DODGE RAM SRT-10 2006 Service Repair Manual

Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 1731 of 5267

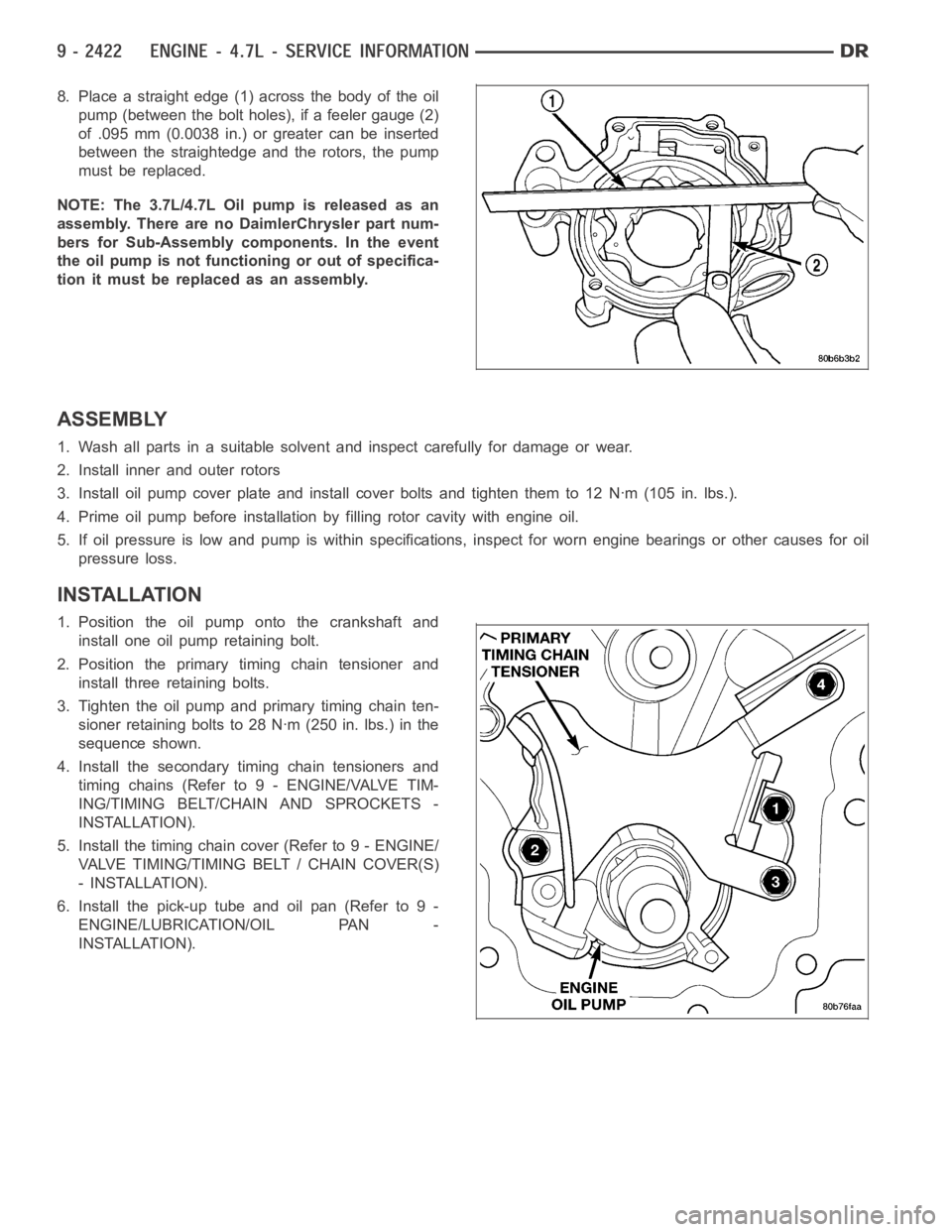

8. Place a straight edge (1) across the body of the oil

pump (between the bolt holes), if a feeler gauge (2)

of .095 mm (0.0038 in.) or greater can be inserted

between the straightedge and the rotors, the pump

must be replaced.

NOTE: The 3.7L/4.7L Oil pump is released as an

assembly. There are no DaimlerChrysler part num-

bers for Sub-Assembly components. In the event

the oil pump is not functioning or out of specifica-

tion it must be replaced as an assembly.

ASSEMBLY

1. Wash all parts in a suitable solvent and inspect carefully for damage or wear.

2. Install inner and outer rotors

3. Install oil pump cover plate and install cover bolts and tighten them to 12Nꞏm(105in.lbs.).

4. Prime oil pump before installation by filling rotor cavity with engine oil.

5. If oil pressure is low and pump is within specifications, inspect for worn engine bearings or other causes for oil

pressure loss.

