torque DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 2149 of 5267

INSPECTION

Discard rusted clamps, broken or worn supports and attaching parts. Replace a component with original equipment

parts, or equivalent. This will assure proper alignment with other parts in the system and provide acceptable exhaust

noise levels.

INSTALLATION

3.7L/4.7L/5.7L ENGINE

1. Position the exhaust pipe for proper clearance with the frame and underbody parts. A minimum clearance of 25

mm (1.0 in.) is required.

2. Position the exhaust pipe to manifold. Install the bolts and nuts. Tighten the nuts to 31 Nꞏm (23 ft. lbs.) torque.

3. Tighten the clamp nuts to 54 Nꞏm (40 ft. lbs.) torque.

4. Lower the vehicle.

5. Start the engine and inspect for exhaust leaks and exhaust system contact with the body panels. Adjust the

alignment, if needed.

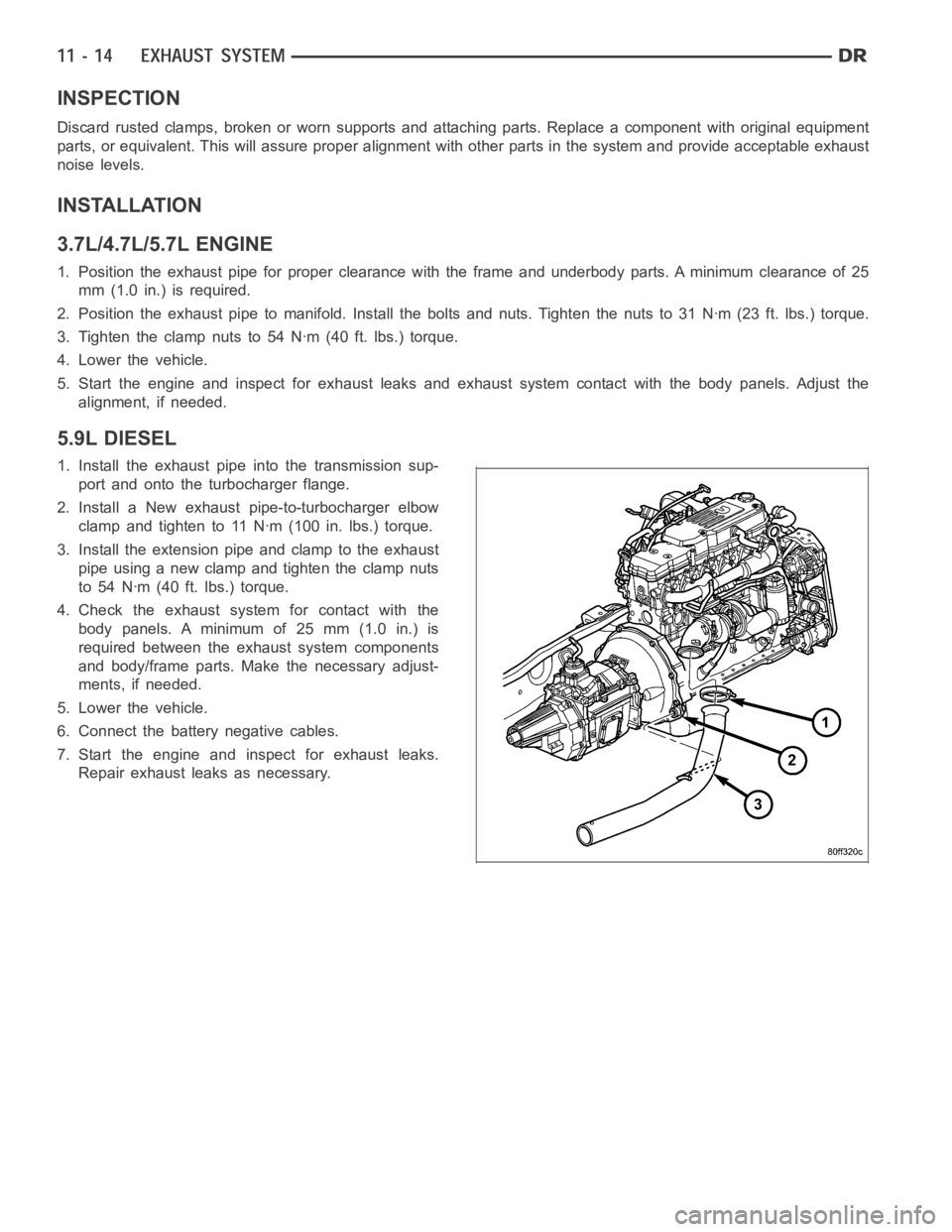

5.9L DIESEL

1. Install the exhaust pipe into the transmission sup-

port and onto the turbocharger flange.

2. Install a New exhaust pipe-to-turbocharger elbow

clamp and tighten to 11 Nꞏm (100 in. lbs.) torque.

3. Install the extension pipe and clamp to the exhaust

pipe using a new clamp and tighten the clamp nuts

to 54 Nꞏm (40 ft. lbs.) torque.

4. Check the exhaust system for contact with the

body panels. A minimum of 25 mm (1.0 in.) is

required between the exhaust system components

and body/frame parts. Make the necessary adjust-

ments, if needed.

5. Lower the vehicle.

6. Connect the battery negative cables.

7. Start the engine and inspect for exhaust leaks.

Repair exhaust leaks as necessary.

