DODGE RAM SRT-10 2006 Service Repair Manual

Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 1391 of 5267

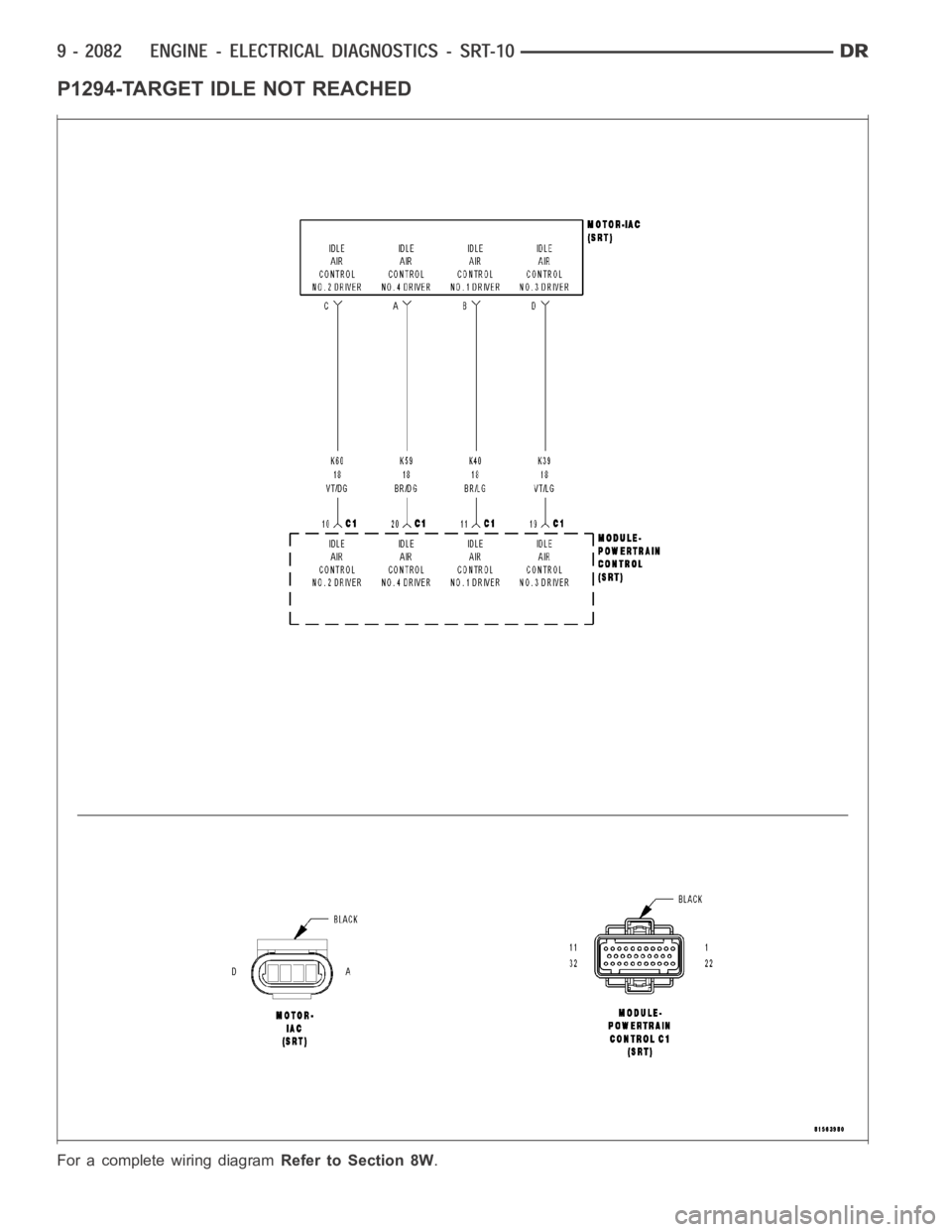

P1294-TARGET IDLE NOT REACHED

For a complete wiring diagramRefer to Section 8W.

Page 1392 of 5267

When Monitored:

With the engine idling and in drive, if automatic. There must not be a MAP sensor trouble code or a throttle

position sensor trouble code.

Set Condition:

Engine idle is not within 200 rpm above or 100 rpm below target idle for 14 seconds. Three separate failures

are required to set a bad trip. Two bad trips are required to set the code.

Possible Causes

GOOD TRIP EQUAL TO ZERO

VACUUM LEAK

AIR INDUCTION SYSTEM

THROTTLE BODY AND THROTTLE LINKAGE

IAC DRIVER CIRCUIT OPEN

PCM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

1.GOOD TRIP EQUAL TO ZERO

Ignition on, engine not running.

NOTE: All MAP Sensor, IAC, and/or TPS codes present must be diagnosed firstbefore proceeding.

With the scan tool, read DTCs and record the related Freeze Frame data.

Is the Good Trip Counter displayed and equal to zero?

Ye s>>

Go To 2

No>>

Refer to the INTERMITTENT CONDITIONSymptom (Diagnostic Procedure).

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

2.VACUUM LEAK

Inspect the Intake Manifold for vacuum leaks.

Inspect the Power Brake Booster for any vacuum leaks.

Inspect the PCV system for proper operation or any vacuum leaks.

Were any problems found?

Ye s>>

Repair vacuum leak as necessary.

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 3

3.AIR INDUCTION SYSTEM

Inspect the Air Induction System for the following problems.

Restrictions: Dirty Air Cleaner, Foreign material in the air intake tube,etc.

