display DODGE RAM 2002 Service Manual PDF

[x] Cancel search | Manufacturer: DODGE, Model Year: 2002, Model line: RAM, Model: DODGE RAM 2002Pages: 2255, PDF Size: 62.07 MB

Page 2194 of 2255

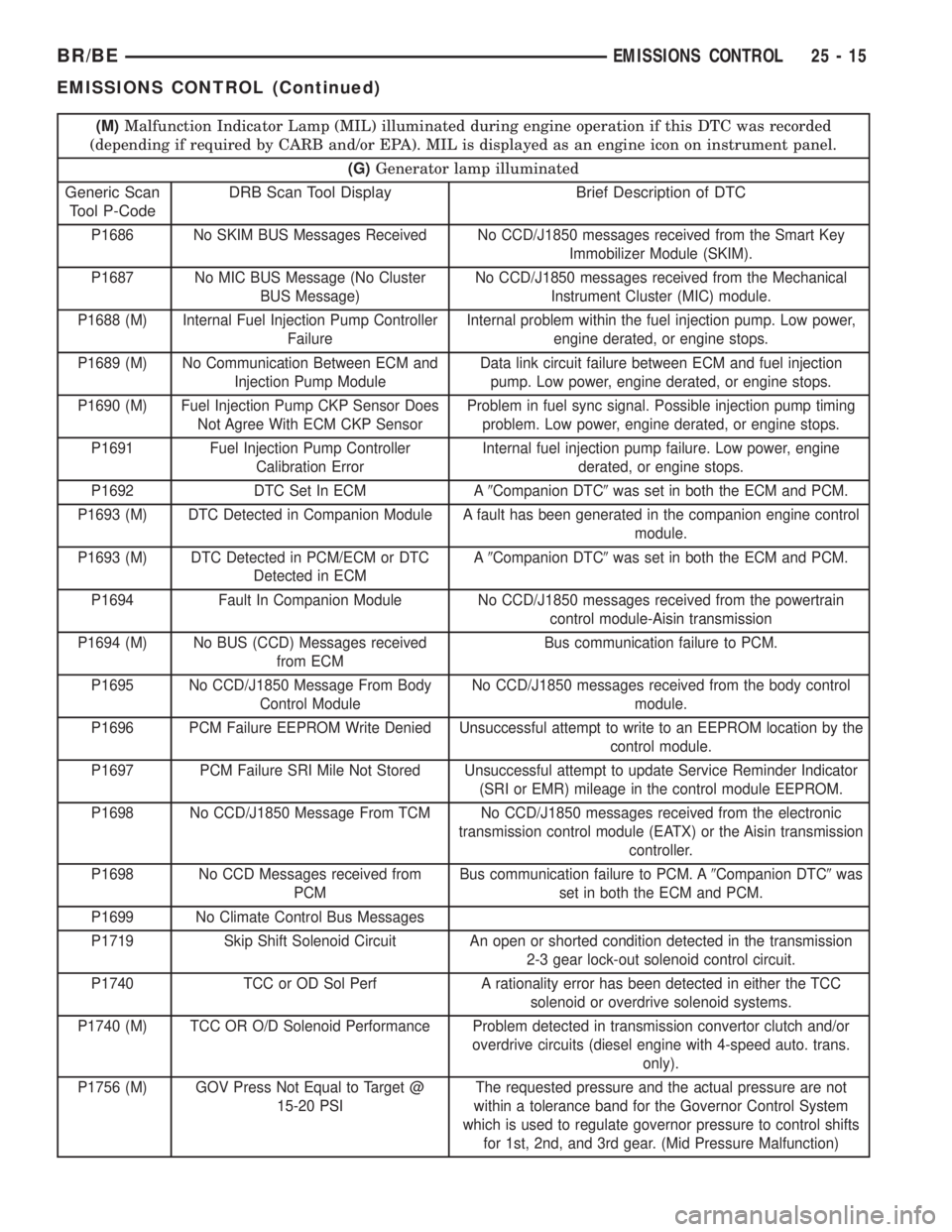

(M)Malfunction Indicator Lamp (MIL) illuminated during engine operation if this DTC was recorded

(depending if required by CARB and/or EPA). MIL is displayed as an engine icon on instrument panel.

(G)Generator lamp illuminated

Generic Scan

Tool P-CodeDRB Scan Tool Display Brief Description of DTC

P1686 No SKIM BUS Messages Received No CCD/J1850 messages received from the Smart Key

Immobilizer Module (SKIM).

P1687 No MIC BUS Message (No Cluster

BUS Message)No CCD/J1850 messages received from the Mechanical

Instrument Cluster (MIC) module.

P1688 (M) Internal Fuel Injection Pump Controller

FailureInternal problem within the fuel injection pump. Low power,

engine derated, or engine stops.

P1689 (M) No Communication Between ECM and

Injection Pump ModuleData link circuit failure between ECM and fuel injection

pump. Low power, engine derated, or engine stops.

P1690 (M) Fuel Injection Pump CKP Sensor Does

Not Agree With ECM CKP SensorProblem in fuel sync signal. Possible injection pump timing

problem. Low power, engine derated, or engine stops.

P1691 Fuel Injection Pump Controller

Calibration ErrorInternal fuel injection pump failure. Low power, engine

derated, or engine stops.

P1692 DTC Set In ECM A9Companion DTC9was set in both the ECM and PCM.

P1693 (M) DTC Detected in Companion Module A fault has been generated in the companion engine control

module.

P1693 (M) DTC Detected in PCM/ECM or DTC

Detected in ECMA9Companion DTC9was set in both the ECM and PCM.

P1694 Fault In Companion Module No CCD/J1850 messages received from the powertrain

control module-Aisin transmission

P1694 (M) No BUS (CCD) Messages received

from ECMBus communication failure to PCM.

P1695 No CCD/J1850 Message From Body

Control ModuleNo CCD/J1850 messages received from the body control

module.

P1696 PCM Failure EEPROM Write Denied Unsuccessful attempt to write to an EEPROM location by the

control module.

P1697 PCM Failure SRI Mile Not Stored Unsuccessful attempt to update Service Reminder Indicator

(SRI or EMR) mileage in the control module EEPROM.

P1698 No CCD/J1850 Message From TCM No CCD/J1850 messages received from the electronic

transmission control module (EATX) or the Aisin transmission

controller.

P1698 No CCD Messages received from

PCMBus communication failure to PCM. A9Companion DTC9was

set in both the ECM and PCM.

P1699 No Climate Control Bus Messages

P1719 Skip Shift Solenoid Circuit An open or shorted condition detected in the transmission

2-3 gear lock-out solenoid control circuit.

P1740 TCC or OD Sol Perf A rationality error has been detected in either the TCC

solenoid or overdrive solenoid systems.

P1740 (M) TCC OR O/D Solenoid Performance Problem detected in transmission convertor clutch and/or

overdrive circuits (diesel engine with 4-speed auto. trans.

only).

P1756 (M) GOV Press Not Equal to Target @

15-20 PSIThe requested pressure and the actual pressure are not

within a tolerance band for the Governor Control System

which is used to regulate governor pressure to control shifts

for 1st, 2nd, and 3rd gear. (Mid Pressure Malfunction)

BR/BEEMISSIONS CONTROL 25 - 15

EMISSIONS CONTROL (Continued)

Page 2195 of 2255

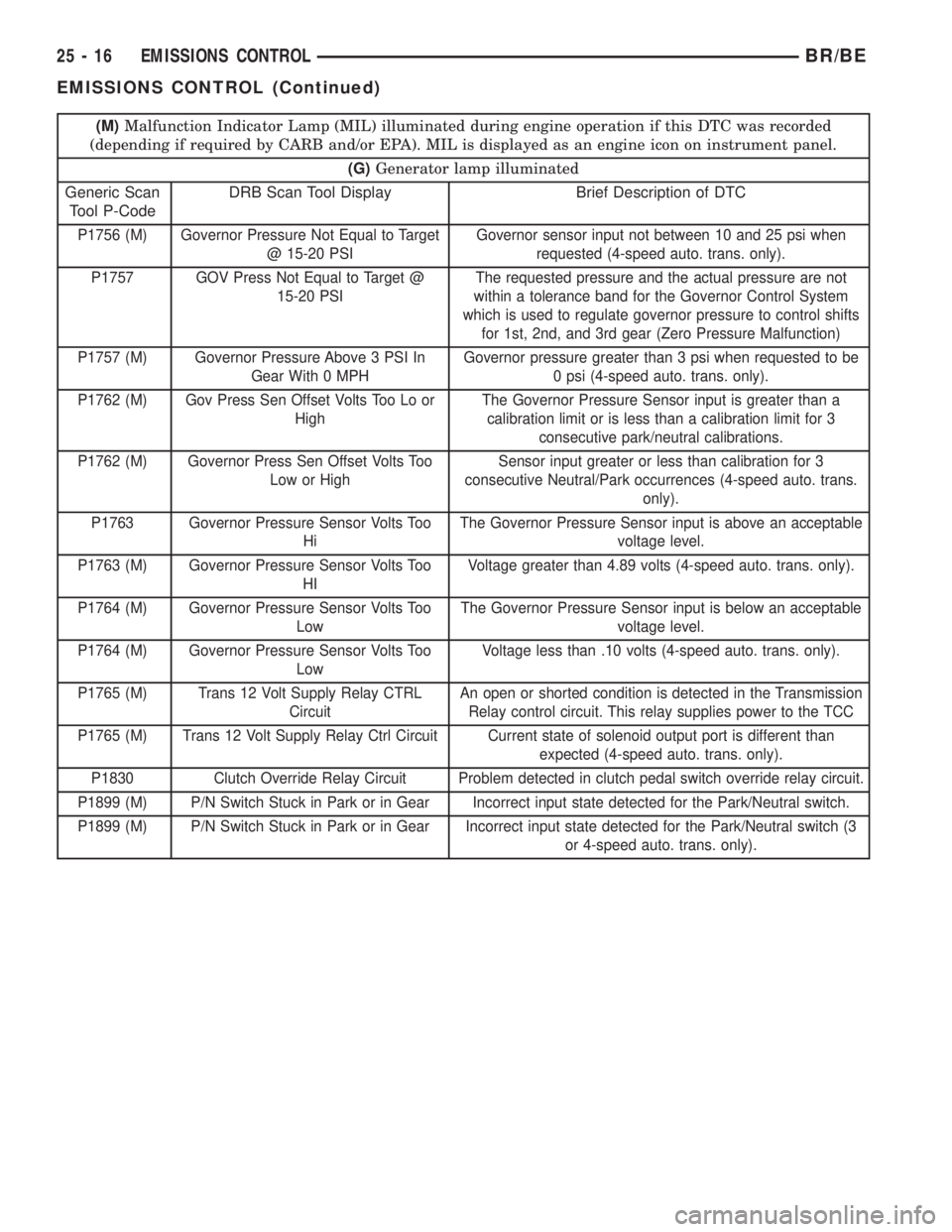

(M)Malfunction Indicator Lamp (MIL) illuminated during engine operation if this DTC was recorded

(depending if required by CARB and/or EPA). MIL is displayed as an engine icon on instrument panel.

