torque DODGE RAM SRT-10 2006 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: RAM SRT-10, Model: DODGE RAM SRT-10 2006Pages: 5267, PDF Size: 68.7 MB

Page 2304 of 5267

8.3L - SRT-10

The IAC motor is inserted into a housing at the front of the intake manifold.The IAC motor and housing are ser-

viced together.

1. Attach electrical connector to IAC motor.

2. Install IAC motor into and housing on manifold. Tighten mounting screwsto 4 Nꞏm (35 in. lbs.) torque.

Page 2322 of 5267

INSTALLATION

Threads of new oxygen sensors are factory coated with anti-seize compoundto aid in removal.DO NOT add any

additional anti-seize compound to threads of a new oxygen sensor.

1. Install O2S sensor. Tighten to 30 Nꞏm (22 ft. lbs.) torque.

2. Connect O2S sensor wire connector.

3. Lower vehicle.

Page 2329 of 5267

INSTALLATION

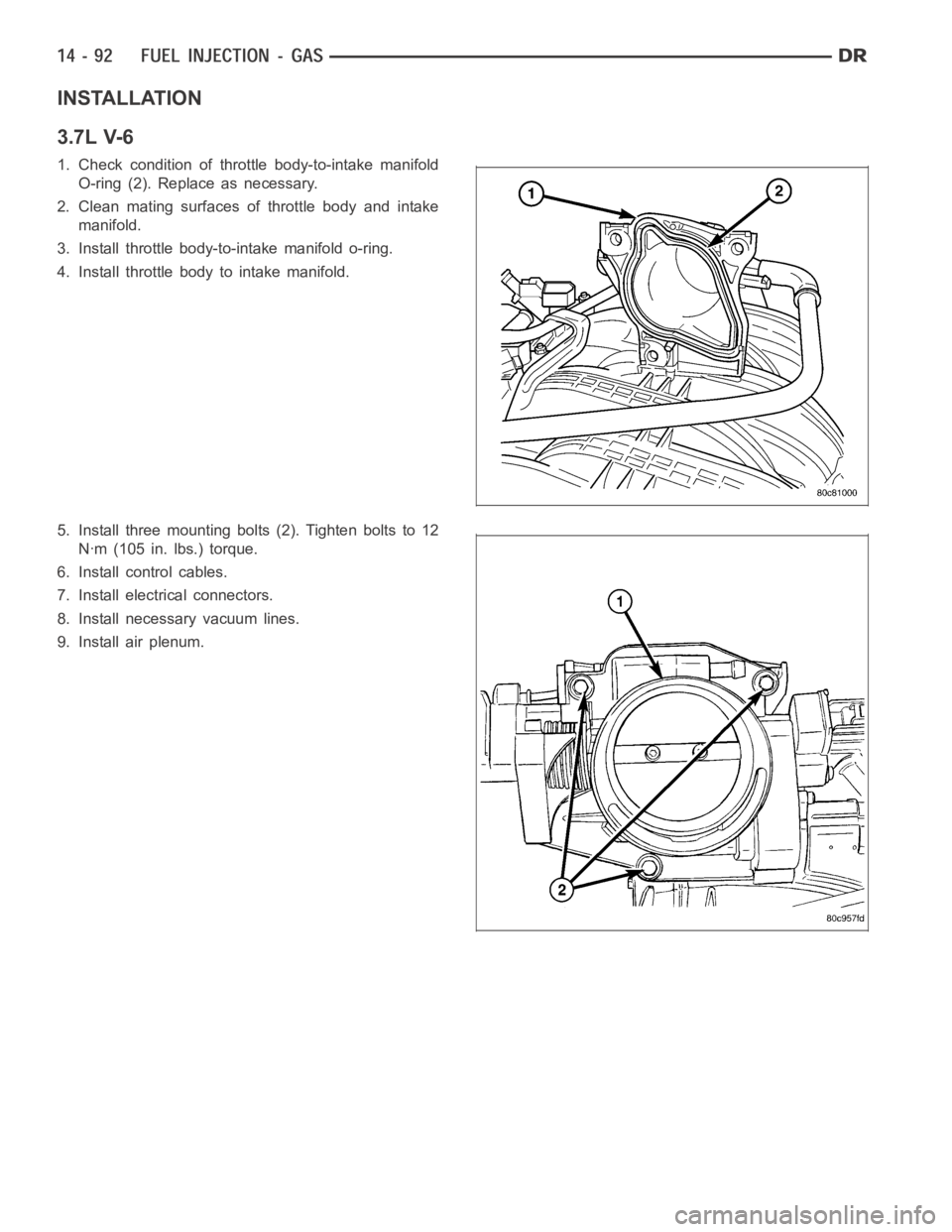

3.7L V-6

1. Check condition of throttle body-to-intake manifold

O-ring (2). Replace as necessary.

2. Clean mating surfaces of throttle body and intake

manifold.

3. Install throttle body-to-intake manifold o-ring.

4. Install throttle body to intake manifold.

5. Install three mounting bolts (2). Tighten bolts to 12

Nꞏm (105 in. lbs.) torque.

