display DODGE RAM 2002 Service Owner's Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2002, Model line: RAM, Model: DODGE RAM 2002Pages: 2255, PDF Size: 62.07 MB

Page 506 of 2255

remains illuminated until the cluster receives an

overdrive off lamp-off message from the PCM, or

until the ignition switch is turned to the Off position,

whichever occurs first.

²Actuator Test- Each time the cluster is put

through the actuator test, the indicator will be

turned on during the bulb check portion of the test to

confirm the functionality of the LED and the cluster

control circuitry.

The PCM continually monitors the overdrive off

switch to determine the proper outputs to the auto-

matic transmission, then sends the proper messages

to the instrument cluster. For further diagnosis of

the overdrive off indicator or the instrument cluster

circuitry that controls the LED, (Refer to 8 - ELEC-

TRICAL/INSTRUMENT CLUSTER - DIAGNOSIS

AND TESTING). For proper diagnosis of the over-

drive control system, the PCM, the CCD data bus, or

the message inputs to the instrument cluster that

control the overdrive off indicator, a DRBIIItscan

tool is required. Refer to the appropriate diagnostic

information.

SEATBELT INDICATOR

DESCRIPTION

A seatbelt indicator is standard equipment on all

instrument clusters. The seatbelt indicator is located

near the lower edge of the instrument cluster overlay,

to the right of center. The seatbelt indicator consists

of a stencilled cutout of the International Control and

Display Symbol icon for ªSeat Beltº in the opaque

layer of the instrument cluster overlay. The dark

outer layer of the overlay prevents the indicator from

being clearly visible when it is not illuminated. A red

lens behind the cutout in the opaque layer of the

overlay causes the icon to appear in red through the

translucent outer layer of the overlay when the indi-

cator is illuminated from behind by a Light Emitting

Diode (LED) soldered onto the instrument cluster

electronic circuit board. The seatbelt indicator is ser-

viced as a unit with the instrument cluster.

OPERATION

The seatbelt indicator gives an indication to the

vehicle operator of the status of the driver side front

seatbelt buckle. This indicator is controlled by a tran-

sistor on the instrument cluster circuit board based

upon the cluster programming, and a hard wired

input from the seatbelt switch in the driver side front

seatbelt through the seat belt switch sense circuit.

The seatbelt indicator Light Emitting Diode (LED)

receives battery current on the instrument cluster

electronic circuit board through the fused ignition

switch output (st-run) circuit whenever the ignitionswitch is in the On or Start positions; therefore, the

indicator will always be off when the ignition switch

is in any position except On or Start. The LED only

illuminates when it is switched to ground by the

instrument cluster transistor. The instrument cluster

will turn on the seatbelt indicator for the following

reasons:

²Seatbelt Reminder Function- Each time the

cluster receives a battery current input on the fused

ignition switch output (st-run) circuit, the indicator

will be illuminated as a seatbelt reminder for about

seven seconds, or until the ignition switch is turned

to the Off position, whichever occurs first. This

reminder function will occur regardless of the status

of the seatbelt switch input to the cluster.

²Driver Side Front Seatbelt Not Buckled-

Following the seatbelt reminder function, each time

the cluster receives a ground input on the seat belt

switch sense circuit (seatbelt switch closed - seatbelt

unbuckled) with the ignition switch in the Start or

On positions, the indicator will be illuminated. The

seatbelt indicator remains illuminated until the seat

belt switch sense input to the cluster is an open cir-

cuit (seatbelt switch opened - seatbelt buckled), or

until the ignition switch is turned to the Off position,

whichever occurs first.

²Actuator Test- Each time the cluster is put

through the actuator test, the indicator will be

turned on during the bulb check portion of the test to

confirm the functionality of the LED and the cluster

control circuitry.

The seatbelt switch input to the instrument cluster

circuitry can be diagnosed using conventional diag-

nostic tools and methods. For further diagnosis of the

seatbelt indicator or the instrument cluster circuitry

that controls the LED, (Refer to 8 - ELECTRICAL/

INSTRUMENT CLUSTER - DIAGNOSIS AND

TESTING).

SERVICE REMINDER

INDICATOR

DESCRIPTION

A Service Reminder Indicator (SRI) is standard

equipment on all instrument clusters. However, on

vehicles not equipped with certain optional heavy

duty emission cycle gasoline engines, this indicator is

electronically disabled. The SRI is located near the

lower edge of the instrument cluster overlay, to the

left of center. The SRI consists of a stencilled cutout

of the words ªMAINT REQDº in the opaque layer of

the instrument cluster overlay. The dark outer layer

of the overlay prevents the indicator from being

clearly visible when it is not illuminated. An amber

lens behind the cutout in the opaque layer of the

BR/BEINSTRUMENT CLUSTER 8J - 27

OVERDRIVE OFF INDICATOR (Continued)

Page 512 of 2255

OPERATION

The upshift indicator gives an indication to the

vehicle operator when the transmission should be

shifted to the next highest gear in order to achieve

the best fuel economy. This indicator is controlled by

a transistor on the instrument cluster circuit board

based upon the cluster programming and electronic

messages received by the cluster from the Powertrain

Control Module (PCM) over the Chrysler Collision

Detection (CCD) data bus. The upshift indicator bulb

receives battery current on the instrument cluster

electronic circuit board through the fused ignition

switch output (st-run) circuit whenever the ignition

switch is in the On or Start positions; therefore, the

lamp will always be off when the ignition switch is in

any position except On or Start. The bulb only illu-

minates when it is provided a path to ground by the

instrument cluster transistor. On models not

equipped with a manual transmission, the incandes-

cent bulb and bulb holder unit are not installed at

the factory when the vehicle is built. The instrument

cluster will turn on the upshift indicator for the fol-

lowing reasons:

²Upshift Lamp-On Message- Each time the

cluster receives an upshift lamp-on message from the

PCM indicating the engine speed and load conditions

are right for a transmission upshift to occur, the

upshift indicator is illuminated. The indicator

remains illuminated until the cluster receives an

upshift lamp-off message from the PCM or until the

ignition switch is turned to the Off position, which-

ever occurs first. The PCM will normally send an

upshift lamp-off message three to five seconds after a

lamp-on message, if an upshift is not performed. The

indicator will then remain off until the vehicle stops

accelerating and is brought back into the range of

indicator operation, or until the transmission is

shifted into another gear.

²Actuator Test- Each time the cluster is put

through the actuator test, the indicator will be

turned on during the bulb check portion of the test to

confirm the functionality of the indicator and the

cluster control circuitry.

The PCM continually monitors the engine speed

and load conditions to determine the proper fuel and

ignition requirements. The PCM then sends the

proper messages to the instrument cluster. If the

upshift indicator fails to light during normal vehicle

operation, replace the bulb with a known good unit.

For further diagnosis of the upshift indicator or the

instrument cluster circuitry that controls the indica-

tor, (Refer to 8 - ELECTRICAL/INSTRUMENT

CLUSTER - DIAGNOSIS AND TESTING). For

proper diagnosis of the PCM, the CCD data bus, or

the message inputs to the instrument cluster that

control the upshift indicator, a DRBIIItscan tool isrequired. Refer to the appropriate diagnostic infor-

mation.

VOLTAGE GAUGE

DESCRIPTION

A voltage gauge is standard equipment on all

instrument clusters. The voltage gauge is located in

the upper left quadrant of the instrument cluster,

above the temperature gauge. The voltage gauge con-

sists of a movable gauge needle or pointer controlled

by the instrument cluster circuitry and a fixed 90

degree scale on the cluster overlay that reads left-to-

right from 8 volts to 18 volts. An International Con-

trol and Display Symbol icon for ªBattery Charging

Conditionº is located directly below the lowest grad-

uation of the gauge scale. The voltage gauge graphics

are white against a black field except for a single red

graduation at each end of the gauge scale, making

them clearly visible within the instrument cluster in

daylight. When illuminated from behind by the panel

lamps dimmer controlled cluster illumination lighting

with the exterior lamps turned On, the white graph-

ics appear blue-green and the red graphics appear

red. The orange gauge needle is internally illumi-

nated. Gauge illumination is provided by replaceable

incandescent bulb and bulb holder units located on

the instrument cluster electronic circuit board. The

voltage gauge is serviced as a unit with the instru-

ment cluster.