(G)Generator lamp illuminated

Generic Scan

Tool P-CodeDRB Scan Tool Display Brief Description of DTC

P1756 (M) Governor Pressure Not Equal to Target

@ 15-20 PSIGovernor sensor input not between 10 and 25 psi when

requested (4-speed auto. trans. only).

P1757 GOV Press Not Equal to Target @

15-20 PSIThe requested pressure and the actual pressure are not

within a tolerance band for the Governor Control System

which is used to regulate governor pressure to control shifts

for 1st, 2nd, and 3rd gear (Zero Pressure Malfunction)

P1757 (M) Governor Pressure Above 3 PSI In

Gear With 0 MPHGovernor pressure greater than 3 psi when requested to be

0 psi (4-speed auto. trans. only).

P1762 (M) Gov Press Sen Offset Volts Too Lo or

HighThe Governor Pressure Sensor input is greater than a

calibration limit or is less than a calibration limit for 3

consecutive park/neutral calibrations.

P1762 (M) Governor Press Sen Offset Volts Too

Low or HighSensor input greater or less than calibration for 3

consecutive Neutral/Park occurrences (4-speed auto. trans.

only).

P1763 Governor Pressure Sensor Volts Too

HiThe Governor Pressure Sensor input is above an acceptable

voltage level.

P1763 (M) Governor Pressure Sensor Volts Too

HIVoltage greater than 4.89 volts (4-speed auto. trans. only).

P1764 (M) Governor Pressure Sensor Volts Too

LowThe Governor Pressure Sensor input is below an acceptable

voltage level.

P1764 (M) Governor Pressure Sensor Volts Too

LowVoltage less than .10 volts (4-speed auto. trans. only).

P1765 (M) Trans 12 Volt Supply Relay CTRL

CircuitAn open or shorted condition is detected in the Transmission

Relay control circuit. This relay supplies power to the TCC

P1765 (M) Trans 12 Volt Supply Relay Ctrl Circuit Current state of solenoid output port is different than

expected (4-speed auto. trans. only).

P1830 Clutch Override Relay Circuit Problem detected in clutch pedal switch override relay circuit.

P1899 (M) P/N Switch Stuck in Park or in Gear Incorrect input state detected for the Park/Neutral switch.

P1899 (M) P/N Switch Stuck in Park or in Gear Incorrect input state detected for the Park/Neutral switch (3

or 4-speed auto. trans. only).

25 - 16 EMISSIONS CONTROLBR/BE

EMISSIONS CONTROL (Continued)

Page 2196 of 2255

DESCRIPTION - TASK MANAGER

The PCM is responsible for efficiently coordinating

the operation of all the emissions-related compo-

nents. The PCM is also responsible for determining if

the diagnostic systems are operating properly. The

software designed to carry out these responsibilities

is call the 'Task Manager'.

DESCRIPTION - MONITORED SYSTEMS

There are new electronic circuit monitors that

check fuel, emission, engine and ignition perfor-

mance. These monitors use information from various

sensor circuits to indicate the overall operation of the

fuel, engine, ignition and emission systems and thus

the emissions performance of the vehicle.

The fuel, engine, ignition and emission systems

monitors do not indicate a specific component prob-

lem. They do indicate that there is an implied prob-

lem within one of the systems and that a specific

problem must be diagnosed.

If any of these monitors detect a problem affecting

vehicle emissions, the Malfunction Indicator Lamp

(MIL) will be illuminated. These monitors generate

Diagnostic Trouble Codes that can be displayed with

the MIL or a scan tool.

The following is a list of the system monitors:

²Misfire Monitor

²Fuel System Monitor

²Oxygen Sensor Monitor

²Oxygen Sensor Heater Monitor

²Catalyst Monitor

²Leak Detection Pump Monitor (if equipped)

All these system monitors require two consecutive

trips with the malfunction present to set a fault.

Refer to the appropriate Powertrain Diagnos-

tics Procedures manual for diagnostic proce-

dures.

The following is an operation and description of

each system monitor :

OXYGEN SENSOR (O2S) MONITOR

Effective control of exhaust emissions is achieved

by an oxygen feedback system. The most important

element of the feedback system is the O2S. The O2S

is located in the exhaust path. Once it reaches oper-

ating temperature 300É to 350ÉC (572É to 662ÉF), the

sensor generates a voltage that is inversely propor-

tional to the amount of oxygen in the exhaust. The

information obtained by the sensor is used to calcu-

late the fuel injector pulse width. This maintains a

14.7 to 1 Air Fuel (A/F) ratio. At this mixture ratio,

the catalyst works best to remove hydrocarbons (HC),

carbon monoxide (CO) and nitrogen oxide (NOx) from

the exhaust.

The O2S is also the main sensing element for the

Catalyst and Fuel Monitors.The O2S can fail in any or all of the following

manners:

²slow response rate

²reduced output voltage

²dynamic shift

²shorted or open circuits

Response rate is the time required for the sensor to

switch from lean to rich once it is exposed to a richer

than optimum A/F mixture or vice versa. As the sen-

sor starts malfunctioning, it could take longer to

detect the changes in the oxygen content of the

exhaust gas.

The output voltage of the O2S ranges from 0 to 1

volt. A good sensor can easily generate any output

voltage in this range as it is exposed to different con-

centrations of oxygen. To detect a shift in the A/F

mixture (lean or rich), the output voltage has to

change beyond a threshold value. A malfunctioning

sensor could have difficulty changing beyond the

threshold value.

OXYGEN SENSOR HEATER MONITOR

If there is an oxygen sensor (O2S) shorted to voltage

DTC, as well as a O2S heater DTC, the O2S fault

MUST be repaired first. Before checking the O2S fault,

verify that the heater circuit is operating correctly.

Effective control of exhaust emissions is achieved

by an oxygen feedback system. The most important

element of the feedback system is the O2S. The O2S

is located in the exhaust path. Once it reaches oper-

ating temperature 300É to 350ÉC (572 É to 662ÉF), the

sensor generates a voltage that is inversely propor-

tional to the amount of oxygen in the exhaust. The

information obtained by the sensor is used to calcu-

late the fuel injector pulse width. This maintains a

14.7 to 1 Air Fuel (A/F) ratio. At this mixture ratio,

the catalyst works best to remove hydrocarbons (HC),

carbon monoxide (CO) and nitrogen oxide (NOx) from

the exhaust.

The voltage readings taken from the O2S sensor

are very temperature sensitive. The readings are not

accurate below 300ÉC. Heating of the O2S sensor is

done to allow the engine controller to shift to closed

loop control as soon as possible. The heating element

used to heat the O2S sensor must be tested to ensure

that it is heating the sensor properly.

The O2S sensor circuit is monitored for a drop in

voltage. The sensor output is used to test the heater

by isolating the effect of the heater element on the

O2S sensor output voltage from the other effects.

LEAK DETECTION PUMP MONITOR (IF EQUIPPED)

The leak detection assembly incorporates two pri-

mary functions: it must detect a leak in the evapora-

tive system and seal the evaporative system so the

leak detection test can be run.

BR/BEEMISSIONS CONTROL 25 - 17

EMISSIONS CONTROL (Continued)

Page 2199 of 2255

DESCRIPTION - COMPONENT MONITORS -

DIESEL ENGINES

There are several electrical components that will

affect vehicle emissions if they malfunction. If one of

these components is malfunctioning, a Diagnostic

Trouble Code (DTC) will be set by either the Power-

train Control Module (PCM) or the Engine Control

Module (ECM). The Malfunction Indicator Lamp

(MIL) will then be illuminated when the engine is

running.

These electrically operated components have input

(rationality) and output (functionality) checks. A

check is done by one or more components to check

the operation of another component.

Example:The Intake Manifold Air Temperature

(IAT) sensor is used to monitor intake manifold air

temperature over a period of time after a cold start.

If the temperature has not risen to a certain specifi-

cation during a specified time, a Diagnostic Trouble

Code (DTC) will be set for a problem in the manifold

air heater system.

All open/short circuit checks, or any component

that has an associated limp-in will set a DTC and

trigger the MIL after 1 trip with the malfunction

present. Components without an associated limp-in

will take two trips to illuminate the MIL.

OPERATION

OPERATION - GAS ENGINES

The Powertrain Control Module (PCM) monitors

many different circuits in the fuel injection, ignition,

emission and engine systems. If the PCM senses a

problem with a monitored circuit often enough to

indicate an actual problem, it stores a Diagnostic

Trouble Code (DTC) in the PCM's memory. If the

problem is repaired or ceases to exist, the PCM can-

cels the code after 40 warm-up cycles. Diagnostic

trouble codes that affect vehicle emissions illuminate

the Malfunction Indicator Lamp (MIL). The MIL is

displayed as an engine icon (graphic) on the instru-

ment panel. Refer to Malfunction Indicator Lamp in

this section.

Certain criteria must be met before the PCM

stores a DTC in memory. The criteria may be a spe-

cific range of engine RPM, engine temperature,

and/or input voltage to the PCM.

The PCM might not store a DTC for a monitored

circuit even though a malfunction has occurred. This

may happen because one of the DTC criteria for the

circuit has not been met.For example, assume the

diagnostic trouble code criteria requires the PCM to

monitor the circuit only when the engine operates

between 750 and 2000 RPM. Suppose the sensor's

output circuit shorts to ground when engine operatesabove 2400 RPM (resulting in 0 volt input to the

PCM). Because the condition happens at an engine

speed above the maximum threshold (2000 rpm), the

PCM will not store a DTC.

There are several operating conditions for which

the PCM monitors and sets DTC's. Refer to Moni-

tored Systems, Components, and Non-Monitored Cir-

cuits in this section.

