torque DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 2115 of 5267

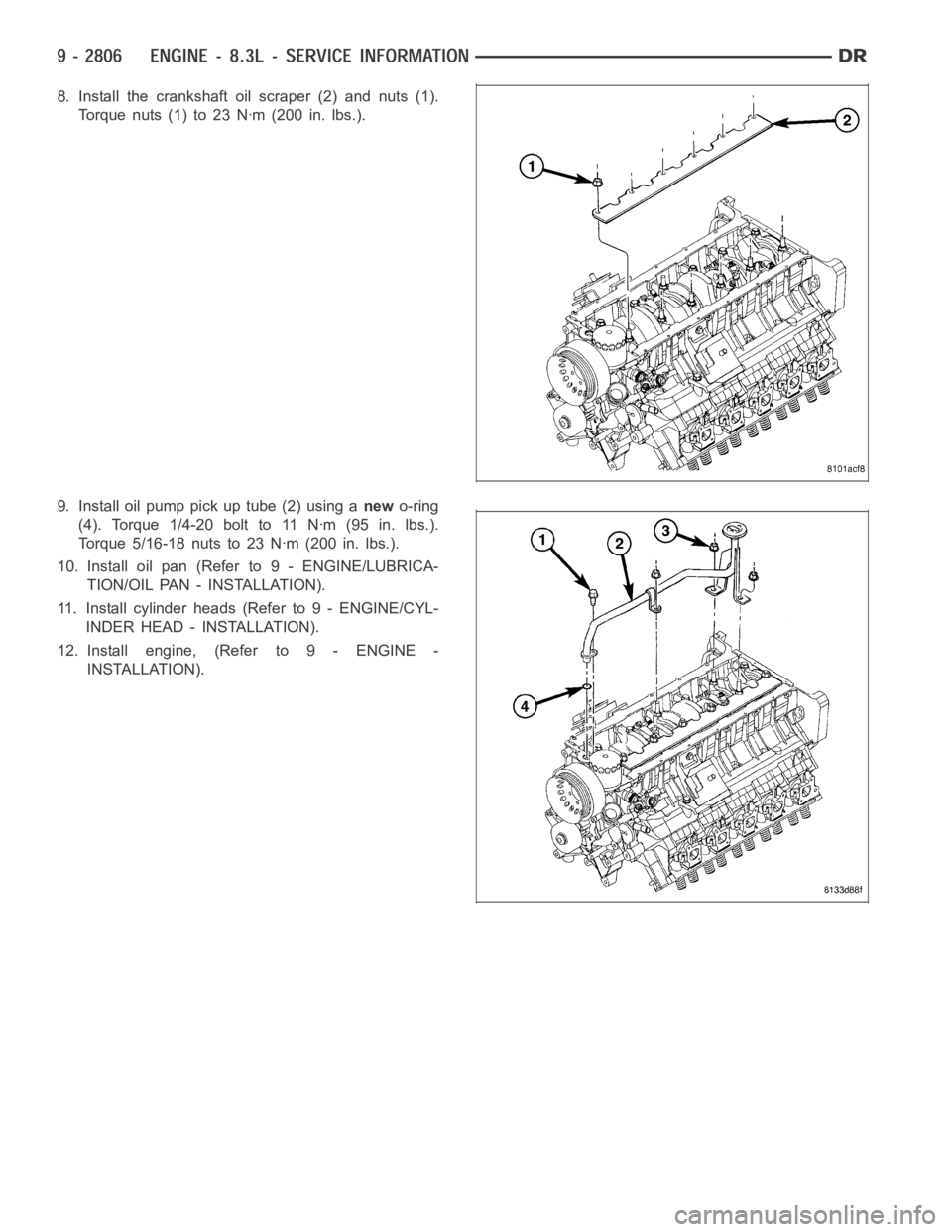

8. Install the crankshaft oil scraper (2) and nuts (1).

Torque nuts (1) to 23 Nꞏm (200 in. lbs.).

9. Install oil pump pick up tube (2) using anewo-ring

(4). Torque 1/4-20 bolt to 11 Nꞏm (95 in. lbs.).

Torque 5/16-18 nuts to 23 Nꞏm (200 in. lbs.).

10. Install oil pan (Refer to 9 - ENGINE/LUBRICA-

TION/OIL PAN - INSTALLATION).

11. Install cylinder heads (Refer to 9 - ENGINE/CYL-

INDER HEAD - INSTALLATION).

12. Install engine, (Refer to 9 - ENGINE -

INSTALLATION).

Page 2119 of 5267

BEARINGS-CONNECTING ROD

DESCRIPTION

The bearing caps are not interchangeable and should be paint marked or scribed at removal to insure correct

assembly.

The bearing shells must be installed so that the tangs are in the machined grooves in the rods and caps.

Limits of taper or out-of-round on any crankshaft journals should be held to 0.013 mm (0.0005 in.). Bearings are

available in 0.025 mm (0.001 in.), 0.051 mm (0.002 in.), 0.076 mm (0.003 in.), 0.254 mm (0.010 in.) and 0.305 mm

(0.012 in.) undersize.Install the bearings in pairs. Do not use a new bearing half with an old bearing half. Do

not file the rods or bearing caps.

STANDARD PROCEDURE

CONNECTING ROD BEARING - FITTING

Fit all rods on one bank until complete. Do not alternate from one bank to another, because when the rods are

assembled to pistons correctly, they are not interchangeable from one bank to another.

The bearing caps are not interchangeable and should be marked at removal toinsure correct assembly.

The bearing shells must be installed so that the tangs are in the machined grooves in the rods and caps.

Limits of taper or out-of-round on any crankshaft journals should be held to 0.013 mm (0.0005 in.). Bearings are

available in 0.025 mm (0.001 in.), 0.051 mm (0.002 in.), 0.076 mm (0.003 in.), 0.254 mm (0.010 in.) and 0.305 mm

(0.012 in.) undersize.Install the bearings in pairs. Do not use a new bearing half with an old bearing half. Do

not file the rods or bearing caps.

1. (Refer to 9 - ENGINE/ENGINE BLOCK/CONNECTING ROD BEARINGS - STANDARD PROCEDURE) - Mea-

suring Connecting Rod Bearing Clearance to determine bearing clearance.

