DODGE RAM SRT-10 2006 Service Repair Manual

RAM SRT-10 2006

DODGE

DODGE

https://www.carmanualsonline.info/img/12/56917/w960_56917-0.png

DODGE RAM SRT-10 2006 Service Repair Manual

Trending: differential, ECU, spark plugs replace, battery capacity, AUX, rims, Water pump

Page 2541 of 5267

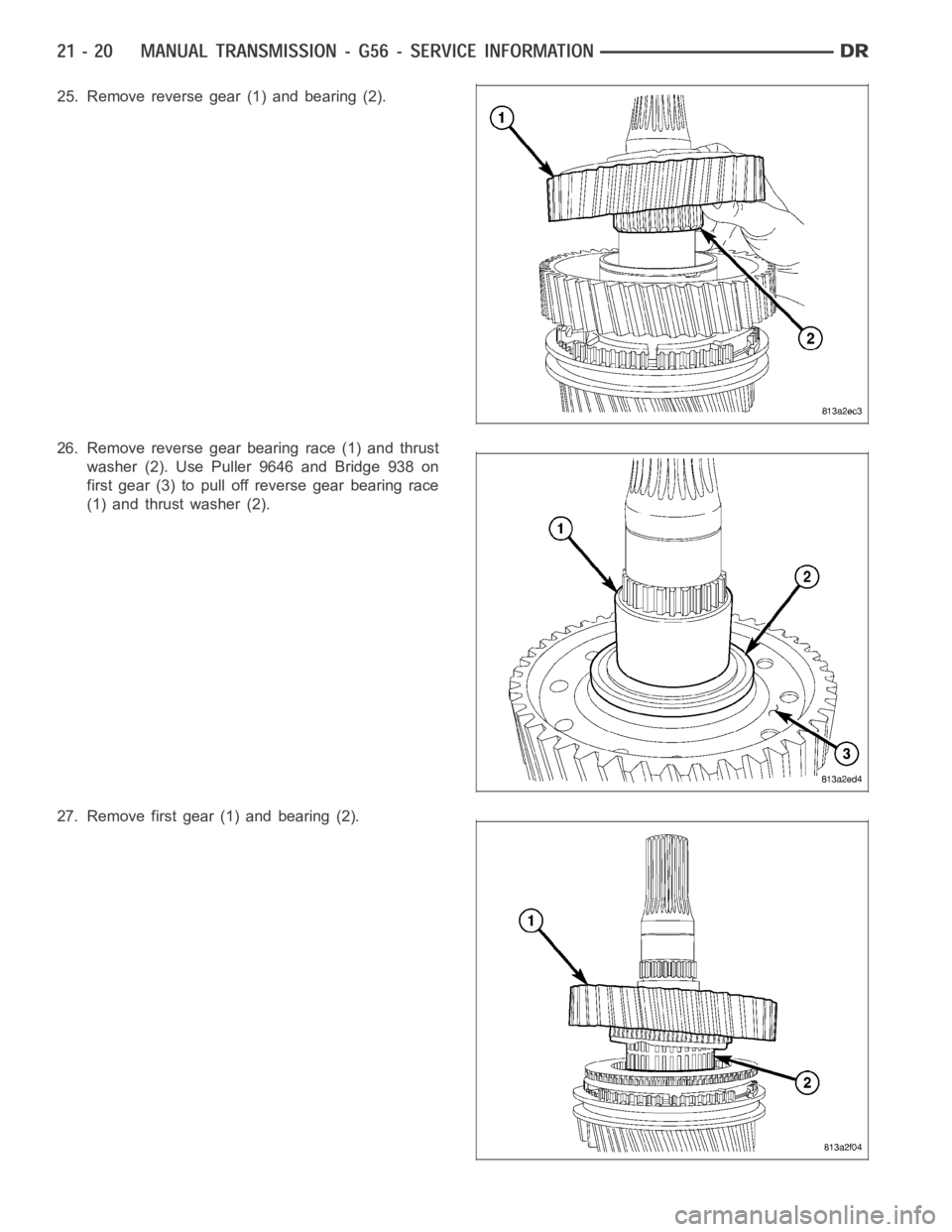

25. Remove reverse gear (1) and bearing (2).

26. Remove reverse gear bearing race (1) and thrust

washer (2). Use Puller 9646 and Bridge 938 on

first gear (3) to pull off reverse gear bearing race

(1) and thrust washer (2).

