DODGE RAM SRT-10 2006 Service Repair Manual

RAM SRT-10 2006

DODGE

DODGE

https://www.carmanualsonline.info/img/12/56917/w960_56917-0.png

DODGE RAM SRT-10 2006 Service Repair Manual

Trending: wheel torque, run flat, bulb, relay, child seat, coolant reservoir, door lock

Page 1821 of 5267

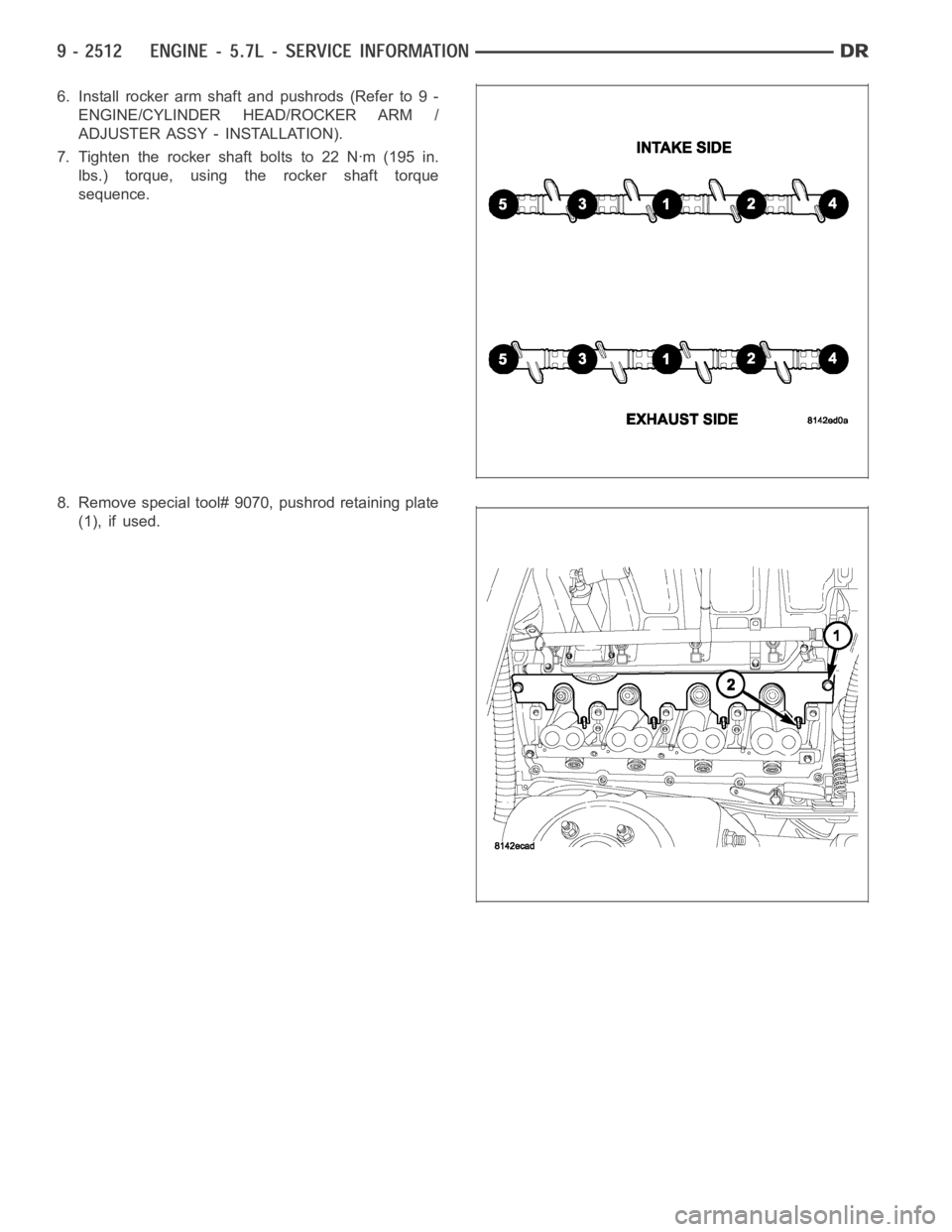

6. Install rocker arm shaft and pushrods (Refer to 9 -

ENGINE/CYLINDER HEAD/ROCKER ARM /

ADJUSTER ASSY - INSTALLATION).

7. Tighten the rocker shaft bolts to 22 Nꞏm (195 in.

lbs.) torque, using the rocker shaft torque

sequence.

