DODGE RAM 2003 Service Repair Manual

Manufacturer: DODGE, Model Year: 2003, Model line: RAM, Model: DODGE RAM 2003Pages: 2895, PDF Size: 83.15 MB

Page 2141 of 2895

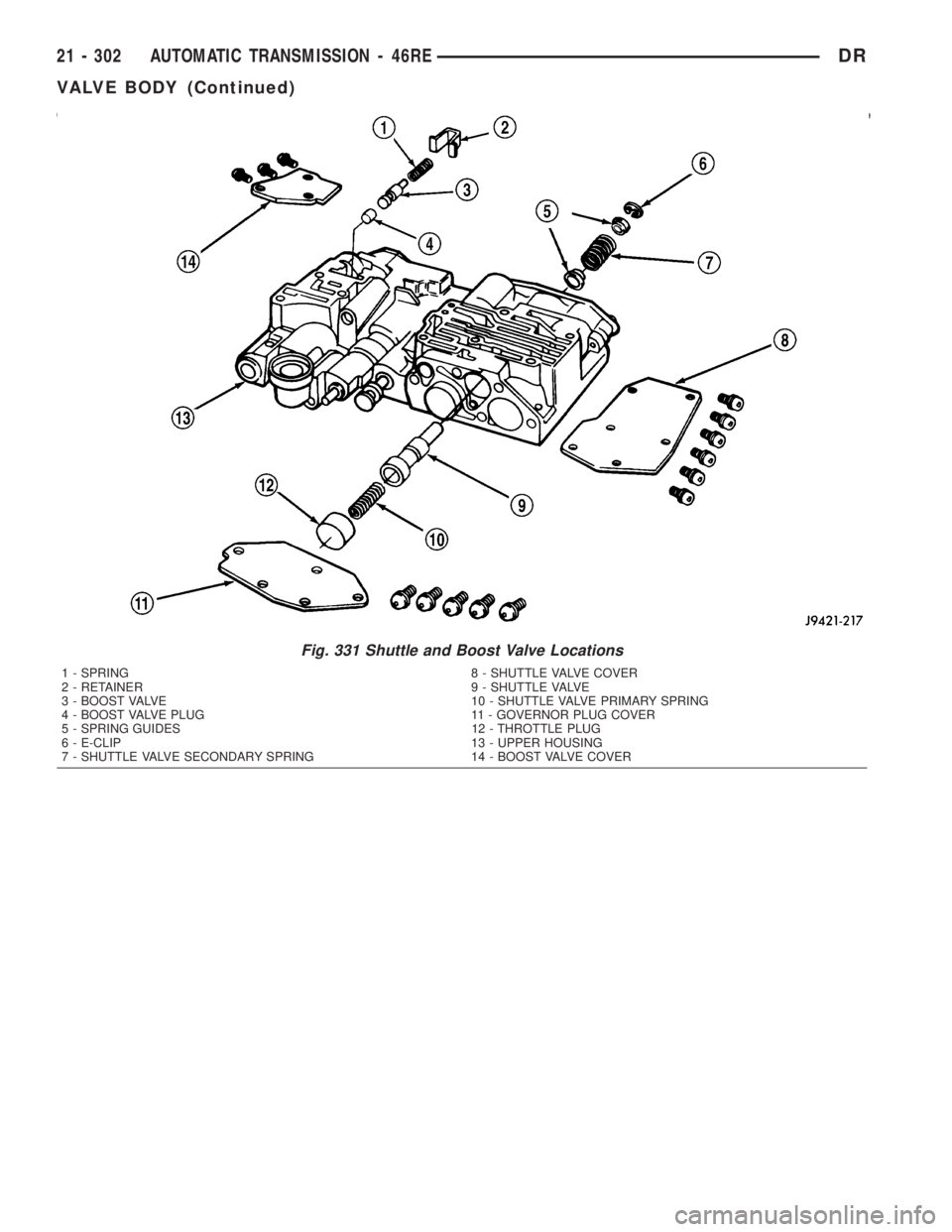

Fig. 331 Shuttle and Boost Valve Locations

1 - SPRING 8 - SHUTTLE VALVE COVER

2 - RETAINER 9 - SHUTTLE VALVE

3 - BOOST VALVE 10 - SHUTTLE VALVE PRIMARY SPRING

4 - BOOST VALVE PLUG 11 - GOVERNOR PLUG COVER

5 - SPRING GUIDES 12 - THROTTLE PLUG

6 - E-CLIP 13 - UPPER HOUSING

7 - SHUTTLE VALVE SECONDARY SPRING 14 - BOOST VALVE COVER

21 - 302 AUTOMATIC TRANSMISSION - 46REDR

VALVE BODY (Continued)

