DODGE RAM SRT-10 2006 Service Repair Manual

RAM SRT-10 2006

DODGE

DODGE

https://www.carmanualsonline.info/img/12/56917/w960_56917-0.png

DODGE RAM SRT-10 2006 Service Repair Manual

Trending: engine oil capacity, spark plugs, AUX, ground clearance, heater, sunroof, diagram

Page 2571 of 5267

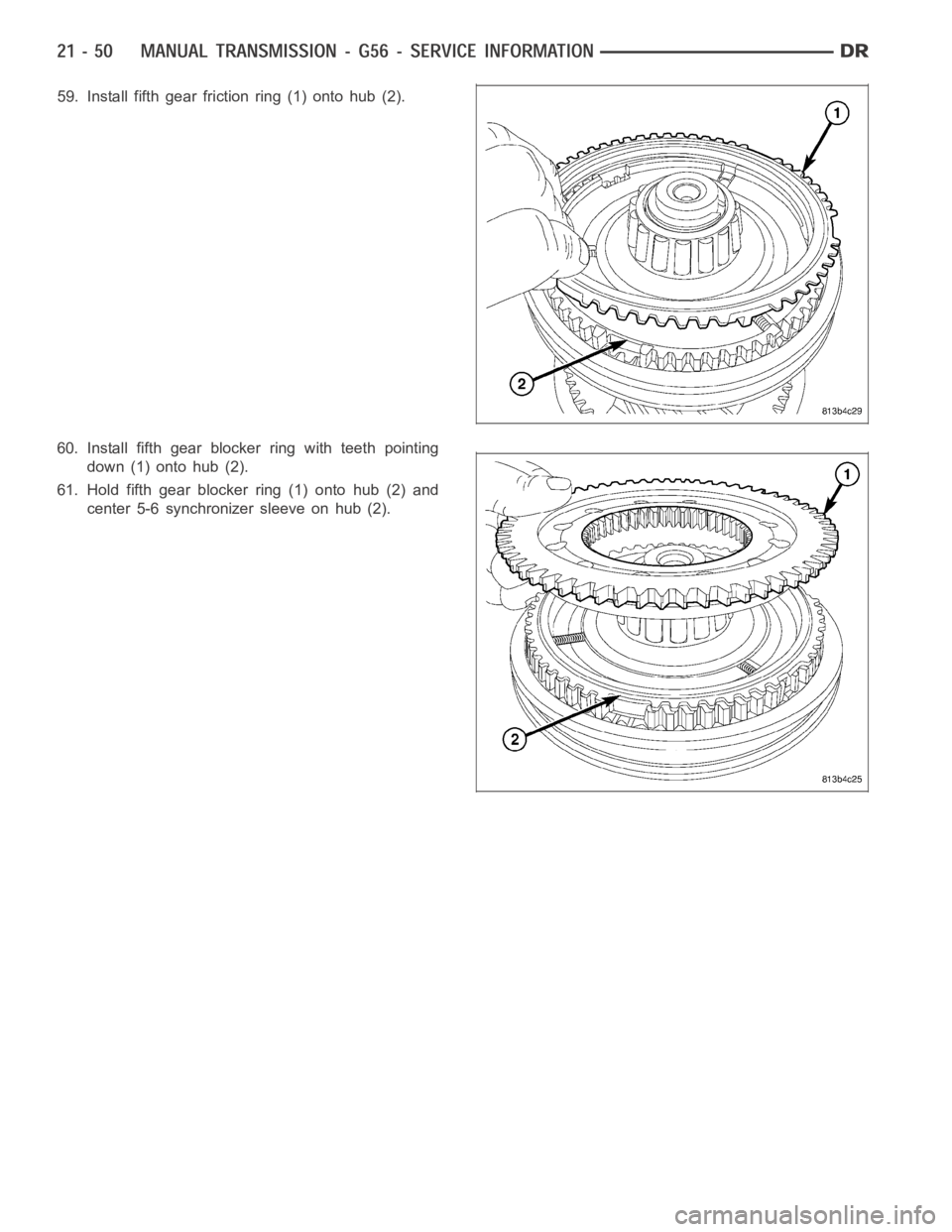

59. Install fifth gear friction ring (1) onto hub (2).

60. Install fifth gear blocker ring with teeth pointing

down (1) onto hub (2).

61. Hold fifth gear blocker ring (1) onto hub (2) and

center 5-6 synchronizer sleeve on hub (2).

