DODGE RAM 2001 Service Repair Manual

Manufacturer: DODGE, Model Year: 2001, Model line: RAM, Model: DODGE RAM 2001Pages: 2889, PDF Size: 68.07 MB

Page 2711 of 2889

(7) With seat back in a normal vertical position,

roll cover upwards and remove.

INSTALLATION

(1) With seat back in a normal vertical position,

roll cover downwards over seat back.

(2) Install hog rings, if equipped.

(3) Engage J-Straps at base of seat back.

(4) Align lumbar handle with lumbar cam and tap

on with rubber mallet until seated.

(5) Install latch release bezel.

(6) Install latch release knob.

(7) Install seat back. (Refer to 23 - BODY/SEATS/

SEAT BACK - SPLIT BENCH - INSTALLATION)

SEAT BACK RECLINER

REMOVAL

(1) Remove seat back. (Refer to 23 - BODY/SEATS/

SEAT BACK - SPLIT BENCH - REMOVAL)

(2) Disengage J-straps at base of seat back and

roll seat back cover upward to access rubber bellows

push-in fasteners.

NOTE: Notice the routing of the recliner cable for

installation.

(3) Remove the push-in fasteners attaching upper

rubber bellows to the seat back frame.

(4) Remove rubber bellows.

(5) Remove seat dump handle, 2±door ªBEº vehi-

cles only.

WARNING: Do not pull on upper recliner handle or

recliner cable end. The recliner lead screw is spring

loaded and will eject if either the handle or cable is

pulled before the lead screw is removed.

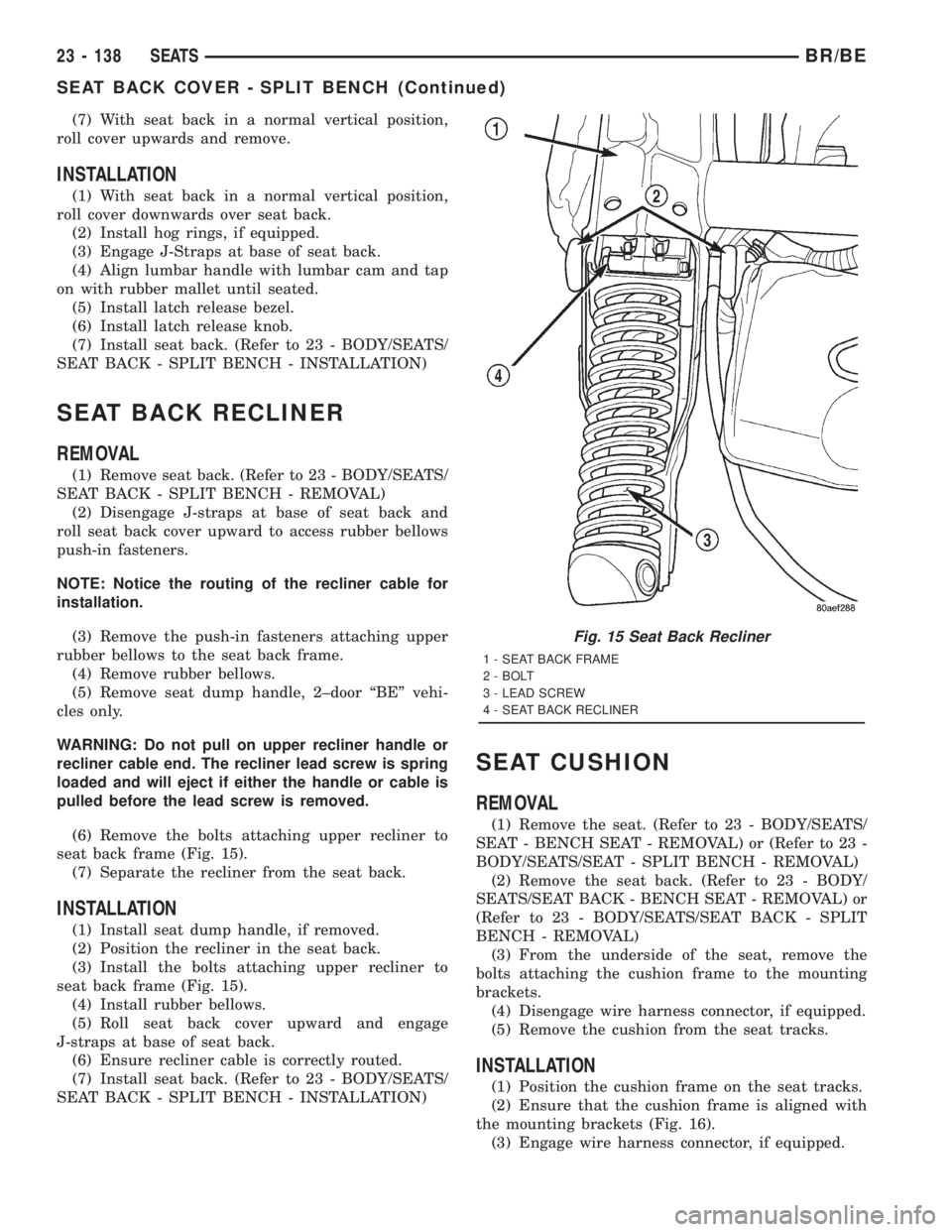

(6) Remove the bolts attaching upper recliner to

seat back frame (Fig. 15).

(7) Separate the recliner from the seat back.

INSTALLATION

(1) Install seat dump handle, if removed.

(2) Position the recliner in the seat back.

(3) Install the bolts attaching upper recliner to

seat back frame (Fig. 15).

(4) Install rubber bellows.

(5) Roll seat back cover upward and engage

J-straps at base of seat back.

(6) Ensure recliner cable is correctly routed.

(7) Install seat back. (Refer to 23 - BODY/SEATS/

SEAT BACK - SPLIT BENCH - INSTALLATION)

SEAT CUSHION

REMOVAL

(1) Remove the seat. (Refer to 23 - BODY/SEATS/

SEAT - BENCH SEAT - REMOVAL) or (Refer to 23 -

BODY/SEATS/SEAT - SPLIT BENCH - REMOVAL)

(2) Remove the seat back. (Refer to 23 - BODY/

SEATS/SEAT BACK - BENCH SEAT - REMOVAL) or

(Refer to 23 - BODY/SEATS/SEAT BACK - SPLIT

BENCH - REMOVAL)

(3) From the underside of the seat, remove the

bolts attaching the cushion frame to the mounting

brackets.

(4) Disengage wire harness connector, if equipped.

(5) Remove the cushion from the seat tracks.