Page 2142 of 2895

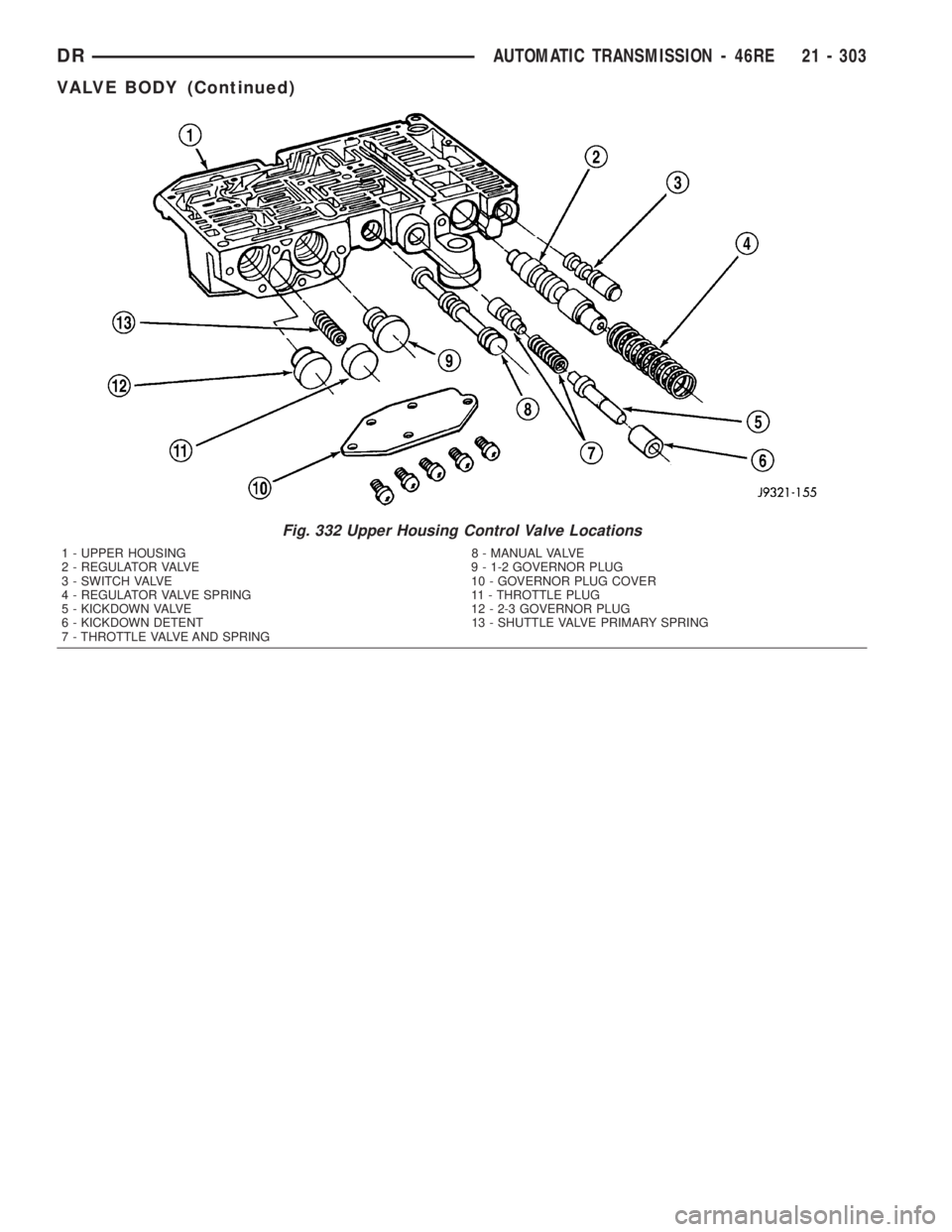

Fig. 332 Upper Housing Control Valve Locations

1 - UPPER HOUSING 8 - MANUAL VALVE

2 - REGULATOR VALVE 9 - 1-2 GOVERNOR PLUG

3 - SWITCH VALVE 10 - GOVERNOR PLUG COVER

4 - REGULATOR VALVE SPRING 11 - THROTTLE PLUG

5 - KICKDOWN VALVE 12 - 2-3 GOVERNOR PLUG

6 - KICKDOWN DETENT 13 - SHUTTLE VALVE PRIMARY SPRING

7 - THROTTLE VALVE AND SPRING

DRAUTOMATIC TRANSMISSION - 46RE 21 - 303

VALVE BODY (Continued)

Page 2143 of 2895

BOOST VALVE TUBE AND BRACE

(1) Position valve body assembly so lower housing

is facing upward (Fig. 334).

(2) Lubricate tube ends and housing ports with

transmission fluid or petroleum jelly.

(3) Start tube in lower housing port first. Then

swing tube downward and work opposite end of tube

into upper housing port (Fig. 334).

(4) Insert and seat each end of tube in housings.

(5) Slide tube brace under tube and into alignment

with valve body screw holes (Fig. 335).

(6) Install and finger tighten three screws that

secure tube brace to valve body housings (Fig. 335).

(7) Bend tube brace tabs up and against tube to

hold it in position (Fig. 336).

(8) Tighten all valve body housing screws to 4 N´m

(35 in. lbs.) torque after tube and brace are installed.

Tighten screws in diagonal pattern starting at center

and working outward.