Leaks: Air Intake tube connection, Air Cleaner housing, etc.

Were any problems found?

Ye s>>

Repair or replace as necessary.

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 4

Page 1393 of 5267

4.THROTTLE BODY AND THROTTLE LINKAGE

Inspect the throttle body plate for carbon build up or other restrictions.

Inspect the throttle linkage for binding and smooth operation.

Ensure the throttle plate is resting on the stop at idle.

Remove IAC, inspect the pintle and its seating surface inside the throttlebody.

Were any problems found?

Ye s>>

Clean and/or replace the throttle body as needed.

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 5

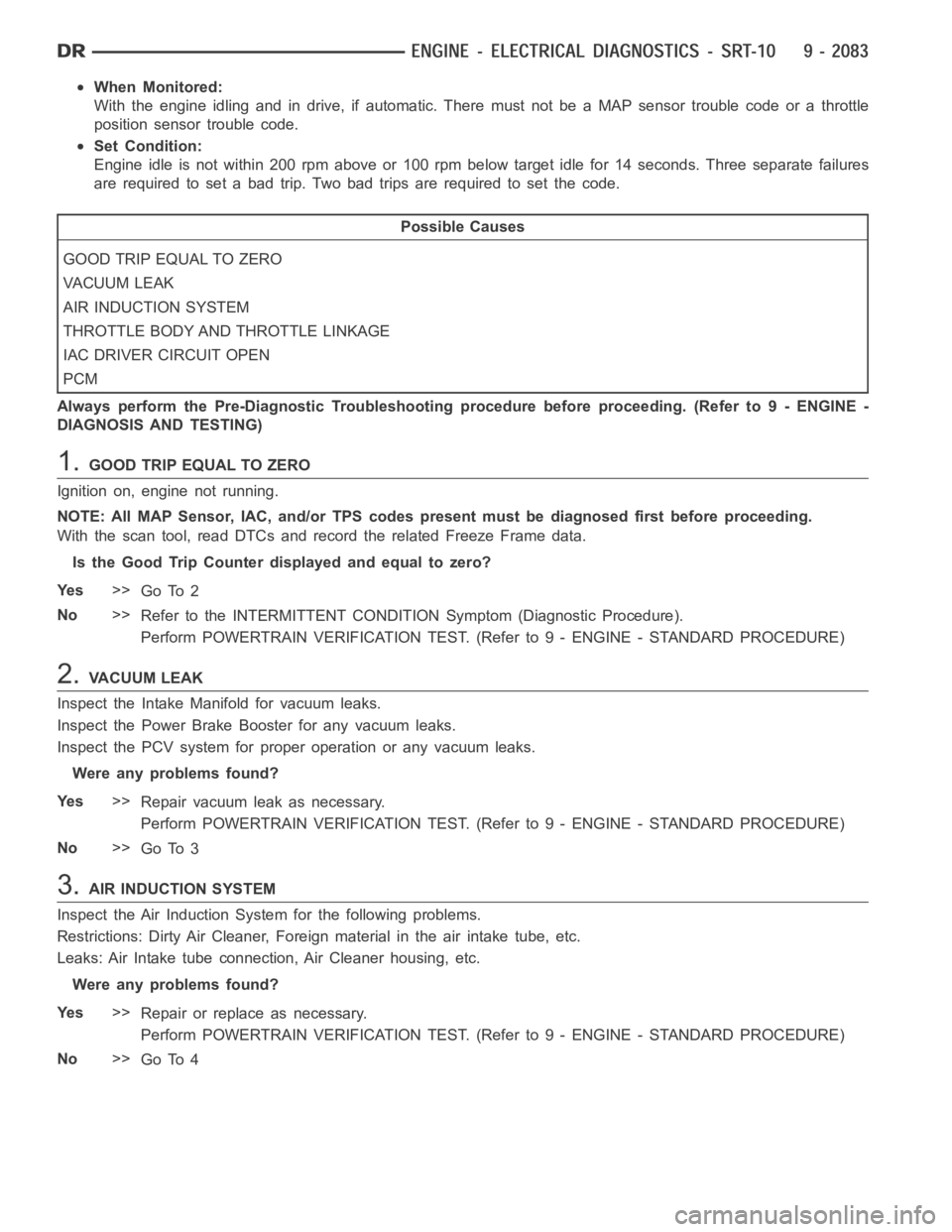

5.IAC DRIVER CIRCUITS OPEN

Turn the ignition off.

Disconnect IAC Motor harness connector.

Disconnect the PCM harness connectors.

Measure the resistance of each of the IAC Driver circuit from the IAC

Motor harness connector to the PCM harness connector.

Is the resistance below 5.0 ohms?

Ye s>>

Go To 6

No>>

Repair the open in the appropriate IAC Driver circuit.

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 -

ENGINE - STANDARD PROCEDURE)

6.PCM

NOTE: Before continuing, check the PCM harness connector terminals for corrosion, damage, or terminal

push out. Repair as necessary.

Using the schematics as a guide, inspect the wire harness and connectors. Pay particular attention to all Power and

Ground circuits.

If there are no possible causes remaining, view repair.

Repair

Replace and program the Powertrain Control Module per Service Information.