OPERATION

The voltage gauge gives an indication to the vehi-

cle operator of the electrical system voltage. This

gauge is controlled by the instrument cluster circuit

board based upon the cluster programming and elec-

tronic messages received by the cluster from the

Powertrain Control Module (PCM) over the Chrysler

Collision Detection (CCD) data bus. The voltage

gauge is an air core magnetic unit that receives bat-

tery current on the instrument cluster electronic cir-

cuit board through the fused ignition switch output

(st-run) circuit whenever the ignition switch is in the

On or Start positions. The cluster is programmed to

move the gauge needle back to the low end of the

scale after the ignition switch is turned to the Off

position. The instrument cluster circuitry controls

the gauge needle position and provides the following

features:

²Charge Fail Message- Each time the cluster

receives a message from the PCM indicating a charge

fail condition (system voltage is 10.8 volts or lower),

the gauge needle is moved to the 8 volt graduation

on the gauge scale and the check gauges indicator is

illuminated. The gauge needle remains on the 8 volt

BR/BEINSTRUMENT CLUSTER 8J - 33

UPSHIFT INDICATOR (Continued)

Page 538 of 2255

(2) Engage license plate lamp wire connector to

body wire harness.

(3) Install screws attaching license plate panel to

cargo box.

(4) Connect the battery negative cable.

MARKER LAMP

REMOVAL

Individual lamps may be replaced by removing the

lamp from the light bar. Using a flat blade screw-

driver, carefully pry lamp to disengage clips attach-

ing ID lamp to retainer.

(1) Disconnect and isolate the battery negative

cable.

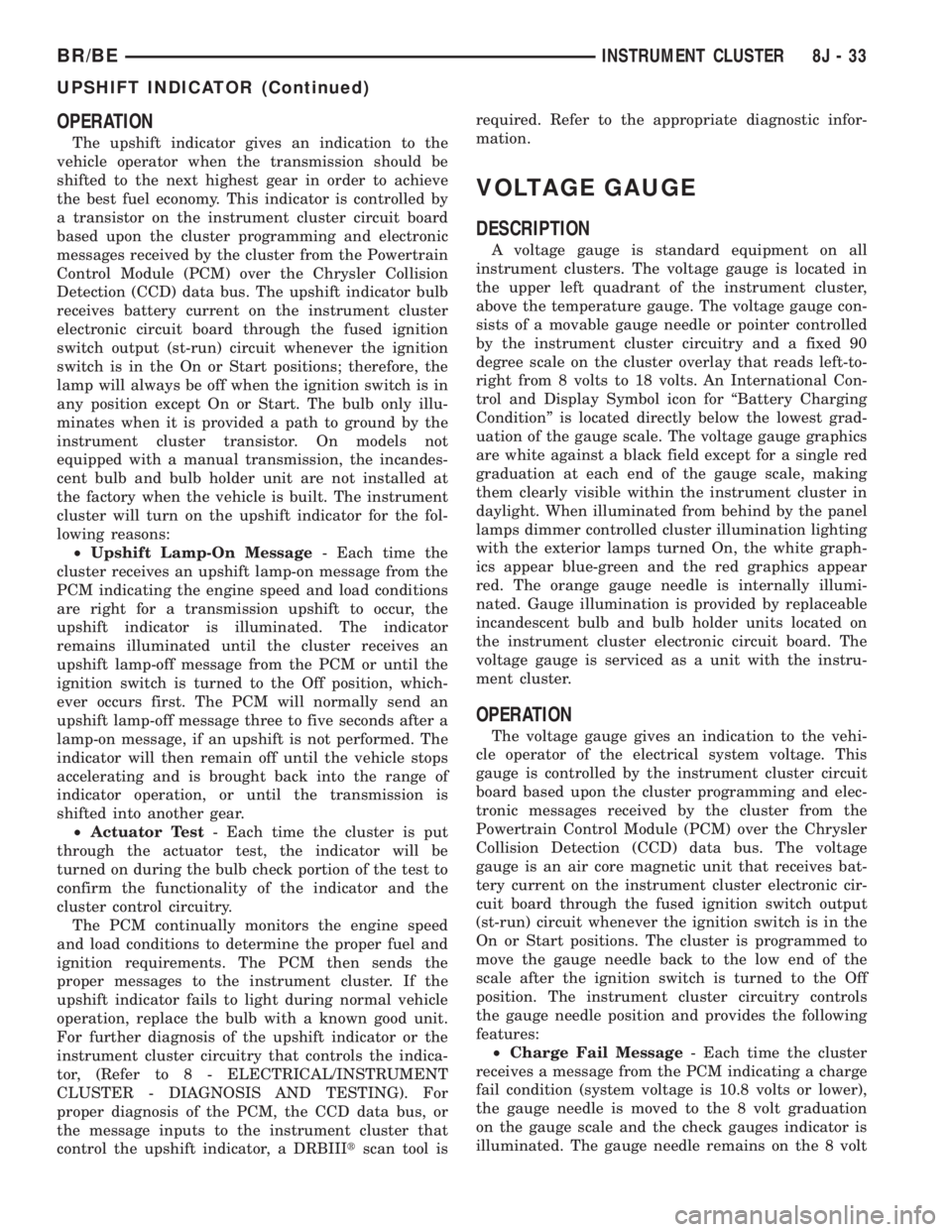

(2) Remove four screws attaching rear ID lamps to

tailgate (Fig. 23).

(3) Separate ID lamps from tailgate.

(4) Disengage ID lamp wire connector from body

wire harness.

(5) Separate ID lamp from vehicle.

INSTALLATION

(1) Position ID lamp on vehicle.

(2) Engage ID lamp wire connector to body wire

harness.

(3) Install screws attaching rear ID lamps to tail-

gate.

(4) Connect the battery negative cable.