INSTALLATION

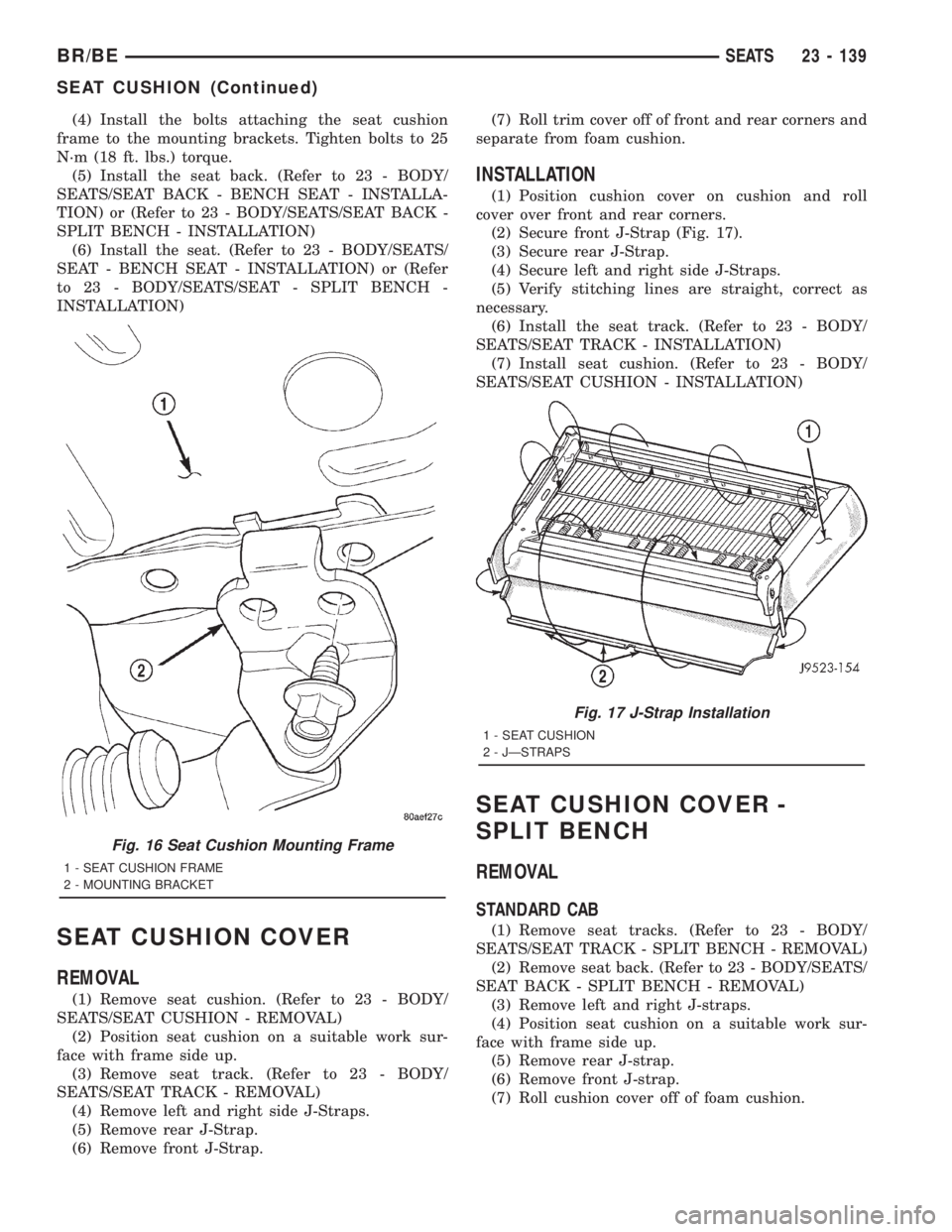

(1) Position the cushion frame on the seat tracks.

(2) Ensure that the cushion frame is aligned with

the mounting brackets (Fig. 16).

(3) Engage wire harness connector, if equipped.

Fig. 15 Seat Back Recliner

1 - SEAT BACK FRAME

2 - BOLT

3 - LEAD SCREW

4 - SEAT BACK RECLINER

23 - 138 SEATSBR/BE

SEAT BACK COVER - SPLIT BENCH (Continued)

Page 2712 of 2889

(4) Install the bolts attaching the seat cushion

frame to the mounting brackets. Tighten bolts to 25

N´m (18 ft. lbs.) torque.

(5) Install the seat back. (Refer to 23 - BODY/

SEATS/SEAT BACK - BENCH SEAT - INSTALLA-

TION) or (Refer to 23 - BODY/SEATS/SEAT BACK -

SPLIT BENCH - INSTALLATION)

(6) Install the seat. (Refer to 23 - BODY/SEATS/

SEAT - BENCH SEAT - INSTALLATION) or (Refer

to 23 - BODY/SEATS/SEAT - SPLIT BENCH -

INSTALLATION)

SEAT CUSHION COVER

REMOVAL

(1) Remove seat cushion. (Refer to 23 - BODY/

SEATS/SEAT CUSHION - REMOVAL)

(2) Position seat cushion on a suitable work sur-

face with frame side up.

(3) Remove seat track. (Refer to 23 - BODY/

SEATS/SEAT TRACK - REMOVAL)

(4) Remove left and right side J-Straps.

(5) Remove rear J-Strap.

(6) Remove front J-Strap.(7) Roll trim cover off of front and rear corners and

separate from foam cushion.

INSTALLATION

(1) Position cushion cover on cushion and roll

cover over front and rear corners.