27. Remove first gear (1) and bearing (2).

Page 2542 of 5267

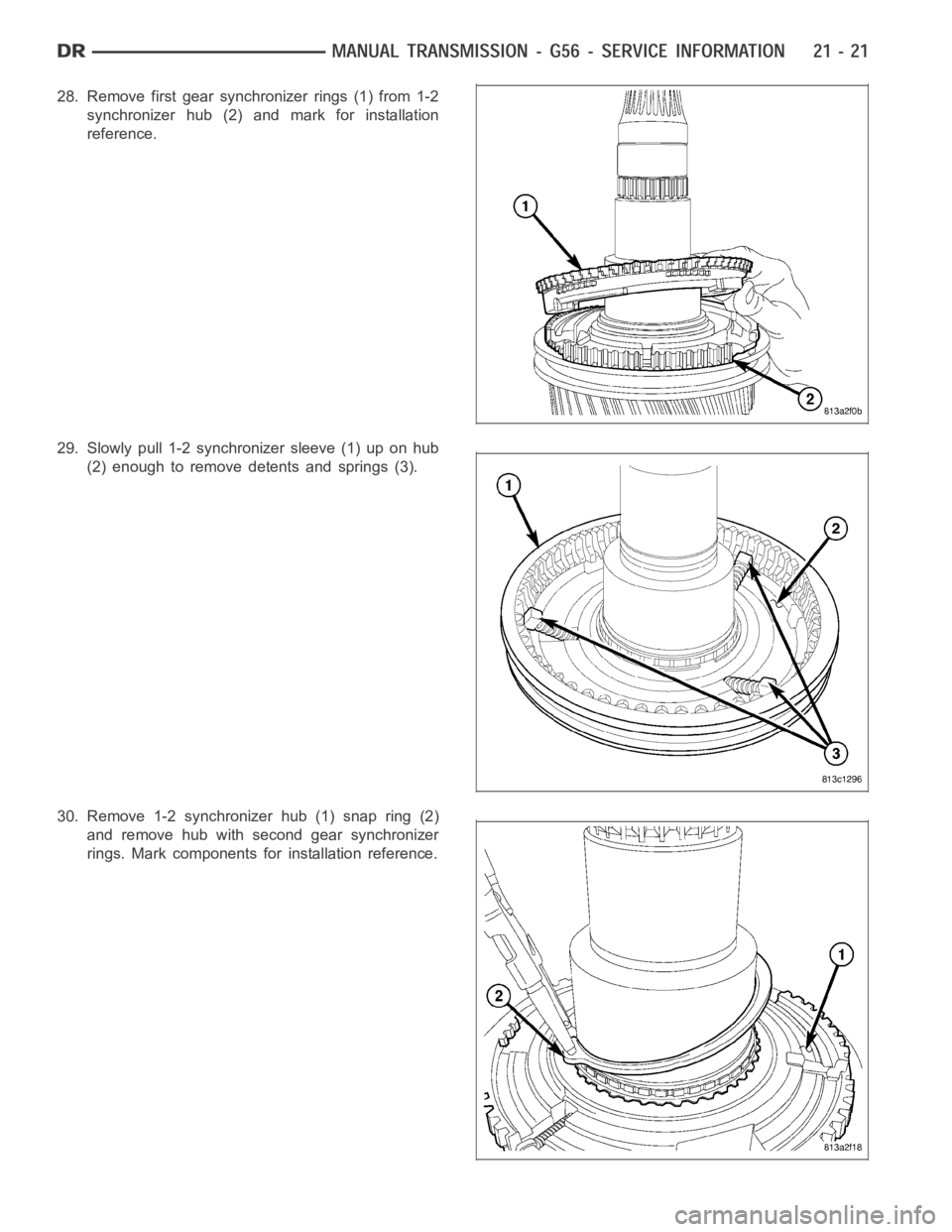

28. Remove first gear synchronizer rings (1) from 1-2

synchronizer hub (2) and mark for installation

reference.

29. Slowly pull 1-2 synchronizer sleeve (1) up on hub

(2) enough to remove detents and springs (3).

30. Remove 1-2 synchronizer hub (1) snap ring (2)

and remove hub with second gear synchronizer

rings. Mark components for installation reference.

Page 2543 of 5267

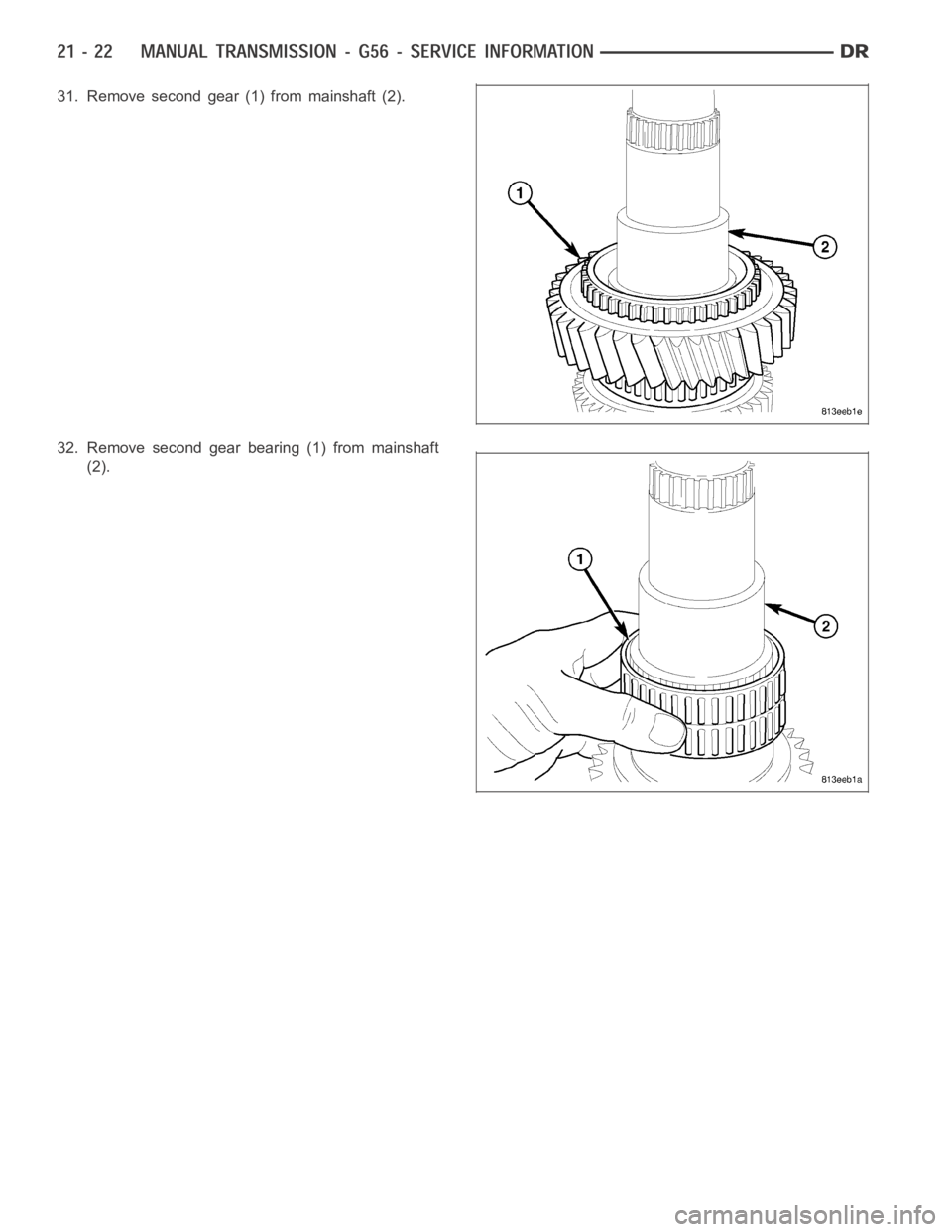

31. Remove second gear (1) from mainshaft (2).

32. Remove second gear bearing (1) from mainshaft

(2).