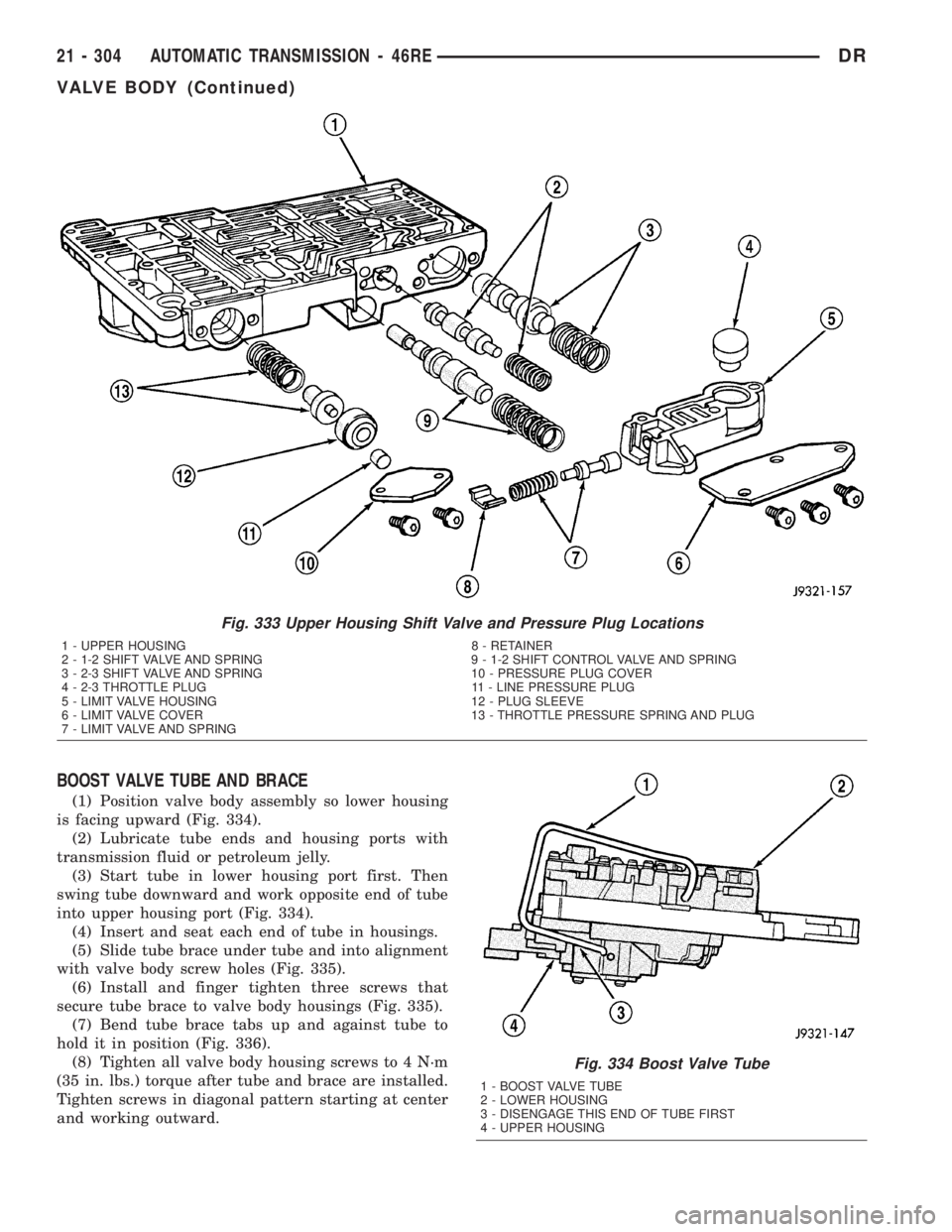

Fig. 333 Upper Housing Shift Valve and Pressure Plug Locations

1 - UPPER HOUSING 8 - RETAINER

2 - 1-2 SHIFT VALVE AND SPRING 9 - 1-2 SHIFT CONTROL VALVE AND SPRING

3 - 2-3 SHIFT VALVE AND SPRING 10 - PRESSURE PLUG COVER

4 - 2-3 THROTTLE PLUG 11 - LINE PRESSURE PLUG

5 - LIMIT VALVE HOUSING 12 - PLUG SLEEVE

6 - LIMIT VALVE COVER 13 - THROTTLE PRESSURE SPRING AND PLUG

7 - LIMIT VALVE AND SPRING

Fig. 334 Boost Valve Tube

1 - BOOST VALVE TUBE

2 - LOWER HOUSING

3 - DISENGAGE THIS END OF TUBE FIRST

4 - UPPER HOUSING

21 - 304 AUTOMATIC TRANSMISSION - 46REDR

VALVE BODY (Continued)

Page 2144 of 2895

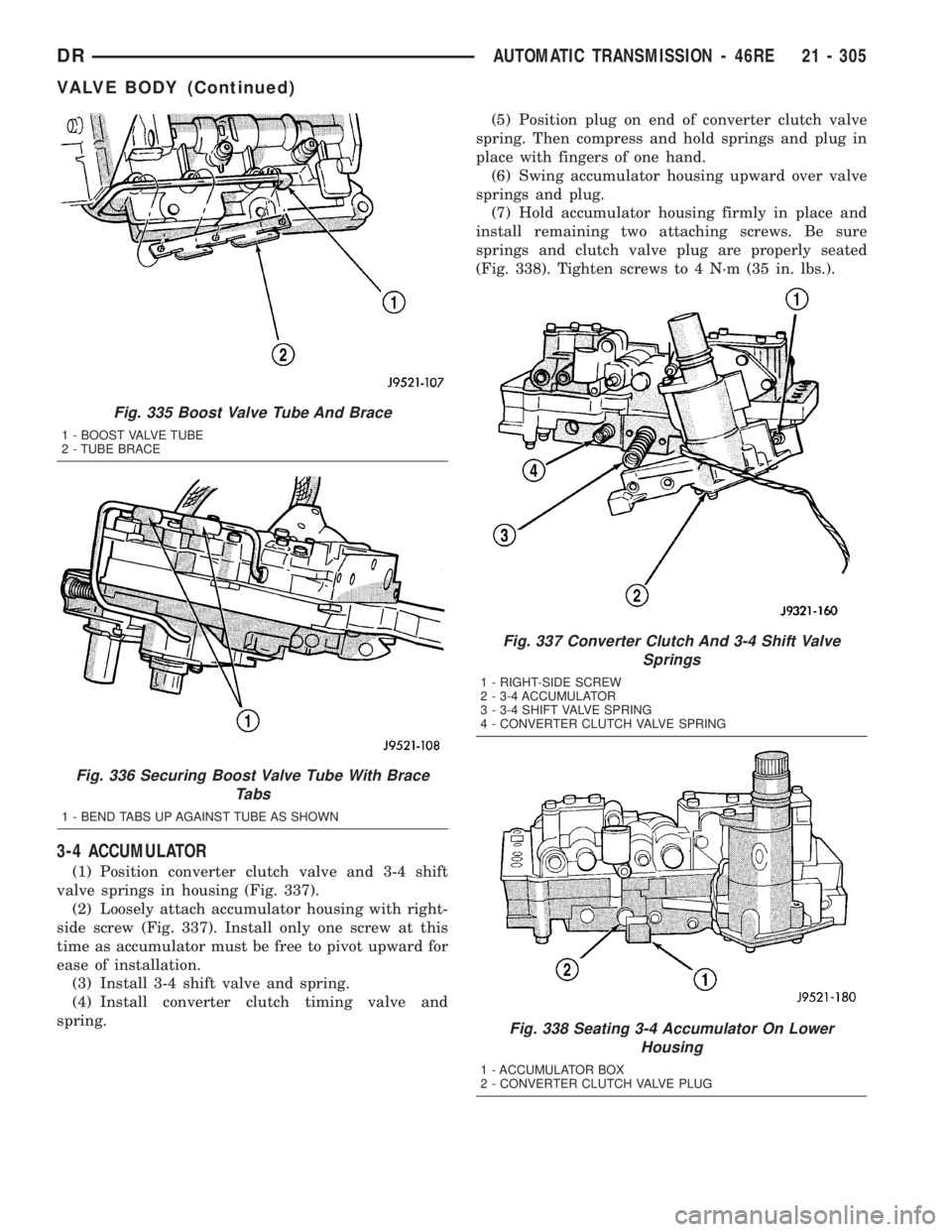

3-4 ACCUMULATOR

(1) Position converter clutch valve and 3-4 shift

valve springs in housing (Fig. 337).

(2) Loosely attach accumulator housing with right-

side screw (Fig. 337). Install only one screw at this

time as accumulator must be free to pivot upward for

ease of installation.

(3) Install 3-4 shift valve and spring.

(4) Install converter clutch timing valve and

spring.(5) Position plug on end of converter clutch valve

spring. Then compress and hold springs and plug in

place with fingers of one hand.

(6) Swing accumulator housing upward over valve

springs and plug.