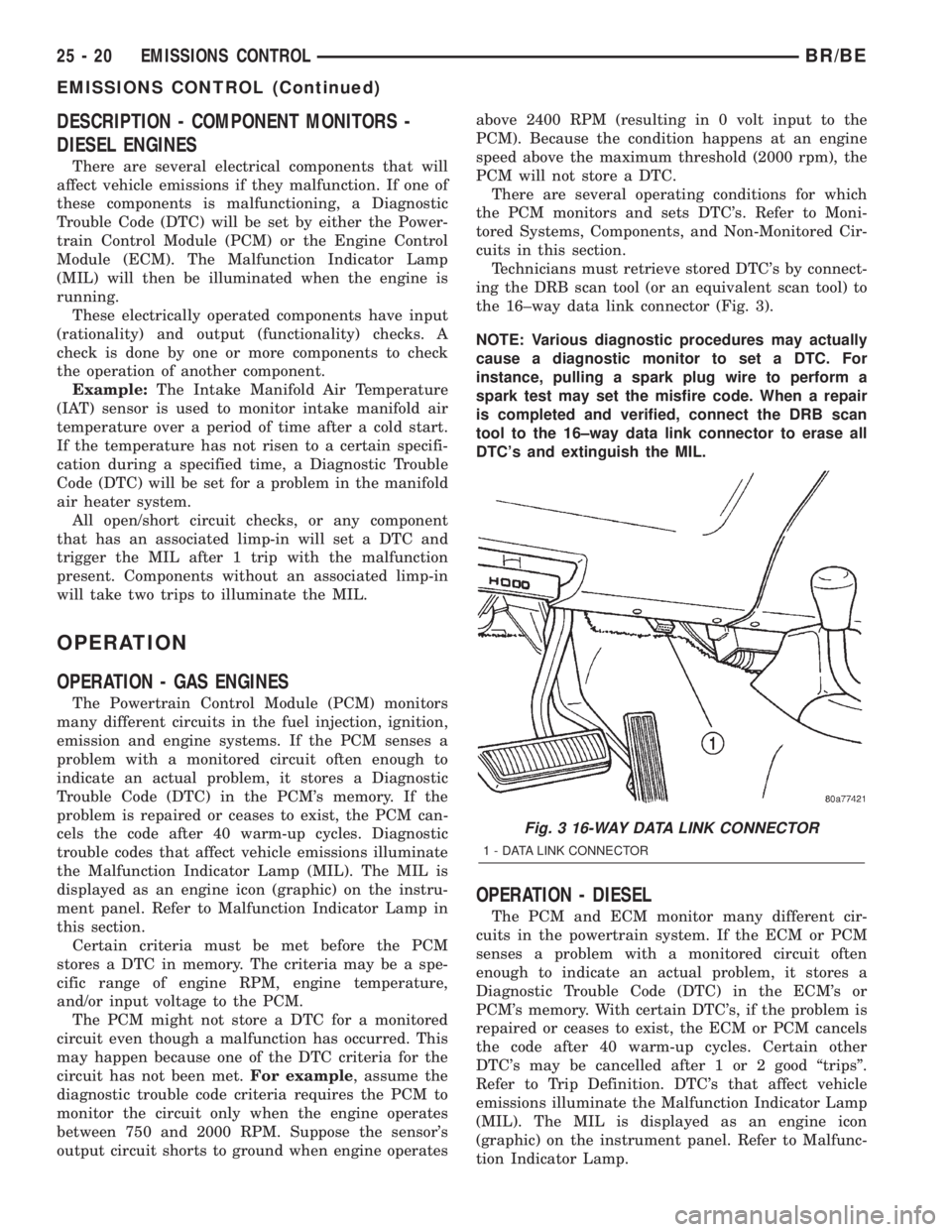

Technicians must retrieve stored DTC's by connect-

ing the DRB scan tool (or an equivalent scan tool) to

the 16±way data link connector (Fig. 3).

NOTE: Various diagnostic procedures may actually

cause a diagnostic monitor to set a DTC. For

instance, pulling a spark plug wire to perform a

spark test may set the misfire code. When a repair

is completed and verified, connect the DRB scan

tool to the 16±way data link connector to erase all

DTC's and extinguish the MIL.

OPERATION - DIESEL

The PCM and ECM monitor many different cir-

cuits in the powertrain system. If the ECM or PCM

senses a problem with a monitored circuit often

enough to indicate an actual problem, it stores a

Diagnostic Trouble Code (DTC) in the ECM's or

PCM's memory. With certain DTC's, if the problem is

repaired or ceases to exist, the ECM or PCM cancels

the code after 40 warm-up cycles. Certain other

DTC's may be cancelled after 1 or 2 good ªtripsº.

Refer to Trip Definition. DTC's that affect vehicle

emissions illuminate the Malfunction Indicator Lamp

(MIL). The MIL is displayed as an engine icon

(graphic) on the instrument panel. Refer to Malfunc-

tion Indicator Lamp.

Fig. 3 16-WAY DATA LINK CONNECTOR

1 - DATA LINK CONNECTOR

25 - 20 EMISSIONS CONTROLBR/BE

EMISSIONS CONTROL (Continued)

Page 2201 of 2255

MIL Illumination

The PCM Task Manager carries out the illumina-

tion of the MIL. The Task Manager triggers MIL illu-

mination upon test failure, depending on monitor

failure criteria.

The Task Manager Screen shows both a Requested

MIL state and an Actual MIL state. When the MIL is

illuminated upon completion of a test for a third trip,

the Requested MIL state changes to OFF. However,

the MIL remains illuminated until the next key

cycle. (On some vehicles, the MIL will actually turn

OFF during the third key cycle) During the key cycle

for the third good trip, the Requested MIL state is

OFF, while the Actual MILL state is ON. After the

next key cycle, the MIL is not illuminated and both

MIL states read OFF.

Diagnostic Trouble Codes (DTCs)

With OBD II, different DTC faults have different

priorities according to regulations. As a result, the

priorities determine MIL illumination and DTC era-

sure. DTCs are entered according to individual prior-

ity. DTCs with a higher priority overwrite lower

priority DTCs.

Priorities

²Priority 0 ÐNon-emissions related trouble codes

²Priority 1 Ð One trip failure of a two trip fault

for non-fuel system and non-misfire.

²Priority 2 Ð One trip failure of a two trip fault

for fuel system (rich/lean) or misfire.

²Priority3ÐTwotrip failure for a non-fuel sys-

tem and non-misfire or matured one trip comprehen-

sive component fault.

²Priority4ÐTwotrip failure or matured fault

for fuel system (rich/lean) and misfire or one trip cat-

alyst damaging misfire.

Non-emissions related failures have no priority.

One trip failures of two trip faults have low priority.

Two trip failures or matured faults have higher pri-

ority. One and two trip failures of fuel system and

misfire monitor take precedence over non-fuel system

and non-misfire failures.

DTC Self Erasure

With one trip components or systems, the MIL is

illuminated upon test failure and DTCs are stored.

Two trip monitors are components requiring failure

in two consecutive trips for MIL illumination. Upon

failure of the first test, the Task Manager enters a

maturing code. If the component fails the test for a

second time the code matures and a DTC is set.

After three good trips the MIL is extinguished and

the Task Manager automatically switches the trip

counter to a warm-up cycle counter. DTCs are auto-matically erased following 40 warm-up cycles if the

component does not fail again.

For misfire and fuel system monitors, the compo-

nent must pass the test under a Similar Conditions

Window in order to record a good trip. A Similar Con-

ditions Window is when engine RPM is within 375

RPM and load is within 10% of when the fault

occurred.

NOTE: It is important to understand that a compo-

nent does not have to fail under a similar window of

operation to mature. It must pass the test under a

Similar Conditions Window when it failed to record

a Good Trip for DTC erasure for misfire and fuel

system monitors.

DTCs can be erased anytime with a DRB III. Eras-

ing the DTC with the DRB III erases all OBD II

information. The DRB III automatically displays a

warning that erasing the DTC will also erase all

OBD II monitor data. This includes all counter infor-

mation for warm-up cycles, trips and Freeze Frame.

Trip Indicator

TheTripis essential for running monitors and

extinguishing the MIL. In OBD II terms, a trip is a

set of vehicle operating conditions that must be met

for a specific monitor to run. All trips begin with a

key cycle.

Good Trip

The Good Trip counters are as follows:

²Specific Good Trip

²Fuel System Good Trip

²Misfire Good Trip

²Alternate Good Trip (appears as a Global Good

Trip on DRB III)

²Comprehensive Components

²Major Monitor

²Warm-Up Cycles

Specific Good Trip

The term Good Trip has different meanings

depending on the circumstances:

²If the MIL is OFF, a trip is defined as when the

Oxygen Sensor Monitor and the Catalyst Monitor

have been completed in the same drive cycle.

²If the MIL is ON and a DTC was set by the Fuel

Monitor or Misfire Monitor (both continuous moni-

tors), the vehicle must be operated in the Similar

Condition Window for a specified amount of time.

²If the MIL is ON and a DTC was set by a Task

Manager commanded once-per-trip monitor (such as

the Oxygen Sensor Monitor, Catalyst Monitor, Purge

Flow Monitor, Leak Detection Pump Monitor, EGR

Monitor or Oxygen Sensor Heater Monitor), a good

trip is when the monitor is passed on the next start-

up.

25 - 22 EMISSIONS CONTROLBR/BE

EMISSIONS CONTROL (Continued)

Page 2202 of 2255

²If the MIL is ON and any other emissions DTC

was set (not an OBD II monitor), a good trip occurs

when the Oxygen Sensor Monitor and Catalyst Mon-

itor have been completed, or two minutes of engine

run time if the Oxygen Sensor Monitor and Catalyst

Monitor have been stopped from running.

Fuel System Good Trip

To count a good trip (three required) and turn off

the MIL, the following conditions must occur:

²Engine in closed loop

²Operating in Similar Conditions Window

²Short Term multiplied by Long Term less than

threshold

²Less than threshold for a predetermined time

If all of the previous criteria are met, the PCM will

count a good trip (three required) and turn off the MIL.

Misfire Good Trip

If the following conditions are met the PCM will

count one good trip (three required) in order to turn

off the MIL:

²Operating in Similar Condition Window

²1000 engine revolutions with no misfire

Warm-Up Cycles

Once the MIL has been extinguished by the Good Trip

Counter, the PCM automatically switches to a Warm-Up

Cycle Counter that can be viewed on the DRB III.

Warm-Up Cycles are used to erase DTCs and Freeze

Frames. Forty Warm-Up cycles must occur in order for

the PCM to self-erase a DTC and Freeze Frame. A

Warm-Up Cycle is defined as follows:

²Engine coolant temperature must start below

and rise above 160É F

²Engine coolant temperature must rise by 40É F

²No further faults occur

Freeze Frame Data Storage

Once a failure occurs, the Task Manager records

several engine operating conditions and stores it in a

Freeze Frame. The Freeze Frame is considered one

frame of information taken by an on-board data

recorder. When a fault occurs, the PCM stores the

input data from various sensors so that technicians

can determine under what vehicle operating condi-

tions the failure occurred.

The data stored in Freeze Frame is usually

recorded when a system fails the first time for two

trip faults. Freeze Frame data will only be overwrit-

ten by a different fault with a higher priority.

CAUTION: Erasing DTCs, either with the DRB III or

by disconnecting the battery, also clears all Freeze

Frame data.

Similar Conditions Window

The Similar Conditions Window displays informa-

tion about engine operation during a monitor. Abso-lute MAP (engine load) and Engine RPM are stored

in this window when a failure occurs. There are two

different Similar conditions Windows: Fuel System

and Misfire.

FUEL SYSTEM

²Fuel System Similar Conditions WindowÐ

An indicator that 'Absolute MAP When Fuel Sys Fail'

and 'RPM When Fuel Sys Failed' are all in the same

range when the failure occurred. Indicated by switch-

ing from 'NO' to 'YES'.

²Absolute MAP When Fuel Sys FailÐ The

stored MAP reading at the time of failure. Informs

the user at what engine load the failure occurred.

²Absolute MAPÐ A live reading of engine load

to aid the user in accessing the Similar Conditions

Window.

²RPM When Fuel Sys FailÐ The stored RPM

reading at the time of failure. Informs the user at

what engine RPM the failure occurred.

²Engine RPMÐ A live reading of engine RPM

to aid the user in accessing the Similar Conditions

Window.

²Adaptive Memory FactorÐ The PCM utilizes

both Short Term Compensation and Long Term Adap-

tive to calculate the Adaptive Memory Factor for

total fuel correction.

²Upstream O2S VoltsÐ A live reading of the

Oxygen Sensor to indicate its performance. For

example, stuck lean, stuck rich, etc.