Page 2572 of 5267

REAR HOUSING

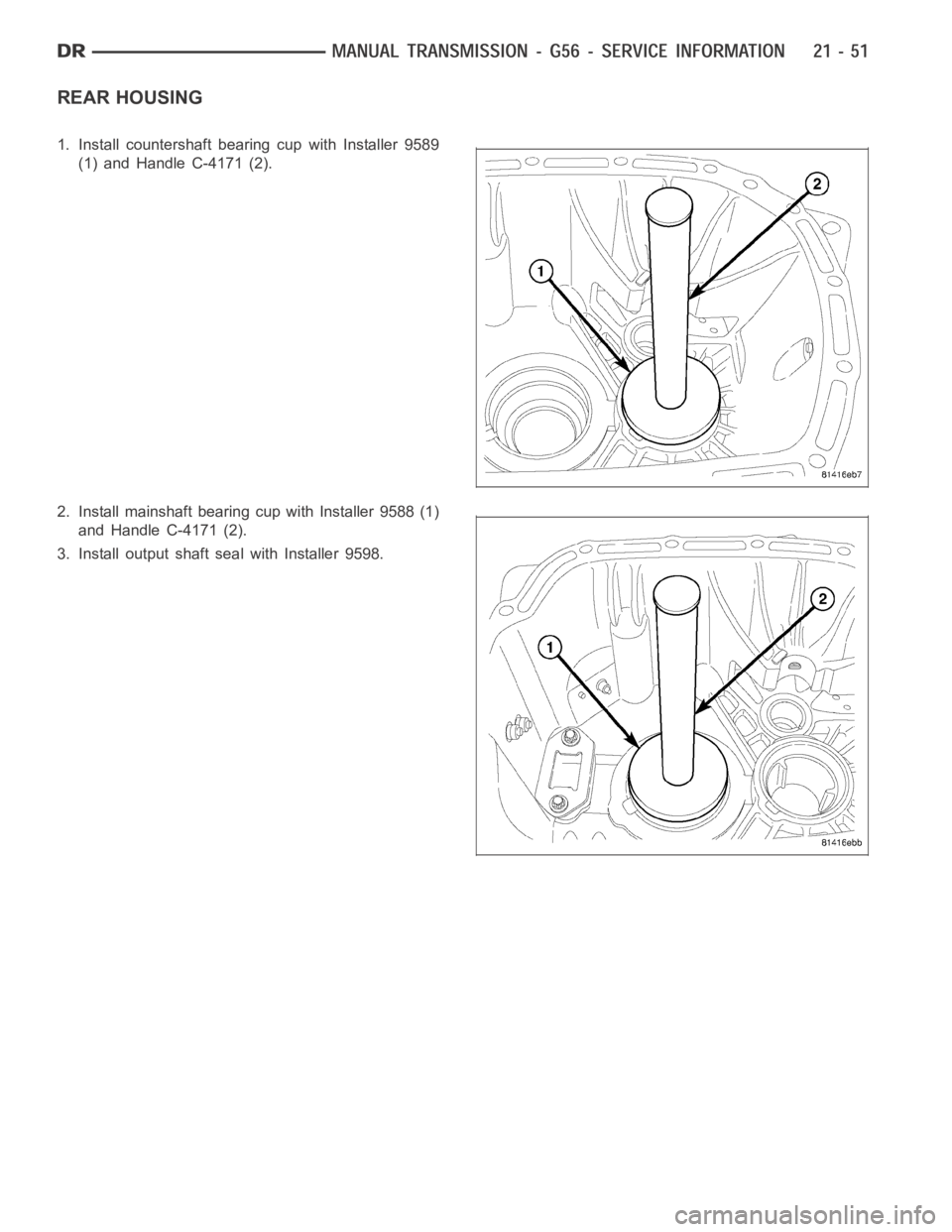

1. Install countershaft bearing cup with Installer 9589

(1) and Handle C-4171 (2).

2. Install mainshaft bearing cup with Installer 9588 (1)

and Handle C-4171 (2).

3. Install output shaft seal with Installer 9598.

Page 2573 of 5267

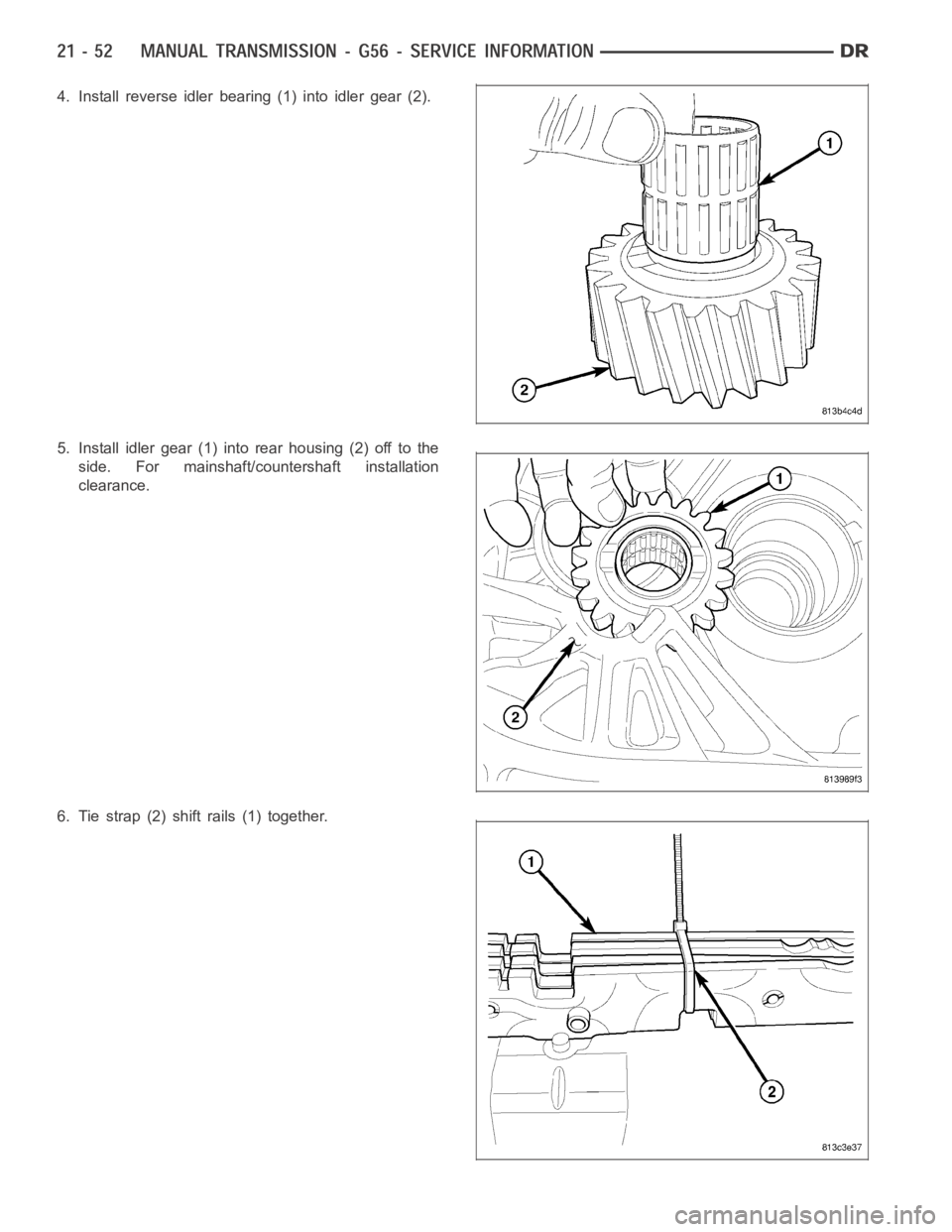

4. Install reverse idler bearing (1) into idler gear (2).

5. Install idler gear (1) into rear housing (2) off to the

side. For mainshaft/countershaft installation

clearance.

