DODGE RAM SRT-10 2006 Service Repair Manual

Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 1411 of 5267

3.CMP WIRE HARNESS INSPECTION

Visually inspect the related wire harness. Look for any chafed, pierced, pinched, or partially broken wires.

Visually inspect the related wire harness connectors. Look for broken, bent, pushed out, or corroded terminals.

Make sure the Crankshaft Position Sensor and the Camshaft Position Sensorare properly installed and the mount-

ing bolt(s) are torqued to specification.

Refer to any TSB that may apply.

Were any of the above conditions present?

Ye s>>

Repair as necessary

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 4

4.TONE WHEEL/PULSE RING INSPECTION

Turn the ignition off.

Remove the Camshaft Position Sensor.

Inspect the Tone Wheel/Pulse Ring for damage, foreign material, or excessive movement.

Were any problems found?

Ye s>>

Repair or replace the Tone Wheel/Pulse Ring as necessary.

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 5

5.CAMSHAFT POSITION SENSOR

If there are no possible causes remaining, view repair.

Repair

Replace the Camshaft Position Sensor.

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

6.CHECKING CKP SIGNAL WITH THE SCAN TOOL LAB

Turn the ignition off.

With the scan tool as a Dual Channel Lab Scope and the Miller special tool #6801, backprobe the (K24) CKP Signal

circuit in the CKP harness connector and PCM harness connector.

WARNING: When the engine is operating, do not stand in a direct line with thefan. Do not put your hand

near the pulleys, belts, or fan. Do not wear loose clothing.

Start the engine.

Observe the lab scope screen.

Are there any irregular or missing signals?

Ye s>>

Go To 7

No>>

Go To 10

Page 1412 of 5267

7.CKP WIRE HARNESS INSPECTION

Visually inspect the related wire harness. Look for any chafed, pierced, pinched, or partially broken wires.

Visually inspect the related wire harness connectors. Look for broken, bent, pushed out, or corroded terminals.

Ensure the Crankshaft Position Sensor and the Camshaft Position Sensor are properly installed and the mounting

bolt(s) are torqued to specification.

Refer to any TSB that may apply.

Were any of the above conditions present?

Ye s>>

Repair as necessary

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 8

8.TONE WHEEL/FLEX PLATE INSPECTION

Remove the Crankshaft Position Sensor.

Inspect the Tone Wheel/Flex Plate slots for damage, foreign material, or excessive movement.

Were any problems found?

Ye s>>

Repair or replace the Tone Wheel/Flex Plate as necessary.

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 9

9.CRANKSHAFT POSITION SENSOR

If there are no possible causes remaining, view repair.

Repair

Replace the Crankshaft Position Sensor.

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

10.CHECKING CKP SIGNAL WITH LAB SCOPE

NOTE: The conditions that set this DTC are not present at this time. The following test may help in identi-

fying the intermittent condition.

Turn the ignition off.

With the scan tool as a Dual Channel Lab Scope and the Miller special tool #6801, backprobe the (K24) CKP Signal

circuit in the PCM harness connector and CKP harness connector.

WARNING: When the engine is operating, do not stand in a direct line with thefan. Do not put your hand

near the pulleys, belts, or fan. Do not wear loose clothing.

Start the engine.

Carefully wiggle the related wire harness and gently tap on the CKP sensor.

Compare the Channel 1 reading to the Channel 2 reading on the lab scope screen.

Both of the readings should be the same.

Were any of the above conditions present?

Ye s>>

Repair the wiring or connector concern.

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Te s t C o m p l e t e .

Page 1413 of 5267

P1398-MIS-FIRE ADAPTIVE NUMERATOR AT LIMIT

For a complete wiring diagramRefer to Section 8W.

When Monitored:

Under closed throttle decel and Fuel Pulse Width equal to zero for 30 seconds.

Set Condition:

One of the CKP sensor target windows has more than 2.86% variance from the reference window.