²SCW Time in Window (Similar Conditions

Window Time in Window)Ð A timer used by the

PCM that indicates that, after all Similar Conditions

have been met, if there has been enough good engine

running time in the SCW without failure detected.

This timer is used to increment a Good Trip.

²Fuel System Good Trip CounterÐATrip

Counter used to turn OFF the MIL for Fuel System

DTCs. To increment a Fuel System Good Trip, the

engine must be in the Similar Conditions Window,

Adaptive Memory Factor must be less than cali-

brated threshold and the Adaptive Memory Factor

must stay below that threshold for a calibrated

amount of time.

²Test Done This TripÐ Indicates that the

monitor has already been run and completed during

the current trip.

MISFIRE

²Same Misfire Warm-Up StateÐ Indicates if

the misfire occurred when the engine was warmed up

(above 160É F).

²In Similar Misfire WindowÐ An indicator

that 'Absolute MAP When Misfire Occurred' and

'RPM When Misfire Occurred' are all in the same

range when the failure occurred. Indicated by switch-

ing from 'NO' to 'YES'.

BR/BEEMISSIONS CONTROL 25 - 23

EMISSIONS CONTROL (Continued)

Page 2227 of 2255

DIESEL - INSTALLATION, WATER PUMP -

5.9L................................7-72

DIESEL - OPERATION.................8E-18

DIESEL - OPERATION.................25-20

DIESEL - OPERATION..........14-106,14-108

DIESEL - OPERATION...................8I-6

DIESEL - OPERATION, BELT

TENSIONERS - 5.9L...................7-23

DIESEL - OPERATION, COOLANT

RECOVERY CONTAINER - 3.9L/5.2L/

5.9L/5.9L............................7-40

DIESEL - OPERATION, ENGINE BLOCK

HEATER - 5.9L........................7-46

DIESEL - OPERATION, ENGINE COOLANT

THERMOSTAT - 5.9L...................7-53

DIESEL - OPERATION, FAN DRIVE

VISCOUS CLUTCH - 5.9L...............7-56

DIESEL - OPERATION, NON-MONITORED

CIRCUITS...........................25-24

DIESEL - OPERATION, RADIATOR - 5.9L . . . 7-62

DIESEL - OPERATION, TRANS COOLER -

5.9L................................7-84

DIESEL - OPERATION, VACUUM PUMP -

5.9L................................7-34

DIESEL - OPERATION, WATER PUMP -

5.9L................................7-72

DIESEL - REMOVAL............14-107,14-108

DIESEL - REMOVAL....................8I-7

DIESEL - REMOVAL, BELT TENSIONERS -

5.9L................................7-23

DIESEL - REMOVAL, COOLANT

RECOVERY CONTAINER - 3.9L/5.2L/

5.9L/5.9L............................7-40

DIESEL - REMOVAL, DRIVE BELTS - 5.9L . . 7-32

DIESEL - REMOVAL, ENGINE BLOCK

HEATER - 5.9L........................7-46

DIESEL - REMOVAL, ENGINE COOLANT

THERMOSTAT - 5.9L...................7-54

DIESEL - REMOVAL, EXHAUST PIPE -

5.9L................................11-9

DIESEL - REMOVAL, MUFFLER - 5.9L.....11-11

DIESEL - REMOVAL, RADIATOR - 5.9L.....7-62

DIESEL - REMOVAL, RADIATOR FAN -

5.9L................................7-43

DIESEL - REMOVAL, TAILPIPE - 5.9L.....11-12

DIESEL - REMOVAL, VACUUM PUMP -

5.9L................................7-34

DIESEL - REMOVAL, WATER PUMP -

5.9L................................7-72

DIESEL ENGINE - DESCRIPTION, FUEL

REQUIREMENTS.......................0-3

DIESEL ENGINE - DIAGNOSIS AND

TESTING............................11-4

DIESEL ENGINE - DIAGNOSIS AND

TESTING, COOLING SYSTEM............7-13

DIESEL ENGINE - INSTALLATION........19-37

DIESEL ENGINE - REMOVAL............19-36

DIESEL ENGINE - STANDARD

PROCEDURE, DRAINING COOLING

SYSTEM 5.9L........................7-15

DIESEL ENGINE - STANDARD

PROCEDURE, REFILLING COOLING

SYSTEM 5.9L........................7-16

DIESEL ENGINE - TORQUE.............14-94

DIESEL ENGINE, SPECIAL TOOLS - 5.9L . . 9-128

DIESEL ENGINES - DESCRIPTION,

COMPONENT MONITORS

..............25-20

DIESEL ENGINES - FUEL SYSTEM

PRESSURES

........................14-62

DIESEL FUEL DELIVERY SYSTEM -

DESCRIPTION

.......................14-55

DIESEL FUEL INJECTION SYSTEM -

DESCRIPTION

.......................14-91

DIESEL FUEL SYSTEM, SPECIAL TOOLS

. . 14-63

DIESEL FUEL TANK - DESCRIPTION

......14-82

DIESEL, SPECIFICATIONS - 5.9L

.........9-127

DIESEL WITH AUTO. TRANS. -

INSTALLATION

..................8P-12,8P-6

DIESEL WITH AUTO. TRANS. -

REMOVAL

.......................8P-5,8P-9

DIFFERENTIAL - ASSEMBLY

....3-126,3-38,3-66,

3-97

DIFFERENTIAL - DISASSEMBLY

. 3-126,3-38,3-65,

3-97

DIFFERENTIAL - INSTALLATION

. 3-126,3-39,3-66,

3-97

DIFFERENTIAL - POWR-LOK - ASSEMBLY

. . 3-99DIFFERENTIAL - POWR-LOK -

DISASSEMBLY........................3-99

DIFFERENTIAL - REMOVAL . 3-125,3-37,3-64,3-96

DIFFERENTIAL - TRAC-LOK - ASSEMBLY . . 3-129,

3-70

DIFFERENTIAL - TRAC-LOK -

DISASSEMBLY...................3-128,3-68

DIFFERENTIAL CASE BEARINGS -

INSTALLATION.........3-102,3-129,3-41,3-72

DIFFERENTIAL CASE BEARINGS -

REMOVAL.............3-102,3-129,3-40,3-72

DIMENSION, SPECIFICATIONS - FRAME....13-8

DIMENSIONS, SPECIFICATIONS - BODY

OPENING...........................23-60

DIODE - INSTALLATION............8W-01-13

DIODE - REMOVAL................8W-01-13

DIODE REPLACEMENT - STANDARD

PROCEDURE.........................24-7

DISASSEMBLY - OVERHEAD CONSOLE

DISASSEMBLY.......................8M-7

DISASSEMBLY, AXLE VACUUM MOTOR....3-34

DISASSEMBLY, DIAGNOSIS AND

TESTING....................21-115,21-287

DISASSEMBLY, DIFFERENTIAL . . 3-126,3-38,3-65,

3-97

DISASSEMBLY, DIFFERENTIAL -

POWR-LOK..........................3-99

DISASSEMBLY, DIFFERENTIAL -

TRAC-LOK......................3-128,3-68

DISASSEMBLY, DISASSEMBLY -

OVERHEAD CONSOLE.................8M-7

DISASSEMBLY, DOUBLE CARDAN

UNIVERSAL JOINTS...................3-10

DISASSEMBLY, DRIVER AIRBAG.........8O-15

DISASSEMBLY, FLYWHEEL..............6-13

DISASSEMBLY, FRONT CLUTCH . . 21-161,21-331

DISASSEMBLY, FRONT SERVO . . . 21-164,21-334

DISASSEMBLY, GLOVE BOX...........23-110

DISASSEMBLY, HVAC HOUSING.........24-35

DISASSEMBLY, INSTRUMENT CLUSTER . . . 8J-10

DISASSEMBLY, MANUAL - NV4500........21-5

DISASSEMBLY, MANUAL - NV5600.......21-49

DISASSEMBLY, OIL PUMP...............9-47

DISASSEMBLY, OIL PUMP.......21-167,21-337

DISASSEMBLY, OVERDRIVE UNIT . 21-173,21-346

DISASSEMBLY, OVERRUNNING CLUTCH

CAM/OVERDRIVE PISTON RETAINER....21-192,

21-364

DISASSEMBLY, PLANETARY GEARTRAIN/

OUTPUT SHAFT...............21-198,21-369

DISASSEMBLY, REAR CLUTCH . . . 21-204,21-376

DISASSEMBLY, REAR SERVO....21-207,21-378

DISASSEMBLY, REMOVAL...............5-11

DISASSEMBLY, SINGLE CARDAN

UNIVERSAL JOINTS....................3-8

DISASSEMBLY, STANDARD PROCEDURE . . . 7-80

DISASSEMBLY, TRANSFER CASE -

NV241HD..........................21-469

DISASSEMBLY, TRANSFER CASE -

NV241LD..........................21-432

DISASSEMBLY, VALVE BODY.....21-237,21-409

DISC - INSTALLATION, CLUTCH...........6-8

DISC - REMOVAL, CLUTCH...............6-7

DISC BRAKE CALIPERS - DESCRIPTION....5-10

DISC BRAKE CALIPERS - OPERATION.....5-10

DISC BRAKE ROTOR, DIAGNOSIS AND

TESTING............................5-20

DISCHARGE (ESD) SENSITIVE DEVICES -

STANDARD PROCEDURE,

ELECTROSTATIC...................8W-01-8

DISCHARGE LINE - INSTALLATION,

SUCTION...........................24-52

DISCHARGE LINE - REMOVAL, SUCTION . . 24-51

DISPLAY TEST MODE - DESCRIPTION,

STATE ..............................25-1

DISTRIBUTION - DESCRIPTION, POWER . 8W-97-1

DISTRIBUTION - OPERATION, POWER . . 8W-97-1

DISTRIBUTION CENTER - DESCRIPTION,

POWER..........................8W-97-8

DISTRIBUTION CENTER - INSTALLATION,

POWER

.........................8W-97-10

DISTRIBUTION CENTER - OPERATION,

POWER

..........................8W-97-8

DISTRIBUTION CENTER - REMOVAL,

POWER

..........................8W-97-8

DISTRIBUTION SYSTEMS, SPECIAL

TOOLS - POWER

...................8W-97-2

DISTRIBUTOR - DESCRIPTION

..........8I-11DISTRIBUTOR - INSTALLATION..........8I-13

DISTRIBUTOR - OPERATION............8I-12

DISTRIBUTOR - REMOVAL..............8I-12

DISTRIBUTOR BUSHING - INSTALLATION . . 9-35

DISTRIBUTOR BUSHING - REMOVAL......9-35

DISTRIBUTOR CAP - DIAGNOSIS AND

TESTING............................8I-14

DISTRIBUTOR ROTOR - DIAGNOSIS AND

TESTING............................8I-14

DOME LAMP - INSTALLATION..........8L-34

DOME LAMP - REMOVAL..............8L-34

DOOR - ADJUSTMENT, CARGO..........23-78

DOOR - INSTALLATION...........23-69,23-78

DOOR - INSTALLATION, BLEND.........24-37