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 1394 of 5267

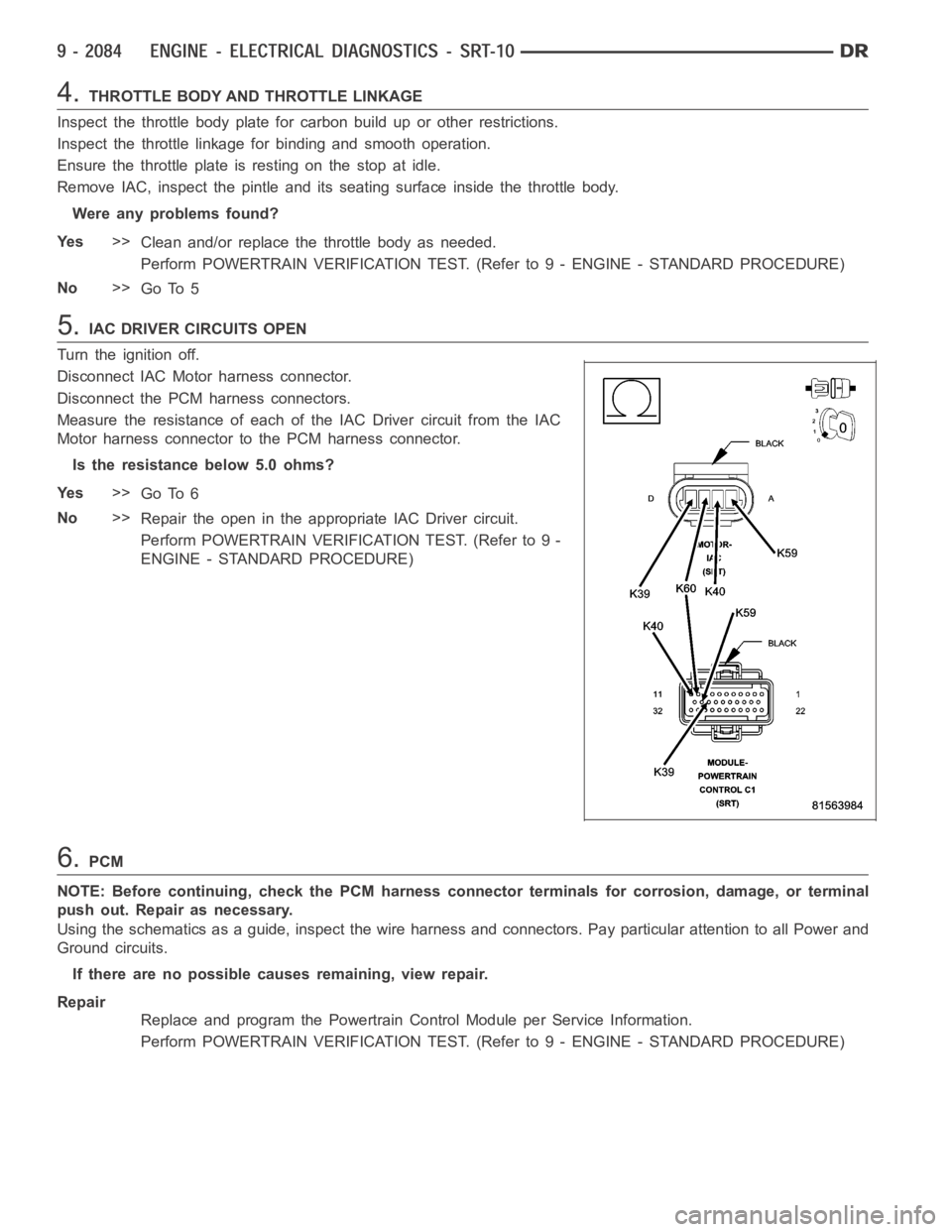

P1296-NO 5-VOLTS TO MAP SENSOR

For a complete wiring diagramRefer to Section 8W.

Page 1395 of 5267

When Monitored:

During power-down and battery voltage greater than 10.4 volts.

Set Condition:

The MAP sensor signal voltage goes below 2.35 volts with the key off for 5 seconds.

Possible Causes

MAP SENSOR VOLTS BELOW 2.3 VOLTS

MAP SENSOR

(F855) 5-VOLT SUPPLY CIRCUIT SHORTED TO GROUND

SHORTED SENSOR

(F855) 5-VOLT SUPPLY CIRCUIT OPEN

PCM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

1.MAP SENSOR VOLTS BELOW 2.3 VOLTS

NOTE: If the P0107 - MAP Sensor Voltage Too Low is also set, diagnose it firstbefore continuing with P1296

- No 5-volts To MAP Sensor.

Ignition on, engine not running.

With the scan tool, read DTCs and record the related Freeze Frame data.

With the scan tool in Sensors, read the MAP Sensor voltage.

Is the voltage below 2.35 volts?

Ye s>>

Go To 2

No>>

Refer to the INTERMITTENT CONDITIONSymptom (Diagnostic Procedure).

