torque DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 2174 of 5267

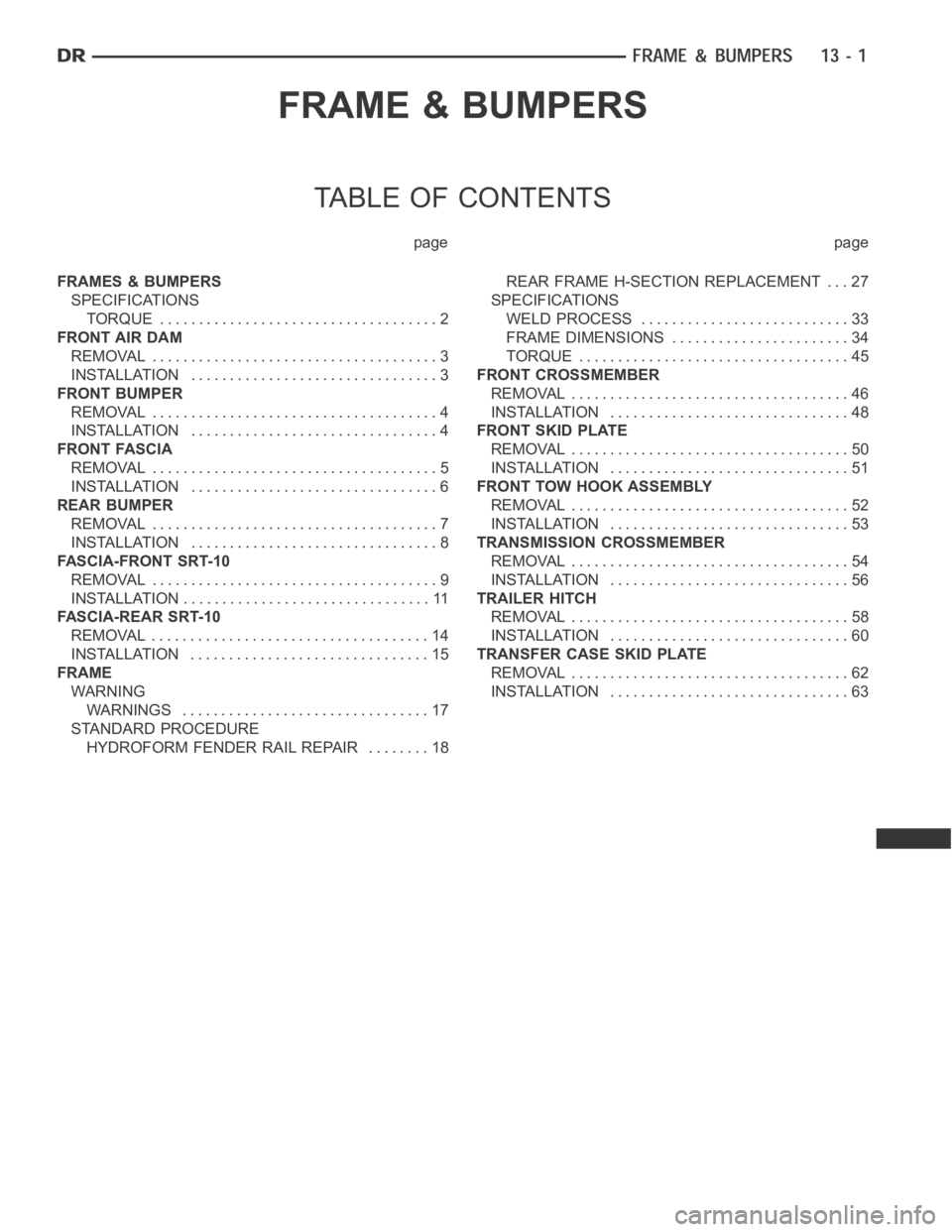

FRAME & BUMPERS

TABLE OF CONTENTS

page page

FRAMES & BUMPERS

SPECIFICATIONS

TORQUE .................................... 2

FRONT AIR DAM

REMOVAL ..................................... 3

INSTALLATION ................................ 3

FRONT BUMPER

REMOVAL ..................................... 4

INSTALLATION ................................ 4

FRONT FASCIA

REMOVAL ..................................... 5

INSTALLATION ................................ 6

REAR BUMPER

REMOVAL ..................................... 7

INSTALLATION ................................ 8

FASCIA-FRONT SRT-10

REMOVAL ..................................... 9

INSTALLATION ................................ 11

FASCIA-REAR SRT-10

REMOVAL .................................... 14

INSTALLATION ............................... 15

FRAME

WARNING

WARNINGS ................................ 17

STANDARD PROCEDURE

HYDROFORM FENDER RAIL REPAIR ........ 18REAR FRAME H-SECTION REPLACEMENT . . . 27

SPECIFICATIONS

WELD PROCESS ........................... 33

FRAME DIMENSIONS ....................... 34

TORQUE ................................... 45

FRONT CROSSMEMBER

REMOVAL .................................... 46

INSTALLATION ............................... 48

FRONT SKID PLATE

REMOVAL .................................... 50

INSTALLATION ............................... 51

FRONT TOW HOOK ASSEMBLY

REMOVAL .................................... 52

INSTALLATION ............................... 53

TRANSMISSION CROSSMEMBER

REMOVAL .................................... 54

INSTALLATION ............................... 56

TRAILER HITCH

REMOVAL .................................... 58

INSTALLATION ............................... 60

TRANSFER CASE SKID PLATE

REMOVAL .................................... 62

INSTALLATION ............................... 63

Page 2175 of 5267

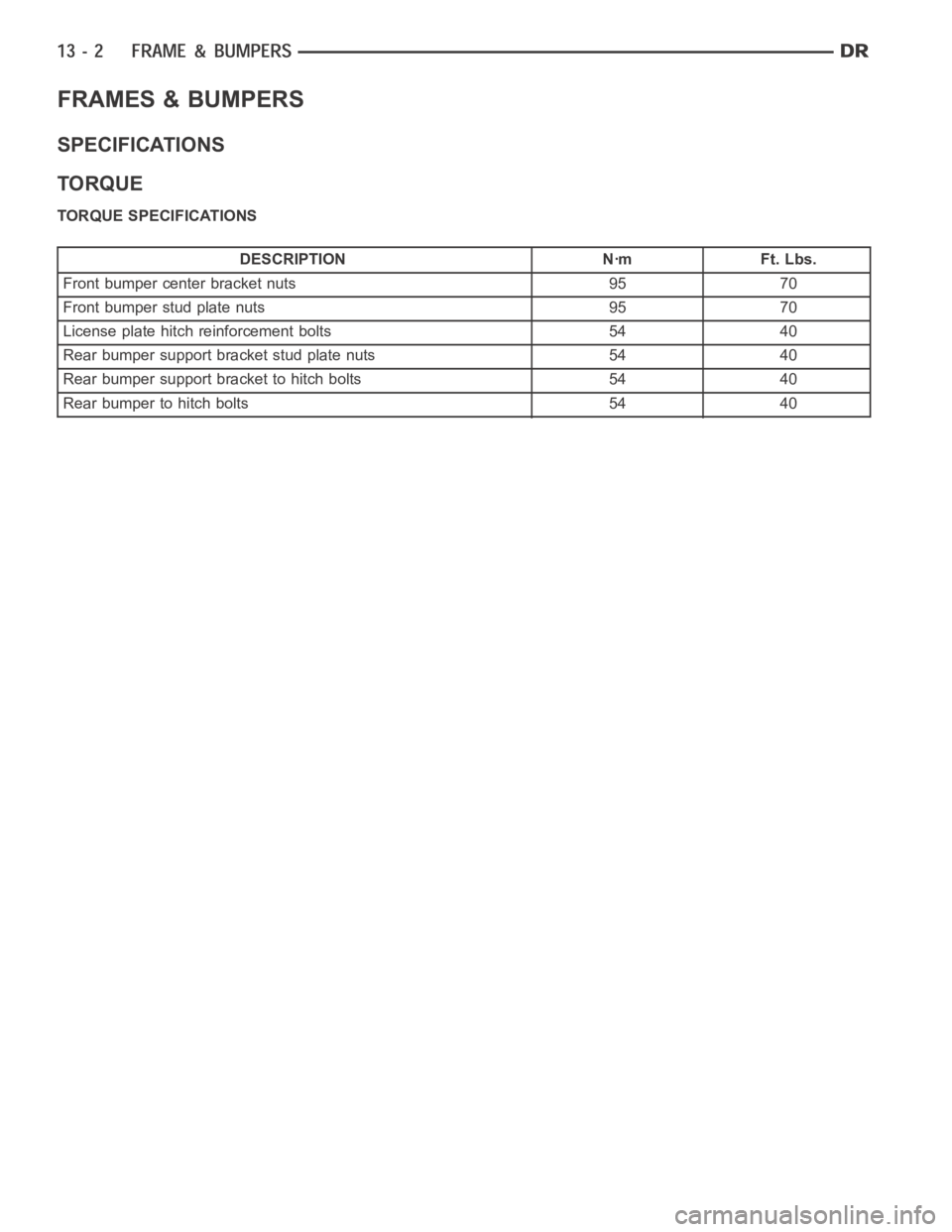

FRAMES & BUMPERS

SPECIFICATIONS

TORQUE

TORQUE SPECIFICATIONS

DESCRIPTION Nꞏm Ft. Lbs.