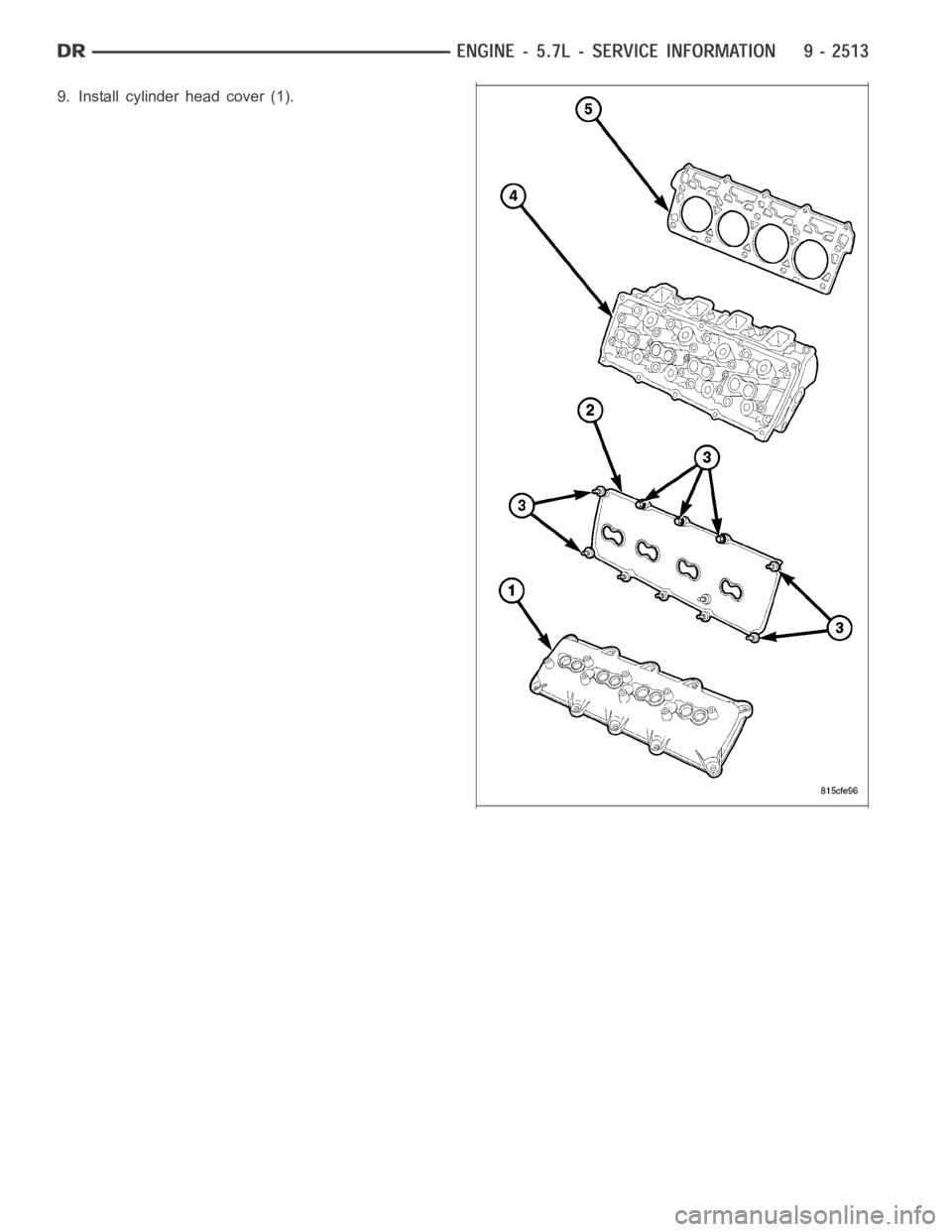

8. Remove special tool# 9070, pushrod retaining plate

(1), if used.

Page 1822 of 5267

9. Install cylinder head cover (1).

Page 1823 of 5267

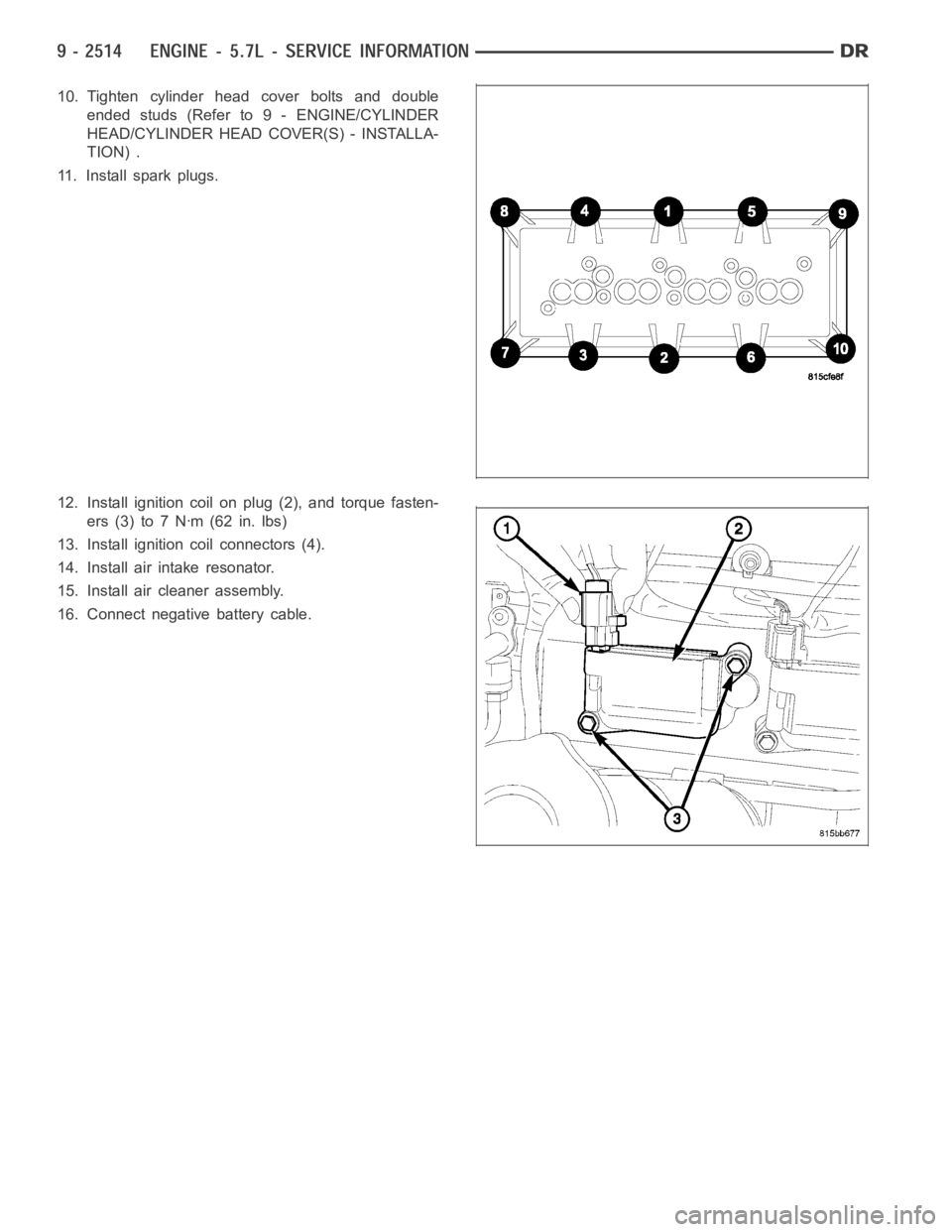

10. Tighten cylinder head cover bolts and double

ended studs (Refer to 9 - ENGINE/CYLINDER

HEAD/CYLINDER HEAD COVER(S) - INSTALLA-

TION) .