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

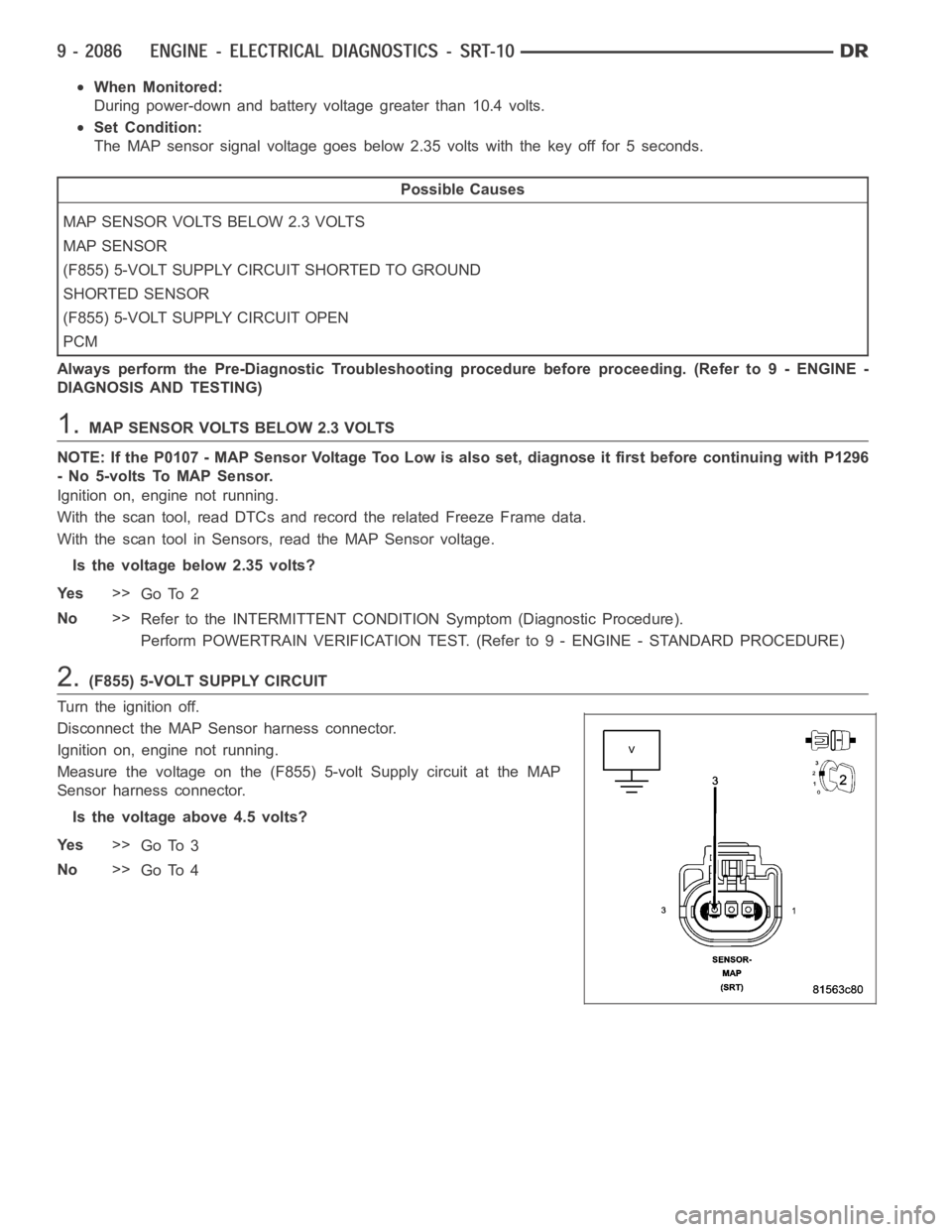

2.(F855) 5-VOLT SUPPLY CIRCUIT

Turn the ignition off.

Disconnect the MAP Sensor harness connector.

Ignition on, engine not running.

Measure the voltage on the (F855) 5-volt Supply circuit at the MAP

Sensor harness connector.

Is the voltage above 4.5 volts?

Ye s>>

Go To 3

No>>

Go To 4

Page 1396 of 5267

3.MAP SENSOR

With the scan tool in Sensors, read the MAP Sensor voltage with the Sensor harness connector disconnected.

Is the voltage above 4.5 volts?

Ye s>>

Replace the MAP Sensor.