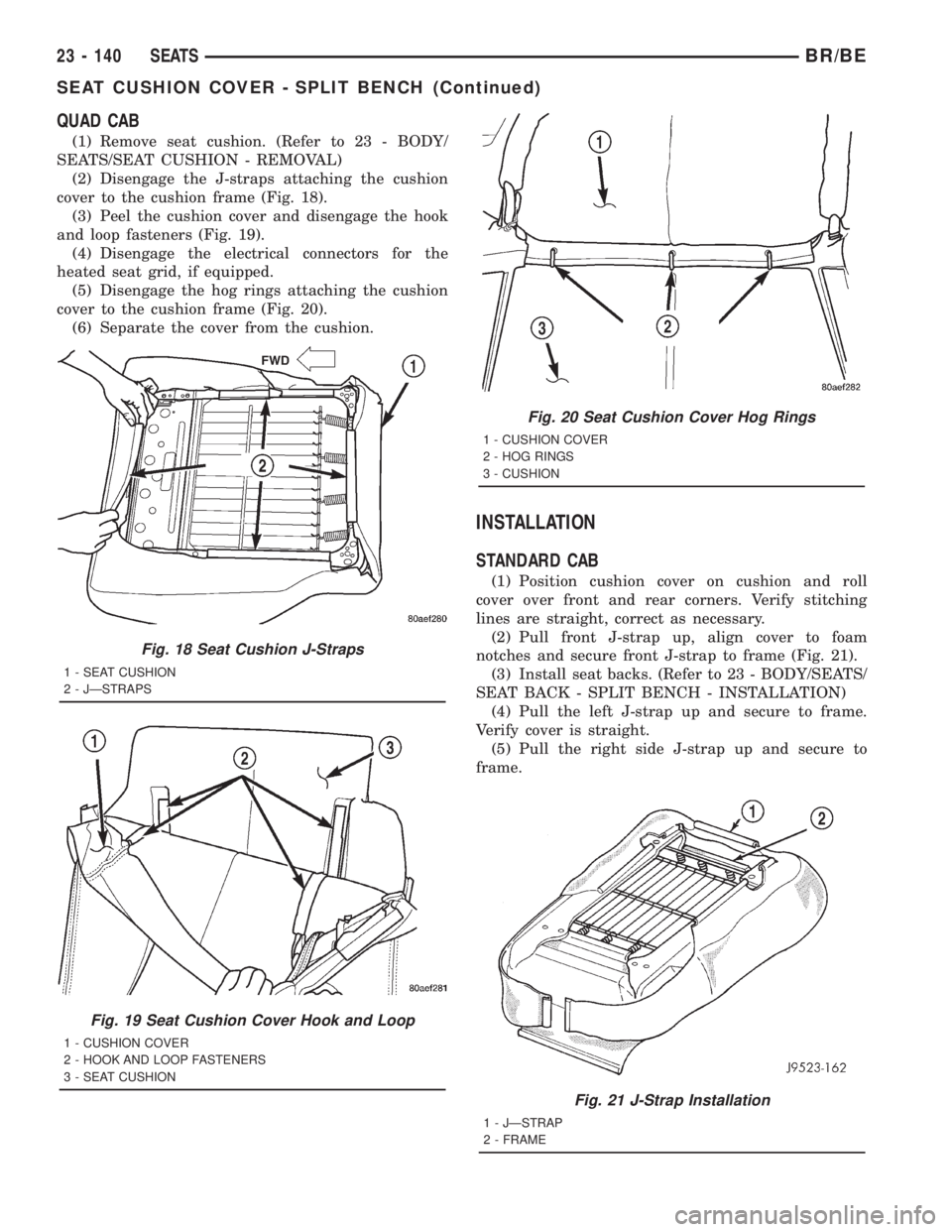

(2) Secure front J-Strap (Fig. 17).

(3) Secure rear J-Strap.

(4) Secure left and right side J-Straps.

(5) Verify stitching lines are straight, correct as

necessary.

(6) Install the seat track. (Refer to 23 - BODY/

SEATS/SEAT TRACK - INSTALLATION)

(7) Install seat cushion. (Refer to 23 - BODY/

SEATS/SEAT CUSHION - INSTALLATION)

SEAT CUSHION COVER -

SPLIT BENCH

REMOVAL

STANDARD CAB

(1) Remove seat tracks. (Refer to 23 - BODY/

SEATS/SEAT TRACK - SPLIT BENCH - REMOVAL)

(2) Remove seat back. (Refer to 23 - BODY/SEATS/

SEAT BACK - SPLIT BENCH - REMOVAL)

(3) Remove left and right J-straps.

(4) Position seat cushion on a suitable work sur-

face with frame side up.

(5) Remove rear J-strap.

(6) Remove front J-strap.

(7) Roll cushion cover off of foam cushion.

Fig. 16 Seat Cushion Mounting Frame

1 - SEAT CUSHION FRAME

2 - MOUNTING BRACKET

Fig. 17 J-Strap Installation

1 - SEAT CUSHION

2 - JÐSTRAPS

BR/BESEATS 23 - 139

SEAT CUSHION (Continued)

Page 2713 of 2889

QUAD CAB

(1) Remove seat cushion. (Refer to 23 - BODY/

SEATS/SEAT CUSHION - REMOVAL)

(2) Disengage the J-straps attaching the cushion

cover to the cushion frame (Fig. 18).

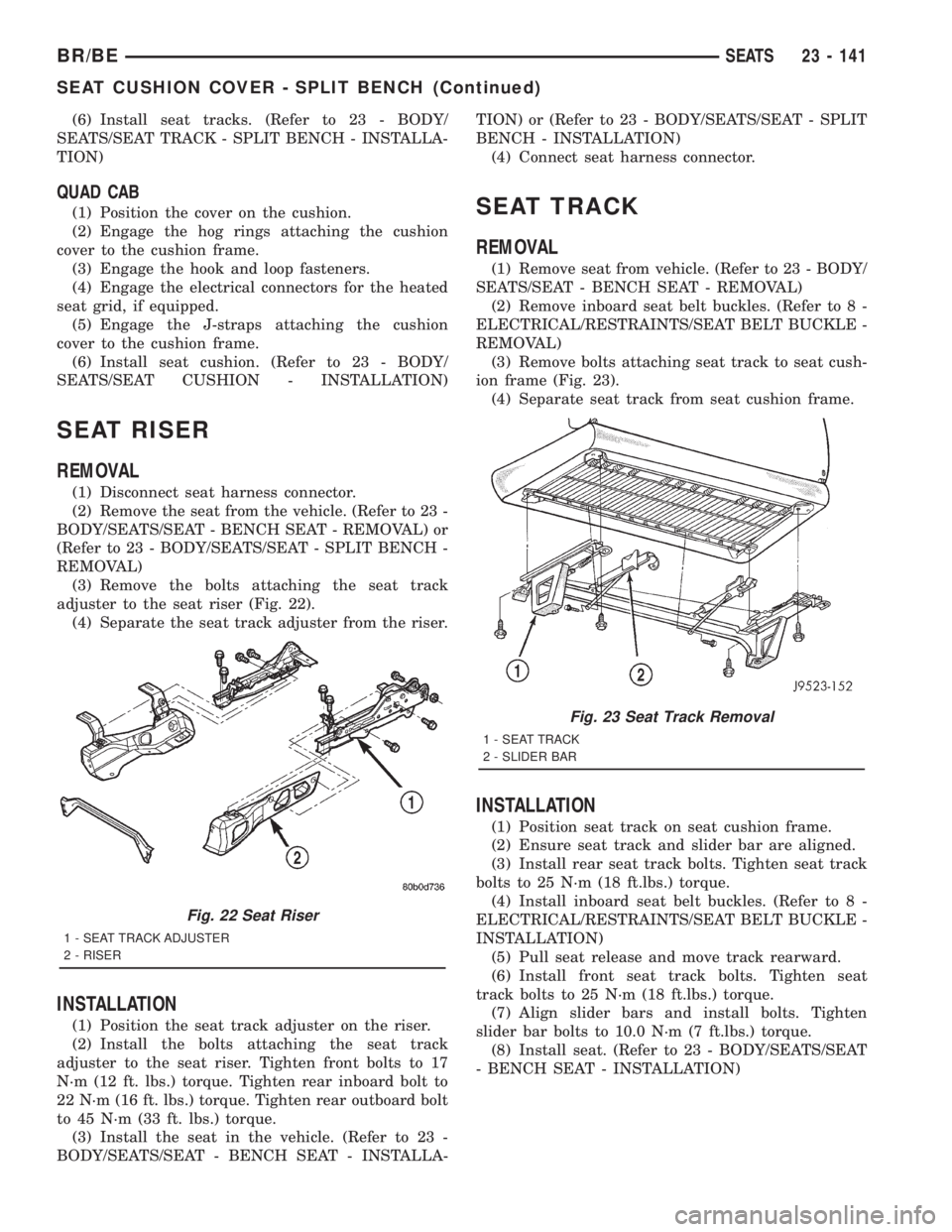

(3) Peel the cushion cover and disengage the hook

and loop fasteners (Fig. 19).

(4) Disengage the electrical connectors for the

heated seat grid, if equipped.

(5) Disengage the hog rings attaching the cushion

cover to the cushion frame (Fig. 20).