2. Before installing the connecting rod cap bolts, the bolt threads shouldbe oiled with engine oil.

3. Install bolts finger tight, then alternately torque each bolt to assemble the cap properly.

4. Tighten the connecting rod bolts to 68 Nꞏm (50 ft. lbs.).

MEASURING CONNECTING ROD BEARING CLEARANCE

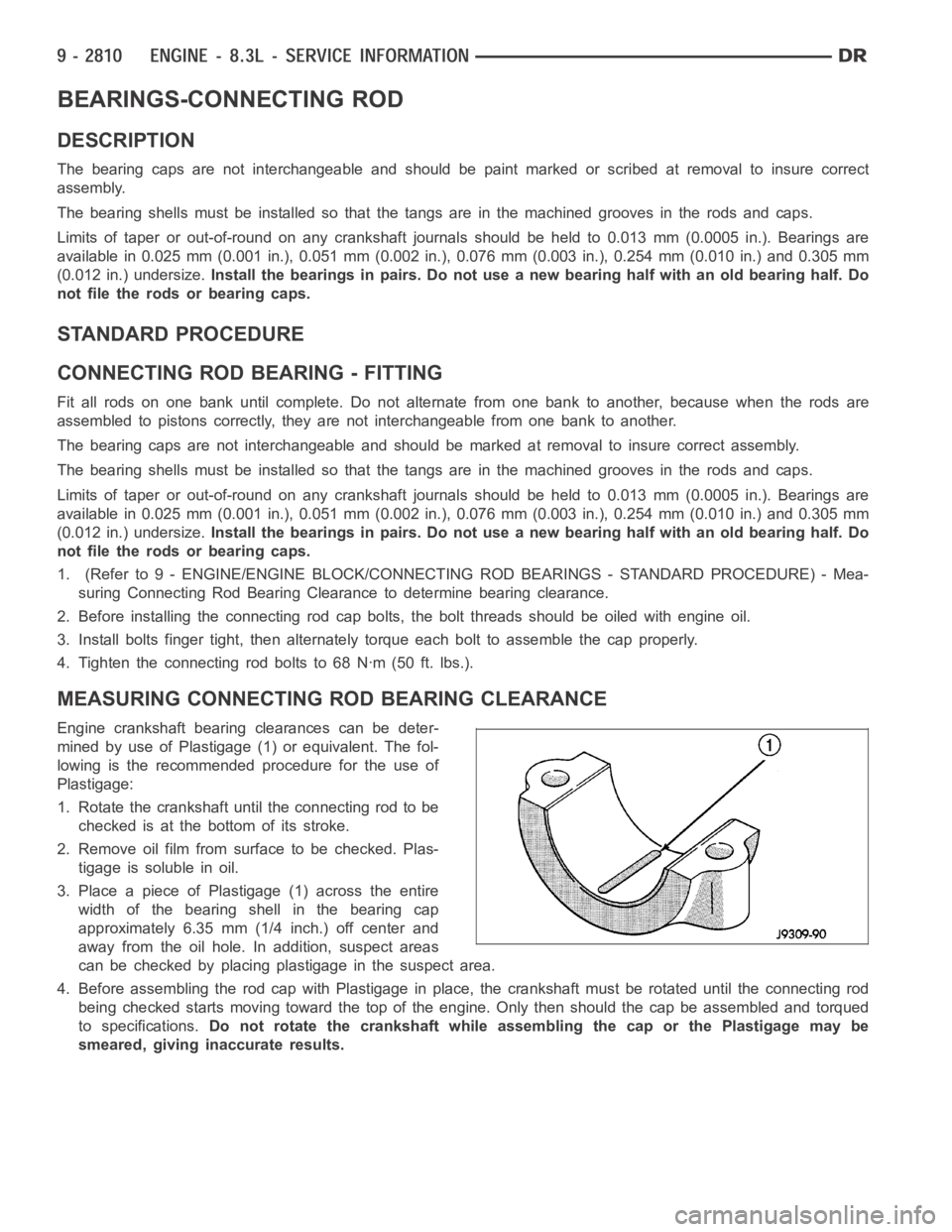

Engine crankshaft bearing clearances can be deter-

mined by use of Plastigage (1) or equivalent. The fol-

lowing is the recommended procedure for the use of

Plastigage:

1. Rotate the crankshaft until the connecting rod to be

checked is at the bottom of its stroke.

2. Remove oil film from surface to be checked. Plas-

tigage is soluble in oil.

3. Place a piece of Plastigage (1) across the entire

width of the bearing shell in the bearing cap

approximately 6.35 mm (1/4 inch.) off center and

away from the oil hole. In addition, suspect areas

can be checked by placing plastigage in the suspect area.

4. Before assembling the rod cap with Plastigage in place, the crankshaft must be rotated until the connecting rod

being checked starts moving toward the top of the engine. Only then should the cap be assembled and torqued

to specifications.Do not rotate the crankshaft while assembling the cap or the Plastigage maybe

smeared, giving inaccurate results.