Page 2150 of 5267

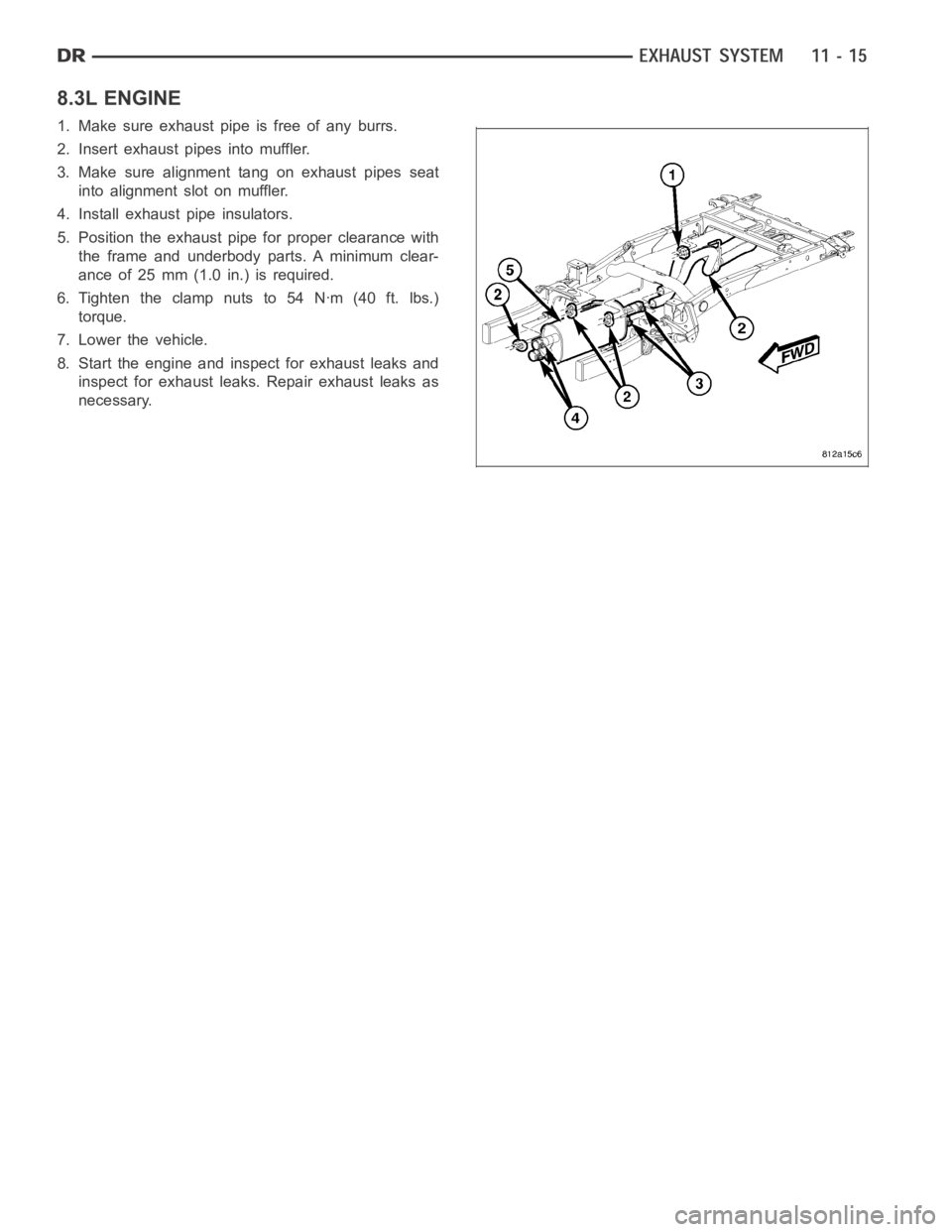

8.3L ENGINE

1. Make sure exhaust pipe is free of any burrs.

2. Insert exhaust pipes into muffler.

3. Make sure alignment tang on exhaust pipes seat

into alignment slot on muffler.

4. Install exhaust pipe insulators.

5. Position the exhaust pipe for proper clearance with

the frame and underbody parts. A minimum clear-

ance of 25 mm (1.0 in.) is required.

6.Tightentheclampnutsto54Nꞏm(40ft.lbs.)

torque.

7. Lower the vehicle.

8. Start the engine and inspect for exhaust leaks and

inspect for exhaust leaks. Repair exhaust leaks as

necessary.