Possible Causes

ADAPTIVE NUMERATOR RELEARN

CMP SENSOR CONNECTOR/WIRING

CKP SENSOR CONNECTOR/WIRING

DAMAGED TONE WHEEL/FLEX PLATE (CRANKSHAFT)

CRANKSHAFT POSITION SENSOR

PCM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

1.ADAPTIVE NUMERATOR RELEARN

NOTE: Check for any TSB’s that may apply to this symptom.

Read and record the Freeze Frame Data. Use this information to help you duplicate the conditions that set the DTC.

Pay particular attention to the DTC set conditions, such as, VSS, MAP, ECT,and Load.

Ignition on, engine not running.

With the scan tool in the miscellaneous menu, choose Clear PCM (battery disconnect) to reset the PCM.

With the scan tool, choose the Misfire Pretest screen.

Road test the vehicle and re-learn the adaptive numerator.

The adaptive numerator is learned when the Adaptive Numerator Done Learning line on the Misfire screen changes

to Yes.

Did the adaptive numerator re-learn?

Ye s>>

Refer to the INTERMITTENT CONDITIONSymptom (Diagnostic Procedure).

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 2

2.CMP CONNECTOR/HARNESS INSPECTION

Turn ignition off.

NOTE: Visually inspect the related wire harness connectors. Look for broken, bent, pushed out, or corroded

terminals.

NOTE: Visually inspect the related wire harness. Look for any chafed, pierced, pinched, or partially broken

wires.

NOTE: Make sure the Camshaft Position Sensor is tight.

NOTE: Refer to any technical service bulletins that may apply.

Were any problems found?

Ye s>>

Repair as necessary.

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 3

Page 1414 of 5267

3.CKP CONNECTOR/HARNESS INSPECTION

NOTE: Visually inspect the Crankshaft Position Sensor and related wire harness connectors. Look for bro-

ken, bent, pushed out, or corroded terminals.

NOTE: Visually inspect the related wire harness. Look for any chafed, pierced, pinched, or partially broken

wires.

NOTE:VerifytheCrankPositionSensorisproperlyinstalled.

Were any problems found?

Ye s>>

Repair as necessary.

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 4

4.TONE WHEEL/FLEX PLATE INSPECTION

Disconnect and remove the Crankshaft Position Sensor.

Inspect the tone wheel/flexplate slots for damage, foreign material, or excessive movement.

Is the tone wheel/flexplate free from defects?

Ye s>>

Go To 5

No>>

Repair/replace tone wheel/flex plate as necessary.

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

5.CRANKSHAFT POSITION SENSOR l

With the scan tool lab scope probe and the Miller special tool #6801, back probe the (K24) CKP Signal circuit in the

PCM harness connector.

WARNING: WARNING: WHEN THE ENGINE IS OPERATING, DO NOT STAND IN A DIRECT LINEWITHTHE

FAN. DO NOT PUT YOUR HANDS NEAR THE PULLEYS, BELTS OR FAN. DO NOT WEAR LOOSE CLOTHING..

Start the engine and observe the lab scope screen for any erratic CKP Sensorpulses.

NOTE: Turn the ignition off before continuing.

Were any erratic Crank Position signals detected.

Ye s .>>

Replace the Crankshaft Position Sensor.

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No.>>

Go To 6

6.PCM

NOTE: Before continuing, check the PCM harness connector terminals for corrosion, damage, or terminal

push out. Repair as necessary.

Using the schematics as a guide, inspect the wire harness and connectors. Pay particular attention to all Power and

Ground circuits.

If there are no possible causes remaining, view repair.

Repair

Replace and program the Powertrain Control Module per Service Information.