6. Install control cables.

7. Install electrical connectors.

8. Install necessary vacuum lines.

9. Install air plenum.

Page 2330 of 5267

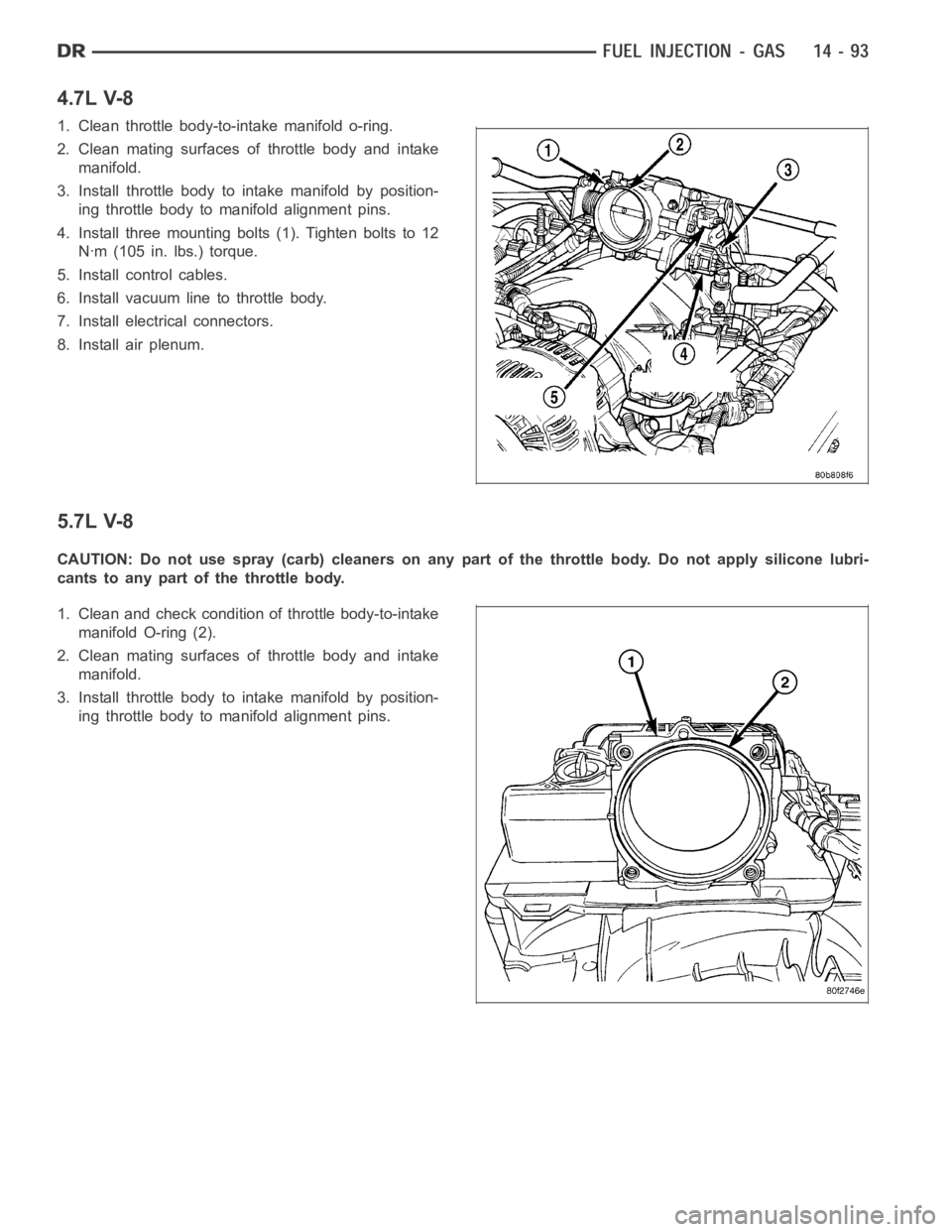

4.7L V-8

1. Clean throttle body-to-intake manifold o-ring.

2. Clean mating surfaces of throttle body and intake

manifold.

3. Install throttle body to intake manifold by position-

ing throttle body to manifold alignment pins.

4. Install three mounting bolts (1). Tighten bolts to 12

Nꞏm (105 in. lbs.) torque.

5. Install control cables.

6. Install vacuum line to throttle body.

7. Install electrical connectors.

8. Install air plenum.

5.7L V-8

CAUTION: Do not use spray (carb) cleaners on any part of the throttle body. Do not apply silicone lubri-

cants to any part of the throttle body.

1. Clean and check condition of throttle body-to-intake

manifold O-ring (2).

2. Clean mating surfaces of throttle body and intake

manifold.

3. Install throttle body to intake manifold by position-

ing throttle body to manifold alignment pins.