Page 2155 of 5267

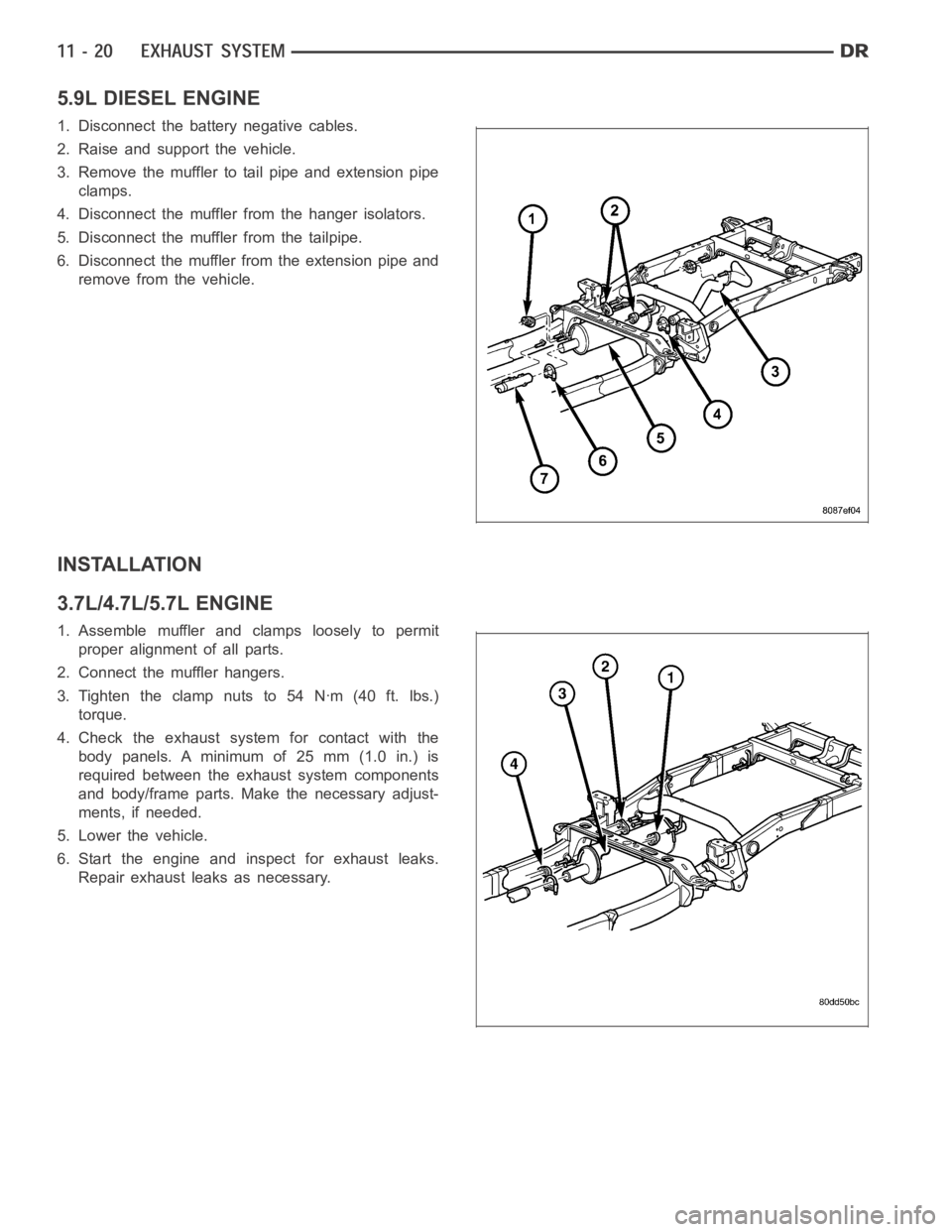

5.9L DIESEL ENGINE

1. Disconnect the battery negative cables.

2. Raise and support the vehicle.

3. Remove the muffler to tail pipe and extension pipe

clamps.

4. Disconnect the muffler from the hanger isolators.

5. Disconnect the muffler from the tailpipe.

6. Disconnect the muffler from the extension pipe and

remove from the vehicle.

INSTALLATION

3.7L/4.7L/5.7L ENGINE

1. Assemble muffler and clamps loosely to permit

proper alignment of all parts.

2. Connect the muffler hangers.

3.Tightentheclampnutsto54Nꞏm(40ft.lbs.)

torque.

4. Check the exhaust system for contact with the

body panels. A minimum of 25 mm (1.0 in.) is

required between the exhaust system components

and body/frame parts. Make the necessary adjust-

ments, if needed.

5. Lower the vehicle.

6. Start the engine and inspect for exhaust leaks.

Repair exhaust leaks as necessary.

Page 2156 of 5267

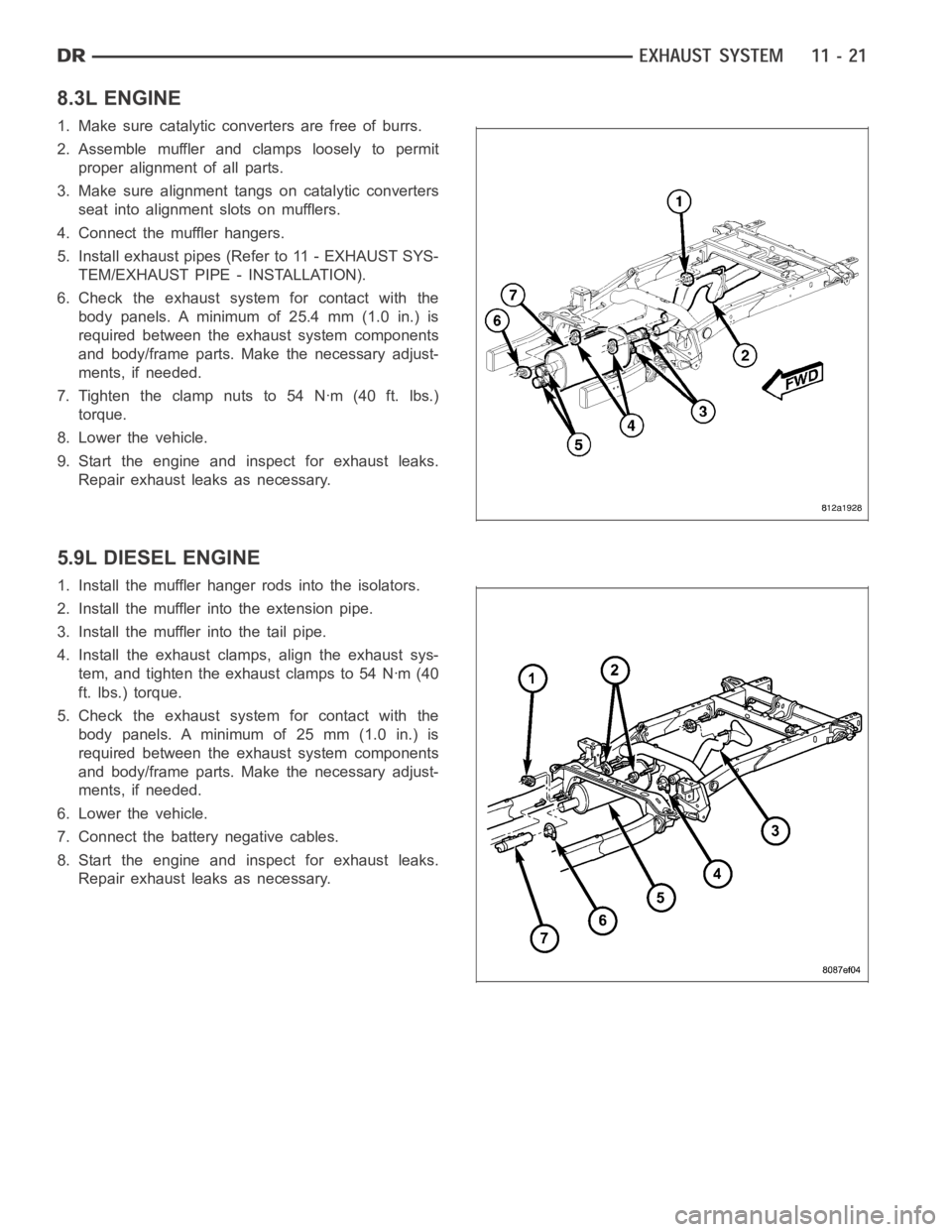

8.3L ENGINE

1. Make sure catalytic converters are free of burrs.

2. Assemble muffler and clamps loosely to permit

proper alignment of all parts.

3. Make sure alignment tangs on catalytic converters

seat into alignment slots on mufflers.

4. Connect the muffler hangers.

5. Install exhaust pipes (Refer to 11 - EXHAUST SYS-

TEM/EXHAUST PIPE - INSTALLATION).