Page 2544 of 5267

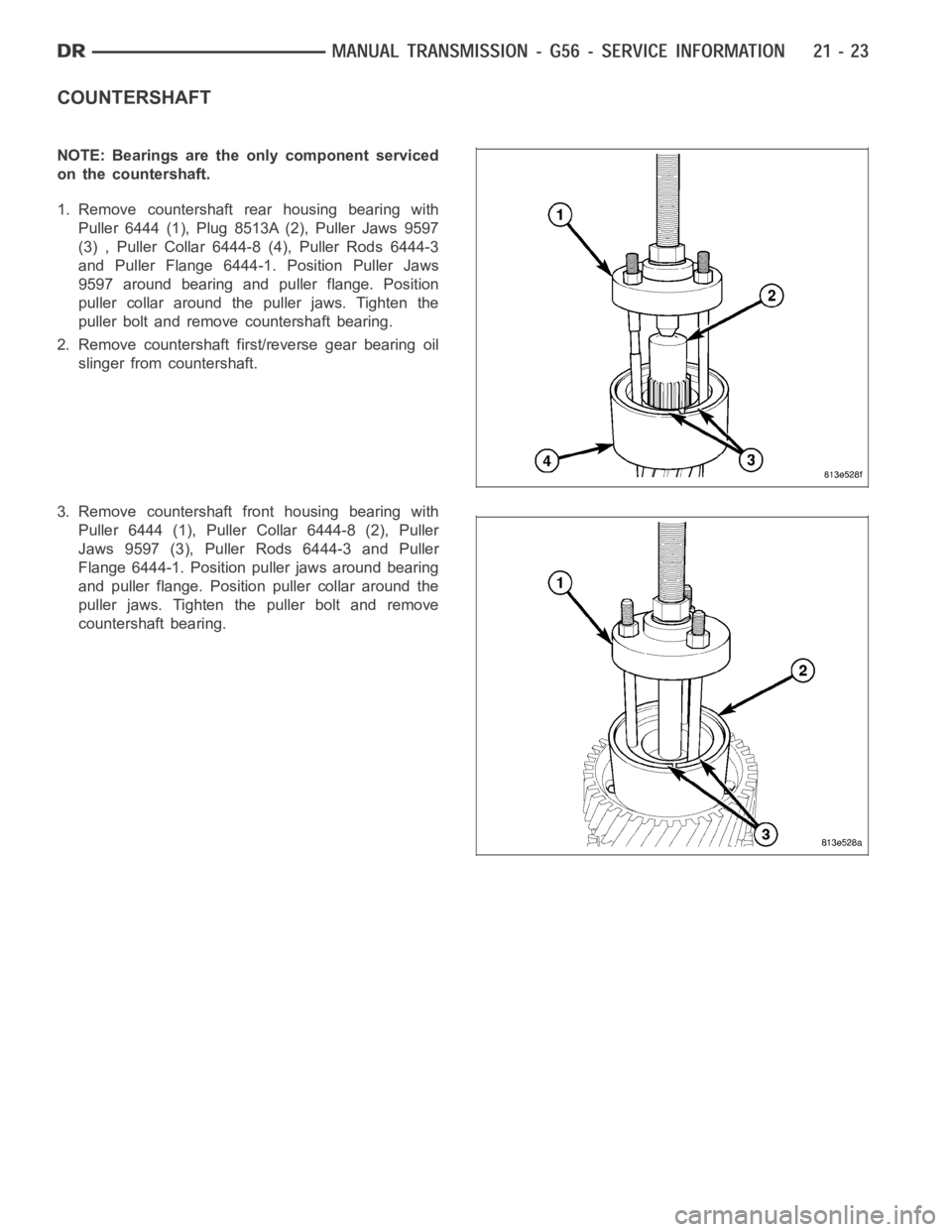

COUNTERSHAFT

NOTE: Bearings are the only component serviced

on the countershaft.

1. Remove countershaft rear housing bearing with

Puller 6444 (1), Plug 8513A (2), Puller Jaws 9597

(3) , Puller Collar 6444-8 (4), Puller Rods 6444-3

and Puller Flange 6444-1. Position Puller Jaws

9597 around bearing and puller flange. Position

puller collar around the puller jaws. Tighten the

puller bolt and remove countershaft bearing.

2. Remove countershaft first/reverse gear bearing oil

slinger from countershaft.

3. Remove countershaft front housing bearing with

Puller 6444 (1), Puller Collar 6444-8 (2), Puller

Jaws 9597 (3), Puller Rods 6444-3 and Puller

Flange 6444-1. Position puller jaws around bearing

and puller flange. Position puller collar around the

puller jaws. Tighten the puller bolt and remove

countershaft bearing.