(6) Separate the cover from the cushion.

INSTALLATION

STANDARD CAB

(1) Position cushion cover on cushion and roll

cover over front and rear corners. Verify stitching

lines are straight, correct as necessary.

(2) Pull front J-strap up, align cover to foam

notches and secure front J-strap to frame (Fig. 21).

(3) Install seat backs. (Refer to 23 - BODY/SEATS/

SEAT BACK - SPLIT BENCH - INSTALLATION)

(4) Pull the left J-strap up and secure to frame.

Verify cover is straight.

(5) Pull the right side J-strap up and secure to

frame.

Fig. 21 J-Strap Installation

1 - JÐSTRAP

2 - FRAME

Fig. 18 Seat Cushion J-Straps

1 - SEAT CUSHION

2 - JÐSTRAPS

Fig. 19 Seat Cushion Cover Hook and Loop

1 - CUSHION COVER

2 - HOOK AND LOOP FASTENERS

3 - SEAT CUSHION

Fig. 20 Seat Cushion Cover Hog Rings

1 - CUSHION COVER

2 - HOG RINGS

3 - CUSHION

23 - 140 SEATSBR/BE

SEAT CUSHION COVER - SPLIT BENCH (Continued)

Page 2714 of 2889

(6) Install seat tracks. (Refer to 23 - BODY/

SEATS/SEAT TRACK - SPLIT BENCH - INSTALLA-

TION)

QUAD CAB

(1) Position the cover on the cushion.

(2) Engage the hog rings attaching the cushion

cover to the cushion frame.

(3) Engage the hook and loop fasteners.

(4) Engage the electrical connectors for the heated

seat grid, if equipped.

(5) Engage the J-straps attaching the cushion

cover to the cushion frame.

(6) Install seat cushion. (Refer to 23 - BODY/

SEATS/SEAT CUSHION - INSTALLATION)

SEAT RISER

REMOVAL

(1) Disconnect seat harness connector.

(2) Remove the seat from the vehicle. (Refer to 23 -

BODY/SEATS/SEAT - BENCH SEAT - REMOVAL) or

(Refer to 23 - BODY/SEATS/SEAT - SPLIT BENCH -

REMOVAL)

(3) Remove the bolts attaching the seat track

adjuster to the seat riser (Fig. 22).

(4) Separate the seat track adjuster from the riser.

INSTALLATION

(1) Position the seat track adjuster on the riser.

(2) Install the bolts attaching the seat track

adjuster to the seat riser. Tighten front bolts to 17

N´m (12 ft. lbs.) torque. Tighten rear inboard bolt to

22 N´m (16 ft. lbs.) torque. Tighten rear outboard bolt

to 45 N´m (33 ft. lbs.) torque.

(3) Install the seat in the vehicle. (Refer to 23 -

BODY/SEATS/SEAT - BENCH SEAT - INSTALLA-TION) or (Refer to 23 - BODY/SEATS/SEAT - SPLIT

BENCH - INSTALLATION)

(4) Connect seat harness connector.

SEAT TRACK

REMOVAL

(1) Remove seat from vehicle. (Refer to 23 - BODY/

SEATS/SEAT - BENCH SEAT - REMOVAL)

(2) Remove inboard seat belt buckles. (Refer to 8 -

ELECTRICAL/RESTRAINTS/SEAT BELT BUCKLE -

REMOVAL)

(3) Remove bolts attaching seat track to seat cush-

ion frame (Fig. 23).

(4) Separate seat track from seat cushion frame.

INSTALLATION

(1) Position seat track on seat cushion frame.

(2) Ensure seat track and slider bar are aligned.

(3) Install rear seat track bolts. Tighten seat track

bolts to 25 N´m (18 ft.lbs.) torque.

(4) Install inboard seat belt buckles. (Refer to 8 -

ELECTRICAL/RESTRAINTS/SEAT BELT BUCKLE -

INSTALLATION)

(5) Pull seat release and move track rearward.

(6) Install front seat track bolts. Tighten seat

track bolts to 25 N´m (18 ft.lbs.) torque.

(7) Align slider bars and install bolts. Tighten

slider bar bolts to 10.0 N´m (7 ft.lbs.) torque.

(8) Install seat. (Refer to 23 - BODY/SEATS/SEAT

- BENCH SEAT - INSTALLATION)

Fig. 22 Seat Riser

1 - SEAT TRACK ADJUSTER

2 - RISER

Fig. 23 Seat Track Removal

1 - SEAT TRACK

2 - SLIDER BAR

BR/BESEATS 23 - 141

SEAT CUSHION COVER - SPLIT BENCH (Continued)

Page 2715 of 2889

SEAT TRACK - SPLIT BENCH

REMOVAL

(1) Remove seat from vehicle. (Refer to 23 -

BODY/SEATS/SEAT - SPLIT BENCH - REMOVAL)