6. Check the exhaust system for contact with the

body panels. A minimum of 25.4 mm (1.0 in.) is

required between the exhaust system components

and body/frame parts. Make the necessary adjust-

ments, if needed.

7.Tightentheclampnutsto54Nꞏm(40ft.lbs.)

torque.

8. Lower the vehicle.

9. Start the engine and inspect for exhaust leaks.

Repair exhaust leaks as necessary.

5.9L DIESEL ENGINE

1. Install the muffler hanger rods into the isolators.

2. Install the muffler into the extension pipe.

3. Install the muffler into the tail pipe.

4. Install the exhaust clamps, align the exhaust sys-

tem, and tighten the exhaust clamps to 54 Nꞏm (40

ft. lbs.) torque.

5. Check the exhaust system for contact with the

body panels. A minimum of 25 mm (1.0 in.) is

required between the exhaust system components

and body/frame parts. Make the necessary adjust-

ments, if needed.

6. Lower the vehicle.

7. Connect the battery negative cables.

8. Start the engine and inspect for exhaust leaks.

Repair exhaust leaks as necessary.

Page 2158 of 5267

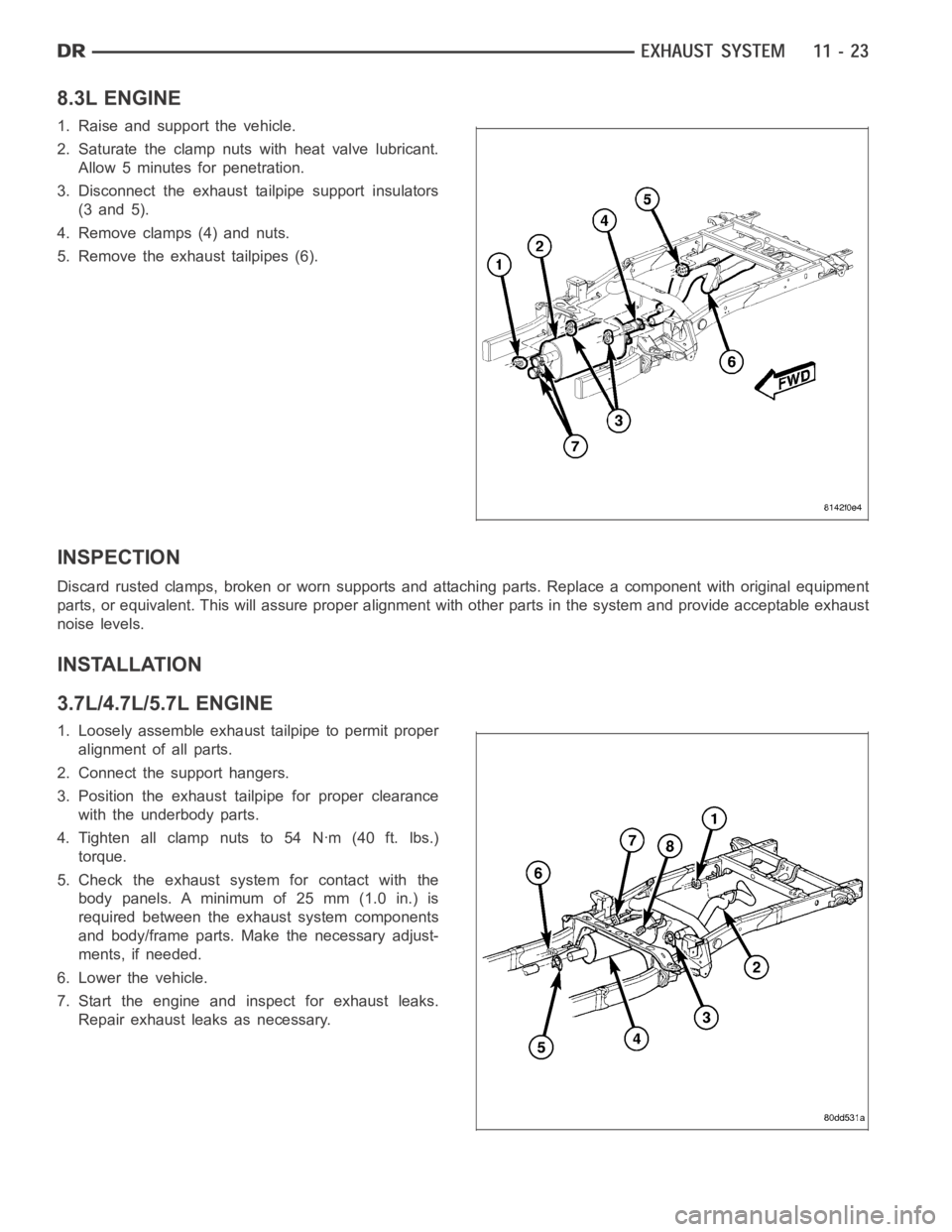

8.3L ENGINE

1. Raise and support the vehicle.

2. Saturate the clamp nuts with heat valve lubricant.

Allow 5 minutes for penetration.

3. Disconnect the exhaust tailpipe support insulators

(3 and 5).

4. Remove clamps (4) and nuts.

5. Remove the exhaust tailpipes (6).

INSPECTION

Discard rusted clamps, broken or worn supports and attaching parts. Replace a component with original equipment

parts, or equivalent. This will assure proper alignment with other parts in the system and provide acceptable exhaust

noise levels.

INSTALLATION

3.7L/4.7L/5.7L ENGINE

1. Loosely assemble exhaust tailpipe to permit proper

alignment of all parts.

2. Connect the support hangers.

3. Position the exhaust tailpipe for proper clearance

with the underbody parts.

4.Tightenallclampnutsto54Nꞏm(40ft.lbs.)

torque.

5. Check the exhaust system for contact with the

body panels. A minimum of 25 mm (1.0 in.) is

required between the exhaust system components

and body/frame parts. Make the necessary adjust-

ments, if needed.

6. Lower the vehicle.

7. Start the engine and inspect for exhaust leaks.

Repair exhaust leaks as necessary.