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 7

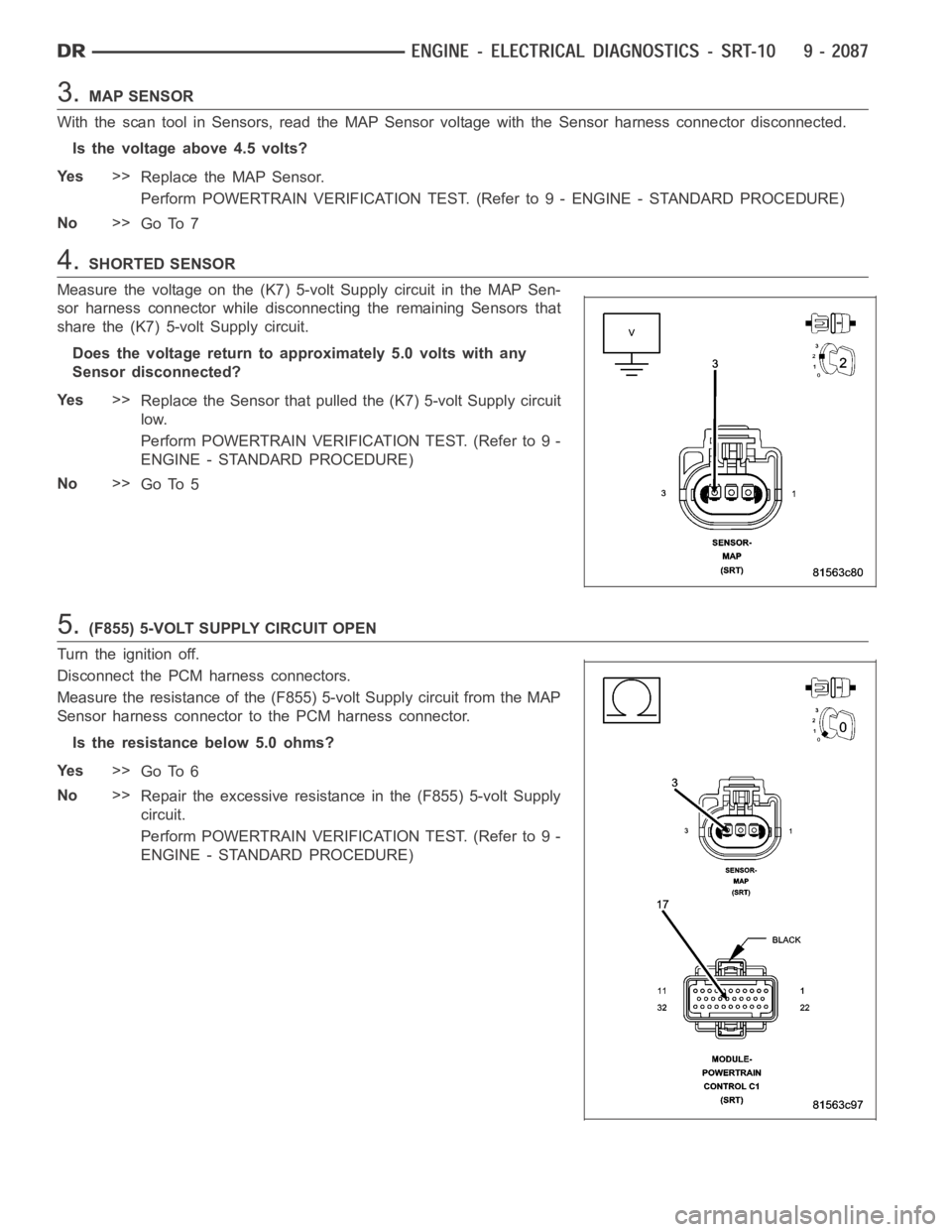

4.SHORTED SENSOR

Measure the voltage on the (K7) 5-volt Supply circuit in the MAP Sen-

sor harness connector while disconnecting the remaining Sensors that

share the (K7) 5-volt Supply circuit.

Does the voltage return to approximately 5.0 volts with any

Sensor disconnected?

Ye s>>

Replace the Sensor that pulled the (K7) 5-volt Supply circuit

low.

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 -

ENGINE - STANDARD PROCEDURE)

No>>

Go To 5

5.(F855) 5-VOLT SUPPLY CIRCUIT OPEN

Turn the ignition off.

Disconnect the PCM harness connectors.

Measure the resistance of the (F855) 5-volt Supply circuit from the MAP

Sensor harness connector to the PCM harness connector.

Is the resistance below 5.0 ohms?

Ye s>>

Go To 6

No>>

Repair the excessive resistance in the (F855) 5-volt Supply

circuit.

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 -

ENGINE - STANDARD PROCEDURE)