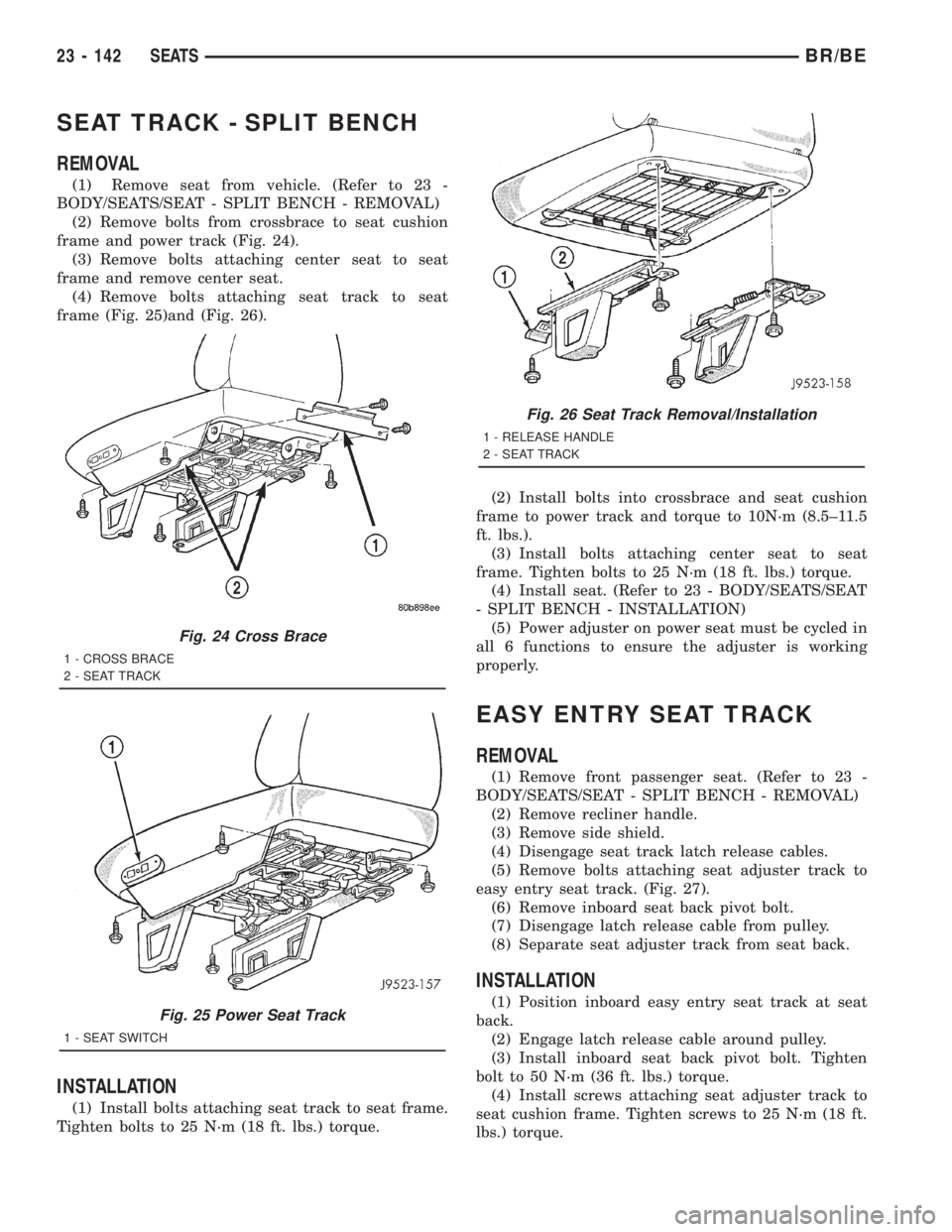

(2) Remove bolts from crossbrace to seat cushion

frame and power track (Fig. 24).

(3) Remove bolts attaching center seat to seat

frame and remove center seat.

(4) Remove bolts attaching seat track to seat

frame (Fig. 25)and (Fig. 26).

INSTALLATION

(1) Install bolts attaching seat track to seat frame.

Tighten bolts to 25 N´m (18 ft. lbs.) torque.(2) Install bolts into crossbrace and seat cushion

frame to power track and torque to 10N´m (8.5±11.5

ft. lbs.).

(3) Install bolts attaching center seat to seat

frame. Tighten bolts to 25 N´m (18 ft. lbs.) torque.

(4) Install seat. (Refer to 23 - BODY/SEATS/SEAT

- SPLIT BENCH - INSTALLATION)

(5) Power adjuster on power seat must be cycled in

all 6 functions to ensure the adjuster is working

properly.

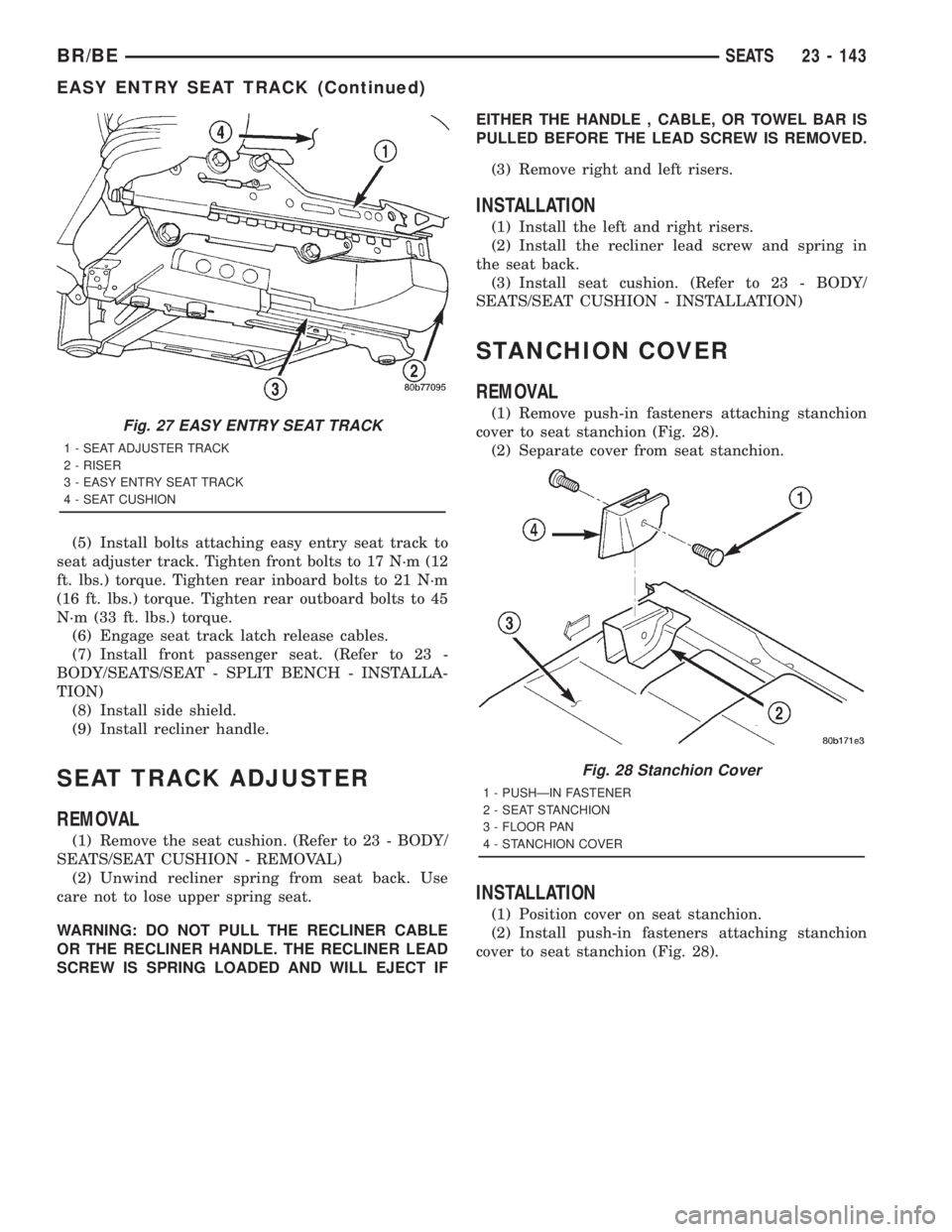

EASY ENTRY SEAT TRACK

REMOVAL

(1) Remove front passenger seat. (Refer to 23 -

BODY/SEATS/SEAT - SPLIT BENCH - REMOVAL)

(2) Remove recliner handle.

(3) Remove side shield.

(4) Disengage seat track latch release cables.

(5) Remove bolts attaching seat adjuster track to

easy entry seat track. (Fig. 27).

(6) Remove inboard seat back pivot bolt.

(7) Disengage latch release cable from pulley.

(8) Separate seat adjuster track from seat back.

INSTALLATION

(1) Position inboard easy entry seat track at seat

back.

(2) Engage latch release cable around pulley.

(3) Install inboard seat back pivot bolt. Tighten

bolt to 50 N´m (36 ft. lbs.) torque.

(4) Install screws attaching seat adjuster track to

seat cushion frame. Tighten screws to 25 N´m (18 ft.

lbs.) torque.