6. Tie strap (2) shift rails (1) together.

Page 2574 of 5267

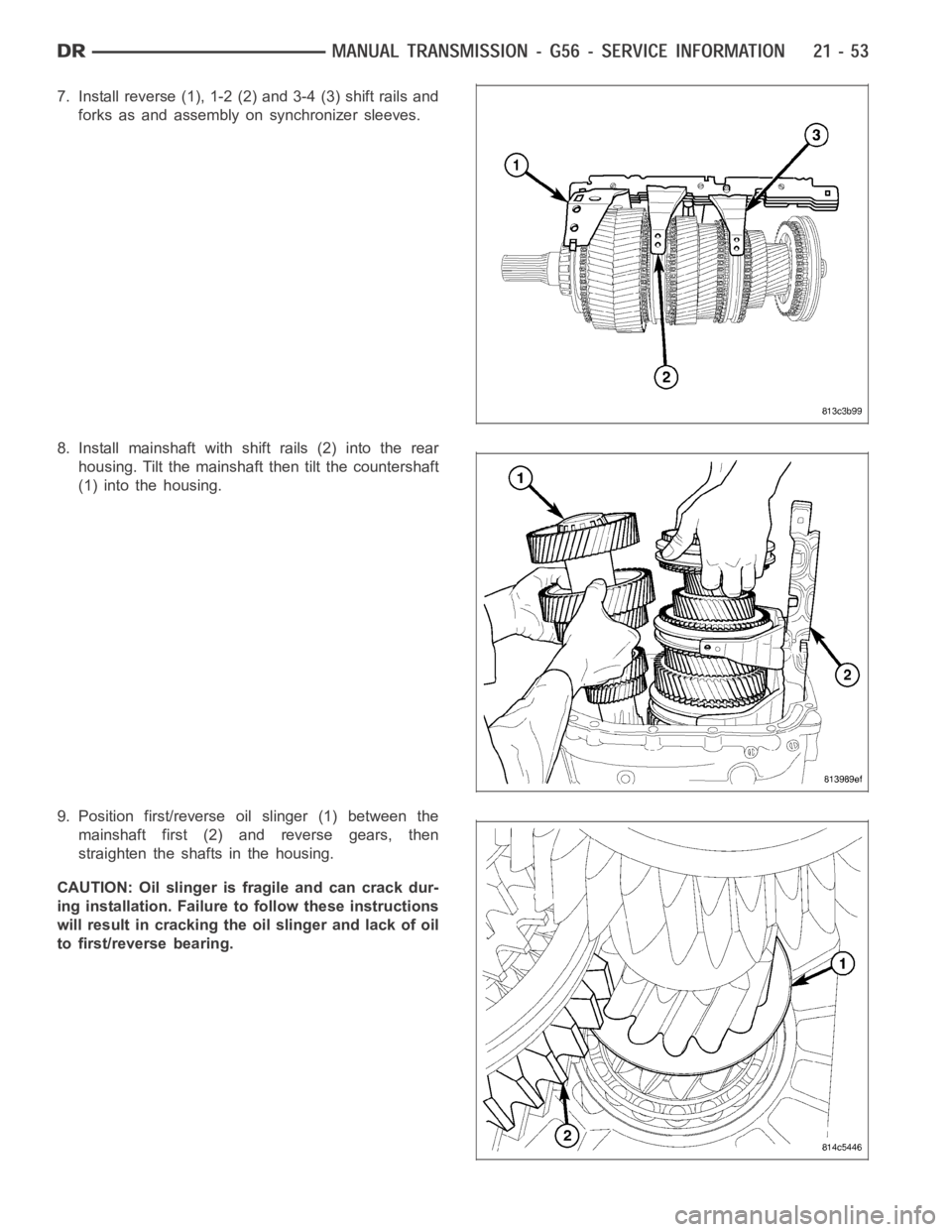

7. Install reverse (1), 1-2 (2) and 3-4 (3) shift rails and

forks as and assembly on synchronizer sleeves.

8. Install mainshaft with shift rails (2) into the rear

housing. Tilt the mainshaft then tilt the countershaft

(1) into the housing.

9. Position first/reverse oil slinger (1) between the

mainshaft first (2) and reverse gears, then

straighten the shafts in the housing.

CAUTION: Oil slinger is fragile and can crack dur-

ing installation. Failure to follow these instructions

will result in cracking the oil slinger and lack of oil

to first/reverse bearing.