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 1415 of 5267

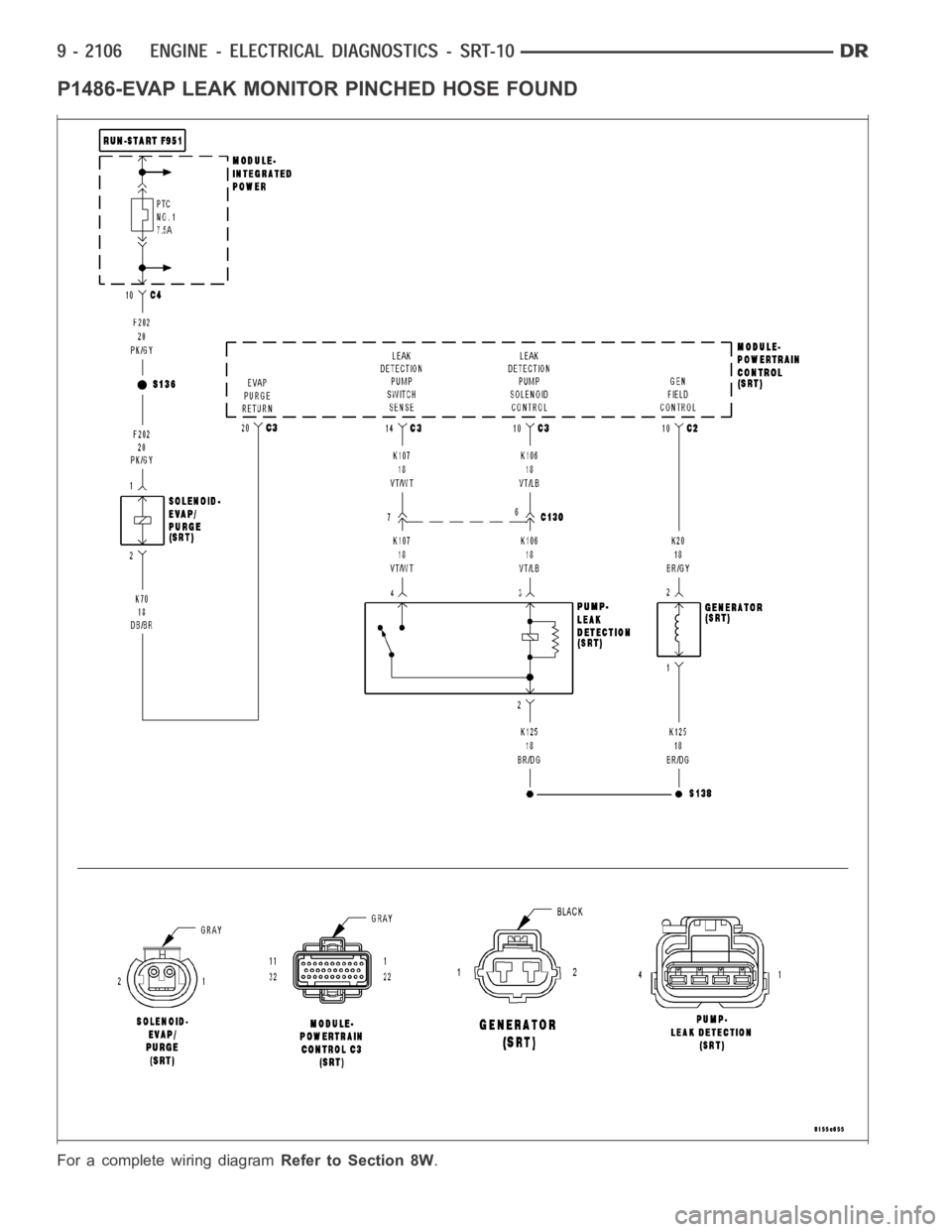

P1486-EVAP LEAK MONITOR PINCHED HOSE FOUND

For a complete wiring diagramRefer to Section 8W.

Page 1416 of 5267

When Monitored:

Immediately after a cold start, with battery/ambient temperature between 40 deg. F and 90 Deg. F and coolant

temperature within 10 Deg. F of battery/ambient.

Set Condition:

LDP test must pass first. If the PCM suspects a pinched hose it will not set a fault until it runs the EVAP purge

flow monitor. If the purge monitor does not pass then the pinched hose faultwill be set.