11. Install spark plugs.

12. Install ignition coil on plug (2), and torque fasten-

ers (3) to 7 Nꞏm (62 in. lbs)

13. Install ignition coil connectors (4).

14. Install air intake resonator.

15. Install air cleaner assembly.

16. Connect negative battery cable.

Page 1824 of 5267

ENGINE BLOCK

CLEANING

Thoroughly clean the oil pan and engine block gasket surfaces.

Use compressed air to clean out:

The galley at the oil filter adaptor hole.

The front and rear oil galley holes.

The feed holes for the crankshaft main bearings.

Once the block has been completely cleaned, apply Loctite PST pipe sealantwith Teflon 592 to the threads of the

front and rear oil galley plugs. Tighten the 1/4 inch NPT plugs to 20 Nꞏm (177in. lbs.) torque. Tighten the 3/8 inch

NPT plugs to 27 Nꞏm (240 in. lbs.) torque.

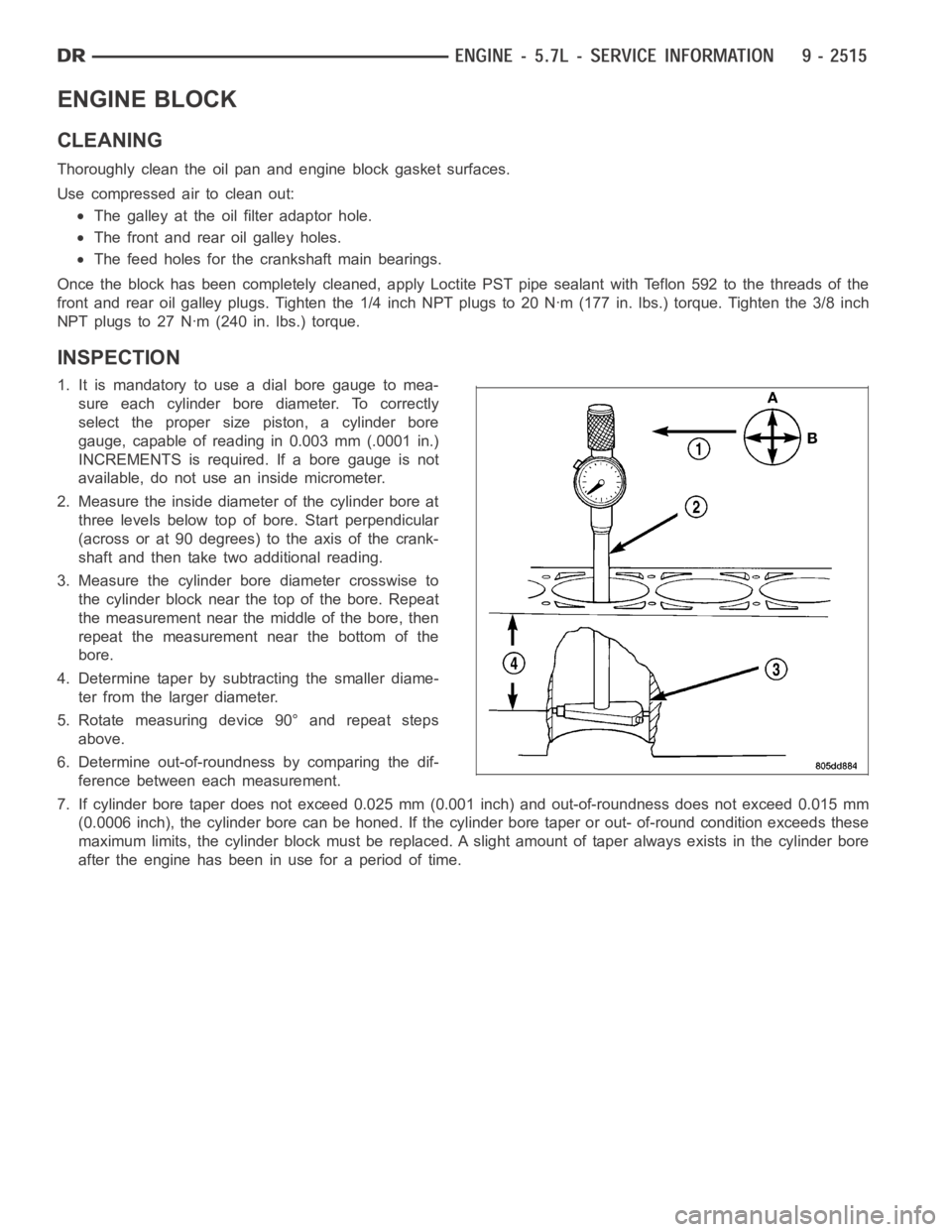

INSPECTION

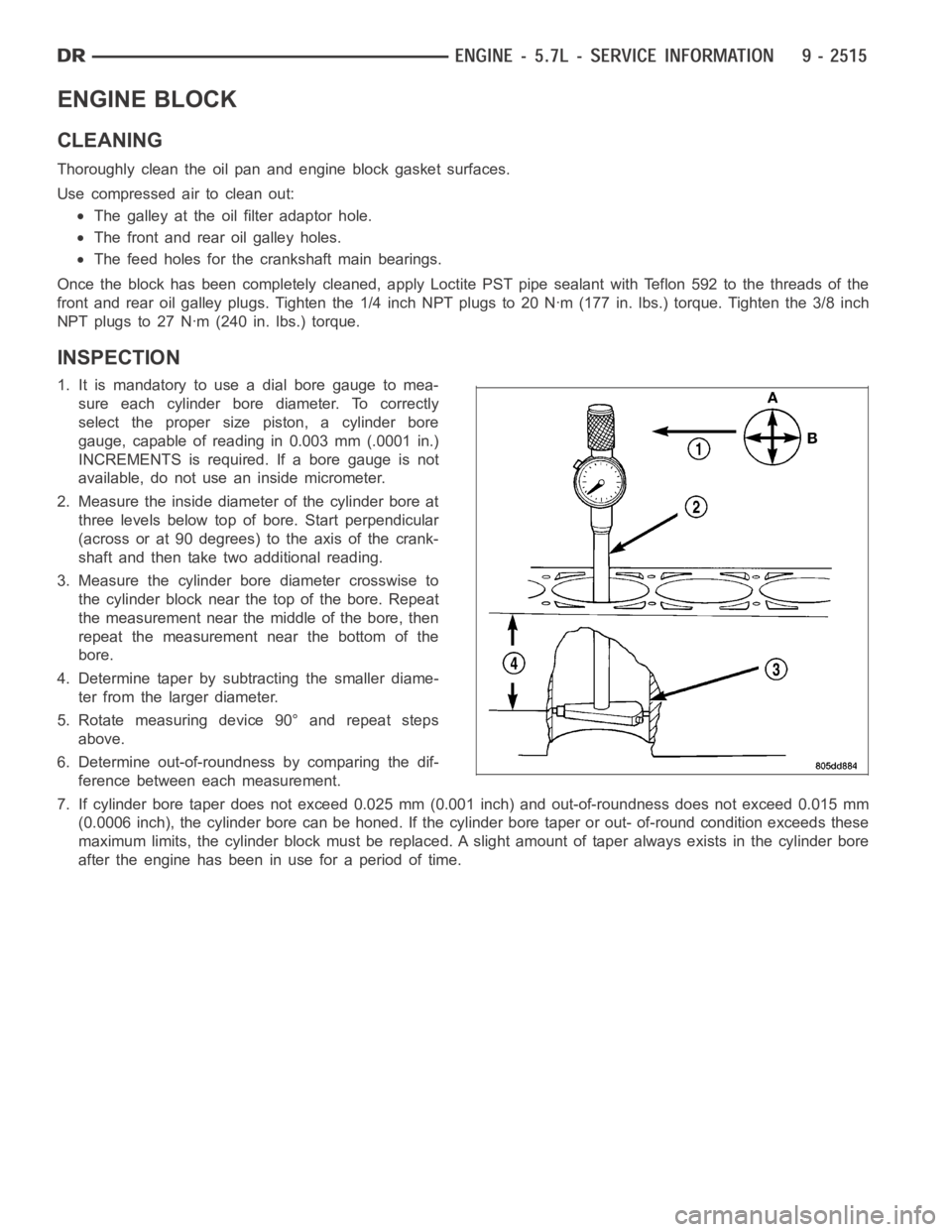

1. It is mandatory to use a dial bore gauge to mea-

sure each cylinder bore diameter. To correctly

select the proper size piston, a cylinder bore

gauge, capable of reading in 0.003 mm (.0001 in.)

INCREMENTS is required. If a bore gauge is not

available, do not use an inside micrometer.

2. Measure the inside diameter of the cylinder bore at

three levels below top of bore. Start perpendicular

(across or at 90 degrees) to the axis of the crank-

shaft and then take two additional reading.

3. Measure the cylinder bore diameter crosswise to

the cylinder block near the top of the bore. Repeat

the measurement near the middle of the bore, then

repeat the measurement near the bottom of the

bore.

4. Determine taper by subtracting the smaller diame-

ter from the larger diameter.

5. Rotate measuring device 90° and repeat steps

above.

6. Determine out-of-roundness by comparing the dif-

ference between each measurement.

7. If cylinder bore taper does not exceed 0.025 mm (0.001 inch) and out-of-roundness does not exceed 0.015 mm

(0.0006 inch), the cylinder bore can be honed. If the cylinder bore taper orout- of-round condition exceeds these

maximum limits, the cylinder block must be replaced. A slight amount of taper always exists in the cylinder bore

after the engine has been in use for a period of time.

Page 1825 of 5267

CAMSHAFT

REMOVAL

REMOVAL - CAMSHAFT CORE HOLE PLUG

CAUTION: Do not damage the rear surface of the camshaft or the core plug sealing surface, when removing

the core plug.