(7) Hold accumulator housing firmly in place and

install remaining two attaching screws. Be sure

springs and clutch valve plug are properly seated

(Fig. 338). Tighten screws to 4 N´m (35 in. lbs.).

Fig. 335 Boost Valve Tube And Brace

1 - BOOST VALVE TUBE

2 - TUBE BRACE

Fig. 336 Securing Boost Valve Tube With Brace

Tabs

1 - BEND TABS UP AGAINST TUBE AS SHOWN

Fig. 337 Converter Clutch And 3-4 Shift Valve

Springs

1 - RIGHT-SIDE SCREW

2 - 3-4 ACCUMULATOR

3 - 3-4 SHIFT VALVE SPRING

4 - CONVERTER CLUTCH VALVE SPRING

Fig. 338 Seating 3-4 Accumulator On Lower

Housing

1 - ACCUMULATOR BOX

2 - CONVERTER CLUTCH VALVE PLUG

DRAUTOMATIC TRANSMISSION - 46RE 21 - 305

VALVE BODY (Continued)

Page 2145 of 2895

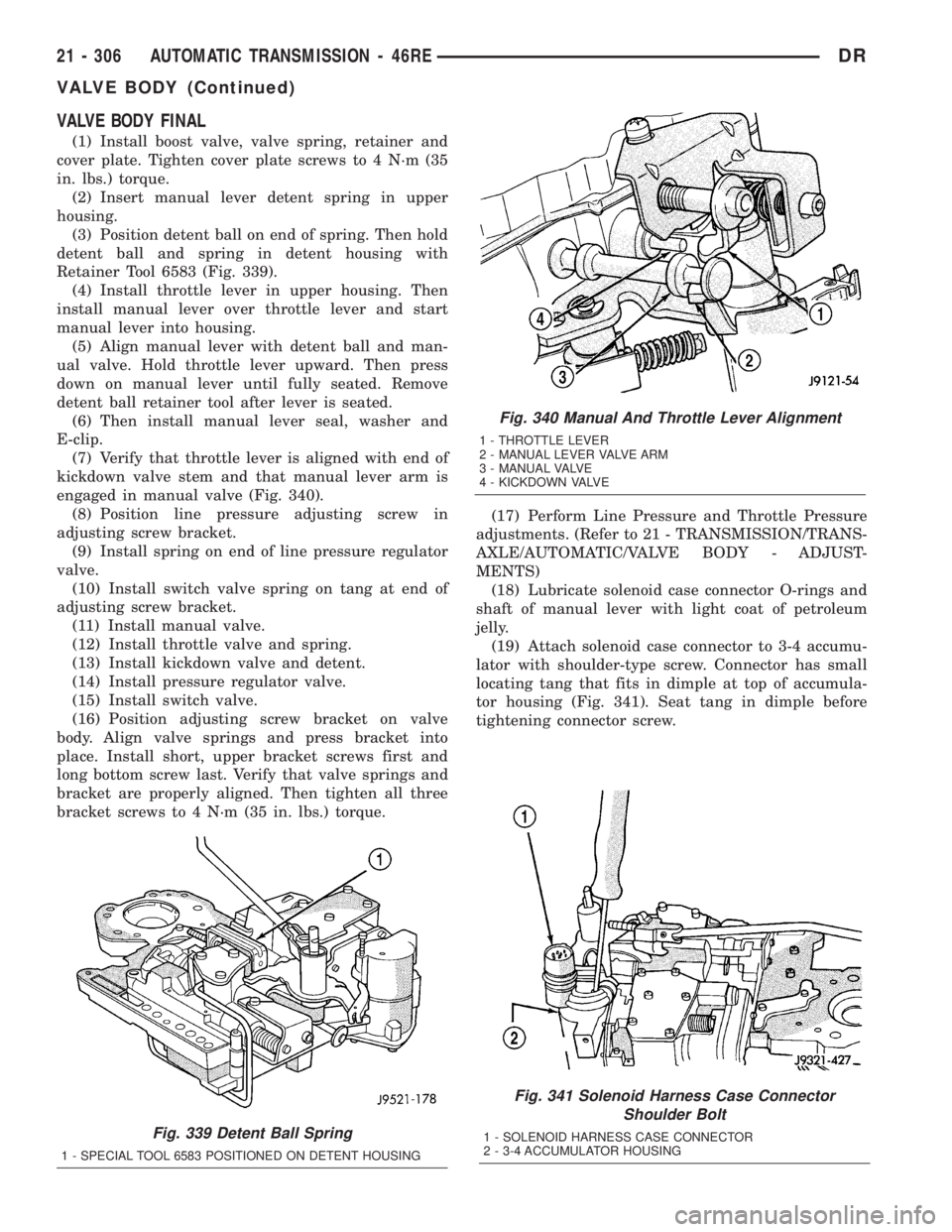

VALVE BODY FINAL

(1) Install boost valve, valve spring, retainer and

cover plate. Tighten cover plate screws to 4 N´m (35

in. lbs.) torque.

(2) Insert manual lever detent spring in upper

housing.

(3) Position detent ball on end of spring. Then hold

detent ball and spring in detent housing with

Retainer Tool 6583 (Fig. 339).

(4) Install throttle lever in upper housing. Then

install manual lever over throttle lever and start

manual lever into housing.

(5) Align manual lever with detent ball and man-

ual valve. Hold throttle lever upward. Then press

down on manual lever until fully seated. Remove

detent ball retainer tool after lever is seated.

(6) Then install manual lever seal, washer and

E-clip.