Possible Causes

EVAP CANISTER OBSTRUCTED

OBSTRUCTION IN HOSE/TUBE BETWEEN EVAP CANISTER AND PURGE SOLENOID

LDP PRESSURE HOSE OBSTRUCTED

LEAK DETECTION PUMP

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

Diagnostic Test

1.VEHICLE HISTORY AND SERVICE BULLETIN INVESTIGATION

Ignition on, engine not running.

With a scan tool, read DTCs and record the related Freeze Frame data if any DTC(s) are present.

Whether or not any DTC(s) are present you will want to check the following items which may assist in repairing the

customer’s complaint successfully.

Check the vehicles repair history.

If the vehicle has a repair history that pertains to the customer’s currentcomplaint, review the repair.

Inspect the vehicle for any aftermarket accessories that may have been installed incorrectly.

Check for any service bulletin(s) related to the customer’s complaint or DTC(s).

If a service bulletin applies, follow the instructions per the service bulletin.

Choose the following scenario that best applies.

The service bulletin repaired the customer’s complaint.

Testing complete.

A DTC is present, no service bulletins apply, or the service bulletin didn’t repair the customer’s complaint.

Go To 2

2.GOOD TRIP EQUAL TO ZERO

Ignition on, engine not running.

With the scan tool, read DTCs.

Is the Good Trip Counter displayed and equal to zero?

Ye s>>

Go To 3

No>>

Go To 8

Page 1417 of 5267

3.EVAP PURGE SOLENOID VACUUM LINE

Turn the ignition off.

Inspect the Purge Solenoid Vacuum line that runs from the Evap Purge Solenoid to the throttle body or intake man-

ifold.

Is the vacuum line plugged or kinked?

Ye s>>

Repair or replace the vacuum line from the solenoid to the throttle body / intake manifold.

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 4

NOTE: Reconnect the vacuum line before continuing.

4.CHECKED FOR OTHER BLOCKED HOSES

To continue testing you will need Miller Tool #6872A (Evap System PressurePump) and #8382 (Gas Cap Tester [

]Adapter).

WARNING: The test equipment is designed to be used to pressurize the vehicles Evaporative System only.

Using the equipment in a manner for which it was not designed could be harmful.

WARNING: Keep lit cigarettes, sparks, flames, and other ignition sourcesaway from the test area to prevent

the ignition of explosive gases. Keep the test area well ventilated.

NOTE: The fuel tank should have between 20% and 80% of full to properly test the Evap System.

Attach the power source clip (red) of Miller Tool #6872A to Battery (+) and the ground clip (black) to Battery (-).

Perform the Evaporative System Pressure Pump self test that is specified on the tester cover.

Remove gas cap and install Miller Tool #8382 on the vehicle. Install gas capto Miller Tool #8382. Attach the pres-

sure supply hose from Miller Tool #6872A to the fitting on #8382.

Disconnect the vacuum supply hose at the Leak Detection Pump.

Connect and apply a continuous vacuum supply (i.e. 20”Hg) to the Leak Detection Pump. A vacuum pump such as

an A/C Recovery unit works well.

Ignition on, engine not running.

With the scan tool perform the “Leak Detect Pump Test”. Follow the scan toolinstructions and then press ENTER.

Select#3–HOLDPSI.

On Miller Tool #6872A, set the Pressure/Hold switch to Open and set the Ventswitch to Closed. Turn the pump

timer On and watch the gauge.

When the gauge pressure reaches 14”H2O, turn the Pressure/Hold Valve to Closed.

Turn the pump timer off.

Disconnect the hose at the Evap Canister that goes to the Fuel Tank.

Did the pressure drop when the hose was disconnected?

Ye s>>

Go To 5

No>>

Repair the obstruction in the Evap System between the Evap Canister and thefuel tank.

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

5.EVAP CANISTER FUNCTION

NOTE: Connect all previously disconnected hoses.

Re-pressurize the Evap System. On Miller Tool #6872A, set the Pressure/Hold switch to Open and set the Vent

switch to Closed.