Page 2159 of 5267

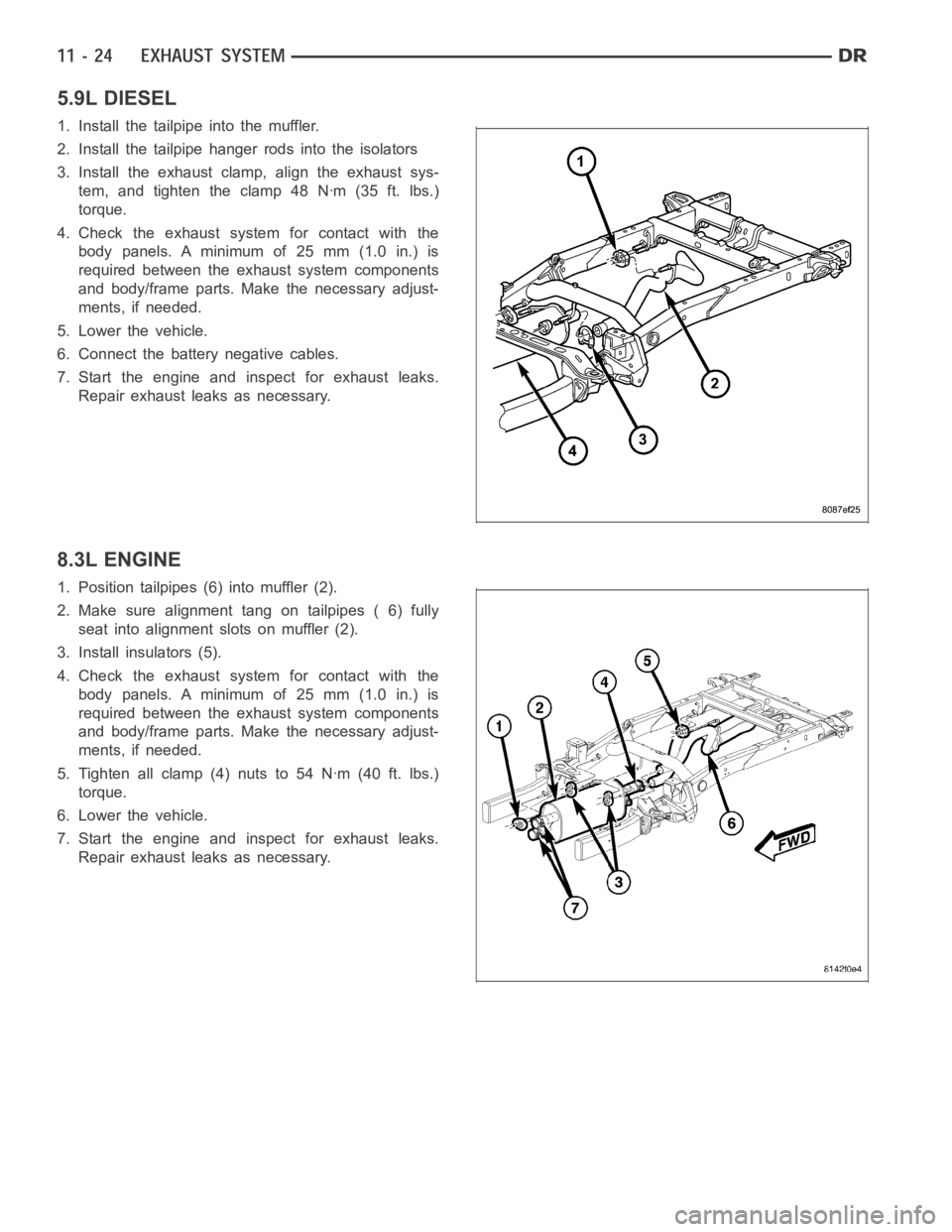

5.9L DIESEL

1. Install the tailpipe into the muffler.

2. Install the tailpipe hanger rods into the isolators

3. Install the exhaust clamp, align the exhaust sys-

tem, and tighten the clamp 48 Nꞏm (35 ft. lbs.)

torque.

4. Check the exhaust system for contact with the

body panels. A minimum of 25 mm (1.0 in.) is

required between the exhaust system components

and body/frame parts. Make the necessary adjust-

ments, if needed.

5. Lower the vehicle.

6. Connect the battery negative cables.

7. Start the engine and inspect for exhaust leaks.

Repair exhaust leaks as necessary.

8.3L ENGINE

1. Position tailpipes (6) into muffler (2).

2. Make sure alignment tang on tailpipes ( 6) fully

seat into alignment slots on muffler (2).

3. Install insulators (5).

4. Check the exhaust system for contact with the

body panels. A minimum of 25 mm (1.0 in.) is

required between the exhaust system components

and body/frame parts. Make the necessary adjust-

ments, if needed.

5. Tighten all clamp (4) nuts to 54 Nꞏm (40 ft. lbs.)

torque.

6. Lower the vehicle.

7. Start the engine and inspect for exhaust leaks.

Repair exhaust leaks as necessary.