INSTALLATION

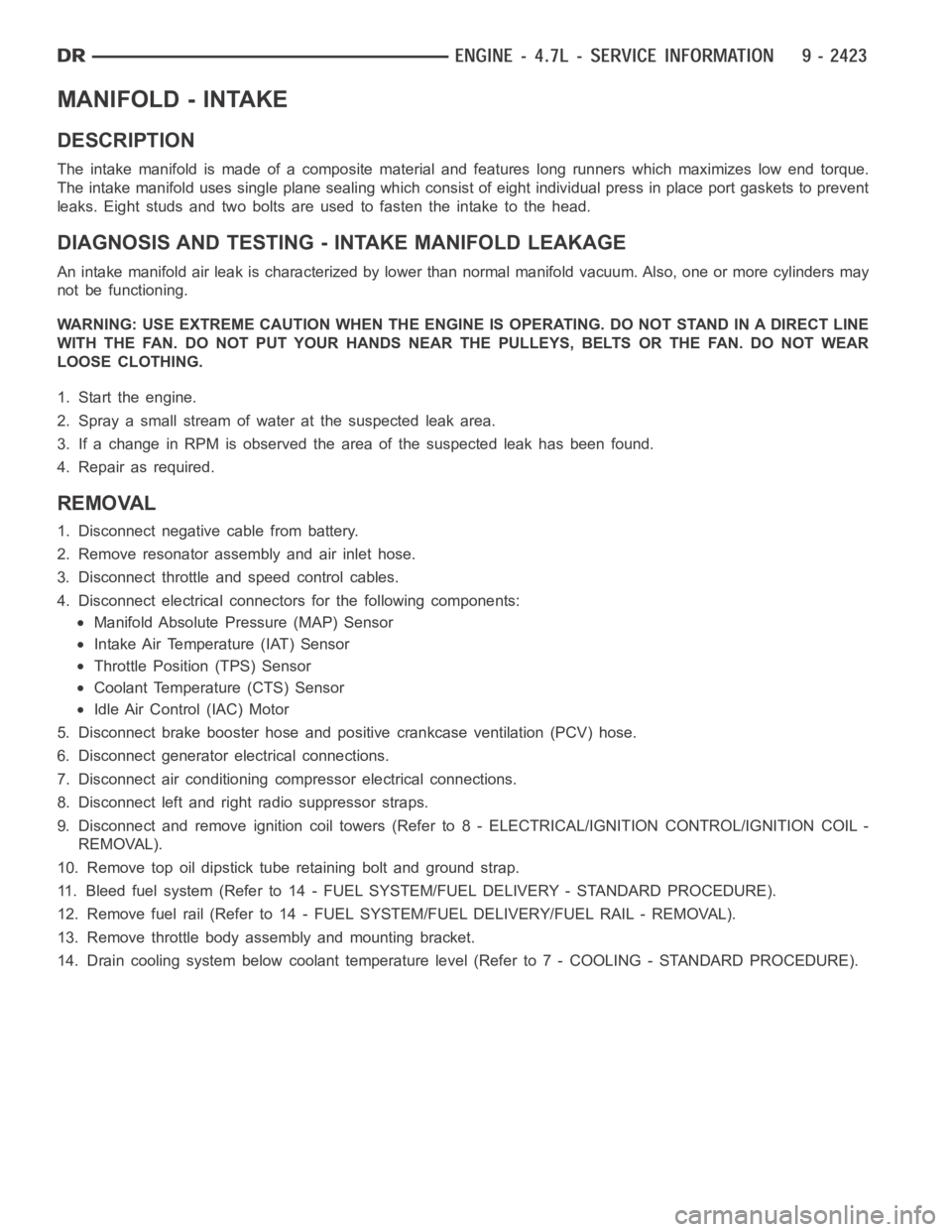

1. Position the oil pump onto the crankshaft and

install one oil pump retaining bolt.

2. Position the primary timing chain tensioner and

install three retaining bolts.

3. Tighten the oil pump and primary timing chain ten-

sioner retaining bolts to 28 Nꞏm (250 in. lbs.) in the

sequence shown.

4. Install the secondary timing chain tensioners and

timing chains (Refer to 9 - ENGINE/VALVE TIM-

ING/TIMING BELT/CHAIN AND SPROCKETS -

INSTALLATION).

5. Install the timing chain cover (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT / CHAIN COVER(S)

- INSTALLATION).

6. Install the pick-up tube and oil pan (Refer to 9 -

ENGINE/LUBRICATION/OIL PAN -

INSTALLATION).

Page 1732 of 5267

MANIFOLD - INTAKE

DESCRIPTION

The intake manifold is made of a composite material and features long runners which maximizes low end torque.

The intake manifold uses single plane sealing which consist of eight individual press in place port gaskets to prevent

leaks. Eight studs and two bolts are used to fasten the intake to the head.

DIAGNOSIS AND TESTING - INTAKE MANIFOLD LEAKAGE

An intake manifold air leak is characterized by lower than normal manifoldvacuum. Also, one or more cylinders may

not be functioning.

WARNING: USE EXTREME CAUTION WHEN THE ENGINE IS OPERATING. DO NOT STAND IN ADIRECT LINE

WITH THE FAN. DO NOT PUT YOUR HANDS NEAR THE PULLEYS, BELTS OR THE FAN. DO NOT WEAR

LOOSE CLOTHING.

1. Start the engine.

2. Spray a small stream of water at the suspected leak area.

3. If a change in RPM is observed the area of the suspected leak has been found.

4. Repair as required.

REMOVAL

1. Disconnect negative cable from battery.

2. Remove resonator assembly and air inlet hose.

3. Disconnect throttle and speed control cables.

4. Disconnect electrical connectors for the following components:

Manifold Absolute Pressure (MAP) Sensor

Intake Air Temperature (IAT) Sensor

Throttle Position (TPS) Sensor

Coolant Temperature (CTS) Sensor

Idle Air Control (IAC) Motor

5. Disconnect brake booster hose and positive crankcase ventilation (PCV)hose.

6. Disconnect generator electrical connections.

7. Disconnect air conditioning compressor electrical connections.

8. Disconnect left and right radio suppressor straps.

9. Disconnect and remove ignition coil towers (Refer to 8 - ELECTRICAL/IGNITION CONTROL/IGNITION COIL -

REMOVAL).