Front bumper center bracket nuts 95 70

Front bumper stud plate nuts 95 70

License plate hitch reinforcement bolts 54 40

Rear bumper support bracket stud plate nuts 54 40

Rear bumper support bracket to hitch bolts 54 40

Rear bumper to hitch bolts 54 40

Page 2218 of 5267

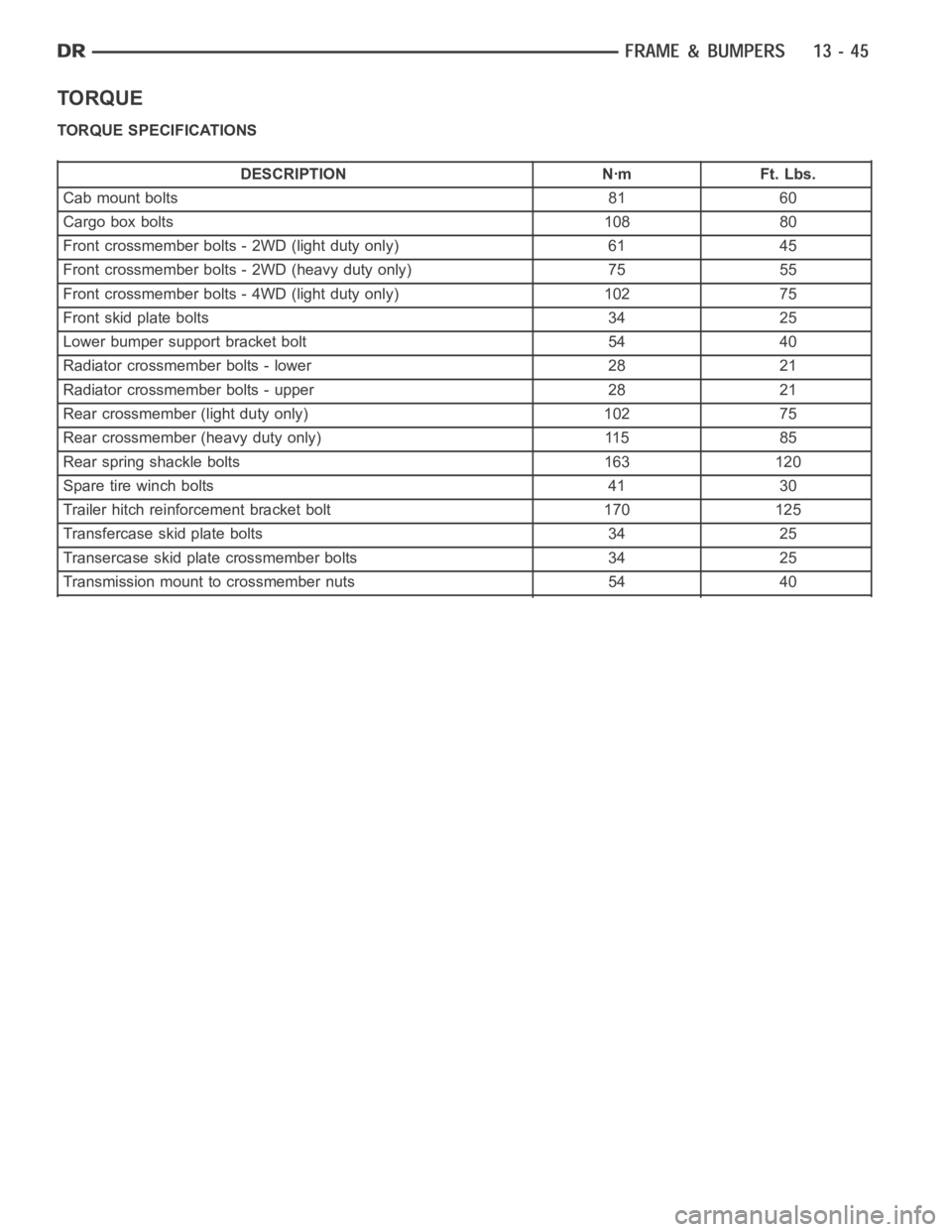

TORQUE

TORQUE SPECIFICATIONS

DESCRIPTION Nꞏm Ft. Lbs.