Page 2166 of 5267

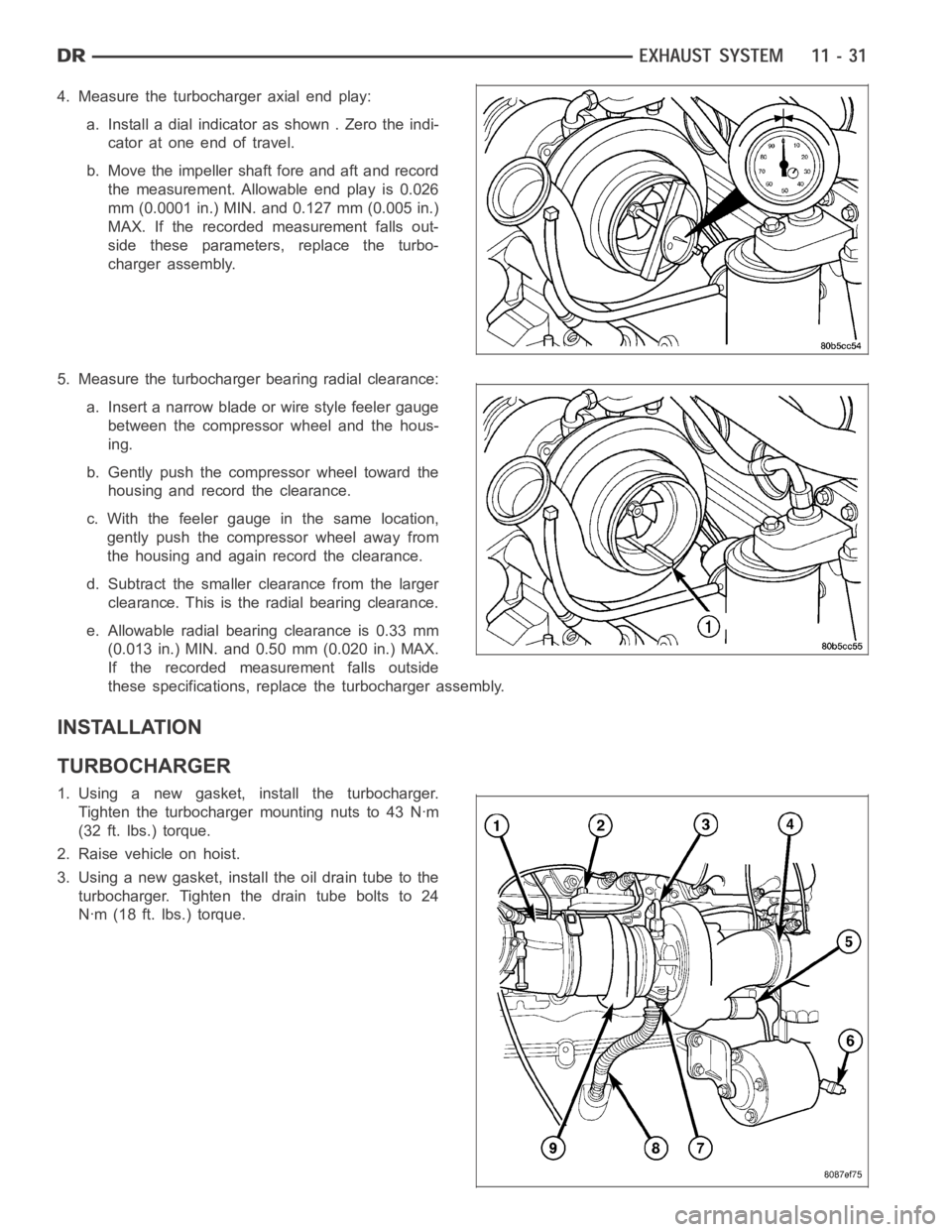

4. Measure the turbocharger axial end play:

a. Install a dial indicator as shown . Zero the indi-

cator at one end of travel.

b. Move the impeller shaft fore and aft and record

the measurement. Allowable end play is 0.026

mm (0.0001 in.) MIN. and 0.127 mm (0.005 in.)

MAX. If the recorded measurement falls out-

side these parameters, replace the turbo-

charger assembly.

5. Measure the turbocharger bearing radial clearance:

a. Insert a narrow blade or wire style feeler gauge

between the compressor wheel and the hous-

ing.

b. Gently push the compressor wheel toward the

housing and record the clearance.

c. With the feeler gauge in the same location,

gently push the compressor wheel away from

the housing and again record the clearance.

d. Subtract the smaller clearance from the larger

clearance. This is the radial bearing clearance.

e. Allowable radial bearing clearance is 0.33 mm

(0.013 in.) MIN. and 0.50 mm (0.020 in.) MAX.

If the recorded measurement falls outside

these specifications, replace the turbocharger assembly.

INSTALLATION

TURBOCHARGER

1. Using a new gasket, install the turbocharger.

Tighten the turbocharger mounting nuts to 43 Nꞏm

(32 ft. lbs.) torque.

2. Raise vehicle on hoist.

3. Using a new gasket, install the oil drain tube to the

turbocharger. Tighten the drain tube bolts to 24

Nꞏm (18 ft. lbs.) torque.