10. Remove top oil dipstick tube retaining bolt and ground strap.

11. Bleed fuel system (Refer to 14 - FUEL SYSTEM/FUEL DELIVERY - STANDARD PROCEDURE).

12. Remove fuel rail (Refer to 14 - FUEL SYSTEM/FUEL DELIVERY/FUEL RAIL - REMOVAL).

13. Remove throttle body assembly and mounting bracket.

14. Drain cooling system below coolant temperature level (Refer to 7 - COOLING - STANDARD PROCEDURE).

Page 1733 of 5267

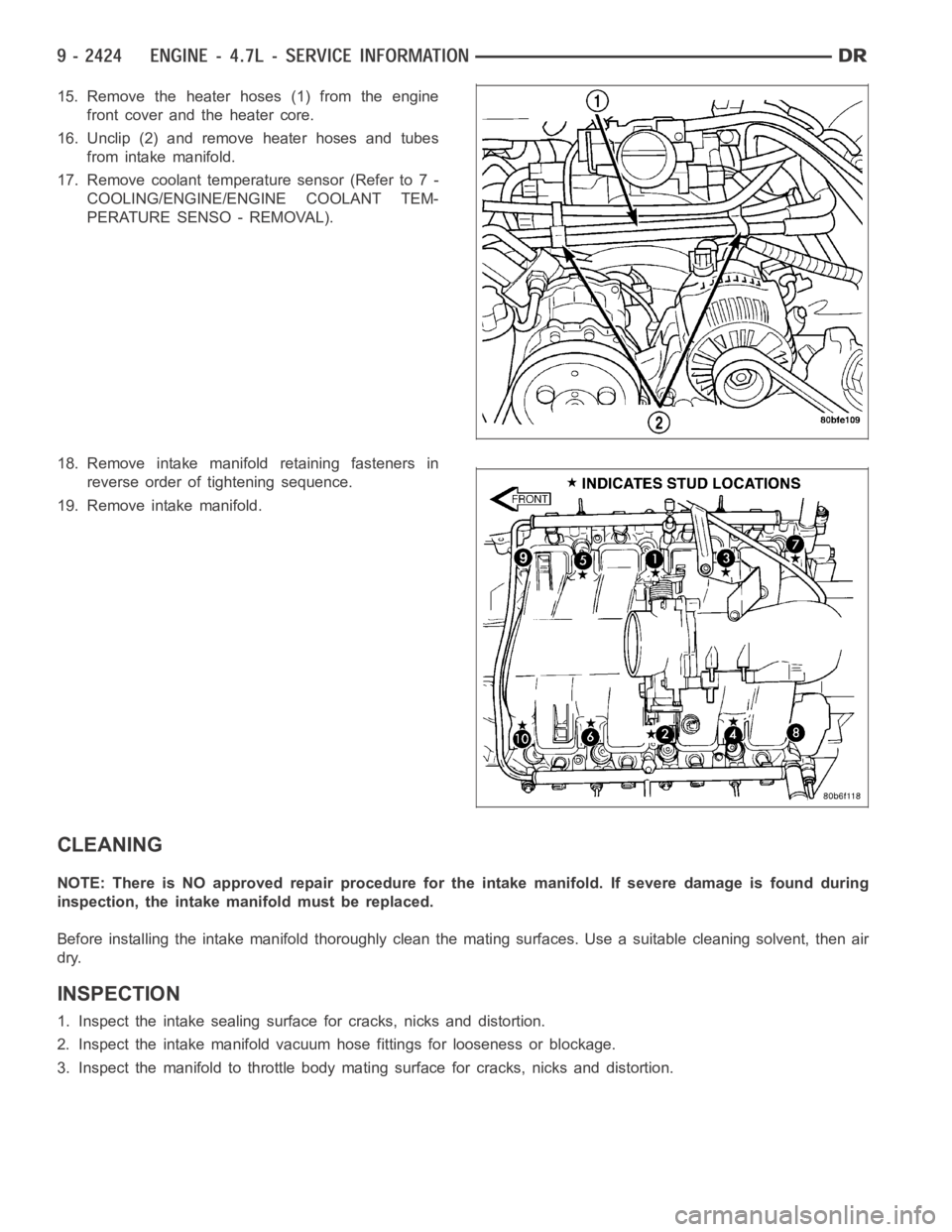

15. Remove the heater hoses (1) from the engine

front cover and the heater core.

16. Unclip (2) and remove heater hoses and tubes

from intake manifold.

17. Remove coolant temperature sensor (Refer to 7 -

COOLING/ENGINE/ENGINE COOLANT TEM-

PERATURE SENSO - REMOVAL).

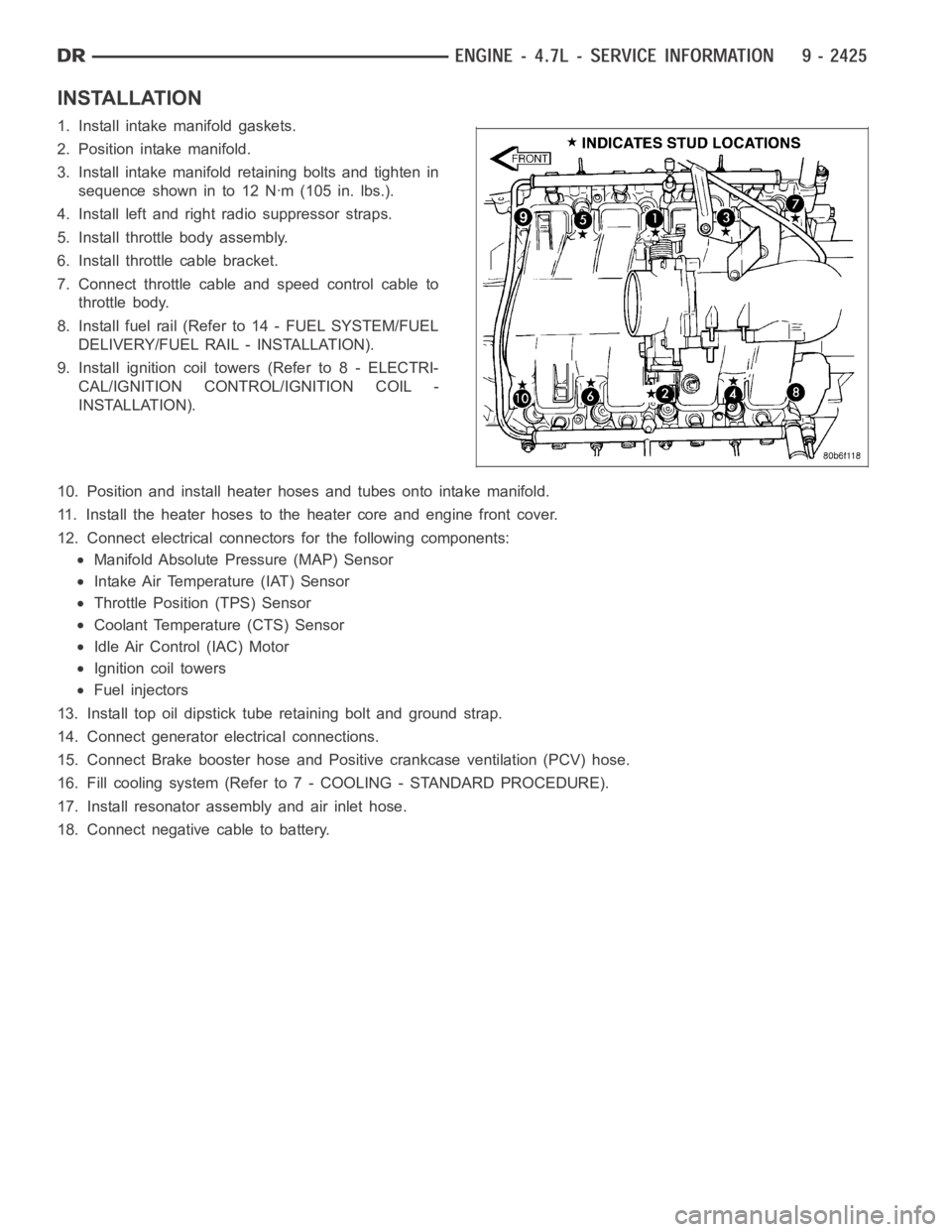

18. Remove intake manifoldretaining fasteners in

reverse order of tightening sequence.

19. Remove intake manifold.

CLEANING

NOTE: There is NO approved repair procedure for the intake manifold. If severe damage is found during

inspection, the intake manifold must be replaced.

Before installing the intake manifoldthoroughly clean the mating surfaces. Use a suitable cleaning solvent, then air

dry.