1. Remove the rear cam bearing core plug.

REMOVAL - CAMSHAFT

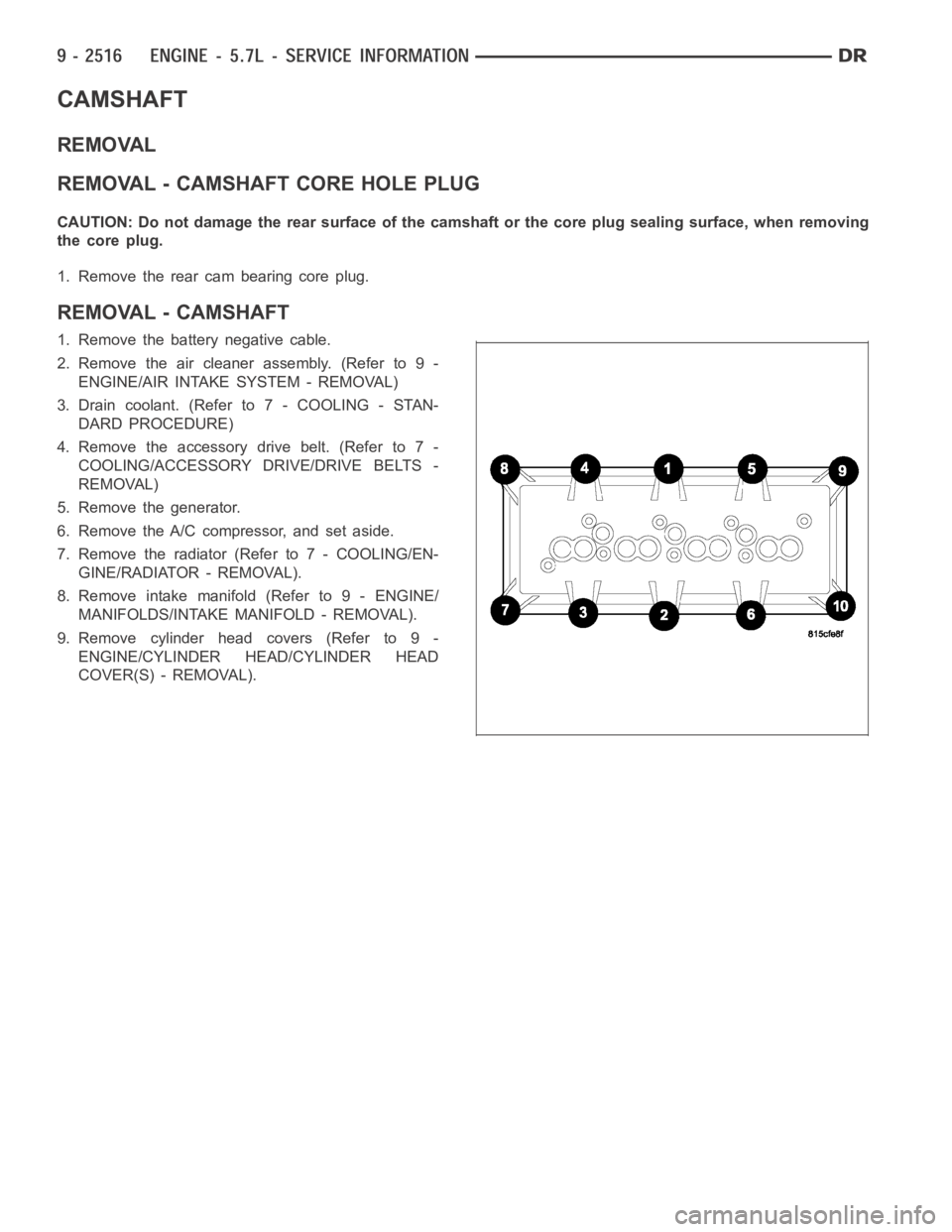

1. Remove the battery negative cable.

2. Remove the air cleaner assembly. (Refer to 9 -

ENGINE/AIR INTAKE SYSTEM - REMOVAL)

3. Drain coolant. (Refer to 7 - COOLING - STAN-

DARD PROCEDURE)

4. Remove the accessory drive belt. (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL)

5. Remove the generator.

6. Remove the A/C compressor, and set aside.

7. Remove the radiator (Refer to 7 - COOLING/EN-

GINE/RADIATOR - REMOVAL).

8. Remove intake manifold (Refer to 9 - ENGINE/

MANIFOLDS/INTAKE MANIFOLD - REMOVAL).

9. Remove cylinder head covers (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL).

Page 1826 of 5267

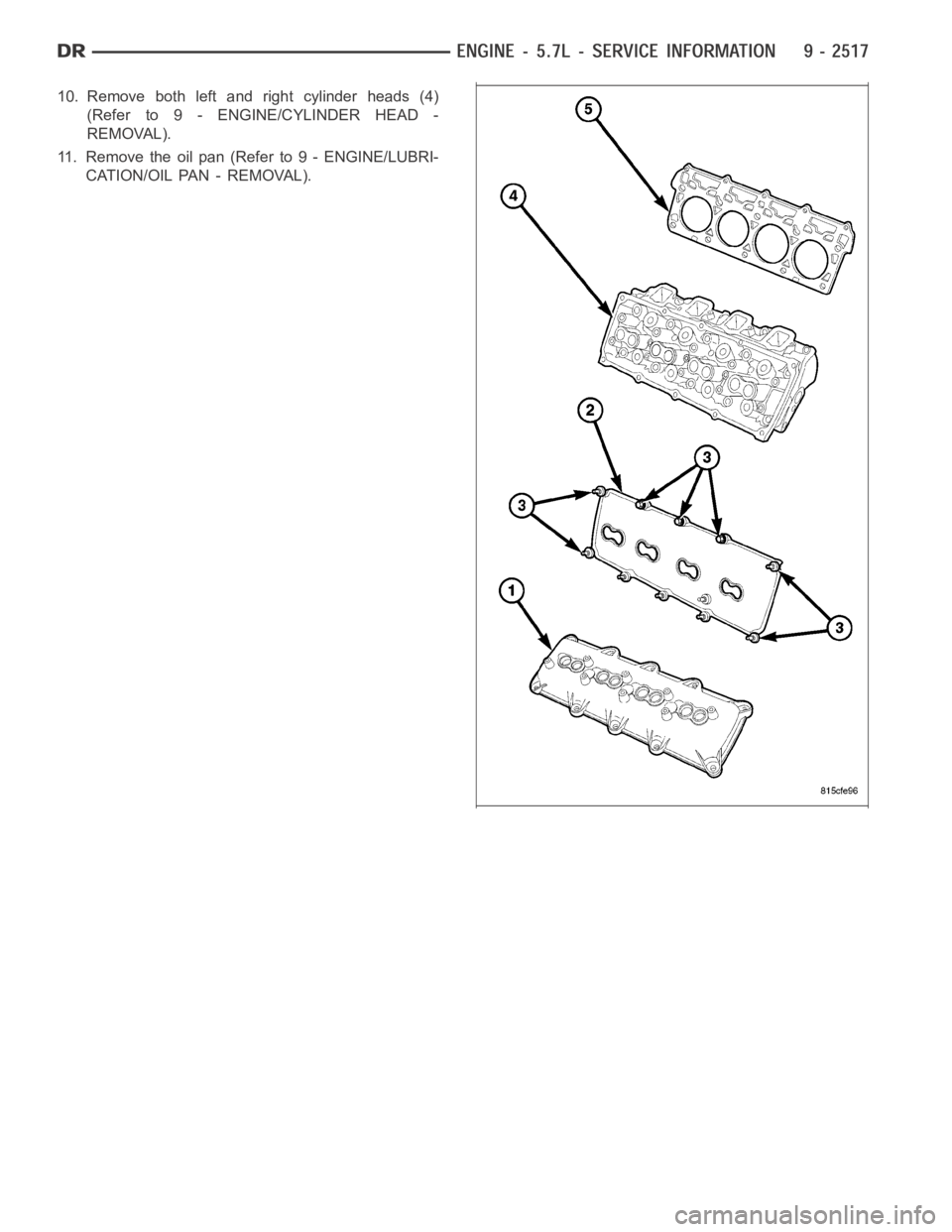

10. Remove both left and right cylinder heads (4)

(Refer to 9 - ENGINE/CYLINDER HEAD -

REMOVAL).