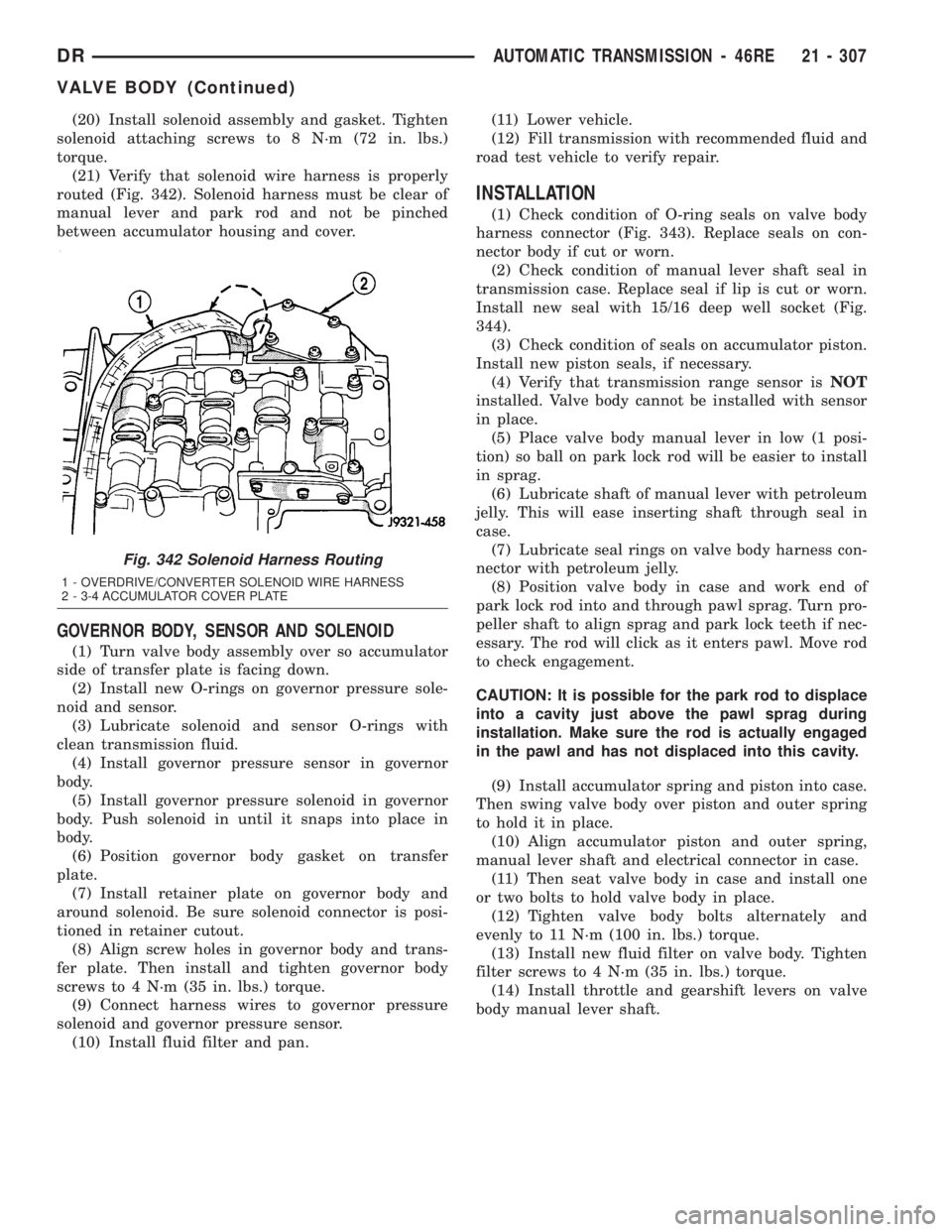

(7) Verify that throttle lever is aligned with end of

kickdown valve stem and that manual lever arm is

engaged in manual valve (Fig. 340).

(8) Position line pressure adjusting screw in

adjusting screw bracket.

(9) Install spring on end of line pressure regulator

valve.

(10) Install switch valve spring on tang at end of

adjusting screw bracket.

(11) Install manual valve.

(12) Install throttle valve and spring.

(13) Install kickdown valve and detent.

(14) Install pressure regulator valve.

(15) Install switch valve.

(16) Position adjusting screw bracket on valve

body. Align valve springs and press bracket into

place. Install short, upper bracket screws first and

long bottom screw last. Verify that valve springs and

bracket are properly aligned. Then tighten all three

bracket screws to 4 N´m (35 in. lbs.) torque.(17) Perform Line Pressure and Throttle Pressure

adjustments. (Refer to 21 - TRANSMISSION/TRANS-

AXLE/AUTOMATIC/VALVE BODY - ADJUST-

MENTS)

(18) Lubricate solenoid case connector O-rings and

shaft of manual lever with light coat of petroleum

jelly.