Page 2167 of 5267

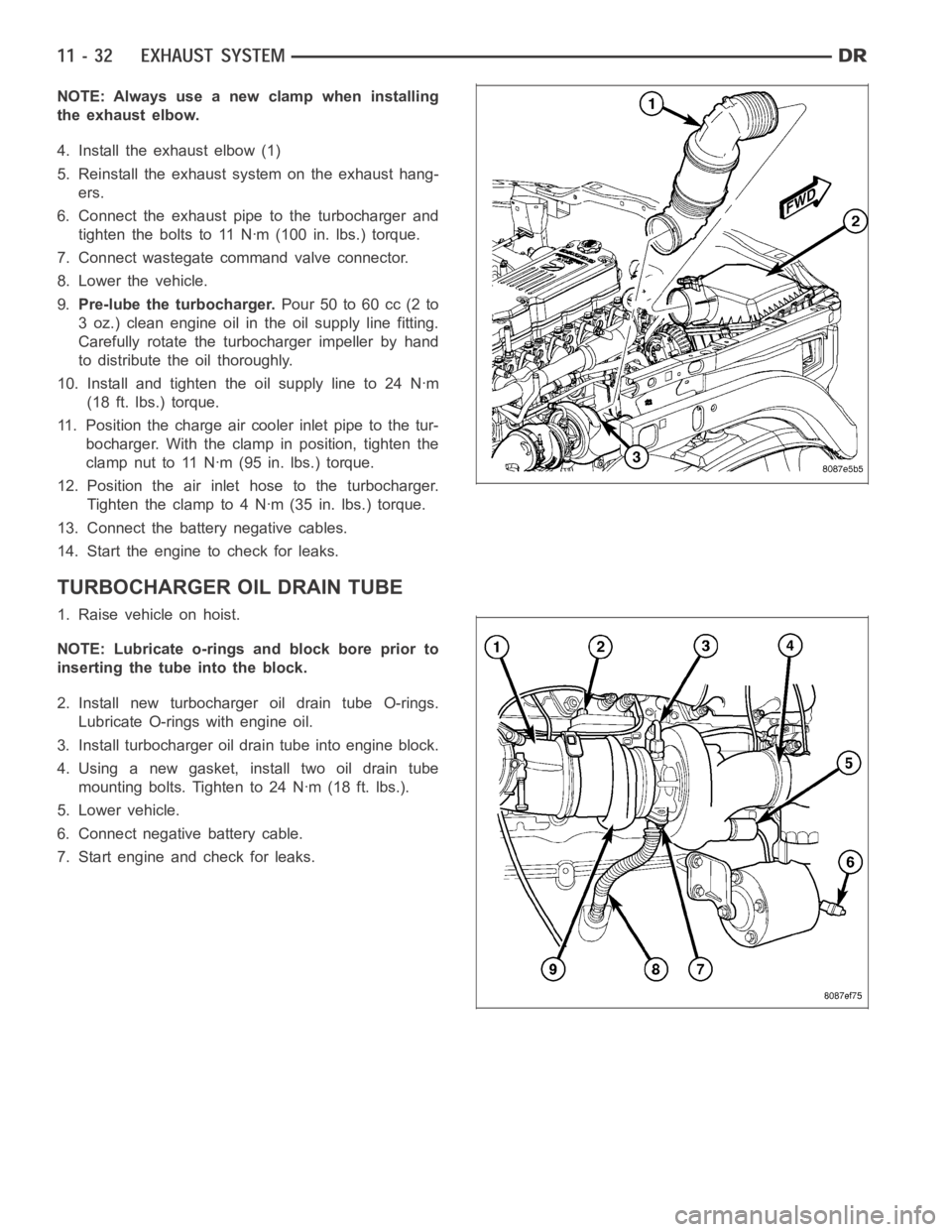

NOTE: Always use a new clamp when installing

the exhaust elbow.

4. Install the exhaust elbow (1)

5. Reinstall the exhaust system on the exhaust hang-

ers.

6. Connect the exhaust pipe to the turbocharger and

tighten the bolts to 11 Nꞏm (100 in. lbs.) torque.

7. Connect wastegate command valve connector.

8. Lower the vehicle.

9.Pre-lube the turbocharger.Pour 50 to 60 cc (2 to

3 oz.) clean engine oil in the oil supply line fitting.

Carefully rotate the turbocharger impeller by hand

to distribute the oil thoroughly.

10. Install and tighten the oil supply line to 24 Nꞏm

(18 ft. lbs.) torque.

11. Position the charge air cooler inlet pipe to the tur-

bocharger. With the clamp in position, tighten the

clamp nut to 11 Nꞏm (95 in. lbs.) torque.

12. Position the air inlet hose to the turbocharger.

Tighten the clamp to 4 Nꞏm (35 in. lbs.) torque.

13. Connect the battery negative cables.

14. Start the engine to check for leaks.

TURBOCHARGER OIL DRAIN TUBE

1. Raise vehicle on hoist.

NOTE: Lubricate o-rings and block bore prior to

inserting the tube into the block.

2. Install new turbocharger oil drain tube O-rings.

Lubricate O-rings with engine oil.

3. Install turbocharger oil drain tube into engine block.

4. Using a new gasket, install two oil drain tube

mounting bolts. Tighten to 24 Nꞏm (18 ft. lbs.).

5. Lower vehicle.

6. Connect negative battery cable.

7. Start engine and check for leaks.

Page 2171 of 5267

CLEANING

CAUTION: Do not use caustic cleaners to clean the charge air cooler. Damageto the charge air cooler will

result.

NOTE: If internal debris cannot be removed from the cooler, the charge air cooler MUST be replaced.

1. If the engine experiences a turbocharger failure or any other situationwhere oil or debris get into the charge air

cooler, the charge air cooler must be cleaned internally.

2. Position the charge air cooler so the inlet and outlet tubes are vertical.

3. Flush the cooler internally with solvent in the direction opposite of normal air flow.

4. Shake the cooler and lightly tap on the end tanks with a rubber mallet to dislodge trapped debris.

5. Continue flushing until all debris or oil are removed.

6. Rinse the cooler with hot soapy water to remove any remaining solvent.

7. Rinse thoroughly with clean water and blow dry with compressed air.

INSPECTION

Visually inspect the charge air cooler for cracks, holes, or damage. Inspect the tubes, fins, and welds for tears,

breaks, or other damage. Replace the charge air cooler if damage is found.

Pressure test the charge air cooler, using Charge Air Cooler Tester Kit No.3824556. This kit is available through

Cummins

Service Products. Instructions are provided with the kit.