Page 2545 of 5267

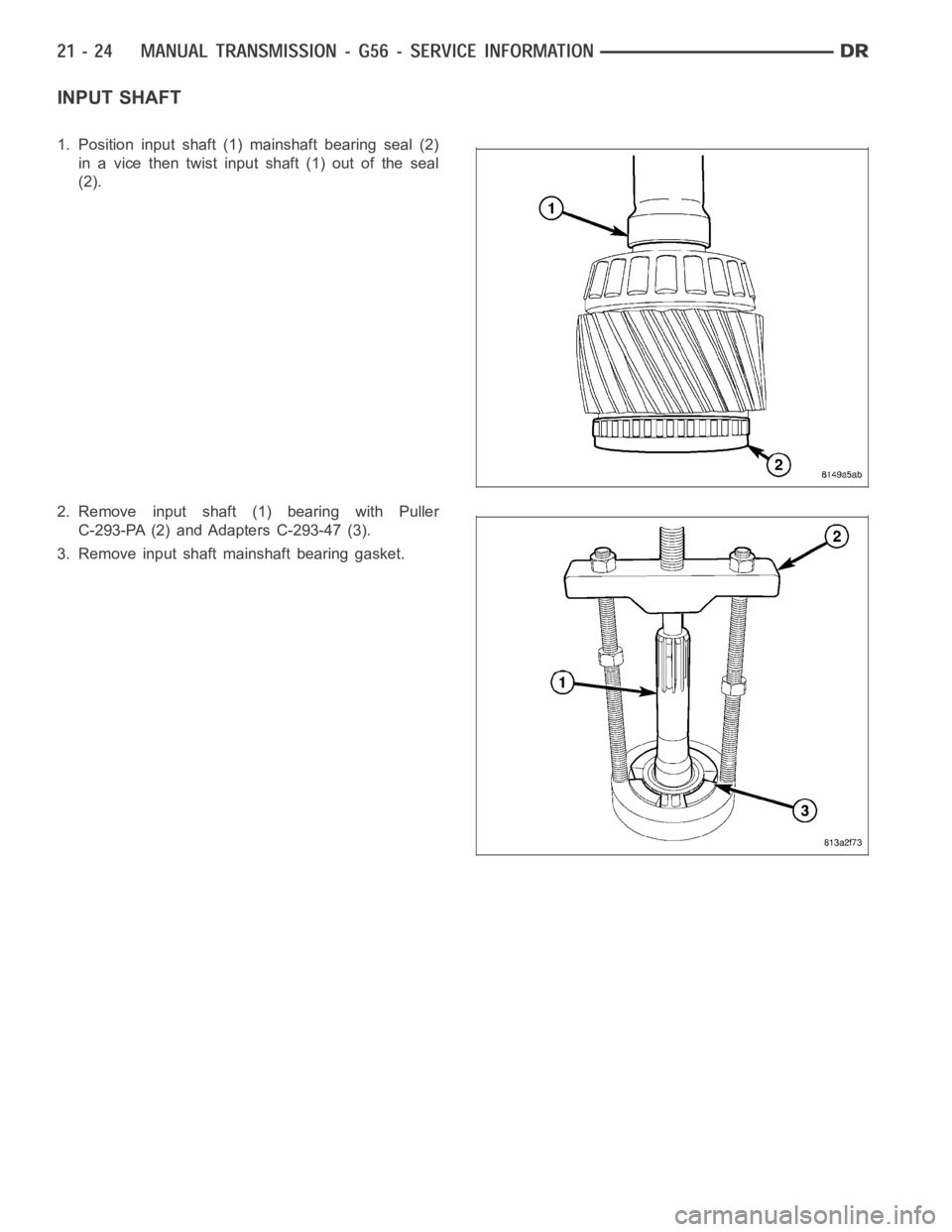

INPUT SHAFT

1. Position input shaft (1) mainshaft bearing seal (2)

in a vice then twist input shaft (1) out of the seal

(2).

2. Remove input shaft (1) bearing with Puller

C-293-PA (2) and Adapters C-293-47 (3).

3. Remove input shaft mainshaft bearing gasket.

Page 2546 of 5267

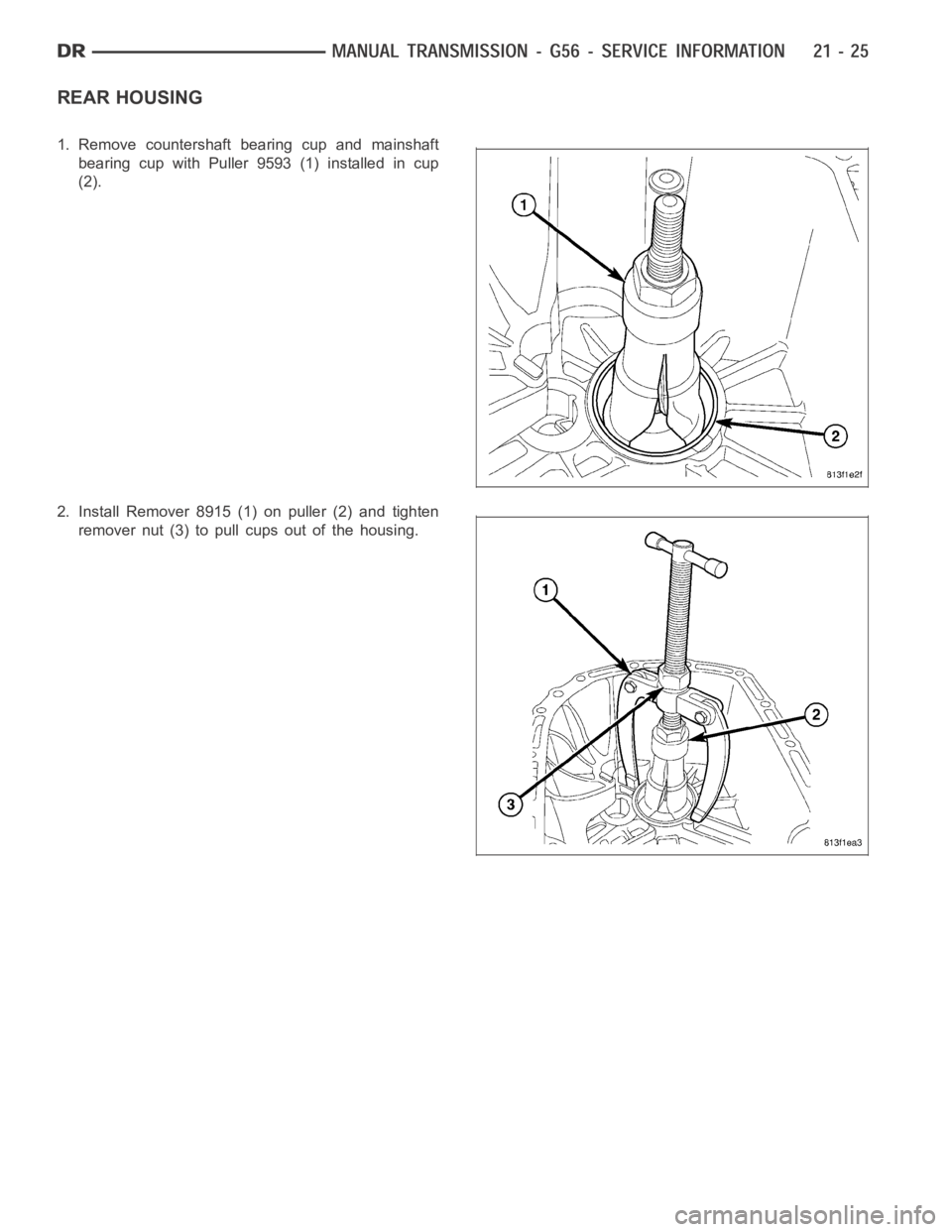

REAR HOUSING

1. Remove countershaft bearing cup and mainshaft

bearing cup with Puller 9593 (1) installed in cup

(2).

2. Install Remover 8915 (1) on puller (2) and tighten

remover nut (3) to pull cups out of the housing.