Page 2575 of 5267

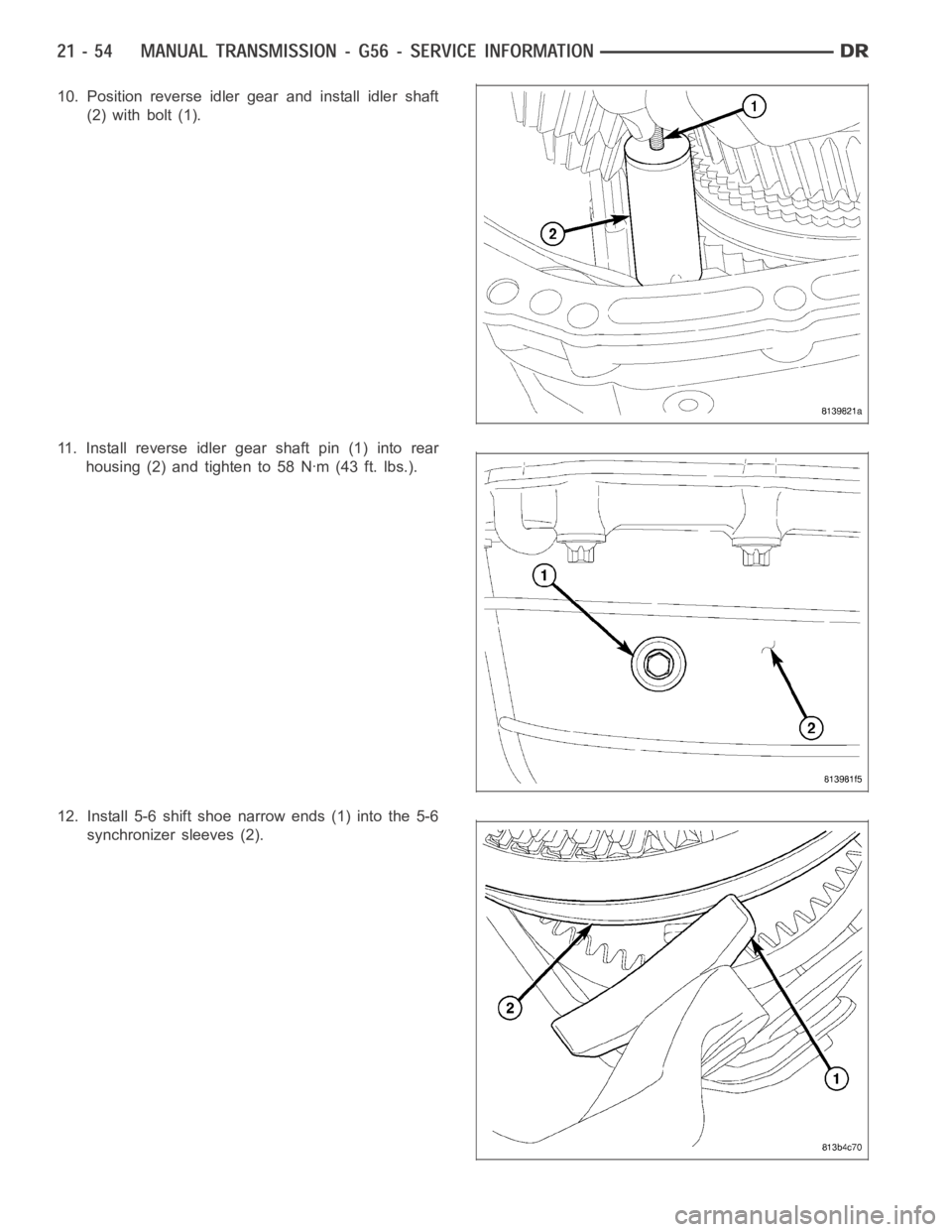

10. Position reverse idler gear and install idler shaft

(2) with bolt (1).

11. Install reverse idler gear shaft pin (1) into rear

housing (2) and tighten to 58 Nꞏm (43 ft. lbs.).

12. Install 5-6 shift shoe narrow ends (1) into the 5-6

synchronizer sleeves (2).