Page 2338 of 5267

INSTALLATION

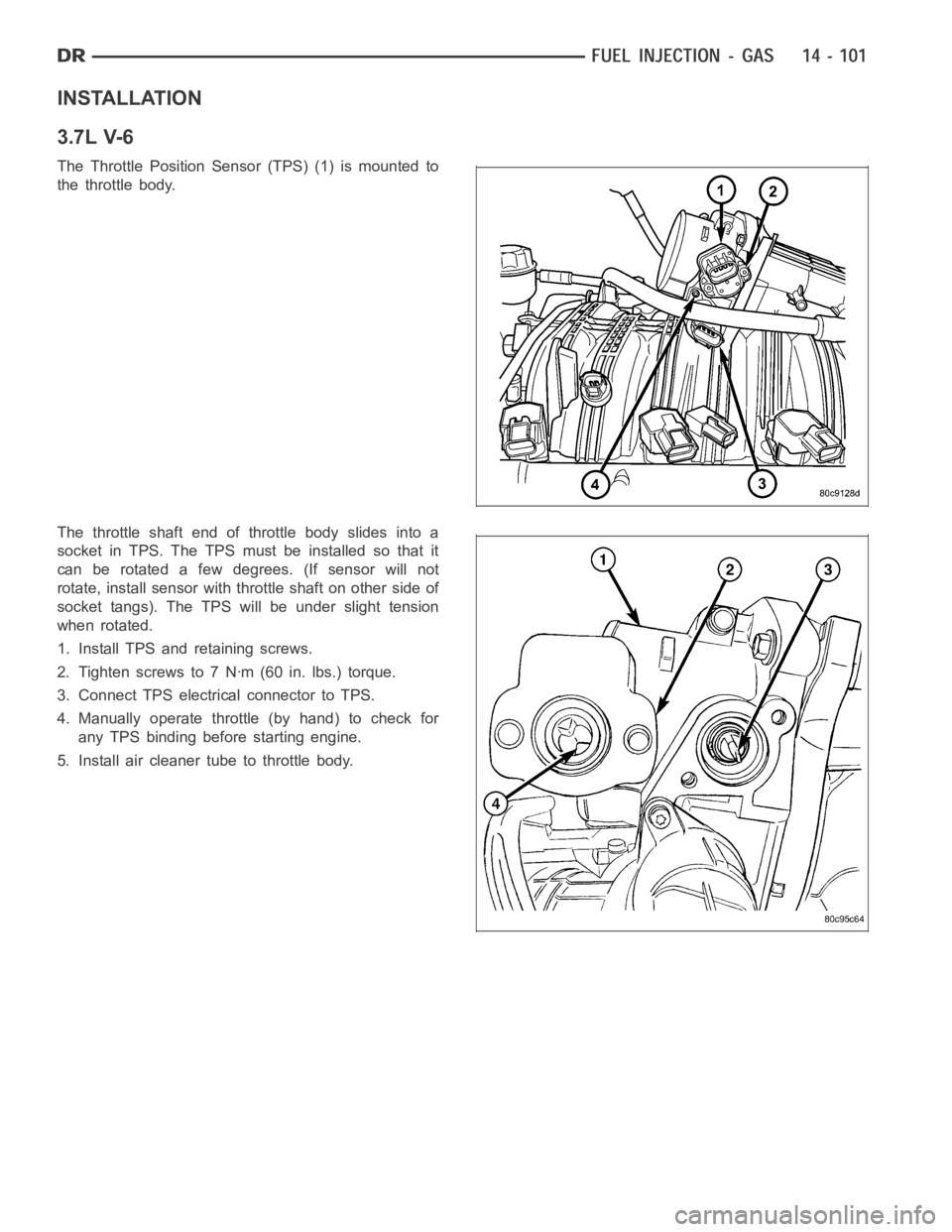

3.7L V-6

The Throttle Position Sensor (TPS) (1) is mounted to

the throttle body.

The throttle shaft end of throttle body slides into a

socket in TPS. The TPS must be installed so that it

can be rotated a few degrees. (If sensor will not

rotate, install sensor with throttle shaft on other side of

socket tangs). The TPS will be under slight tension

when rotated.

1. Install TPS and retaining screws.

2. Tighten screws to 7 Nꞏm (60 in. lbs.) torque.

3. Connect TPS electrical connector to TPS.

4. Manually operate throttle (by hand) to check for

any TPS binding before starting engine.