Page 2547 of 5267

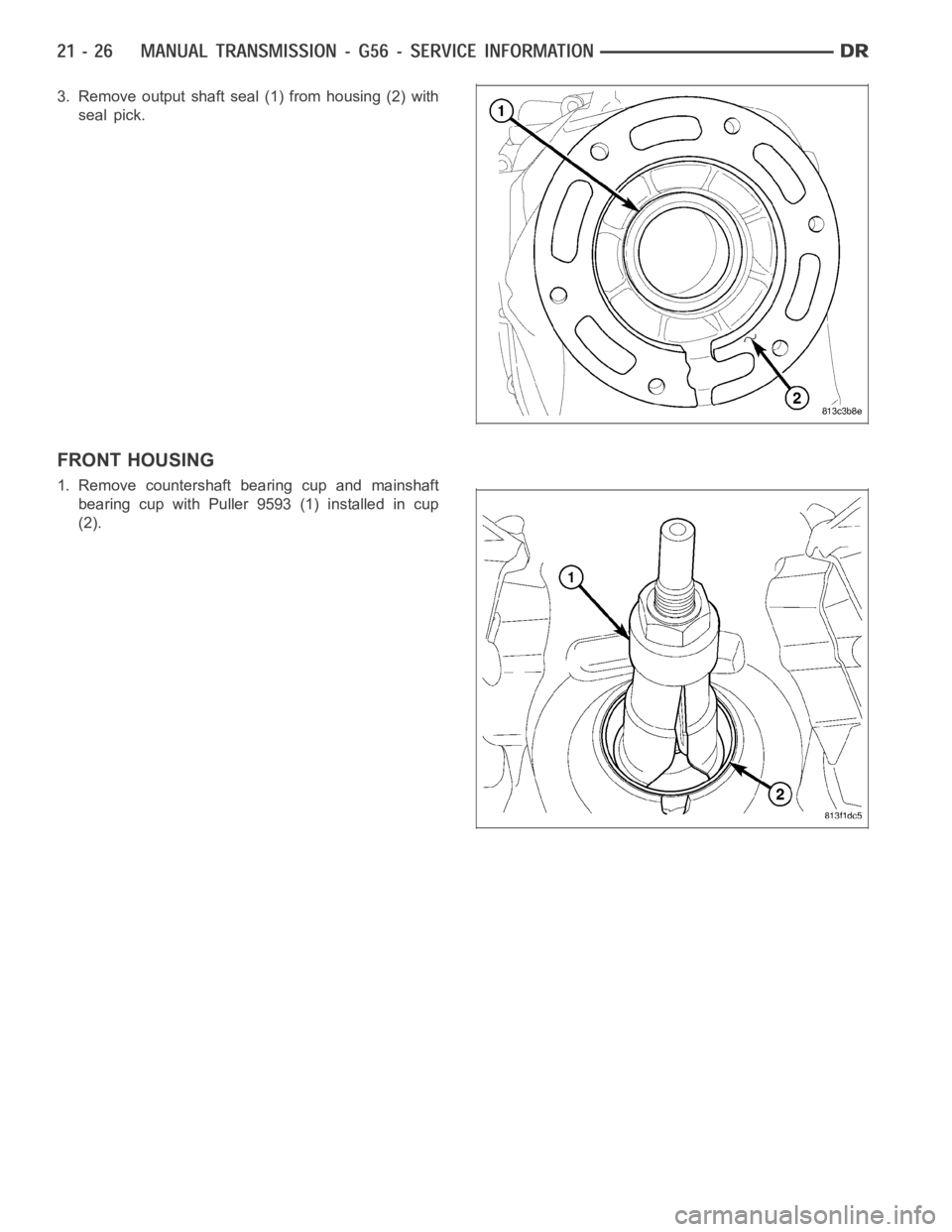

3. Remove output shaft seal (1) from housing (2) with

seal pick.

FRONT HOUSING

1. Remove countershaft bearing cup and mainshaft

bearing cup with Puller 9593 (1) installed in cup

(2).