Page 2576 of 5267

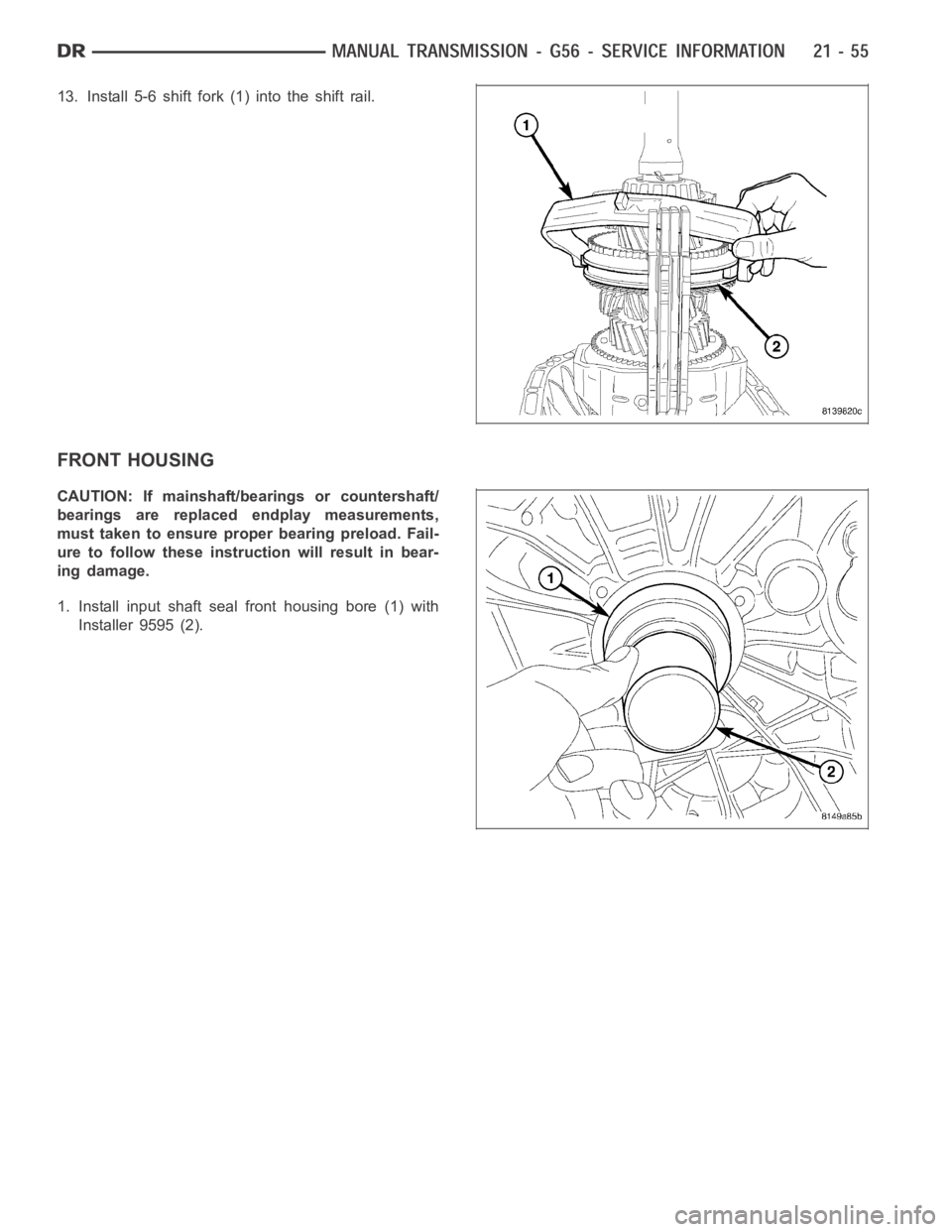

13. Install 5-6 shift fork (1) into the shift rail.

FRONT HOUSING

CAUTION: If mainshaft/bearings or countershaft/

bearings are replaced endplay measurements,

must taken to ensure proper bearing preload. Fail-

ure to follow these instruction will result in bear-

ing damage.

1. Install input shaft seal front housing bore (1) with

Installer 9595 (2).

Page 2577 of 5267

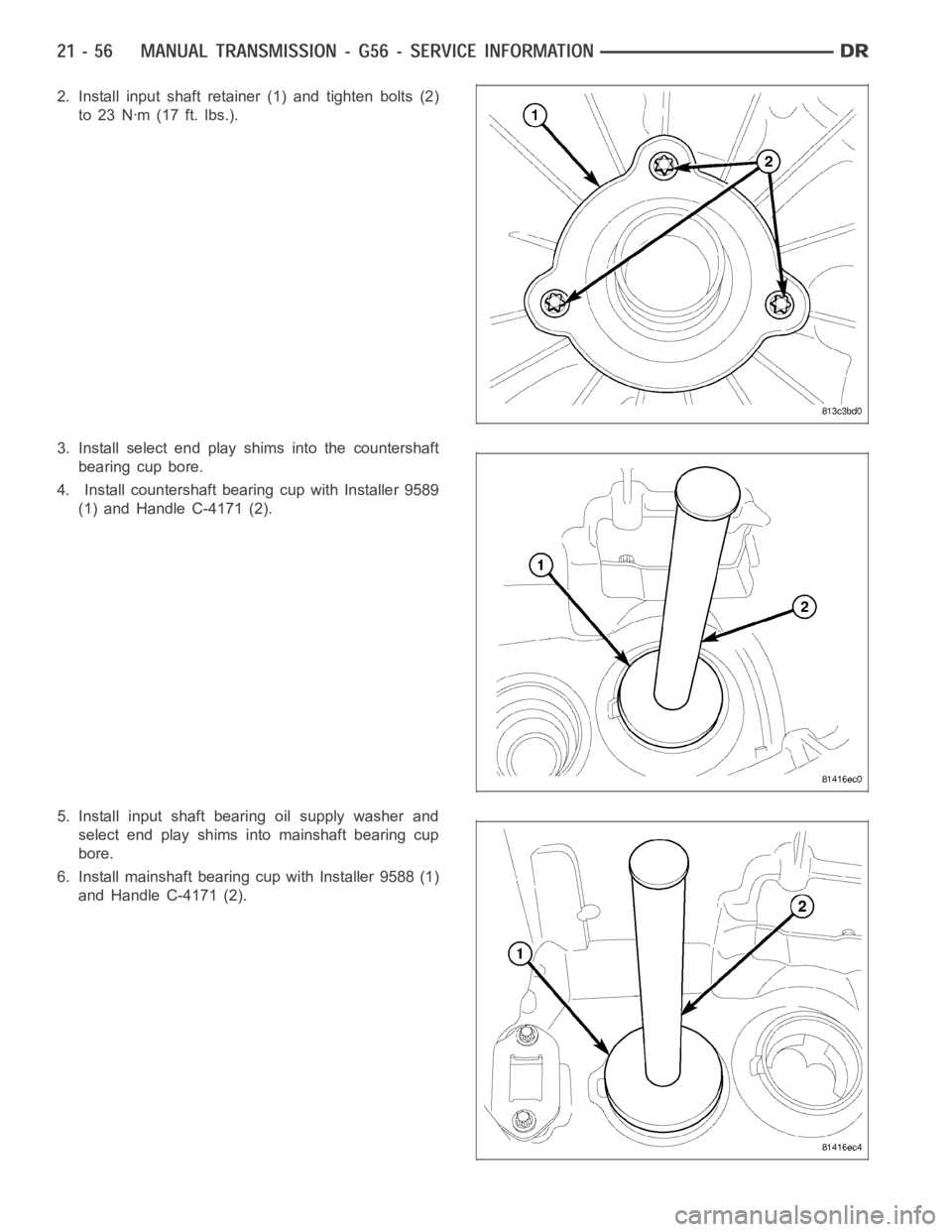

2. Install input shaft retainer (1) and tighten bolts (2)

to 23 Nꞏm (17 ft. lbs.).

3. Install select end play shims into the countershaft

bearing cup bore.

4. Install countershaft bearing cup with Installer 9589

(1) and Handle C-4171 (2).

5. Install input shaft bearing oil supply washer and

select end play shims into mainshaft bearing cup

bore.