DOOR - INSTALLATION, FUEL FILL.......23-95

DOOR - INSTALLATION, HEAT/DEFROST . . . 24-38

DOOR - INSTALLATION, PANEL/DEFROST . . 24-38

DOOR - INSTALLATION, RECIRCULATION . . 24-39

DOOR - REMOVAL...............23-69,23-78

DOOR - REMOVAL, BLEND.............24-37

DOOR - REMOVAL, FUEL FILL..........23-95

DOOR - REMOVAL, HEAT/DEFROST......24-37

DOOR - REMOVAL, PANEL/DEFROST.....24-38

DOOR - REMOVAL, RECIRCULATION.....24-38

DOOR ACTUATOR - INSTALLATION,

BLEND.............................24-25

DOOR ACTUATOR - INSTALLATION,

HEAT/DEFROST......................24-27

DOOR ACTUATOR - INSTALLATION,

PANEL/DEFROST.....................24-27

DOOR ACTUATOR - INSTALLATION,

RECIRCULATION.....................24-28

DOOR ACTUATOR - REMOVAL, BLEND....24-25

DOOR ACTUATOR - REMOVAL,

HEAT/DEFROST......................24-26

DOOR ACTUATOR - REMOVAL,

PANEL/DEFROST.....................24-26

DOOR ACTUATOR - REMOVAL,

RECIRCULATION.....................24-27

DOOR AJAR SWITCH - DESCRIPTION....8L-34

DOOR AJAR SWITCH - DIAGNOSIS AND

TESTING...........................8L-34

DOOR AJAR SWITCH - INSTALLATION....8L-35

DOOR AJAR SWITCH - REMOVAL........8L-35

DOOR CYLINDER LOCK SWITCH -

DESCRIPTION........................8N-5

DOOR CYLINDER LOCK SWITCH -

DIAGNOSIS AND TESTING..............8N-6

DOOR CYLINDER LOCK SWITCH -

INSTALLATION.......................8N-6

DOOR CYLINDER LOCK SWITCH -

OPERATION..........................8N-5

DOOR CYLINDER LOCK SWITCH -

REMOVAL...........................8N-6

DOOR FORE/AFT - ADJUSTMENT, FRONT . . 23-69

DOOR GLASS - INSTALLATION..........23-70

DOOR GLASS - REMOVAL.............23-70

DOOR GLASS RUN WEATHERSTRIP -

INSTALLATION, FRONT...............23-153

DOOR GLASS RUN WEATHERSTRIP -

REMOVAL, FRONT...................23-152

DOOR INNER BELT WEATHERSTRIP -

INSTALLATION, FRONT...............23-153

DOOR INNER BELT WEATHERSTRIP -

REMOVAL, FRONT...................23-153

DOOR IN/OUT - ADJUSTMENT, FRONT....23-70

DOOR LATCH - ADJUSTMENT, FRONT....23-73

DOOR OPENING SEAL - INSTALLATION . . 23-152

DOOR OPENING SEAL - REMOVAL......23-152

DOOR OUTER BELT WEATHERSTRIP -

INSTALLATION, FRONT...............23-153

DOOR OUTER BELT WEATHERSTRIP -

REMOVAL, FRONT...................23-153

DOOR SEAL - INSTALLATION, B-PILLAR . 23-151

DOOR SEAL - REMOVAL, B-PILLAR.....23-151

DOOR SECOND WEATHERSTRIP -

INSTALLATION, FRONT...............23-154

DOOR SECOND WEATHERSTRIP -

REMOVAL, FRONT...................23-154

DOOR SILL TRIM - INSTALLATION......23-121

DOOR SILL TRIM - REMOVAL.........23-121

DOOR SPEAKER - INSTALLATION, FRONT . 8A-19

DOOR SPEAKER - INSTALLATION, REAR

. . 8A-21

DOOR SPEAKER - REMOVAL, FRONT

.....8A-19

DOOR SPEAKER - REMOVAL, REAR

......8A-20

DOOR UP/DOWN - ADJUSTMENT, FRONT

. 23-70

DOOR UPPER CORNER SEAL -

INSTALLATION, FRONT

...............23-154

10 INDEXBR/BE

Description Group-Page Description Group-Page Description Group-Page

Page 2237 of 2255

MINI-TRIP COMPUTER - DIAGNOSIS

AND TESTING, COMPASS.............8M-10

MIRROR - DESCRIPTION, AUTOMATIC

DAY / NIGHT........................8N-11

MIRROR - DESCRIPTION, SIDEVIEW.....8N-14

MIRROR - DIAGNOSIS AND TESTING,

AUTOMATIC DAY/NIGHT...............8N-12

MIRROR - DIAGNOSIS AND TESTING,

SIDEVIEW..........................8N-14

MIRROR - INSTALLATION, AUTOMATIC

DAY / NIGHT........................8N-13

MIRROR - INSTALLATION, SIDE VIEW....23-98

MIRROR - LOW MOUNTED -

INSTALLATION, SIDE VIEW.............23-98

MIRROR - LOW MOUNTED - REMOVAL,

SIDE VIEW..........................23-98

MIRROR - OPERATION, AUTOMATIC DAY

/ NIGHT............................8N-12

MIRROR - OPERATION, SIDEVIEW.......8N-14

MIRROR - REMOVAL, AUTOMATIC DAY /

NIGHT.............................8N-13

MIRROR - REMOVAL, REAR VIEW......23-126

MIRROR - REMOVAL, SIDE VIEW........23-97

MIRROR - REMOVAL, SIDEVIEW........8N-15

MIRROR FLAG - INSTALLATION, SIDE

VIEW..............................23-75

MIRROR FLAG - REMOVAL, SIDE VIEW . . . 23-74

MIRROR GLASS - INSTALLATION, SIDE

VIEW..............................23-98

MIRROR GLASS - REMOVAL, SIDE VIEW . . 23-98

MIRROR GRID - DESCRIPTION, HEATED....8G-4

MIRROR GRID - DIAGNOSIS AND

TESTING, HEATED.....................8G-4

MIRROR GRID - OPERATION, HEATED.....8G-4

MIRROR SUPPORT BRACKET -

INSTALLATION, REARVIEW............23-126

MIRROR SWITCH - DESCRIPTION........8G-2

MIRROR SWITCH - DESCRIPTION,

POWER............................8N-13

MIRROR SWITCH - DIAGNOSIS AND

TESTING, HEATED.....................8G-3

MIRROR SWITCH - INSTALLATION,

POWER............................8N-14

MIRROR SWITCH - OPERATION..........8G-3

MIRROR SWITCH - OPERATION, POWER . . 8N-13

MIRROR SWITCH - REMOVAL, POWER . . . 8N-13

MIRROR SYSTEM - DESCRIPTION,

HEATED.............................8G-1

MIRROR SYSTEM - DIAGNOSIS AND

TESTING, HEATED.....................8G-2

MIRROR SYSTEM - OPERATION, HEATED . . 8G-2

MIRRORS - DESCRIPTION, POWER......8N-11

MIRRORS - OPERATION, POWER........8N-11

MODE - DESCRIPTION, CIRCUIT

ACTUATION TEST.....................25-2

MODE - DESCRIPTION, STATE DISPLAY

TEST...............................25-1

MODES OF OPERATION - DESCRIPTION . . . 8E-15

MODULE - DESCRIPTION, AIRBAG

CONTROL...........................8O-6

MODULE - DESCRIPTION, CENTRAL

TIMER..............................8E-1

MODULE - DESCRIPTION, DAYTIME

RUNNING LAMP......................8L-9

MODULE - DESCRIPTION, FUEL PUMP....14-12

MODULE - DESCRIPTION, FUEL TANK....14-82

MODULE - DESCRIPTION, HEATED SEAT . . 8E-20

MODULE - DESCRIPTION, WIPER

.......8R-13

MODULE - DIAGNOSIS AND TESTING,

CENTRAL TIMER

......................8E-4

MODULE - DIAGNOSIS AND TESTING,

HEATED SEAT

.......................8E-21

MODULE - INSTALLATION, AIRBAG

CONTROL

...........................8O-8

MODULE - INSTALLATION, CENTRAL

TIMER

..............................8E-6

MODULE - INSTALLATION, DAYTIME

RUNNING LAMP

......................8L-9

MODULE - INSTALLATION, ENGINE

CONTROL

..........................8E-14

MODULE - INSTALLATION, FUEL PUMP

. . . 14-13

MODULE - INSTALLATION, FUEL TANK

....14-83

MODULE - INSTALLATION, HEATED SEAT

. . 8E-23

MODULE - INSTALLATION, WIPER

.......8R-14

MODULE - OPERATION, AIRBAG

CONTROL

...........................8O-6

MODULE - OPERATION, CENTRAL TIMER

. . 8E-3MODULE - OPERATION, DAYTIME

RUNNING LAMP......................8L-9

MODULE - OPERATION, FUEL PUMP.....14-13

MODULE - OPERATION, FUEL TANK......14-82

MODULE - OPERATION, HEATED SEAT....8E-20

MODULE - OPERATION, WIPER.........8R-14

MODULE - REMOVAL, AIRBAG CONTROL . . 8O-7

MODULE - REMOVAL, CENTRAL TIMER....8E-5

MODULE - REMOVAL, DAYTIME

RUNNING LAMP......................8L-9

MODULE - REMOVAL, ENGINE CONTROL . . 8E-14

MODULE - REMOVAL, FUEL PUMP.......14-13

MODULE - REMOVAL, FUEL TANK.......14-83

MODULE - REMOVAL, HEATED SEAT.....8E-23

MODULE - REMOVAL, WIPER...........8R-14

MOLDING - INSTALLATION, ROOF JOINT . . 23-91

MOLDING - REMOVAL, ROOF JOINT......23-91

MOLDINGS - INSTALLATION, BODY SIDE . . 23-87

MOLDINGS - REMOVAL, BODY SIDE.....23-86

MONITORED SYSTEMS - DESCRIPTION . . . 25-17

MONITORS - DIESEL ENGINES -

DESCRIPTION, COMPONENT............25-20

MONITORS - GAS ENGINES -

DESCRIPTION, COMPONENT............25-19

MOTOR - ASSEMBLY, AXLE VACUUM......3-34

MOTOR - DESCRIPTION, AXLE VACUUM . . . 3-31

MOTOR - DESCRIPTION, BLOWER.......24-31

MOTOR - DESCRIPTION, IDLE AIR

CONTROL..........................14-40

MOTOR - DESCRIPTION, LUMBAR.......8N-19

MOTOR - DESCRIPTION, POWER LOCK....8N-7

MOTOR - DESCRIPTION, STARTER.......8F-37

MOTOR - DESCRIPTION, WINDOW......8N-26

MOTOR - DIAGNOSIS AND TESTING,

BLOWER...........................24-32

MOTOR - DIAGNOSIS AND TESTING,

LUMBAR...........................8N-19

MOTOR - DIAGNOSIS AND TESTING,

POWER LOCK........................8N-7

MOTOR - DIAGNOSIS AND TESTING,

STARTER ...........................8F-38

MOTOR - DIAGNOSIS AND TESTING,

VACUUM............................3-32

MOTOR - DIAGNOSIS AND TESTING,

WINDOW...........................8N-26

MOTOR - DISASSEMBLY, AXLE VACUUM . . . 3-34

MOTOR - INSTALLATION, AXLE VACUUM . . . 3-34

MOTOR - INSTALLATION, BLOWER......24-32

MOTOR - INSTALLATION, STARTER......8F-40

MOTOR - OPERATION, AXLE VACUUM.....3-31

MOTOR - OPERATION, BLOWER.........24-31