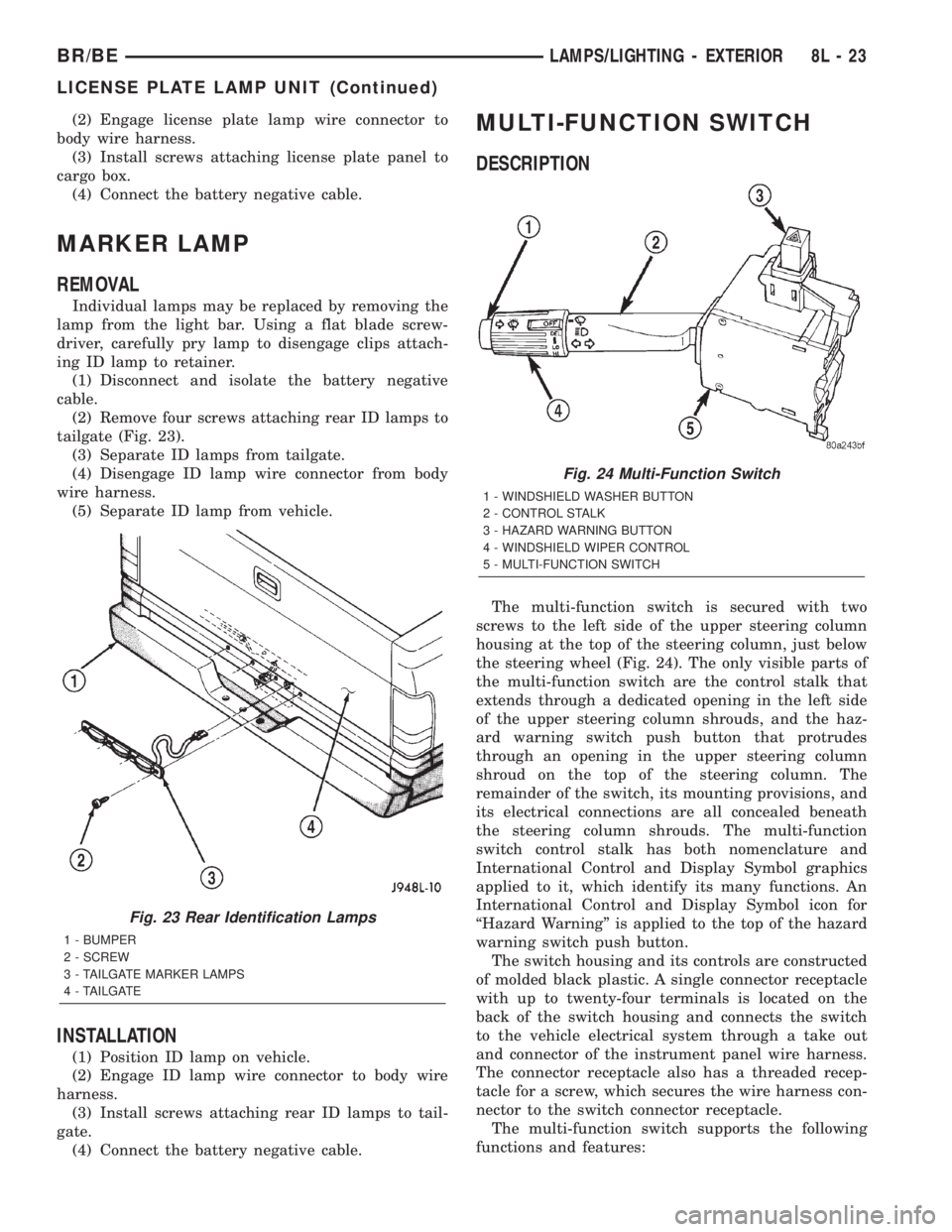

MULTI-FUNCTION SWITCH

DESCRIPTION

The multi-function switch is secured with two

screws to the left side of the upper steering column

housing at the top of the steering column, just below

the steering wheel (Fig. 24). The only visible parts of

the multi-function switch are the control stalk that

extends through a dedicated opening in the left side

of the upper steering column shrouds, and the haz-

ard warning switch push button that protrudes

through an opening in the upper steering column

shroud on the top of the steering column. The

remainder of the switch, its mounting provisions, and

its electrical connections are all concealed beneath

the steering column shrouds. The multi-function

switch control stalk has both nomenclature and

International Control and Display Symbol graphics

applied to it, which identify its many functions. An

International Control and Display Symbol icon for

ªHazard Warningº is applied to the top of the hazard

warning switch push button.

The switch housing and its controls are constructed

of molded black plastic. A single connector receptacle

with up to twenty-four terminals is located on the

back of the switch housing and connects the switch

to the vehicle electrical system through a take out

and connector of the instrument panel wire harness.

The connector receptacle also has a threaded recep-

tacle for a screw, which secures the wire harness con-

nector to the switch connector receptacle.

The multi-function switch supports the following

functions and features:

Fig. 23 Rear Identification Lamps

1 - BUMPER

2 - SCREW

3 - TAILGATE MARKER LAMPS

4 - TAILGATE

Fig. 24 Multi-Function Switch

1 - WINDSHIELD WASHER BUTTON

2 - CONTROL STALK

3 - HAZARD WARNING BUTTON

4 - WINDSHIELD WIPER CONTROL

5 - MULTI-FUNCTION SWITCH

BR/BELAMPS/LIGHTING - EXTERIOR 8L - 23

LICENSE PLATE LAMP UNIT (Continued)

Page 554 of 2255

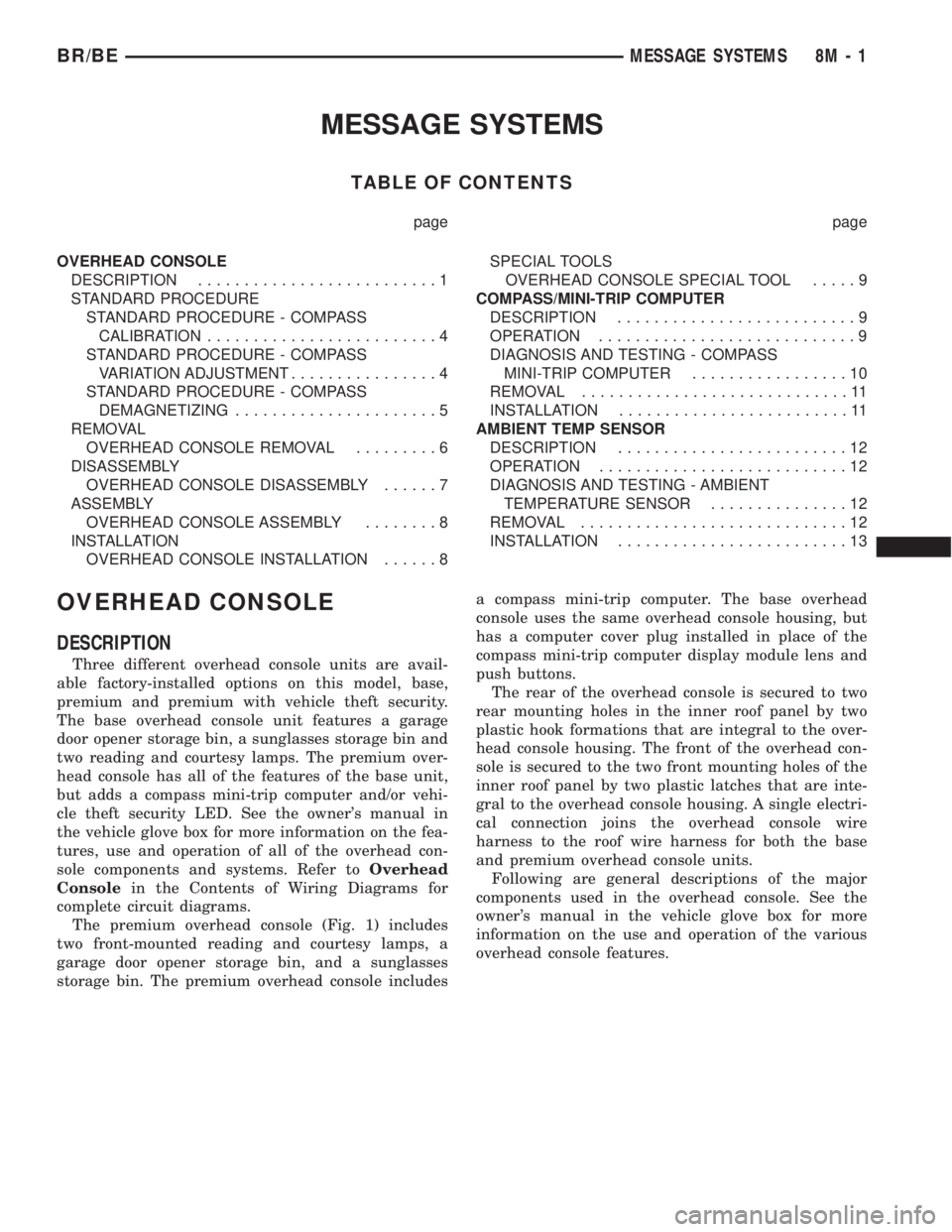

MESSAGE SYSTEMS

TABLE OF CONTENTS

page page

OVERHEAD CONSOLE

DESCRIPTION..........................1

STANDARD PROCEDURE

STANDARD PROCEDURE - COMPASS

CALIBRATION.........................4

STANDARD PROCEDURE - COMPASS

VARIATION ADJUSTMENT................4

STANDARD PROCEDURE - COMPASS

DEMAGNETIZING......................5

REMOVAL

OVERHEAD CONSOLE REMOVAL.........6

DISASSEMBLY

OVERHEAD CONSOLE DISASSEMBLY......7

ASSEMBLY

OVERHEAD CONSOLE ASSEMBLY........8

INSTALLATION

OVERHEAD CONSOLE INSTALLATION......8SPECIAL TOOLS

OVERHEAD CONSOLE SPECIAL TOOL.....9

COMPASS/MINI-TRIP COMPUTER

DESCRIPTION..........................9

OPERATION............................9

DIAGNOSIS AND TESTING - COMPASS

MINI-TRIP COMPUTER.................10

REMOVAL.............................11

INSTALLATION.........................11

AMBIENT TEMP SENSOR

DESCRIPTION.........................12

OPERATION...........................12

DIAGNOSIS AND TESTING - AMBIENT

TEMPERATURE SENSOR...............12

REMOVAL.............................12

INSTALLATION.........................13

OVERHEAD CONSOLE

DESCRIPTION

Three different overhead console units are avail-

able factory-installed options on this model, base,

premium and premium with vehicle theft security.