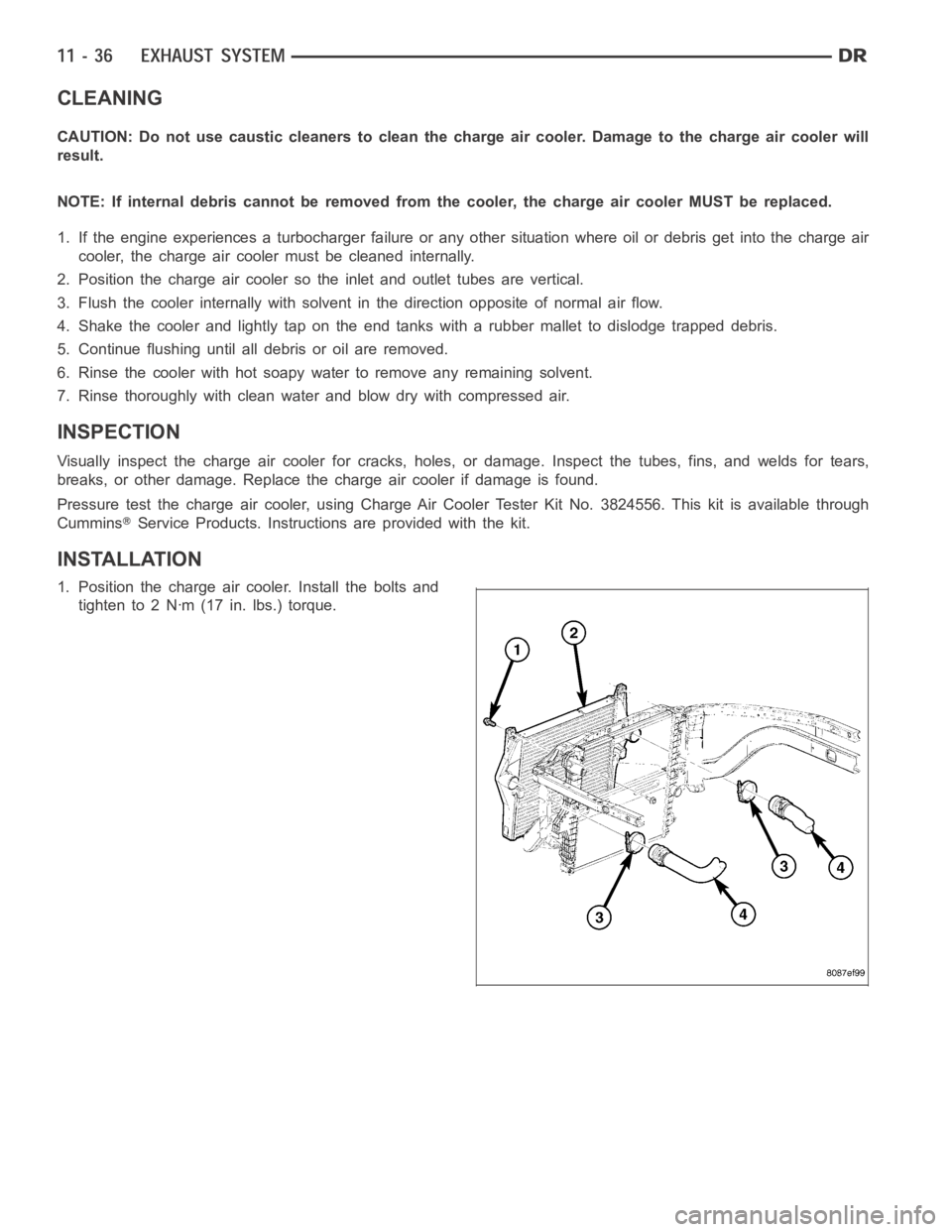

INSTALLATION

1. Position the charge air cooler. Install the bolts and

tighten to 2 Nꞏm (17 in. lbs.) torque.

Page 2172 of 5267

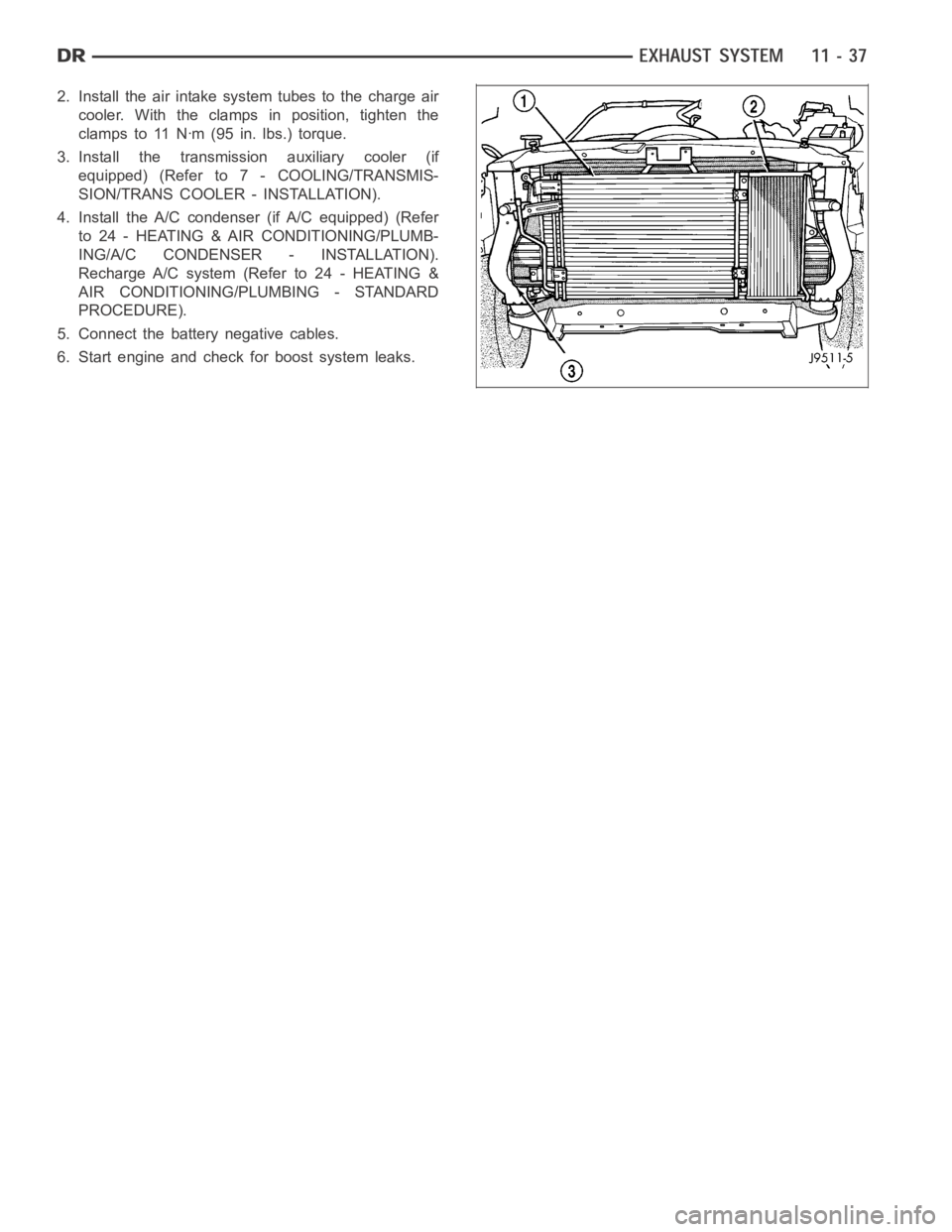

2. Install the air intake system tubes to the charge air

cooler. With the clamps in position, tighten the

clamps to 11 Nꞏm (95 in. lbs.) torque.

3. Install the transmission auxiliary cooler (if

equipped) (Refer to 7 - COOLING/TRANSMIS-

SION/TRANS COOLER - INSTALLATION).

4. Install the A/C condenser (if A/C equipped) (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMB-

ING/A/C CONDENSER - INSTALLATION).

Recharge A/C system (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - STANDARD

PROCEDURE).

5. Connect the battery negative cables.

6. Start engine and check for boost system leaks.