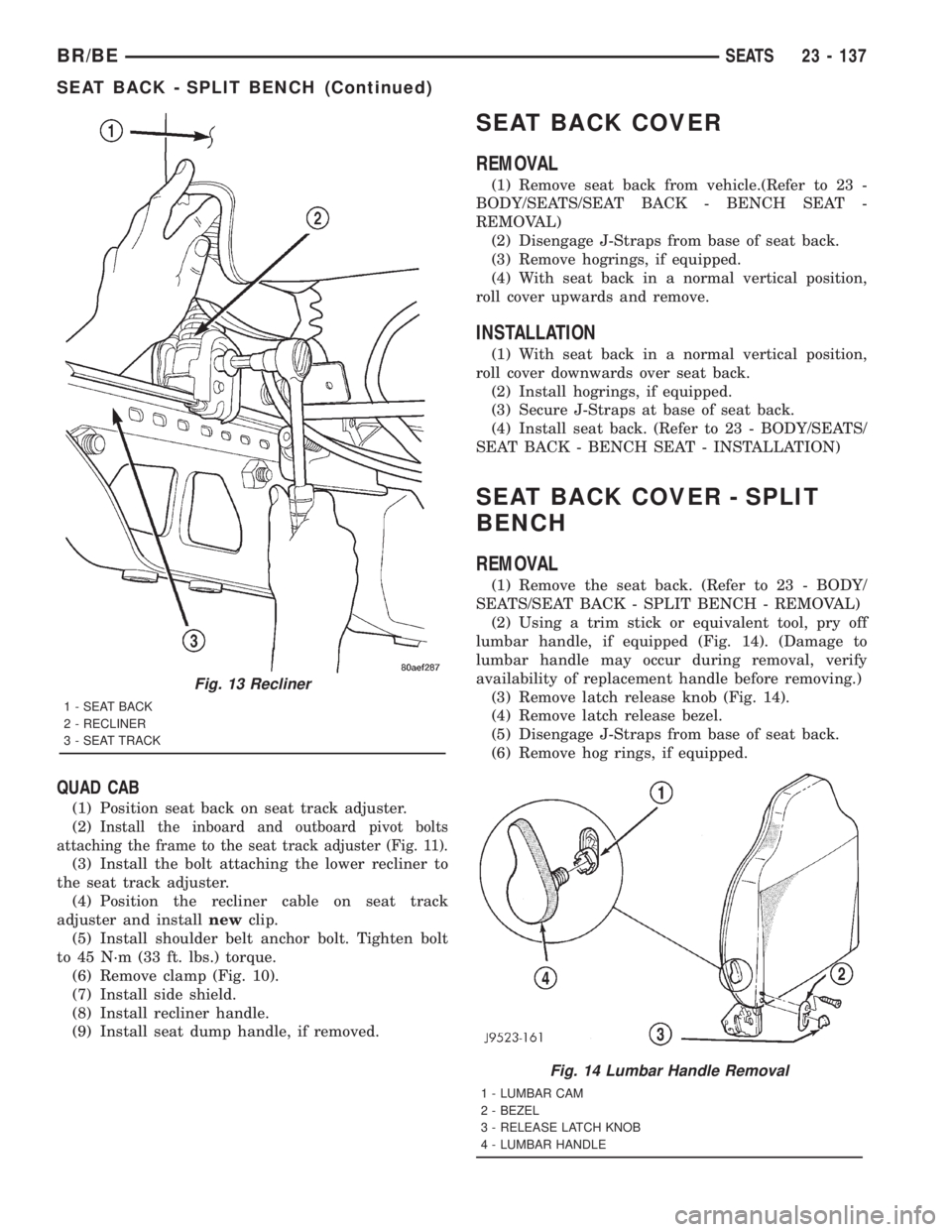

(7) From the underside of the seat, remove the

inboard pivot bolt (Fig. 11).

WARNING: DO NOT REMOVE UPPER RECLINER

HANDLE, PULL ON UPPER RECLINER HANDLE OR

RECLINER CABLE END. THE RECLINER LEAD

SCREW IS SPRING LOADED AND WILL EJECT IF

EITHER THE HANDLE OR CABLE IS PULLED

BEFORE THE LEAD SCREW IS REMOVED.