Page 2127 of 5267

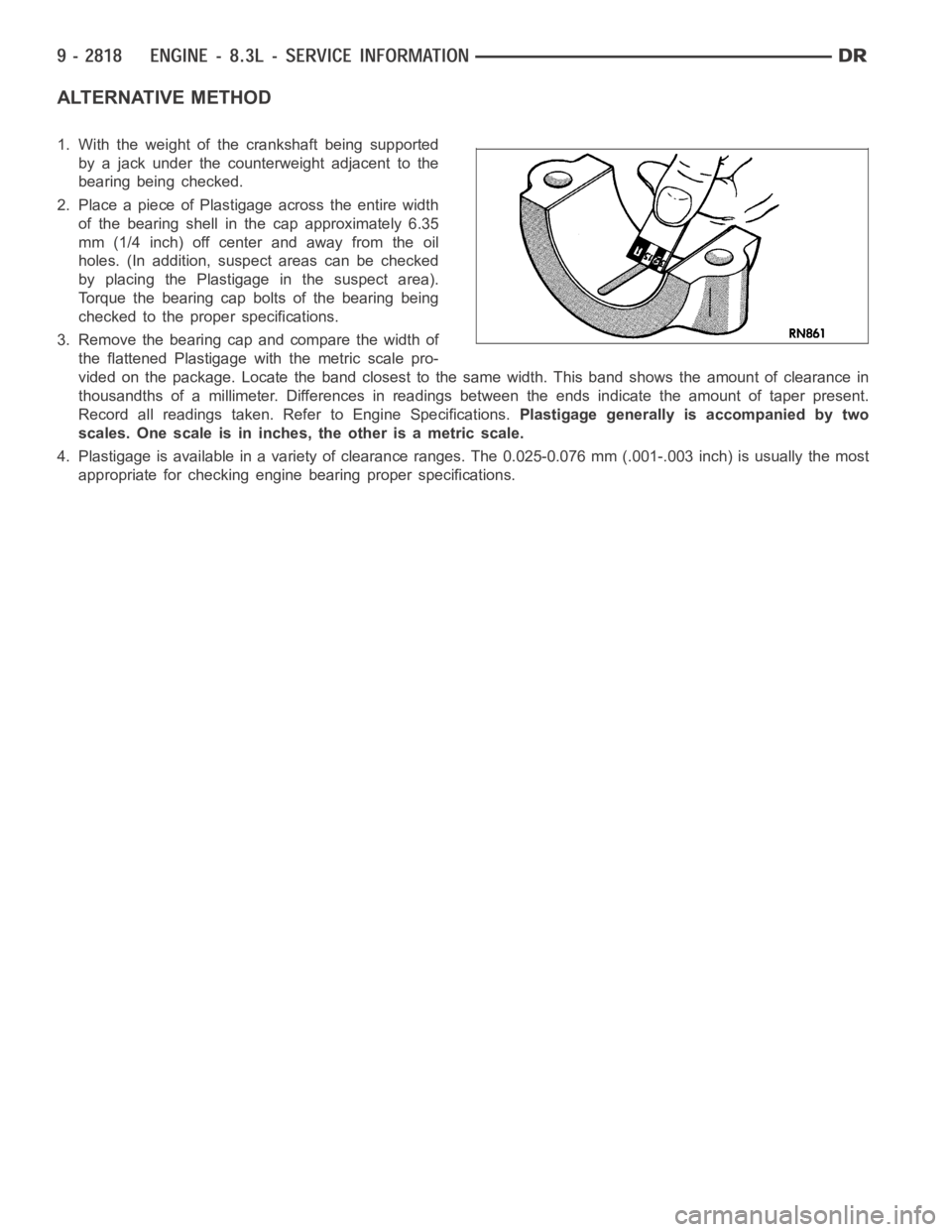

ALTERNATIVE METHOD

1. With the weight of the crankshaft being supported

by a jack under the counterweight adjacent to the

bearing being checked.

2. Place a piece of Plastigage across the entire width

of the bearing shell in the cap approximately 6.35

mm (1/4 inch) off center and away from the oil

holes. (In addition, suspect areas can be checked

by placing the Plastigage in the suspect area).

Torque the bearing cap bolts of the bearing being

checked to the proper specifications.

3. Remove the bearing cap and compare the width of

the flattened Plastigage with the metric scale pro-

vided on the package. Locate the band closest to the same width. This band shows the amount of clearance in

thousandths of a millimeter. Differences in readings between the ends indicate the amount of taper present.

Record all readings taken. Refer to Engine Specifications.Plastigage generally is accompanied by two

scales. One scale is in inches, the other is a metric scale.

4. Plastigage is available in a variety of clearance ranges. The 0.025-0.076 mm (.001-.003 inch) is usually the most

appropriate for checking engine bearing proper specifications.

Page 2132 of 5267

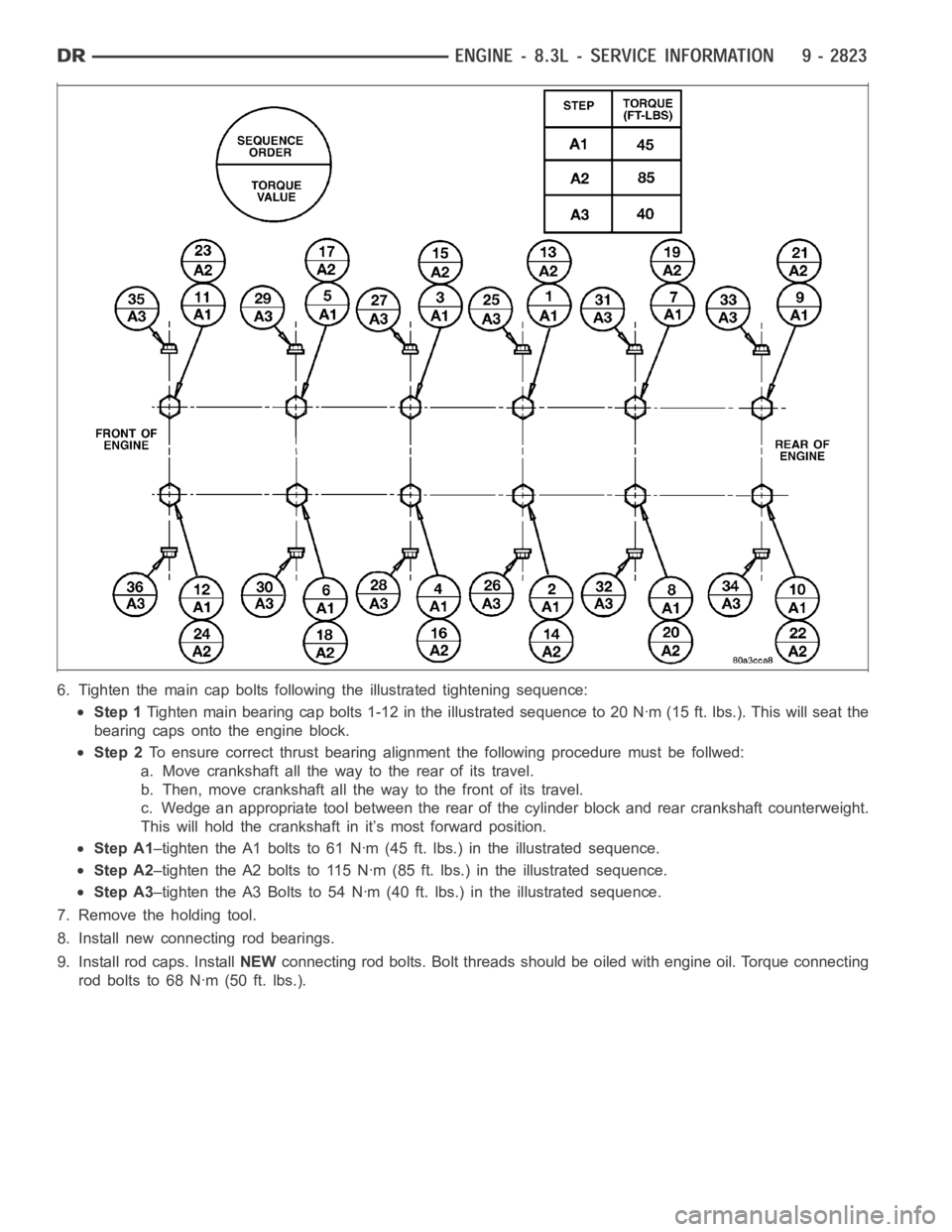

6. Tighten the main cap bolts following the illustrated tightening sequence:

Step 1Tighten main bearing cap bolts 1-12 inthe illustrated sequence to 20 Nꞏm (15 ft. lbs.). This will seat the

bearing caps onto the engine block.

Step 2To ensure correct thrust bearing alignment the following procedure must be follwed:

a. Move crankshaft all the way to the rear of its travel.

b. Then, move crankshaft all the way to the front of its travel.

c. Wedge an appropriate tool between the rear of the cylinder block and rearcrankshaft counterweight.

This will hold the crankshaft in it’s most forward position.

Step A1–tighten the A1 bolts to 61 Nꞏm (45 ft. lbs.) in the illustrated sequence.

Step A2–tighten the A2 bolts to 115 Nꞏm (85 ft. lbs.) in the illustrated sequence.

Step A3–tighten the A3 Bolts to 54 Nꞏm (40 ft. lbs.) in the illustrated sequence.

7. Remove the holding tool.

8. Install new connecting rod bearings.

9. Install rod caps. InstallNEWconnecting rod bolts. Bolt threads should be oiled with engine oil. Torqueconnecting

rod bolts to 68 Nꞏm (50 ft. lbs.).