11. Remove the oil pan (Refer to 9 - ENGINE/LUBRI-

CATION/OIL PAN - REMOVAL).

Page 1827 of 5267

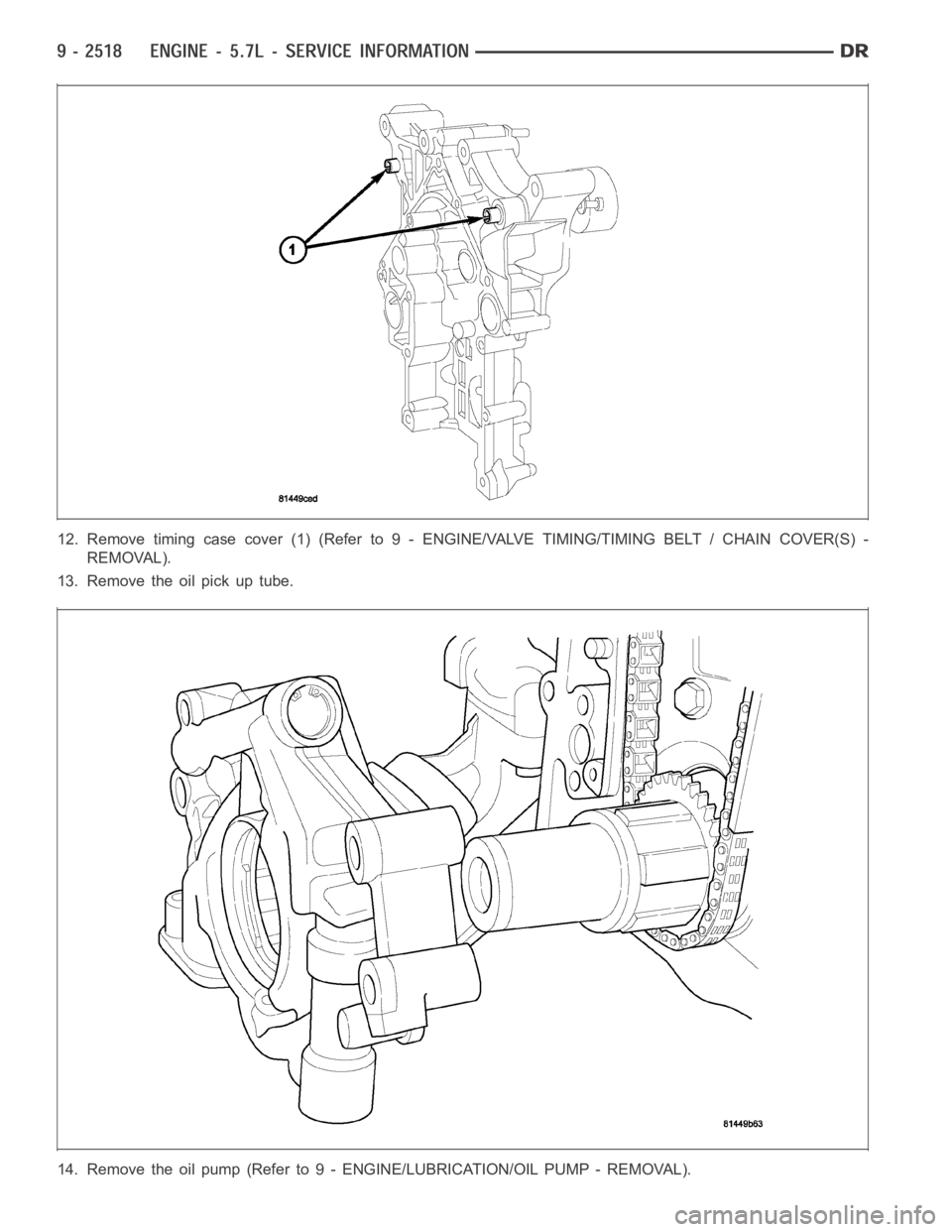

12. Remove timing case cover (1) (Refer to 9 - ENGINE/VALVE TIMING/TIMING BELT / CHAIN COVER(S) -

REMOVAL).