Page 2548 of 5267

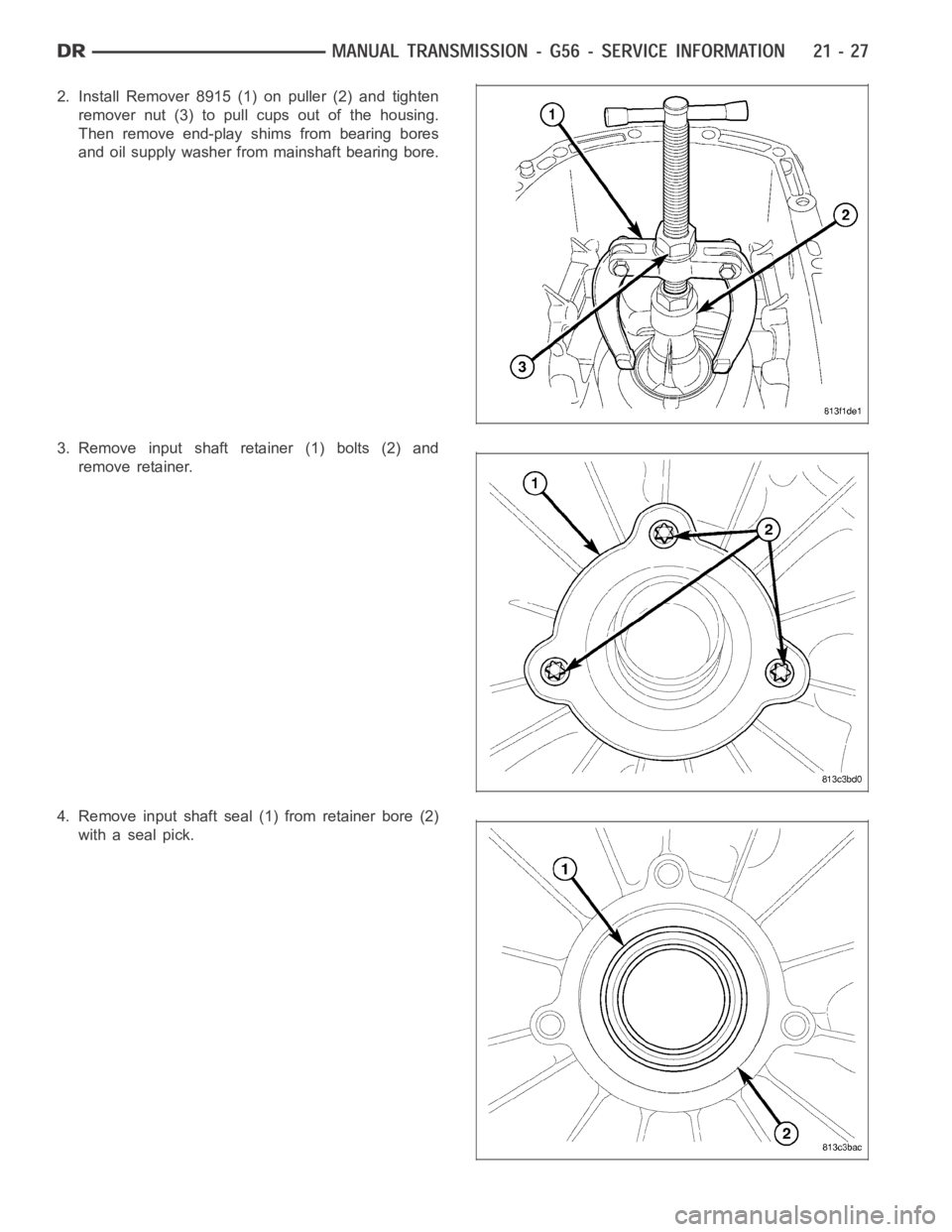

2. Install Remover 8915 (1) on puller (2) and tighten

remover nut (3) to pull cups out of the housing.

Then remove end-play shims from bearing bores

and oil supply washer from mainshaft bearing bore.

3. Remove input shaft retainer (1) bolts (2) and

remove retainer.

4. Remove input shaft seal (1) from retainer bore (2)

with a seal pick.

Page 2549 of 5267

CLEANING

Clean gears, shafts, shift components and transmission housings with a standard parts cleaning solvent. Do not use

acid or corrosive base solvents. Dry all parts except bearings with compressed air.

Clean shaft bearings with a mild solvent such as MOPAR

degreasing solvent, Gunkor similar solvents. Do not

dry the bearings with compressed air. Allow the bearings to either air dry or wipe them dry with clean shop towels.

INSPECTION

NOTE: Minor corrosion, nicks, or pitting can be

smoothed with 400 grit emery and polished out

with crocus cloth.

Bearings:Inspect for worn, chipped, cracked, flat-

spotted or brinnelled.

Gears:Inspect for worn, chipped or cracked teeth.

Inspect bearing surfaces for wear or flat-spotted.

Mainshaft:Inspect for worn splines, snap ring

grooves and threads.

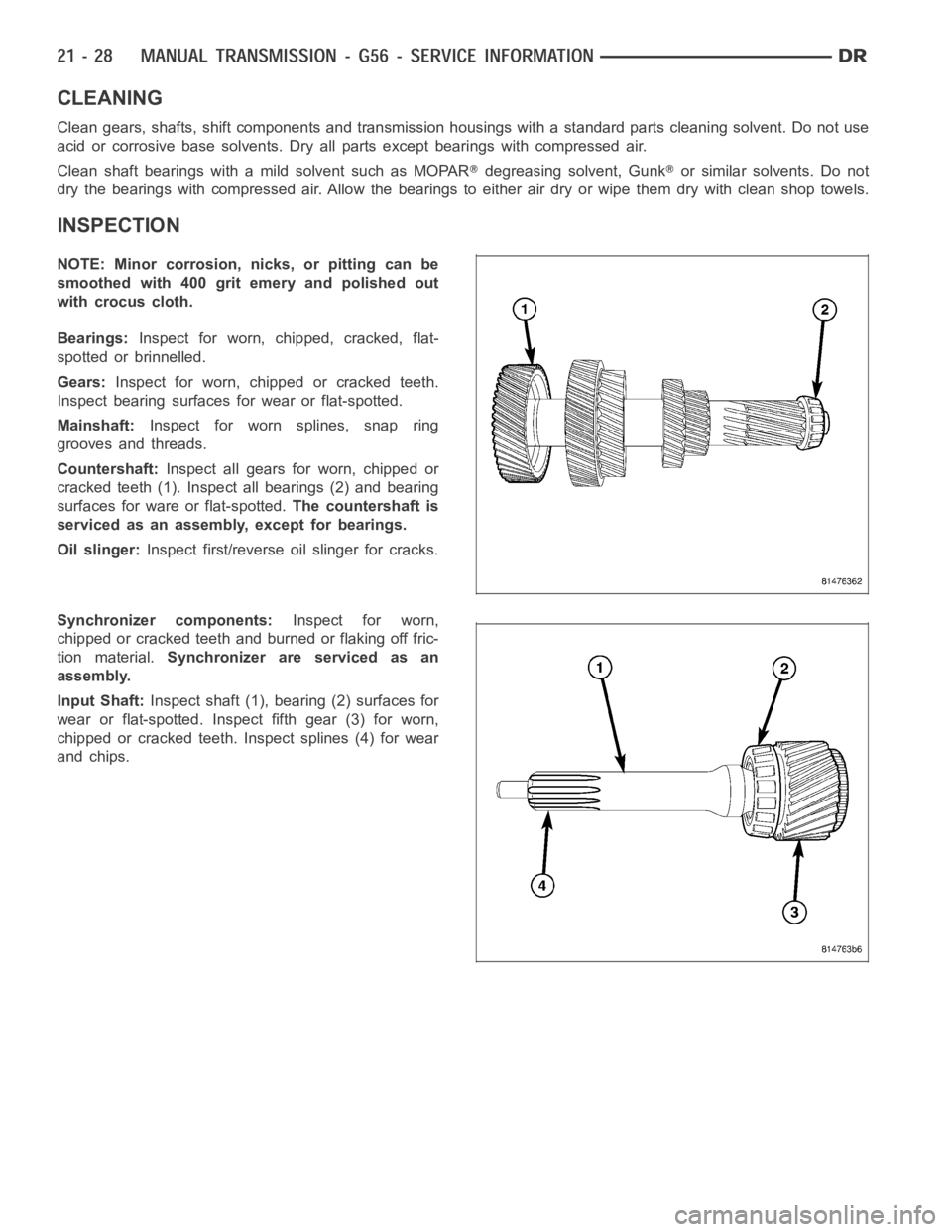

Countershaft:Inspect all gears for worn, chipped or

cracked teeth (1). Inspect all bearings (2) and bearing

surfaces for ware or flat-spotted.The countershaft is

serviced as an assembly, except for bearings.

Oil slinger:Inspect first/reverse oil slinger for cracks.

Synchronizer components:Inspect for worn,

chipped or cracked teeth and burned or flaking off fric-

tion material.Synchronizer are serviced as an

assembly.