Page 1397 of 5267

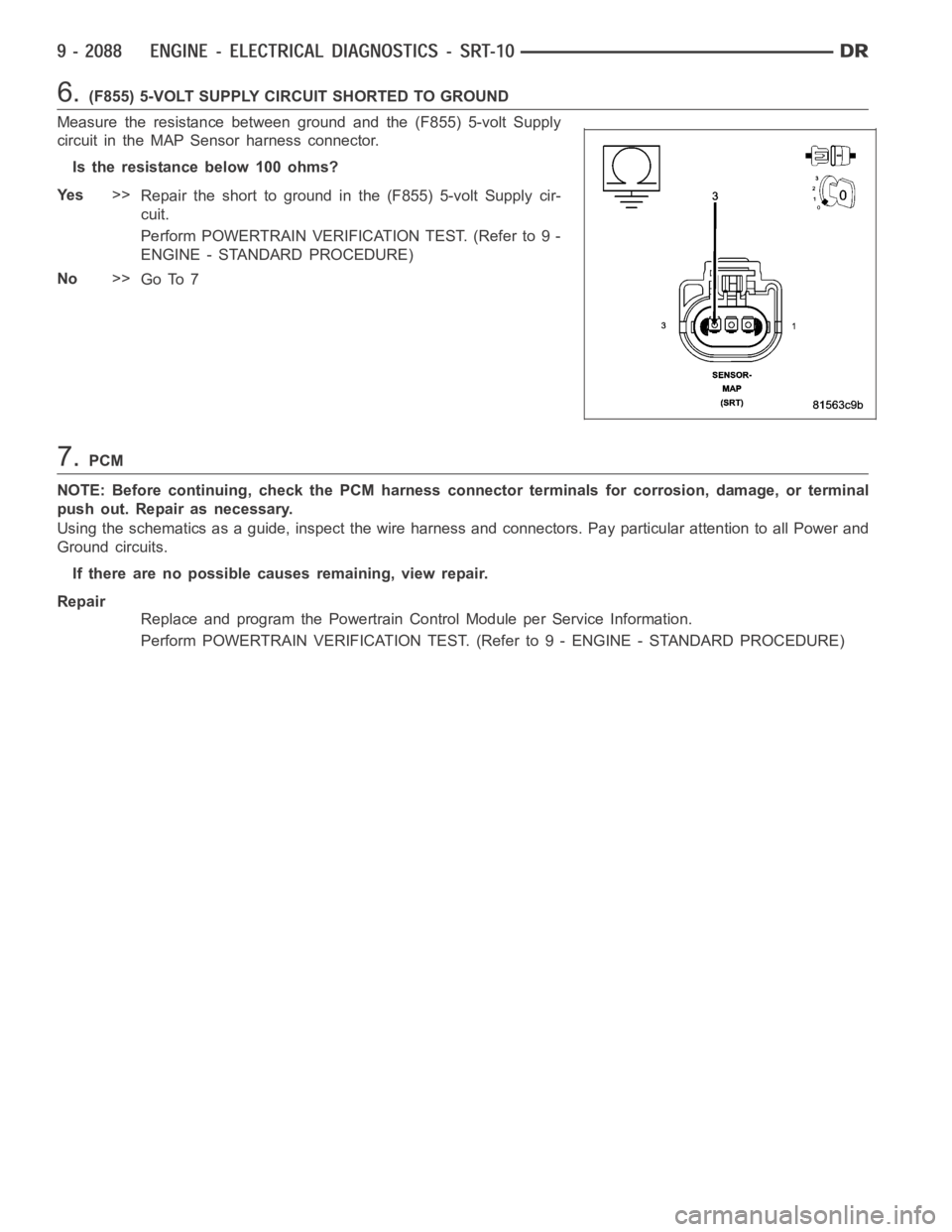

6.(F855) 5-VOLT SUPPLY CIRCUIT SHORTED TO GROUND

Measure the resistance between ground and the (F855) 5-volt Supply

circuit in the MAP Sensor harness connector.

Istheresistancebelow100ohms?

Ye s>>

Repair the short to ground in the (F855) 5-volt Supply cir-

cuit.

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 -

ENGINE - STANDARD PROCEDURE)

No>>

Go To 7

7.PCM

NOTE: Before continuing, check the PCM harness connector terminals for corrosion, damage, or terminal

push out. Repair as necessary.

Using the schematics as a guide, inspect the wire harness and connectors. Pay particular attention to all Power and

Ground circuits.

If there are no possible causes remaining, view repair.

Repair

Replace and program the Powertrain Control Module per Service Information.

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 1398 of 5267

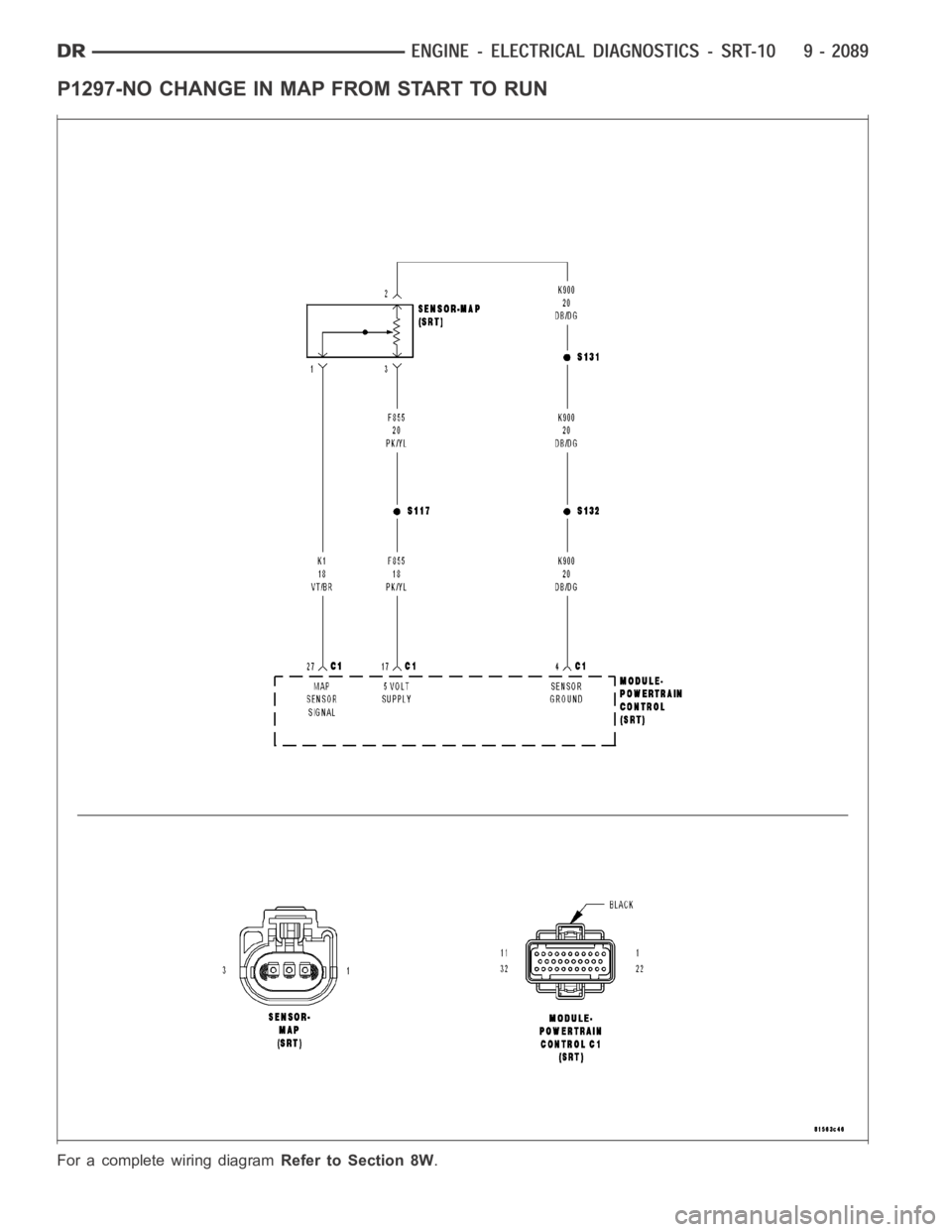

P1297-NO CHANGE IN MAP FROM START TO RUN

For a complete wiring diagramRefer to Section 8W.