5. Install air cleaner tube to throttle body.

Page 2339 of 5267

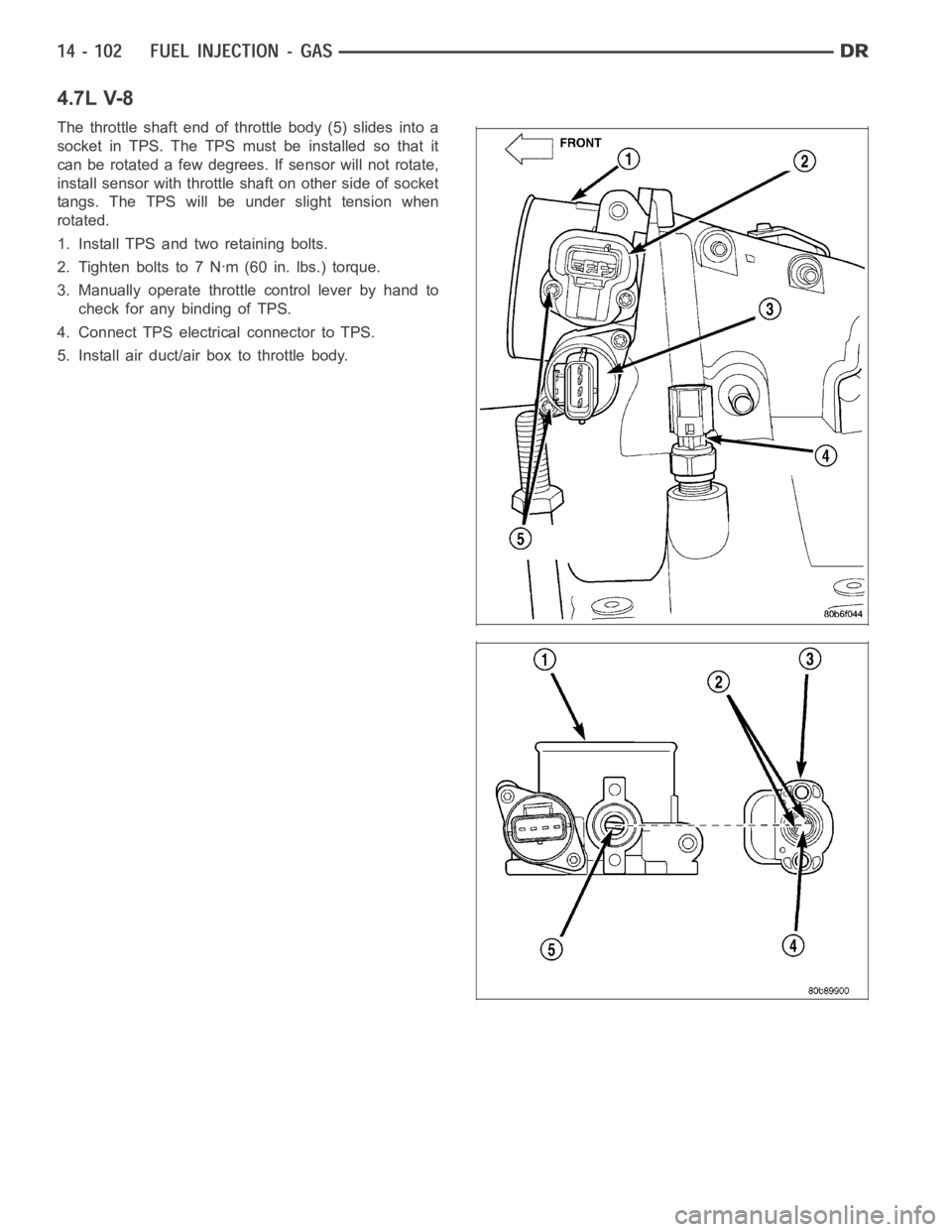

4.7L V-8

The throttle shaft end of throttle body (5) slides into a

socket in TPS. The TPS must be installed so that it

can be rotated a few degrees. If sensor will not rotate,

install sensor with throttle shaft on other side of socket

tangs. The TPS will be under slight tension when

rotated.

1. Install TPS and two retaining bolts.

2. Tighten bolts to 7 Nꞏm (60 in. lbs.) torque.

3. Manually operate throttle control lever by hand to

check for any binding of TPS.