MOTOR - OPERATION, IDLE AIR

CONTROL..........................14-40

MOTOR - OPERATION, LUMBAR........8N-19

MOTOR - OPERATION, POWER LOCK.....8N-7

MOTOR - OPERATION, STARTER.........8F-37

MOTOR - REMOVAL, AXLE VACUUM......3-34

MOTOR - REMOVAL, BLOWER..........24-32

MOTOR - REMOVAL, STARTER..........8F-38

MOTOR - REMOVAL, WINDOW..........8N-26

MOTOR RELAY - DESCRIPTION,

BLOWER...........................24-22

MOTOR RELAY - DESCRIPTION,

STARTER ...........................8F-41

MOTOR RELAY - DIAGNOSIS AND

TESTING, BLOWER...................24-22

MOTOR RELAY - INSTALLATION,

BLOWER...........................24-23

MOTOR RELAY - INSTALLATION,

STARTER ...........................8F-42

MOTOR RELAY - OPERATION, BLOWER . . . 24-22

MOTOR RELAY - OPERATION, STARTER . . . 8F-41

MOTOR RELAY - REMOVAL, BLOWER....24-23

MOTOR RELAY - REMOVAL, STARTER....8F-42

MOTOR RESISTOR BLOCK -

DESCRIPTION, BLOWER...............24-23

MOTOR RESISTOR BLOCK - DIAGNOSIS

AND TESTING, BLOWER...............24-23

MOTOR RESISTOR BLOCK -

INSTALLATION, BLOWER

..............24-24

MOTOR RESISTOR BLOCK - OPERATION,

BLOWER

...........................24-23

MOTOR RESISTOR BLOCK - REMOVAL,

BLOWER

...........................24-24

MOTOR SWITCH - DESCRIPTION,

BLOWER

...........................24-24

MOTOR SWITCH - DIAGNOSIS AND

TESTING, BLOWER

...................24-25MOTOR SWITCH - OPERATION, BLOWER . . 24-24

MOTOR SWITCH - REMOVAL, BLOWER . . . 24-25

MOUNT - INSTALLATION, FRONT....9-174,9-42,

9-98

MOUNT - INSTALLATION, REAR . 9-174,9-42,9-98

MOUNT - REMOVAL, FRONT....9-173,9-41,9-97

MOUNT - REMOVAL, REAR.....9-174,9-42,9-98

MOUNTED - INSTALLATION, SIDE VIEW

MIRROR - LOW......................23-98

MOUNTED - REMOVAL, SIDE VIEW

MIRROR - LOW......................23-98

MOUNTED STOP LAMP - INSTALLATION,

CENTER HIGH........................8L-6

MOUNTED STOP LAMP - REMOVAL,

CENTER HIGH........................8L-6

MOUNTED STOP LAMP UNIT -

INSTALLATION, CENTER HIGH...........8L-6

MOUNTED STOP LAMP UNIT -

REMOVAL, CENTER HIGH...............8L-6

MOUNTING - STANDARD PROCEDURE,

MATCH .............................22-3

MUFFLER - 3.9L/5.2L/5.9L/8.0L -

INSTALLATION.......................11-10

MUFFLER - 3.9L/5.2L/5.9L/8.0L -

REMOVAL..........................11-10

MUFFLER - 5.9L DIESEL - INSTALLATION . 11-11

MUFFLER - 5.9L DIESEL - REMOVAL.....11-11

MULTI-FUNCTION SWITCH -

DESCRIPTION.......................8L-23

MULTI-FUNCTION SWITCH - DIAGNOSIS

AND TESTING.......................8L-25

MULTI-FUNCTION SWITCH -

INSTALLATION.......................8L-28

MULTI-FUNCTION SWITCH - OPERATION . . 8L-24

MULTI-FUNCTION SWITCH - REMOVAL . . . 8L-27

NAME PLATES - INSTALLATION,

EXTERIOR..........................23-89

NAME PLATES - REMOVAL, EXTERIOR....23-89

NECK SEAL - DIAGNOSIS AND TESTING,

RADIATOR CAP-TO-FILLER..............7-65

NEGATIVE CABLE INSTALLATION,

GASOLINE ENGINE...................8F-22

NEGATIVE CABLE REMOVAL, GASOLINE

ENGINE............................8F-22

NIGHT MIRROR - DESCRIPTION,

AUTOMATIC DAY.....................8N-11

NIGHT MIRROR - INSTALLATION,

AUTOMATIC DAY.....................8N-13

NIGHT MIRROR - OPERATION,

AUTOMATIC DAY.....................8N-12

NIGHT MIRROR - REMOVAL,

AUTOMATIC DAY.....................8N-13

NOISE - DIAGNOSIS AND TESTING,

WIND...............................23-3

NOISE OR VIBRATION - DIAGNOSIS AND

TESTING, TIRE.......................22-9

NOISE SUPPRESSION COMPONENTS -

DESCRIPTION, RADIO.................8A-12

NOISE SUPPRESSION COMPONENTS -

DIAGNOSIS AND TESTING, RADIO.......8A-12

NON-DEPLOYED AIRBAGS - STANDARD

PROCEDURE, HANDLING...............8O-4

NON-MONITORED CIRCUITS - DIESEL -

OPERATION.........................25-24

NON-MONITORED CIRCUITS - GAS

ENGINES - OPERATION................25-24

NOZZLE - DESCRIPTION, WASHER.......8R-9

NOZZLE - INSTALLATION, WASHER.......8R-9

NOZZLE - OPERATION, WASHER.........8R-9

NOZZLE - REMOVAL, WASHER...........8R-9

NUMBER - DESCRIPTION, VEHICLE

IDENTIFICATION....................Intro.-1

NV241 - DESCRIPTION, TRANSFER CASE . . . 0-5

NV241HD - ASSEMBLY, TRANSFER CASE . 21-480

NV241HD - CLEANING, TRANSFER CASE . 21-476

NV241HD - DESCRIPTION, TRANSFER

CASE.............................21-465

NV241HD - DISASSEMBLY, TRANSFER

CASE.............................21-469

NV241HD - INSPECTION, TRANSFER

CASE.............................21-476

NV241HD - INSTALLATION, TRANSFER

CASE

.............................21-494

NV241HD - OPERATION, TRANSFER

CASE

.............................21-467

NV241HD - REMOVAL, TRANSFER CASE

. 21-469

NV241HD - TRANSFER CASE

..........21-495

NV241LD - ASSEMBLY, TRANSFER CASE

. 21-445

20 INDEXBR/BE

Description Group-Page Description Group-Page Description Group-Page

Page 2246 of 2255

SPECIFICATIONS - BODY GAP AND

FLUSH MEASUREMENTS...............23-56

SPECIFICATIONS - BODY OPENING

DIMENSIONS........................23-60

SPECIFICATIONS - BODY SEALER

LOCATIONS.........................23-47

SPECIFICATIONS - BRAKE FLUID.........5-15

SPECIFICATIONS - EXTERIOR LAMPS......8L-4

SPECIFICATIONS - FLUID CAPACITIES......0-6

SPECIFICATIONS - FRAME DIMENSION....13-8

SPECIFICATIONS - FUEL INJECTION

PUMP DATA PLATE...................14-77

SPECIFICATIONS - GENERATOR RATINGS . . 8F-26

SPECIFICATIONS - IGNITION TIMING......8I-4

SPECIFICATIONS - INTERIOR LAMPS.....8L-33

SPECIFICATIONS - POWER STEERING

GEAR..............................19-21

SPECIFICATIONS - PROPELLER SHAFT......3-6

SPECIFICATIONS - SPARK PLUG CABLE

RESISTANCE..........................8I-3

SPECIFICATIONS - SPARK PLUGS.........8I-3

SPECIFICATIONS - SPECIAL TOOLS.......8F-7

SPECIFICATIONS - SPECIFICATIONS......24-46

SPECIFICATIONS - STARTING SYSTEM....8F-36

SPECIFICATIONS - STRUCTURAL

ADHESIVE LOCATIONS................23-44

SPECIFICATIONS - TIRE REVOLUTIONS

PER MILE...........................22-9

SPECIFICATIONS - TORQUE.............7-18

SPECIFICATIONS - TORQUE....9-127,9-17,9-71

SPECIFICATIONS - TORQUE.............11-5

SPECIFICATIONS - TORQUE CHART....5-3,5-37

SPECIFICATIONS - TORQUE CHART . 19-21,19-41,

19-43,19-9

SPECIFICATIONS - TORQUE CHART . . . 2-15,2-26,

2-8

SPECIFICATIONS - TORQUE CHART......22-11

SPECIFICATIONS - TORQUE

SPECIFICATIONS.....................23-61

SPECIFICATIONS - TORQUE

SPECIFICATIONS......................24-8

SPECIFICATIONS - TRANSFER CASE....21-458,

21-495

SPECIFICATIONS - TRANSMISSION.....21-144,

21-314

SPECIFICATIONS - WELD LOCATIONS.....23-4

SPECIFICATIONS, CLUTCH...............6-7

SPECIFICATIONS, FUEL SYSTEM

PRESSURE - GAS ENGINES.............14-3

SPECIFICATIONS, MANUAL - NV4500.....21-38

SPECIFICATIONS, MANUAL - NV5600.....21-79

SPECIFICATIONS, SPECIFICATIONS.......24-46

SPECIFICATIONS, SPECIFICATIONS -

TORQUE............................23-61

SPECIFICATIONS, SPECIFICATIONS -

TORQUE............................24-8

SPECIFICATIONS, TORQUE..............13-1

SPECIFICATIONS, TORQUE - FUEL

DELIVERY...........................14-4

SPECIFICATIONS, TORQUE - GAS FUEL

INJECTION..........................14-35

SPECIFICATIONS, TORQUE -

GENERATOR/CHARGING SYSTEM........8F-27

SPECIFICATIONS, TORQUE - IGNITION.....8I-2

SPECIFICATIONS, TORQUE - STARTING

SYSTEM............................8F-37

SPEED CONTROL SERVO - DESCRIPTION . . 8P-6

SPEED CONTROL SERVO - OPERATION....8P-6

SPEED CONTROL SYSTEM -

DESCRIPTION

........................8P-1

SPEED CONTROL SYSTEM - OPERATION

. . . 8P-2

SPEED CONTROL SYSTEM - TORQUE

.....8P-4

SPEED INPUT - DESCRIPTION, VEHICLE

. . . 8P-2

SPEED SENSOR - DESCRIPTION

. . 21-209,21-381

SPEED SENSOR - DESCRIPTION, FRONT

WHEEL

.............................5-38

SPEED SENSOR - DIAGNOSIS AND

TESTING, REAR WHEEL

................5-40

SPEED SENSOR - INSTALLATION, REAR

WHEEL

.............................5-40

SPEED SENSOR - OPERATION

. . . 21-209,21-381

SPEED SENSOR - OPERATION, FRONT

WHEEL

.............................5-38

SPEED SENSOR - REMOVAL, REAR

WHEEL

.............................5-40

SPEEDOMETER - DESCRIPTION

.........8J-29

SPEEDOMETER - OPERATION

...........8J-30SPEEDS - DESCRIPTION, TIRE

PRESSURE FOR HIGH..................22-7

SPLASH SHIELD - INSTALLATION, REAR . . 23-96

SPLASH SHIELD - REMOVAL, REAR......23-96

SPLASH SHIELDS - INSTALLATION,