Turn the pump timer On and watch the gauge.

When the gauge pressure reaches 14” H2O, turn the Pressure/Hold Valve Closed.

Turn the pump timer off.

Page 1418 of 5267

Disconnect the LDP Pressure hose at the Evap Canister. The LDP Pressure hose is the hose that connects the

Evap Canister to the Leak Detection Pump.

Did pressure drop when the hose was disconnected?

Ye s>>

Go To 6

No>>

Replace the Evap Canister.

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

6.EVAP CANISTER FUNCTION

NOTE: Connect all previously disconnected hoses.

Re-pressurize the Evap System. On Miller Tool #6872A, set the Pressure/Hold switch to Open and set the Vent

switch to Closed.

Turn the pump timer On and watch the gauge.

When the gauge pressure reaches 14” H2O, turn the Pressure/Hold Valve Closed.

Turn the pump timer off.

Disconnect the Evap hoses at the Evap Purge Solenoid.

Did pressure drop when the hose was disconnected?

Ye s>>

Go To 7

No>>

Repair or replace the hose / tube assembly as necessary.

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

7.LEAK DETECTION PUMP HOSE

Disconnect and remove the LDP pressure hose. The LDP pressure hose is the hose that connects the Evap Can-

ister to the Leak Detection Pump.

Inspect the LDP pressure hose for anyobstructions or physical damage.

Is the LDP pressure hose free of defects?

Ye s>>

Replace the Leak Detection Pump.

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Repair or replace the hose / tube assembly as necessary.

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

8.LDP MONITOR TEST

At this time, the conditions required to set the DTC are not present.

NOTE: Use the Freeze Frame data to help you duplicate the conditions that set the DTC. Pay particular

attention to the DTC setconditions, such as, VSS, MAP, ECT, and Load.

NOTE: A thorough visual inspection of the Evap system hoses, tubes, and connections may save time in

you diagnosis. Look for any physical damage or signs of wetness at connections. The strong smell of fuel

vapors may aid diagnosis also.

NOTE: Refer to any Service Bulletins that may apply

With the scan tool, perform the LDP Monitor Test. This will force the PCM to run the LDP Monitor. If the monitor

fails, further diagnosis is required to find a faulty component. If the monitor passes, the condition is not present at

this time.

Did the monitor test fail?

Ye s>>

Check the one trip faults to determine the DTC that was set during the LDP monitor test. Continue

diagnosis as necessary.

No>>

Te s t C o m p l e t e .