4. Connect TPS electrical connector to TPS.

5. Install air duct/air box to throttle body.

Page 2341 of 5267

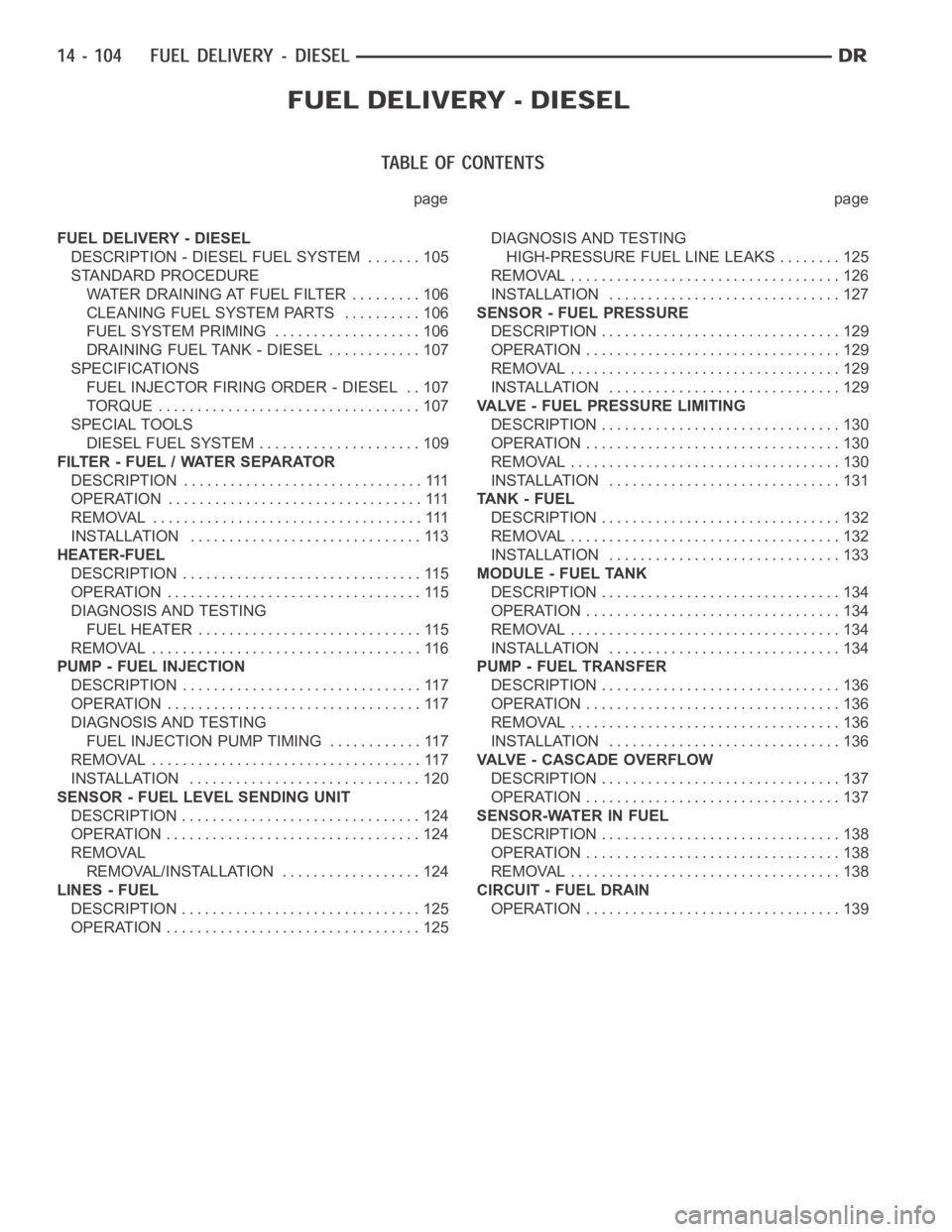

page page

FUEL DELIVERY - DIESEL

DESCRIPTION - DIESEL FUEL SYSTEM ....... 105

STANDARD PROCEDURE

WATER DRAINING AT FUEL FILTER ......... 106

CLEANING FUEL SYSTEM PARTS .......... 106

FUEL SYSTEM PRIMING................... 106

DRAINING FUEL TANK - DIESEL............ 107

SPECIFICATIONS

FUEL INJECTOR FIRING ORDER - DIESEL . . 107

TORQUE .................................. 107

SPECIAL TOOLS

DIESEL FUEL SYSTEM . .................... 109

FILTER - FUEL / WATER SEPARATOR

DESCRIPTION ............................... 111

OPERATION ................................. 111

REMOVAL ................................... 111

INSTALLATION .............................. 113

HEATER-FUEL

DESCRIPTION ............................... 115

OPERATION ................................. 115

DIAGNOSIS AND TESTING

FUEL HEATER ............................. 115

REMOVAL ................................... 116

PUMP - FUEL INJECTION

DESCRIPTION ............................... 117

OPERATION ................................. 117

DIAGNOSIS AND TESTING

FUEL INJECTION PUMP TIMING ............ 117

REMOVAL ................................... 117

INSTALLATION .............................. 120

SENSOR - FUEL LEVEL SENDING UNIT

DESCRIPTION ............................... 124

OPERATION ................................. 124

REMOVAL

REMOVAL/INSTALLATION .................. 124

LINES - FUEL

DESCRIPTION ............................... 125

OPERATION ................................. 125DIAGNOSIS AND TESTING

HIGH-PRESSURE FUEL LINE LEAKS........ 125

REMOVAL ................................... 126

INSTALLATION .............................. 127

SENSOR - FUEL PRESSURE

DESCRIPTION ............................... 129

OPERATION ................................. 129

REMOVAL ................................... 129

INSTALLATION .............................. 129

VALVE - FUEL PRESSURE LIMITING

DESCRIPTION ............................... 130

OPERATION ................................. 130

REMOVAL ................................... 130

INSTALLATION .............................. 131

TA N K - F U E L

DESCRIPTION ............................... 132

REMOVAL ................................... 132

INSTALLATION .............................. 133

MODULE - FUEL TANK

DESCRIPTION ............................... 134

OPERATION ................................. 134

REMOVAL ................................... 134

INSTALLATION .............................. 134

PUMP - FUEL TRANSFER

DESCRIPTION ............................... 136

OPERATION ................................. 136

REMOVAL ................................... 136

INSTALLATION .............................. 136

VALVE - CASCADE OVERFLOW

DESCRIPTION ............................... 137

OPERATION ................................. 137

SENSOR-WATER IN FUEL

DESCRIPTION ............................... 138

OPERATION ................................. 138

REMOVAL ................................... 138

CIRCUIT - FUEL DRAIN

OPERATION ................................. 139

Page 2344 of 5267

WARNING: The fuel injection pump supplies extremely high fuel pressure toeach individual injector

through the high-pressure lines. Fuel under this amount of pressure can penetrate the skin and cause per-

sonal injury. Wear safety goggles and adequate protective clothing. Do not loosen fuel fittings while engine

is running.

WARNING: Engine may start while cranking starter motor.