Cab mount bolts 81 60

Cargo box bolts 108 80

Front crossmember bolts - 2WD (light duty only) 61 45

Front crossmember bolts - 2WD (heavy duty only) 75 55

Front crossmember bolts - 4WD (light duty only) 102 75

Front skid plate bolts 34 25

Lower bumper support bracket bolt 54 40

Radiator crossmember bolts - lower 28 21

Radiator crossmember bolts - upper 28 21

Rear crossmember (light duty only) 102 75

Rear crossmember (heavy duty only) 115 85

Rear spring shackle bolts 163 120

Sparetirewinchbolts 41 30

Trailer hitch reinforcement bracket bolt 170 125

Transfercase skid plate bolts 34 25

Transercase skid plate crossmember bolts 34 25

Transmission mount to crossmember nuts 54 40

Page 2238 of 5267

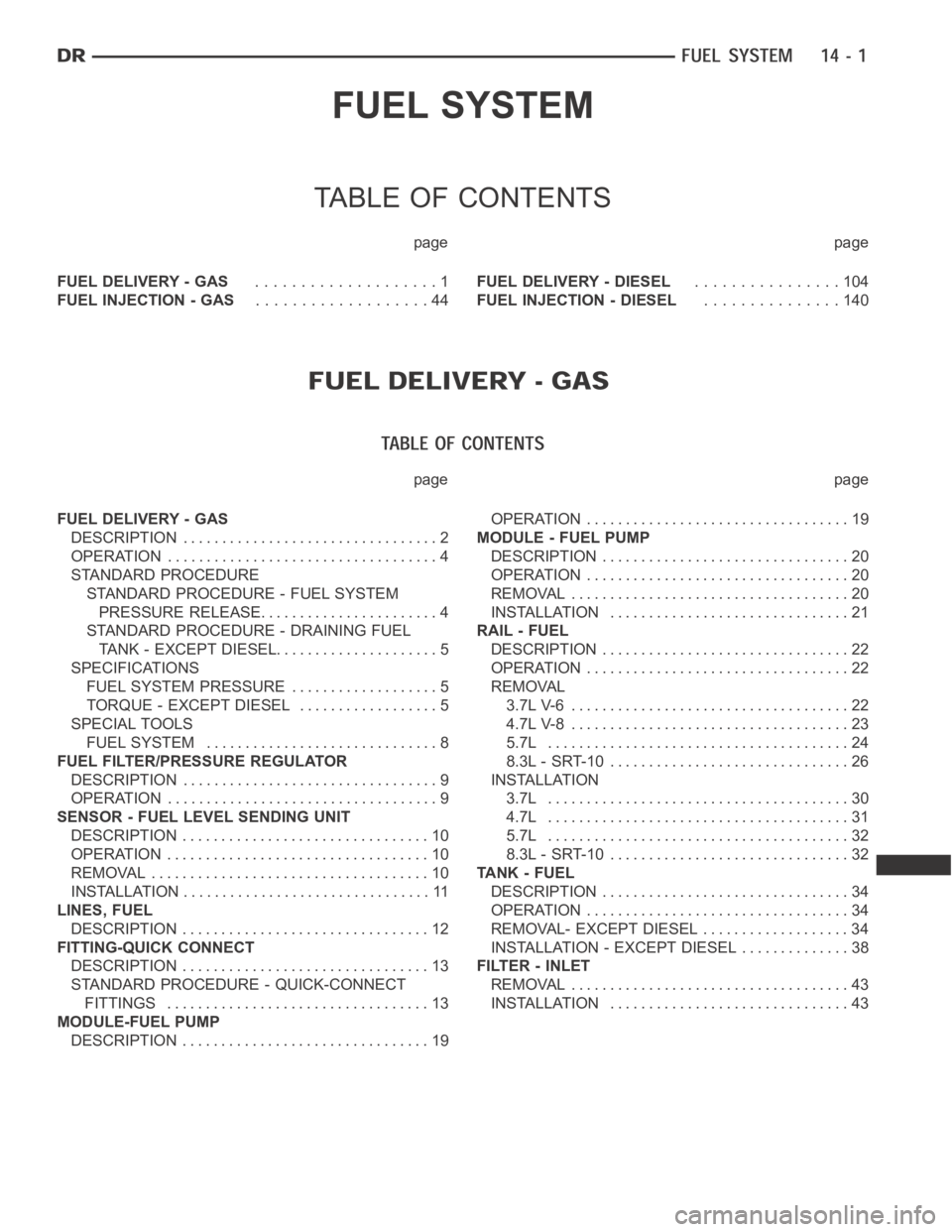

FUEL SYSTEM

TABLE OF CONTENTS

page page

FUEL DELIVERY - GAS....................1

FUEL INJECTION - GAS...................44FUEL DELIVERY - DIESEL................104

FUEL INJECTION - DIESEL...............140

page page

FUEL DELIVERY - GAS

DESCRIPTION ................................. 2

OPERATION ................................... 4

STANDARD PROCEDURE

STANDARD PROCEDURE - FUEL SYSTEM

PRESSURE RELEASE........................ 4

STANDARD PROCEDURE - DRAINING FUEL

TANK - EXCEPT DIESEL...................... 5

SPECIFICATIONS

FUEL SYSTEM PRESSURE ................... 5

TORQUE - EXCEPT DIESEL.................. 5

SPECIAL TOOLS

FUEL SYSTEM.............................. 8

FUEL FILTER/PRESSURE REGULATOR

DESCRIPTION ................................. 9

OPERATION ................................... 9

SENSOR - FUEL LEVEL SENDING UNIT

DESCRIPTION ................................ 10

OPERATION .................................. 10

REMOVAL .................................... 10

INSTALLATION ................................ 11

LINES, FUEL

DESCRIPTION ................................ 12

FITTING-QUICK CONNECT

DESCRIPTION ................................ 13

STANDARD PROCEDURE - QUICK-CONNECT

FITTINGS .................................. 13

MODULE-FUEL PUMP

DESCRIPTION ................................ 19OPERATION .................................. 19

MODULE - FUEL PUMP

DESCRIPTION ................................ 20

OPERATION .................................. 20

REMOVAL .................................... 20

INSTALLATION ............................... 21

RAIL - FUEL

DESCRIPTION ................................ 22

OPERATION .................................. 22

REMOVAL

3.7L V-6 .................................... 22

4.7L V-8 .................................... 23

5.7L ....................................... 24

8.3L - SRT-10 ............................... 26

INSTALLATION

3.7L ....................................... 30

4.7L ....................................... 31

5.7L ....................................... 32

8.3L - SRT-10 ............................... 32

TA N K - F U E L