The base overhead console unit features a garage

door opener storage bin, a sunglasses storage bin and

two reading and courtesy lamps. The premium over-

head console has all of the features of the base unit,

but adds a compass mini-trip computer and/or vehi-

cle theft security LED. See the owner's manual in

the vehicle glove box for more information on the fea-

tures, use and operation of all of the overhead con-

sole components and systems. Refer toOverhead

Consolein the Contents of Wiring Diagrams for

complete circuit diagrams.

The premium overhead console (Fig. 1) includes

two front-mounted reading and courtesy lamps, a

garage door opener storage bin, and a sunglasses

storage bin. The premium overhead console includesa compass mini-trip computer. The base overhead

console uses the same overhead console housing, but

has a computer cover plug installed in place of the

compass mini-trip computer display module lens and

push buttons.

The rear of the overhead console is secured to two

rear mounting holes in the inner roof panel by two

plastic hook formations that are integral to the over-

head console housing. The front of the overhead con-

sole is secured to the two front mounting holes of the

inner roof panel by two plastic latches that are inte-

gral to the overhead console housing. A single electri-

cal connection joins the overhead console wire

harness to the roof wire harness for both the base

and premium overhead console units.

Following are general descriptions of the major

components used in the overhead console. See the

owner's manual in the vehicle glove box for more

information on the use and operation of the various

overhead console features.

BR/BEMESSAGE SYSTEMS 8M - 1

Page 556 of 2255

GARAGE DOOR OPENER STORAGE BIN

A compartment near the front of the overhead con-

sole is designed to hold most garage door opener

remote control transmitters. The transmitter is

mounted within the compartment with an adhesive-

backed hook and loop fastener patch and, when the

compartment is closed, a push button in the center of

the compartment door is depressed to actuate the

transmitter.

A transmitter mounting kit including the adhesive-

backed hook and loop fastener material is available

for service. The garage door opener storage bin door

and the push button with three assorted length

adapter pegs are also available for service replace-

ment.

The garage door opener storage compartment door

is opened by pressing the integral latch towards the

front of the vehicle. When the compartment door is

opened, the push button unit is removed from the

compartment by squeezing the latch tabs and pulling

the unit downward. With the push button removed,

the garage door opener can be installed in the com-

partment using the adhesive-backed hook and loop

fastener material provided.

With the transmitter mounted in the storage bin,

adapter pegs located on the garage door opener push

button unit are selected and mounted on one of two

posts on the back side of the push button. The com-

bination of the adapter peg length and the push but-

ton post location must be suitable to depress the

button of the transmitter when the push button in

the center of the garage door opener storage bin door

is depressed. When the proper combination has been

selected, the push button is reinstalled in the com-

partment and the compartment door is closed.

SUNGLASS STORAGE BIN

A sunglasses storage bin is included in the over-

head console. The storage bin is located near the rear

of the overhead console and is held in the closed posi-

tion by a latch that is integral to the storage bin

door. The interior of the bin is lined with a foam rub-

ber padding material to protect the sunglasses from

being scratched. Dampening springs that are located

on the back of the overhead console reading andcourtesy lamp housing contact the hinges of the sun-

glasses storage bin for a smooth opening action.

The sunglasses storage bin and door unit is avail-

able for service replacement. The hinge dampening

springs are serviced as a unit with the overhead con-

sole reading and courtesy lamp housing.

The sunglasses storage bin is opened by pressing

the latch on the rear edge of the door towards the

front of the vehicle, then pulling the bin downward to

the open position. The integral latch on the sun-

glasses bin door will automatically engage when the

bin is closed. See the owner's manual in the vehicle

glove box for more information on the use and oper-

ation of the sunglasses storage bin.

COMPASS

While in the compass/temperature mode, the com-

pass will display the direction in which the vehicle is

pointed using the eight major compass headings

(Examples: north is N, northeast is NE), along with

the outside ambient temperature. When the compass

unit is placed in the compass/compass in degrees

mode, the compass will display the direction the

vehicle is heading using the eight major compass

headings and in degrees (0 to 359 degrees). North is

0 degrees, East is 90 degrees, South is 180 degrees

and West is 270 degrees. It will not display the head-

ings in minutes or seconds.

The self-calibrating compass unit requires no

adjusting in normal use. The compass unit will com-

pensate for magnetism the body of the vehicle may

acquire during normal use. However, avoid placing

anything magnetic directly on the roof of the vehicle.

Magnetic mounts for an antenna, a repair order hat,

or a funeral procession flag can exceed the compen-

sating ability of the compass unit if placed on the

roof panel. If the vehicle roof should become magne-

tized, the demagnetizing and calibration procedures

found in this group may be required to restore proper

compass operation.