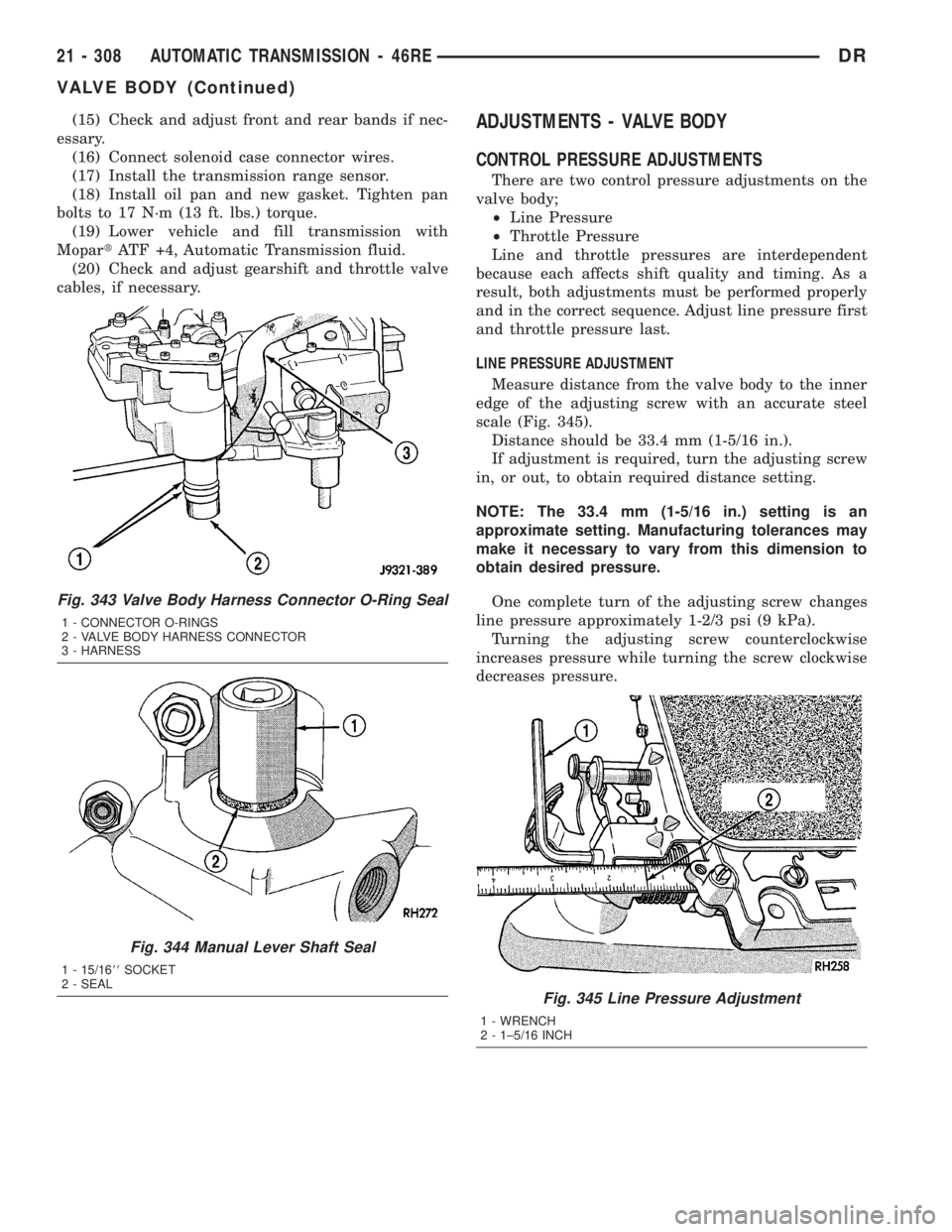

(19) Attach solenoid case connector to 3-4 accumu-

lator with shoulder-type screw. Connector has small

locating tang that fits in dimple at top of accumula-

tor housing (Fig. 341). Seat tang in dimple before

tightening connector screw.

Fig. 339 Detent Ball Spring

1 - SPECIAL TOOL 6583 POSITIONED ON DETENT HOUSING

Fig. 340 Manual And Throttle Lever Alignment

1 - THROTTLE LEVER

2 - MANUAL LEVER VALVE ARM

3 - MANUAL VALVE

4 - KICKDOWN VALVE

Fig. 341 Solenoid Harness Case Connector

Shoulder Bolt

1 - SOLENOID HARNESS CASE CONNECTOR

2 - 3-4 ACCUMULATOR HOUSING

21 - 306 AUTOMATIC TRANSMISSION - 46REDR

VALVE BODY (Continued)

Page 2146 of 2895

(20) Install solenoid assembly and gasket. Tighten

solenoid attaching screws to 8 N´m (72 in. lbs.)

torque.

(21) Verify that solenoid wire harness is properly

routed (Fig. 342). Solenoid harness must be clear of

manual lever and park rod and not be pinched

between accumulator housing and cover.

GOVERNOR BODY, SENSOR AND SOLENOID

(1) Turn valve body assembly over so accumulator

side of transfer plate is facing down.

(2) Install new O-rings on governor pressure sole-

noid and sensor.

(3) Lubricate solenoid and sensor O-rings with

clean transmission fluid.

(4) Install governor pressure sensor in governor

body.

(5) Install governor pressure solenoid in governor

body. Push solenoid in until it snaps into place in

body.

(6) Position governor body gasket on transfer

plate.

(7) Install retainer plate on governor body and

around solenoid. Be sure solenoid connector is posi-

tioned in retainer cutout.

(8) Align screw holes in governor body and trans-

fer plate. Then install and tighten governor body

screws to 4 N´m (35 in. lbs.) torque.

(9) Connect harness wires to governor pressure

solenoid and governor pressure sensor.

(10) Install fluid filter and pan.(11) Lower vehicle.

(12) Fill transmission with recommended fluid and

road test vehicle to verify repair.

INSTALLATION

(1) Check condition of O-ring seals on valve body

harness connector (Fig. 343). Replace seals on con-

nector body if cut or worn.

(2) Check condition of manual lever shaft seal in

transmission case. Replace seal if lip is cut or worn.

Install new seal with 15/16 deep well socket (Fig.

344).

(3) Check condition of seals on accumulator piston.

Install new piston seals, if necessary.

(4) Verify that transmission range sensor isNOT

installed. Valve body cannot be installed with sensor

in place.

(5) Place valve body manual lever in low (1 posi-

tion) so ball on park lock rod will be easier to install

in sprag.

(6) Lubricate shaft of manual lever with petroleum

jelly. This will ease inserting shaft through seal in

case.

(7) Lubricate seal rings on valve body harness con-

nector with petroleum jelly.

(8) Position valve body in case and work end of

park lock rod into and through pawl sprag. Turn pro-

peller shaft to align sprag and park lock teeth if nec-

essary. The rod will click as it enters pawl. Move rod

to check engagement.

CAUTION: It is possible for the park rod to displace

into a cavity just above the pawl sprag during

installation. Make sure the rod is actually engaged

in the pawl and has not displaced into this cavity.

(9) Install accumulator spring and piston into case.

Then swing valve body over piston and outer spring

to hold it in place.

(10) Align accumulator piston and outer spring,

manual lever shaft and electrical connector in case.

(11) Then seat valve body in case and install one

or two bolts to hold valve body in place.

(12) Tighten valve body bolts alternately and

evenly to 11 N´m (100 in. lbs.) torque.

(13) Install new fluid filter on valve body. Tighten

filter screws to 4 N´m (35 in. lbs.) torque.

(14) Install throttle and gearshift levers on valve

body manual lever shaft.

Fig. 342 Solenoid Harness Routing

1 - OVERDRIVE/CONVERTER SOLENOID WIRE HARNESS

2 - 3-4 ACCUMULATOR COVER PLATE

DRAUTOMATIC TRANSMISSION - 46RE 21 - 307

VALVE BODY (Continued)

Page 2147 of 2895

(15) Check and adjust front and rear bands if nec-

essary.

(16) Connect solenoid case connector wires.

(17) Install the transmission range sensor.

(18) Install oil pan and new gasket. Tighten pan

bolts to 17 N´m (13 ft. lbs.) torque.

(19) Lower vehicle and fill transmission with

MopartATF +4, Automatic Transmission fluid.

(20) Check and adjust gearshift and throttle valve

cables, if necessary.ADJUSTMENTS - VALVE BODY

CONTROL PRESSURE ADJUSTMENTS

There are two control pressure adjustments on the

valve body;

²Line Pressure

²Throttle Pressure

Line and throttle pressures are interdependent

because each affects shift quality and timing. As a

result, both adjustments must be performed properly

and in the correct sequence. Adjust line pressure first

and throttle pressure last.