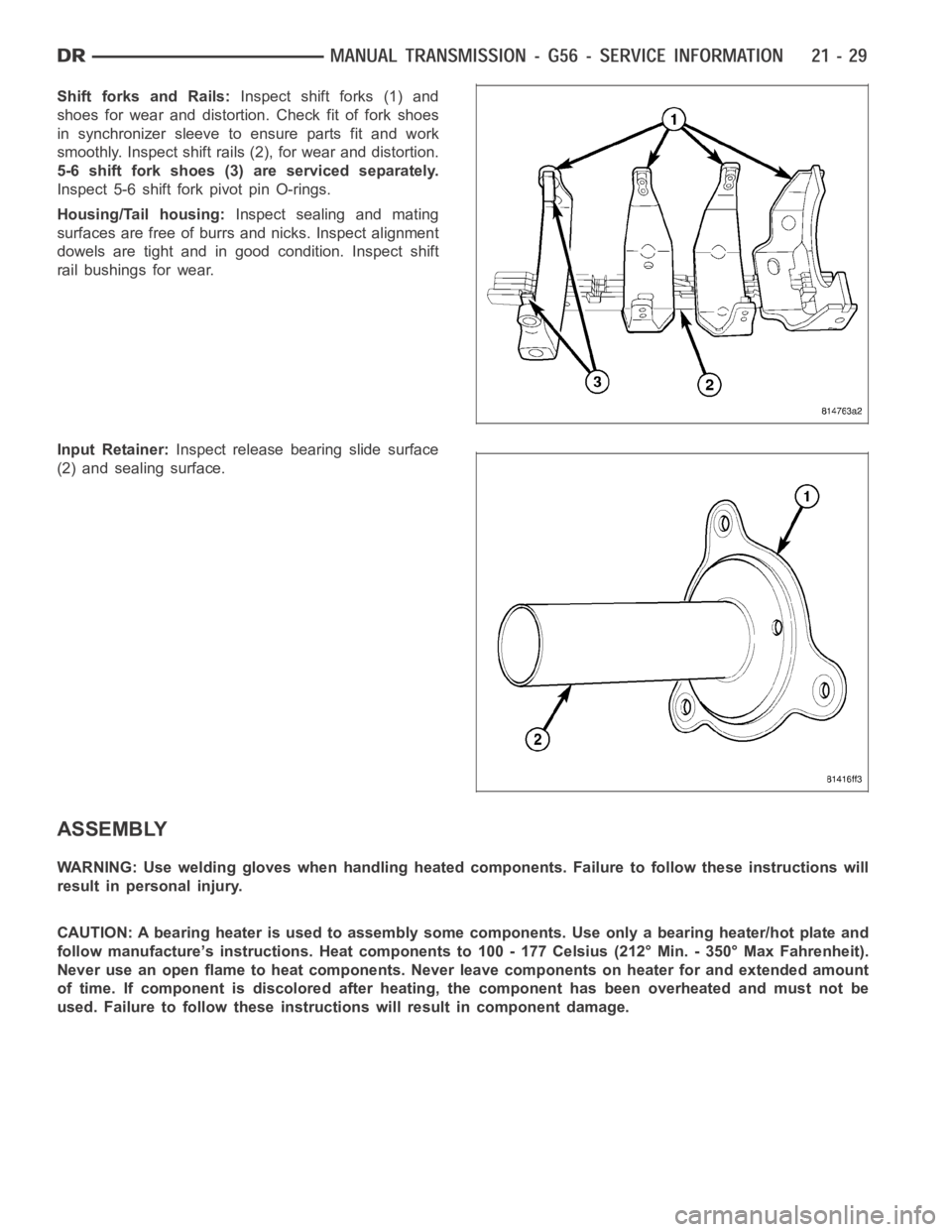

Input Shaft:Inspect shaft (1), bearing (2) surfaces for

wear or flat-spotted. Inspect fifth gear (3) for worn,

chipped or cracked teeth. Inspect splines (4) for wear

and chips.