INSPECTION

1. Inspect the intake sealing surface for cracks, nicks and distortion.

2. Inspect the intake manifold vacuum hose fittings for looseness or blockage.

3. Inspect the manifold to throttlebody mating surface for cracks, nicks and distortion.

Page 1734 of 5267

INSTALLATION

1. Install intake manifold gaskets.

2. Position intake manifold.

3. Install intake manifold retaining bolts and tighten in

sequence shown in to 12 Nꞏm (105 in. lbs.).

4. Install left and right radio suppressor straps.

5. Install throttle body assembly.

6. Install throttle cable bracket.

7. Connect throttle cable and speed control cable to

throttle body.

8. Install fuel rail (Refer to 14 - FUEL SYSTEM/FUEL

DELIVERY/FUEL RAIL - INSTALLATION).

9. Install ignition coil towers (Refer to 8 - ELECTRI-

CAL/IGNITION CONTROL/IGNITION COIL -

INSTALLATION).

10. Position and install heater hoses and tubes onto intake manifold.

11. Install the heater hoses to the heater core and engine front cover.

12. Connect electrical connectors for the following components:

Manifold Absolute Pressure (MAP) Sensor

Intake Air Temperature (IAT) Sensor

Throttle Position (TPS) Sensor

Coolant Temperature (CTS) Sensor

Idle Air Control (IAC) Motor

Ignition coil towers

Fuel injectors

13. Install top oil dipstick tube retaining bolt and ground strap.

14. Connect generator electrical connections.

15. Connect Brake booster hose and Positive crankcase ventilation (PCV) hose.

16. Fill cooling system (Refer to 7 - COOLING - STANDARD PROCEDURE).

17. Install resonator assembly and air inlet hose.

18. Connect negative cable to battery.

Page 1735 of 5267

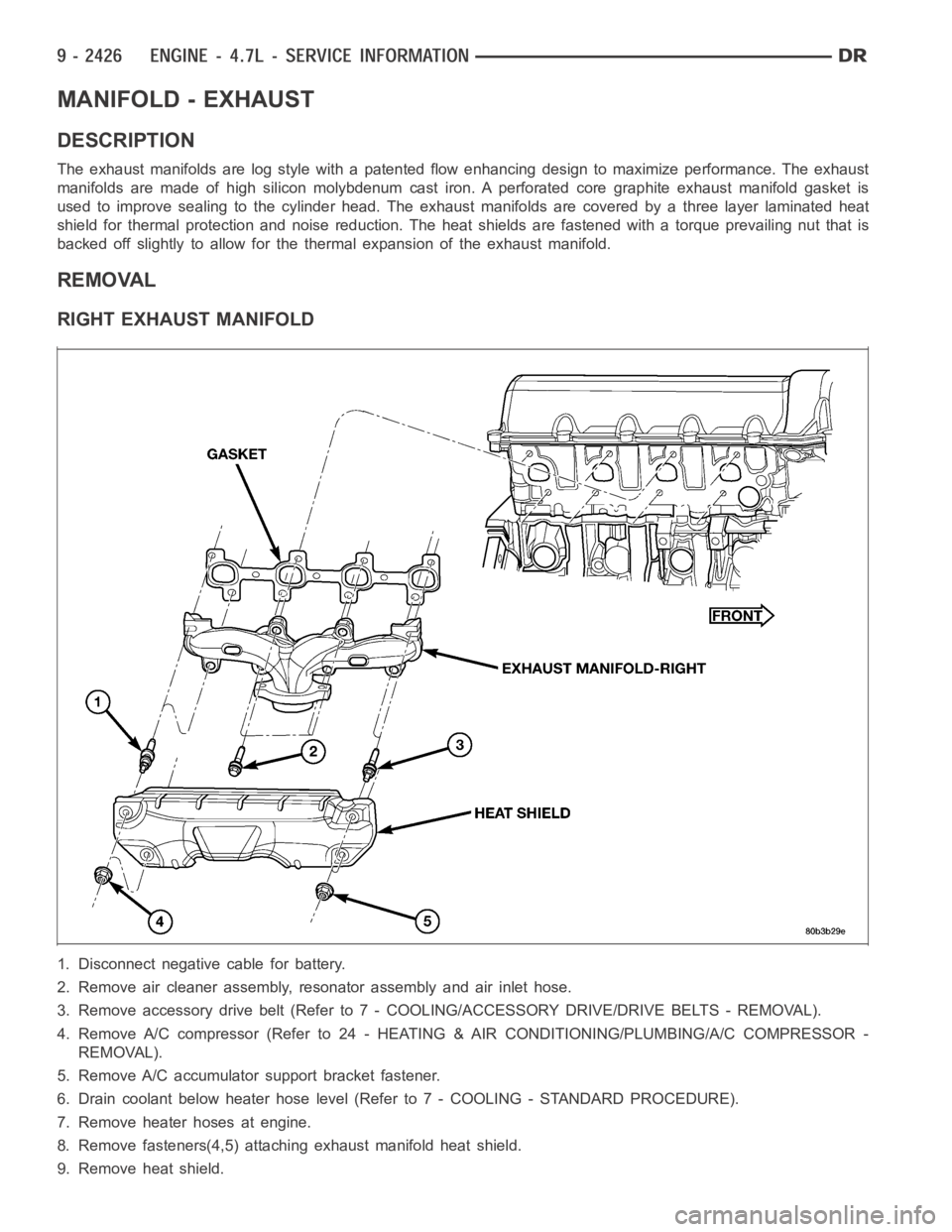

MANIFOLD - EXHAUST

DESCRIPTION

The exhaust manifolds are log style with a patented flow enhancing design to maximize performance. The exhaust

manifolds are made of high silicon molybdenum cast iron. A perforated coregraphite exhaust manifold gasket is

used to improve sealing to the cylinder head. The exhaust manifolds are covered by a three layer laminated heat

shield for thermal protection and noise reduction. The heat shields are fastened with a torque prevailing nut that is

backed off slightly to allow for the thermal expansion of the exhaust manifold.

REMOVAL

RIGHT EXHAUST MANIFOLD

1. Disconnect negative cable for battery.

2. Remove air cleaner assembly, resonator assembly and air inlet hose.

3. Remove accessory drive belt (Refer to 7 - COOLING/ACCESSORY DRIVE/DRIVE BELTS - REMOVAL).

4. Remove A/C compressor (Refer to 24 -HEATING & AIR CONDITIONING/PLUMBING/A/C COMPRESSOR -

REMOVAL).