FRONT END.........................23-92

SPLASH SHIELDS - REMOVAL, FRONT

END ...............................23-92

SPLICE INFORMATION - DESCRIPTION,

CONNECTOR, GROUND..............8W-01-6

SPLICING - STANDARD PROCEDURE,

WIRE...........................8W-01-13

SPLIT BENCH - INSTALLATION, SEAT....23-134

SPLIT BENCH - INSTALLATION, SEAT

BACK.............................23-136

SPLIT BENCH - INSTALLATION, SEAT

BACK COVER.......................23-137

SPLIT BENCH - INSTALLATION, SEAT

CUSHION COVER....................23-140

SPLIT BENCH - INSTALLATION, SEAT

TRACK............................23-142

SPLIT BENCH - REMOVAL, SEAT.......23-133

SPLIT BENCH - REMOVAL, SEAT BACK . . 23-135

SPLIT BENCH - REMOVAL, SEAT BACK

COVER............................23-137

SPLIT BENCH - REMOVAL, SEAT

CUSHION COVER....................23-139

SPLIT BENCH - REMOVAL, SEAT TRACK . 23-142

SPOOL VALVE - INSTALLATION..........19-28

SPOOL VALVE - REMOVAL.............19-26

SPORT - INSTALLATION, FRONT

BUMPER............................13-5

SPORT - INSTALLATION, FRONT FASCIA . . . 13-3

SPORT - REMOVAL, FRONT BUMPER......13-5

SPORT - REMOVAL, FRONT FASCIA.......13-3

SPRING - INSTALLATION.......2-12,2-23,2-28

SPRING - REMOVAL...........2-11,2-23,2-27

SPRING AND SHOCK - DIAGNOSIS AND

TESTING............................2-25

SPRINGS - INSTALLATION, VALVES AND

VALVE ..............................9-84

SPRINGS - REMOVAL, VALVES AND

VALVE ..............................9-82

SPRINGS - STANDARD PROCEDURE,

VALVES, GUIDES......................9-23

SPRINGS - STANDARD PROCEDURE,

VALVES,GUIDES.....................9-138

SPROCKETS - INSTALLATION, TIMING

BELT/CHAIN.....................9-111,9-55

SPROCKETS - REMOVAL, TIMING

BELT/CHAIN.....................9-111,9-54

STABILIZER BAR - INSTALLATION....2-12,2-23,

2-29

STABILIZER BAR - REMOVAL....2-12,2-23,2-29

STANCHION COVER - INSTALLATION....23-143

STANCHION COVER - REMOVAL........23-143

STANDARD CAB - INSTALLATION........8O-19

STANDARD CAB - REMOVAL...........8O-18

STARTER MOTOR - DESCRIPTION.......8F-37

STARTER MOTOR - DIAGNOSIS AND

TESTING...........................8F-38

STARTER MOTOR - INSTALLATION.......8F-40

STARTER MOTOR - OPERATION.........8F-37

STARTER MOTOR - REMOVAL..........8F-38

STARTER MOTOR RELAY - DESCRIPTION . 8F-41

STARTER MOTOR RELAY -

INSTALLATION.......................8F-42

STARTER MOTOR RELAY - OPERATION . . . 8F-41

STARTER MOTOR RELAY - REMOVAL.....8F-42

STARTER RELAY - DIAGNOSIS AND

TESTING...........................8F-41

STARTING - DESCRIPTION.............8F-31

STARTING - OPERATION...............8F-31

STARTING - STANDARD PROCEDURE,

JUMP................................0-7

STARTING SYSTEM - DIAGNOSIS AND

TESTING...........................8F-32

STARTING SYSTEM - SPECIFICATIONS,

TORQUE............................8F-37

STARTING SYSTEM, SPECIFICATIONS.....8F-36

STATE DISPLAY TEST MODE -

DESCRIPTION........................25-1

STATIONARY GLASS - DESCRIPTION

....23-145

STATIONARY GLASS - OPERATION

......23-145

STEERING - DESCRIPTION

..............19-1

STEERING - OPERATION

................19-1

STEERING COLUMN OPENING COVER -

INSTALLATION

......................23-114STEERING COLUMN OPENING COVER -

REMOVAL.........................23-113

STEERING FLOW AND PRESSURE -

DIAGNOSIS AND TESTING, POWER.......19-4

STEERING GEAR HOUSING PLUG -

INSTALLATION.......................19-30

STEERING GEAR HOUSING PLUG -

REMOVAL..........................19-29

STEERING GEAR LEAKAGE - DIAGNOSIS

AND TESTING, POWER................19-16

STEERING GEAR, SPECIAL TOOLS -

POWER............................19-22

STEERING GEAR, SPECIFICATIONS -

POWER............................19-21

STEERING LINKAGE, SPECIAL TOOLS....19-41,

19-44

STEERING PUMP - INITIAL OPERATION -

STANDARD PROCEDURE, POWER.......19-33

STEERING PUMP, SPECIAL TOOLS -

POWER............................19-38

STEERING SYSTEM - DIAGNOSIS AND

TESTING, POWER.....................19-2

STEERING SYSTEM - STANDARD

PROCEDURE, FLUSHING POWER........19-34

STEERING WHEEL - INSTALLATION......19-15

STEERING WHEEL - REMOVAL..........19-15

STEM SEAL - INSTALLATION, VALVE......9-83

STEM SEALS - REMOVAL, VALVE.........9-82

STOP LAMP - INSTALLATION, CENTER

HIGH MOUNTED......................8L-6

STOP LAMP - REMOVAL, CENTER HIGH

MOUNTED...........................8L-6

STOP LAMP UNIT - INSTALLATION,

CENTER HIGH MOUNTED...............8L-6

STOP LAMP UNIT - REMOVAL, CENTER

HIGH MOUNTED......................8L-6

STORAGE BIN - INSTALLATION.........23-114

STORAGE BIN - REMOVAL............23-114

STOWAGE TRAY - INSTALLATION, REAR

FLOOR............................23-121

STOWAGE TRAY - REMOVAL, REAR

FLOOR............................23-121

STRAP - INSTALLATION, CAB-TO-BED

GROUND...........................8A-14

STRAP - INSTALLATION, ENGINE-TO-

BODY GROUND......................8A-13

STRAP - INSTALLATION, HEATER CORE

GROUND...........................8A-14

STRAP - REMOVAL, CAB-TO-BED

GROUND...........................8A-13

STRAP - REMOVAL, ENGINE-TO-BODY

GROUND...........................8A-12

STRAP - REMOVAL, HEATER CORE

GROUND...........................8A-14

STRETCH - INSPECTION, MEASURING

TIMING CHAIN..................9-111,9-54

STRIKER - INSTALLATION, GLOVE BOX

LATCH ............................23-112

STRIKER - INSTALLATION, LATCH . 23-103,23-66,

23-73

STRIKER - LOWER - INSTALLATION,

LATCH .............................23-82

STRIKER - LOWER - REMOVAL, LATCH . . . 23-82

STRIKER - REMOVAL, GLOVE BOX

LATCH ............................23-111

STRIKER - REMOVAL, LATCH....23-103,23-66,

23-73

STRIKER - UPPER - INSTALLATION,

LATCH .............................23-82

STRIKER - UPPER - REMOVAL, LATCH . . . 23-82

STRIPE - INSTALLATION, TAPE..........23-89

STRIPE - REMOVAL, TAPE.............23-88

STRIPES AND DECALS - INSTALLATION,

BODY..............................23-87

STRIPES AND DECALS - REMOVAL,

BODY..............................23-87

STRUCTURAL ADHESIVE LOCATIONS,

SPECIFICATIONS.....................23-44

STUDS - INSTALLATION...............22-12

STUDS - REMOVAL...................22-12

SUCTION AND DISCHARGE LINE -

INSTALLATION.......................24-52

SUCTION AND DISCHARGE LINE -

REMOVAL

..........................24-51

SUN VISOR - INSTALLATION

..........23-127

SUN VISOR - REMOVAL

..............23-127

SUPPLIES - DESCRIPTION, 5 VOLT

......8E-17

SUPPLIES - OPERATION, 5 VOLT

........8E-19

BR/BEINDEX 29

Description Group-Page Description Group-Page Description Group-Page

Page 2248 of 2255

SYSTEM - DIAGNOSIS AND TESTING,

POWER LOCK & REMOTE KEYLESS

ENTRY..............................8N-5

SYSTEM - DIAGNOSIS AND TESTING,

POWER SEAT.......................8N-16

SYSTEM - DIAGNOSIS AND TESTING,

POWER STEERING....................19-2

SYSTEM - DIAGNOSIS AND TESTING,

STARTING..........................8F-32

SYSTEM - DIAGNOSIS AND TESTING,

TURN SIGNAL & HAZARD WARNING......8L-3

SYSTEM - DIAGNOSIS AND TESTING,

VACUUM...........................24-10

SYSTEM - DIAGNOSIS AND TESTING,

VEHICLE THEFT SECURITY..............8Q-3

SYSTEM - DIAGNOSIS AND TESTING,

WIPER & WASHER....................8R-3

SYSTEM - INSPECTION, BATTERY........8F-6

SYSTEM - INSPECTION, WIPER &

WASHER............................8R-6

SYSTEM - LEAKS - DIAGNOSIS AND

TESTING, CHARGE AIR COOLER.........11-18

SYSTEM - OPERATION, AIR INJECTION . . . 25-28

SYSTEM - OPERATION, BATTERY.........8F-2

SYSTEM - OPERATION, CHIME

WARNING...........................8B-1

SYSTEM - OPERATION, COOLING..........7-4

SYSTEM - OPERATION, FUEL DELIVERY . . . 14-2

SYSTEM - OPERATION, HEATED MIRROR . . 8G-2

SYSTEM - OPERATION, HEATED SEAT.....8G-6

SYSTEM - OPERATION, INSTRUMENT

PANEL..............................23-106

SYSTEM - OPERATION, POWER SEAT....8N-16

SYSTEM - OPERATION, REMOTE

KEYLESS ENTRY......................8N-4

SYSTEM - OPERATION, SPEED CONTROL . . 8P-2

SYSTEM - OPERATION, TURN SIGNAL &

HAZARD WARNING....................8L-2

SYSTEM - SPECIAL TOOLS, AIRBAG......8O-6

SYSTEM - SPECIFICATIONS, TORQUE -

GENERATOR/CHARGING...............8F-27

SYSTEM - SPECIFICATIONS, TORQUE -

STARTING..........................8F-37

SYSTEM - STANDARD PROCEDURE,

BLEEDING ABS BRAKE.................5-36

SYSTEM - STANDARD PROCEDURE,

FLUSHING POWER STEERING...........19-34