Page 2550 of 5267

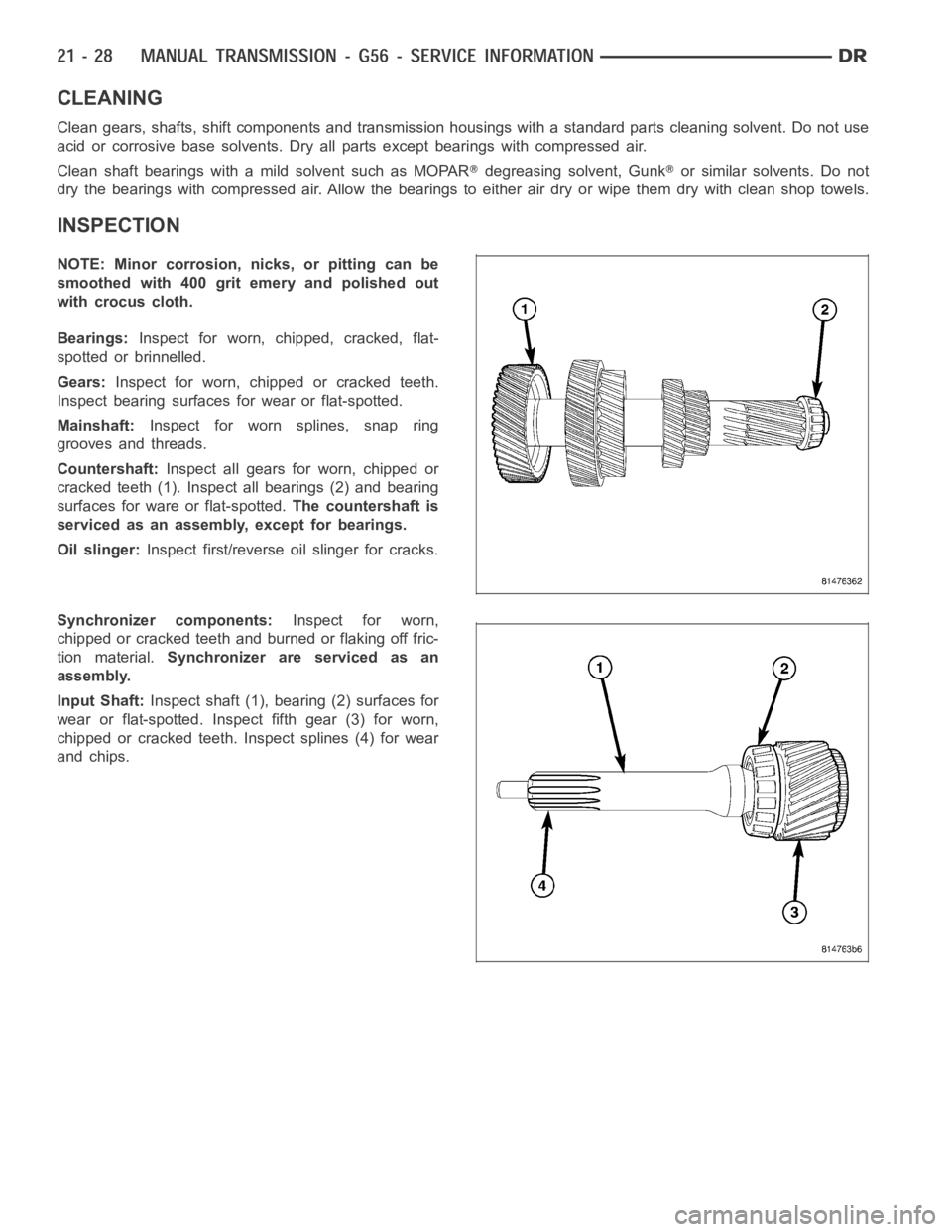

Shift forks and Rails:Inspect shift forks (1) and

shoes for wear and distortion. Check fit of fork shoes

in synchronizer sleeve to ensure parts fit and work

smoothly. Inspect shift rails(2), for wear and distortion.

5-6 shift fork shoes (3) are serviced separately.

Inspect 5-6 shift fork pivot pin O-rings.

Housing/Tail housing:Inspect sealing and mating

surfaces are free of burrs and nicks. Inspect alignment

dowels are tight and in good condition. Inspect shift

rail bushings for wear.

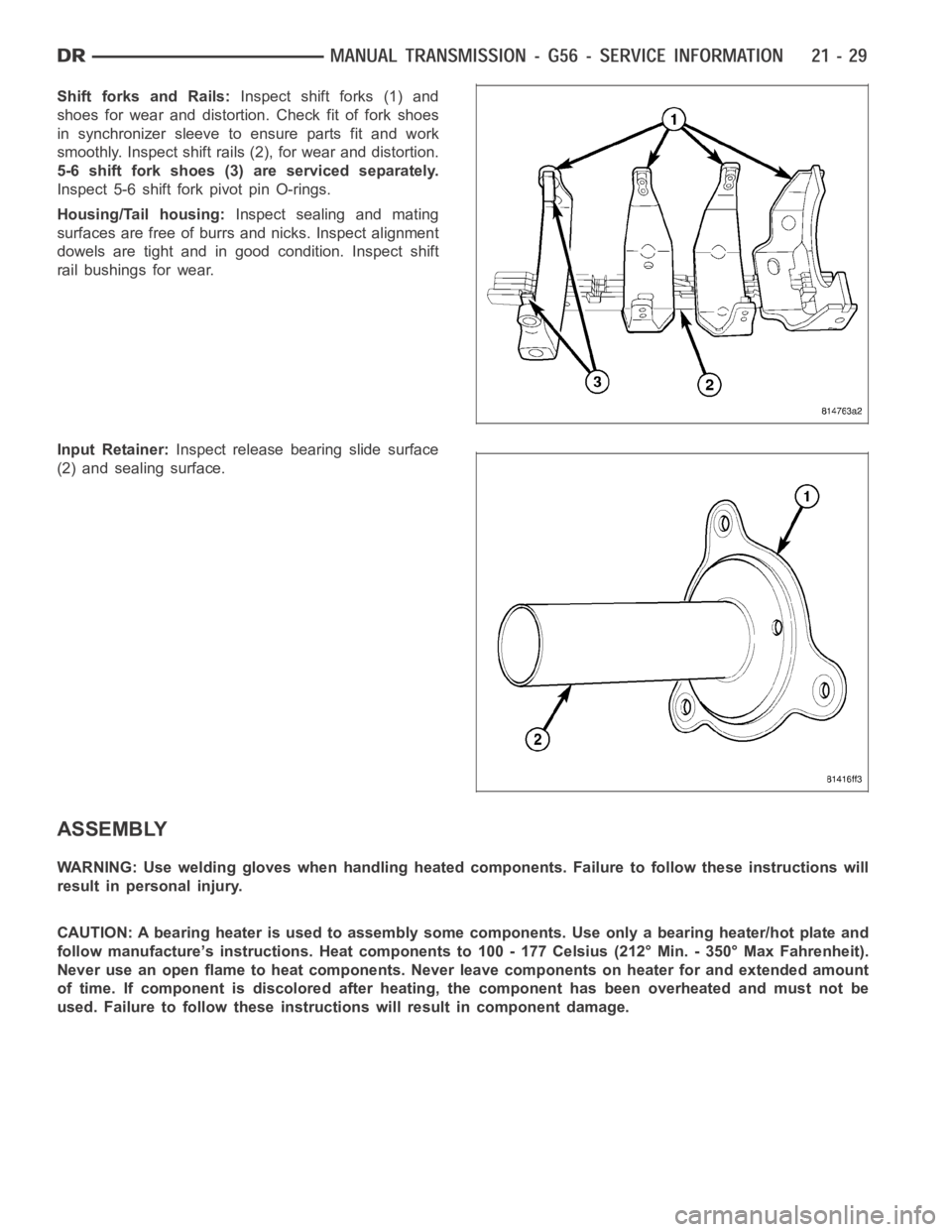

Input Retainer:Inspect release bearing slide surface

(2) and sealing surface.

ASSEMBLY

WARNING: Use welding gloves when handling heated components. Failure to follow these instructions will

result in personal injury.

CAUTION:Abearingheaterisusedtoassemblysomecomponents.Useonlyabearing heater/hot plate and

follow manufacture’s instructions. Heat components to 100 - 177 Celsius (212° Min. - 350° Max Fahrenheit).

Never use an open flame to heat components. Never leave components on heater for and extended amount

of time. If component is discolored after heating, the component has been overheated and must not be

used. Failure to follow these instructions will result in component damage.

Trending: fuses, open hood, parking brake, air condition, open gas tank, transmission fluid, diagnostic menu