Page 1419 of 5267

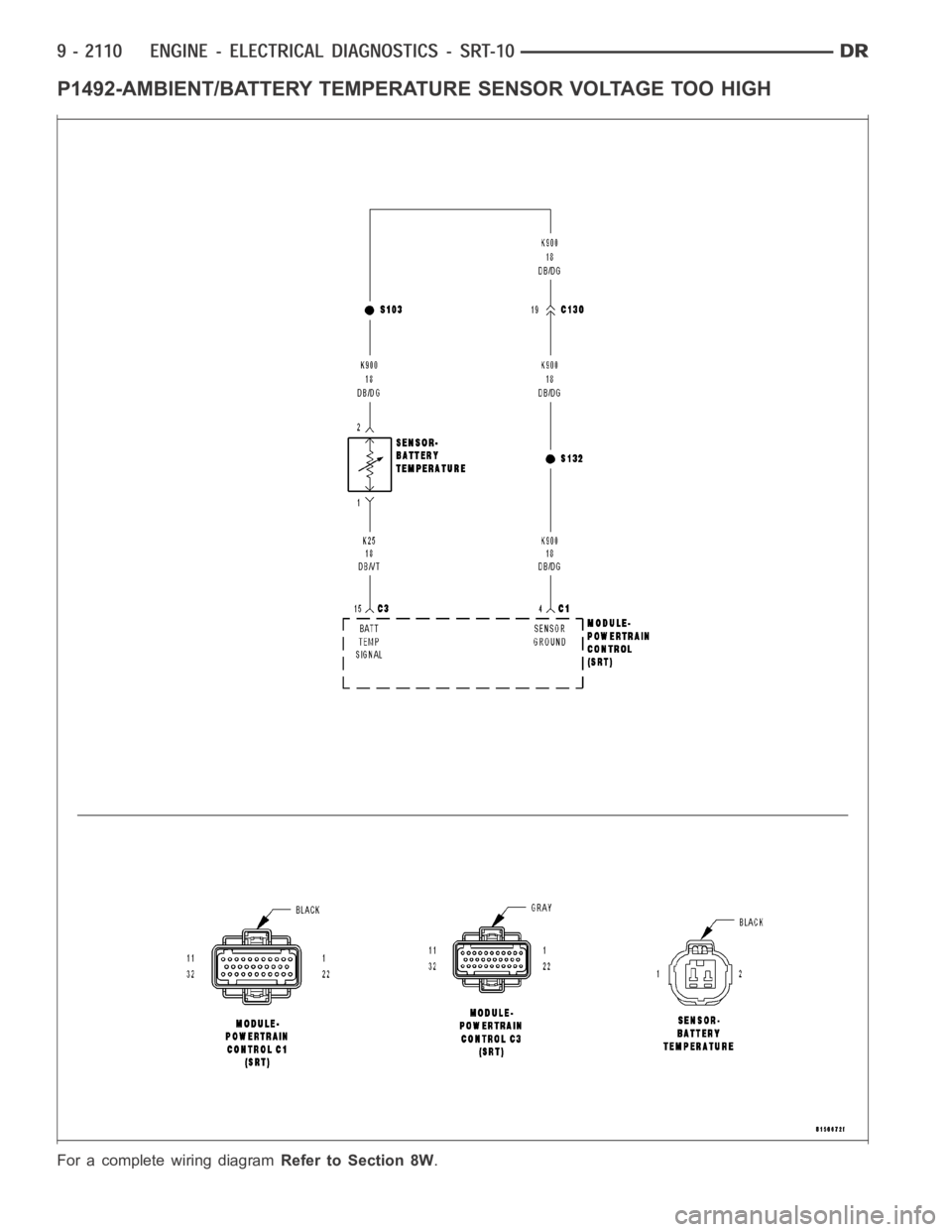

P1492-AMBIENT/BATTERY TEMPERATURE SENSOR VOLTAGE TOO HIGH

For a complete wiring diagramRefer to Section 8W.

Page 1420 of 5267

When Monitored:

With the ignition key on.

Set Condition:

The PCM senses the voltage from the Battery Temperature Sensor above 4.9 volts for 3 seconds.

Possible Causes

BATTERY TEMP SENSOR VOLTAGE ABOVE 4.8 VOLTS

BATTERY TEMPERATURE SENSOR

(K25) BATTERY TEMP SIGNAL CIRCUIT SHORTED TO VOLTAGE

(K25) BATTERY TEMP SIGNAL CIRCUIT OPEN

(K900) SENSOR GROUND CIRCUIT OPEN

PCM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

1.BATTERY TEMP SENSOR VOLTAGE ABOVE 4.8 VOLTS

Ignition on, engine not running.

Record all DTCs and the related Freeze Frame data.

With the scan tool, monitor the Battery Temperature Sensor voltage.

Is the voltage above 4.8 volts?

Ye s>>

Go To 2

No>>

Refer to the INTERMITTENT CONDITIONSymptom (Diagnostic Procedure).