Fig. 24 Cross Brace

1 - CROSS BRACE

2 - SEAT TRACK

Fig. 25 Power Seat Track

1 - SEAT SWITCH

Fig. 26 Seat Track Removal/Installation

1 - RELEASE HANDLE

2 - SEAT TRACK

23 - 142 SEATSBR/BE

Page 2716 of 2889

(5) Install bolts attaching easy entry seat track to

seat adjuster track. Tighten front bolts to 17 N´m (12

ft. lbs.) torque. Tighten rear inboard bolts to 21 N´m

(16 ft. lbs.) torque. Tighten rear outboard bolts to 45

N´m (33 ft. lbs.) torque.

(6) Engage seat track latch release cables.

(7) Install front passenger seat. (Refer to 23 -

BODY/SEATS/SEAT - SPLIT BENCH - INSTALLA-

TION)

(8) Install side shield.

(9) Install recliner handle.

SEAT TRACK ADJUSTER

REMOVAL

(1) Remove the seat cushion. (Refer to 23 - BODY/

SEATS/SEAT CUSHION - REMOVAL)

(2) Unwind recliner spring from seat back. Use

care not to lose upper spring seat.

WARNING: DO NOT PULL THE RECLINER CABLE

OR THE RECLINER HANDLE. THE RECLINER LEAD

SCREW IS SPRING LOADED AND WILL EJECT IFEITHER THE HANDLE , CABLE, OR TOWEL BAR IS

PULLED BEFORE THE LEAD SCREW IS REMOVED.

(3) Remove right and left risers.

INSTALLATION

(1) Install the left and right risers.

(2) Install the recliner lead screw and spring in

the seat back.

(3) Install seat cushion. (Refer to 23 - BODY/

SEATS/SEAT CUSHION - INSTALLATION)

STANCHION COVER

REMOVAL

(1) Remove push-in fasteners attaching stanchion

cover to seat stanchion (Fig. 28).

(2) Separate cover from seat stanchion.

INSTALLATION

(1) Position cover on seat stanchion.

(2) Install push-in fasteners attaching stanchion

cover to seat stanchion (Fig. 28).

Fig. 27 EASY ENTRY SEAT TRACK

1 - SEAT ADJUSTER TRACK

2 - RISER

3 - EASY ENTRY SEAT TRACK

4 - SEAT CUSHION

Fig. 28 Stanchion Cover

1 - PUSHÐIN FASTENER

2 - SEAT STANCHION

3 - FLOOR PAN

4 - STANCHION COVER

BR/BESEATS 23 - 143

EASY ENTRY SEAT TRACK (Continued)

Page 2717 of 2889

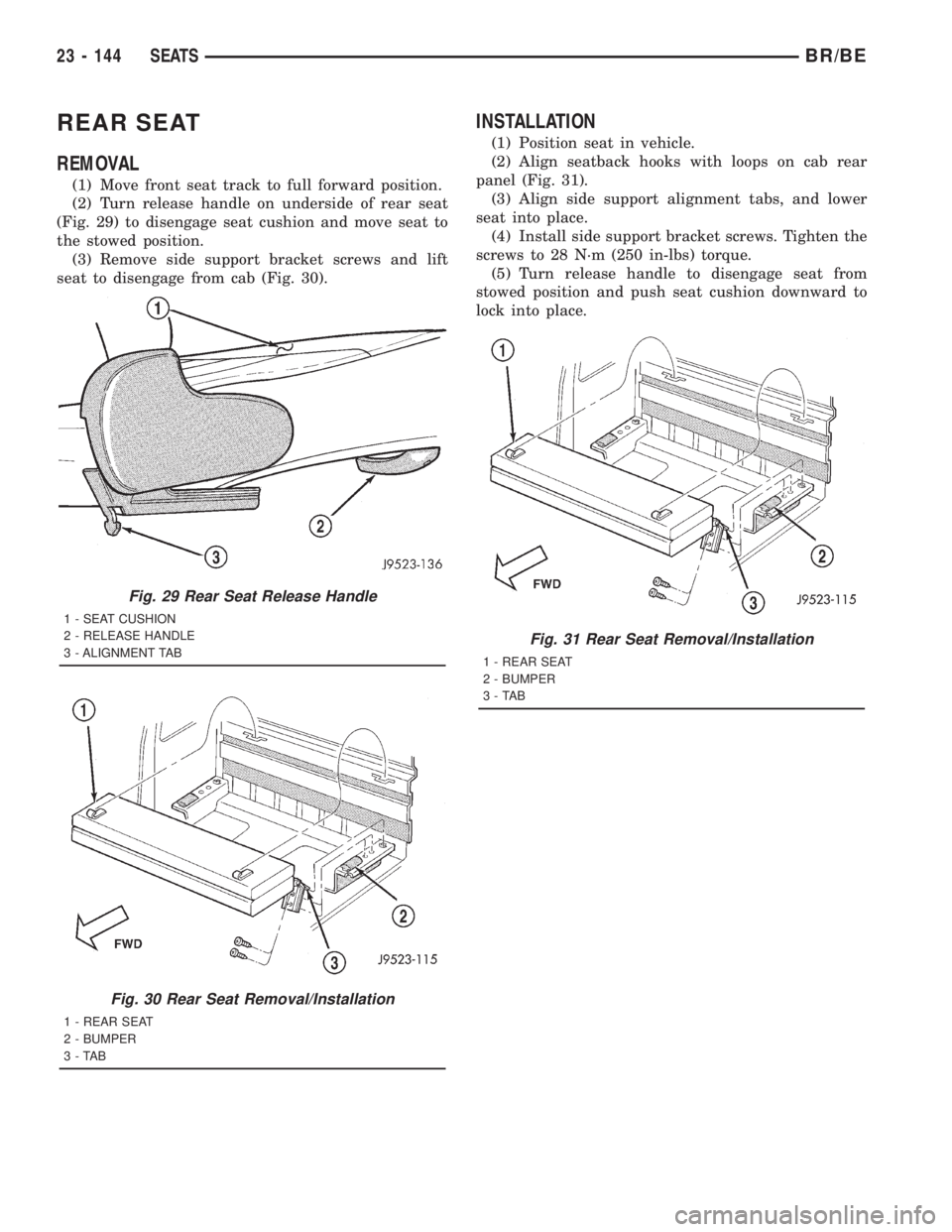

REAR SEAT

REMOVAL

(1) Move front seat track to full forward position.

(2) Turn release handle on underside of rear seat

(Fig. 29) to disengage seat cushion and move seat to

the stowed position.

(3) Remove side support bracket screws and lift

seat to disengage from cab (Fig. 30).

INSTALLATION

(1) Position seat in vehicle.

(2) Align seatback hooks with loops on cab rear

panel (Fig. 31).

(3) Align side support alignment tabs, and lower

seat into place.

(4) Install side support bracket screws. Tighten the

screws to 28 N´m (250 in-lbs) torque.

(5) Turn release handle to disengage seat from

stowed position and push seat cushion downward to

lock into place.