(8) Remove clip attaching recliner cable (Fig. 12)to

seat track adjuster and separate the cable from the

seat track adjuster.

(9)

Remove the inboard and outboard pivot bolts

attaching the frame to the seat track adjuster (Fig. 13).

(10) Remove recliner lower bolt.

(11) Separate seat back from seat track adjuster.

INSTALLATION

STANDARD CAB

(1) Align seat cushion with seat back and install

shoulder bolt through seat back into seat cushion

frame on inboard side. Tighten bolt to 49 N´m (36

ft.lbs.) torque.

(2) Install bolts through seat back latch into seat

cushion frame. Tighten bolts to 25 N´m (18 ft.lbs.)

torque.(3) Connect rear end flap J-Straps and pull rear

J-Strap up and secure to frame.

(4) Install seat in vehicle.

(5) Connect power seat switch connector, if

equipped.

Fig. 10 Shoulder Belt Clamp

1 - CLAMP

2 - SEAT BACK

3 - SHOULDER BELT

Fig. 11 Pivot Bolt

1 - SEAT BACK FRAME

2 - RECLINER

3 - SEAT TRACK ADJUSTER

4 - RISER

5 - SEAT CUSHION FRAME

Fig. 12 Recliner Cable

1 - POWER SEAT SWITCH

2 - PIVOT BOLT

3 - RECLINER CABLE

4 - LOWER RECLINER BOLT

5 - SEAT TRACK

6 - SEAT RISER

7 - SEAT TRACK ADJUSTER

23 - 136 SEATSBR/BE

SEAT BACK - SPLIT BENCH (Continued)

Page 2710 of 2889

QUAD CAB

(1) Position seat back on seat track adjuster.

(2)

Install the inboard and outboard pivot bolts

attaching the frame to the seat track adjuster (Fig. 11).

(3) Install the bolt attaching the lower recliner to

the seat track adjuster.

(4) Position the recliner cable on seat track

adjuster and installnewclip.

(5) Install shoulder belt anchor bolt. Tighten bolt

to 45 N´m (33 ft. lbs.) torque.

(6) Remove clamp (Fig. 10).

(7) Install side shield.

(8) Install recliner handle.

(9) Install seat dump handle, if removed.

SEAT BACK COVER

REMOVAL

(1) Remove seat back from vehicle.(Refer to 23 -

BODY/SEATS/SEAT BACK - BENCH SEAT -

REMOVAL)

(2) Disengage J-Straps from base of seat back.

(3) Remove hogrings, if equipped.

(4) With seat back in a normal vertical position,

roll cover upwards and remove.

INSTALLATION

(1) With seat back in a normal vertical position,

roll cover downwards over seat back.

(2) Install hogrings, if equipped.

(3) Secure J-Straps at base of seat back.

(4) Install seat back. (Refer to 23 - BODY/SEATS/

SEAT BACK - BENCH SEAT - INSTALLATION)

SEAT BACK COVER - SPLIT

BENCH

REMOVAL

(1) Remove the seat back. (Refer to 23 - BODY/

SEATS/SEAT BACK - SPLIT BENCH - REMOVAL)

(2) Using a trim stick or equivalent tool, pry off

lumbar handle, if equipped (Fig. 14). (Damage to

lumbar handle may occur during removal, verify

availability of replacement handle before removing.)

(3) Remove latch release knob (Fig. 14).

(4) Remove latch release bezel.

(5) Disengage J-Straps from base of seat back.

(6) Remove hog rings, if equipped.

Fig. 14 Lumbar Handle Removal

1 - LUMBAR CAM

2 - BEZEL

3 - RELEASE LATCH KNOB

4 - LUMBAR HANDLE

Fig. 13 Recliner

1 - SEAT BACK

2 - RECLINER

3 - SEAT TRACK

BR/BESEATS 23 - 137

SEAT BACK - SPLIT BENCH (Continued)