DESCRIPTION ................................ 34

OPERATION .................................. 34

REMOVAL- EXCEPT DIESEL ................... 34

INSTALLATION - EXCEPT DIESEL . ............. 38

FILTER - INLET

REMOVAL .................................... 43

INSTALLATION ............................... 43

Page 2242 of 5267

8. Connect other end of jumper wire to positive side of battery.

9. Connect one end of a second jumper wire to remaining injector terminal.

CAUTION: Powering an injector for more than a few seconds will permanentlydamage the injector.

10. Momentarily touch other end of jumper wire to negative terminal of battery for no more than a few seconds.

11. Place a rag or towel below fuel line quick-connect fitting at fuel rail.

12. Disconnect quick-connect fitting at fuel rail. Refer to Quick-Connect Fittings.

13. Return fuel pump relay to PDC.

14. One or more Diagnostic Trouble Codes (DTC’s) may have been stored in PCMmemory due to fuel pump relay

removal. The DRB

scantoolmustbeusedtoeraseaDTC.

STANDARD PROCEDURE - DRAINING FUEL TANK - EXCEPT DIESEL

WARNING: The fuel system may be under constant fuel pressure even with the engine off. This pressure

must be released before servicing fuel tank.

Two different procedures may be used to drain fuel tank: through the fuel fill fitting on tank, or using a diagnostic

scan tool to activate the fuel pump relay. Due to a one-way check valve installed into the fuel fill opening fitting at

the tank, the tank cannot be drained conventionally at the fill cap.

The quickest draining procedure involves removing the rubber fuel fill hose at the fuel tank.

As an alternative procedure, the electric fuel pump may be activated allowingtanktobedrainedatfuelrailcon-

nection. Refer to diagnostic scan tool for fuel pump activation procedures. Before disconnecting fuel line at fuel rail,

release fuel pressure. Refer to the Fuel System Pressure Release Procedure for procedures. Attach end of special

test hose tool number 6631 or 6539 at fuel rail disconnection (tool number 6631isusedon5/16”fuellineswhile

tool number 6539 is used on 3/8” fuel lines). Position opposite end of this hose tool to an approved gasoline drain-

ing station. Activate fuel pump and drain tank until empty.

If electric fuel pump is not operating, fuel must be drained through fuel fill fitting at tank. Refer to following proce-

dures.

1. Release fuel system pressure.

2. Raise vehicle.

3. Thoroughly clean area around fuel fill fitting and rubber fuel fill hoseat tank.

4. If vehicle is equipped with 4 doors and a 6 foot (short) box, remove left-rear tire/wheel.

5. Loosen clamp and disconnect rubber fuel fill hose at tank fitting. Usingan approved gas holding tank, drain fuel

tank through this fitting.

SPECIFICATIONS

FUEL SYSTEM PRESSURE

58 psi +/- 2 psi

TORQUE - EXCEPT DIESEL

DESCRIPTION N-m Ft. Lbs. In. Lbs.