THERMOMETER

The thermometer displays the outside ambient

temperature in whole degrees. The temperature dis-

play can be changed from Fahrenheit to Celsius

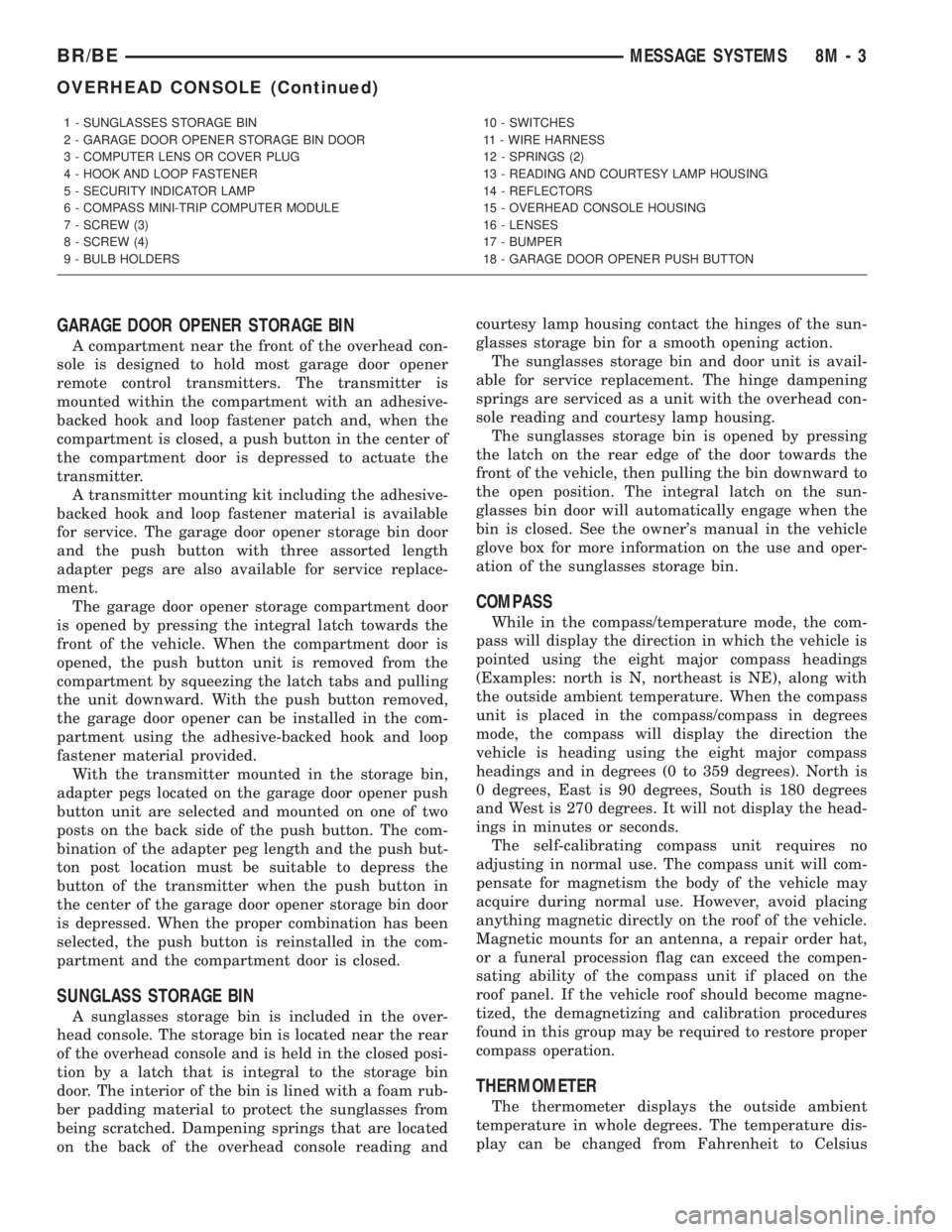

1 - SUNGLASSES STORAGE BIN

2 - GARAGE DOOR OPENER STORAGE BIN DOOR

3 - COMPUTER LENS OR COVER PLUG

4 - HOOK AND LOOP FASTENER

5 - SECURITY INDICATOR LAMP

6 - COMPASS MINI-TRIP COMPUTER MODULE

7 - SCREW (3)

8 - SCREW (4)

9 - BULB HOLDERS10 - SWITCHES

11 - WIRE HARNESS

12 - SPRINGS (2)

13 - READING AND COURTESY LAMP HOUSING

14 - REFLECTORS

15 - OVERHEAD CONSOLE HOUSING

16 - LENSES

17 - BUMPER

18 - GARAGE DOOR OPENER PUSH BUTTON

BR/BEMESSAGE SYSTEMS 8M - 3

OVERHEAD CONSOLE (Continued)

Page 557 of 2255

using the U.S./Metric push button. The displayed

temperature is not an instant reading of conditions,

but an average temperature. It may take the ther-

mometer display several minutes to respond to a

major temperature change, such as driving out of a

heated garage into winter temperatures.

When the ignition switch is turned to the Off posi-

tion, the last displayed temperature reading stays in

the thermometer unit memory. When the ignition

switch is turned to the On position again, the ther-

mometer will display the memory temperature if the

engine coolant temperature is above about 43É C

(109É F). If the engine coolant temperature is below

about 43É C (109É F), the thermometer will display

the actual temperature sensed by the ambient tem-

perature sensor. The thermometer temperature dis-

play update interval varies with the vehicle speed;

therefore, if the temperature reading seems inaccu-

rate, drive the vehicle for at least three minutes

while maintaining a speed of 48 kilometers-per-hour

(30 miles-per-hour) or higher.

The thermometer function is supported by an

ambient temperature sensor. The sensor is mounted

outside the passenger compartment near the front

and center of the vehicle, and is hard wired to the

module. The ambient temperature sensor is available

as a separate service item.

STANDARD PROCEDURE

STANDARD PROCEDURE - COMPASS

CALIBRATION

CAUTION: Do not place any external magnets, such

as magnetic roof mount antennas, in the vicinity of

the compass. Do not use magnetic tools when ser-

vicing the overhead console.

The electronic compass unit features a self-cali-

brating design, which simplifies the calibration pro-

cedure. This feature automatically updates the

compass calibration while the vehicle is being driven.

This allows the compass unit to compensate for small

changes in the residual magnetism that the vehicle

may acquire during normal use. If the compass read-

ings appear to be erratic or out of calibration, per-

form the following calibration procedure. Also, new

service replacement compass mini-trip computer

modules must have their compass calibrated using

this procedure. Do not attempt to calibrate the com-

pass near large metal objects such as other vehicles,

large buildings, or bridges; or, near overhead or

underground power lines.

(1) Start the engine. If the compass/temperature

data is not currently being displayed, momentarily

depress and release the Step push button to stepthrough the display options until you have reached

the compass/temperature display.

(2) Depress both the U.S./Metric and the Step

push buttons at the same time for more than six sec-

onds, until ªCALº appears in the display, then release

both push buttons. The ªCALº in the display indi-

cates that the compass is in the calibration mode.

(3) Drive the vehicle on a level surface, at least

fifty feet away from large metal objects and power

lines, in all four compass directions, such as driving

around a city block several times or driving in two to

three complete circles at a slow to medium speed.

(4) When the calibration is successfully completed,

ªCALº will disappear from the display and normal

compass mini-trip computer operation will resume.

NOTE: If the ªCALº message remains in the display,

either there is excessive magnetism near the com-

pass, or the unit is faulty. Repeat the calibration

procedure at least one more time.

NOTE: If the wrong direction is still indicated in the

compass display, the area selected for calibration

may be too close to a strong magnetic field. Repeat

the calibration procedure in another location.

STANDARD PROCEDURE - COMPASS

VARIATION ADJUSTMENT

Compass variance, also known as magnetic decli-

nation, is the difference in angle between magnetic

north and true geographic north. In some geographic

locations, the difference between magnetic and geo-

graphic north is great enough to cause the compass

to give false readings. If this problem occurs, the

compass variance must be set. There are two meth-

ods that can be used to enter this information into

the compass mini-trip computer module. They are

the zone method and the direct method.

ZONE METHOD

(1) Using the Variance Settings map, find your

geographic location and note the zone number (Fig.

2).

(2) Turn the ignition switch to the On position. If

the compass/temperature data is not currently being

displayed, momentarily depress and release the Step

push button to step through the display options until

you have reached the compass/temperature display.

(3) Depress both the U.S./Metric and the Step

push buttons at the same time and hold them down

for more than 100 milliseconds, but not more than

one second. The compass mini-trip computer will

enter the variation adjustment mode and ªVARº

along with the current variance zone will appear in

the display.

8M - 4 MESSAGE SYSTEMSBR/BE

OVERHEAD CONSOLE (Continued)

Page 558 of 2255

(4) Momentarily depress and release the Step push

button to step through the zone numbers, until the

zone number for your geographic location appears in

the display.

(5) After five seconds, the displayed zone will auto-

matically be set in the compass mini-trip computer

module memory and normal operation will resume.

(6) Confirm that the correct directions are now

indicated by the compass.

DIRECT METHOD

(1) Turn the vehicle so it is headed in either the

north or south direction. The vehicle must be headed

within 45 degrees of north or south for this procedure

to work. The vehicle may be moving or stationary.

(2) Turn the ignition switch to the On position. If

the compass/temperature data is not currently being

displayed, momentarily depress and release the Step

push button to step through the display options until

you have reached the compass/temperature display.

(3) Depress both the U.S./Metric and the Step

push buttons at the same time and hold them down

for more than 100 milliseconds, but not more than

one second. The compass mini-trip computer will

enter the variation adjustment mode and ªVARº

along with the current variance zone will appear in

the display.

(4) Within the next five seconds, momentarily

depress and release the U.S./Metric push button. The

variance zone will automatically be set in the com-pass mini-trip computer module memory and normal

operation will resume.