Page 2133 of 5267

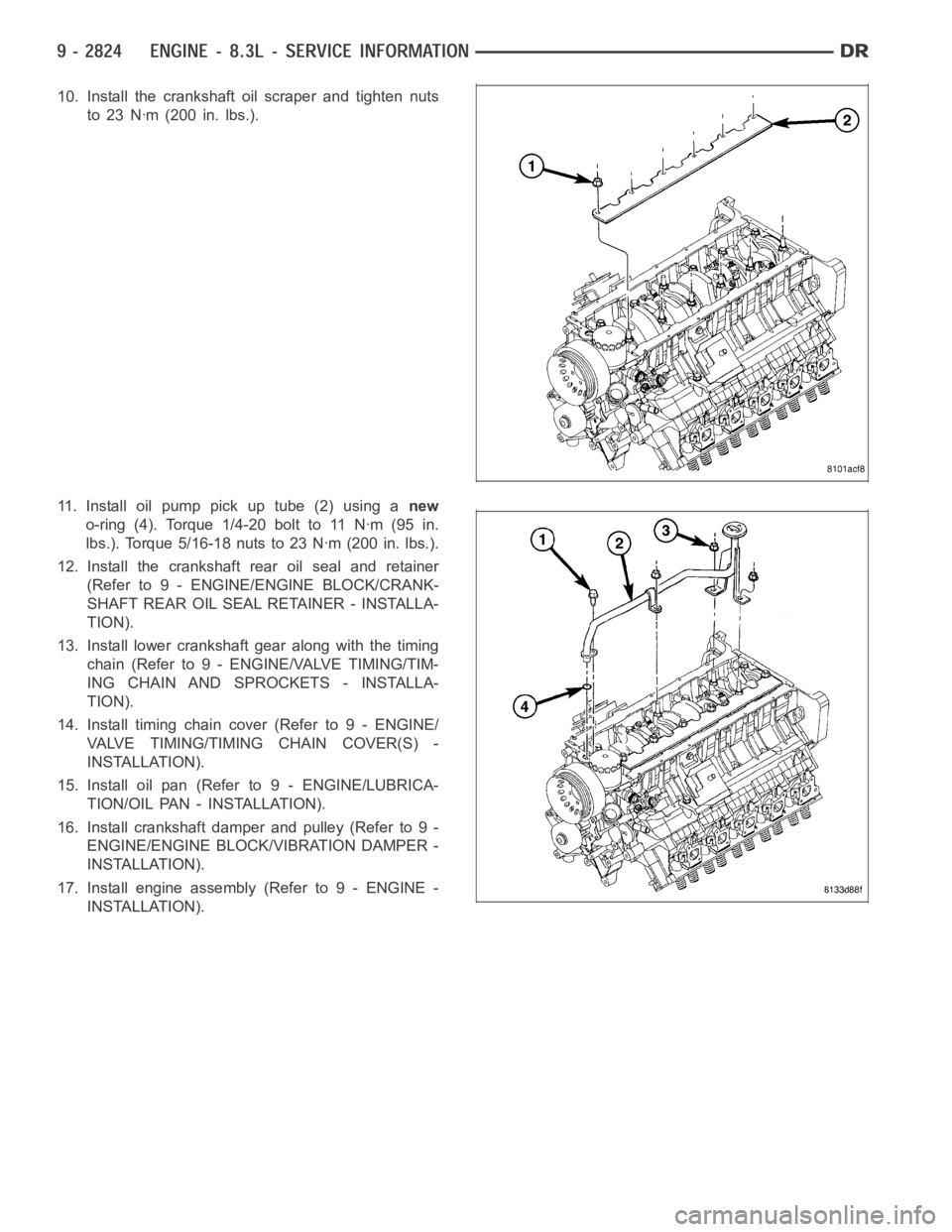

10. Install the crankshaft oil scraper and tighten nuts

to 23 Nꞏm (200 in. lbs.).

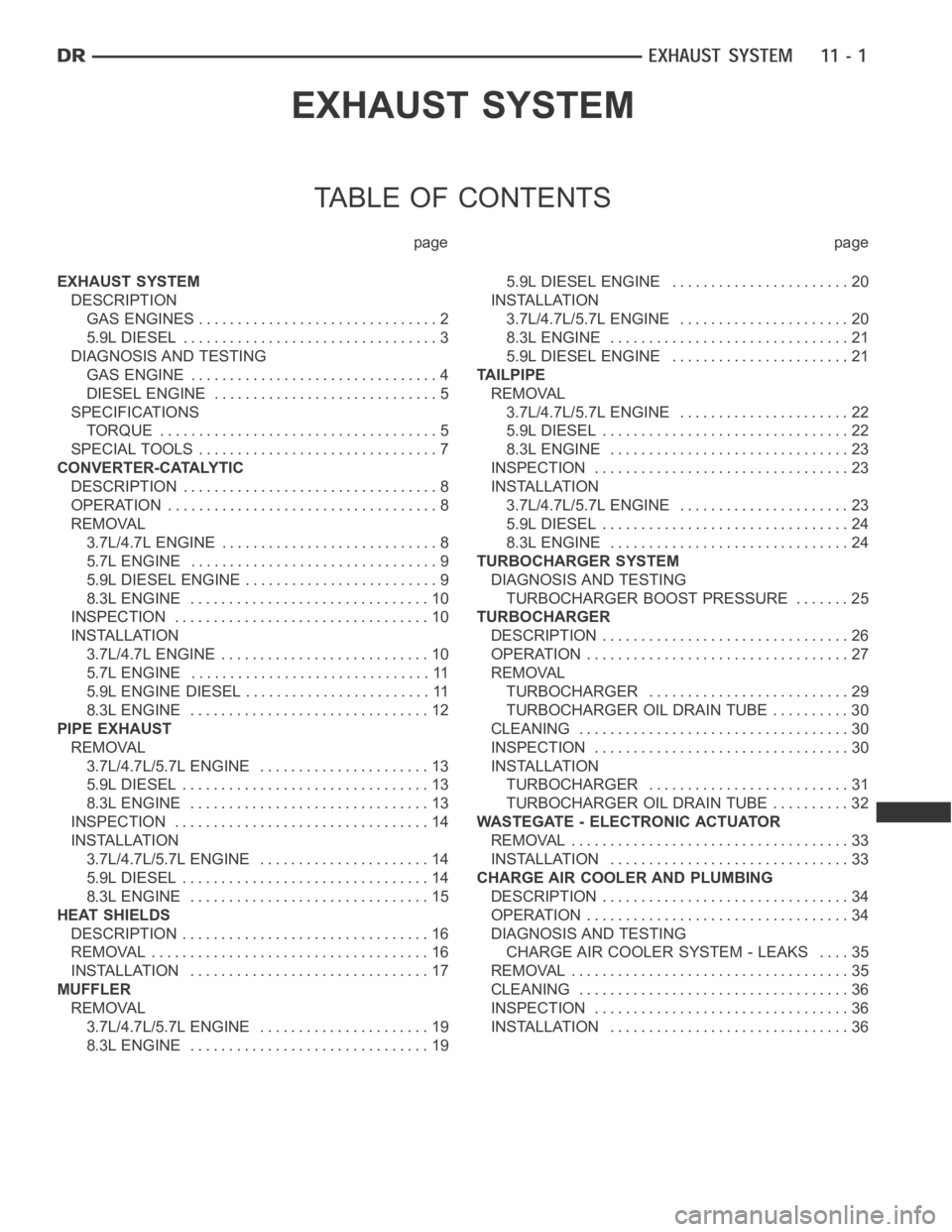

11.Installoilpumppickuptube(2)usinganew

o-ring (4). Torque 1/4-20 bolt to 11 Nꞏm (95 in.

lbs.). Torque 5/16-18 nuts to 23 Nꞏm (200 in. lbs.).