6. Install mainshaft bearing cup with Installer 9588 (1)

and Handle C-4171 (2).

Page 2578 of 5267

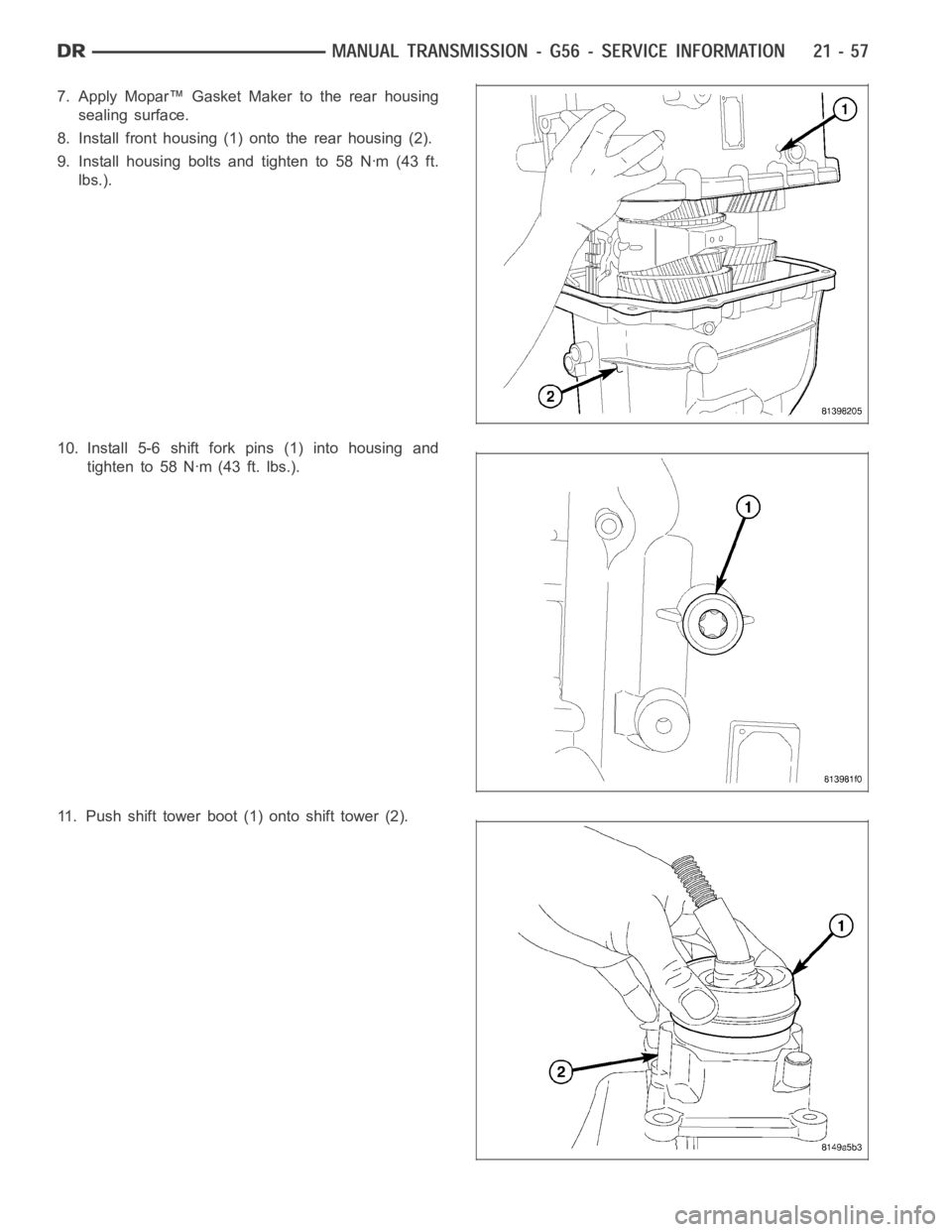

7. Apply Mopar™ Gasket Maker to the rear housing

sealing surface.

8. Install front housing (1) onto the rear housing (2).

9. Install housing bolts and tighten to 58 Nꞏm (43 ft.

lbs.).

10. Install 5-6 shift fork pins (1) into housing and

tighten to 58 Nꞏm (43 ft. lbs.).