5. Remove A/C accumulator support bracket fastener.

6. Drain coolant below heater hose level (Refer to 7 - COOLING - STANDARD PROCEDURE).

7. Remove heater hoses at engine.

8. Remove fasteners(4,5) attaching exhaust manifold heat shield.

9. Remove heat shield.

Page 1736 of 5267

10. Remove upper exhaust manifold attaching fasteners (1,3).

11. Raise vehicle on hoist.

12. Disconnect exhaust pipe from manifold.

13. Remove fasteners attaching starter. Move starter aside.

14. Remove lower exhaust manifold attaching fasteners.

15. Remove exhaust manifold and gasket. Manifold is removed from below theengine compartment.

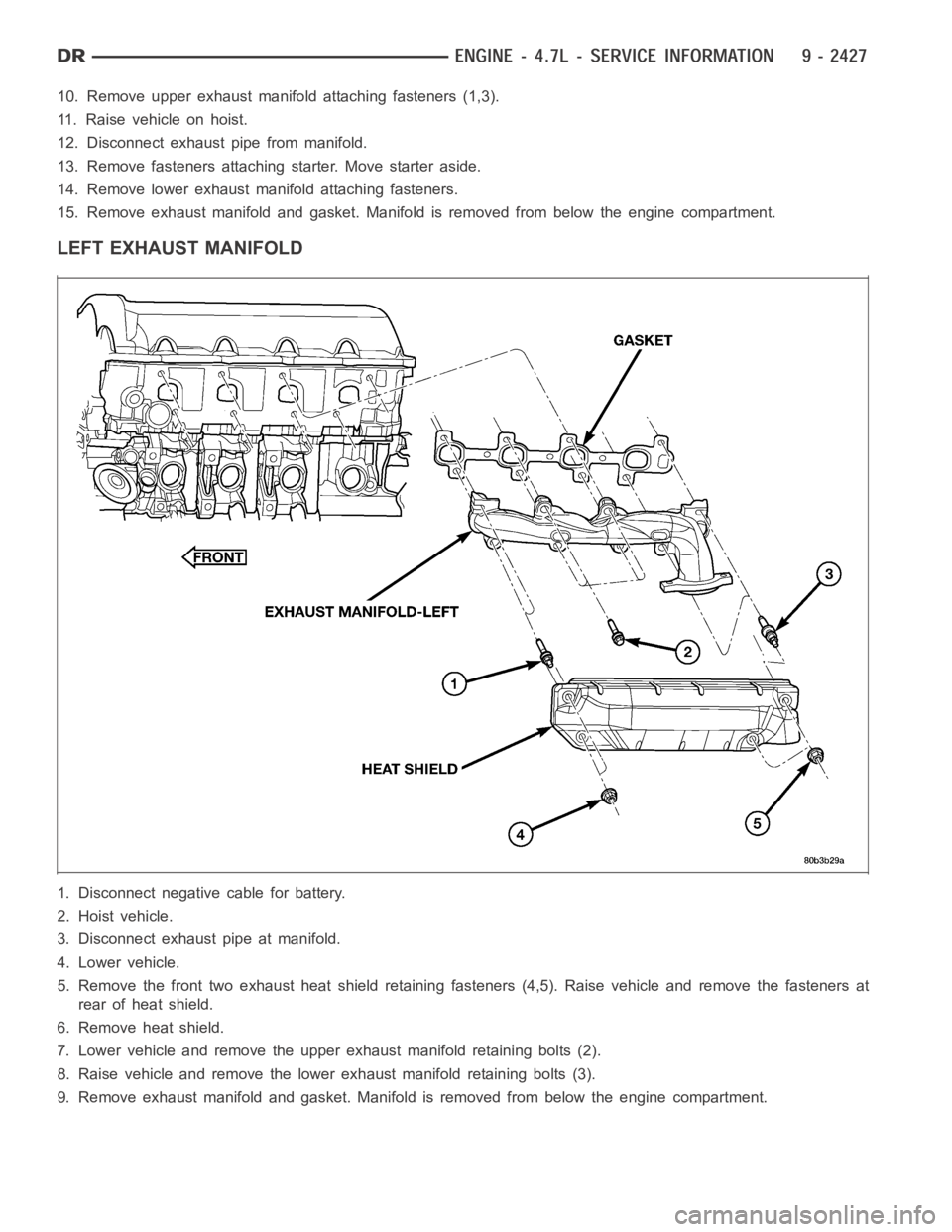

LEFT EXHAUST MANIFOLD

1. Disconnect negative cable for battery.

2. Hoist vehicle.

3. Disconnect exhaust pipe at manifold.

4. Lower vehicle.

5. Remove the front two exhaust heat shield retaining fasteners (4,5). Raise vehicle and remove the fasteners at

rear of heat shield.