12. Install the crankshaft rear oil seal and retainer

(Refer to 9 - ENGINE/ENGINE BLOCK/CRANK-

SHAFT REAR OIL SEAL RETAINER - INSTALLA-

TION).

13. Install lower crankshaft gear along with the timing

chain (Refer to 9 - ENGINE/VALVE TIMING/TIM-

ING CHAIN AND SPROCKETS - INSTALLA-

TION).

14. Install timing chain cover (Refer to 9 - ENGINE/

VALVE TIMING/TIMING CHAIN COVER(S) -

INSTALLATION).

15. Install oil pan (Refer to 9 - ENGINE/LUBRICA-

TION/OIL PAN - INSTALLATION).

16. Install crankshaft damper and pulley (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

INSTALLATION).

17. Install engine assembly (Refer to 9 - ENGINE -

INSTALLATION).

Page 2136 of 5267

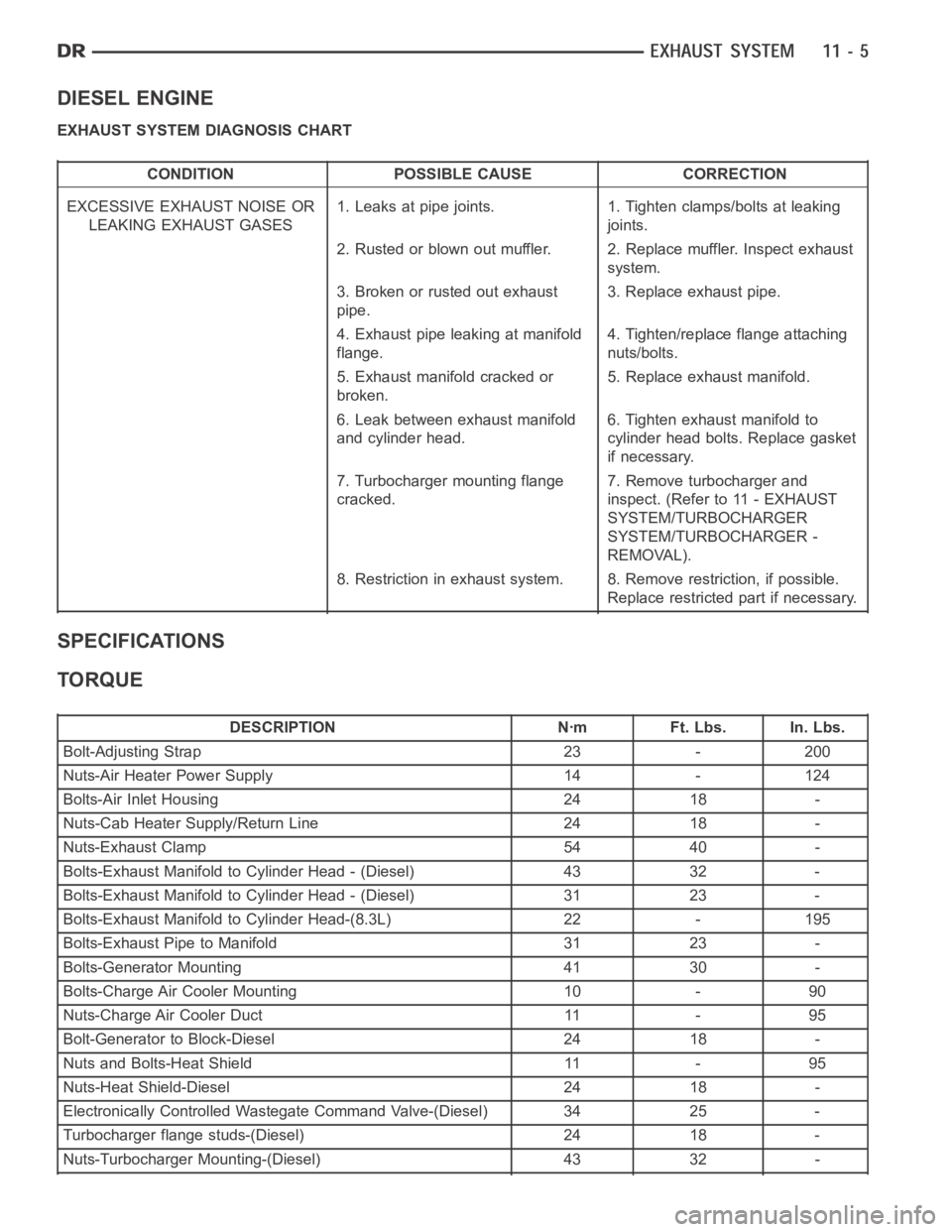

EXHAUST SYSTEM

TABLE OF CONTENTS

page page

EXHAUST SYSTEM

DESCRIPTION

GAS ENGINES ............................... 2

5.9L DIESEL ................................. 3

DIAGNOSIS AND TESTING

GAS ENGINE ................................ 4

DIESEL ENGINE............................. 5

SPECIFICATIONS

TORQUE .................................... 5

SPECIAL TOOLS ............................... 7

CONVERTER-CATALYTIC

DESCRIPTION ................................. 8

OPERATION ................................... 8

REMOVAL

3.7L/4.7L ENGINE ............................ 8

5.7L ENGINE ................................ 9

5.9L DIESEL ENGINE ......................... 9

8.3L ENGINE ............................... 10

INSPECTION ................................. 10

INSTALLATION

3.7L/4.7L ENGINE ........................... 10

5.7L ENGINE ............................... 11

5.9L ENGINE DIESEL ........................ 11

8.3L ENGINE ............................... 12

PIPE EXHAUST

REMOVAL

3.7L/4.7L/5.7L ENGINE ...................... 13

5.9L DIESEL ................................ 13

8.3L ENGINE ............................... 13

INSPECTION ................................. 14

INSTALLATION

3.7L/4.7L/5.7L ENGINE ...................... 14

5.9L DIESEL ................................ 14

8.3L ENGINE ............................... 15

HEAT SHIELDS

DESCRIPTION ................................ 16

REMOVAL .................................... 16

INSTALLATION ............................... 17

MUFFLER

REMOVAL

3.7L/4.7L/5.7L ENGINE ...................... 19

8.3L ENGINE ............................... 195.9L DIESEL ENGINE....................... 20

INSTALLATION

3.7L/4.7L/5.7L ENGINE ...................... 20

8.3L ENGINE ............................... 21

5.9L DIESEL ENGINE....................... 21

TAILPIPE

REMOVAL

3.7L/4.7L/5.7L ENGINE ...................... 22

5.9L DIESEL................................ 22

8.3L ENGINE ............................... 23

INSPECTION ................................. 23

INSTALLATION

3.7L/4.7L/5.7L ENGINE ...................... 23

5.9L DIESEL................................ 24

8.3L ENGINE ............................... 24

TURBOCHARGER SYSTEM

DIAGNOSIS AND TESTING

TURBOCHARGER BOOST PRESSURE ....... 25

TURBOCHARGER

DESCRIPTION ................................ 26

OPERATION .................................. 27

REMOVAL

TURBOCHARGER .......................... 29

TURBOCHARGER OIL DRAIN TUBE .......... 30

CLEANING ................................... 30

INSPECTION ................................. 30

INSTALLATION

TURBOCHARGER .......................... 31

TURBOCHARGER OIL DRAIN TUBE .......... 32

WASTEGATE - ELECTRONIC ACTUATOR

REMOVAL .................................... 33

INSTALLATION ............................... 33

CHARGE AIR COOLER AND PLUMBING

DESCRIPTION ................................ 34

OPERATION .................................. 34

DIAGNOSIS AND TESTING

CHARGE AIR COOLER SYSTEM - LEAKS.... 35

REMOVAL .................................... 35

CLEANING ................................... 36

INSPECTION ................................. 36

INSTALLATION ............................... 36

Page 2140 of 5267

DIESEL ENGINE

EXHAUST SYSTEM DIAGNOSIS CHART

CONDITION POSSIBLE CAUSE CORRECTION

EXCESSIVE EXHAUST NOISE OR

LEAKING EXHAUST GASES1. Leaks at pipe joints. 1. Tighten clamps/bolts at leaking

joints.

2. Rusted or blown out muffler. 2. Replace muffler. Inspect exhaust

system.

3. Broken or rusted out exhaust

pipe.3. Replace exhaust pipe.

4. Exhaust pipe leaking at manifold

flange.4. Tighten/replace flange attaching

nuts/bolts.

5. Exhaust manifold cracked or

broken.5. Replace exhaust manifold.

6. Leak between exhaust manifold

and cylinder head.6. Tighten exhaust manifold to

cylinder head bolts. Replace gasket

if necessary.

7. Turbocharger mounting flange

cracked.7. Remove turbocharger and

inspect. (Refer to 11 - EXHAUST

SYSTEM/TURBOCHARGER

SYSTEM/TURBOCHARGER -

REMOVAL).

8. Restriction in exhaust system. 8. Remove restriction, if possible.

Replace restricted part if necessary.

SPECIFICATIONS

TORQUE

DESCRIPTION Nꞏm Ft. Lbs. In. Lbs.