13. Remove the oil pick up tube.

14. Remove the oil pump (Refer to 9 - ENGINE/LUBRICATION/OIL PUMP - REMOVAL).

Page 1828 of 5267

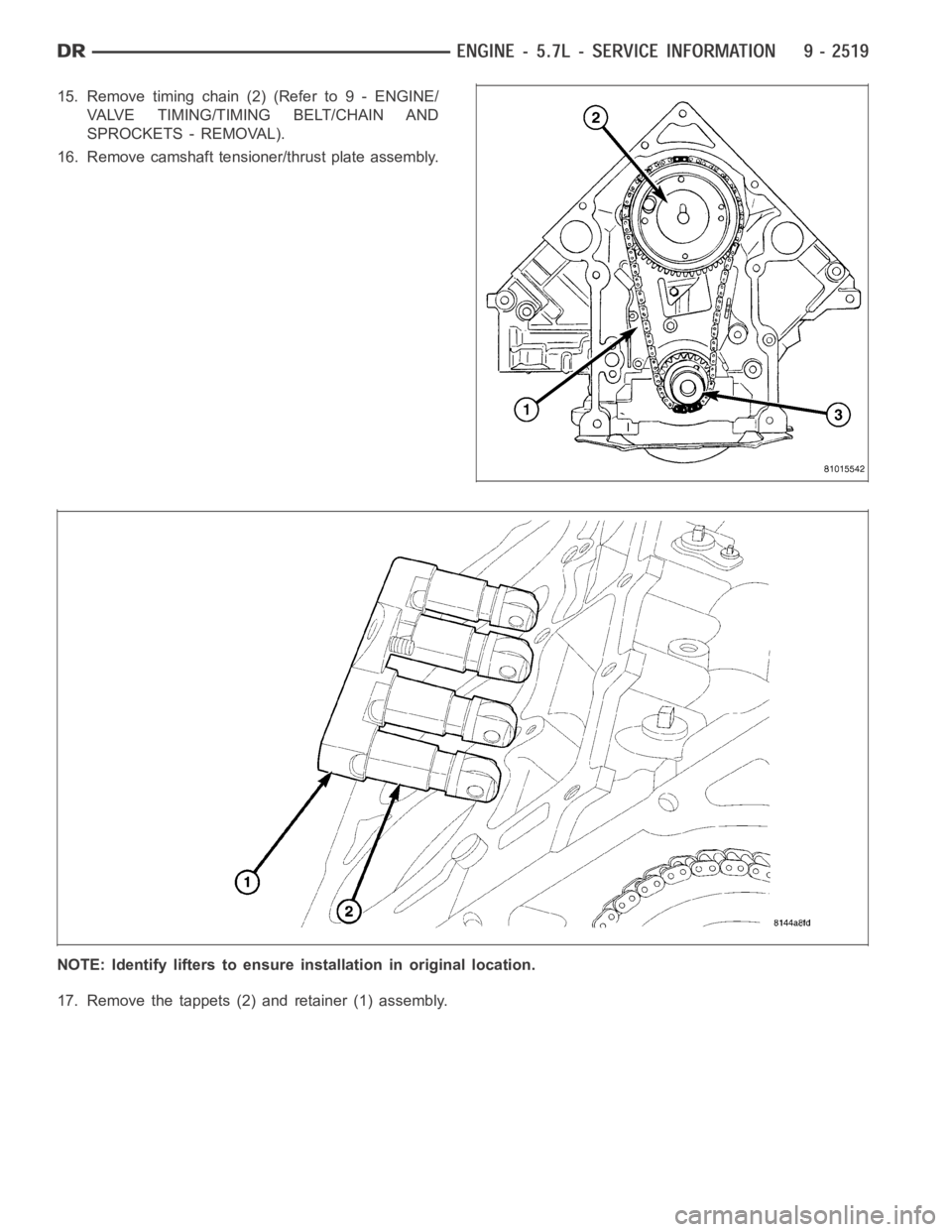

15. Remove timing chain (2) (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT/CHAIN AND

SPROCKETS - REMOVAL).

16. Remove camshaft tensioner/thrust plate assembly.

NOTE: Identify lifters to ensure installation in original location.