(5) If the ªVARº in the display flashes twice before

the compass mini-trip computer module resumes nor-

mal operation, the new variance zone setting was not

accepted. Reorient the vehicle so it is headed within

45 degrees of north or south and repeat this proce-

dure.

STANDARD PROCEDURE - COMPASS

DEMAGNETIZING

A degaussing tool (Special Tool 6029) is used to

demagnetize, or degauss, the overhead console for-

ward mounting screw and the roof panel above the

overhead console. Equivalent units must be rated as

continuous duty for 110/115 volts and 60 Hz. They

must also have a field strength of over 350 gauss at 7

millimeters (0.25 inch) beyond the tip of the probe.

To demagnetize the roof panel and the overhead

console forward mounting screw, proceed as follows:

(1) Be certain that the ignition switch is in the Off

position, before you begin the demagnetizing proce-

dure.

(2) Connect the degaussing tool to an electrical

outlet, while keeping the tool at least 61 centimeters

(2 feet) away from the compass unit.

(3) Slowly approach the head of the overhead con-

sole forward mounting screw with the degaussing

tool connected.

Fig. 2 Variance Settings

BR/BEMESSAGE SYSTEMS 8M - 5

OVERHEAD CONSOLE (Continued)

Page 560 of 2255

DISASSEMBLY

OVERHEAD CONSOLE DISASSEMBLY

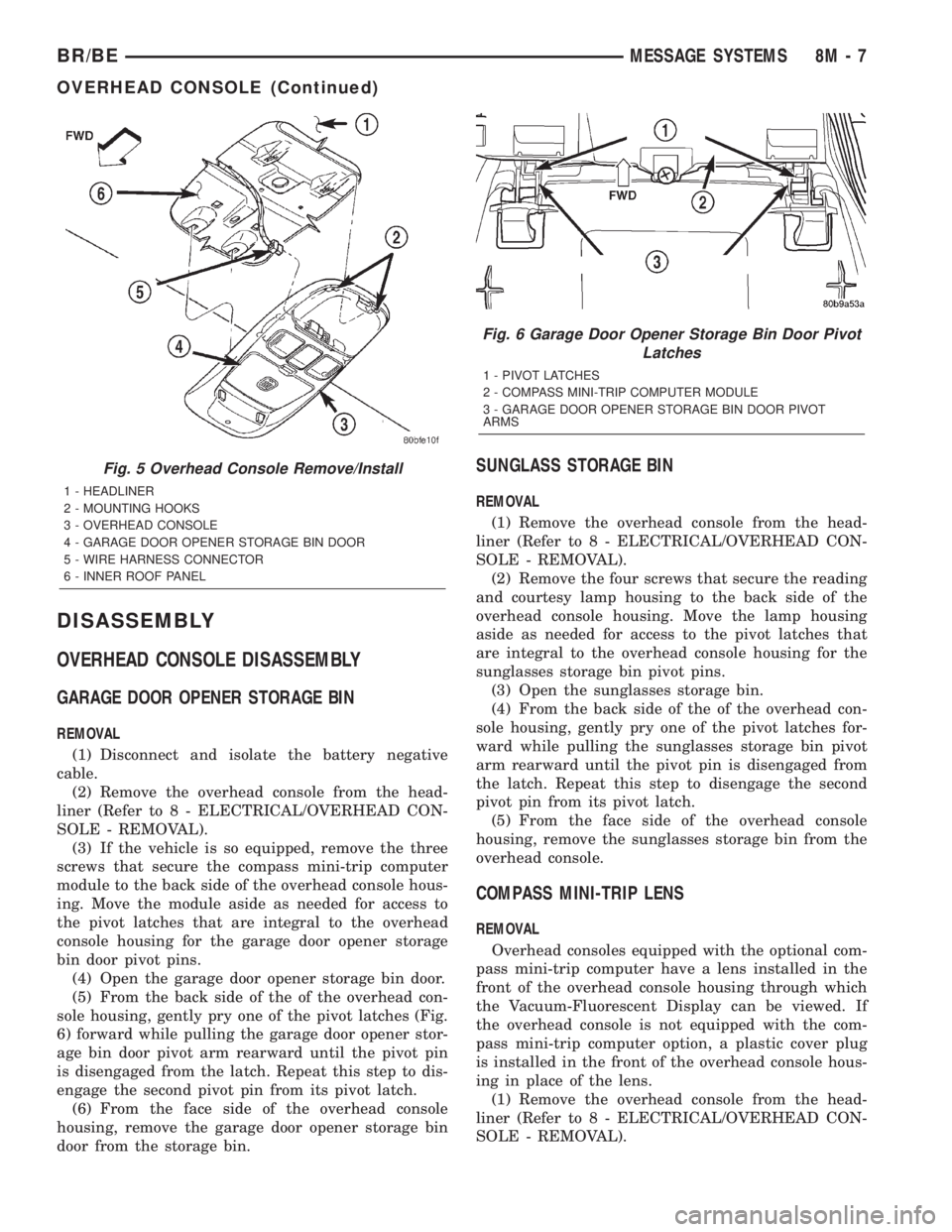

GARAGE DOOR OPENER STORAGE BIN

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the overhead console from the head-

liner (Refer to 8 - ELECTRICAL/OVERHEAD CON-

SOLE - REMOVAL).

(3) If the vehicle is so equipped, remove the three

screws that secure the compass mini-trip computer

module to the back side of the overhead console hous-

ing. Move the module aside as needed for access to

the pivot latches that are integral to the overhead

console housing for the garage door opener storage

bin door pivot pins.

(4) Open the garage door opener storage bin door.

(5) From the back side of the of the overhead con-

sole housing, gently pry one of the pivot latches (Fig.

6) forward while pulling the garage door opener stor-

age bin door pivot arm rearward until the pivot pin

is disengaged from the latch. Repeat this step to dis-

engage the second pivot pin from its pivot latch.

(6) From the face side of the overhead console

housing, remove the garage door opener storage bin

door from the storage bin.

SUNGLASS STORAGE BIN

REMOVAL

(1) Remove the overhead console from the head-

liner (Refer to 8 - ELECTRICAL/OVERHEAD CON-

SOLE - REMOVAL).

(2) Remove the four screws that secure the reading

and courtesy lamp housing to the back side of the

overhead console housing. Move the lamp housing

aside as needed for access to the pivot latches that

are integral to the overhead console housing for the

sunglasses storage bin pivot pins.

(3) Open the sunglasses storage bin.

(4) From the back side of the of the overhead con-

sole housing, gently pry one of the pivot latches for-

ward while pulling the sunglasses storage bin pivot

arm rearward until the pivot pin is disengaged from

the latch. Repeat this step to disengage the second

pivot pin from its pivot latch.

(5) From the face side of the overhead console

housing, remove the sunglasses storage bin from the

overhead console.

COMPASS MINI-TRIP LENS

REMOVAL

Overhead consoles equipped with the optional com-

pass mini-trip computer have a lens installed in the

front of the overhead console housing through which

the Vacuum-Fluorescent Display can be viewed. If

the overhead console is not equipped with the com-

pass mini-trip computer option, a plastic cover plug

is installed in the front of the overhead console hous-

ing in place of the lens.

(1) Remove the overhead console from the head-

liner (Refer to 8 - ELECTRICAL/OVERHEAD CON-

SOLE - REMOVAL).