Fig. 29 Rear Seat Release Handle

1 - SEAT CUSHION

2 - RELEASE HANDLE

3 - ALIGNMENT TAB

Fig. 30 Rear Seat Removal/Installation

1 - REAR SEAT

2 - BUMPER

3-TAB

Fig. 31 Rear Seat Removal/Installation

1 - REAR SEAT

2 - BUMPER

3-TAB

23 - 144 SEATSBR/BE

Page 2718 of 2889

STATIONARY GLASS

TABLE OF CONTENTS

page page

STATIONARY GLASS

DESCRIPTION..........................145

OPERATION............................145

BACKLITE

REMOVAL.............................145

INSTALLATION..........................145

BACKLITE LATCH AND KEEPER

REMOVAL.............................146

INSTALLATION..........................146

BACKLITE VENT GLASS

REMOVAL.............................147INSTALLATION..........................147

WINDSHIELD

DESCRIPTION..........................148

REMOVAL.............................148

INSTALLATION..........................148

QUARTER WINDOW

REMOVAL.............................151

INSTALLATION..........................151

STATIONARY GLASS

DESCRIPTION

Windshields are made of two pieces of glass with a

plastic inner layer. Windshields and selected station-

ary glass are structural members of the vehicle. The

windshield glass is bonded to the windshield frame

with urethane adhesive.

OPERATION

Windshields and other stationary glass protect the

occupants from the effects of the elements. Wind-

shields are also used to retain some airbags in posi-

tion during deployment. Urethane bonded glass is

difficult to salvage during removal. The urethane

bonding is difficult to cut or clean from any surface.

Before removing the glass, check the availability of

replacement components.

BACKLITE

REMOVAL

It is difficult to salvage the backlite during the

removal operation. The backlite is part of the struc-

tural support for the roof. The urethane bonding

used to secure the glass to the fence is difficult to cut

or clean from any surface. Since the molding is set in

urethane, it is unlikely it would be salvaged. Before

removing the backlite, check the availability from the

parts supplier.

The backlite is attached to the window frame with

urethane adhesive. The urethane adhesive is applied

cold and seals the surface area between the window

opening and the glass. The primer adheres the ure-

thane adhesive to the backlite.(1) Roll down door glass.

(2) Remove headliner. (Refer to 23 - BODY/INTE-

RIOR/HEADLINER - REMOVAL).

(3) Remove rear closer panel trim. (Refer to 23 -

BODY/INTERIOR/REAR CLOSURE PANEL TRIM -

REMOVAL).

(4) Bend backlite retaining tabs (Fig. 1) inward

against glass.

(5) Using a suitable pneumatic knife from inside

the vehicle, cut urethane holding backlite frame to

opening fence.

(6) Separate glass from vehicle.

INSTALLATION

(1) Clean urethane adhesive from around backlite

opening fence.

Fig. 1 Backlite Tabs

1 - BACKLITE

2-TAB

BR/BESTATIONARY GLASS 23 - 145

Page 2719 of 2889

(2) If necessary, apply black-out primer to outer

edge of replacement backlite frame.

(3) If black-out primer was pre-applied on backlite,

clean bonding surface with Isopropyl alcohol and

clean lint free cloth. Allow 3 minutes for drying time.

(4) Apply black-out primer to backlite opening

fence.

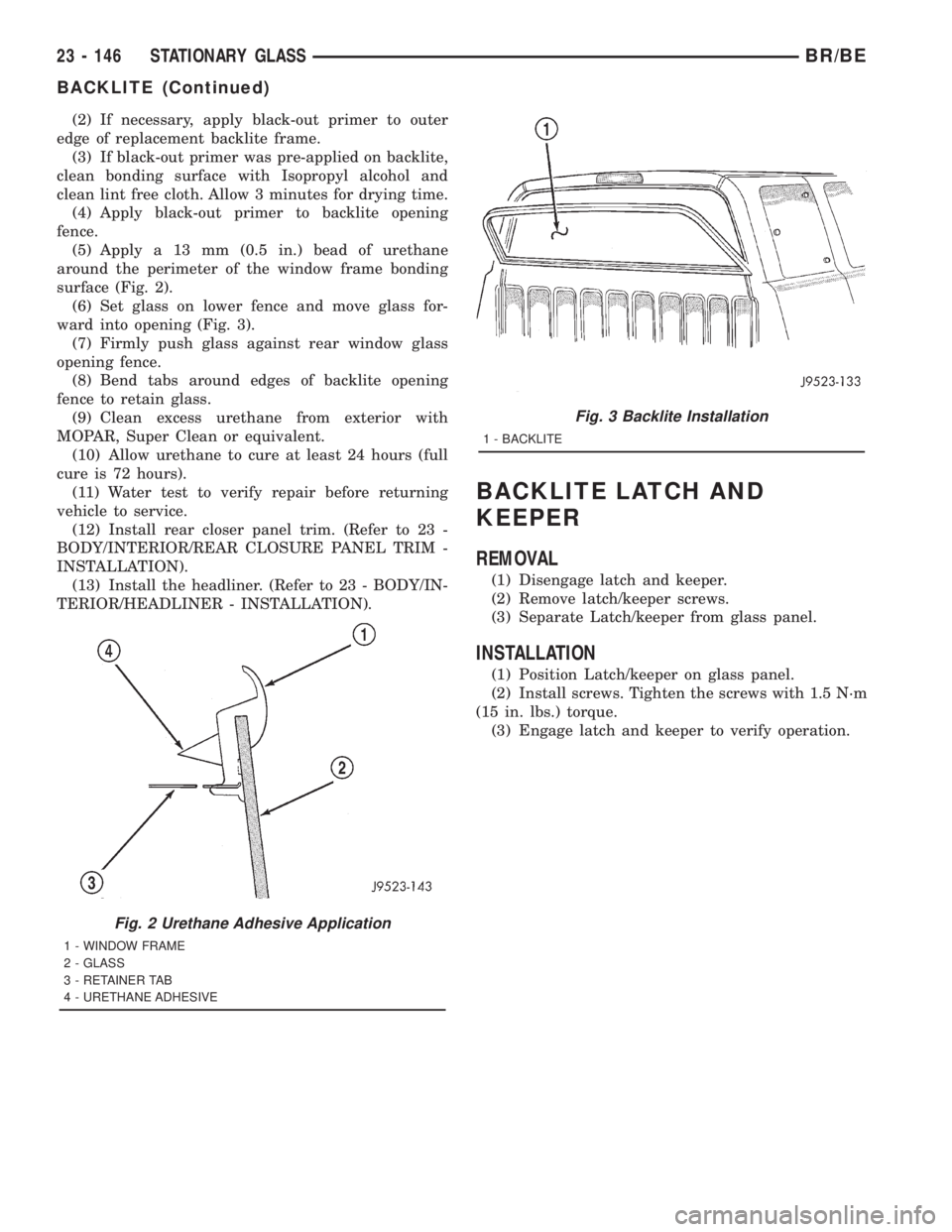

(5) Apply a 13 mm (0.5 in.) bead of urethane

around the perimeter of the window frame bonding

surface (Fig. 2).

(6) Set glass on lower fence and move glass for-

ward into opening (Fig. 3).

(7) Firmly push glass against rear window glass

opening fence.

(8) Bend tabs around edges of backlite opening

fence to retain glass.

(9) Clean excess urethane from exterior with

MOPAR, Super Clean or equivalent.

(10) Allow urethane to cure at least 24 hours (full

cure is 72 hours).