6. Remove heat shield.

7. Lower vehicle and remove the upper exhaust manifold retaining bolts (2).

8. Raise vehicle and remove the lower exhaust manifold retaining bolts (3).

9. Remove exhaust manifold and gasket. Manifold is removed from below the engine compartment.

Page 1737 of 5267

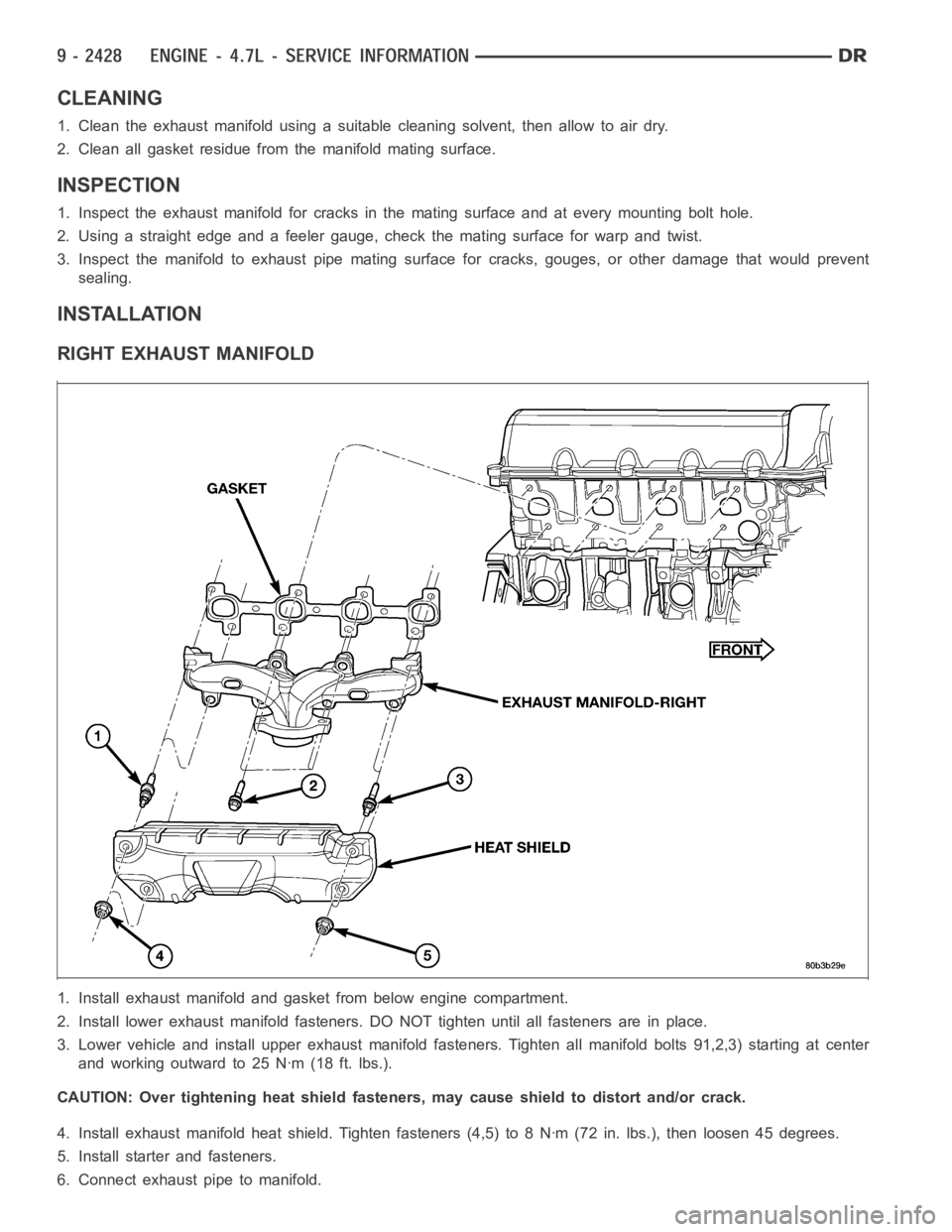

CLEANING

1. Clean the exhaust manifold using a suitable cleaning solvent, then allowtoairdry.

2. Clean all gasket residue from the manifold mating surface.

INSPECTION

1. Inspect the exhaust manifold for cracks in the mating surface and at every mounting bolt hole.

2. Using a straight edge and a feeler gauge, check the mating surface for warp and twist.

3. Inspect the manifold to exhaust pipe mating surface for cracks, gouges,or other damage that would prevent

sealing.

INSTALLATION

RIGHT EXHAUST MANIFOLD

1. Install exhaust manifold and gasket from below engine compartment.

2. Install lower exhaust manifold fasteners. DO NOT tighten until all fastenersareinplace.

3. Lower vehicle and install upper exhaust manifold fasteners. Tighten all manifold bolts 91,2,3) starting at center

and working outward to 25 Nꞏm (18 ft. lbs.).

CAUTION: Over tightening heat shield fasteners, may cause shield to distort and/or crack.