11. Push shift tower boot (1) onto shift tower (2).

Page 2579 of 5267

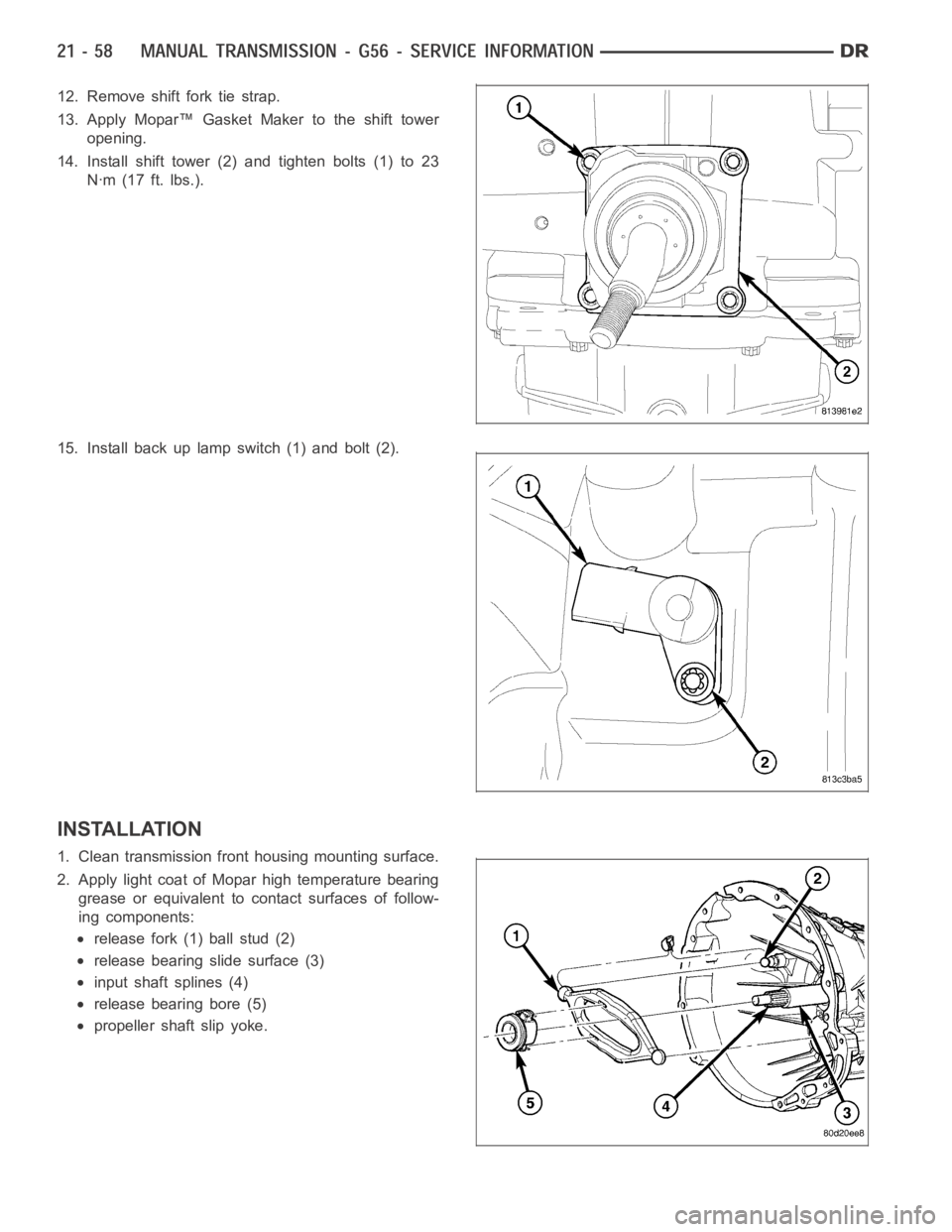

12. Remove shift fork tie strap.

13. Apply Mopar™ Gasket Maker to the shift tower

opening.

14. Install shift tower (2) and tighten bolts (1) to 23

Nꞏm (17 ft. lbs.).