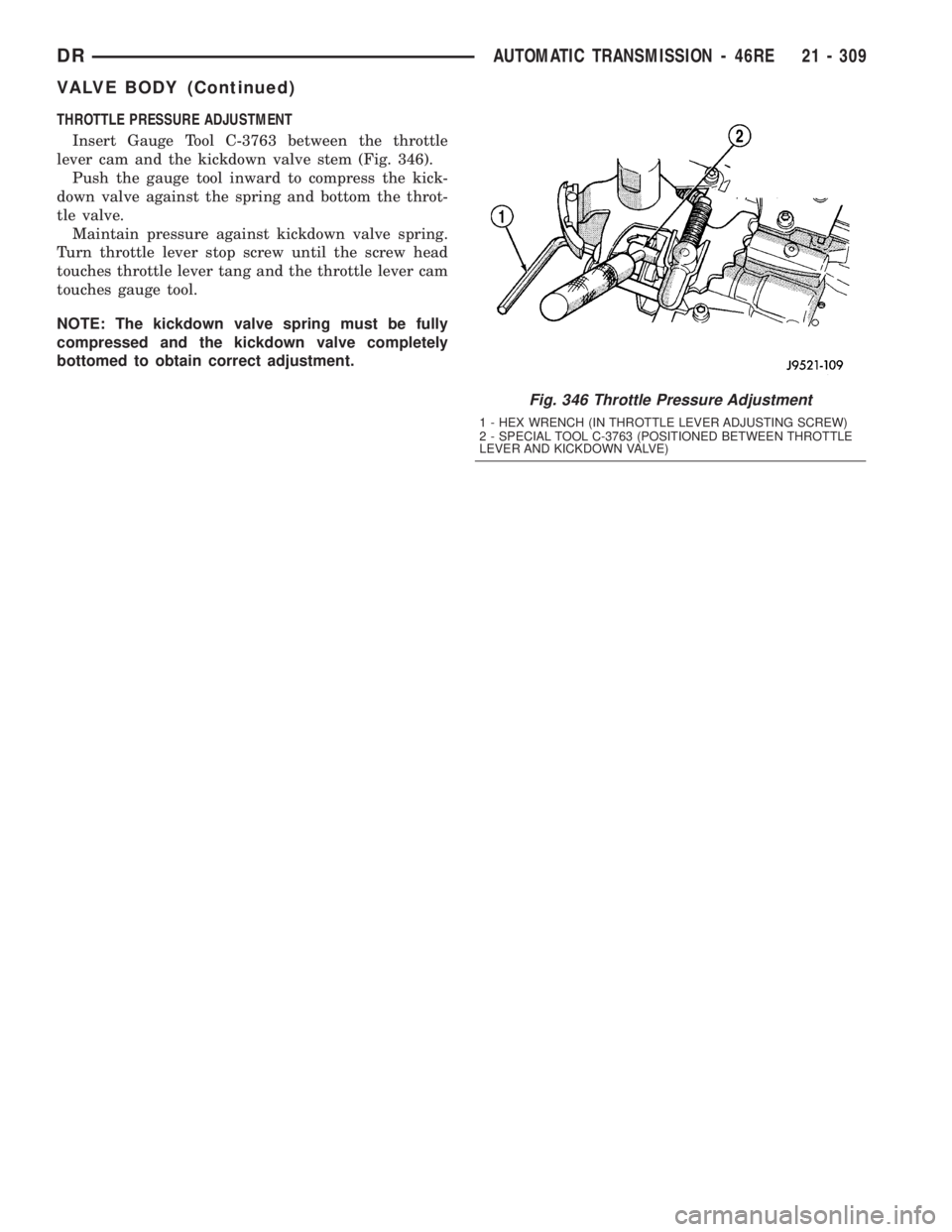

LINE PRESSURE ADJUSTMENT

Measure distance from the valve body to the inner

edge of the adjusting screw with an accurate steel

scale (Fig. 345).

Distance should be 33.4 mm (1-5/16 in.).

If adjustment is required, turn the adjusting screw

in, or out, to obtain required distance setting.

NOTE: The 33.4 mm (1-5/16 in.) setting is an

approximate setting. Manufacturing tolerances may

make it necessary to vary from this dimension to

obtain desired pressure.

One complete turn of the adjusting screw changes

line pressure approximately 1-2/3 psi (9 kPa).

Turning the adjusting screw counterclockwise

increases pressure while turning the screw clockwise

decreases pressure.

Fig. 343 Valve Body Harness Connector O-Ring Seal

1 - CONNECTOR O-RINGS

2 - VALVE BODY HARNESS CONNECTOR

3 - HARNESS

Fig. 344 Manual Lever Shaft Seal

1 - 15/1688SOCKET

2 - SEAL

Fig. 345 Line Pressure Adjustment

1 - WRENCH

2 - 1±5/16 INCH

21 - 308 AUTOMATIC TRANSMISSION - 46REDR

VALVE BODY (Continued)

Page 2148 of 2895

THROTTLE PRESSURE ADJUSTMENT

Insert Gauge Tool C-3763 between the throttle

lever cam and the kickdown valve stem (Fig. 346).

Push the gauge tool inward to compress the kick-

down valve against the spring and bottom the throt-

tle valve.

Maintain pressure against kickdown valve spring.

Turn throttle lever stop screw until the screw head

touches throttle lever tang and the throttle lever cam

touches gauge tool.

NOTE: The kickdown valve spring must be fully

compressed and the kickdown valve completely

bottomed to obtain correct adjustment.