DRAINING FUEL TANK - DIESEL

Due to a one-way check valve installed into the fuel fill opening fitting atthe tank, the tank cannot be drained con-

ventionally at the fill cap.

1. Raise vehicle.

2. If vehicle is equipped with 4 doors and a 6 foot (short) box, remove left-rear tire/wheel.

3. Thoroughly clean area at top of fuel tank around fuel tank module.

4. Loosen clamp and disconnect rubber fuel fill hose at tank.

5. Drain fuel tank by attaching drain hose from an approved diesel fuel draining station to the fuel fill fitting of tank.

SPECIFICATIONS

FUEL INJECTOR FIRING ORDER - DIESEL

1–5–3–6–2–4

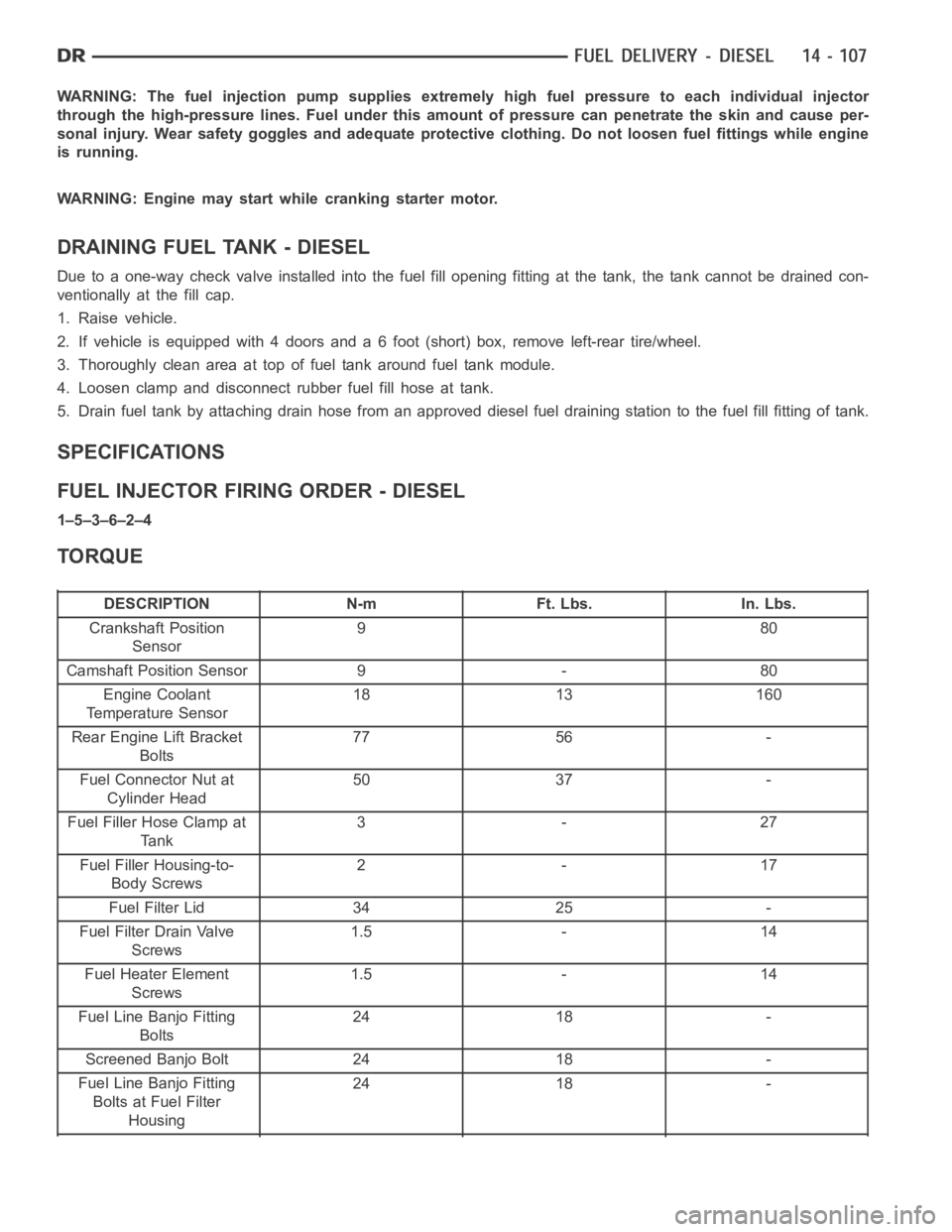

TORQUE

DESCRIPTION N-m Ft. Lbs. In. Lbs.