Page 1399 of 5267

When Monitored:

With engine RPM +/- 64 of target idle and the throttle blade at closed throttle.

Set Condition:

Too small of a difference is seen between barometric pressure with ignition on (engine running) and manifold

vacuum for 8.80 seconds.

Possible Causes

GOOD TRIP EQUAL TO ZERO

MAP SENSOR VACUUM PORT

MAP SENSOR VOLTAGE BELOW 3.19 VOLTS

(F855) 5-VOLT SUPPLY CIRCUIT OPEN

(F855) 5-VOLT SUPPLY CIRCUIT SHORTED TO GROUND

MAP SENSOR

(K1) MAP SENSOR SIGNAL CIRCUIT SHORTED TO GROUND

(K1) MAP SENSOR SIGNAL CIRCUIT SHORTED TO (K900) SENSOR GROUND CIRCUIT

PCM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)

1.GOOD TRIP EQUAL TO ZERO

NOTE: If a MAP high or Low DTC set along with P1297, diagnose the High or Low DTC first before con-

tinuing.

Ignition on, engine not running.

With the scan tool, read DTCs and record the related Freeze Frame data.

Is the Good Trip Counter displayed and equal to zero?

Ye s>>

Go To 2

No>>

Refer to the INTERMITTENT CONDITIONSymptom (Diagnostic Procedure).

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

2.MAP SENSOR VACUUM PORT

Turn the ignition off.

Remove the MAP Sensor.

Inspect the vacuum port, check for restrictions or any foreign materials.

Were any restriction found?

Ye s>>

Repair as necessary.

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 3

3.MAP SENSOR VOLTAGE BELOW 3.19 VOLTS

Install the MAP Sensor.

Ignition on, engine not running.

With the scan tool, read the MAP Sensor voltage.

Is the voltage below 3.19 volts?

Ye s>>

Go To 4

No>>

Refer to the INTERMITTENT CONDITIONSymptom (Diagnostic Procedure).

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

Page 1400 of 5267

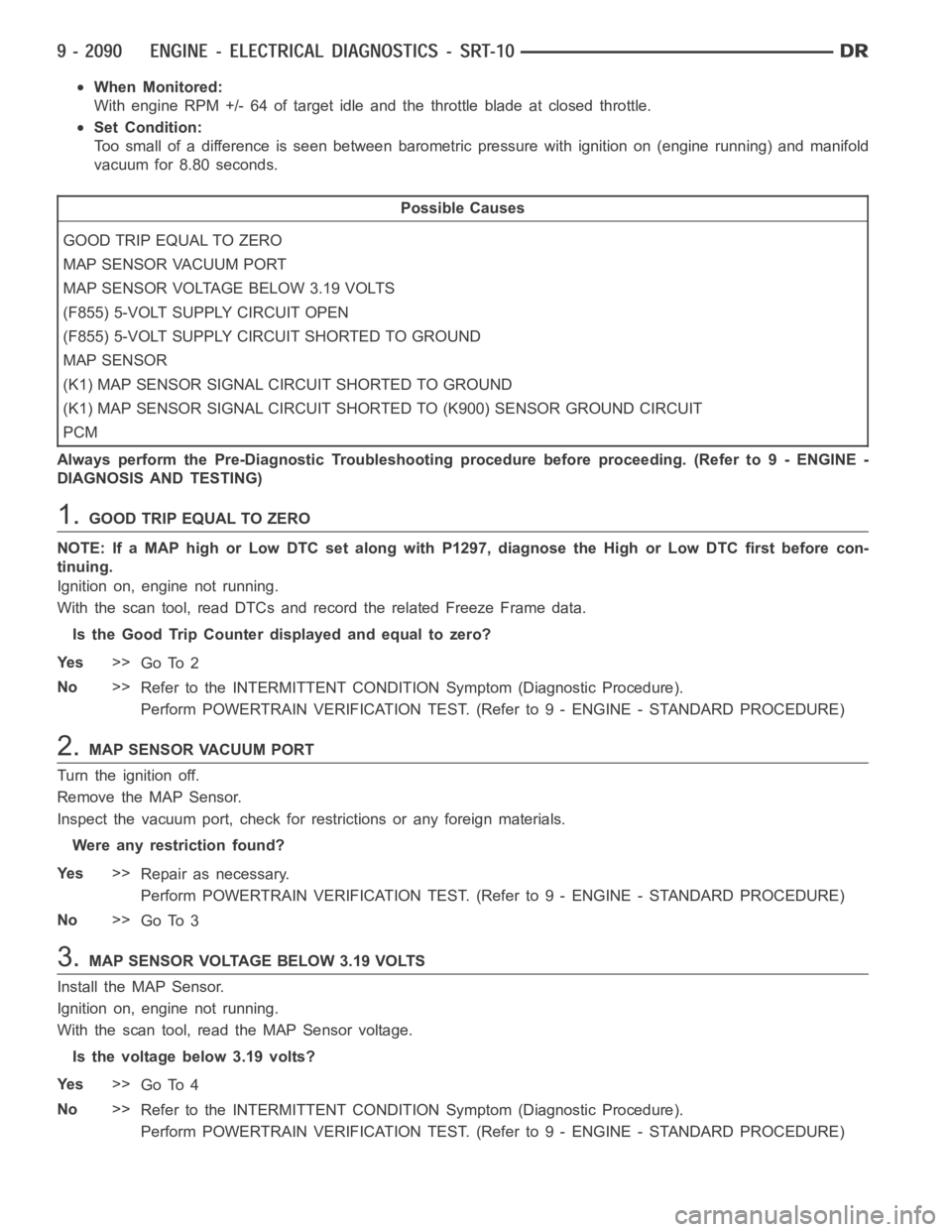

4.(F855) 5-VOLT SUPPLY CIRCUIT

Turn the ignition off.