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

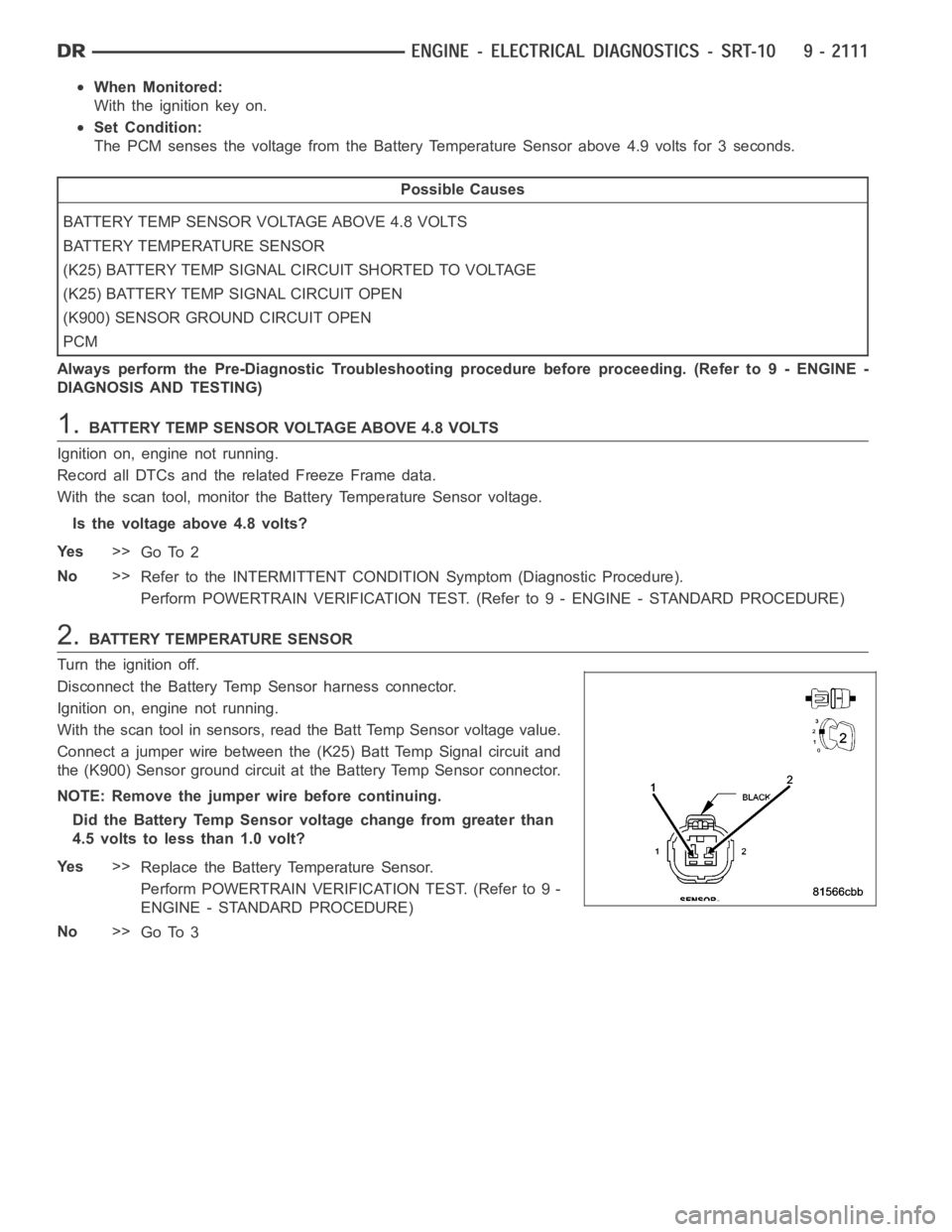

2.BATTERY TEMPERATURE SENSOR

Turn the ignition off.

Disconnect the Battery Temp Sensor harness connector.

Ignition on, engine not running.

With the scan tool in sensors, read the Batt Temp Sensor voltage value.

Connect a jumper wire between the (K25) Batt Temp Signal circuit and

the (K900) Sensor ground circuit at the Battery Temp Sensor connector.

NOTE: Remove the jumper wire before continuing.

Did the Battery Temp Sensor voltage change from greater than

4.5 volts to less than 1.0 volt?

Ye s>>

Replace the Battery Temperature Sensor.

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 -

ENGINE - STANDARD PROCEDURE)

No>>

Go To 3