Accelerator Pedal Bracket

Mounting12 - 105

Accelerator Pedal Position

Sensor Bracket-to-Battery

Tray Bolts3-30

Crankshaft Position

Sensor - 3.7L28 21 -

Crankshaft Position

Sensor - 4.7L28 21 -

Page 2276 of 5267

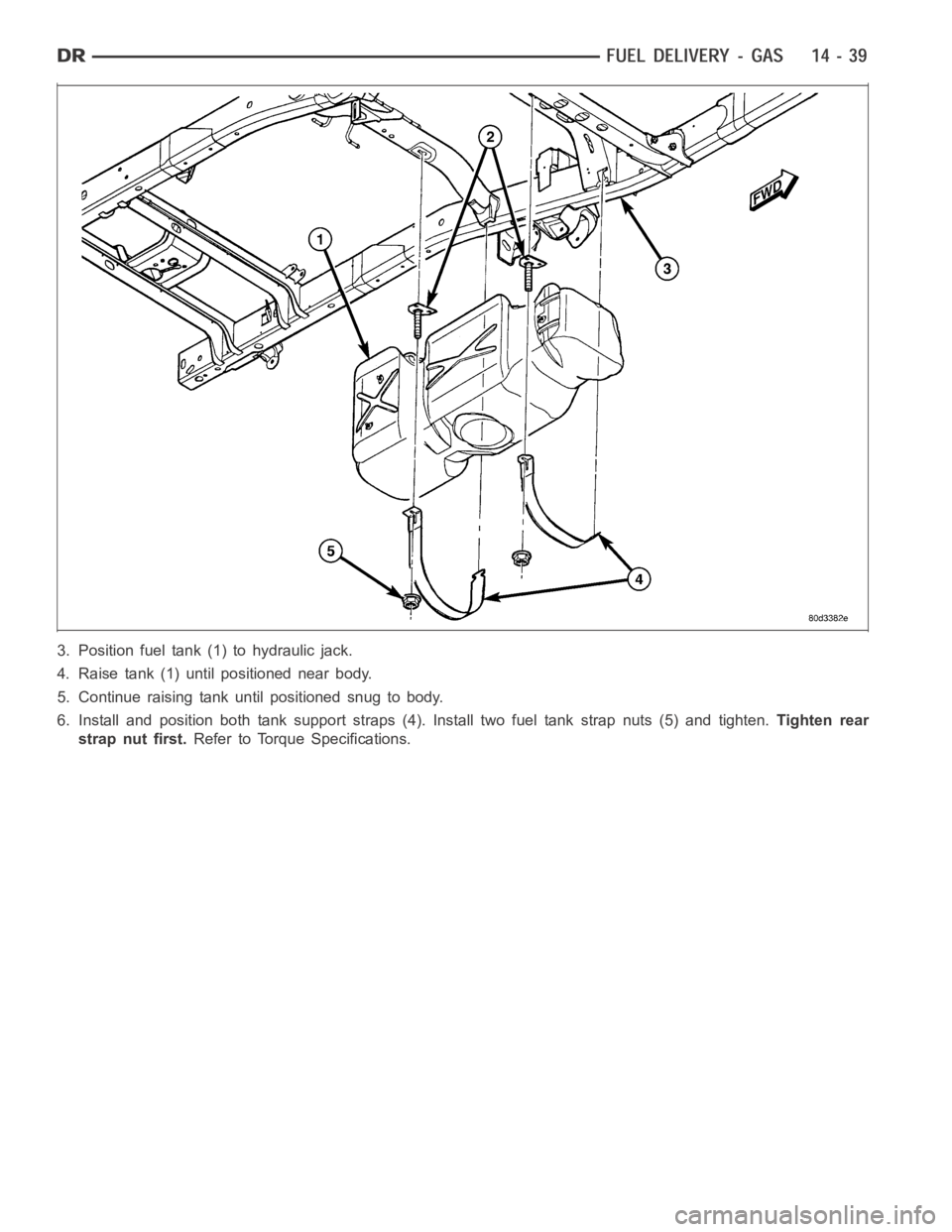

3. Position fuel tank (1) to hydraulic jack.

4. Raise tank (1) until positioned near body.

5. Continue raising tank until positioned snug to body.

6. Install and position both tank support straps (4). Install two fuel tankstrap nuts (5) and tighten.Tighten rear

strap nut first.Refer to Torque Specifications.