Bolt-Adjusting Strap 23 - 200

Nuts-Air Heater Power Supply 14 - 124

Bolts-Air Inlet Housing 24 18 -

Nuts-Cab Heater Supply/Return Line 24 18 -

Nuts-Exhaust Clamp 54 40 -

Bolts-Exhaust Manifold to Cylinder Head - (Diesel) 43 32 -

Bolts-Exhaust Manifold to Cylinder Head - (Diesel) 31 23 -

Bolts-Exhaust Manifold to Cylinder Head-(8.3L) 22 - 195

Bolts-Exhaust Pipe to Manifold 31 23 -

Bolts-Generator Mounting 41 30 -

Bolts-Charge Air Cooler Mounting 10 - 90

Nuts-Charge Air Cooler Duct 11 - 95

Bolt-Generator to Block-Diesel 24 18 -

Nuts and Bolts-Heat Shield 11 - 95

Nuts-Heat Shield-Diesel 24 18 -

Electronically Controlled Wastegate Command Valve-(Diesel) 34 25 -

Turbocharger flange studs-(Diesel) 24 18 -

Nuts-Turbocharger Mounting-(Diesel) 43 32 -

Page 2145 of 5267

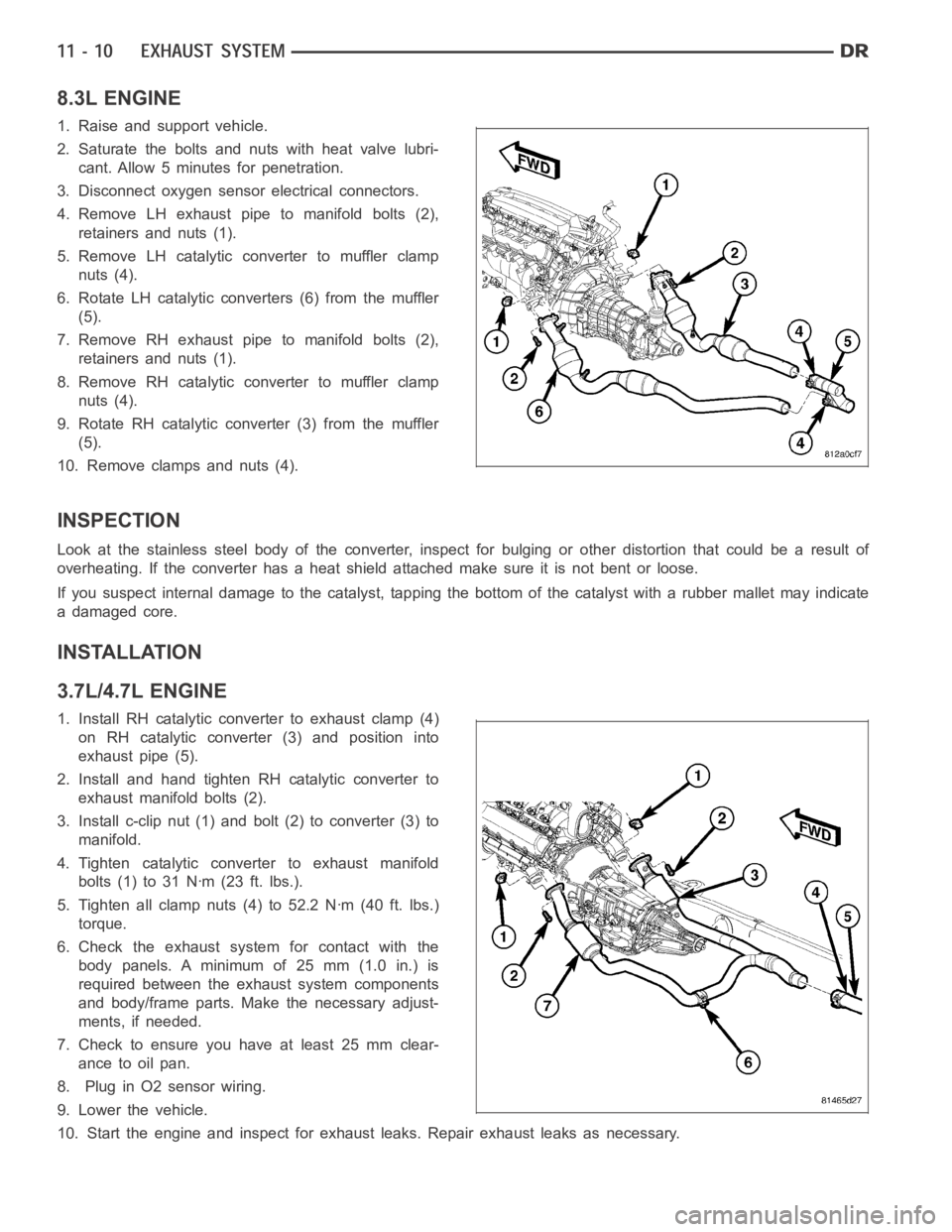

8.3L ENGINE

1. Raise and support vehicle.

2. Saturate the bolts and nuts with heat valve lubri-

cant. Allow 5 minutes for penetration.

3. Disconnect oxygen sensor electrical connectors.

4. Remove LH exhaust pipe to manifold bolts (2),

retainers and nuts (1).

5. Remove LH catalytic converter to muffler clamp

nuts (4).

6. Rotate LH catalytic converters (6) from the muffler

(5).

7. Remove RH exhaust pipe to manifold bolts (2),

retainers and nuts (1).

8. Remove RH catalytic converter to muffler clamp

nuts (4).

9. Rotate RH catalytic converter (3) from the muffler

(5).

10. Remove clamps and nuts (4).

INSPECTION