Fig. 346 Throttle Pressure Adjustment

1 - HEX WRENCH (IN THROTTLE LEVER ADJUSTING SCREW)

2 - SPECIAL TOOL C-3763 (POSITIONED BETWEEN THROTTLE

LEVER AND KICKDOWN VALVE)

DRAUTOMATIC TRANSMISSION - 46RE 21 - 309

VALVE BODY (Continued)

Page 2149 of 2895

AUTOMATIC TRANSMISSION - 48RE

TABLE OF CONTENTS

page page

AUTOMATIC TRANSMISSION - 48RE

DESCRIPTION........................312

OPERATION..........................314

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - AUTOMATIC

TRANSMISSION.....................320

DIAGNOSIS AND TESTING - PRELIMINARY. . 320

DIAGNOSIS AND TESTING - ROAD

TESTING...........................320

DIAGNOSIS AND TESTING - HYDRAULIC

PRESSURE TEST....................321

DIAGNOSIS AND TESTING - AIR TESTING

TRANSMISSION CLUTCH AND BAND

OPERATION........................324

DIAGNOSIS AND TESTING - CONVERTER

HOUSING FLUID LEAK................324

DIAGNOSIS AND TESTING - DIAGNOSIS

CHARTS...........................325

STANDARD PROCEDURE - ALUMINUM

THREAD REPAIR.....................337

REMOVAL............................337

DISASSEMBLY........................339

CLEANING...........................345

INSPECTION.........................345

ASSEMBLY...........................346

INSTALLATION........................353

SCHEMATICS AND DIAGRAMS

HYDRAULIC SCHEMATICS.............355

SPECIFICATIONS

TRANSMISSION.....................368

SPECIAL TOOLS

RE TRANSMISSION..................370

ACCUMULATOR

DESCRIPTION........................372

OPERATION..........................373

INSPECTION.........................373

BANDS

DESCRIPTION........................373

OPERATION..........................374

ADJUSTMENTS

ADJUSTMENT - BANDS...............374

BRAKE TRANSMISSION SHIFT INTERLOCK

SYSTEM

DESCRIPTION........................375

OPERATION..........................375

DIAGNOSIS AND TESTING - BRAKE

TRANSMISSION SHIFT INTERLOCK......375

ADJUSTMENTS - BRAKE TRANSMISSION

SHIFT INTERLOCK...................376ELECTRONIC GOVERNOR

DESCRIPTION........................376

OPERATION..........................377

REMOVAL............................378

INSTALLATION........................379

EXTENSION HOUSING SEAL

REMOVAL............................380

INSTALLATION........................380

FLUID AND FILTER

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - EFFECTS OF

INCORRECT FLUID LEVEL.............381

DIAGNOSIS AND TESTING - CAUSES OF

BURNT FLUID.......................381

DIAGNOSIS AND TESTING - FLUID

CONTAMINATION....................381

STANDARD PROCEDURE

STANDARD PROCEDURE - FLUID LEVEL

CHECK............................381

STANDARD PROCEDURE - FLUID AND

FILTER REPLACEMENT...............383

STANDARD PROCEDURE - TRANSMISSION

FILL...............................383

FRONT CLUTCH

DESCRIPTION........................384

OPERATION..........................384

DISASSEMBLY........................384

INSPECTION.........................385

ASSEMBLY...........................386

FRONT SERVO

DESCRIPTION........................387

OPERATION..........................387

DISASSEMBLY........................388

CLEANING...........................388

INSPECTION.........................388

ASSEMBLY...........................388

GEARSHIFT CABLE

DIAGNOSIS AND TESTING - GEARSHIFT

CABLE.............................389

REMOVAL............................389

INSTALLATION........................390

ADJUSTMENTS

GEARSHIFT CABLE..................391

OIL PUMP

DESCRIPTION........................392

OPERATION..........................392

DISASSEMBLY........................393

CLEANING...........................393

INSPECTION.........................393

ASSEMBLY...........................393

21 - 310 AUTOMATIC TRANSMISSION - 48REDR

Page 2150 of 2895

OUTPUT SHAFT FRONT BEARING

REMOVAL............................395

INSTALLATION........................395

OUTPUT SHAFT REAR BEARING

REMOVAL............................395

INSTALLATION........................396

OVERDRIVE CLUTCH

DESCRIPTION........................396

OPERATION..........................396

OVERDRIVE SWITCH

DESCRIPTION........................397

OPERATION..........................397

DIAGNOSIS AND TESTING - OVERDRIVE

ELECTRICAL CONTROLS..............397

REMOVAL............................397

INSTALLATION........................397

OVERDRIVE UNIT

REMOVAL............................398

DISASSEMBLY........................399

CLEANING...........................405

INSPECTION.........................406

ASSEMBLY...........................406

INSTALLATION........................414

OVERRUNNING CLUTCH CAM/OVERDRIVE

PISTON RETAINER

DESCRIPTION........................415

OPERATION..........................415

DISASSEMBLY........................415

CLEANING...........................416

INSPECTION.........................416

ASSEMBLY...........................416

PISTONS

DESCRIPTION........................418

OPERATION..........................418

PLANETARY GEARTRAIN/OUTPUT SHAFT

DESCRIPTION........................420

OPERATION..........................420

DISASSEMBLY........................421

INSPECTION.........................422

ASSEMBLY...........................423

REAR CLUTCH

DESCRIPTION........................426

OPERATION..........................427

DISASSEMBLY........................427

CLEANING...........................428

INSPECTION.........................428

ASSEMBLY...........................428REAR SERVO

DESCRIPTION........................429

OPERATION..........................429

DISASSEMBLY........................430

CLEANING...........................430

ASSEMBLY...........................430

SHIFT MECHANISM

DESCRIPTION........................430

OPERATION..........................430

SOLENOID

DESCRIPTION........................431

OPERATION..........................431

SPEED SENSOR

DESCRIPTION........................431

OPERATION..........................431

THROTTLE VALVE CABLE

DESCRIPTION........................432

ADJUSTMENTS - THROTTLE VALVE CABLE . 432

TORQUE CONVERTER

DESCRIPTION........................434

OPERATION..........................438

REMOVAL............................439

INSTALLATION........................439

TORQUE CONVERTER DRAINBACK VALVE

DESCRIPTION........................440

OPERATION..........................440

STANDARD PROCEDURE - TORQUE

CONVERTER DRAINBACK VALVE........440

TRANSMISSION RANGE SENSOR

DESCRIPTION........................441

OPERATION..........................441

DIAGNOSIS AND TESTING - TRANSMISSION

RANGE SENSOR (TRS)................442

REMOVAL............................443

INSTALLATION........................444

TRANSMISSION TEMPERATURE SENSOR

DESCRIPTION........................445

OPERATION..........................445

VALVE BODY

DESCRIPTION........................445

OPERATION..........................450

REMOVAL............................464

DISASSEMBLY........................465

CLEANING...........................476

INSPECTION.........................476

ASSEMBLY...........................477

INSTALLATION........................486

ADJUSTMENTS - VALVE BODY...........487

DRAUTOMATIC TRANSMISSION - 48RE 21 - 311