(11) Water test to verify repair before returning

vehicle to service.

(12) Install rear closer panel trim. (Refer to 23 -

BODY/INTERIOR/REAR CLOSURE PANEL TRIM -

INSTALLATION).

(13) Install the headliner. (Refer to 23 - BODY/IN-

TERIOR/HEADLINER - INSTALLATION).

BACKLITE LATCH AND

KEEPER

REMOVAL

(1) Disengage latch and keeper.

(2) Remove latch/keeper screws.

(3) Separate Latch/keeper from glass panel.

INSTALLATION

(1) Position Latch/keeper on glass panel.

(2) Install screws. Tighten the screws with 1.5 N´m

(15 in. lbs.) torque.

(3) Engage latch and keeper to verify operation.

Fig. 2 Urethane Adhesive Application

1 - WINDOW FRAME

2 - GLASS

3 - RETAINER TAB

4 - URETHANE ADHESIVE

Fig. 3 Backlite Installation

1 - BACKLITE

23 - 146 STATIONARY GLASSBR/BE

BACKLITE (Continued)

Page 2720 of 2889

BACKLITE VENT GLASS

REMOVAL

(1) Close and latch sliding vent glass.

(2) Remove rear closure panel trim, if necessary.

(Refer to 23 - BODY/INTERIOR/REAR CLOSURE

PANEL TRIM - REMOVAL).

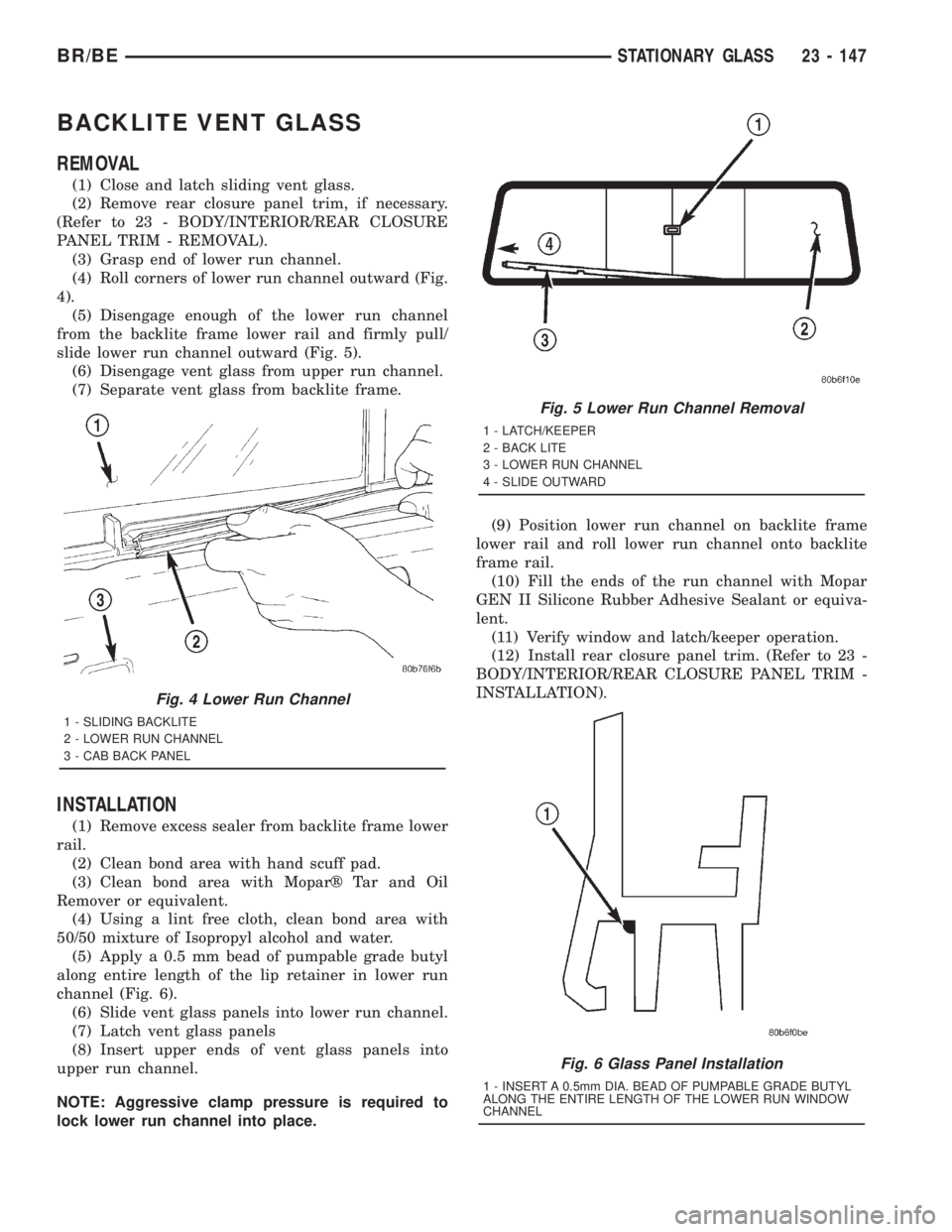

(3) Grasp end of lower run channel.

(4) Roll corners of lower run channel outward (Fig.

4).

(5) Disengage enough of the lower run channel

from the backlite frame lower rail and firmly pull/

slide lower run channel outward (Fig. 5).

(6) Disengage vent glass from upper run channel.

(7) Separate vent glass from backlite frame.

INSTALLATION

(1) Remove excess sealer from backlite frame lower

rail.

(2) Clean bond area with hand scuff pad.

(3) Clean bond area with Moparž Tar and Oil

Remover or equivalent.

(4) Using a lint free cloth, clean bond area with

50/50 mixture of Isopropyl alcohol and water.

(5) Apply a 0.5 mm bead of pumpable grade butyl

along entire length of the lip retainer in lower run

channel (Fig. 6).

(6) Slide vent glass panels into lower run channel.

(7) Latch vent glass panels

(8) Insert upper ends of vent glass panels into

upper run channel.

NOTE: Aggressive clamp pressure is required to

lock lower run channel into place.(9) Position lower run channel on backlite frame

lower rail and roll lower run channel onto backlite

frame rail.

(10) Fill the ends of the run channel with Mopar

GEN II Silicone Rubber Adhesive Sealant or equiva-

lent.

(11) Verify window and latch/keeper operation.

(12) Install rear closure panel trim. (Refer to 23 -

BODY/INTERIOR/REAR CLOSURE PANEL TRIM -

INSTALLATION).

Fig. 4 Lower Run Channel

1 - SLIDING BACKLITE

2 - LOWER RUN CHANNEL

3 - CAB BACK PANEL

Fig. 5 Lower Run Channel Removal

1 - LATCH/KEEPER

2 - BACK LITE

3 - LOWER RUN CHANNEL

4 - SLIDE OUTWARD

Fig. 6 Glass Panel Installation

1 - INSERT A 0.5mm DIA. BEAD OF PUMPABLE GRADE BUTYL

ALONG THE ENTIRE LENGTH OF THE LOWER RUN WINDOW

CHANNEL

BR/BESTATIONARY GLASS 23 - 147