Look at the stainless steel body of the converter, inspect for bulging or other distortion that could be a result of

overheating. If the converter has a heat shield attached make sure it is notbent or loose.

If you suspect internal damage to the catalyst, tapping the bottom of the catalyst with a rubber mallet may indicate

a damaged core.

INSTALLATION

3.7L/4.7L ENGINE

1. Install RH catalytic converter to exhaust clamp (4)

on RH catalytic converter (3) and position into

exhaust pipe (5).

2. Install and hand tighten RH catalytic converter to

exhaust manifold bolts (2).

3. Install c-clip nut (1) and bolt (2) to converter (3) to

manifold.

4. Tighten catalytic converter to exhaust manifold

bolts(1)to31Nꞏm(23ft.lbs.).

5. Tighten all clamp nuts (4) to 52.2 Nꞏm (40 ft. lbs.)

torque.

6. Check the exhaust system for contact with the

body panels. A minimum of 25 mm (1.0 in.) is

required between the exhaust system components

and body/frame parts. Make the necessary adjust-

ments, if needed.

7. Check to ensure you have at least 25 mm clear-

ance to oil pan.

8. Plug in O2 sensor wiring.

9. Lower the vehicle.

10. Start the engine and inspect for exhaust leaks. Repair exhaust leaks asnecessary.

Page 2146 of 5267

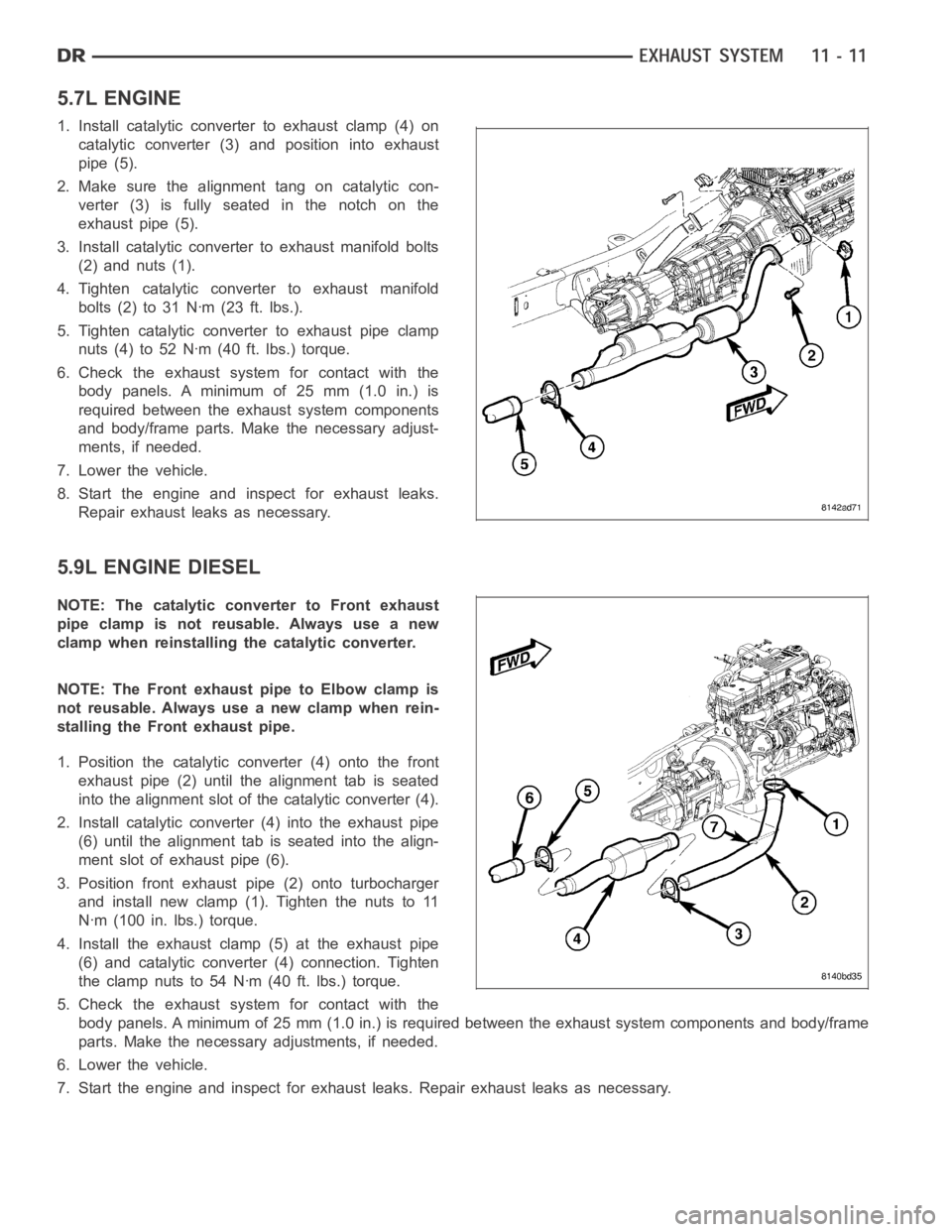

5.7L ENGINE

1. Install catalytic converter to exhaust clamp (4) on

catalytic converter (3) and position into exhaust

pipe (5).

2. Make sure the alignment tang on catalytic con-

verter (3) is fully seated in the notch on the

exhaust pipe (5).