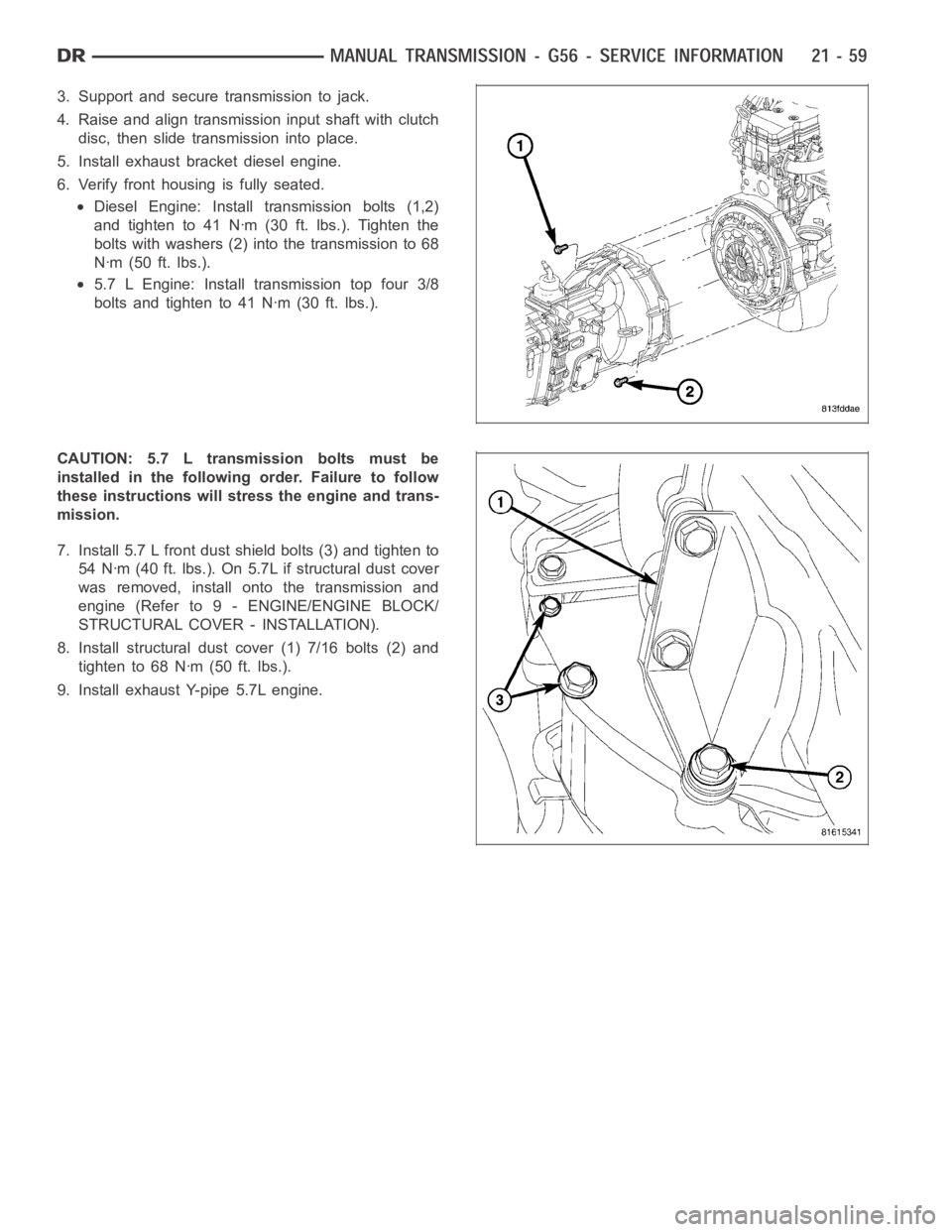

15. Install back up lamp switch (1) and bolt (2).

INSTALLATION

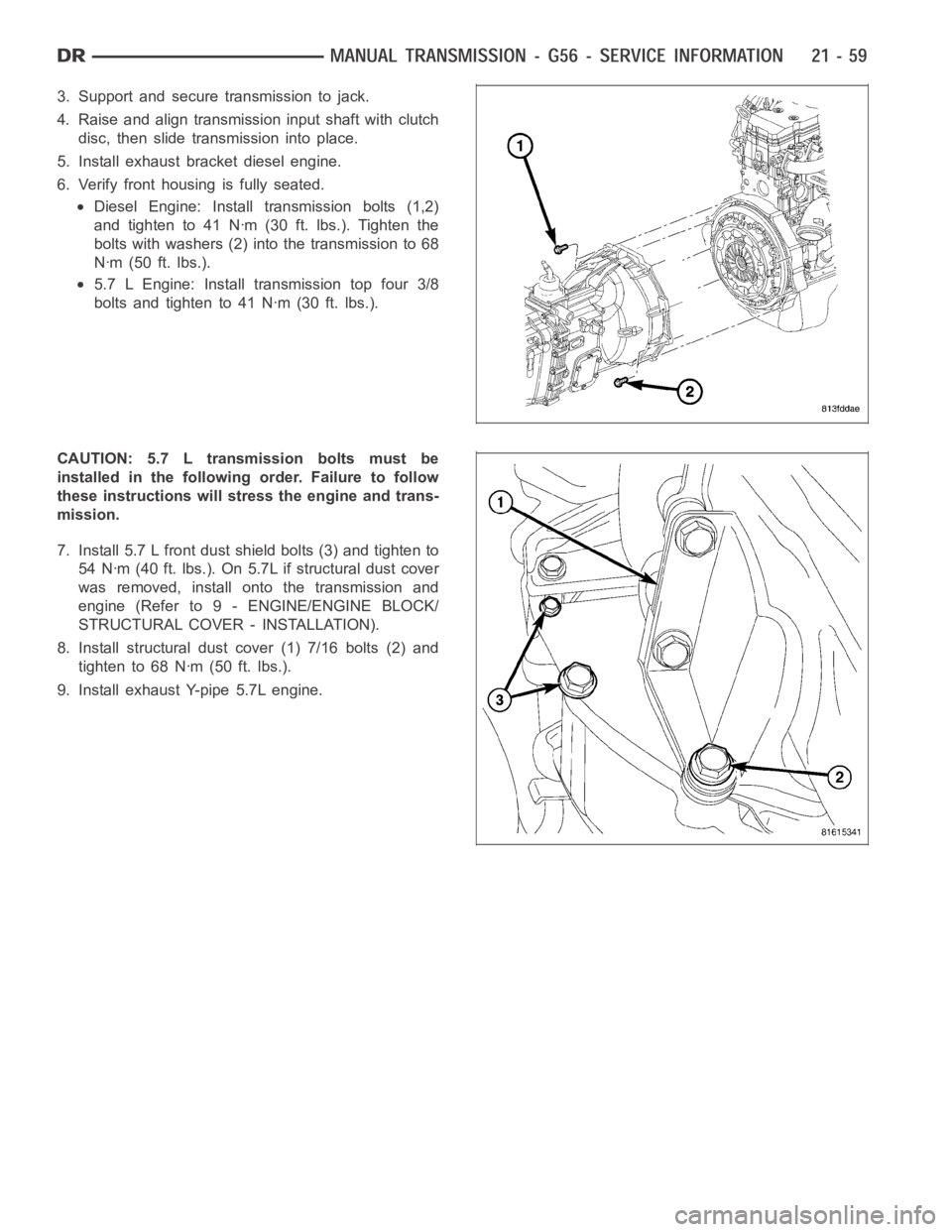

1. Clean transmission front housing mounting surface.

2. Apply light coat of Mopar high temperature bearing

grease or equivalent to contact surfaces of follow-

ing components:

release fork (1) ball stud (2)

release bearing slide surface (3)

input shaft splines (4)

release bearing bore (5)

propeller shaft slip yoke.

Page 2580 of 5267

3. Support and secure transmission to jack.

4. Raise and align transmission input shaft with clutch

disc, then slide transmission into place.

5. Install exhaust bracket diesel engine.

6. Verify front housing is fully seated.

Diesel Engine: Install transmission bolts (1,2)

and tighten to 41 Nꞏm (30 ft. lbs.). Tighten the

bolts with washers (2) into the transmission to 68

Nꞏm (50 ft. lbs.).

5.7 L Engine: Install transmission top four 3/8

bolts and tighten to 41 Nꞏm (30 ft. lbs.).

CAUTION: 5.7 L transmission bolts must be

installed in the followingorder. Failure to follow

these instructions will stress the engine and trans-

mission.

7. Install 5.7 L front dust shield bolts (3) and tighten to

54 Nꞏm (40 ft. lbs.). On 5.7L if structural dust cover

was removed, install onto the transmission and

engine (Refer to 9 - ENGINE/ENGINE BLOCK/

STRUCTURAL COVER - INSTALLATION).

8. Install structural dust cover (1) 7/16 bolts (2) and

tighten to 68 Nꞏm (50 ft. lbs.).

9. Install exhaust Y-pipe 5.7L engine.

Trending: lug pattern, warning light, overheating, snow chains, steering, gas tank size, odometer