4. Install exhaust manifold heat shield. Tighten fasteners (4,5) to 8 Nꞏm (72 in. lbs.), then loosen 45 degrees.

5. Install starter and fasteners.

6. Connect exhaust pipe to manifold.

Page 1738 of 5267

7. Connect heater hoses at engine.

8. Install fastener attaching A/C accumulator.

9. Install A/C compressor and fasteners.

10. Install accessory drive belt (Refer to 7 - COOLING/ACCESSORY DRIVE/DRIVE BELTS - INSTALLATION).

11. Install air cleaner assembly, resonator assembly and air inlet hose.

12. Install battery and connect cables.

13. Fill cooling system (Refer to 7 - COOLING - STANDARD PROCEDURE).

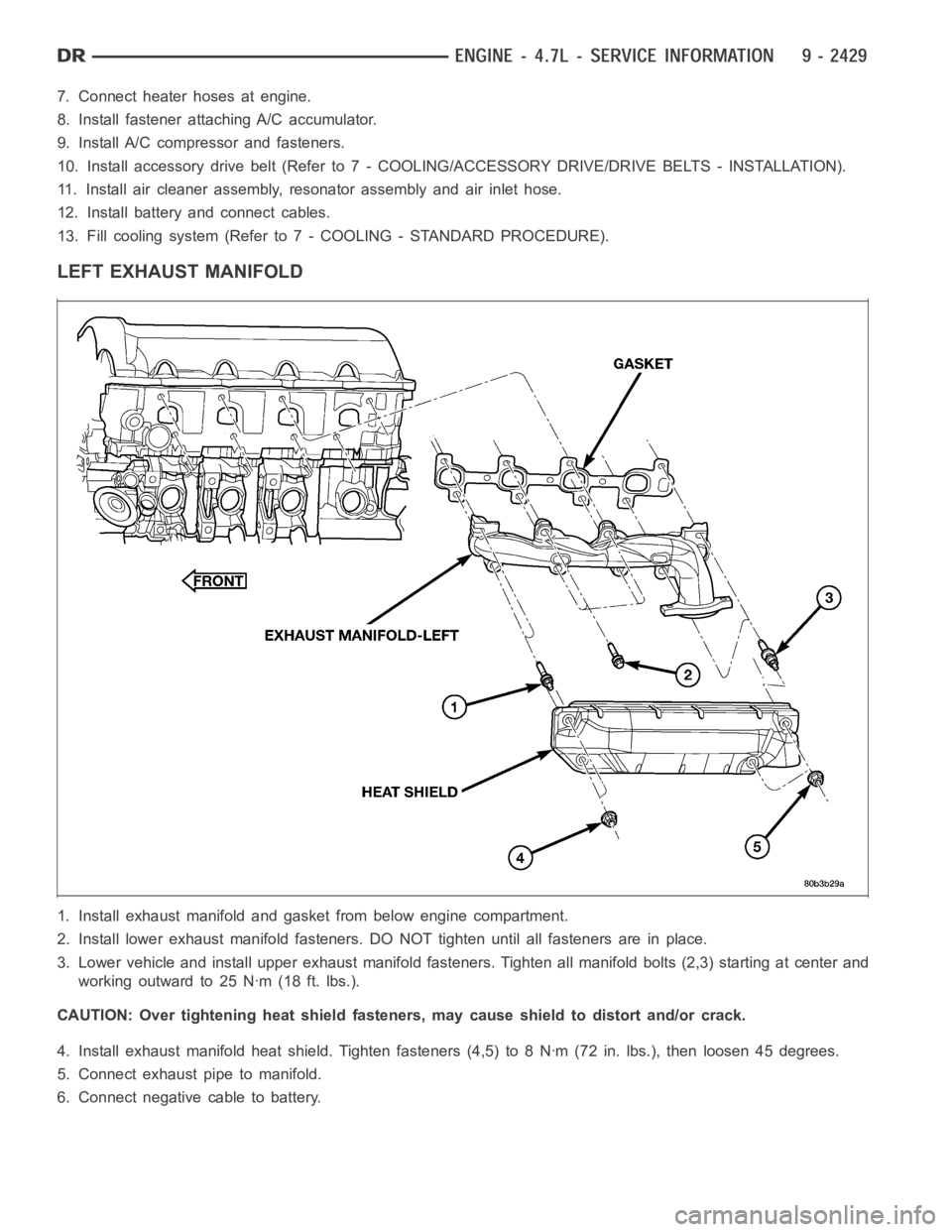

LEFT EXHAUST MANIFOLD

1. Install exhaust manifold and gasket from below engine compartment.

2. Install lower exhaust manifold fasteners. DO NOT tighten until all fastenersareinplace.

3. Lower vehicle and install upper exhaust manifold fasteners. Tighten all manifold bolts (2,3) starting at center and

working outward to 25 Nꞏm (18 ft. lbs.).

CAUTION: Over tightening heat shield fasteners, may cause shield to distort and/or crack.

4. Install exhaust manifold heat shield. Tighten fasteners (4,5) to 8 Nꞏm (72 in. lbs.), then loosen 45 degrees.

5. Connect exhaust pipe to manifold.

6. Connect negative cable to battery.

Page 1739 of 5267

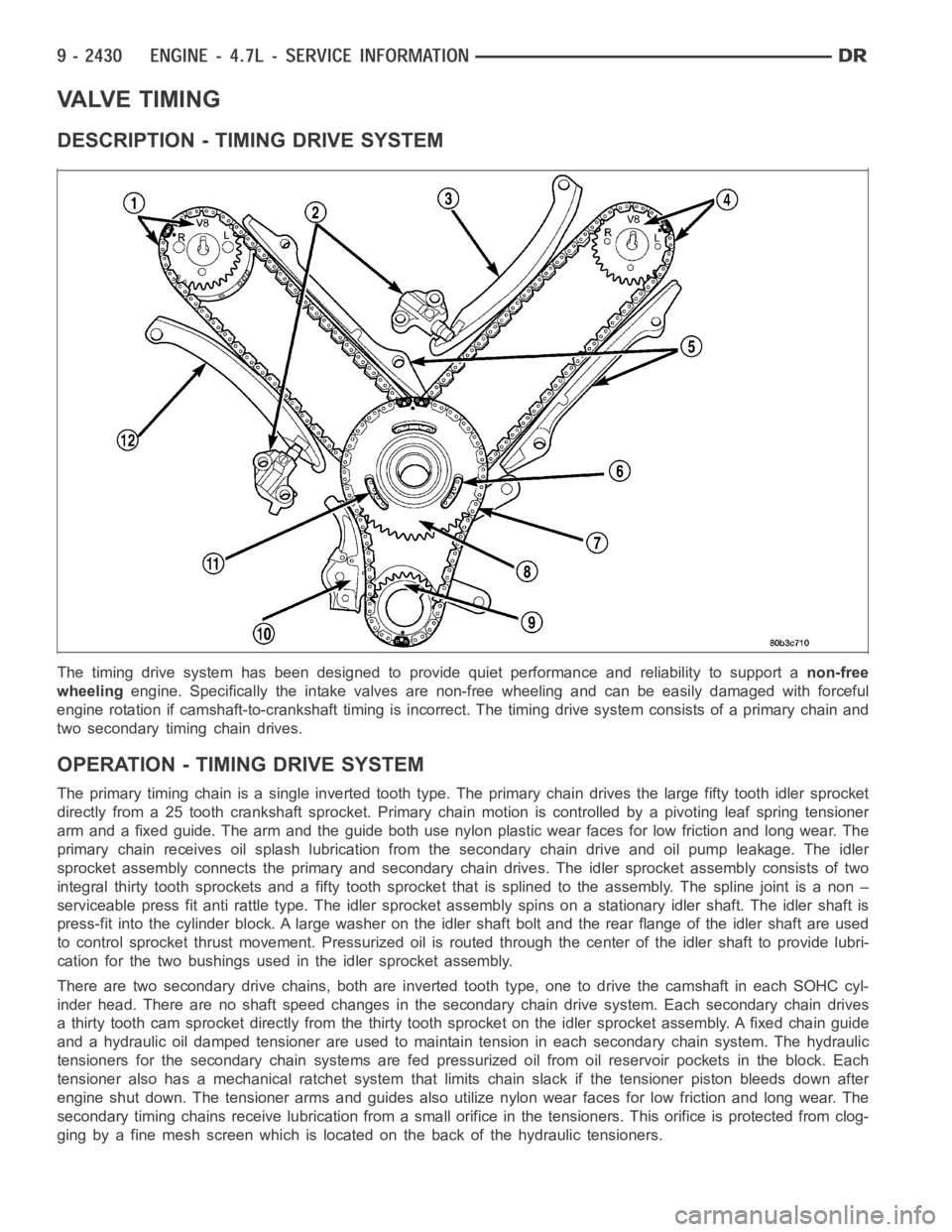

VALVE TIMING

DESCRIPTION - TIMING DRIVE SYSTEM

The timing drive system has been designed to provide quiet performance andreliability to support anon-free

wheelingengine. Specifically the intake valves are non-free wheeling and can be easily damaged with forceful

engine rotation if camshaft-to-crankshaft timing is incorrect. The timing drive system consists of a primary chain and

two secondary timing chain drives.

OPERATION - TIMING DRIVE SYSTEM

The primary timing chain is a single inverted tooth type. The primary chaindrives the large fifty tooth idler sprocket

directly from a 25 tooth crankshaft sprocket. Primary chain motion is controlled by a pivoting leaf spring tensioner

arm and a fixed guide. The arm and the guide both use nylon plastic wear facesfor low friction and long wear. The

primary chain receives oil splash lubrication from the secondary chain drive and oil pump leakage. The idler

sprocket assembly connects the primary and secondary chain drives. The idler sprocket assembly consists of two

integral thirty tooth sprockets and afifty tooth sprocket that is splinedto the assembly. The spline joint is a non –

serviceable press fit anti rattle type. The idler sprocket assembly spinson a stationary idler shaft. The idler shaft is

press-fit into the cylinder block. A large washer on the idler shaft bolt and the rear flange of the idler shaft are used

to control sprocket thrust movement. Pressurized oil is routed through the center of the idler shaft to provide lubri-

cation for the two bushings used in the idler sprocket assembly.