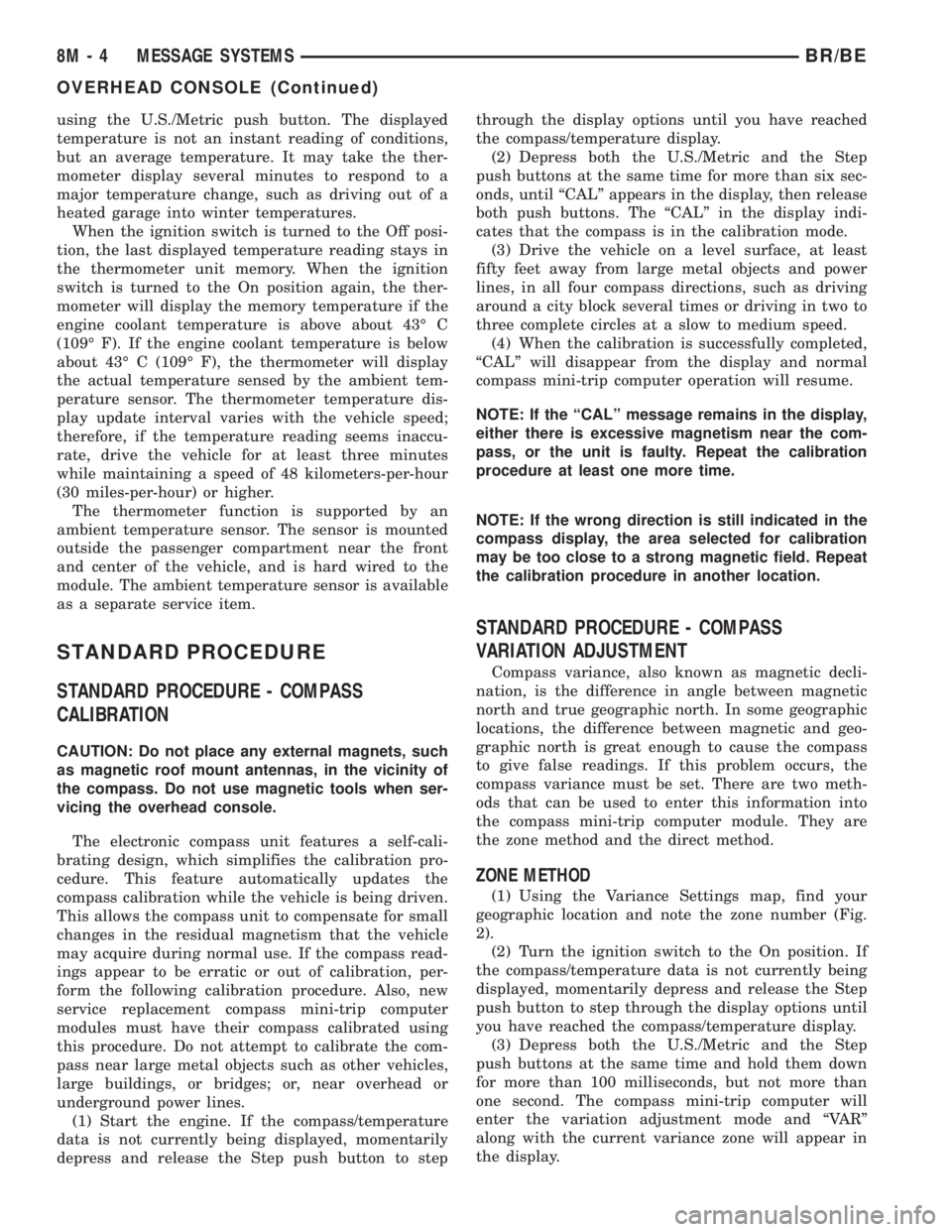

Fig. 5 Overhead Console Remove/Install

1 - HEADLINER

2 - MOUNTING HOOKS

3 - OVERHEAD CONSOLE

4 - GARAGE DOOR OPENER STORAGE BIN DOOR

5 - WIRE HARNESS CONNECTOR

6 - INNER ROOF PANEL

Fig. 6 Garage Door Opener Storage Bin Door Pivot

Latches

1 - PIVOT LATCHES

2 - COMPASS MINI-TRIP COMPUTER MODULE

3 - GARAGE DOOR OPENER STORAGE BIN DOOR PIVOT

ARMS

BR/BEMESSAGE SYSTEMS 8M - 7

OVERHEAD CONSOLE (Continued)

Page 561 of 2255

(2) If the vehicle is so equipped, remove the com-

pass mini-trip computer module from the overhead

console (Refer to 8 - ELECTRICAL/OVERHEAD

CONSOLE/COMPASS/MINI-TRIP COMPUTER -

REMOVAL).

(3) From the back side of the overhead console,

push downward firmly and evenly on the rear of the

trip computer lens to disengage the rear mounting

boss, or the snap features of the cover plug from the

overhead console housing.

(4) From the face of the overhead console, pull the

trip computer lens or the cover plug rearward far

enough to disengage the four forward mounting tabs

from the overhead console housing.

(5) Remove the trip computer lens or the cover

plug from the overhead console housing.

ASSEMBLY

OVERHEAD CONSOLE ASSEMBLY

GARAGE DOOR OPENER STORAGE BIN

INSTALLATION

(1) From the face side of the overhead console

housing, position the garage door opener storage bin

door pivot arms through the openings in the front of

the storage bin.

(2) From the back side of the of the overhead con-

sole housing, align one of the pivot pins of the garage

door opener storage bin door with the pivot latch

integral to the overhead console housing. Press the

pivot arm forward until the pivot pin is engaged in

the latch. Repeat this step to engage the second pivot

pin with its pivot latch.

(3) Close the garage door opener storage bin door.

(4) If the vehicle is so equipped, position the com-

pass mini-trip computer module to the back side of

the overhead console housing. Install and tighten the

three screws that secure the module to the housing.

Tighten the screws to 2.2 N´m (20 in. lbs.).

(5) Install the overhead console onto the headliner

(Refer to 8 - ELECTRICAL/OVERHEAD CONSOLE -

INSTALLATION).