Crankshaft Position

Sensor980

Camshaft Position Sensor 9 - 80

Engine Coolant

Temperature Sensor18 13 160

Rear Engine Lift Bracket

Bolts77 56 -

Fuel Connector Nut at

Cylinder Head50 37 -

Fuel Filler Hose Clamp at

Ta n k3-27

Fuel Filler Housing-to-

Body Screws2-17

Fuel Filter Lid 34 25 -

Fuel Filter Drain Valve

Screws1.5 - 14

Fuel Heater Element

Screws1.5 - 14

Fuel Line Banjo Fitting

Bolts24 18 -

Screened Banjo Bolt 24 18 -

Fuel Line Banjo Fitting

Bolts at Fuel Filter

Housing24 18 -

Page 2350 of 5267

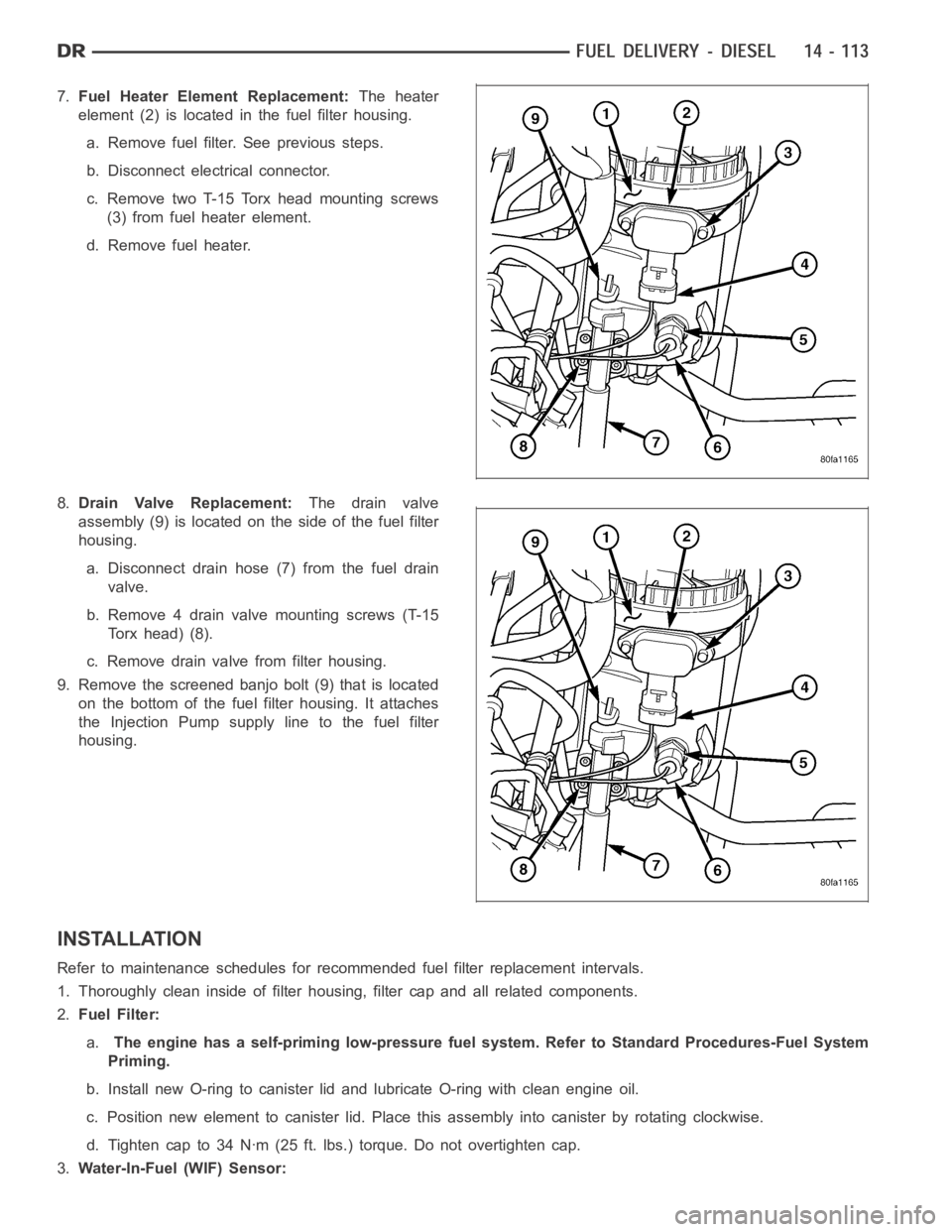

7.Fuel Heater Element Replacement:The heater

element (2) is located in the fuel filter housing.

a. Remove fuel filter. See previous steps.

b. Disconnect electrical connector.

c. Remove two T-15 Torx head mounting screws

(3) from fuel heater element.

d. Remove fuel heater.

8.Drain Valve Replacement:The drain valve

assembly (9) is located on the side of the fuel filter

housing.

a. Disconnect drain hose (7) from the fuel drain

valve.

b. Remove 4 drain valve mounting screws (T-15

Torx head) (8).

c. Remove drain valve from filter housing.

9. Remove the screened banjo bolt (9) that is located

on the bottom of the fuel filter housing. It attaches

the Injection Pump supply line to the fuel filter

housing.