Page 2283 of 5267

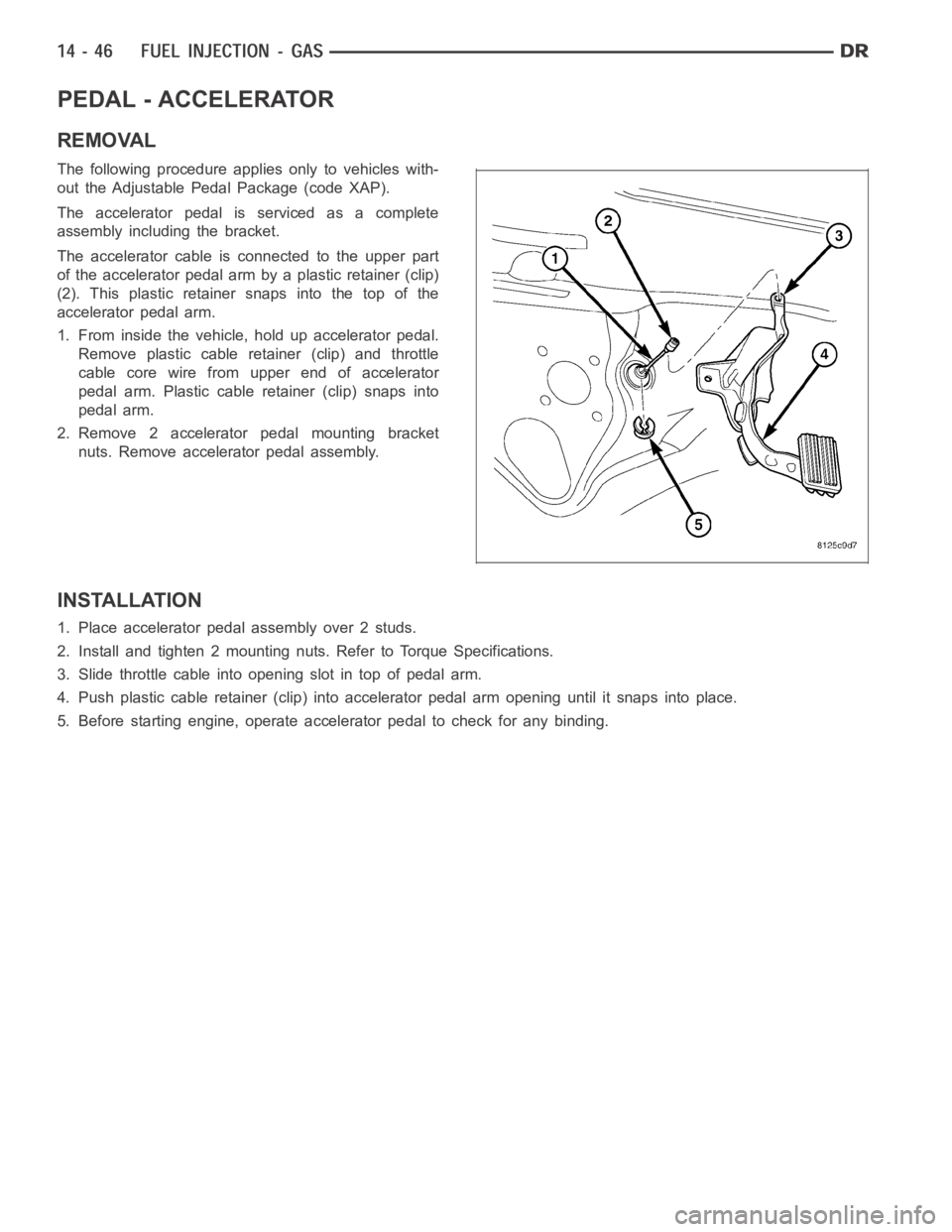

PEDAL - ACCELERATOR

REMOVAL

The following procedure applies only to vehicles with-

out the Adjustable Pedal Package (code XAP).

The accelerator pedal is serviced as a complete

assembly including the bracket.

The accelerator cable is connected to the upper part

of the accelerator pedal arm by a plastic retainer (clip)

(2). This plastic retainer snaps into the top of the

accelerator pedal arm.

1. From inside the vehicle, hold up accelerator pedal.

Remove plastic cable retainer (clip) and throttle

cable core wire from upper end of accelerator

pedal arm. Plastic cable retainer (clip) snaps into

pedal arm.

2. Remove 2 accelerator pedal mounting bracket

nuts. Remove accelerator pedal assembly.