3. Install catalytic converter to exhaust manifold bolts

(2) and nuts (1).

4. Tighten catalytic converter to exhaust manifold

bolts(2)to31Nꞏm(23ft.lbs.).

5. Tighten catalytic converter to exhaust pipe clamp

nuts (4) to 52 Nꞏm (40 ft. lbs.) torque.

6. Check the exhaust system for contact with the

body panels. A minimum of 25 mm (1.0 in.) is

required between the exhaust system components

and body/frame parts. Make the necessary adjust-

ments, if needed.

7. Lower the vehicle.

8. Start the engine and inspect for exhaust leaks.

Repair exhaust leaks as necessary.

5.9L ENGINE DIESEL

NOTE: The catalytic converter to Front exhaust

pipe clamp is not reusable. Always use a new

clamp when reinstalling the catalytic converter.

NOTE: The Front exhaust pipe to Elbow clamp is

not reusable. Always use a new clamp when rein-

stalling the Front exhaust pipe.

1. Position the catalytic converter (4) onto the front

exhaust pipe (2) until the alignment tab is seated

into the alignment slot of the catalytic converter (4).

2. Install catalytic converter (4) into the exhaust pipe

(6) until the alignment tab is seated into the align-

ment slot of exhaust pipe (6).

3. Position front exhaust pipe (2) onto turbocharger

and install new clamp (1). Tighten the nuts to 11

Nꞏm (100 in. lbs.) torque.

4. Install the exhaust clamp (5) at the exhaust pipe

(6) and catalytic converter (4) connection. Tighten

the clamp nuts to 54 Nꞏm (40 ft. lbs.) torque.

5. Check the exhaust system for contact with the

body panels. A minimum of 25 mm (1.0 in.) is required between the exhaust system components and body/frame

parts. Make the necessary adjustments, if needed.

6. Lower the vehicle.

7. Start the engine and inspect for exhaust leaks. Repair exhaust leaks as necessary.

Page 2147 of 5267

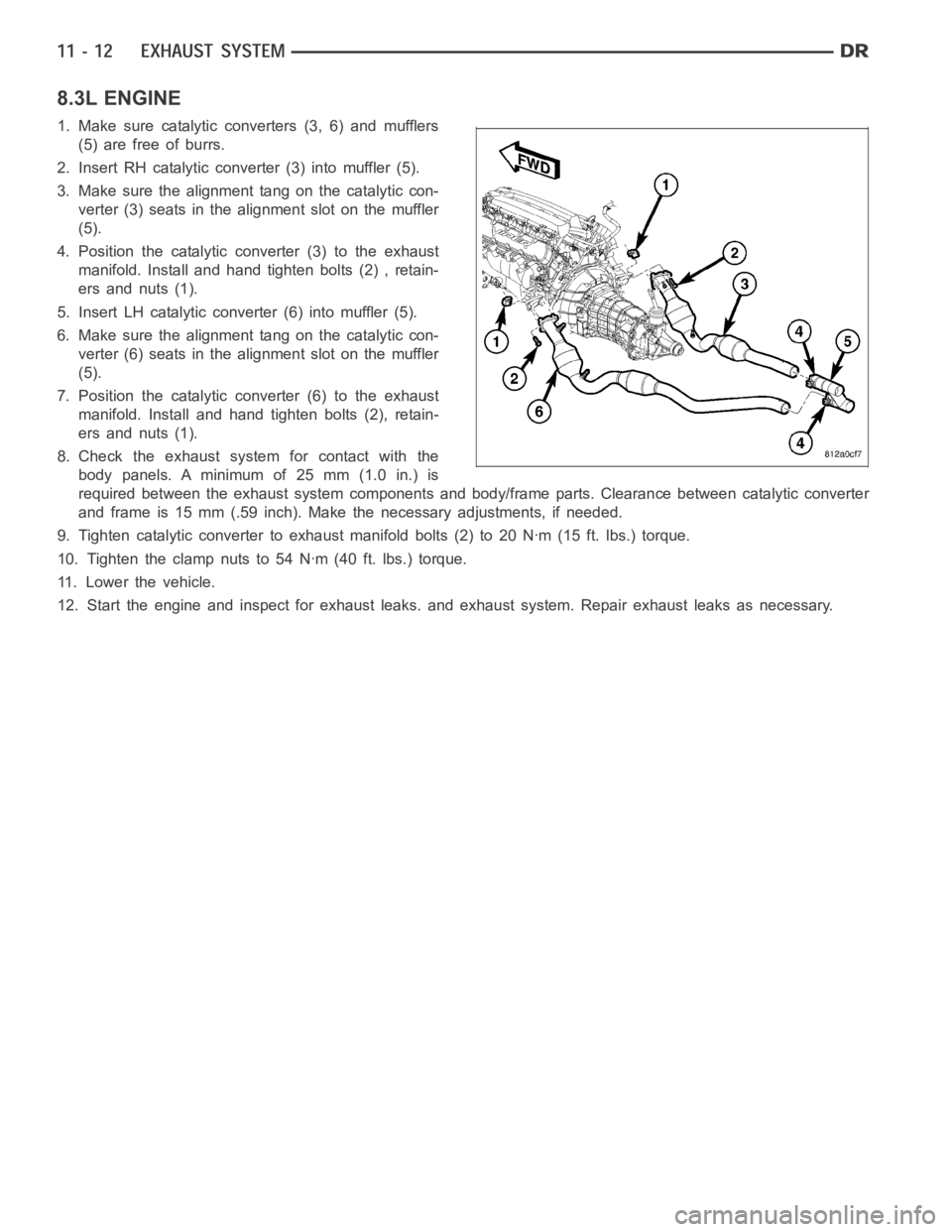

8.3L ENGINE

1. Make sure catalytic converters (3, 6) and mufflers

(5) are free of burrs.

2. Insert RH catalytic converter (3) into muffler (5).

3. Make sure the alignment tang on the catalytic con-

verter (3) seats in the alignment slot on the muffler

(5).

4. Position the catalytic converter (3) to the exhaust

manifold. Install and hand tighten bolts (2) , retain-

ers and nuts (1).

5. Insert LH catalytic converter (6) into muffler (5).

6. Make sure the alignment tang on the catalytic con-

verter (6) seats in the alignment slot on the muffler

(5).

7. Position the catalytic converter (6) to the exhaust

manifold. Install and hand tighten bolts (2), retain-

ers and nuts (1).

8. Check the exhaust system for contact with the

body panels. A minimum of 25 mm (1.0 in.) is

required between the exhaust system components and body/frame parts. Clearance between catalytic converter

and frame is 15 mm (.59 inch). Make the necessary adjustments, if needed.

9. Tighten catalytic converter to exhaust manifold bolts (2) to 20 Nꞏm (15 ft. lbs.) torque.

10. Tighten the clamp nuts to 54 Nꞏm (40 ft. lbs.) torque.

11. Lower the vehicle.

12. Start the engine and inspect for exhaust leaks. and exhaust system. Repair exhaust leaks as necessary.