Disconnect the MAP Sensor harness connector.

Ignition on, engine not running.

Measure the voltage on the (F855) 5-volt Supply circuit at the MAP

Sensor harness connector.

Is the voltage between 4.5 to 5.2 volts?

Ye s>>

Go To 5

No>>

Go To 8

5.MAP SENSOR

With the scan tool, monitor the MAP Sensor voltage with Sensor harness connector disconnected.

Is the voltage above 1.2 volts?

Ye s>>

Replace the MAP Sensor.

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No>>

Go To 6

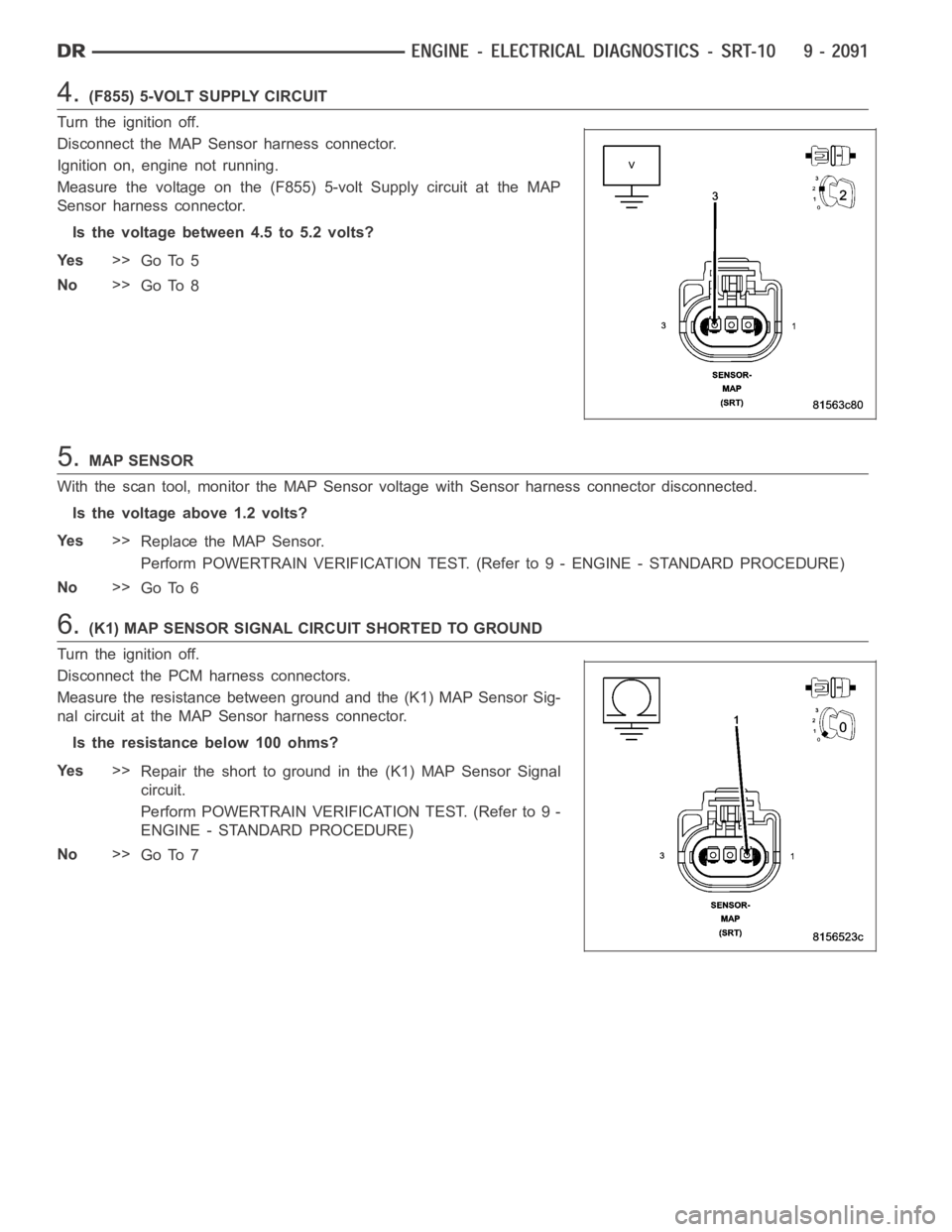

6.(K1) MAP SENSOR SIGNAL CIRCUIT SHORTED TO GROUND

Turn the ignition off.

Disconnect the PCM harness connectors.

Measure the resistance between ground and the (K1) MAP Sensor Sig-

nal circuit at the MAP Sensor harness connector.

Istheresistancebelow100ohms?

Ye s>>

Repair the short to ground in the (K1) MAP Sensor Signal

circuit.

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 -

ENGINE - STANDARD PROCEDURE)

No>>

Go To 7