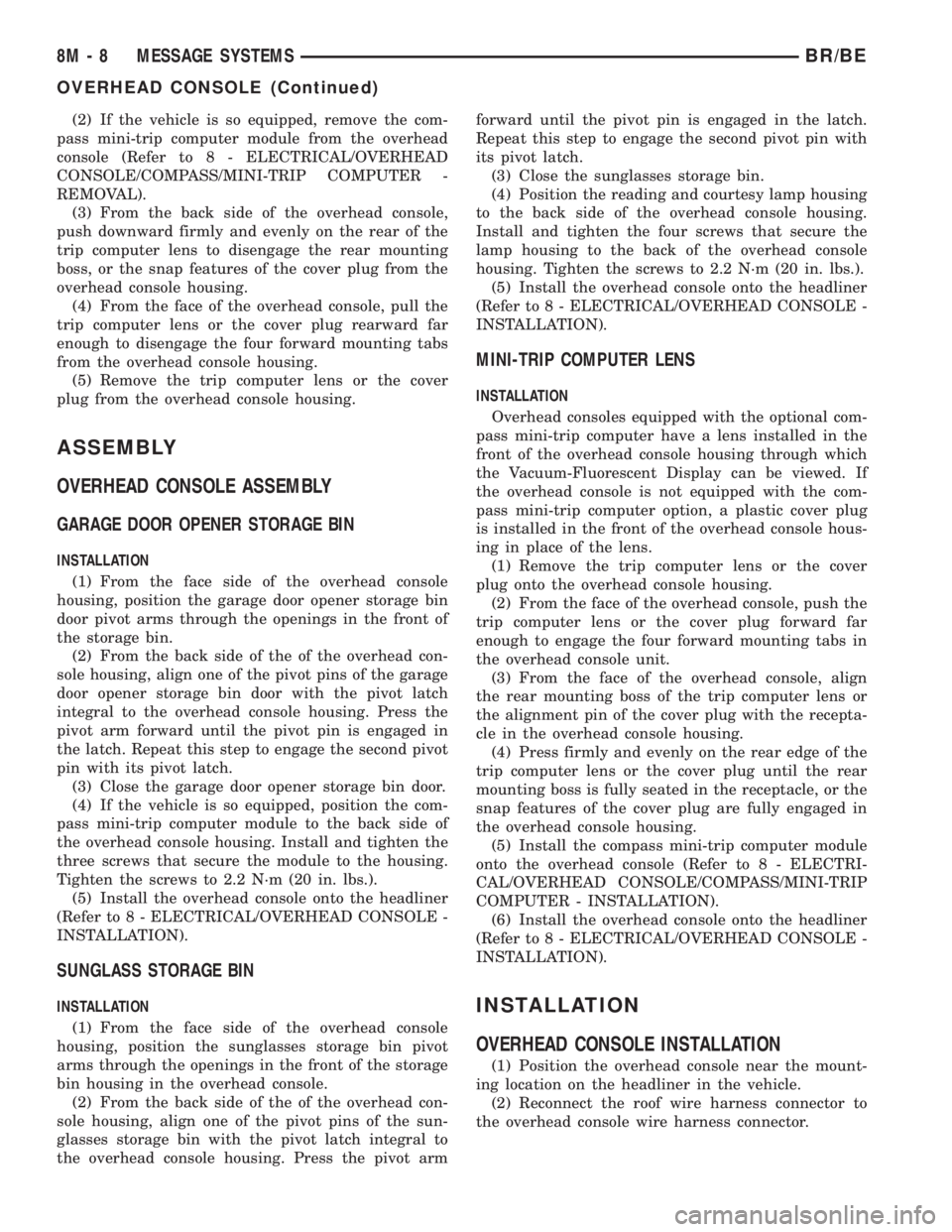

SUNGLASS STORAGE BIN

INSTALLATION

(1) From the face side of the overhead console

housing, position the sunglasses storage bin pivot

arms through the openings in the front of the storage

bin housing in the overhead console.

(2) From the back side of the of the overhead con-

sole housing, align one of the pivot pins of the sun-

glasses storage bin with the pivot latch integral to

the overhead console housing. Press the pivot armforward until the pivot pin is engaged in the latch.

Repeat this step to engage the second pivot pin with

its pivot latch.

(3) Close the sunglasses storage bin.

(4) Position the reading and courtesy lamp housing

to the back side of the overhead console housing.

Install and tighten the four screws that secure the

lamp housing to the back of the overhead console

housing. Tighten the screws to 2.2 N´m (20 in. lbs.).

(5) Install the overhead console onto the headliner

(Refer to 8 - ELECTRICAL/OVERHEAD CONSOLE -

INSTALLATION).

MINI-TRIP COMPUTER LENS

INSTALLATION

Overhead consoles equipped with the optional com-

pass mini-trip computer have a lens installed in the

front of the overhead console housing through which

the Vacuum-Fluorescent Display can be viewed. If

the overhead console is not equipped with the com-

pass mini-trip computer option, a plastic cover plug

is installed in the front of the overhead console hous-

ing in place of the lens.

(1) Remove the trip computer lens or the cover

plug onto the overhead console housing.

(2) From the face of the overhead console, push the

trip computer lens or the cover plug forward far

enough to engage the four forward mounting tabs in

the overhead console unit.

(3) From the face of the overhead console, align

the rear mounting boss of the trip computer lens or

the alignment pin of the cover plug with the recepta-

cle in the overhead console housing.

(4) Press firmly and evenly on the rear edge of the

trip computer lens or the cover plug until the rear

mounting boss is fully seated in the receptacle, or the

snap features of the cover plug are fully engaged in

the overhead console housing.

(5) Install the compass mini-trip computer module

onto the overhead console (Refer to 8 - ELECTRI-

CAL/OVERHEAD CONSOLE/COMPASS/MINI-TRIP

COMPUTER - INSTALLATION).

(6) Install the overhead console onto the headliner

(Refer to 8 - ELECTRICAL/OVERHEAD CONSOLE -

INSTALLATION).

INSTALLATION

OVERHEAD CONSOLE INSTALLATION

(1) Position the overhead console near the mount-

ing location on the headliner in the vehicle.

(2) Reconnect the roof wire harness connector to

the overhead console wire harness connector.

8M - 8 MESSAGE SYSTEMSBR/BE

OVERHEAD CONSOLE (Continued)

Page 562 of 2255

(3) Engage the two mounting hooks on the rear of

the overhead console housing in the mounting holes

in the inner roof panel.

(4) Slide the overhead console forward far enough

to align the two latches on the front of the housing

with their receptacles in the inner roof panel.

(5) Push upward firmly and evenly on the front of

the overhead console until each of the two latches is

fully engaged in its receptacle in the inner roof panel.

(6) Close the garage door opener storage bin door.

(7) Reconnect the battery negative cable.

SPECIAL TOOLS

OVERHEAD CONSOLE SPECIAL TOOL

COMPASS/MINI-TRIP

COMPUTER

DESCRIPTION

The compass mini-trip computer is located in the

premium overhead console on models equipped with

this option. Two compass mini-trip computer units

are available. One unit is used on vehicles not

equipped with the Vehicle Theft Security System

(VTSS) option, and the other is used on vehicles with

the VTSS option. Both compass mini-trip computer

units include the electronic control module, a Vacu-

um-Fluorescent Display (VFD), a compass flux-gate

unit and two push button function switches.

Compass mini-trip computer units for vehicles

equipped with the VTSS include a red Light-Emit-

ting Diode (LED) on their electronic circuit board.

This LED protrudes through the bottom of the lens

on the front of the overhead console unit, and serves

as the security indicator lamp. Refer toSecurity

Indicator Lampin Vehicle Theft/Security Systems

for more information on this feature.

The compass mini-trip computer module contains a

central processing unit and interfaces with other

electronic modules in the vehicle on the Chrysler Col-

lision Detection (CCD) data bus network. The CCD

data bus network allows the sharing of sensor infor-

mation. This helps to reduce wire harness complexity,

reduce internal controller hardware, and reduce com-

ponent sensor current loads. At the same time, thissystem provides increased reliability, enhanced diag-

nostics, and allows the addition of many new feature

capabilities.

The compass mini-trip computer provides several

electronic functions and features. Some of the func-

tions and features that the compass mini-trip com-

puter module supports and/or controls, include the

following display options:

²Compass and temperature- provides the out-

side temperature and one of eight compass readings

to indicate the direction the vehicle is facing.

²Compass and compass in degrees- provides

one of eight compass readings to indicate the direc-

tion the vehicle is facing and provides the compass

direction in degrees.

²Trip odometer (ODO)- shows the distance

travelled since the last trip computer reset.

²Average fuel economy (AVG ECO)- shows

the average fuel economy since the last trip computer

reset.

²Instant fuel economy (ECO)- shows the

present fuel economy based upon the current vehicle

distance and fuel used information.

²Distance to empty (DTE)- shows the esti-

mated distance that can be travelled with the fuel

remaining in the fuel tank. This estimated distance

is computed using the average miles-per-gallon from

the last 30 gallons of fuel used.

²Elapsed time (ET)- shows the accumulated

ignition-on time since the last trip computer reset.

²Blank screen- the compass mini-trip VFD is

turned off.

The ambient temperature sensor is hard wired to

the compass mini-trip computer module. Data input

for all other compass mini-trip computer functions,

including VFD dimming level, is received through

CCD data bus messages. The compass mini-trip com-

puter uses its internal programming and all of these

inputs to calculate and display the requested data. If

the data displayed is incorrect, perform the self-diag-

nostic tests as described in this group. If these tests

prove inconclusive, the use of a DRBIIItscan tool

and the proper Diagnostic Procedures manual are

recommended for further testing of the compass

mini-trip computer module and the CCD data bus.

The compass mini-trip computer module cannot be

repaired, and is available for service only as a unit. If

faulty or damaged, the complete module must be

replaced.

OPERATION

The compass mini-trip computer only operates with

the ignition switch in the On position. When the igni-

tion switch is turned to the On position, all of the

segments in the compass mini-trip computer VFD

will be turned on for one second, then the display

Degaussing Tool 6029

BR/BEMESSAGE SYSTEMS 8M - 9

OVERHEAD CONSOLE (Continued)