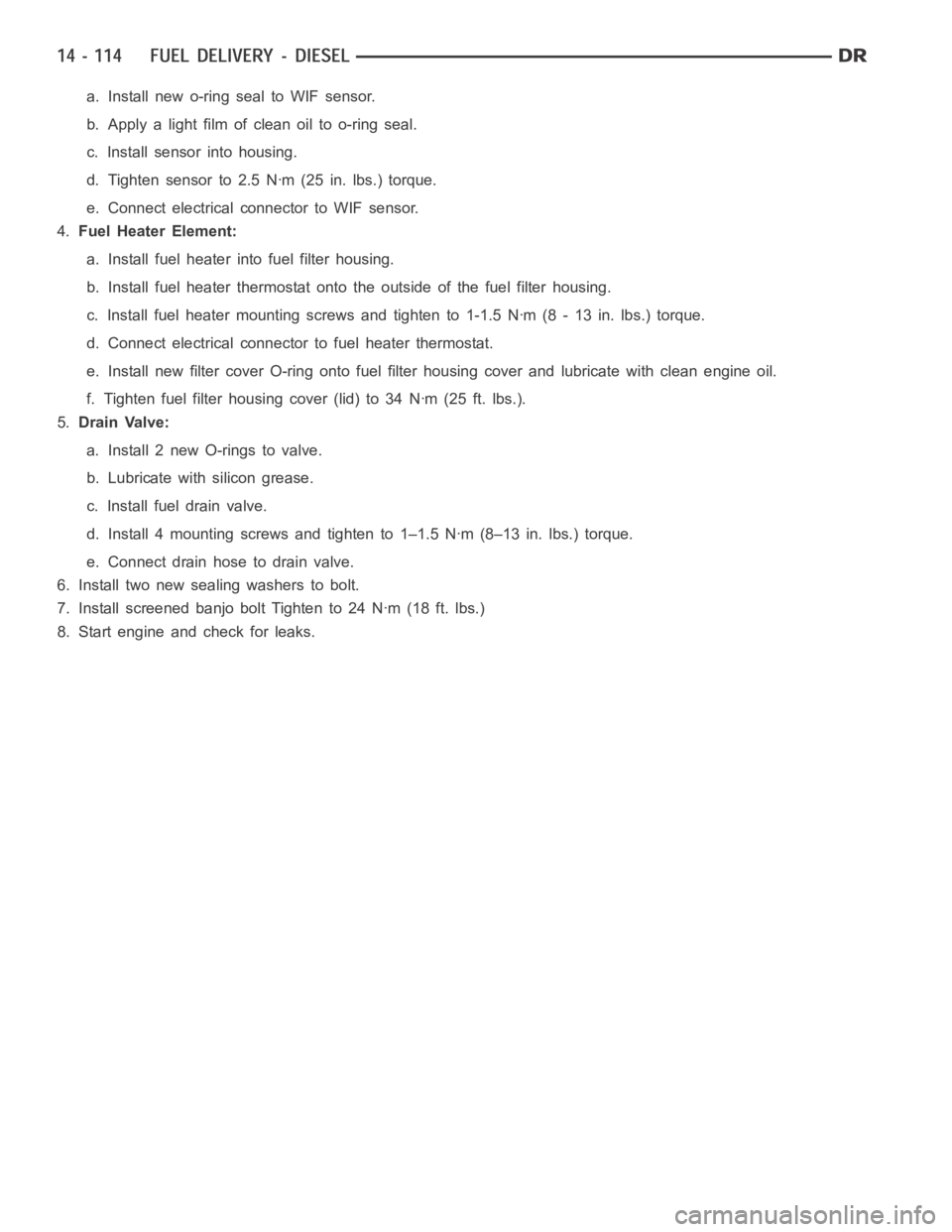

INSTALLATION

Refer to maintenance schedules for recommended fuel filter replacement intervals.

1. Thoroughly clean inside of filter housing, filter cap and all related components.

2.Fuel Filter:

a.The engine has a self-priming low-pressure fuel system. Refer to StandardProcedures-Fuel System

Priming.

b. Install new O-ring to canister lid and lubricate O-ring with clean engine oil.

c. Position new element to canister lid. Place this assembly into canisterby rotating clockwise.

d. Tighten cap to 34 Nꞏm (25 ft. lbs.) torque. Do not overtighten cap.

3.Water-In-Fuel (WIF) Sensor:

Page 2351 of 5267

a. Install new o-ring seal to WIF sensor.

b. Apply a light film of clean oil to o-ring seal.

c. Install sensor into housing.

d. Tighten sensor to 2.5 Nꞏm (25 in. lbs.) torque.

e. Connect electrical connector to WIF sensor.

4.Fuel Heater Element:

a. Install fuel heater into fuel filter housing.

b. Install fuel heater thermostat onto the outside of the fuel filter housing.

c. Install fuel heater mounting screws and tighten to 1-1.5 Nꞏm (8 - 13 in. lbs.) torque.

d. Connect electrical connector to fuel heater thermostat.

e. Install new filter cover O-ring onto fuel filter housing cover and lubricate with clean engine oil.

f. Tighten fuel filter housing cover (lid) to 34 Nꞏm (25 ft. lbs.).

5.Drain Valve:

a. Install 2 new O-rings to valve.

b. Lubricate with silicon grease.

c. Installfueldrainvalve.

d. Install 4 mounting screws and tighten to 1–1.5 Nꞏm (8–13 in. lbs.) torque.

e. Connect drain hose to drain valve.

6. Install two new sealing washers to bolt.

7. Install screened banjo bolt Tighten to 24 Nꞏm (18 ft. lbs.)

8. Start engine and check for leaks.