INSTALLATION

1. Place accelerator pedal assembly over 2 studs.

2. Install and tighten 2 mounting nuts. Refer to Torque Specifications.

3. Slide throttle cable into opening slot in top of pedal arm.

4. Push plastic cable retainer (clip) into accelerator pedal arm opening until it snaps into place.

5. Before starting engine, operate accelerator pedal to check for any binding.

Page 2291 of 5267

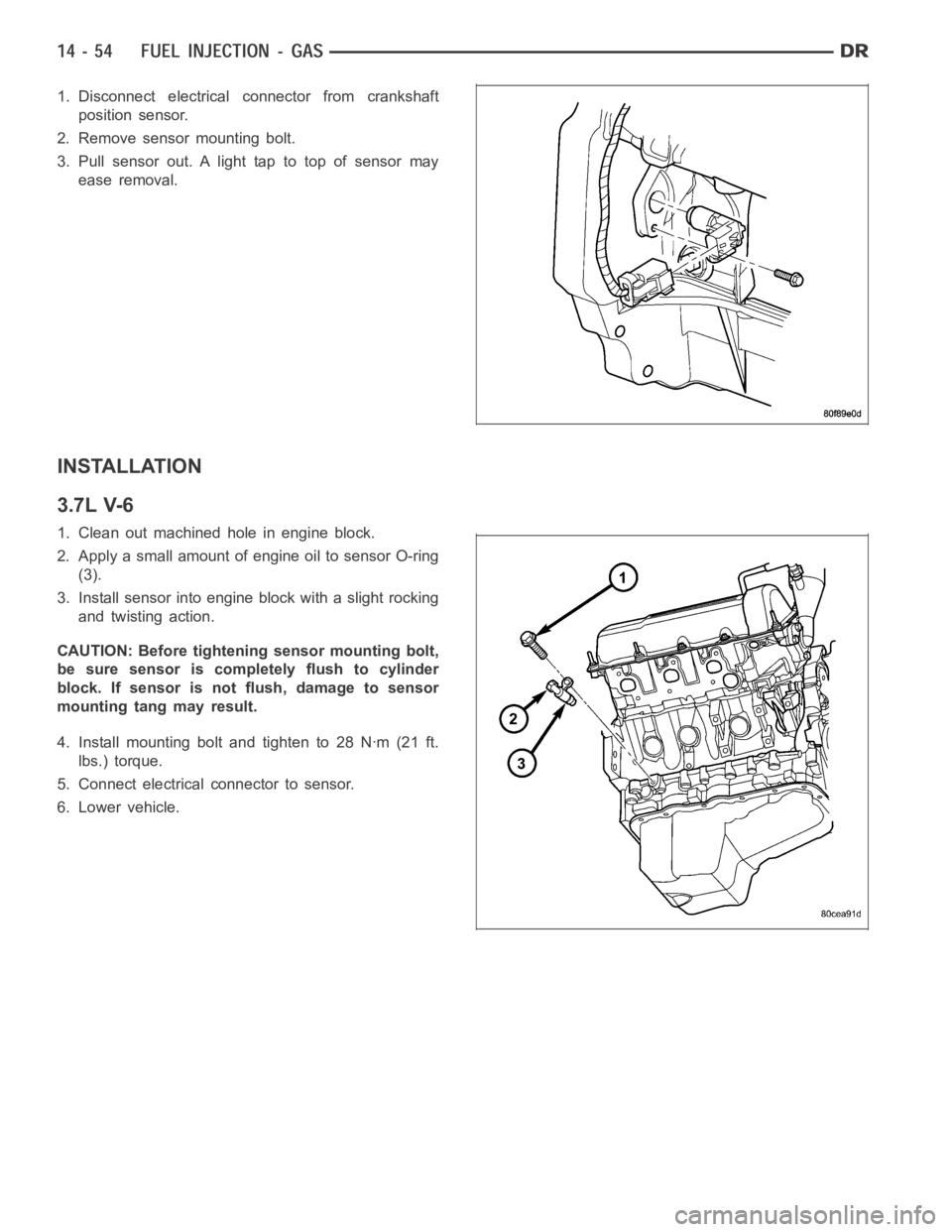

1. Disconnect electrical connector from crankshaft

position sensor.

2. Remove sensor mounting bolt.

3. Pull sensor out. A light tap to top of sensor may

ease removal.

INSTALLATION

3.7L V-6

1. Clean out machined hole in engine block.

2. Apply a small amount of engine oil to sensor O-ring

(3).

3. Install sensor into engine block with a slight rocking

and twisting action.

CAUTION: Before tightening sensor mounting bolt,

be sure sensor is completely flush to cylinder

block. If sensor is not flush, damage to sensor

mounting tang may result.

4. Install mounting bolt and tighten to 28 Nꞏm (21 ft.

lbs.) torque.

5. Connect electrical connector to sensor.

6. Lower vehicle.

Page 2292 of 5267

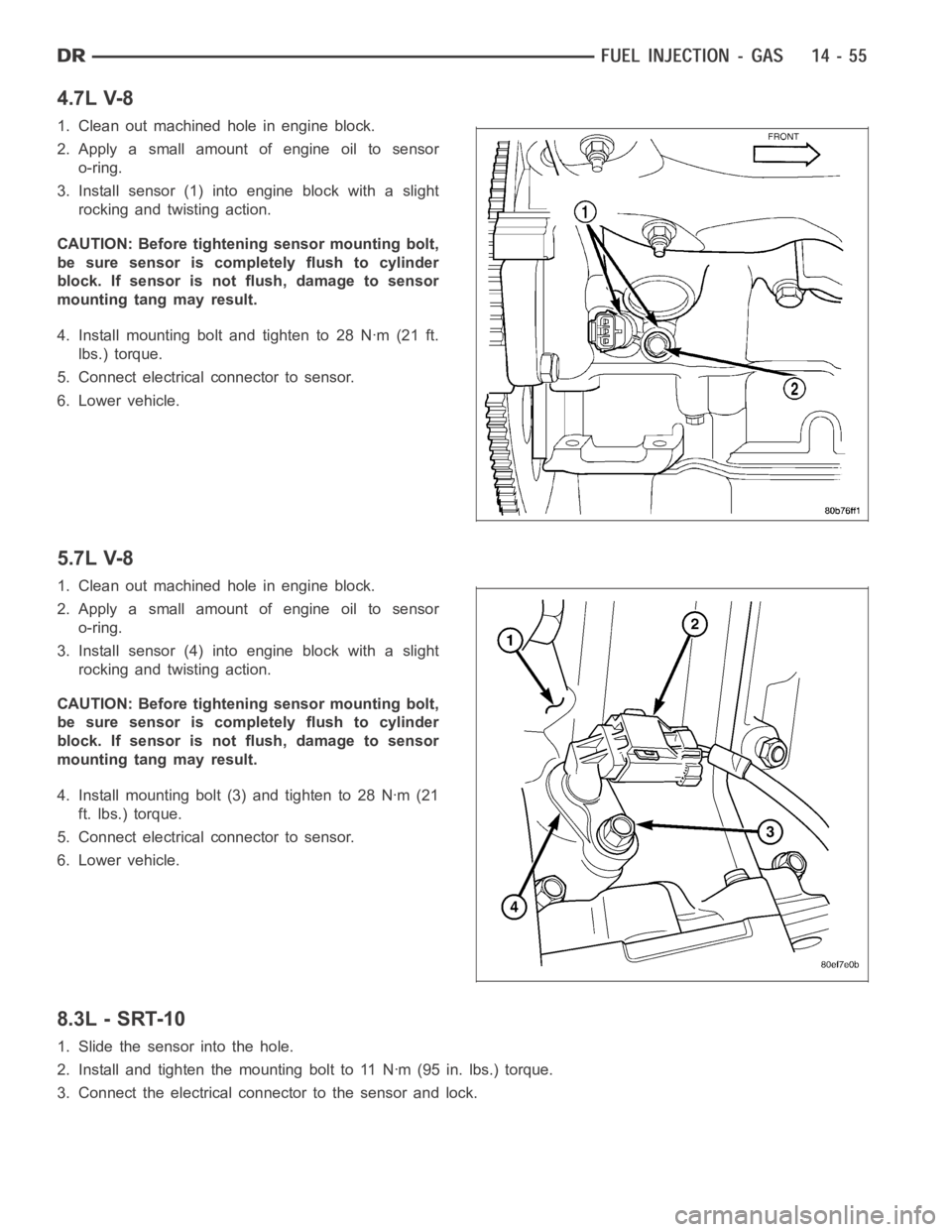

4.7L V-8

1. Clean out machined hole in engine block.

2. Apply a small amount of engine oil to sensor

o-ring.