There are two secondary drive chains, both are inverted tooth type, one to drive the camshaft in each SOHC cyl-

inder head. There are no shaft speed changes in the secondary chain drive system. Each secondary chain drives

a thirty tooth cam sprocket directly from the thirty tooth sprocket on the idler sprocket assembly. A fixed chain guide

and a hydraulic oil damped tensioner are used to maintain tension in each secondary chain system. The hydraulic

tensioners for the secondary chainsystems are fed pressurized oil from oil reservoir pockets in the block. Each

tensioner also has a mechanical ratchet system that limits chain slack if the tensioner piston bleeds down after

engine shut down. The tensioner arms and guides also utilize nylon wear faces for low friction and long wear. The

secondary timing chains receive lubrication from a small orifice in the tensioners. This orifice is protected from clog-

ging by a fine mesh screen which is located on the back of the hydraulic tensioners.

Page 1740 of 5267

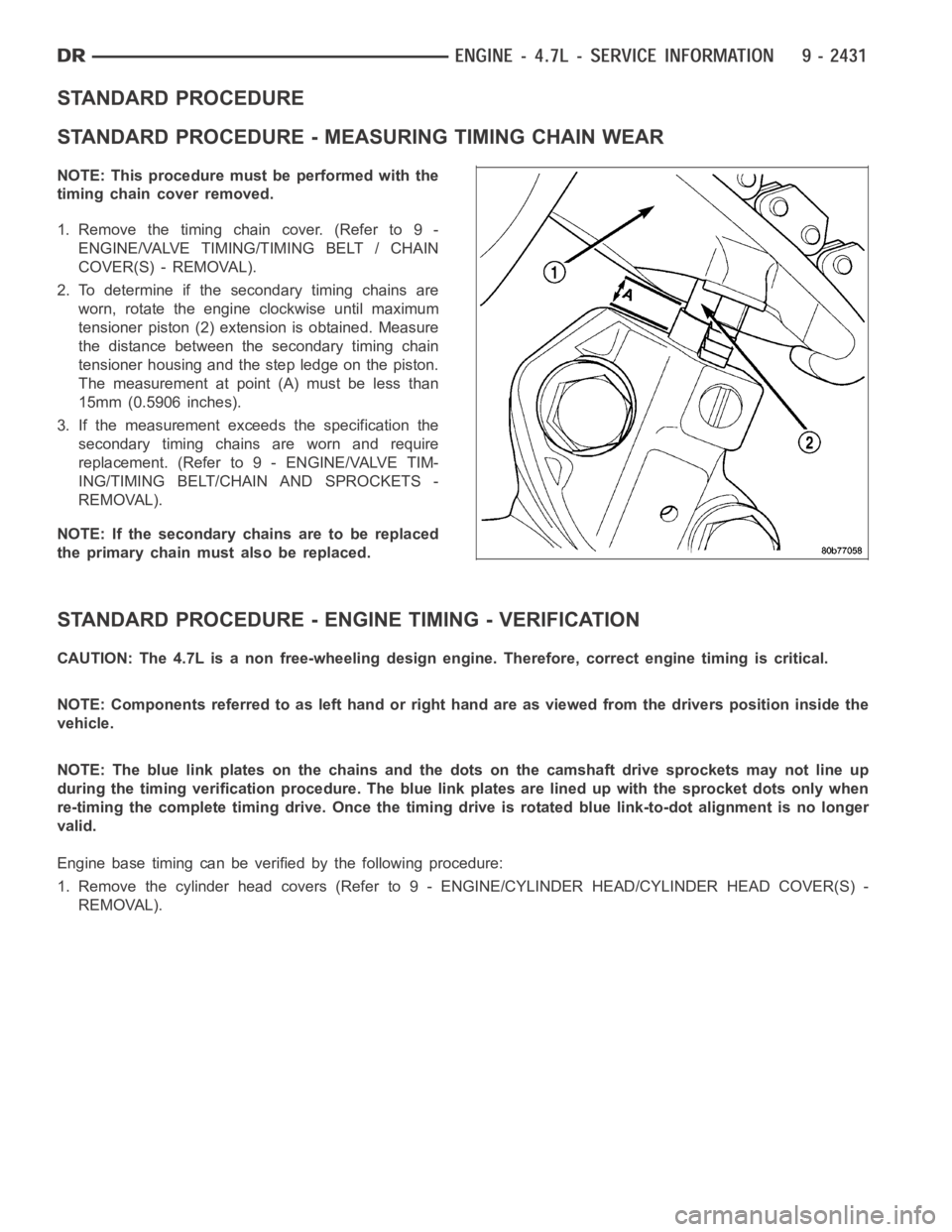

STANDARD PROCEDURE

STANDARD PROCEDURE - MEASURING TIMING CHAIN WEAR

NOTE: This procedure must be performed with the

timing chain cover removed.

1.Removethetimingchaincover.(Referto9-

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL).

2. To determine if the secondary timing chains are

worn, rotate the engine clockwise until maximum

tensioner piston (2) extension is obtained. Measure

the distance between the secondary timing chain

tensioner housing and the step ledge on the piston.

The measurement at point (A) must be less than

15mm (0.5906 inches).

3. If the measurement exceeds the specification the

secondary timing chains are worn and require

replacement. (Refer to 9 - ENGINE/VALVE TIM-

ING/TIMING BELT/CHAIN AND SPROCKETS -

REMOVAL).

NOTE: If the secondary chains are to be replaced

the primary chain must also be replaced.

STANDARD PROCEDURE - ENGINE TIMING - VERIFICATION

CAUTION: The 4.7L is a non free-wheeling design engine. Therefore, correct engine timing is critical.

NOTE: Components referred to as left hand or right hand are as viewed from thedriverspositioninsidethe

vehicle.

NOTE: The blue link plates on the chains and the dots on the camshaft drive sprockets may not line up

during the timing verification procedure. The blue link plates are lined up with the sprocket dots only when

re-timing the complete timing drive.Once the timing drive is rotated bluelink-to-dot alignment is no longer

valid.

Engine base timing can be verified by the following procedure:

1. Remove the cylinder head covers (Refer to 9 - ENGINE/CYLINDER HEAD/CYLINDERHEADCOVER(S)-

REMOVAL).