SYSTEM - TORQUE, AIR INJECTION......25-29

SYSTEM - TORQUE, EVAP..............25-32

SYSTEM - TORQUE, SPEED CONTROL.....8P-4

SYSTEM 5.9L DIESEL ENGINE -

STANDARD PROCEDURE, DRAINING

COOLING............................7-15

SYSTEM 5.9L DIESEL ENGINE -

STANDARD PROCEDURE, REFILLING

COOLING............................7-16

SYSTEM 5.9L/8.0L ENGINES -

STANDARD PROCEDURE, DRAINING

COOLING............................7-15

SYSTEM 5.9L/8.0L ENGINES -

STANDARD PROCEDURE, REFILLING

COOLING............................7-16

SYSTEM AIR LEAK VACUUM TEST -

DIAGNOSIS AND TESTING, FUEL........14-57

SYSTEM AIRFLOW - DESCRIPTION,

HVAC..............................24-30

SYSTEM CHARGE - STANDARD

PROCEDURE, REFRIGERANT............24-46

SYSTEM CLEANING/REVERSE FLUSHING

- STANDARD PROCEDURE, COOLING......7-17

SYSTEM DIESEL ENGINE - DIAGNOSIS

AND TESTING, COOLING................7-13

SYSTEM EVACUATE - STANDARD

PROCEDURE, REFRIGERANT............24-46

SYSTEM FLOW - 5.9L DIESEL -

DESCRIPTION, COOLING.................7-2

SYSTEM FLOW - 5.9L ENGINE -

DESCRIPTION, COOLING.................7-1

SYSTEM GAS ENGINE - DIAGNOSIS AND

TESTING, COOLING

.....................7-7

SYSTEM LEAKS - DIAGNOSIS AND

TESTING, COOLING

.....................7-5

SYSTEM LEAKS - DIAGNOSIS AND

TESTING, REFRIGERANT

...............24-43

SYSTEM PARTS - STANDARD

PROCEDURES, CLEANING FUEL

.........14-61

SYSTEM PRESSURE - GAS ENGINES -

SPECIFICATIONS, FUEL

.................14-3SYSTEM PRESSURE RELEASE -

STANDARD PROCEDURE, FUEL..........14-3

SYSTEM PRESSURES, DIESEL ENGINES

- FUEL.............................14-62

SYSTEM REQUIREMENTS -

DESCRIPTION, COOLING................24-1

SYSTEM SERVICE EQUIPMENT -

STANDARD PROCEDURE,

REFRIGERANT.......................24-45

SYSTEM SERVICE PORT - DESCRIPTION,

REFRIGERANT........................24-1

SYSTEM SERVICE PORT - OPERATION,

REFRIGERANT........................24-2

SYSTEM, SPECIAL TOOLS - DIESEL

FUEL..............................14-63

SYSTEM, SPECIAL TOOLS - FUEL . . . 14-35,14-4

SYSTEM, SPECIFICATIONS - STARTING . . . 8F-36

SYSTEMS - DESCRIPTION, MONITORED . . 25-17

SYSTEMS, SPECIAL TOOLS - AUDIO......8A-4

SYSTEMS, SPECIAL TOOLS - POWER

DISTRIBUTION....................8W-97-2

TABLE, SPECIFICATIONS - A/C

APPLICATION........................24-7

TACHOMETER - DESCRIPTION..........8J-30

TACHOMETER - OPERATION............8J-30

TAIL LAMP - DESCRIPTION............8L-29

TAIL LAMP - INSTALLATION............8L-30

TAIL LAMP - OPERATION..............8L-29

TAIL LAMP - REMOVAL................8L-29

TAIL LAMP UNIT - INSTALLATION.......8L-30

TAIL LAMP UNIT - REMOVAL...........8L-30

TAILGATE - INSTALLATION.............23-67

TAILGATE - REMOVAL.................23-67

TAILPIPE - 3.9L/5.2L/5.9L - INSPECTION . . 11-11

TAILPIPE - 3.9L/5.2L/5.9L -

INSTALLATION.......................11-11

TAILPIPE - 3.9L/5.2L/5.9L - REMOVAL....11-11

TAILPIPE - 5.9L DIESEL - INSPECTION....11-12

TAILPIPE - 5.9L DIESEL - INSTALLATION . . 11-13

TAILPIPE - 5.9L DIESEL - REMOVAL.....11-12

TAILPIPE - 5.9L HD/8.0L - INSPECTION . . . 11-12

TAILPIPE - 5.9L HD/8.0L -

INSTALLATION.......................11-12

TAILPIPE - 5.9L HD/8.0L - REMOVAL.....11-12

TANK - DESCRIPTION, DIESEL FUEL.....14-82

TANK - DESCRIPTION, FUEL............14-18

TANK - INSTALLATION, FUEL...........14-20

TANK - OPERATION, FUEL..............14-18

TANK - REMOVAL, FUEL...............14-18

TANK CHECK VALVE - DESCRIPTION,

FUEL..............................14-21

TANK CHECK VALVE - INSTALLATION,

FUEL..............................14-23

TANK CHECK VALVE - REMOVAL, FUEL . . . 14-22

TANK MODULE - DESCRIPTION, FUEL....14-82

TANK MODULE - INSTALLATION, FUEL....14-83

TANK MODULE - OPERATION, FUEL......14-82

TANK MODULE - REMOVAL, FUEL.......14-83

TAPE STRIPE - INSTALLATION..........23-89

TAPE STRIPE - REMOVAL..............23-88

TAPPETS - DIAGNOSIS AND TESTING,

HYDRAULIC......................9-36,9-91

TASK MANAGER - DESCRIPTION........25-17

TASK MANAGER - OPERATION..........25-21

TEMP SENSOR - 5.9L - DESCRIPTION,

ENGINE COOLANT.....................7-47

TEMP SENSOR - 5.9L - INSTALLATION,

ENGINE COOLANT.....................7-47

TEMP SENSOR - 5.9L - OPERATION,

ENGINE COOLANT.....................7-47

TEMP SENSOR - 5.9L - REMOVAL,

ENGINE COOLANT.....................7-47

TEMP SENSOR - DESCRIPTION,

AMBIENT..........................8M-12

TEMP SENSOR - INSTALLATION,

AMBIENT..........................8M-13

TEMP SENSOR - OPERATION, AMBIENT . . 8M-12

TEMP SENSOR - REMOVAL, AMBIENT . . . 8M-12

TEMPERATURE GAUGE - DESCRIPTION,

ENGINE

............................8J-18

TEMPERATURE GAUGE - OPERATION,

ENGINE

............................8J-19

TEMPERATURE SENSOR - DESCRIPTION,

BATTERY

...........................8F-27

TEMPERATURE SENSOR - DESCRIPTION,

FUEL

.............................14-104

TEMPERATURE SENSOR - DESCRIPTION,

TRANSMISSION

...............21-218,21-390TEMPERATURE SENSOR - DIAGNOSIS

AND TESTING, AMBIENT..............8M-12

TEMPERATURE SENSOR -

INSTALLATION, BATTERY..............8F-28

TEMPERATURE SENSOR - OPERATION,

BATTERY...........................8F-27

TEMPERATURE SENSOR - OPERATION,

FUEL.............................14-104

TEMPERATURE SENSOR - OPERATION,

TRANSMISSION...............21-218,21-390

TEMPERATURE SENSOR - REMOVAL,

BATTERY...........................8F-27

TEMPORARY - DESCRIPTION, SPARE

TIRE................................22-6

TENSIONERS - 5.9L - DESCRIPTION,

BELT ...............................7-19

TENSIONERS - 5.9L - INSTALLATION,

BELT ...............................7-20

TENSIONERS - 5.9L - OPERATION, BELT . . . 7-19

TENSIONERS - 5.9L - REMOVAL, BELT.....7-19

TENSIONERS - 5.9L DIESEL -

DESCRIPTION, BELT...................7-23

TENSIONERS - 5.9L DIESEL -

INSTALLATION, BELT...................7-23

TENSIONERS - 5.9L DIESEL -

OPERATION, BELT.....................7-23

TENSIONERS - 5.9L DIESEL - REMOVAL,

BELT ...............................7-23

TENSIONERS - 8.0L - DESCRIPTION,

BELT ...............................7-20

TENSIONERS - 8.0L - INSTALLATION,

BELT ...............................7-22

TENSIONERS - 8.0L - OPERATION, BELT.....7-21

TENSIONERS - 8.0L - REMOVAL, BELT.....7-21

TERMINAL - INSTALLATION.........8W-01-13

TERMINAL - REMOVAL.............8W-01-13

TEST - DIAGNOSIS AND TESTING, FUEL

INJECTOR..........................14-99

TEST - DIAGNOSIS AND TESTING, FUEL

PRESSURE LEAK DOWN................14-2

TEST - DIAGNOSIS AND TESTING, FUEL

PUMP AMPERAGE....................14-10

TEST - DIAGNOSIS AND TESTING, FUEL

PUMP CAPACITY......................14-9

TEST - DIAGNOSIS AND TESTING, FUEL

PUMP PRESSURE.....................14-9

TEST - DIAGNOSIS AND TESTING, FUEL

SYSTEM AIR LEAK VACUUM............14-57

TEST - DIAGNOSIS AND TESTING,

HYDRAULIC PRESSURE.........21-270,21-98

TEST - DIAGNOSIS AND TESTING, ROAD . . . 8P-4

TEST - DIAGNOSIS AND TESTING,

VACUUM SUPPLY.....................8P-3

TEST - STANDARD PROCEDURE,

BUILT-IN INDICATOR..................8F-10

TEST - STANDARD PROCEDURE,

HYDROMETER.......................8F-11

TEST - STANDARD PROCEDURE,

IGNITION-OFF DRAW..................8F-13

TEST - STANDARD PROCEDURE, LOAD . . . 8F-12

TEST - STANDARD PROCEDURE,

OPEN-CIRCUIT VOLTAGE...............8F-12

TEST - STANDARD PROCEDURE,

VERIFICATION........................8O-5

TEST MODE - DESCRIPTION, CIRCUIT

ACTUATION

..........................25-2

TEST MODE - DESCRIPTION, STATE

DISPLAY

............................25-1

TETHER - INSTALLATION, CHILD

.........8O-9

TETHER - REMOVAL, CHILD

.............8O-9

THEFT SECURITY - DESCRIPTION,

VEHICLE

............................8Q-1

THEFT SECURITY - OPERATION, VEHICLE

. . 8Q-2

THEFT SECURITY SYSTEM - DIAGNOSIS

AND TESTING, VEHICLE

................8Q-3

THERMOSTAT - 5.9L - DESCRIPTION,

ENGINE COOLANT

.....................7-48

THERMOSTAT - 5.9L - INSTALLATION,

ENGINE COOLANT

.....................7-49

THERMOSTAT - 5.9L - OPERATION,

ENGINE COOLANT

.....................7-48

THERMOSTAT - 5.9L - REMOVAL,

ENGINE COOLANT

.....................7-48

THERMOSTAT - 5.9L DIESEL -

DESCRIPTION, ENGINE COOLANT

.........7-53

THERMOSTAT - 5.9L DIESEL -

INSTALLATION, ENGINE COOLANT

........7-54

BR/BEINDEX 31

Description Group-Page Description Group-Page Description Group-Page