3. Install sensor (1) into engine block with a slight

rocking and twisting action.

CAUTION: Before tightening sensor mounting bolt,

be sure sensor is completely flush to cylinder

block. If sensor is not flush, damage to sensor

mounting tang may result.

4. Install mounting bolt and tighten to 28 Nꞏm (21 ft.

lbs.) torque.

5. Connect electrical connector to sensor.

6. Lower vehicle.

5.7L V-8

1. Clean out machined hole in engine block.

2. Apply a small amount of engine oil to sensor

o-ring.

3. Install sensor (4) into engine block with a slight

rocking and twisting action.

CAUTION: Before tightening sensor mounting bolt,

be sure sensor is completely flush to cylinder

block. If sensor is not flush, damage to sensor

mounting tang may result.

4. Install mounting bolt (3) and tighten to 28 Nꞏm (21

ft. lbs.) torque.

5. Connect electrical connector to sensor.

6. Lower vehicle.

8.3L - SRT-10

1. Slide the sensor into the hole.

2. Install and tighten the mounting bolt to 11 Nꞏm (95 in. lbs.) torque.

3. Connect the electrical connector to the sensor and lock.

Page 2303 of 5267

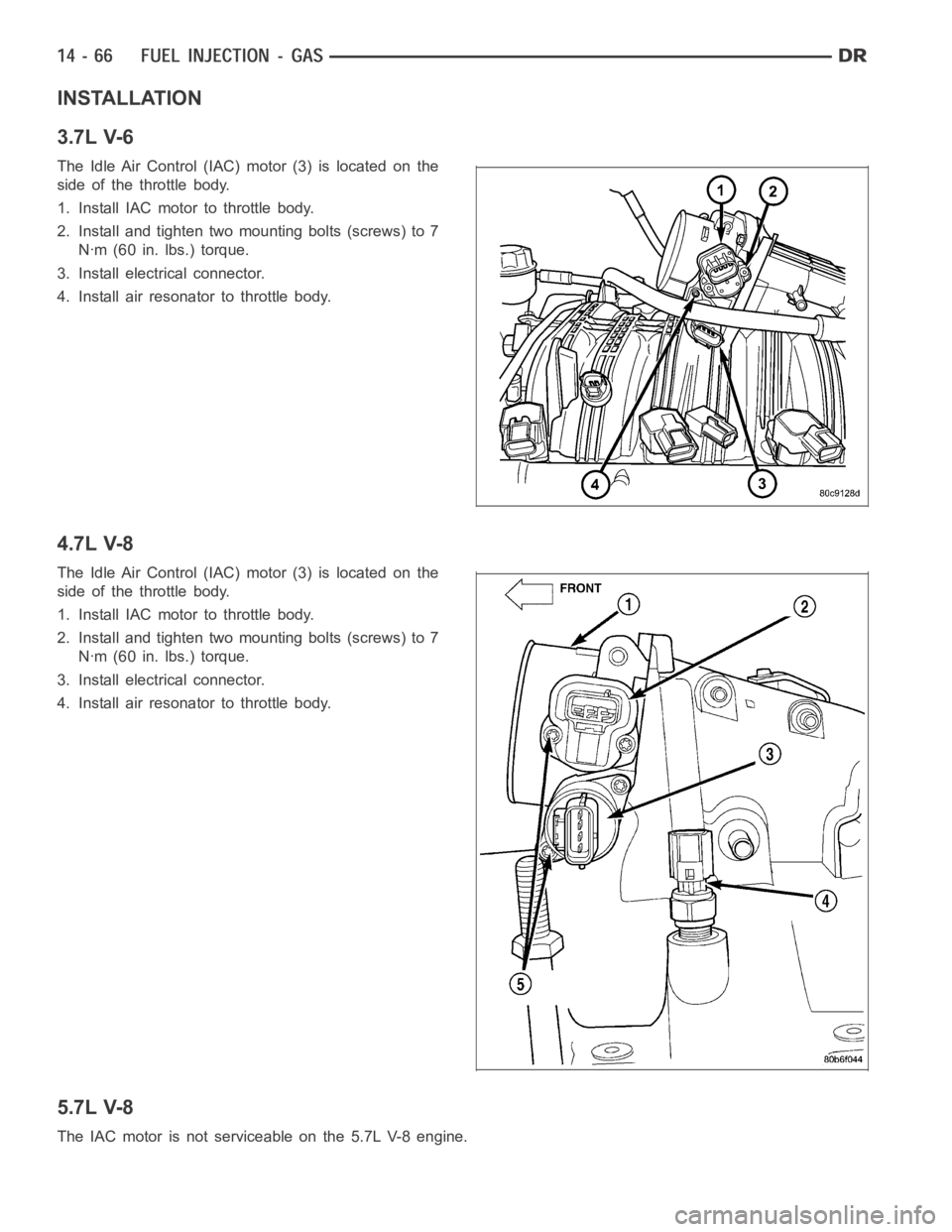

INSTALLATION

3.7L V-6

The Idle Air Control (IAC) motor (3) is located on the

side of the throttle body.

1. Install IAC motor to throttle body.

2. Install and tighten two mounting bolts (screws) to 7

Nꞏm (60 in. lbs.) torque.

3. Install electrical connector.

4. Install air resonator to throttle body.

4.7L V-8

The Idle Air Control (IAC) motor (3) is located on the

side of the throttle body.

1. Install IAC motor to throttle body.

2. Install and tighten two mounting bolts (screws) to 7

Nꞏm (60 in. lbs.) torque.

3. Install electrical connector.

4. Install air resonator to throttle body.

5.7L V-8

The IAC motor is not serviceable on the 5.7L V-8 engine.