17. Remove the tappets (2) and retainer (1) assembly.

Page 1829 of 5267

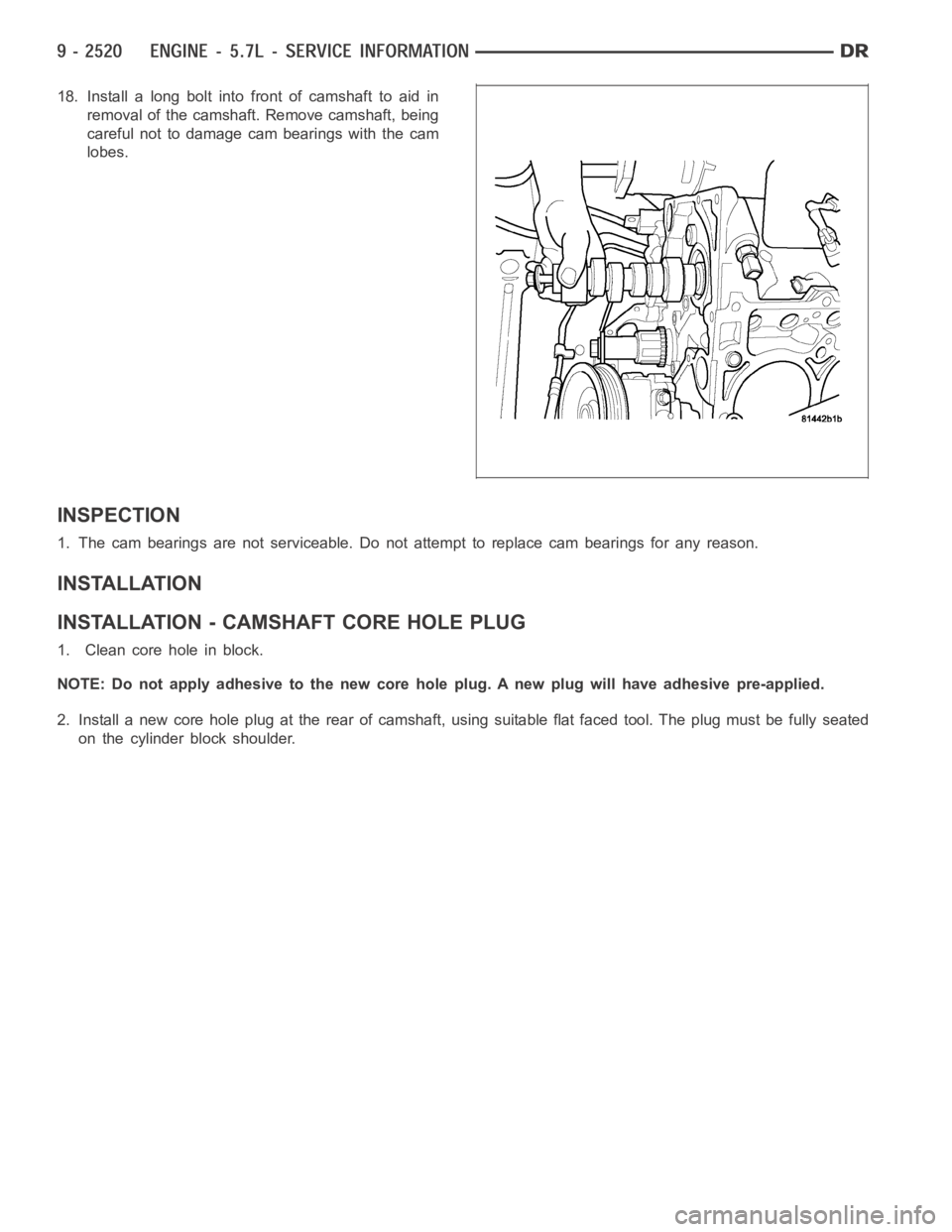

18. Install a long bolt into front of camshaft to aid in

removal of the camshaft. Remove camshaft, being

careful not to damage cam bearings with the cam

lobes.

INSPECTION

1. The cam bearings are not serviceable. Do not attempt to replace cam bearings for any reason.

INSTALLATION

INSTALLATION - CAMSHAFT CORE HOLE PLUG

1. Clean core hole in block.

NOTE: Do not apply adhesive to the new core hole plug. A new plug will have adhesive pre-applied.

2. Install a new core hole plug at the rear of camshaft, using suitable flat faced tool. The plug must be fully seated

on the cylinder block shoulder.

Page 1830 of 5267

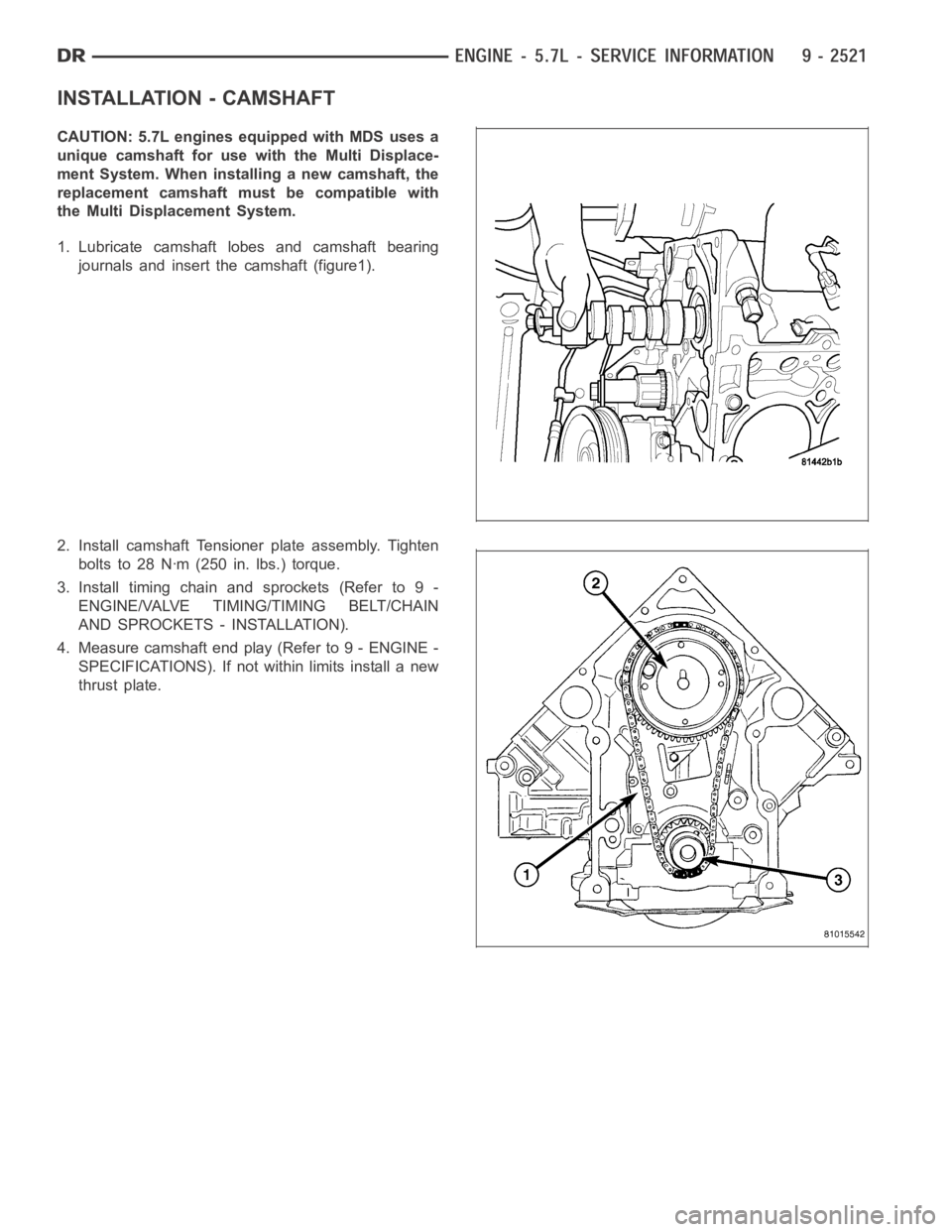

INSTALLATION - CAMSHAFT

CAUTION: 5.7L engines equipped with MDS uses a

unique camshaft for use with the Multi Displace-

ment System. When installing a new camshaft, the

replacement camshaft must be compatible with

the Multi Displacement System.

1. Lubricate camshaft lobes and camshaft bearing

journals and insert the camshaft (figure1).

2. Install camshaft Tensioner plate assembly. Tighten

bolts to 28 Nꞏm (250 in. lbs.) torque.

3. Install timing chain and sprockets (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT/CHAIN

AND SPROCKETS - INSTALLATION).

4. Measure camshaft end play (Refer to 9 - ENGINE -

SPECIFICATIONS). If not within limits install a new

thrust plate.

Trending: refrigerant type, engine oil capacity, hood release, fuse, reset, Coolant leak, inflation pressure